Page 1

5. ENGINE REMOVAL/INSTALLATION

5-0

5

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

ENGINE REMOVAL/INSTALLATION

__________________________________________________________________________________

SERVICE INFORMATION........................................................ 5-1

ENGINE REMOVAL................................................................. 5-2

ENGINE INSTALLATION........................................................ 5-4

5

Page 2

5. ENGINE REMOVAL/INSTALLATION

5-1

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• Parts requiring engine removal for servicing:

Crankcase

Crankshaft

TORQUE VALUES

Engine mounting bolt 4.5_ 5.5kg-m

Rear shock absorber lower mount bolt 2.4_ 3.0kg-m

Engine hanger bracket bolt 3.5_ 4.5kg-m

4.5_ 5.5kg-m

3.5_ 4.5kg-m

4.5_ 5.5kg-m

Page 3

5. ENGINE REMOVAL/INSTALLATION

5-2

ENGINE REMOVAL

Remove the frame body cover. (!12-5)

Remove the two bolts attaching the air

cleaner case.

Loosen the band between the air cleaner and

carburetor to remove the air cleaner case.

Remove the carburetor cap.

Disconnect the oil pump control cable from

the pump body.

Disconnect the oil inlet line from the oil

pump.

Disconnect the auto bystarter, A.C.

generator and starter motor wire connectors.

Remove the spark plug cap.

After the oil inlet line is disconnected,

plug the oil line opening to prevent oil

from flowing out.

*

Carburetor Cap

Oil Inlet Line

Oil Pump Control

Cable

Band

Air Cleaner Case

AC Generator Wire Connector

Spark Plug Cap

Bolt

Page 4

5. ENGINE REMOVAL/INSTALLATION

5-3

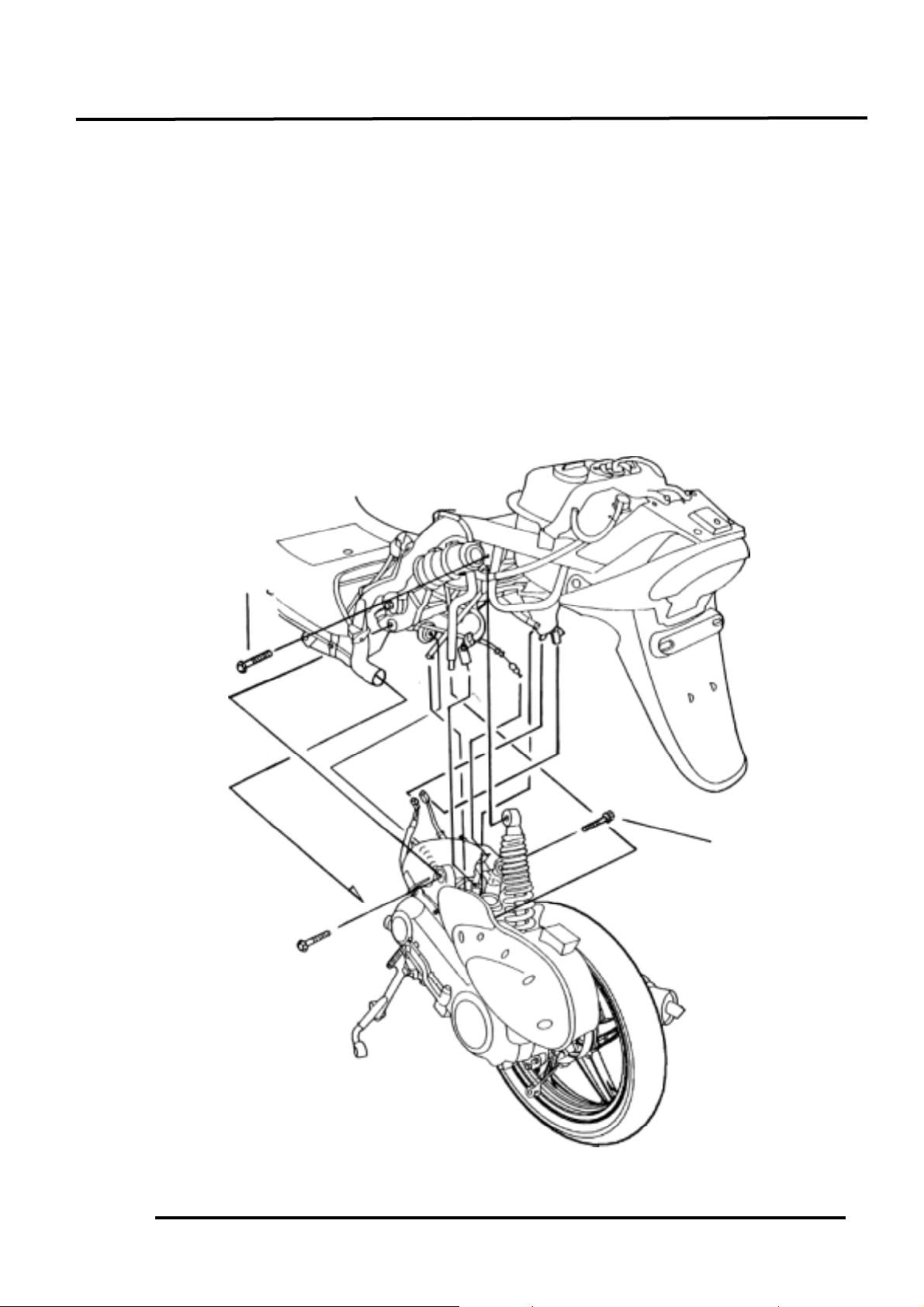

Remove the rear brake adjusting nut and

disconnect the brake cable from the

crankcase.

Remove the rear brake cable clamp and rear

brake cable.

Remove the cooling air tube band on the left

crankcase cover and disconnect the cooling

air tube.

Remove the rear shock absorber lower

mount bolt.

Remove the right and left engine mounting

nuts.

Take out the right and left engine mounting

bolts.

Lift the frame upward to separate it from

the engine and be careful not to damage the

rear fender.

ENGINE HANGER BRACKET REMOVAL

Remove the engine hanger bracket bolt and

engine hanger bracket.

The installation sequence is the reserve of

removal.

Torque: 3.5_ 4.5kg-m

Engine Mounting Nuts

Rear Brake Cable

Clamp

Rear Shock Absorber Lower Mount Bolt

Engine Hanger Bracket Bolt

Engine Hanger Bracket

Page 5

5. ENGINE REMOVAL/INSTALLATION

5-4

ENGINE HANGER BRACKET

INSPECTION

Inspect the stopper rubbers and bushings

for damage and replace with new ones if

necessary.

ENGINE INSTALLATION

Install the engine in the reverse order of

removal.

Torque Values:

Engine mounting bolt : 4.5_ 5.5kg-m

Rear shock absorber lower mount bolt:

: 2.4_ 3.0kg-m

Perform the following inspections and

adjustments after installation.

• Throttle cable

• Oil pump control cable (!3-11)

• Rear brake cable (!3-5)

• Oil pump bleeding (!3-11)

Cables and wires should be routed

properly.

*

Bushings

Engine Hanger

Stopper Rubbers

Loading...

Loading...