Page 1

13. CRANKCASE/CRANKSHAFT

XCITING 500

13

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

13

CRANKCASE/CRANKSHAFT

__________________________________________________________________________________

SCHEMATIC DRAWING ------------------------------------------------- 13- 1

SERVICE INFORMATION------------------------------------------------ 13- 2

TROUBLESHOOTING----------------------------------------------------- 13- 2

CAM CHAIN/CAM CHAIN GUIDE REMOVAL --------------------- 13- 3

CRANKCASE SEPARATION -------------------------------------------- 13- 4

CRANKCASE ASSEMBLY ----------------------------------------------- 13-11

13-0

Page 2

13. CRANKCASE/CRANKSHAFT

SCHEMATIC DRAWING

XCITING 500

13-1

Page 3

13. CRANKCASE/CRANKSHAFT

m

d

XCITING 500

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• This section covers crankcase separation to service the crankshaft and balancer. The engine must

be removed for this operation.

• When separating the crankcase, never use a driver to pry the crankcase mating surfaces apart

forcedly to prevent damaging the mating surfaces.

• When installing the crankcase, do not use an iron hammer to tap it.

• The following parts must be removed before separating the crankcase.

Cylinder head (section 8)

Cylinder/piston (section 9)

Drive and driven pulley (section 10)

A.C. generator/starter clutch (section 12)

Starter motor (section 19)

Oil pump (section 4)

SPECIFICATIONS Unit: mm (in)

Ite

Main bearing oil clearance

Crankshaft

TORQUE VALUES

Crankcase bolt 12 N•m (1.2 kgf•m, 9 lbf•ft)

Cam chain guide bolt 20 N•m (2 kgf•m, 15 lbf•ft)

Oil pipe bolt 43 N•m (4.3 kgf•m, 31 lbf•ft)

SPECIAL TOOLS

Bearing puller E037

Oil seal & bearing driver E014

Connecting rod big end side

clearance

Runout

0.025 (0.001)~0.041 (0.0016) 0.07 (0.003)

0.05 (0.002)~0.5 (0.02) 0.8 (0.031)

Standar

⎯ 0.06 (0.002)

Service Limit

TROUBLESHOOTING

Excessive engine noise

• Worn connecting to small end

• Worn or damaged crankshaft bearings

13-2

Page 4

13. CRANKCASE/CRANKSHAFT

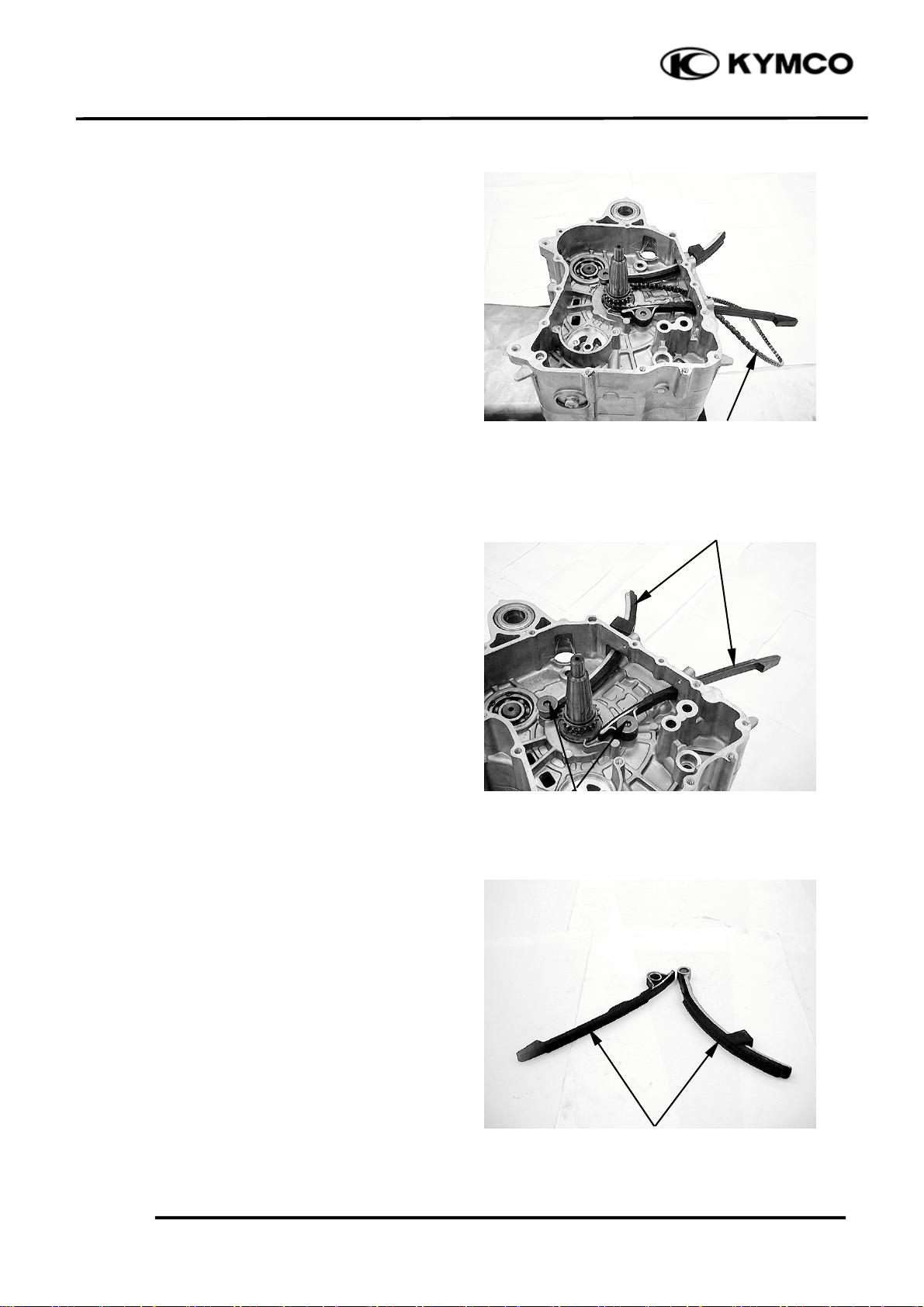

CAM CHAIN/CAM CHAIN GUIDE

REMOVAL

Remove the starter driven gear (page 12-4).

Remove the cylinder (page 9-3).

Remove the cam chain from the right

crankcase.

Cam Chain

Cam Chain Guides

XCITING 500

Remove the bolts and cam chain guides.

INSPECTION

Cam chain guide

Inspect the cam chain slipper surface of the

cam chain guide for wear or damage.

Bolts

13-3

Slipper Surface

Page 5

13. CRANKCASE/CRANKSHAFT

t

Cam chain

Inspect the cam chain for cracks or stiff.

Bolts

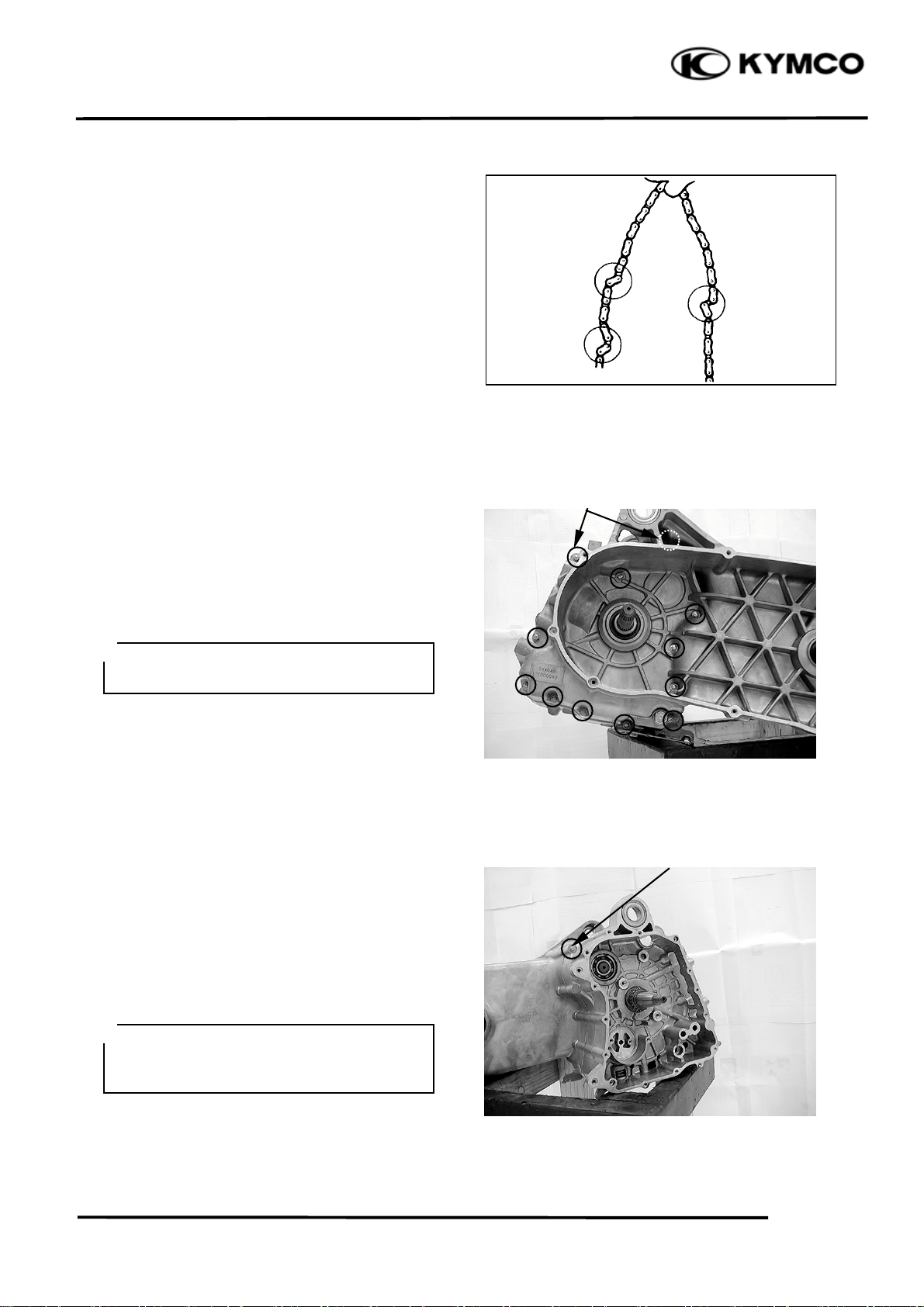

CRANKCASE SEPARATION

Remove the parts required for crankcase

separation (page 13-2).

XCITING 500

Remove the twelve bolts from left crankcase.

*

Loosen the bolts in a crisscross pattern in

several steps.

Remove the bolt from right crankcase.

Place the crankcase assembly with the left

side down and separate the right crankcase

from the left crankcase.

*

Separate the right crankcase from the left

crankcase while tapping them at several

locations with a soft hammer.

Bol

13-4

Page 6

13. CRANKCASE/CRANKSHAFT

r

t

Dowel Pins

Remove the dowel pins and O-ring.

Remove the oil collar and O-rings from the

left crankcase.

Clean of the sealant from the left and right

crankcase mating surfaces.

Oil Collar/O-rings Dowel Pin/O-ring

Washe

XCITING 500

Remove the washer from the crankshaft.

Remove the balancer shaft from the left

crankcase.

Remove the crankshaft from the left

crankcase.

Crankshaf

13-5

Page 7

13. CRANKCASE/CRANKSHAFT

r

Bolts/Outer Washe

RIGHT CRANKCASE DISASSEMBLY

Remove the two bolts, outer washer, oil pipe

and inner washers.

Oil Pipe/Inner Washers

Inner Washers

RIGHT CRANKCASE ASSEMBLY

Install the inner washers onto the right

crankcase.

XCITING 500

Install the oil pipe with the thick side face

upward.

Thick Side

Oil Pipe

13-6

Page 8

13. CRANKCASE/CRANKSHAFT

r

Bolts/Outer Washe

Install the outer washers and two bolts.

Tighten the two bolts to the specified torque.

Torque: 43 N•m (4.3 kgf•m, 31 lbf•ft)

XCITING 500

CRANKSHAFT/CRANKCASE

SELECTION

Crankcase and crankshaft are select fitted.

Record the main journal O.D. code (- or

+)

Record the main journal bearing I.D. color

code (green, brown or yellow).

Record the right or left crankcase main

journal I.D. code (A or B).

If the crankcase and/or crankshaft are

replaced, select them with the following

fitting table.

The “U” mark in the table indicates that

mating is possible in the crossed code.

Main Journal Bearing I.D. Color Cod

Main Journal O.D. Code

e

Main journal O.D. code

Main journal bearing I.D. color code

/Crankcase main journal I.D. code

Green/A U

Green/B U

Brown/A U

Yellow/B U

13-7

+-

Crankcase Main Journal I.D. Code

Page 9

13. CRANKCASE/CRANKSHAFT

XCITING 500

MAIN BEARING INSPECTION

Inspect the bearing inserts for unusual wear,

damage or peeling and replace the crankcase

if necessary.

Main bearing oil clearance

Clean off any oil from the main bearing

inserts and crankshaft journals.

Measure and record the crankshaft main

journal O.D..

Measure and record the main bearing I.D..

Calculate the oil clearance by subtracting the

journal O.D. from bearing I.D..

Standard:

0.025 – 0.041 mm (0.001 – 0.0016 in)

Service limit: 0.07 mm (0.003 in)

Replace the crankcase if the service limit is

exceeded.

Select the replacement crankcase (page 13-7).

Bearing

Runout Side Clearance Runout

CRANKSHAFT INSPECTION

Measure the connecting rod big end side

clearance.

Service limit: 0.8 mm (0.031 in)

Measure the crankshaft runout.

Service limit: 0.06 mm (0.002 in)

BALANCER SHAFT INSPECTION

Inspect the balance shaft gear teeth.

Burrs/chips/roughness/wear → Replace.

Journals

Bolts

Balancer Shaft

13-8

Page 10

13. CRANKCASE/CRANKSHAFT

r

BALANCER SHAFT BEARING

REPLACMENT

Remove the crankshaft and balancer shaft

(page 13-4).

Turn the inner race of each bearing with your

finger.

The bearings should turn smoothly and

quietly. Also check that the bearing outer race

fits tightly in the crankcase.

Replace the bearings if the races does not turn

smoothly and quietly, or if they fit loosely in

the crankcase.

Bearing Pulle

Remove the balancer shaft bearing from the

left crankcase using the special tool.

XCITING 500

Special tool: Bearing puller E037

Remove the bearing snap ring from right

crankcase.

Bearing

Bolts

13-9

Snap Ring

Page 11

13. CRANKCASE/CRANKSHAFT

r

XCITING 500

Remove the balancer shaft bearing from the

right crankcase.

Install the snap ring into the right crankcase.

Bearing

Snap Ring

Install the new bearings to the right and left

crankcase using special tool.

Special tool:

Oil seal & bearing driver E014

Oil Seal & Bring Drive

Breaing

13-10

Page 12

13. CRANKCASE/CRANKSHAFT

t

t

r

Crankshaf

CRANKCASE ASSEMBLY

Install the crankshaft to the left crankcase.

Align Balancer Shaf

Install the balancer shaft to align the punch

mark with the “O” mark on the crankshaft.

XCITING 500

Install the washer onto the crankshaft.

13-11

Left Front Cover

Washe

Page 13

13. CRANKCASE/CRANKSHAFT

t

XCITING 500

Install the oil collar and O-rings

Clean the right and left crankcase mating

surface thoroughly, being careful not to

damage them.

Install the dowel pins and O-ring.

Apply a light but through coating of sealant

(Threebond 1215 or equivalent) to all

crankcase mating surfaces except the oil

passage area.

Dowel Pins

Oil Collar/O-rings Dowel Pin/O-ring

Bol

Install the right crankcase over the left

crankcase.

Install and turn in the right crankcase bolt but

do not tighten it.

Install and tighten the left crankcase bolts in a

crisscross pattern in 2 – 3 steps to the

specified torque.

Torque: 12 N•m (1.2 kgf•m, 9 lbf•ft)

Tighten the right crankcase bolt to the

specified torque.

Torque: 12 N•m (1.2 kgf•m, 9 lbf•ft)

Bolts

Make sure that the crankshaft turns smoothly.

13-12

Page 14

13. CRANKCASE/CRANKSHAFT

XCITING 500

Install the cam chain guides to the right

crankcase and tighten the bolts to the

specified torque.

Torque: 20 N•m (2 kgf•m, 15 lbf•ft)

Install the cam chain to right crankcase.

Cam Chain Guides

Cam Chain

13-13

Loading...

Loading...