Page 1

16. BRAKE SYSTEM

XCITING 500

16

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

BRAKE SYSTEM

__________________________________________________________________________________

SCHEMATIC DRAWING ------------------------------------------------- 16- 1

SERVICE INFORMATION------------------------------------------------ 16- 2

TROUBLESHOOTING----------------------------------------------------- 16- 3

BRAKE FLUID -------------------------------------------------------------- 16- 4

BRAKE PAD ----------------------------------------------------------------- 16-10

BRAKE DISC INSPECTION ---------------------------------------------- 16-13

FRONT MASTER CYLINDER ------------------------------------------- 16-14

REAR MASTER CYLINDER --------------------------------------------- 16-18

DELAY VALVE------------------------------------------------------------- 16-22

FRONT BRAKE CALIPER ------------------------------------------------ 16-24

REAR/PARKING BRAKE CALIPER------------------------------------ 16-26

16

PARKING BRAKE LEVER LINK --------------------------------------- 16-31

16-0

Page 2

16. BRAKE SYSTEM

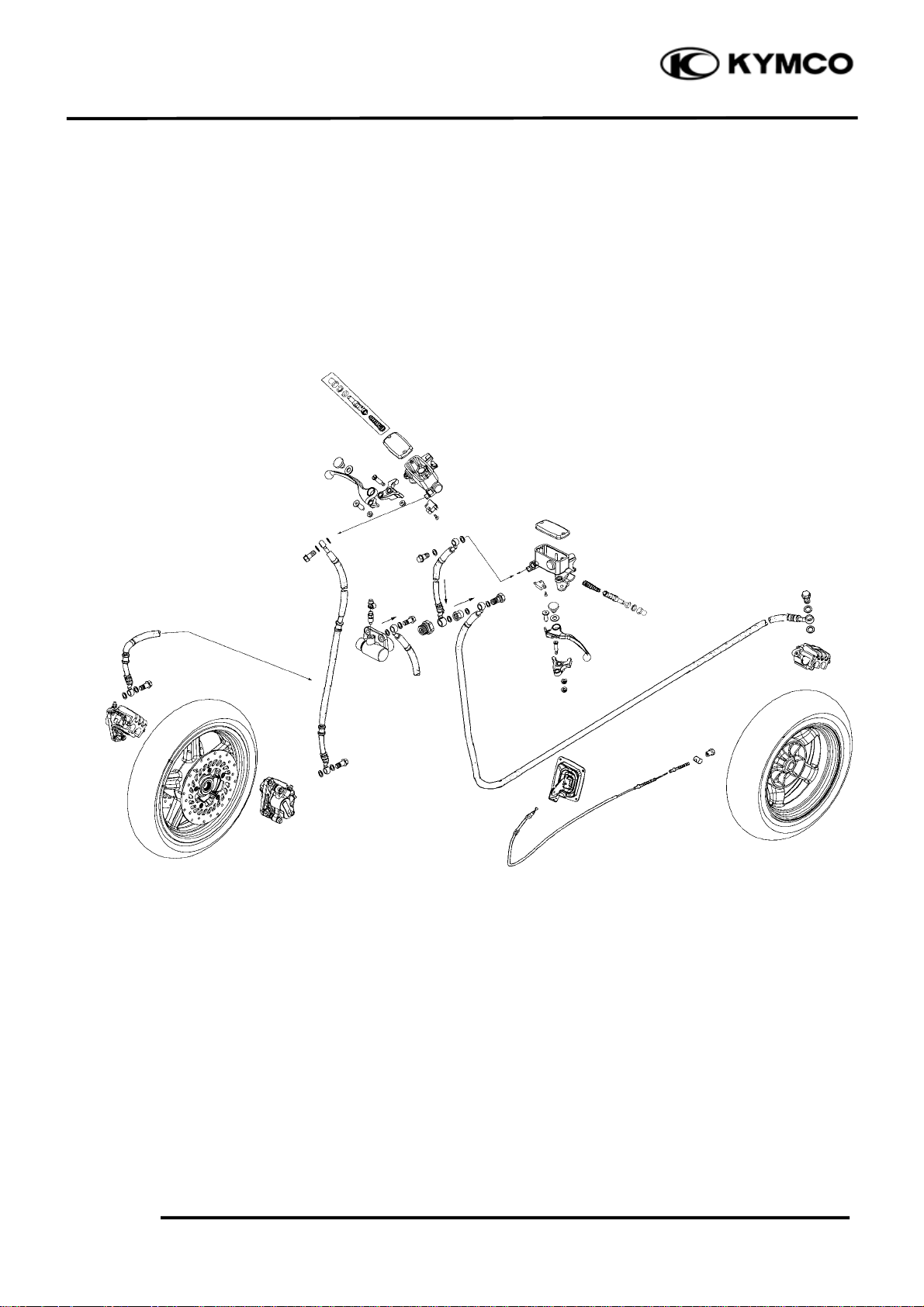

SCHEMATIC DRAWING

XCITING 500

16-1

Page 3

16. BRAKE SYSTEM

r

XCITING 500

SERVICE INFORMATION

GENERAL

*

Frequent inhalation of brake pad dust, regardless of material composition could be hazardous

to your health.

Avoid breathing dust particles.

• A contaminated brake disc or pad reduces stopping power. Discard contaminated parts and clean

a contaminated disc with high quality brake degreasing agent.

• Avoid spilling brake fluid on painted, plastic or rubber parts. Place a rag over these parts

whenever the system is serviced.

• This section covers maintenance of the front and rear hydraulic brake system.

• Never allow contamination (dirt, water, etc.) to get into and open reservoir.

• Once the hydraulic system has been opened, or if the brake feel spongy, the system must be bled.

• Always use fresh DOT 4 brake fluid from a sealed container when servicing the system. Do not

mix different types of fluid as they may not be compatible.

• Always check brake operation before riding the vehicle.

SPECIFICATIONS

ITEM STANDARD SERVICE LIMIT

Front

Rea

Specified brake fluid DOT 4 ⎯

Brake disc thickness 4.8 – 5.2 (0.19 – 0.20) 4 (0.16)

Brake disc runout ⎯ 0.03 (0.012)

Specified brake fluid DOT 4 ⎯

Brake disc thickness 4.8 – 5.2 (0.19 – 0.20) 4 (0.16)

Brake disc warpage ⎯ 0.03 (0.012)

Unit: mm (in)

16-2

Page 4

16. BRAKE SYSTEM

TORQUE VALUES

Master cylinder reservoir cover screw 2 N•m (0.2 kgf•m, 1.4 lbf•ft)

Master cylinder holder bolt 12 N•m (1.2 kgf•m, 9 lbf•ft)

Brake lever pivot bolt 6 N•m (0.6 kgf•m, 4.3 lbf•ft)

Brake lever pivot nut 6 N•m (0.6 kgf•m, 4.3 lbf•ft)

Brake light switch screw 1 N•m (0.1 kgf•m, 0.7 lbf•ft)

Brake caliper mounting bolt 32 N•m (3.2 kgf•m, 23 lbf•ft)

ALOC bolt: replace with a new one.

Brake caliper bleed screw 6 N•m (0.6 kgf•m, 4.3 lbf•ft)

Brake pad pin 18 N•m (1.8 kgf•m, 13 lbf•ft)

Front/Rear caliper pad pin plug 2 N•m (0.2 kgf•m, 1.4 lbf•ft)

Brake hose oil bolt 35 N•m (3.5 kgf•m, 25 lbf•ft)

Delay valve bleed screw 6 N•m (0.6 kgf•m, 4.3 lbf•ft)

TROUBLESHOOTING

XCITING 500

Brake lever soft or spongy Brake lever hard

• Air in the hydraulic system • Clogged/restricted brake system

• Low brake fluid level • Sticking/worn caliper piston

• Clogged fluid passage • Caliper not sliding properly

• Contaminated brake disc/pad • Clogged/restricted fluid passage

• Warped/deformed brake disc • Worn caliper piston seal

• Worn brake disc/pad • Sticking/worn master cylinder piston

• Sticking/worn master cylinder piston • Bent brake lever

• Contaminated master cylinder

• Contaminated caliper Brake drag

• Caliper not sliding properly • Contaminated brake disc/pad

• Leaking hydraulic system • Worn brake disc/pad

• Worn caliper piston seal • Warped/deformed brake disc

• Worn master cylinder piston cups • Caliper not sliding properly

• Bent brake lever

16-3

Page 5

16. BRAKE SYSTEM

m

BRAKE FLUID

Check

Brake fluid: (page 3-18)

Brake hose:

Cracks/wear/damage → Replace.

Apply the brake lever several times.

Fluid leakage → Replace.

Brake hose clamp:

Loosen → Tighten

FLUID REPLACEMENT

Front brake

*

Avoid spilling brake fluid on painted,

plastic or rubber parts and so on. Place a

rag over these parts whenever the system

is serviced.

XCITING 500

Place the scooter on a level surface and keep

the handlebar straight.

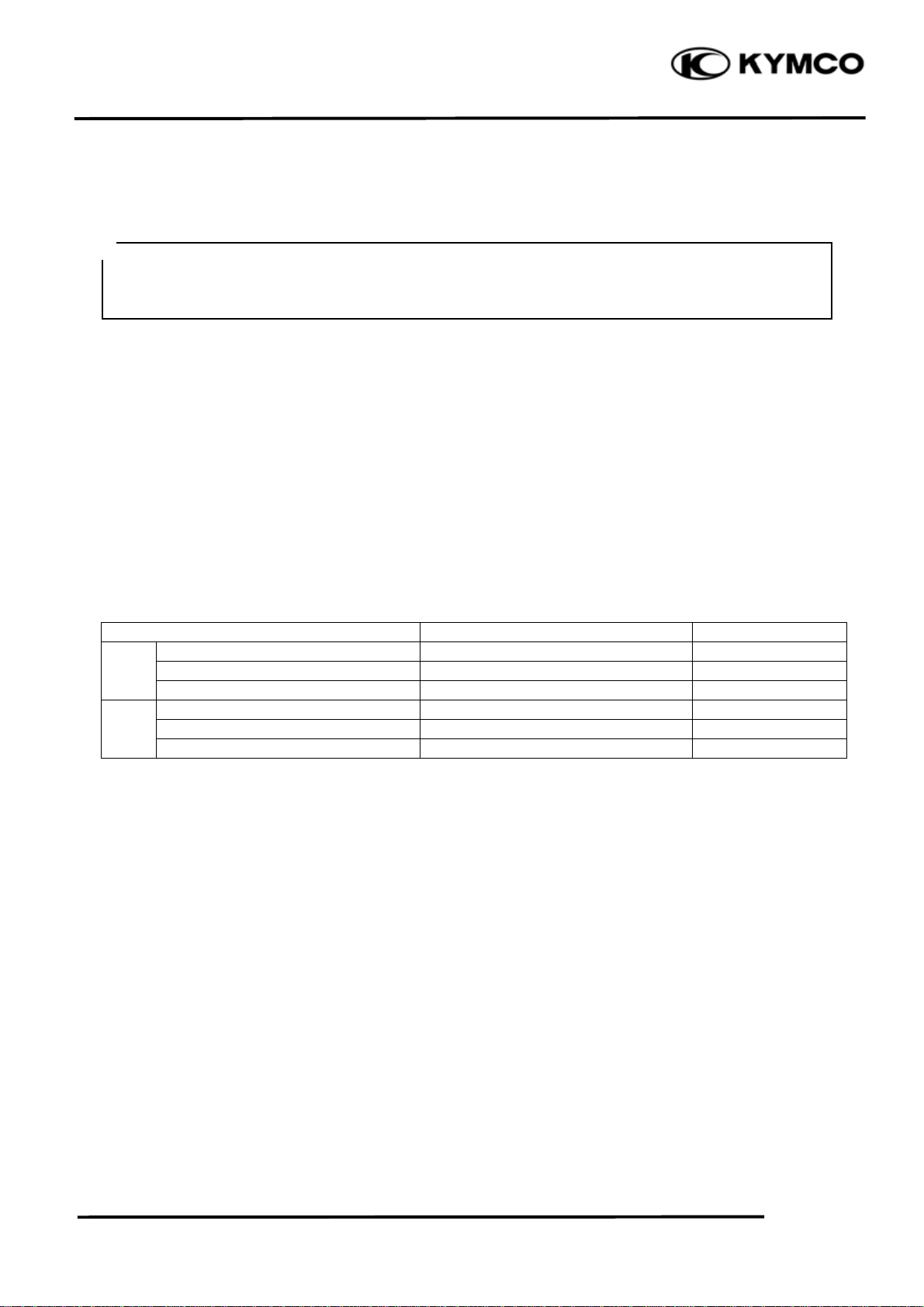

Remove the master cylinder reservoir cap and

diaphragm.

Suck up the old brake fluid as much as

possible.

Fill the reservoir with new brake fluid.

Specification and classification: DOT 4

Screws Cap/Diaphrag

16-4

Page 6

16. BRAKE SYSTEM

r

t

XCITING 500

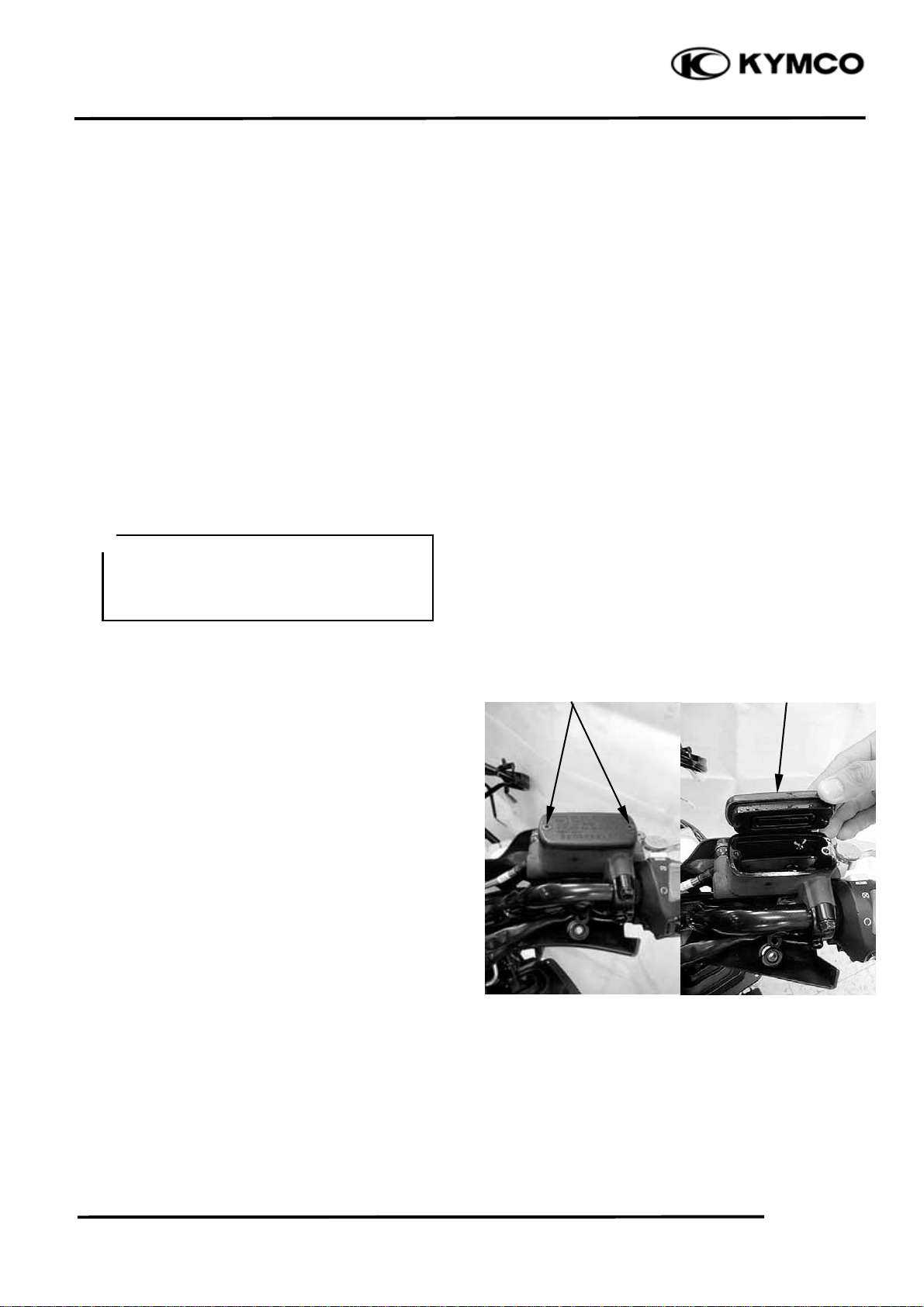

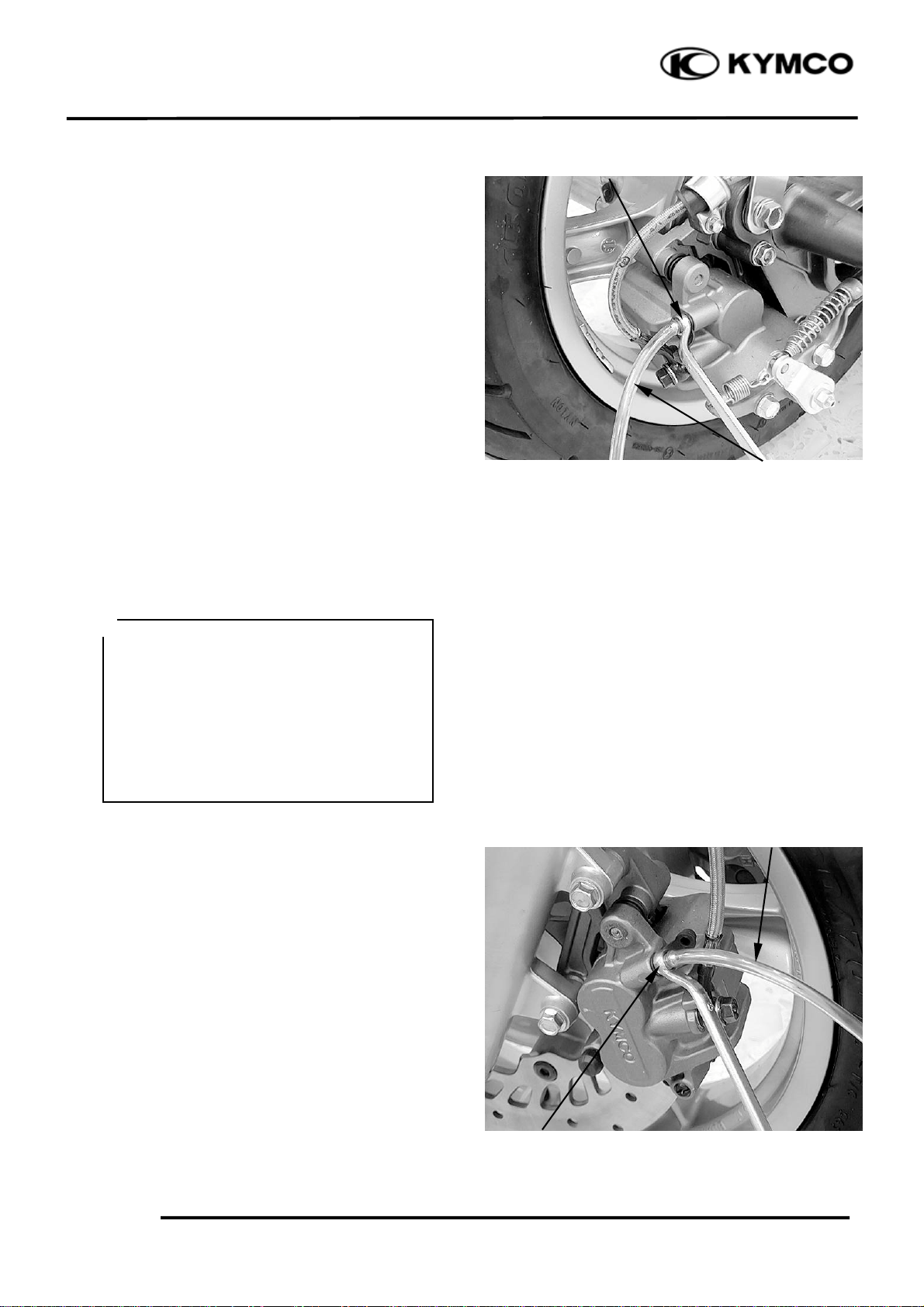

Connect a clear hose to the left front caliper

air bleed screw and insert the other end of the

hose into a receptacle.

Loosen the air bleed screw and pump the

brake lever until the old brake fluid is

completely out of the brake system.

Clear Hose

Left Front Caliper Air Bleed Screw

Brake Leve

Close the air bleed screw and disconnect the

clear hose. Fill the reservoir with new brake

fluid to the upper end of the inspection

window.

Tighten the bleed screw to the specified

torque.

Torque: 6 N•m (0.6 kgf•m, 4.3 lbf•ft)

Combination brake

*

Avoid spilling brake fluid on painted,

plastic or rubber parts and so on. Place a

rag over these parts whenever the system

is serviced.

Place the scooter on a level surface and keep

the handlebar straight.

Shock Absorber Lower Mount Bol

16-5

Page 7

16. BRAKE SYSTEM

m

XCITING 500

Remove the master cylinder reservoir cap and

diaphragm.

Suck up the old brake fluid as much as

possible.

Fill the reservoir with new brake fluid.

Specification and classification: DOT 4

Step 1:

Connect a clear hose to the delay valve air

bleed screw and insert the other end of the

hose into a receptacle.

Loosen the air bleed screw and pump the

brake lever until the old brake fluid is

completely out of the brake system. Close

the air bleed screw and disconnect the clear

hose. Fill the reservoir with new brake fluid

to the upper end of the inspection window.

Screws Cap/Diaphrag

Clear Hose

Step 2:

Connect a clear hose to the right front

caliper air bleed screw. The right brake fluid

replacement is the same way as that of the

step 1.

Relay Valve Air Bleed Screw

Right Front Caliper Air Bleed Screw

Clear Hose

16-6

Page 8

16. BRAKE SYSTEM

XCITING 500

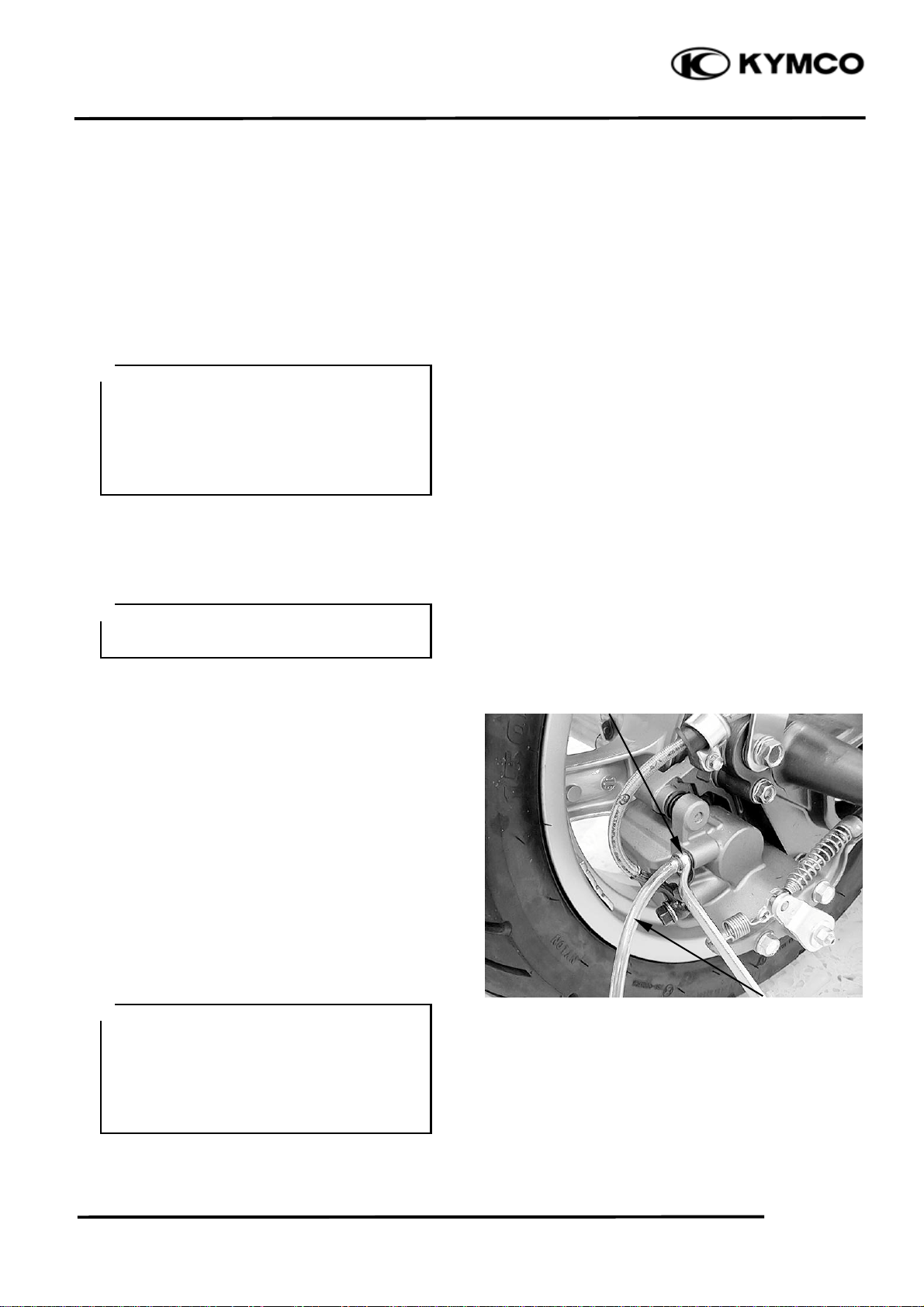

Step 3:

Connect a clear hose to the rear caliper air

bleed screw. The rear brake fluid

replacement is the same way as that of the

step 1.

BLEEDING THE HYDRAULIC BRAKE

SYSTEM

Rear Caliper Air Bleed Screw

Clear Hose

*

Bleed the brake fluid circuit:

● The system has been disassembled.

● A brake hose or brake pipe have been

loosened or removed.

● The brake fluid has been very low.

● The brake operation has been faulty.

A loss of braking performance may occur

if the brake system is not properly bled.

Air bleeding steps (Front brake):

1. Add the proper brake fluid to the reservoir.

2. Install the diaphragm. Be careful not to spill

any fluid or allow the reservoir to overflow.

3. Connect the clear plastic hose tightly to the

left front caliper air bleed screw.

4. Place the other end of the hose into a

container.

5. Slowly apply the brake lever several times.

6. Pull the lever in and hold it.

7. Loosen the bleed screw and allow the

lever to travel towards its limit.

Clear Hose

Left Front Caliper Air Bleed Screw

16-7

Page 9

16. BRAKE SYSTEM

8. Tighten the bleed screw when the lever

limit has been reached, then release the

lever.

9. Repeat steps (5) to (7) until all the air

bubbles have disappeared from the fluid.

10. Tighten the bleed screw.

Torque: 6 N•m (0.6 kgf•m, 4.3 lbf•ft)

*

If bleeding is difficult, it may be

necessary to let the brake fluid settle for

a few hours.

Repeat the bleeding procedure when the

tiny bubbles in the system have

disappeared.

12. Add brake fluid to the proper level and

install the master cylinder reservoir cap

and diaphragm.

XCITING 500

*

Check the operation of the brake after

bleeding the brake system.

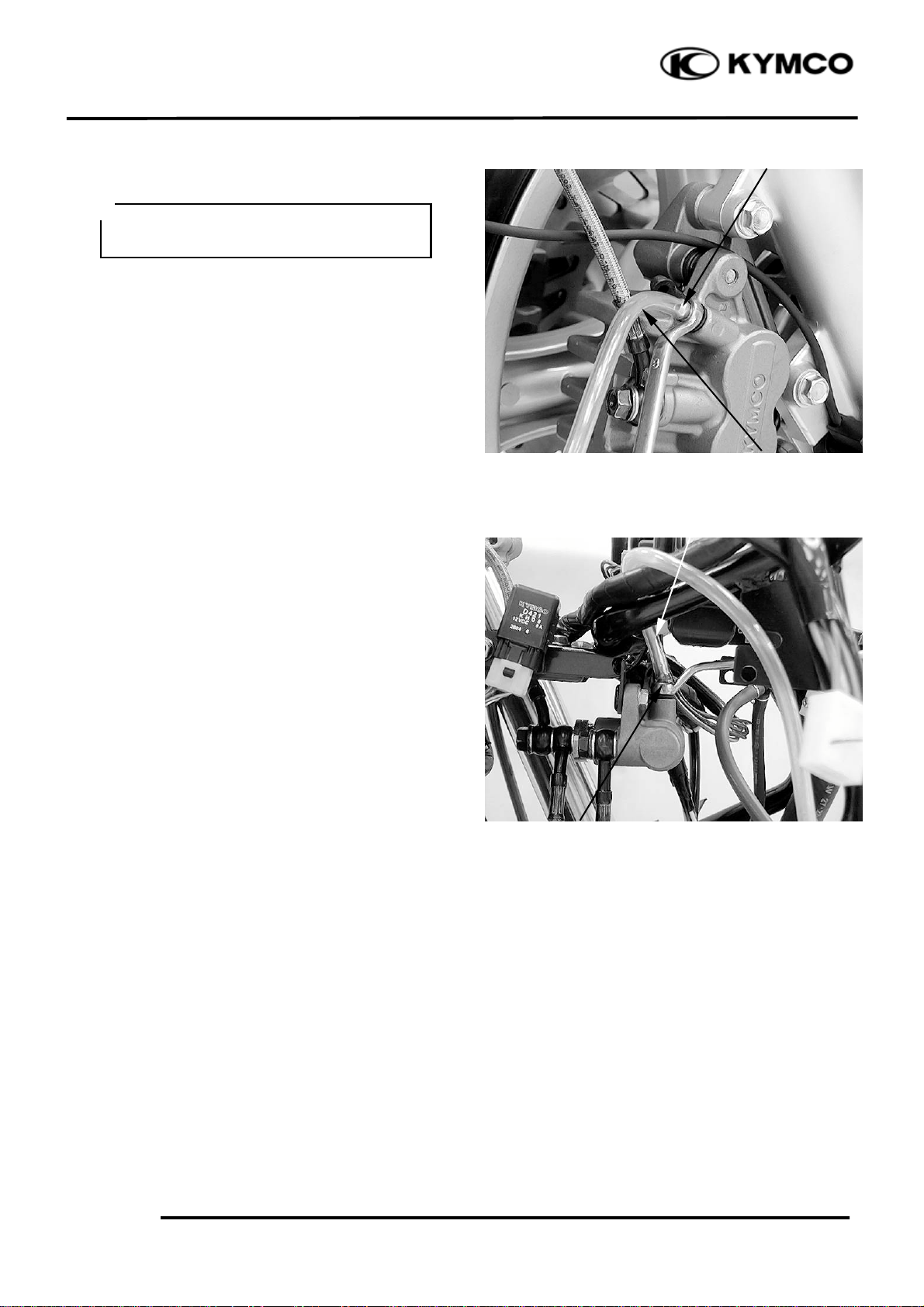

Air bleeding steps (combination brake):

The combination brake system air bleeding is

the same manner as that of the front brake

one.

Bleed the air from the rear side (rear caliper)

and then the front side (right front caliper and

delay valve).

Tighten the bleed screw.

Torque: 6 N•m (0.6 kgf•m, 4.3 lbf•ft)

*

If bleeding is difficult, it may be

necessary to let the brake fluid settle for

a few hours.

Repeat the bleeding procedure when the

tiny bubbles in the system have

disappeared.

Rear Caliper Air Bleed Screw

Clear Hose

16-8

Page 10

16. BRAKE SYSTEM

Add brake fluid to the proper level.

*

Check the operation of the brake after

bleeding the brake system.

Install the master cylinder reservoir cap and

diaphragm.

XCITING 500

Right Front Caliper Air Bleed Screw

Clear Hose

Clear Hose

16-9

Relay Valve Air Bleed Screw

Page 11

16. BRAKE SYSTEM

BRAKE PAD

BRAKE PAD REPLACEMENT

Front brake:

Push the caliper pistons all the way in by

pushing the caliper body inward to provide

clearance for new pads.

*

Always replace the brake pads in pairs to

ensure even disc pressure.

XCITING 500

Caliper body

Remove the pad pin plug and loosen the pad

pin.

Remove the pad pin and the brake pads.

Make sure that the pad spring is installed in

original position.

Install new pads so that the their ends rest on

the pad retainer on the bracket properly.

Caliper body

Pad Pin Plug Pad Pin

Pad Pin

Install the pad pin by pushing the pads

against the pad spring to align the pad pin

holes in the pads and caliper.

Brake Pads

16-10

Page 12

16. BRAKE SYSTEM

XCITING 500

Tighten the pad pin to the specified torque.

Torque: 18 N•m (1.8 kgf•m, 13 lbf•ft)

Install the pad pin plug to the specified

torque.

Torque: 3 N•m (0.3 kgf•m, 2.2 lbf•ft)

Rear/Parking brake:

Remove the pad pin plug and loosen the pad

pin.

*

Always replace the brake pads in pairs to

ensure even disc pressure.

Pad Pin Pad Pin Plug

Remove the mount bolts and rear/parking

brake caliper from the rear fork.

Remove the pad pin and brake pads.

16-11

Pad Pin Plug Pad Pin

Rear/Parking Caliper Body Bolts

Page 13

16. BRAKE SYSTEM

Installation steps:

Turn the parking brake caliper piston

clockwise and push it into the parking brake

caliper.

Install the pad pin by pushing the pads

against the pad spring to align the pad pin

holes in the pads and caliper.

XCITING 500

Parking Brake Caliper Piston

Pin

*

Align the pin on the pad with the groove

on the parking brake caliper piston.

Install the rear/parking brake caliper to the

rear fork.

Install and tighten the new rear/parking brake

caliper mounting blots to the specified torque.

Torque: 32 N•m (3.2 kgf•m, 23 lbf•ft)

Groove

Rear/Parking Caliper Body Bolts

16-12

Page 14

16. BRAKE SYSTEM

XCITING 500

Tighten the pad pin to the specified torque.

Torque: 18 N•m (1.8 kgf•m, 13 lbf•ft)

Install the pad pin plug to the specified

torque.

Torque: 3 N•m (0.3 kgf•m, 2.2 lbf•ft)

BRAKE DISC INSPECTION

Visually inspect the brake disc for damage or

cracks.

Measure the brake disc thickness.

Pad Pin Pad Pin Plug

Service limits:Front: 4mm (0.16 in)

Rear: 4mm (0.16 in)

Replace the brake disc if the smallest

measurement is less than the service limit.

Measure the brake disc warpage.

Service limits:0.30 mm (0.012 in)

16-13

Page 15

16. BRAKE SYSTEM

r

XCITING 500

FRONT MASTER CYLINDER

REMOVAL

When removing the brake hose bolt, cover

the end of the hose to prevent contamination.

Secure the hose to prevent fluid from leaking

out.

Remove the upper handlebar cover (page 2-

5).

Drain the front brake hydraulic system (page

16-4).

Remove the two screws and lower handlebar

cover.

Disconnect the brake light connectors from

front master cylinder.

Lower Handlebar Cove

Screws

Remove the brake hose oil bolt, sealing

washers and brake hose eyelet.

Brake Light Switch Connectors

Sealing Washers

Bolt Brake Hose

16-14

Page 16

16. BRAKE SYSTEM

r

t

r

XCITING 500

Remove the bolts from the master cylinder

holder and remove the master cylinder

assembly.

DISASSEMBLY

Remove the brake lever pivot bolt and nut.

Remove the brake lever.

Master Cylinder Bolts

Holde

Nut Brake Leve

Remove the screw and brake light switch.

16-15

Pivot Bol

Brake Light Switch

Screw

Page 17

16. BRAKE SYSTEM

t

r

XCITING 500

ASSEMBLY

Install the brake light switch and tighten the

screw to the specified torque.

Torque: 1 N•m (0.1 kgf•m, 0.7 lbf•ft)

Apply silicone grease to the master piston tip.

Install the brake lever.

Apply silicone grease to the brake lever pivot

bolt sliding surface.

Install and tighten the pivot bolt to the

specified torque.

Brake Light Switch

Screw

Nut Brake Leve

Torque: 6 N•m (0.6 kgf•m, 4.3 lbf•ft)

Install and tighten the pivot nut to the

specified torque.

Torque: 6 N•m (0.6 kgf•m, 4.3 lbf•ft)

INSTALLATION

Align the pin on the master cylinder holder

with the hole on the handlebar.

Pivot Bol

Pin Hole

16-16

Page 18

16. BRAKE SYSTEM

Install the front master cylinders and holders

with the “UP” mark facing up.

Install the bolts and tighten the upper bolt

first then tighten the lower bolt to the

specified torque.

Torque: 12 N•m (1.2 kgf•m, 9 lbf•ft)

Rest the brake hose eyelet against the stopper.

Install the brake hose eyelet with the oil bolt

and new sealing washers.

Tighten the oil bolt to the specified torque.

XCITING 500

Bolts

“UP” Mark

Sealing Washers

Torque: 35 N•m (3.5 kgf•m, 25 lbf•ft)

Connect the brake light switch connectors.

Fill the reservoir to the upper level and bleed

the brake system (page 16-7).

Bolt Brake Hose

16-17

Brake Light Switch Connectors

Page 19

16. BRAKE SYSTEM

r

t

REAR MASTER CYLINDER

REMOVAL

When removing the brake hose bolt, cover

the end of the hose to prevent contamination.

Secure the hose to prevent fluid from leaking

out.

Remove the upper handlebar cover (page 2-

5).

Drain the combination brake hydraulic

system (page 16-5).

Remove the two screws and lower handlebar

cover.

Disconnect the brake light switch connectors

from master cylinder.

XCITING 500

Lower Handlebar Cove

Screws

Remove the brake hose oil bolt, sealing

washers and brake hose eyelet.

Brake Light Switch Connectors

Sealing Washers

Brake Hose Bol

16-18

Page 20

16. BRAKE SYSTEM

t

r

t

t

Remove the bolts from the master cylinder

holder and remove the master cylinder

assembly.

DISASSEMBLY

Remove the brake lever pivot bolt and nut.

Remove the brake lever.

XCITING 500

Holder Master Cylinde

Bol

Brake Lever Nu

Remove the screw and brake light switch.

16-19

Pivot Bol

Screw

Brake Light Switch

Page 21

16. BRAKE SYSTEM

t

t

ASSEMBLY

Install the brake light switch and tighten the

screw to the specified torque.

Torque: 1 N•m (0.1 kgf•m, 0.7 lbf•ft)

XCITING 500

Screw

Brake Light Switch

Apply silicone grease to the master piston tip.

Install the brake lever.

Apply silicone grease to the brake lever pivot

bolt sliding surface.

Install and tighten the pivot bolt to the

specified torque.

Torque: 6 N•m (0.6 kgf•m, 4.3 lbf•ft)

Install and tighten the pivot nut to the

specified torque.

Torque: 6 N•m (0.6 kgf•m, 4.3 lbf•ft)

INSTALLATION

Align the pin on the master cylinder holder

with the hole on the handlebar.

Brake Lever Nu

Pivot Bol

Hole Pin

16-20

Page 22

16. BRAKE SYSTEM

t

r

t

Install the rear master cylinders and holders

with the “UP” mark facing up.

Install the bolts and tighten the upper bolt

first then tighten the lower bolt to the

specified torque.

Torque: 12 N•m (1.2 kgf•m, 9 lbf•ft)

XCITING 500

“UP” Mark Master Cylinde

Bol

Rest the brake hose eyelet against the stopper.

Install the brake hose eyelet with the oil bolt

and new sealing washers.

Tighten the oil bolt to the specified torque.

Torque: 35 N•m (3.5 kgf•m, 25 lbf•ft)

Connect the brake light switch connectors.

Fill the reservoir to the upper level and bleed

the brake system (page 16-8).

Sealing Washers

Brake Hose Bol

16-21

Brake Light Switch Connectors

Page 23

16. BRAKE SYSTEM

DELAY VAVLE

REMOVAL

When removing the brake hose bolt, cover

the end of the hose to prevent contamination.

Secure the hose to prevent fluid from leaking

out.

Remove the front cover (page 2-11).

Drain the combination brake hydraulic

system (page 16-5).

Remove the brake hose oil bolt, sealing

washers and brake hose eyelets.

Remove the two nuts and delay valve.

XCITING 500

Sealing Washers Sealing Washers

Bolts Brake Hose

Nuts

Delay Valve

16-22

Page 24

16. BRAKE SYSTEM

XCITING 500

INSTALLATION

Install the delay valve and tighten the nuts

securely.

Install the brake hose eyelets and new sealing

washers.

Tighten the brake hose bolt to the specified

torque while rest the brake hose eyelet

against the stopper on the delay valve.

Nuts

Delay Valve

Sealing Washers Sealing Washers

Torque: 35 N•m (3.5 kgf•m, 25 lbf•ft)

Fill the reservoir to the upper level and bleed

the brake system (page 16-8).

Bolts Brake Hose

16-23

Page 25

16. BRAKE SYSTEM

r

r

FRONT BRAKE CALIPER

REMOVAL

Drain the front brake hydraulic system (left

front brake caliper: page 16-4) or

combination brake hydraulic system (right

front brake caliper: page 16-5).

Remove the brake pads (page 16-10).

Remove the oil bolts, sealing washers and

brake hose from the brake caliper.

Remove the mount bolts and front brake

caliper.

XCITING 500

Brake Hose

Bolts Sealing Washers

Bolts

DISASSEMBLY

Remove pad spring from the caliper body.

*

Do not remove the retainer from the

bracket unless replacement.

Brake Calipe

Sealing Washers Sealing Washers

Pad Spring Retaine

16-24

Page 26

16. BRAKE SYSTEM

t

r

XCITING 500

Remove the caliper bracket from the caliper

body.

*

Do not remove the caliper and bracket

pins unless replacement.

ASSEMBLY

Apply silicone grease to the boots inside.

Install the caliper bracket to the caliper.

Install the pad spring into the caliper body as

shown.

Boots Bracke

Bolts Brake Hose

Pad Spring

INSTALLATION

Install the front caliper onto the fork leg.

Install and tighten the new front caliper

mount bolts to the specified torque.

Torque: 32 N•m (3.2 kgf•m, 23 lbf•ft)

16-25

Bolts Brake Hose

Bolts

Brake Calipe

Page 27

16. BRAKE SYSTEM

XCITING 500

Install the brake hose eyelet to the caliper

body with new sealing washers and oil bolts.

Push the brake hose eyelet to the stopper on

the caliper, then tighten the oil bolts to the

specified torque.

Torque: 35 N•m (3.5 kgf•m, 25 lbf•ft)

Install the brake pads (page 16-10).

Fill and bleed the hydraulic system (page 16-

7 or page 16-8).

REAR/PARKING BRAKE

CALIPER

REMOVAL

Remove the muffler (page 2-15).

Drain the rear brake hydraulic system (page

16-5).

Brake Hose

Bolts Sealing Washers

Disconnect the parking brake cable from the

brake arm.

Remove the pad pin plug and loosen the pad

pin.

Remove the brake pad (page 16-11).

Remove the oil bolt, sealing washers and

brake hose from the brake caliper.

Arm Brake Cable

Brake Hose

Bolts Sealing Washers

16-26

Page 28

16. BRAKE SYSTEM

t

r

XCITING 500

Remove the mount bolts and rear/parking

brake caliper from the rear fork.

DISASSEMBLY (REAR BRAKE)

Remove the pad spring from the caliper body.

*

Do not remove the retainer from the

bracket unless replacement.

Rear/Parking Brake Caliper Bolts

Brake Hose

Remove the caliper bracket from the caliper

body.

*

Do not remove the caliper and bracket

pins unless replacement.

ASSEMBLY (REAR BRAKE)

Apply silicone grease to the boot inside.

Apply silicone grease to the boot inside.

Install the caliper bracket to the caliper.

16-27

Pad Spring Retaine

Bracke

Boots

Page 29

16. BRAKE SYSTEM

t

m

XCITING 500

Install the pad spring into the caliper body as

shown.

DISASSEMBLY (PARKING BRAKE)

Remove the lock nut and parking brake arm.

Pad Spring

Brake Ar

Remove the parking brake shaft and push rod.

Lock Nu

Brake Shaft Push Rod

16-28

Page 30

16. BRAKE SYSTEM

t

t

t

Removed the two bolts, gasket and parking

brake bracket.

ASSEMBLY (PARKING BRAKE)

Install the gasket.

XCITING 500

Bolts

Bracke

Gaske

Install the parking brake bracket and tighten

the bolts to the specified torque.

Torque: 32 N•m (3.2 kgf•m, 23 lbf•ft)

Apply silicone grease to the parking brake

shaft rolling surface.

Install the parking brake shaft.

16-29

Brake Shaf

Page 31

16. BRAKE SYSTEM

t

m

Temporarily install the brake arm and the

lock nut.

INSTALLATION

Install the brake pads (page 16-12).

XCITING 500

Brake Ar

Lock Nu

Rear/Parking Brake Caliper Bolts

Install the rear/parking brake caliper to the

rear fork and tighten the new mount bolts to

specified torque.

Torque: 32 N•m (3.2 kgf•m, 23 lbf•ft)

Install the brake hose eyelet to the caliper

body with new sealing washers and oil bolts.

Push the brake hose eyelet to the stopper on

the caliper, then tighten the oil bolts to the

specified torque.

Torque: 35 N•m (3.5 kgf•m, 25 lbf•ft)

Fill and bleed the hydraulic system (page 16-

8).

Brake Hose

Bolts Sealing Washers

16-30

Page 32

16. BRAKE SYSTEM

m

r

t

XCITING 500

Connect the parking brake cable.

Adjust the parking brake (page 3- 21).

PARKING BRAKE LEVER LINK

REMOVAL

Remove the inner cover (page 2-14).

Ar

Brake Cable

Brake Cable

Loosen the lock nut and disconnect the

parking brake cable from the parking braking

brake lever link.

Disconnect the parking brake switch

connector.

Lock Nu

16-31

Parking Brake Switch Connecto

Page 33

16. BRAKE SYSTEM

XCITING 500

Remove the two nuts and parking brake lever

link.

DISASSEMBLY

Remove the two screws and parking brake

switch.

Parking Brake Lever Link

Nuts

Parking Brake Switch

ASSEMBLY

Assembly is in the reverse order of

disassembly.

INSTALLATION

Installation is in the reverse order of removal.

Screw

16-32

Loading...

Loading...