Kymco MO X500 Service Manual - chap 03 (manutenzione)

3. INSPECTION/ADJUSTMENT

XCITING 500

3

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

INSPECTION/ADJUSTMENT

__________________________________________________________________________________

SERVICE INFORMATION-------------------------------------------------- 3- 1

MAINTENANCE SCHEDULE---------------------------------------------- 3- 3

FUEL LINE--------------------------------------------------------------------- 3- 5

THROTTLE OPERATION--------------------------------------------------- 3- 5

AIR CLEANER ---------------------------------------------------------------- 3- 6

CRANKCASE BREATHER ------------------------------------------------- 3- 7

SPARK PLUG------------------------------------------------------------------ 3- 7

VALVE CLEARANCE------------------------------------------------------- 3- 9

ENGINE OIL------------------------------------------------------------------- 3-10

ENGINE OIL FILTER CARTRIDGE -------------------------------------- 3-13

ENGINE IDLE SPEED ------------------------------------------------------- 3-14

RADIATOR COOLANT ----------------------------------------------------- 3-15

COOLING SYSTEM---------------------------------------------------------- 3-16

SECONDARY AIR SUPPLY SYSTEM ----------------------------------- 3-17

TRANSMISSION OIL-------------------------------------------------------- 3-17

BRAKE FLUED --------------------------------------------------------------- 3-18

BRAKE PAD WEAR --------------------------------------------------------- 3-19

BRAKE SYSTEM ------------------------------------------------------------- 3-19

BRAKE LOCK OPERATION -----------------------------------------------3-20

HEADLIGHT AIM-------------------------------------------------------------3-21

SIDE STAND---------- ---------------------------------------------------------3-22

SUSPENSION-------------------------------------------------------------------3-22

NUTS, BOLTS, FASTENERS------------------------------------------------3-23

WHEELS/TIRES--------------------------------------------------------- ------3-23

STEERING HEAD BEARINGS----------------------------------------------3-24

3

3-0

3. INSPECTION/ADJUSTMENT

y

XCITING 500

SERVICE INFORMATION

GENERAL

Place the scooter on al level ground before starting any work.

Gasoline is extremely flammable and is explosive under certain conditions.

Work in a well ventilated area. Smoking or allowing flames or sparks in the work area or where

the gasoline is stored can cause a fire or explosion.

If the engine must be running to do some work, make sure the area is well ventilated. Never run

the engine in an enclosed area.

The exhaust contains poisonous carbon monoxide gas that may cause loss of consciousness and

may lead to death. Run the engine in an open area or with an exhaust evacuation sustem in and

enclosed area.

SPECIFICATIONS

ITEM SPECIFICATIONS

Throttle free play 2-6 mm (1/16 – 1/4 in)

Spark plug NGK CR8E

Spark plug gap 0.6 – 0.7 mm (0.024 – 0.028 in)

IN 0.1 mm (0.004 in)Valve clearance

EX 0.1 mm (0.004 in)

At draining 2.0 liter (2.1 US pt, 1.8 lmp qt)

Engine oil capacity

Recommended engine oil

Engine idle speed 1400±100 rpm

Final reduction oil capacit

Recommended final reduction oil SAE 90

Recommended brake fluid DOT 4

Parking brake lever stroke 3 – 6 notch

Tire size

Tire air pressure

Minimum tire tread depth

At draining/oil filter change 2.1 liter (2.2 US pt, 1.9 lmp qt)

Total amount 2.5 liter (2.6 US pt, 2.3 lmp qt)

KYMCO 4-stroke oil or equivalent

motor oil API service classification: SJ

Viscosity: 5W50

At draining 0.45 liter (0.48 US pt, 0.4 lmp qt)

Total amount 0.55 liter (0.57 US pt, 0.5 lmp qt)

Front 120/70-15

Rear 150/70-14

Solo riding

Two up riding

Front 200 kPa (2 kgf/cm2, 29 psi)

Rear 250 kPa (2.5 kgf/cm

Front 225 kPa (2.25 kgf/cm2, 32 psi)

Rear 250 kPa (2.5 kgf/cm

2

, 36 psi)

2

, 36 psi)

Front 1.6 mm (0.06 in)

Rear 2.0 mm (0.08 in)

3-1

3. INSPECTION/ADJUSTMENT

TORQURE VALUES

Engine oil drain plug 25 N•m (2.5 kgf•m, 18 lbf•ft)

Oil strainer screen cap 15 N•m (1.5 kgf•m, 11 lbf•ft)

Apply oil to the threads and seating surface.

Oil filter cartridge 10 N•m (1 kgf•m, 7 lbf•ft)

Apply oil to the threads and seating surface.

Transmission oil drain bolt 24 N•m (2.4 kgf•m, 18 lbf•ft)

Transmission oil filler bolt 24 N•m (2.4 kgf•m, 18 lbf•ft)

Spark plug 12 N•m (1.2 kgf•m, 9 lbf•ft)

Tappet adjust nut 9 N•m (0.9 kgf•m, 6 lbf•ft)

SPECIAL TOOLS

Tappet adjuster E036

Oil filter cartridge wrench E052

XCITING 500

3-2

3. INSPECTION/ADJUSTMENT

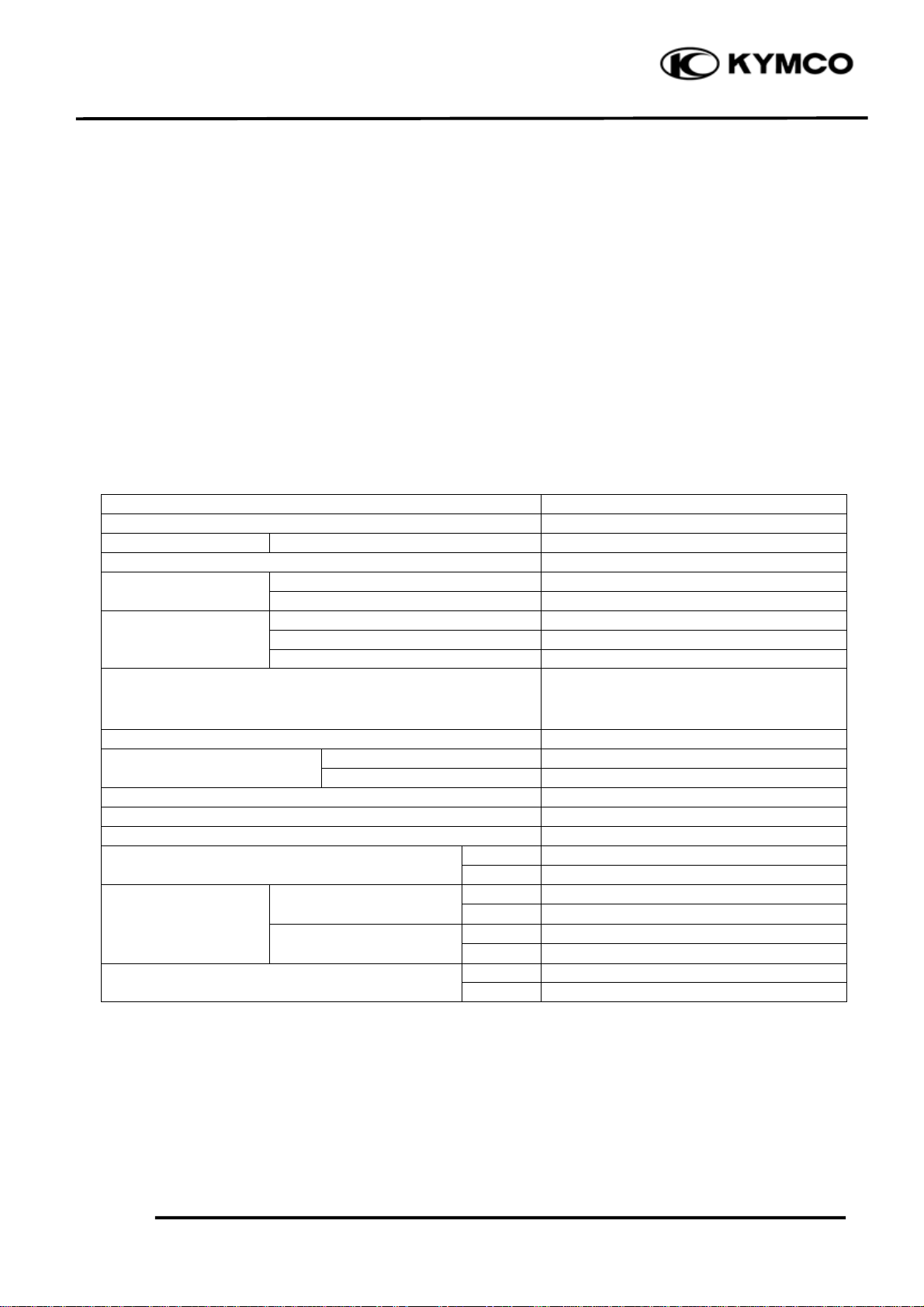

MAINTENANCE SCHEDULE

Perform the pre-ride inspection in the owner’s manual at each scheduled maintenance period.

This interval should be judged by odometer reading or months, whichever comes first.

I: INSPECT AND CLEAN, ADJUST, LUBRICATE OR REPLACE IF NECESSARY

C: CLEAN R: REPLACE A: ADJUST L: LUBRICATE

XCITING 500

3-3

3. INSPECTION/ADJUSTMENT

NOTE:

1 At higher odometer readings, repeat at the frequency interval established here.

2 Service more frequently if the scooter is ridden in unusually wet or dusty areas.

3 Service more frequently when riding in rain or at full throttle.

4 Inspect every 18000 km (12000 mi) after replacement.

5 Replace every 1 year, or every 10000km (6000mi), whichever comes first.

6 Replace every 2 year, or at indicated odometer interval, whichever comes first.

7 Replace every 2 years. Replacement requires mechanical skill.

XCITING 500

3-4

3. INSPECTION/ADJUSTMENT

r

r

FUEL LINE

Remove the floorboard. (

Check the fuel lines for deterioration, damage

or leakage. Replace the fuel line if necessary.

*

• Do not smoke or allow flames o

sparks in your working area.

FUEL FILTER

Visually check the fuel filter. If accumulation

of sediment or clogging is found, replace the

fuel filter with a new one.

page 2-6

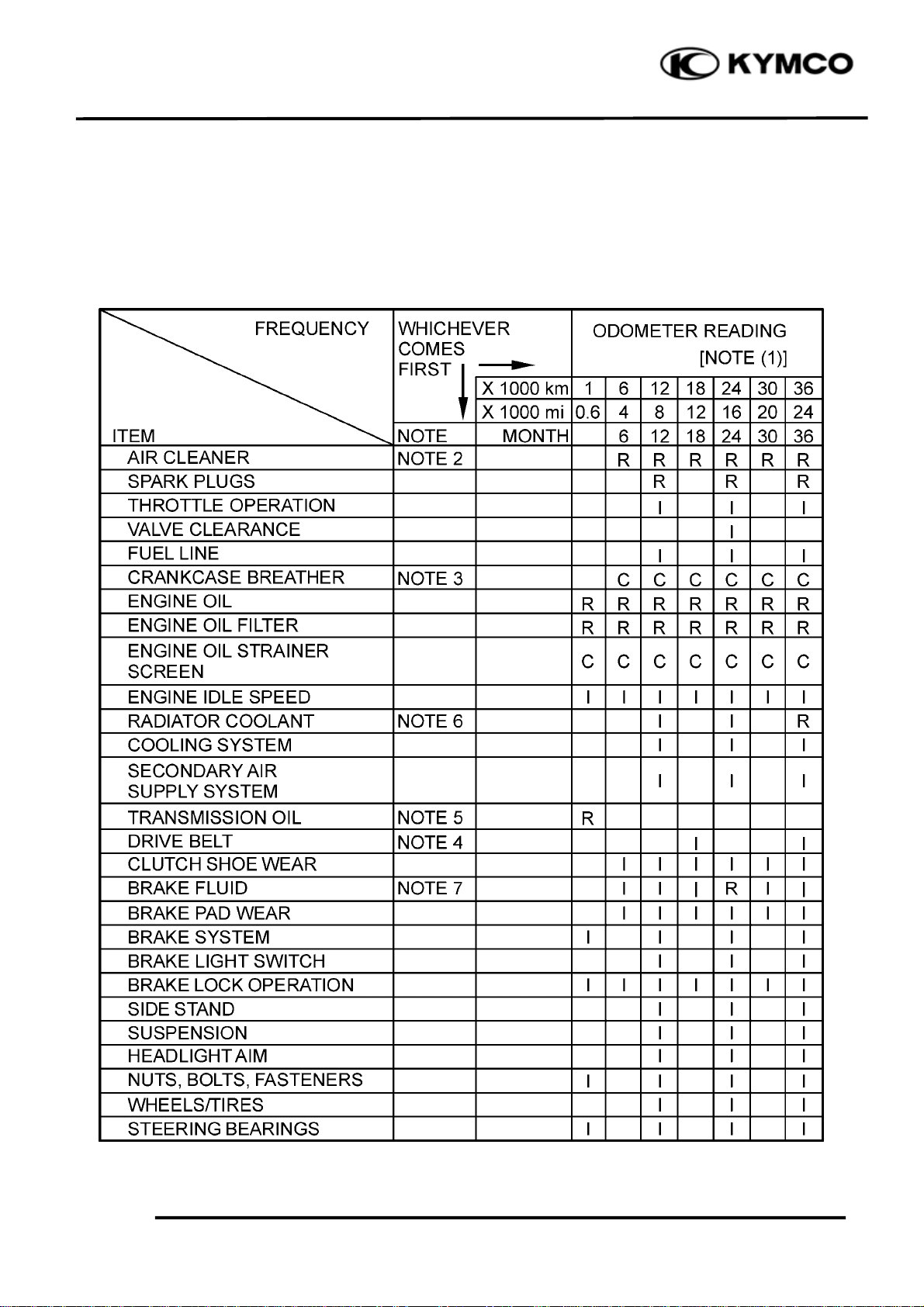

THROTTLE OPERATION

Check for smooth throttle grip full opening

and automatic full closing in all steering

positions.

Check the throttle cables and replace them if

they are deteriorated, kinked or damaged.

Lubricate the throttle cables, if throttle

operation is not smooth.

).

XCITING 500

Fuel Lines

Fuel Filte

Measure the throttle grip free play.

Free Play: 2~6 mm (1/16~1/4 in)

Throttle grip free play can be adjusted at

either end of the throttle cable.

Minor adjustment is made with the upper

adjuster.

Slide the rubber sleeve back to expose the

throttle cable adjuster.

Adjust the free play by loosening the lock nut

and turning the adjuster.

3-5

3. INSPECTION/ADJUSTMENT

r

r

t

t

XCITING 500

Major adjustments are made with the lower

adjuster.

Remove the seat luggage box (page 2-3).

Adjust the free play by loosening the lock nut

and turning the adjuster.

After adjustment, tighten the lock nut

securely.

Recheck the throttle operation.

Replace any damaged parts, if necessary.

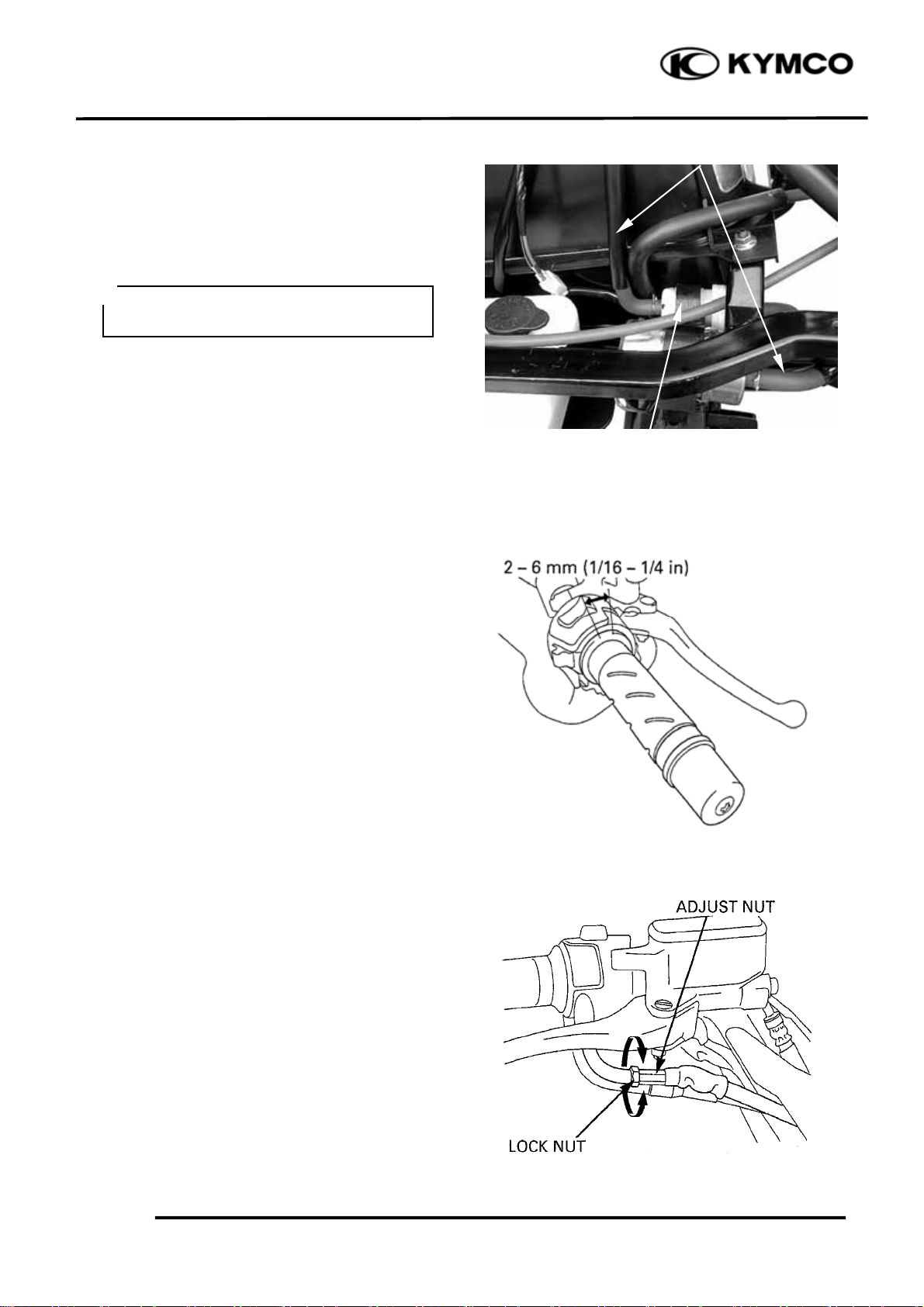

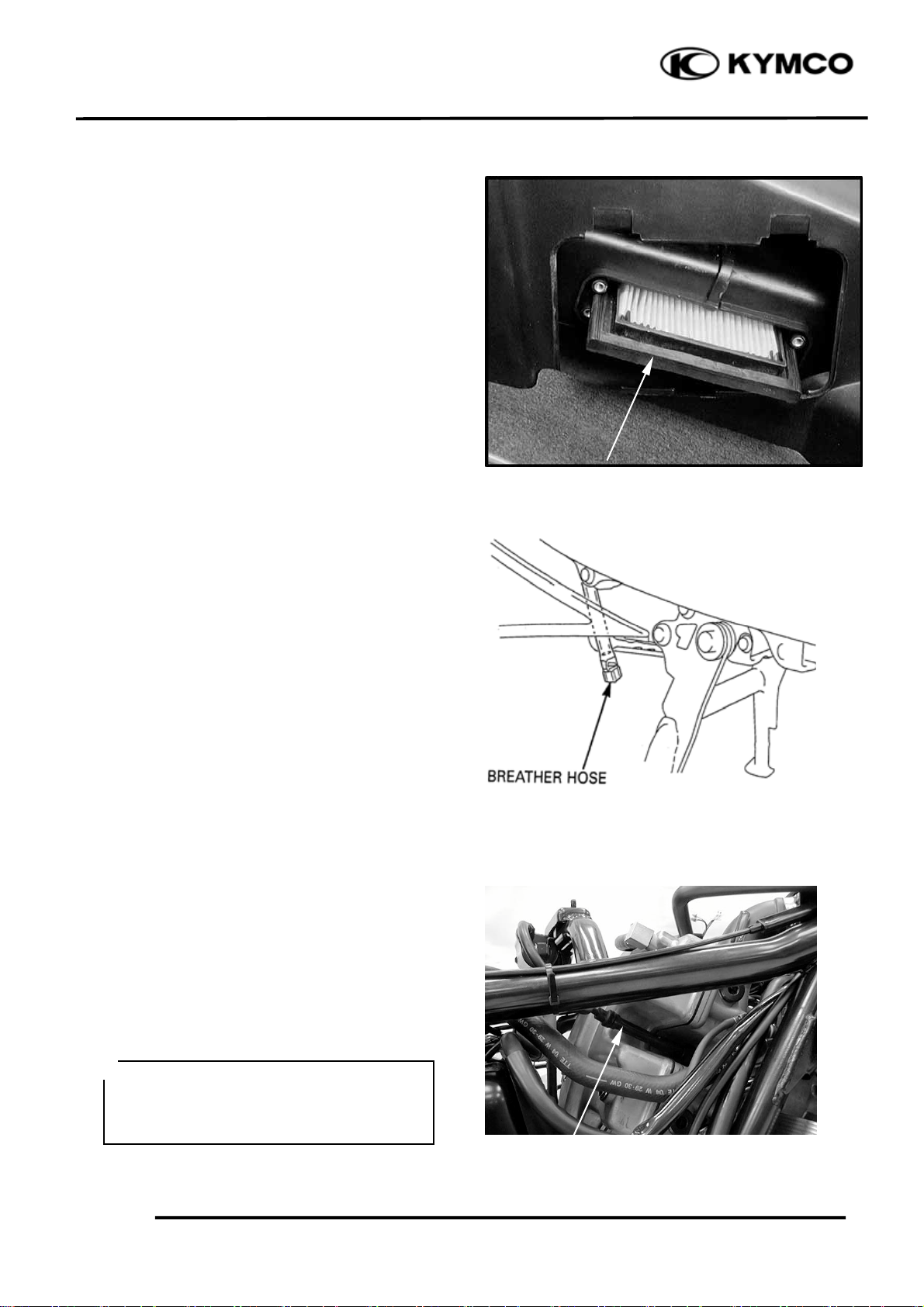

AIR CLEANER

The air cleaner should be serviced at regular

intervals. Service more frequently when

riding in unusually wet or dusty areas.

Adjust Nu

Lock Nu

Unlock the seat with the ignition key.

Open the seat.

Remove the air cleaner cover.

Remove the screws and air cleaner housing

cover

Air Cleaner Cove

Air Cleaner Housing Cove

3-6

3. INSPECTION/ADJUSTMENT

t

Remove the air cleaner element by pull it out.

Discard the air cleaner element.

Install a new air cleaner element. Use the

KYMCO genuine air cleaner element or an

equivalent air cleaner element specified for

your model. Using the wrong. KYMCO air

cleaner element or a non-KYMCO air cleaner

which is not of equivalent quality may cause

premature engine wear or performance

problems.

Install the removed parts in the reverse order

of removal.

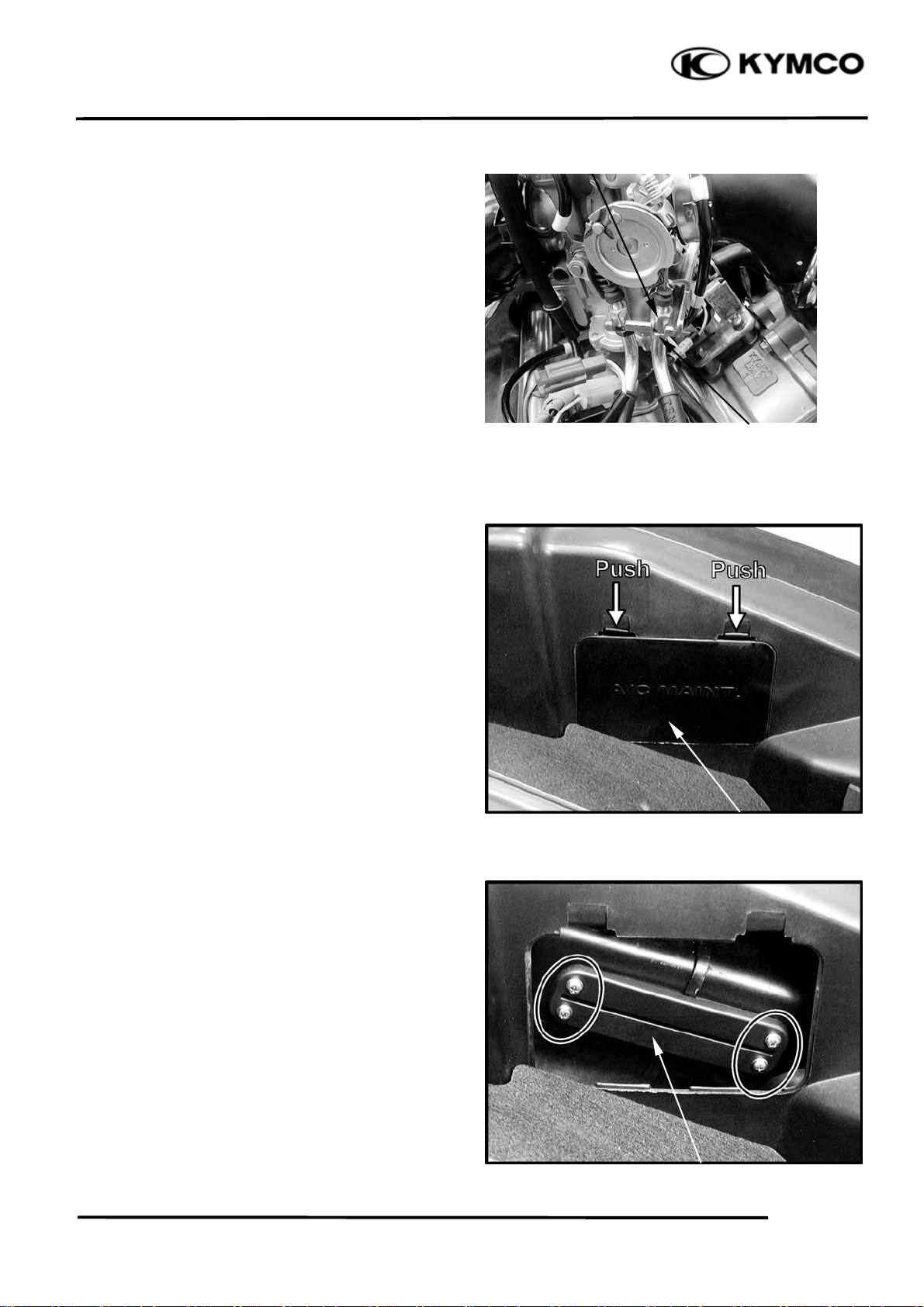

CRANKCASE BREATHER

XCITING 500

Screws

Air Cleaner Elemen

Remove the crankcase breather tube plug

from the tube and drain deposits into a

suitable container.

Reinstall the crankcase breather tube plug.

Service more frequently when riding in rain,

at full throttle, or after the scooter is washed

or overturned. Service if the deposit level can

be seen in the transparent section of the drain

tube.

SPARK PLUG

REMOVAL

Remove the spark plug maintenance lid (page

2-4).

Disconnect the spark plug cap and clean

around the spark plug base.

*

Clean around the spark plug base with

compressed air before removing, and be

sure that no debris is allowed to enter the

combustion chamber.

3-7

Spark Plug Cap

Loading...

Loading...