Kymco MO P50 Service Manual - chap 03 (manutenzione)

3. INSPECTION/ADJUSTMENT

3-0

3

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

INSPECTION/ADJUSTMENT

__________________________________________________________________________________

INSPECTION AND MAINTENANCE SCHEDULE..................... 3- 1

BRAKE SYSTEM ..................................................................... 3- 4

MOVING DEVICE.................................................................... 3- 6

DAMPING DEVICE.................................................................. 3- 7

POWER DRIVE SYSTEM ......................................................... 3- 7

ELECTRICAL EQUIPMENT..................................................... 3- 8

ENGINE................................................................................... 3- 9

OTHERS .................................................................................. 3-12

3

3. INSPECTION/ADJUSTMENT

3-1

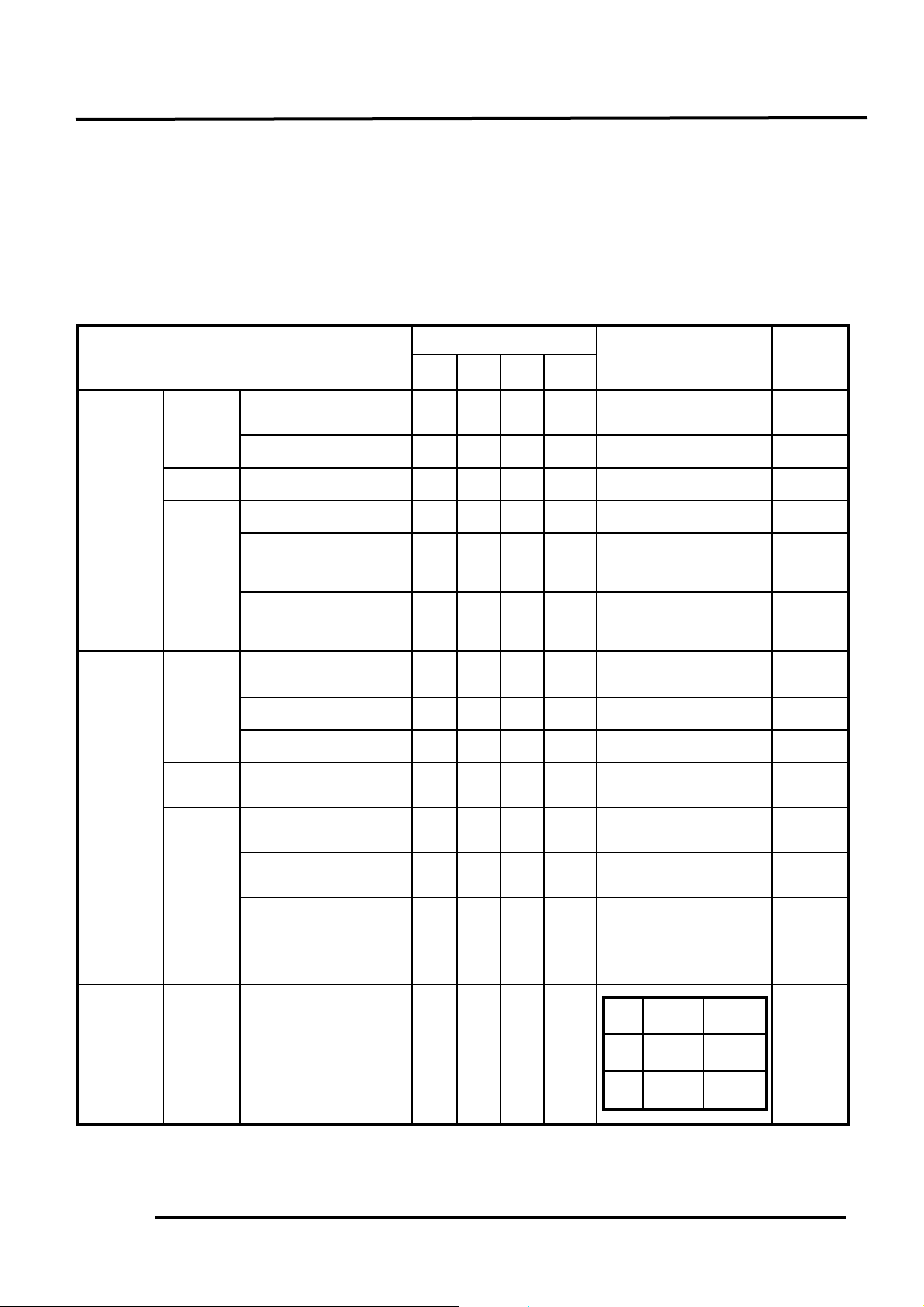

INSPECTION AND MAINTENANCE SCHEDULE

(Note) 1. ○ means time for inspection.

2. ☆ means regular replacement for the specified parts.

This inspection and maintenance schedule is based upon average riding conditions.

Machines subjected to serve use, or ridden in unusually dusty areas, require more frequent

servicing.

Frequency

Inspection & Maintenance Item

Preride

1st

month

Every 6

months

Every 12

months

Judgment Standards

Remarks

Check for looseness

and vertical play

○

Steering

handlebar

Operating performance

○

○

Right/left turning angle

○

Suspension

Damage

○

○

Check for front fork

pivot installation

○

○

Check

steering

stem

Front

fork

Check front fork pivot

for looseness and

abnormal noise

○

Check

steering

stem

Front/rear brake lever

free play

○

○

Free play:

10_ 20mm

Brake lever operation

○

Brake

Lever

Brake performance

○○○

Lever/

Cable

Looseness, abnormal

noise and damage

○

○

Brake

System

Drum-to-lining

clearance

○

○

Brake shoe and lining

wear

☆

Indicator

type

Brake

drum/

shoe

Brake drum wear and

damage

○

Standard:

Rear : 110 mm

Service Limits:

Rear : 111 mm

Moving

Device

Tire

Tire pressure

○○○

Front

Rear

1

rider

1.50

kg/cm_

1.75

kg/cm_

Tire

Size

70/90-16

90/80-16

3. INSPECTION/ADJUSTMENT

3-2

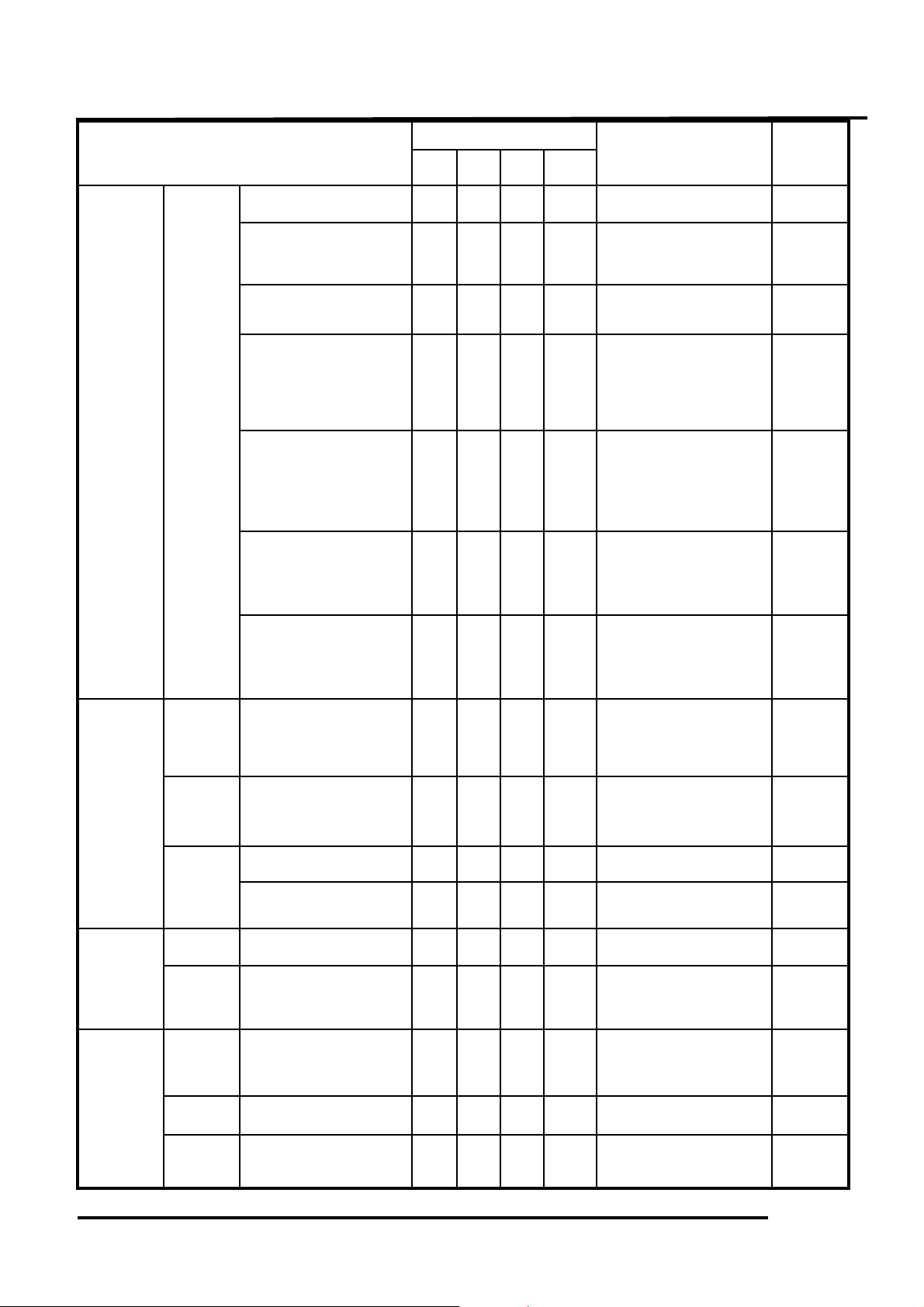

Frequency

Inspection & Maintenance Item

Preride

1st

month

Every 6

months

Every 12

months

Judgment Standards

Remarks

Tire crack and damage

○○○

Tire groove and

abnormal wear

○○○

Groove Depth:

Front: 0.8mm

Rear : 0.8mm

Imbedded objects,

gravel, etc.

○○○

Moving

Device

Motor-

cycle

Axle nut looseness

○

○

Torque Values:

Front axle nut

5.0_ 7.0kg-m

Rear axle nut

11.0_ 13.0kg-m

Axle nut

torque

Check wheel rim, rim

edge and spoke plate

for damage

○

○

Rim runout at rim end:

Front: Axial 2.0mm

Radial 2.0mm

Rear: Axial 2.0mm

Radial 2.0mm

Check front wheel

bear-ing for excessive

play and abnormal

noise

○

Check front wheel

bear-ing for excessive

play and abnormal

noise

○

Frame

Spring

Damage

Shock

spring

free

length

Suspen-

sion arm

Connecting parts

loose-ness and arm

damage

○

Shock

Oil leakage and damage

○

Damping

Device

absorber

Assembly parts looseness abnormal noise

○

Power

Clutch

Operation

○○○

Drive

System

Transmis

-sion case

Oil leakage and oil

level

○

○

Oil level:

Oil check bolt hole

at lower hole edge

Rear wheel

transmission case

Ignition

device

Spark plug condition

○○Plug gap:

0.6_ 0.7mm

Electrical

Equipment

Battery

Terminal connection

○

Wires

Loose connection and

damage

○

3. INSPECTION/ADJUSTMENT

3-3

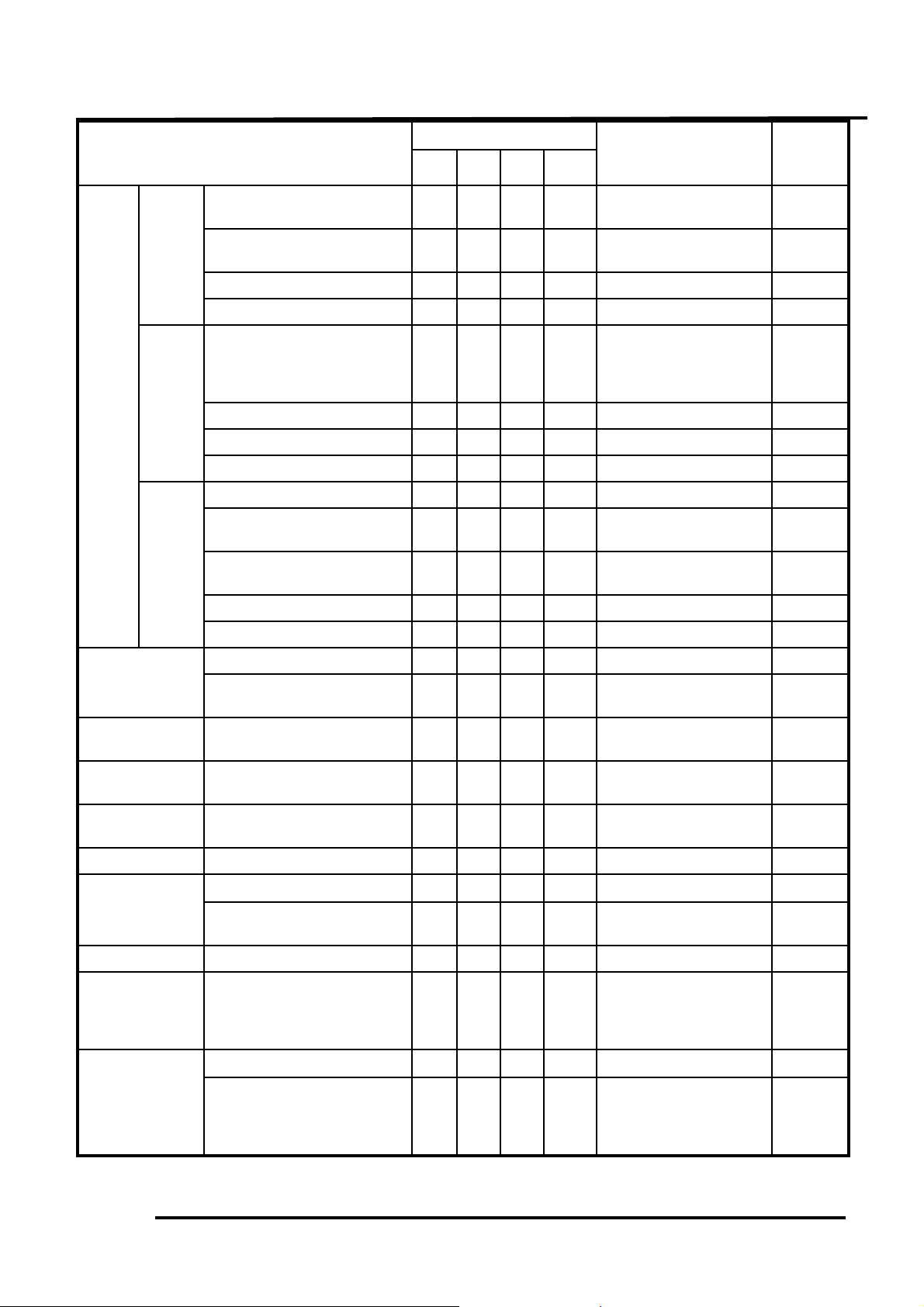

Frequency

Inspection & Maintenance Item

Preride

1st

month

Every 6

months

Every 12

months

Judgment Standards

Remarks

Performance and abnormal

noise

○

○

Body

Conditions at low and high

speeds

○○○

Exhaust smoke

○

○

Air cleaner

○

○

Oil quality and quantity

○

○

r Oil level indicator

Indicator light comes

on when oil is

insufficient

Engine

Oil leakage

○

○

Oil level

○

Lubrication

system

Check oil filter for clogging

○

Fuel leakage

Carburetor, throttle valve

and auto bystarter

○

Check fuel filter for

clogging

○

Fuel level

○

Fuel

System

Fuel tube replacement

☆ Every 4 years

Operation

Lights & Winker

Winking action, dirt and

damage

○

Buzzer &

Steering Lock

Operation

○

Rearview Mirror

& Reflector

Rearview mirror position

○

Rearview

Mirror

Reflector &

License Plate

Dirt and damage

○

Counter

Operation

○

Exhaust

Joint looseness and damage

○

Muffler

Exhaust muffler

performance

○

Body & Frame

Looseness and damage

○

Abnormal

Conditions

Happened Last

Time

Check if the abnormal

conditions occur again

○

Lubrication points

○

○

Others

Remove carbon deposits on

combustion chamber,

breather hole and exhaust

muffler

○

Loading...

Loading...