Page 1

20. LIGHTS/METERS/SWITCHES

XCITING 500

20

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

LIGHTS/METERS/SWITCHES

__________________________________________________________________________________

SERVICE INFORMATION------------------------------------------------ 20- 1

BULB REPLACEMENT --------------------------------------------------- 20- 2

SPEED SENSOR ------------------------------------------------------------ 20- 5

BRAKE LIGHT SWITCH-------------------------------------------------- 20- 7

IGNITION SWITCH -------------------------------------------------------- 20- 7

HANDLEBAR SWITCH --------------------------------------------------- 20- 8

PARKING SWITCH -------------------------------------------------------- 20-10

LUGGAGE BOX LIGHT SWITCH -------------------------------------- 20-10

OIL PRESSURE SWITCH------------------------------------------------- 20-10

FUEL UNIT ------------------------------------------------------------------ 20-13

SIDE STAND SWITCH ---------------------------------------------------- 20-15

HORN ------------------------------------------------------------------------- 20-16

BANK ANGLE SENSOR -------------------------------------------------- 20-17

HEATER CONTROL UNIT ----------------------------------------------- 20-18

20

20-0

Page 2

20. LIGHTS/METERS/SWITCHES

XCITING 500

SERVICE INFORMATION

GENERAL

*

A halogen head light bulb becomes very hot while the head light is on, and remains for a while

after it is turned off. Be sure to let it cool down before servicing.

• Note the following when replacing the halogen headlight bulb

ä Wear clean gloves while replacing the bulb. Do not put finger prints on the headlight bulb,

as they may create hot spots on the bulb and cause it to fail.

ä If you touch the bulb with your bare hands, clean it with a cloth moistened with alcohol to

prevent its early failure.

ä Be sure to install the dust cover after replacing the bulb.

• Check the battery condition before performing any inspection that requires proper battery

voltage.

• A continuity test can be made with the switches installed on the scooter.

• Route the wires and cables properly after servicing each component.

20-1

Page 3

20. LIGHTS/METERS/SWITCHES

r

BULB REPLACEMENT

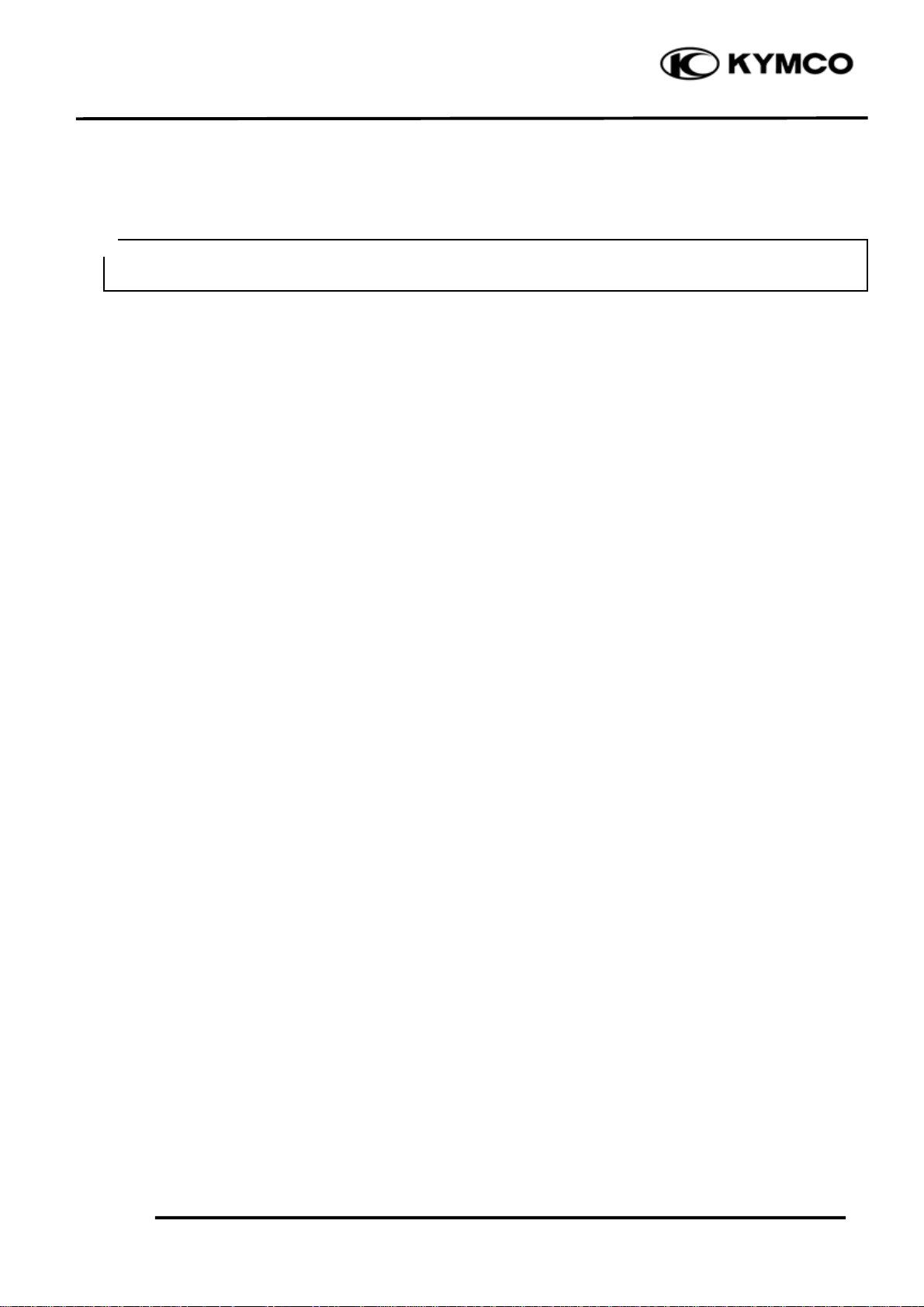

HEADLIGHT

*

A halogen headlight bulb becomes very

hot while the headlight is ON, and

remain for a while after it is turned OFF.

Be sure to let it cool down before

servicing.

Remove the front cover (page 2-11)

Disconnect the headlight connector from the

headlight bulb and remove the dust cover.

Unhook the retainer and remove the bulb from

the headlight case.

XCITING 500

Headlight Connector Dust Cove

Retainer Bulb

*

Avoid touching the halogen headlight

bulb. Finger prints can create hot spots

that cause a bulb to break.

Install a new bulb in the headlight case, by

aligning the bulb tab with the case groove.

Hook the retainer.

Install the dust cover properly on to the

headlight and connect the headlight connector

POSITION LIGHT

Remove the front cover (page 2-11).

Remove the bulb socket and position light bulb.

Remove the bulb and replace with a new one.

Installation is in the reverse order of removal.

Socket

Bulb

20-2

Page 4

20. LIGHTS/METERS/SWITCHES

t

XCITING 500

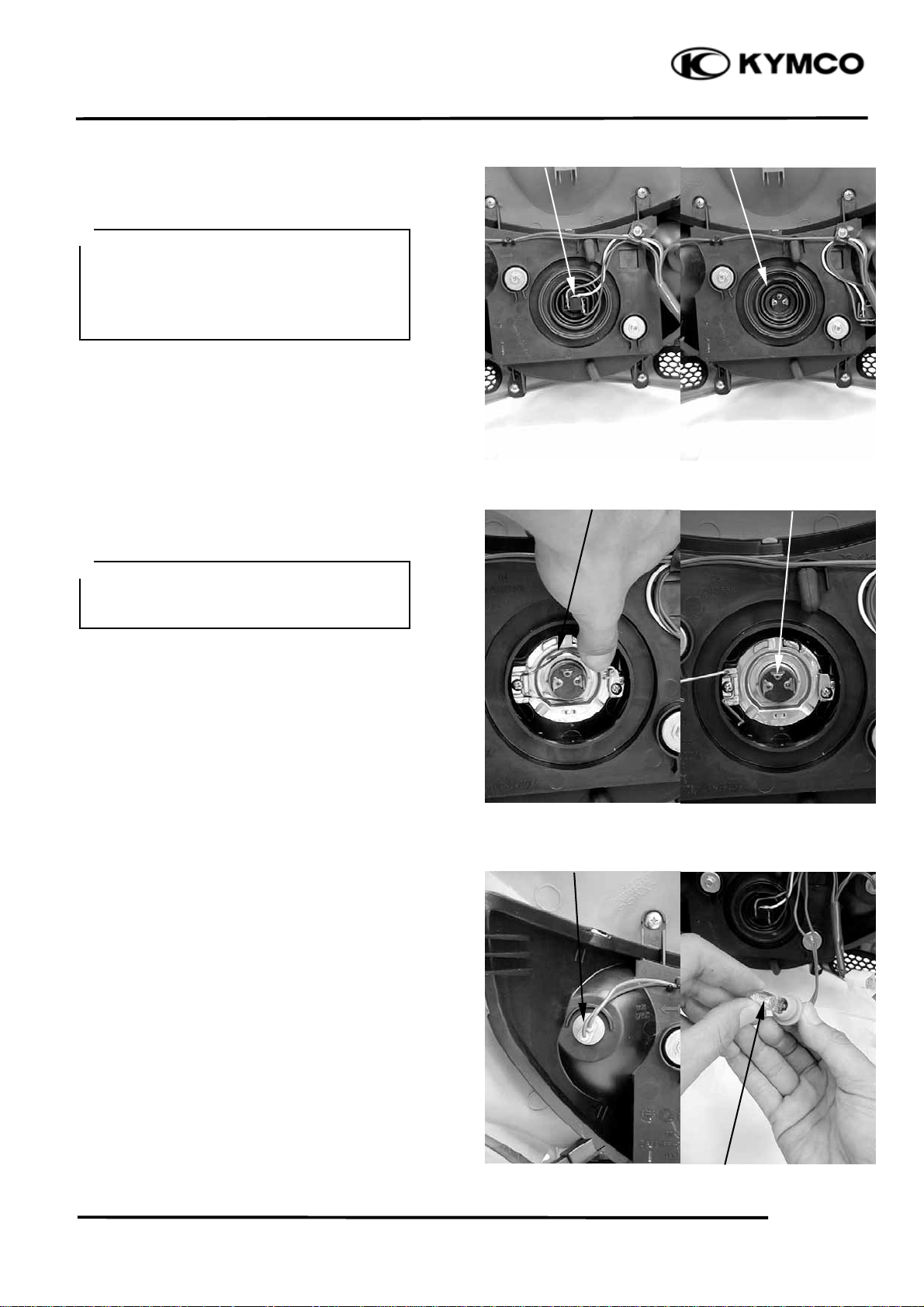

FRONT TURN SIGNAL

Remove the front cover (page 2-11).

Turn the bulb socket counterclockwise to

remove it.

Remove the bulb and replace with a new one.

Installation is in the reverse order of removal.

TAILLIGHT/BRAKE LIGHT, REAR TURN

SIGNAL

Remove the six screws and lens.

Socket Bulb

Screws

Taillight/Brake light

Remove the two screws and remove the

taillight/brake light.

20-3

Lens

Screws

Taillight/Brake Ligh

Page 5

20. LIGHTS/METERS/SWITCHES

r

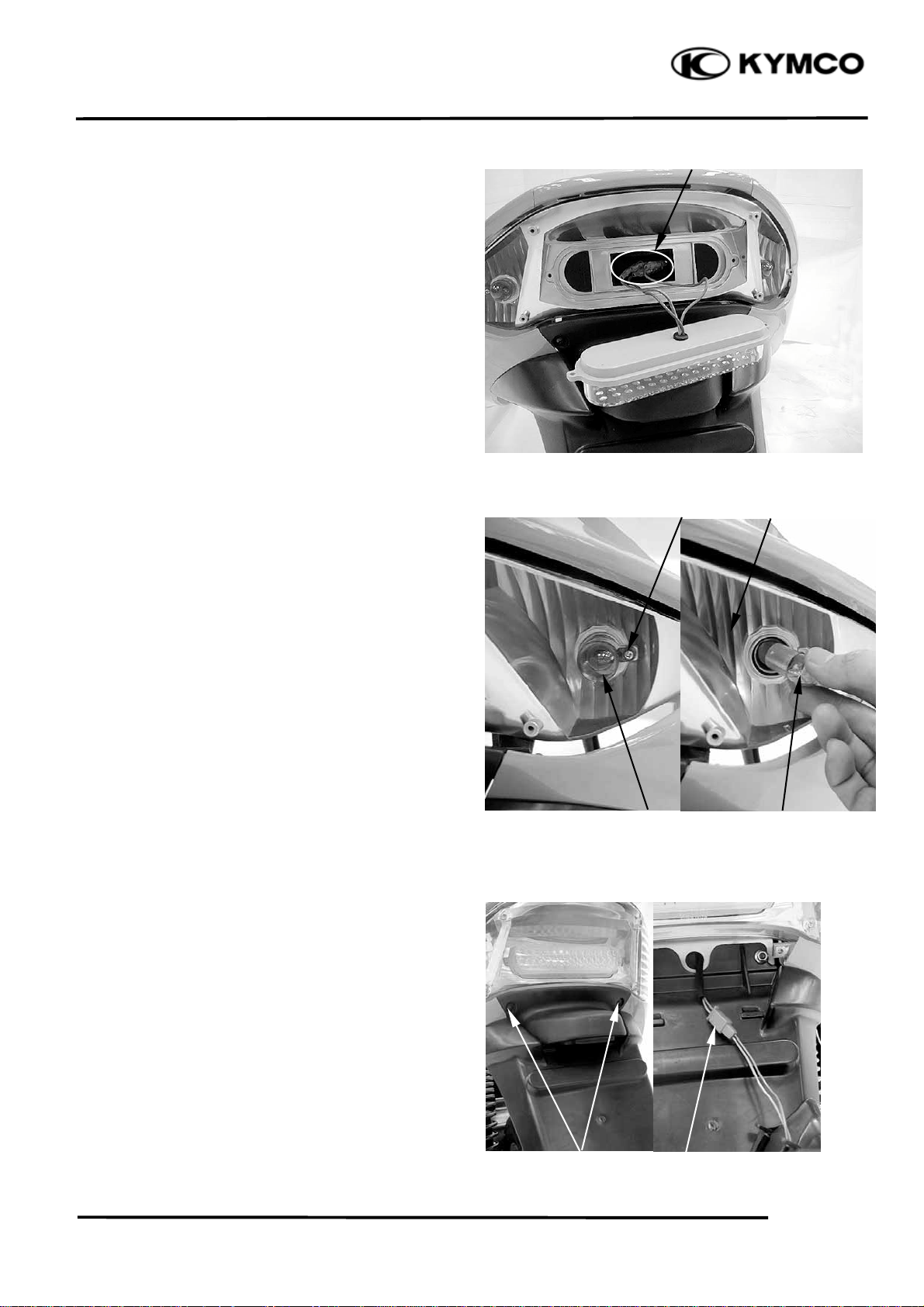

Connectors

Disconnect the taillight/brake light connectors.

Installation is in the reverse order of removal.

Screw

Rear turn signal

Remove the screw and bulb cap.

Remove the bulb and replace with a new one.

XCITING 500

Installation is in the reverse order of removal.

LICENSE LIGHT

Remove two screws.

Disconnect the license light connector and

remove the license light.

Cap Bulb

Screws Connecto

20-4

Page 6

20. LIGHTS/METERS/SWITCHES

r

r

r

Remove the bulb socket and license light bulb.

Remove the bulb and replace with a new one.

Installation is in the reverse order of removal.

Socket Bulb

Speed Sensor connecto

SPEED SENSOR

REMOVAL/INSTALLATION

Remove the front cover (page 2-11).

XCITING 500

Disconnect the speed sensor connector.

Remove the bolt and speed sensor.

Installation is in the reverse order of removal.

INSPECTION

Measure the speed sensor to speed sensor guide

clearance.

Standard (A): 0.3 – 1.2 mm (0.0012 – 0.048 in)

Bolt Speed Senso

Speed Senso

20-5

Speed Sensor Guide

Page 7

20. LIGHTS/METERS/SWITCHES

r

t

Speed Senso

ADJUSTMENT

Remove the bolt and speed sensor.

Bol

Remove the speed sensor cap.

XCITING 500

Loosen the lock screws and adjust speed sensor

to the standard clearance.

Standard: 0.3 – 1.2 mm (0.0012 – 0.048 in)

Cap

Lock Screw

Lock Screw

20-6

Page 8

20. LIGHTS/METERS/SWITCHES

XCITING 500

BRAKE LIGHT SWITCH

Remove the upper handlebar cover (page 2-5).

Disconnect front or rear light switch connector

and check for continuity between the switch

terminals.

There should be continuity with the front or rear

brake lever squeezed, and there should be no

continuity with the front or rear brake lever is

released.

IGNITION SWITCH

INSPECTION

Brake Light Switch

Connector Ignition Switch (Comb Switch)

Remove the front cover (page 2-11).

Disconnect the ignition switch connector and

check for continuity at the switch side connector

terminals.

Continuity should exist between the color code

wires as follows:

20-7

Page 9

20. LIGHTS/METERS/SWITCHES

Light Switch

HANDLEBAR SWITCH

INSPECTION

Remove the front cover (page 2-11).

Right handlebar switch

Disconnect the right handlebar switch connector

and check for continuity at switch side connector

terminals.

Continuity should exist between the color code

wires as follows:

Starter Switch

XCITING 500

Hazard Switch

Engine Stop Switch

20-8

Page 10

20. LIGHTS/METERS/SWITCHES

XCITING 500

Left handlebar switch

Disconnect the left handlebar switch connector

and check for continuity at switch side connector

terminals.

Continuity should exist between the color code

wires as follows:

Turn Signal Switch (Winker Switch)

Horn Switch

Passing Switch

20-9

Dimmer Switch

Page 11

20. LIGHTS/METERS/SWITCHES

r

r

r

XCITING 500

PARKING SWITCH

INSPECTION

Remove the front cover (page 2-11).

Disconnect the parking switch connector and

check for continuity between the switch

terminals.

There should be continuity with the parking

lever pull up, and there should be no continuity

with the front brake lever is push down.

LUGGAGE BOX LIGHT SWITCH

INSPECTION

Remove the luggage box (page 2-3).

Parking Brake Switch Connecto

Luggage Box Light Switch

Disconnect the luggage box light switch

connector and check for continuity between the

switch terminals.

There should be no continuity with the luggage

box light switch pushed, and there should be

continuity with the luggage box light switch is

released.

OIL PRESSURE SWITCH

INSPECTION

If the oil pressure warning indicator stays on

while the engine running, check the engine oil

level before inspection.

Make sure that the oil pressure warning

indicator come on with the ignition switch ON.

Switch Connecto

Oil Pressure Warning Indicato

20-10

Page 12

20. LIGHTS/METERS/SWITCHES

r

Dust Cove

If the indicator does not come on, inspect as

follow:

Remove the dust cover and disconnect oil

pressure switch terminal.

Oil Pressure Switch Terminal

Short the oil pressure switch wire terminal with

the ground using a jumper wire.

The oil pressure warning indicator comes on

with the ignition switch is ON.

If the light does not comes on, check the fuse

and wires for a loose connection or an open

circuit.

XCITING 500

Start the engine and make sure that the light

goes out.

If the light does not go out, check the internal oil

for leak.

If the engine oil does not leak, replace the oil

pressure switch (see below).

REMOVAL/INSTALLATION

Remove the dust cover and disconnect oil

pressure switch terminal.

Remove the oil pressure switch from the

crankcase.

Oil Pressure Switch

20-11

Page 13

20. LIGHTS/METERS/SWITCHES

r

Apply sealant to the oil pressure switch threads

as shown.

Install the oil pressure switch onto the crankcase,

tighten it to the specified torque.

Torque: 22 N•m (2.2 kgf•m, 16 lbf•ft)

Oil Pressure Switch Terminal

Connect the oil pressure switch terminal to the

switch.

XCITING 500

Install the dust cover.

Dust Cove

20-12

Page 14

20. LIGHTS/METERS/SWITCHES

r

t

Fuel Uni

FUEL UNIT

REMOVAL

Remove the floorboard (page 2-6).

Disconnect the fuel unit connector.

Fuel Unit Wire

Retaine

Turn the fuel unit retainer counterclockwise and

remove it.

XCITING 500

Remove the fuel unit.

*

Be careful not to bend or damage the

fuel unit float arm.

20-13

Page 15

20. LIGHTS/METERS/SWITCHES

INSPECTION

Connect the fuel unit wire connectors and turn

the ignition switch “ON”.

XCITING 500

*

Before performing the following test,

operate the turn signals to determine that

the battery circuit is normal.

Check the fuel meter for correct indication by

moving the fuel unit float up and down.

Float Position Display

Upper Much (Full)

Lower Less (Empty)

Wire Terminals Display

Free From Much to Less

Apply From Less to Much

The fuel meter is normal if it operates as above

indicated. If not, check for poorly connected

terminals or shorted wires.

Upper

INSTALLATION

Install the O-ring and fuel unit.

*

Align the groove on the fuel unit with

the flange on the fuel tank.

Lower

Groove

Flange

20-14

Page 16

20. LIGHTS/METERS/SWITCHES

t

r

r

Install the fuel unit retainer.

*

Align the arrow mark on the fuel unit

retainer with the arrow mark on the fuel

tank.

XCITING 500

SIDE STAND SWITCH

INSPECTION

Remove the left floor skirt (page 2-5).

Disconnect the side stand switch connector.

There should be continuity between the

Yellow/Green and Green with the side stand

retracted.

There should be continuity between the

Yellow/Black and Green with the side stand

applied.

REMOVAL

Remove the left floor skirt (page 2-5).

Disconnect the side stand switch connector.

Remove the bolt and side stand switch from the

side stand.

Side Stand Switch Connecto

Luggage Box Light Connecto

20-15

Bol

Page 17

20. LIGHTS/METERS/SWITCHES

t

r

Installs the side stand switch aligning the switch

pin with the side stand hole.

Install and tighten the side stand switch bolt

securely.

Hole Pin

Connecto

HORN

INSPECTION

Remove the front cover (page 2-11)

XCITING 500

Disconnect the horn connectors from the horn.

Connect a 12 V battery to the horn terminals.

The horn is normal if it sounds when the 12 V

battery is connected across the horn terminals.

REMOVAL/INSTALLATION

Remove the front cover (page 2-11)

Disconnect the horn connectors from the horn.

Remove the nut and horn.

Installation is in the reverse order of removal.

Horn

Nu

20-16

Page 18

20. LIGHTS/METERS/SWITCHES

r

BANK ANGLE SENSOR

INSPECTION

Support the scooter level surface.

Remove the meter panel (page 2-13).

Turn the ignition switch to “ON” and measure

the voltage between the following terminals of

the bank angle sensor connector with the

connector connected.

TERMINAL STANDARD

Black/Blue Battery voltage

Black/White Battery voltage – (0-1 V)

Bank Angle Senso

XCITING 500

The engine should stop as you incline the bank

angle sensor approximately degrees to the left or

right.

REMOVAL/INSTALLATION

Disconnect the bank angle sensor connector.

Remove the two screws, washers and bank angle

sensor.

20-17

Bank Angle Sensor Screws/Washers

Page 19

20. LIGHTS/METERS/SWITCHES

t

t

Installation is in the reverse order of removal.

*

Install the bank angle sensor with its

“UP” mark facing up.

Tighten the mounting screws securely.

XCITING 500

HEATER CONTROL UNIT

INSPECTION

Heater control unit inspection

1.Open ignition switch to check if the brown

/blue wire of it is enough voltage.

2.Put the heater controller unit in refrigerator. Start

engine after keeping the temperature under 10 ±

4℃.

3.Check if the yellow wire of heater controller

unit has output voltage.

Start engine and if the temperature of heater

controller unit is under 10 ± 4℃. Check if the

white/yellow wire of heater controller unit has

output voltage. If it has not any voltage. It is

damaged.

REMOVAL/INSTALLATION

Remove the side body cover (page 2-8).

Remove the nut and heater control unit.

Installation is in the reverse order of removal.

Nu

Heater Control Uni

20-18

Loading...

Loading...