Page 1

18. IGNITION SYSTEM

XCITING 500

18

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

IGNITION SYSTEM

__________________________________________________________________________________

IGNITION SYSTEM LAYOUT------------------------------------------- 18-1

SERVICE INFORMATION------------------------------------------------ 18-2

TROUBLESHOOTING----------------------------------------------------- 18-2

IGNITION COIL INSPECTION ------------------------------------------ 18-4

IGNITION CONTROL MODULE ---------------------------------------- 18-5

18

18-0

Page 2

18. IGNITION SYSTEM

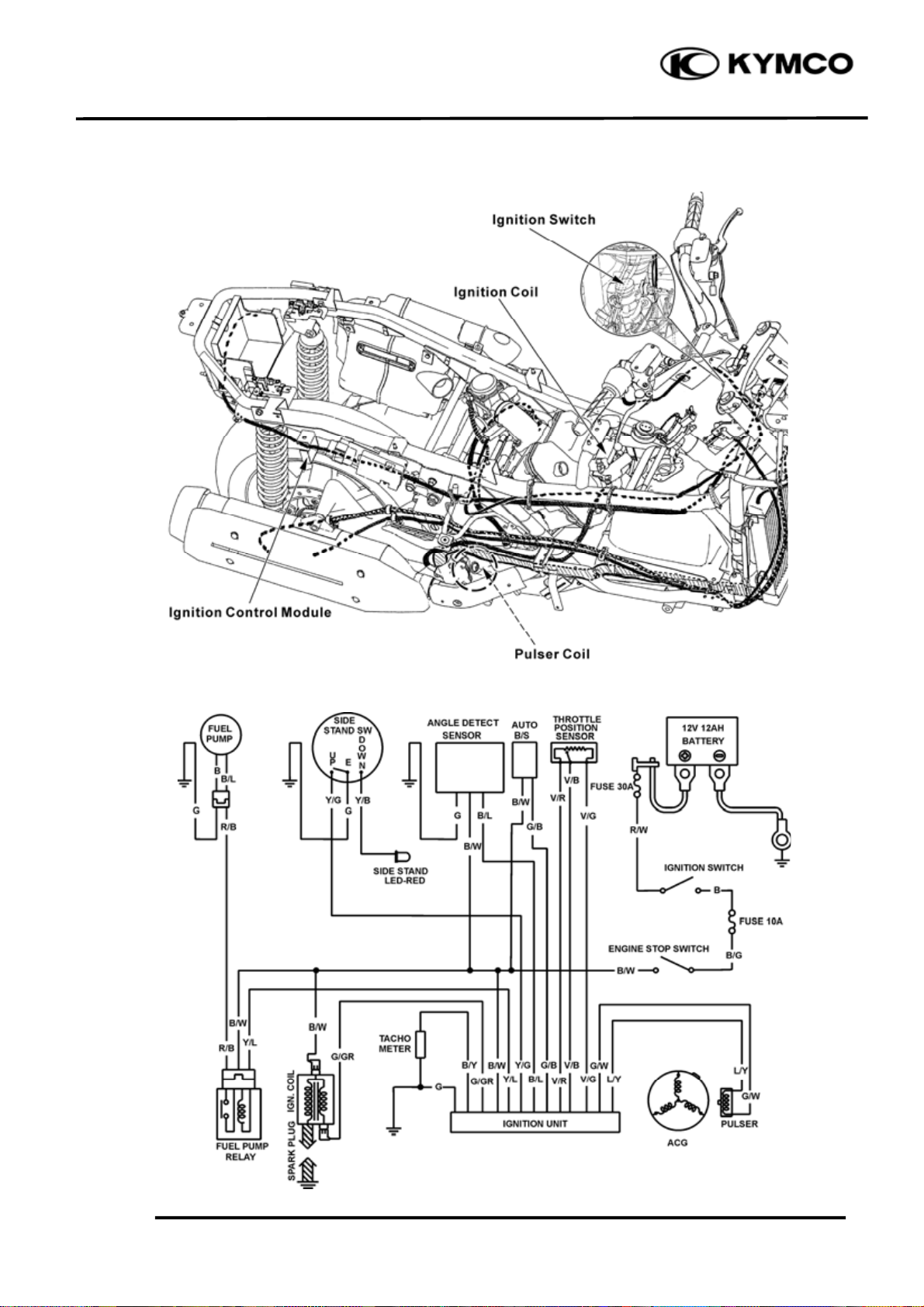

IGNITION SYSTEM LAYOUT

XCITING 500

IGNITION CIRCUIT

18-1

Page 3

18. IGNITION SYSTEM

XCITING 500

SERVICE INFORMATION

GENERAL INSTRUCTIONS

● Some electrical components may be damaged if terminals or connectors are connected or

disconnected while the ignition switch is “ON” and current is present.

● When servicing the ignition system, always follow the steps in the troubleshooting on page ???.

● The ignition timing cannot be adjusted since the ignition control module is factory preset.

● The ignition control module may be damaged if dropped. Also, if the connector is disconnected

when current is flowing, the excessive voltage may damage the ignition control module. Always

turn off the ignition switch before servicing.

● A faulty ignition system is often related to poor connections. Check those connections before

proceeding.

● Make sure the battery is adequately charged. Using the starter motor with a weak battery results in

a slower engine cranking speed as well as no spark at the spark plug.

● Use a spark plug of the correct heat range. Using spark plug with an incorrect heat range can

damage the engine.

● See section 12 for ignition pulse generator removal/installation.

● See section 20 for following components:

ä Ignition switch

ä Engine stop switch

SPECIFICATIONS

Item Standard

Spark plug NGK-CR8E

Spark plug gap 0.7 mm (0.028 in)

Ignition system Full transistor digital ignition

Ignition timing TPS

TROUBLESHOOTING

LOW PEAK VOLTAGE

● Cranking speed is too low (battery is undercharged).

● Poorly connected connectors or an open circuit in the ignition system.

● Faulty ignition-coil.

● Faulty ignition control module.

NO PEAK VOLTAGE

● Short circuit in engine stop switch or ignition switch wire.

● Faulty engine stop switch or ignition switch.

● Loose or poorly connected ignition control module connectors.

● Open circuit or poor connection in ground wire of the ignition control module.

● Faulty ignition pulse generator.

● Faulty ignition control module.

18-2

Page 4

18. IGNITION SYSTEM

PEAK VOLTAGE IS NORMAL, BUT NO SPARK JUMPS AT THE PLUG

● Faulty spark plug or leaking ignition coil secondary current.

● Faulty ignition coil.

XCITING 500

18-3

Page 5

18. IGNITION SYSTEM

XCITING 500

IGNITION COIL INSPECTION

IGNITION COIL PRIMARY PEAK

VOLTAGE

Remove the floorboard (page 2-6).

Check cylinder compression and check that the

spark plugs is installed correctly in the cylinder.

Disconnect the spark plug cap from the spark

plug.

Connect known good spark plug to the spark

plug cap and ground the spark plugs to the

cylinder as done in the spark test.

Spark Plug Cap

Turn the ignition switch to “ON” and engine

stop switch ON.

Connect the multimeter (+) probe to the

Black/White wire and the multimeter (-) to the

body ground.

Check for initial voltage at this time.

The battery voltage should be measured.

If the initial voltage cannot be measured, check

the power supply circuit.

Spark Plug Cap

Spark Plug Cap

18-4

Page 6

18. IGNITION SYSTEM

r

IGNITION PULSE GENERATOR

INSPECTION

Remove the luggage box (page 2-3).

Disconnect the ignition pulse generator

connector.

Measure the ignition pulse generator resistance

between the Green/White wire and Blue/Yellow

wire.

Standard: 516Ω (20ºC/68ºF)

IGNITION COIL

REMOVAL/INSTALLATION

Remove the floorboard (page 2-6).

Disconnect the spark plug cap from the spark

plug (page 18-4).

XCITING 500

Ignition Pulse Generator Connecto

Disconnect the ignition coil primary connectors.

Remove the two nuts and the ignition coil.

Installation is in the reverse order of removal.

IGNITION CONTROL MODULE

REMOVAL/INSTALLATION

Remove the side body cover (page 2-8).

Disconnect the ignition control module

connectors and remove the ignition control

module.

Spark Plug Cap

Ignition Control Module Connectors

18-5

Ignition Control Module

Page 7

18. IGNITION SYSTEM

/

/Gr

RESISTANCE INSPECTION

Measure the resistance between the terminals.

B

W G/B V/B

XCITING 500

*

Due to the semiconductor in circuit, it

is necessary to use a specified tester for

accurate testing. Use of an improper

tester in an improper range may give

false readings.

G

G

V/G

L/Y

G/W B/Y V/R Y/L B/L Y/G

Unit: Ω

(+)

(-)

L/Y 91.6K 6.67M 6.68M 46.2K 49.5K 150K 46.2K 12.59M 49.7K

G/GR 9.5M 9.3M ←↑9.23M 9M 9.16M 8.97M 8.96M ↑

G/W 91.8K 6.67M 6.68M ↑ 47K 50.3K 150.9K 47K 12.59M 50.3K ↑

B/Y 15.96M ↑ 15.6M 994 ↑ 15.33M 14.88M 15.04M 14.74M 3.35M 14.7M ↑

L/Y G/GR G/W B/Y B/W G/B G V/R V/B V/G Y/L B/L Y/G

B/W 15.96M ↑ 15.6M 994 ↑ 14.96M 14.88M 15.02M 14.74M 3.35M 14.7M ↑

G/B ↑ ←← ←←←←←←↑

G 44.3K ↑ 44.9K 6.62M 6.63M ↑ 3.54K 103.9K ∞ 12.51M 3.54K ↑

V/R 47.5K ↑ 48.4K 6.62M 6.63M ↑ 3.53K 100.2K 3.54K 12.51M 1.99K ↑

V/B 148.5K ↑ 149.4K 6.75M 6.76M ↑ 102.8K 99.3K 102.7K 12.67M 101.2K ↑

V/G 44.3K ↑ 44.9K 6.62M 6.63M ↑ ∞ 3.55K 103.9K 12.51M 3.55K ↑

Y/L 8.13M ↑ 8.1M ←↑7.81M 7.77M 7.91M 7.72M 7.72M ↑

B/L 47.5K ↑ 48.4K 6.62M 6.62M ↑ 3.53K 1.99K 102.2K 3.53K 12.51M ↑

Y/G ↑ ←←←←←←←←←

18-6

Loading...

Loading...