Page 1

By KWANG YANG Motor Co., Ltd.

First Edition, Dec 2006

All rights reserved. Any reproduction or

unauthorized use without the written permission of

KWANG YANG Motor Co., Ltd.

is expressly prohibited.

T100LA0975

Page 2

PREFACE

This Service Manual describes the

technical features and servicing

procedures for the KYMCO Mongoose

90/70/50-4T/50-2T & MXER

90R/70R/50R-4T/50R-2T.

Section 1 contains the precautions for

all operations stated in this manual.

Read them carefully before starting any

operation.

Section 2 is the removal/installation

procedures for the frame covers which

are subject to higher removal/installation

frequency during maintenance and

servicing operations.

Section 3 describes the inspection/

adjustment procedures, safety rules and

service information for each part,

starting from periodic maintenance.

Sections 4 through 17 give instructions

for disassembly, assembly and

inspection of engine, chassis frame and

electrical equipment.

Most sections start with an assembly or

system illustration and troubleshooting

for the section. The subsequent pages

give detailed procedures for the section.

KWANG YANG MOTOR CO., LTD.

OVERSEAS SALES DEPARTMENT

OVERSEAS SERVICE SECTION

TABLE OF CONTENTS

GENERAL INFORMATION 1

FRAME COVERS/EXHAUST MUFFLER 2

INSPECTION/ADJUSTMENT 3

LUBRICATION SYSTEM 4

FUEL SYSTEM 5

ENGINE REMOVAL 6

CYLINDER HEAD/VALVES 7

CYLINDER/PISTON 8

DRIVE AND DRIVEN PULLEYS

9

FINAL REDUCTION/TRANSMISSION

SYSTEM

10

CRANKCASE/CRANKSHAFT

11

FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION/STEERING

SYSTEM

12

REAR WHEEL /SWING

ARM/HYDRAULIC BRAKE

13

BATTERY/CHARGING SYSTEM/A.C.

GENERATOR

14

IGNITION SYSTEM 15

STARTING SYSTEM 16

BULBS REMOVAL/INSTRUMENT/HORN 17

CHASSIS

ELECTRICAL

EQUIPMENT

ENGINE

The information and contents included in

this manual may be different from the

vehicle in case specifications are changed.

KYMCO reserves the right to make

changes at any time without notice and

without incurring any obligation.

Page 3

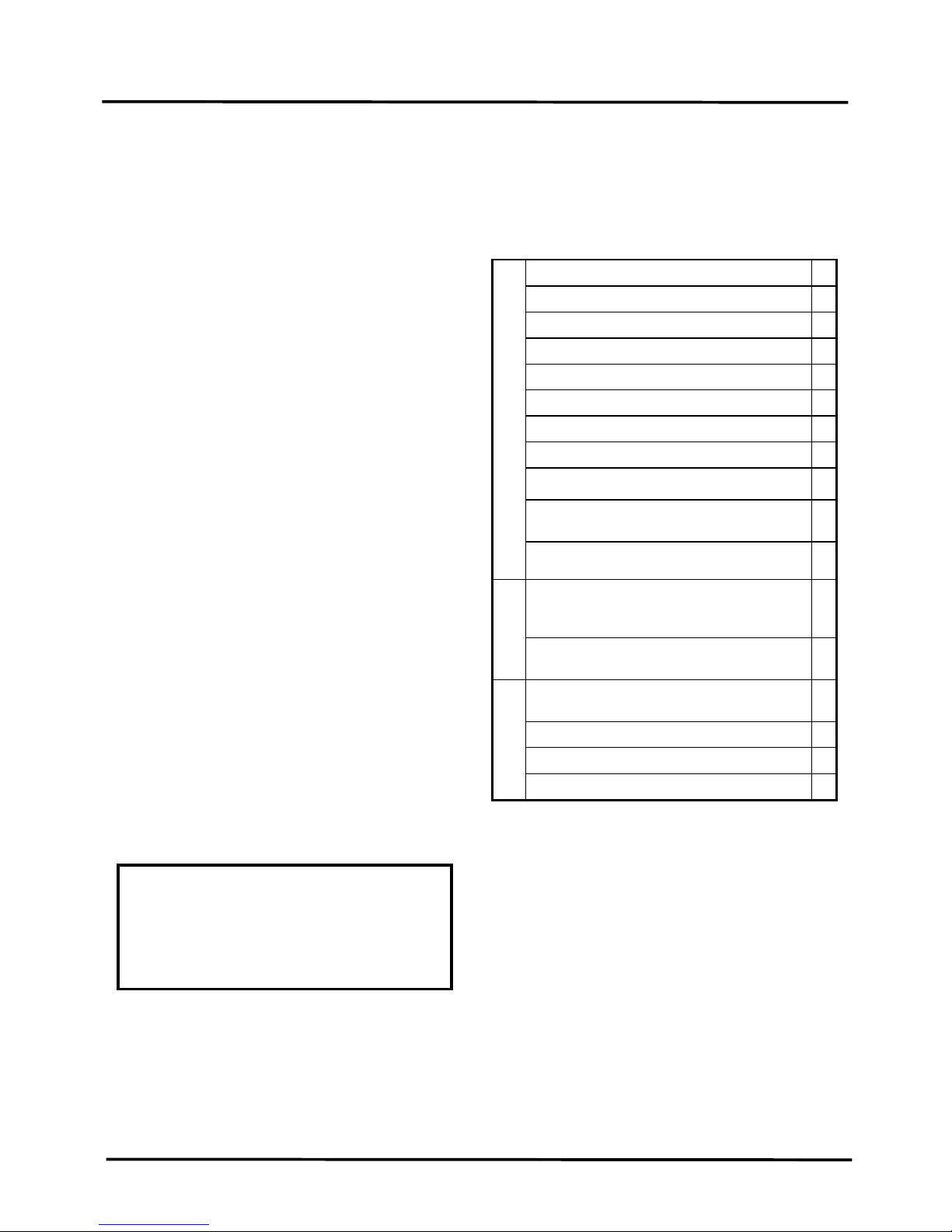

1. GENERAL INFORMATION

1-0

1

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

GENERAL INFORMATION

__________________________________________________________________________________

SERIAL NUMBER---------------------------------------------------------- 1- 1

SPECIFICATIONS ---------------------------------------------------------- 1- 2

SERVICE PRECAUTIONS ------------------------------------------------ 1- 6

TORQUE VALUES --------------------------------------------------------- 1-14

SPECIAL TOOLS ----------------------------------------------------------- 1-16

LUBRICATION POINTS -------------------------------------------------- 1-17

CABLE & HARNESS ROUTING ---------------------------------------- 1-20

WIRING DIAGRAMS ------------------------------------------------------ 1-23

TROUBLESHOOTING----------------------------------------------------- 1-28

1

Page 4

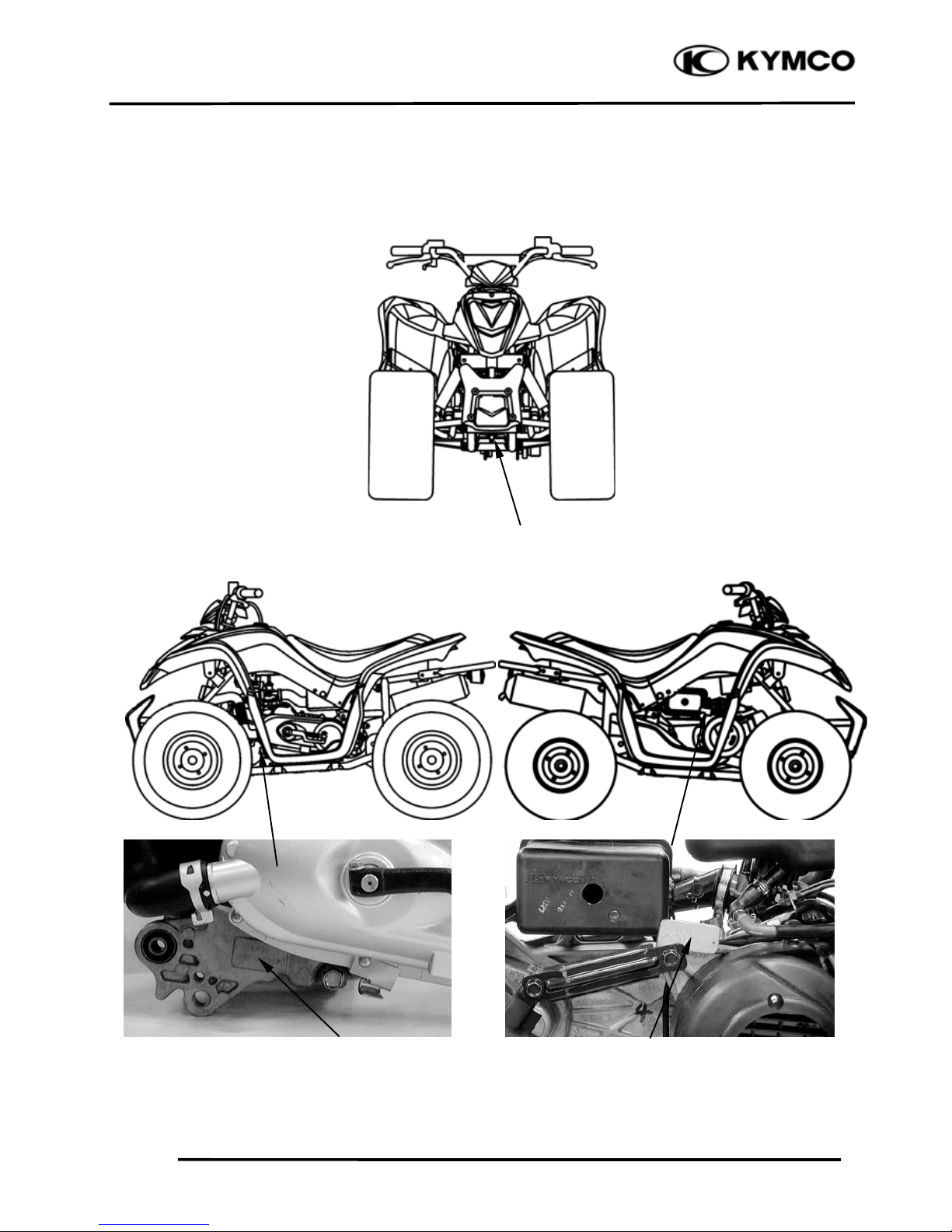

1. GENERAL INFORMATION

1-1

SERIAL NUMBER

Location of Engine Serial Numbe

r

(90cc/70cc/50cc-4T)

Location of Frame Serial Numbe

r

Location of Engine Serial Number (50cc-2T)

Page 5

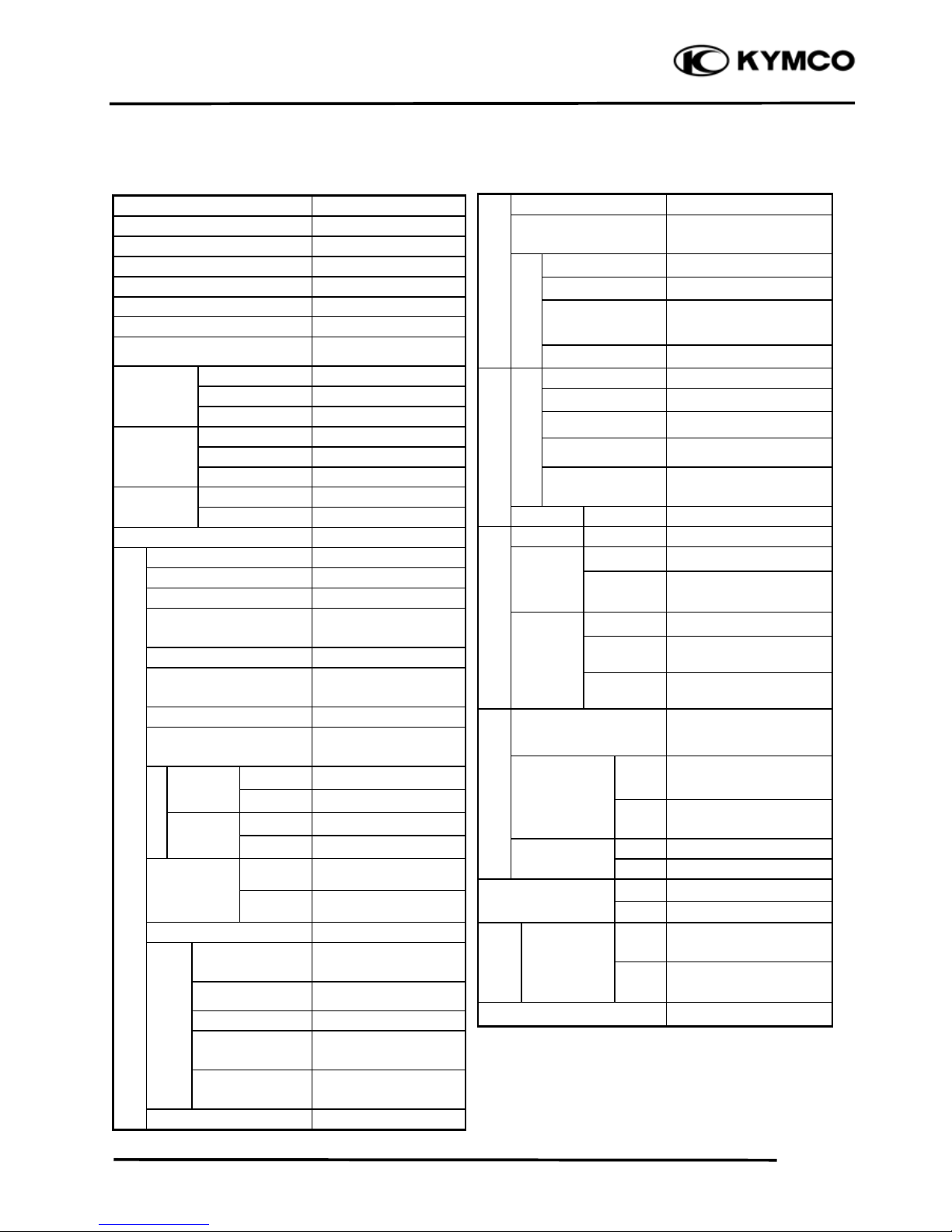

1. GENERAL INFORMATION

1-2

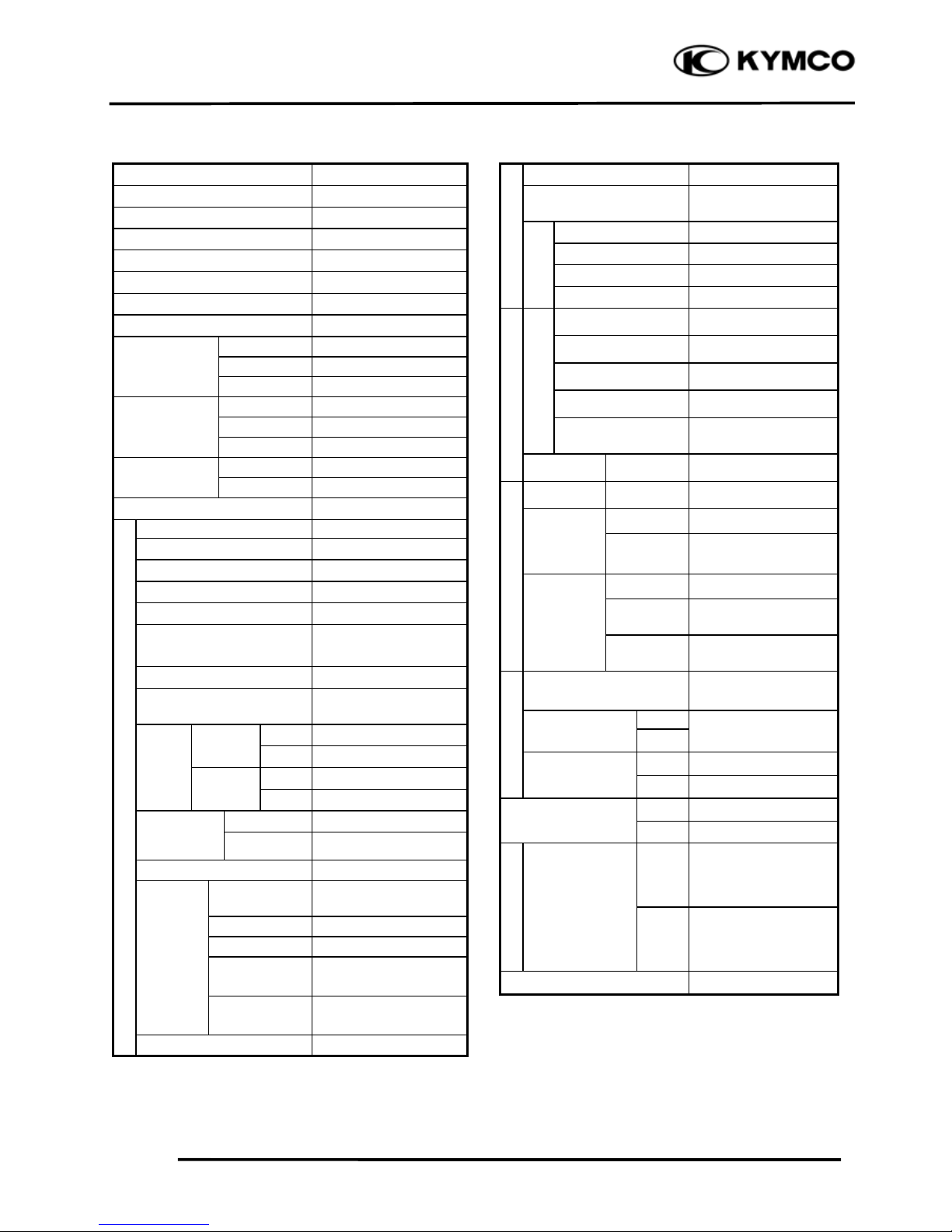

SPECIFICATIONS

Mongoose 90/MXER 90R

Model No. LA20

Overall length 1430 mm (57.2 in)

Overall width 905 mm (36.2 in)

Overall height 910 mm (36.4 in)

Wheel base 965 mm (38.6 in)

Engine type O.H.C.

Displacement 89.9 cc (5.5 cu-in)

Fuel Used

92# nonleaded gasoline

Front wheel 58 kg (127.6 lbs)

Rear wheel 56.5 kg (124.3 lbs)

Net weight

Total 114.5 kg (251.9 lbs)

Front wheel 61.5 kg (135.3 lbs)

Rear wheel 58.5 kg (128.7 lbs)

Gross

weight

Total 120 kg (264 lbs)

Front wheel 18*7-8

Tires

Rear wheel 18*9-8

Ground clearance 104 mm (4.16 in)

Starting system Motor & Kick starter

Type Gasoline, 4-stroke

Cylinder arrangement Single cylinder

Combustion chamber

type

Semi-sphere

Valve arrangement O.H.C., chain drive

Bore x stroke

47X51.8 mm

(1.85X2.04 in)

Compression ratio 10:1

Compression pressure

1600 kPa (16

kgf/cm², 227.2 psi)

Intake Open 2° (ATDC)

(1mm) Close 26° (ABDC)

Exhaust Open 44° (BBDC)

Port

timin

g

(1mm) Close -17° (BTDC)

Intake 0.1 mm (0.004 in)

Valve

clearance

(cold)

Exhaust 0.1 mm (0.004 in)

Idle speed 1800 rpm

Lubrication type

Forced pressure &

Wet sump

Oil pump type

Inner/outer rotor type

Oil filter type Full-flow filtration

Oil capacity

0.8 L (0.7 lmp qt,

0.85 US qt)

Lubrication System

Oil exchanging

capacity

0.7 L (0.62 lmp qt,

0.74 US qt)

Engine

Cooling Type Air cooling

Air cleaner type Sponge

Fuel capacity

5.5 L (12.1 lmp gal,

1.45 US gal)

Type PTE

Main jet No. #80

Venturi

dia.(mm)

φ16

Fuel System

Carburetor

Throttle type PISTON

Type CDI

Ignition timing 13°BTDC/1800rpm

Contact breaker Non-contact point type

Spark plug NGK CR7HSA

Ignition System

Spark plug gap

0.6~0.7 mm (0.024~

0.028 in)

Electrical Equipment

Battery Capacity 12V4AH

Clutch Type CVT

Type Helical gear

Transm

is-sion

Gear

Operation

Automatic centrifugal

Type

Type V-Belt

Primary

reduction

0.8~2.5

Power Drive System

Reduction

Gear

Final

reduction

9.255

FR/RR tire rolling

circumference

1436 mm (57.44 in)

Front

25 kPa (0.25 kg/cm²,

3.6 psi)

Tire pressure

Rear

25 kPa (0.25 kg/cm²,

3.6 psi)

Left 35°

Moving Device

Turning angle

Right 35°

RearDisk brake

Brake system type

Front Drum brake

Front

Swing axle

Damping

Device

Suspension

type

Rear

Swing arm

Frame type Steel tube frame

Page 6

1. GENERAL INFORMATION

1-3

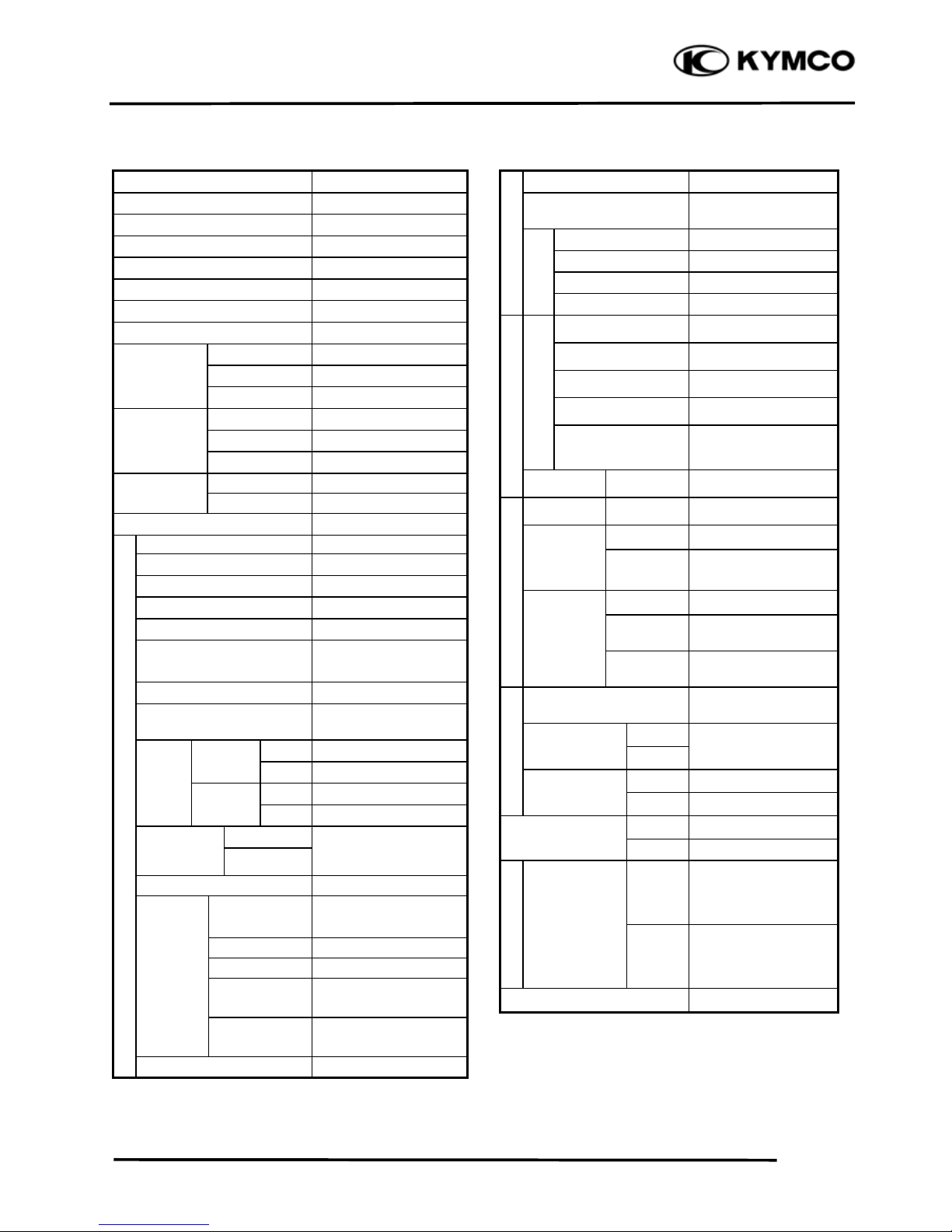

Mongoose 70/MXER 70R

Model No. LA15

Overall length 1415 mm (56.6 in)

Overall width 880 mm (35.2 in)

Overall height 910 mm (36.4 in)

Wheel base 965 mm (38.6 in)

Engine type O.H.C.

Displacement 69.4 cc (4.25 cu-in)

Fuel Used 92# nonleaded gasoline

Front wheel 53 kg (116.6 lbs)

Rear wheel 52 kg (114.4 lbs)

Net weight

Total 105 (231 lbs)

Front wheel 57 kg (125.4 lbs)

Rear wheel 54 kg (118.8 lbs)

Gross weight

Total 111 kg (244.2 lbs)

Front wheel 16*8-7

Tires

Rear wheel 16*8-7

Ground clearance 85 mm (3.4 in)

Starting system Motor & Kick starter

Type Gasoline, 4-stroke

Cylinder arrangement Single cylinder

Combustion chamber type Semi-sphere

Valve arrangement O.H.C., chain drive

Bore x stroke

47X40 mm

(1.88X1.6 in)

Compression ratio 7.9:1

Compression pressure

1400 kPa (14 kgf/c

m

²,

200 psi)

Open 6° (ATDC)

Intake

(1mm)

Close 28° (ABDC)

Open 38° (BBDC)

Port

timin

g

Exhaust

(1mm)

Close -6° (BTDC)

Intake 0.04 mm (0.0016 in)

Valve

clearance

(cold)

Exhaust 0.04 mm (0.0016 in)

Idle speed 2000rpm

Lubrication

type

Forced pressure &

Wet sump

Oil pump type Inner/outer rotor type

Oil filter type Full-flow filtration

Oil capacity

0.8 L (0.7 lmp qt,

0.85 US qt)

Lubrication System

Oil exchanging

capacity

0.7 L (0.62 lmp qt,

0.74 US qt)

Engine

Cooling Type Air cooling

Air cleaner type Sponge

Fuel capacity

5.5 L (12.1 lmp gal,

1.45 US gal)

Type PTE

Main jet No. #85

Venturi dia.(mm) φ16

Fuel S

y

stem

Carbureto

Throttle type PISTON

Type CDI

Ignition timing 13°BTDC/1800rpm

Contact breaker Non-contact point type

Spark plug NGK CR7HSA

Ignition System

Spark plug gap

0.6~0.7 mm

(0.024~0.028 in)

Electrical E

q

ui

p

ment

Battery Capacity 12V4AH

Clutch Type CVT

Type Helical gear

Transmission Gea

r

Operation

Automatic centrifugal

Type

Type V-Belt

Primary

reduction

0.8~3.1

Power Drive S

y

stem

Reduction

Gear

Final

reduction

27.257

FR/RR tire rolling

circumference

1266 mm (50.64 in)

Front

Tire pressure

Rear

25 kPa (0.25 kg/c

m

²,

3.6 psi)

Left 35°

Moving Device

Turning angle

Right 35°

Rear Disk brake

Brake system type

Front Drum brake

Front Swing axle

Damping Device

Suspension type

Rear Swing arm

Frame type Steel tube frame

Page 7

1. GENERAL INFORMATION

1-4

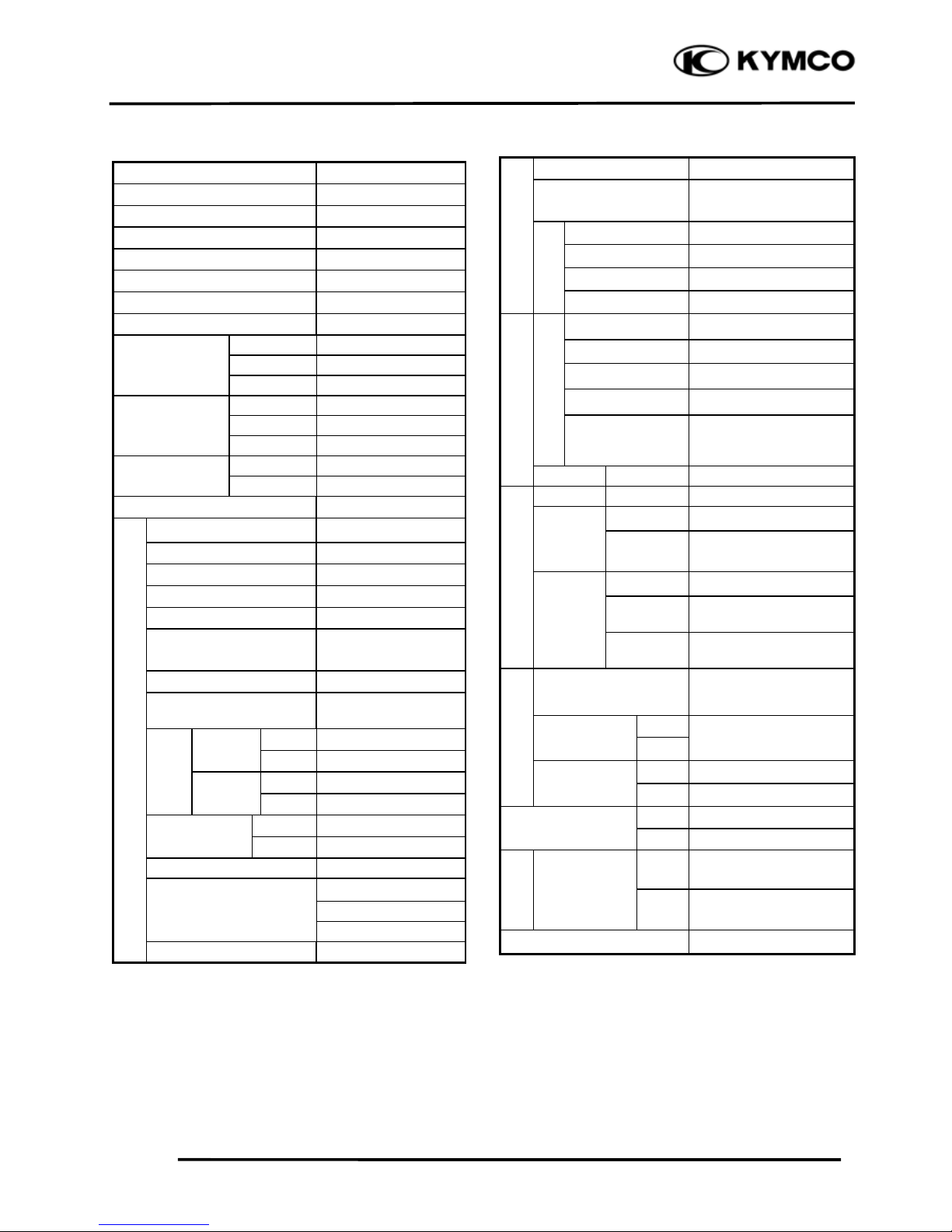

Mongoose 50-4T /MXER 50R-4T

Model No. LB10

Overall length 1430 mm (58 in)

Overall width 870 mm (34.8 in)

Overall height 900 mm (37.8 in)

Wheel base 965 (38.6 in)

Engine type O.H.C.

Displacement 49.5 cc (3.01 cu-in)

Fuel Used 92# nonleaded gasoline

Front wheel

51 kg (132lbs)

Rear wheel

50 kg (132 lbs)

Net weight

Total

101 kg (264 lbs)

Front wheel

55 kg (138.6 lbs)

Rear wheel

53 kg (134.2 lbs)

Gross weight

Total

108 kg (272.8 lbs)

Front wheel 16*8-7

Tires

Rear wheel 16*8-7

Ground clearance 130 mm (7.6 in)

Starting system Motor & Kick starter

Type Gasoline, 4-stroke

Cylinder arrangement Single cylinder

Combustion chamber type Semi-sphere

Valve arrangement O.H.C., chain drive

Bore x stroke

39X41.4 mm

(1.54X1.63 in)

Compression ratio 10:1

Compression pressure

1400 kPa (14 kgf/c

m

2

,

200 psi)

Open 2° (BTDC)

Intake

(1mm)

Close 26° (ABDC)

Open 44° (BBDC)

Port

timin

g

Exhaust

(1mm)

Close -17° (ATDC)

Intake

Valve

clearance

(cold)

Exhaust

0.04 mm (0.0016 in)

Idle speed (rpm) 2000rpm

Lubrication

type

Forced pressure &

Wet sump

Oil pump type Inner/outer rotor type

Oil filter type Full-flow filtration

Oil capacity

0.8 L (0.7 lmp qt,

0.84US qt)

Lubrication System

Oil exchanging

capacity

0.7 L (0.62 lmp

qt,0.74US qt)

Engine

Cooling Type Air cooling

Air cleaner type Sponge

Fuel capacity

5.5 L (12.1 lmp gal,

1.45 US gal)

Type PTE

Main jet No. #80

Venturi dia.(mm) φ16

Fuel S

y

stem

Carbureto

Throttle type PISTON

Type CDI

Ignition timing 13°BTDC/2000rpm

Contact breaker Non-contact point type

Spark plug NGK CR7HSA

Ignition System

Spark plug gap

0.6~0.7 mm (0.024

~0.028 in)

Electrical E

q

ui

p

ment

Battery Capacity 12V4AH

Clutch Type CVT

Type Helical gear

Transmission Gea

r

Operation

Automatic centrifugal

Type

Type V-Belt

Primary

reduction

0.8~2.5

Power Drive S

y

stem

Reduction

Gear

Final

reduction

27.136

FR/RR tire rolling

circumference

1546/1514 mm

(61.84/60.56 in)

Front

Tire pressure

Rear

25 kPa (0.25 kgf/cm

2

,

3.6 psi)

Left 35°

Moving Device

Turning angle

Right 35°

Rear Disk brake

Brake system type

Front Drum brake

Front Swing axle

Damping Device

Suspension

type

Rear Swing arm

Frame type Steel tube frame

Page 8

1. GENERAL INFORMATION

1-5

Mongoose 50-2T /MXER 50R-2T

Name & Model No. LA10

Overall length 1385 mm (55.4 in)

Overall width 875 mm (35 in)

Overall height 890 mm (35.6 in)

Wheel base 900 mm (36 in)

Engine type 2-stroke.

Displacement 49.4 cc (3.02 cu-in)

Fuel Used 92# nonleaded gasoline

Front wheel 49.6 kg (109.12 lbs)

Net weight Rear wheel 50.7 kg (111.54 lbs)

Total 100.3 kg (220.66 lbs)

Front wheel 54.6 kg (120.12 lbs)

Gross weight Rear wheel 55.7 kg (122.54 lbs)

Total 110.3 kg (242.66 lbs)

Front wheel 16*8-7

Tires

Rear wheel 16*8-7

Ground clearance 72 mm (2.88 in)

Starting system

Motor & Kick starte

r

Type Gasoline, 2-stroke

Cylinder arrangement Single cylinder

Combustion chamber type Semi-sphere

Valve arrangement Reed valve & piston

Bore x stroke

39X41.4 mm

(1.56X1.656 in)

Compression ratio 7.2:1

Compression pressure

1200 kPa (12 kgf/c

m

2

,

170.4 psi)

Intake

Open Automatic controlled

Port

(1mm)

Close Automatic controlled

timin

g

Exhaust

Open ─

(1mm)

Close ─

Valve clearance

Intake ─

(cold)

Exhaust ─

Idle speed 2000 rpm

Lubrication type Separate type

Oil pump type Plunger type

Oil filter type Full-flow filtration

Engine

Cooling Type Air cooling

Air cleaner type & No Sponge

Fuel capacity

5.5 L (12.1 lmp gal, 1.45

US gal)

Type PB

Main jet No. 82

Venturi dia.(mm) φ14

Fuel System

Carburetor

Throttle type PISTON

Type CDI

Ignition timin

g

15°BTDC/1700r

pm

Contact breaker Non-contact point type

Spark plug NGK BR8HAS

Ignition System

Spark plug gap

0.6~0.7 mm

(0.024~0.028 in)

Electrical Equipment

Battery Capacity 12V4AH

Clutch Type CVT

Type Helical gear

Transmission Gear

Operation

Automatic centrifugal

Type

Type V-Belt

Primary

reduction

0.895~3.113

Power Drive System

Reduction

Gear

Final

reduction

11.05

FR/RR tire rolling

circumference

1247 mm (49.88 in)

Fron

t

Tire pressure

Rear

25 kPa (0.25 kgf/cm

2

,

3.6 psi)

Turning Left 35°

Moving Device

angle

Right 35°

Brake system

Rea

r

Drum brake

type Front Drum brake

Front

Swing axle

Damping

Suspension

type

Rear

Swing arm

Frame type Steel tube frame

Page 9

1. GENERAL INFORMATION

1-6

SERVICE PRECAUTIONS

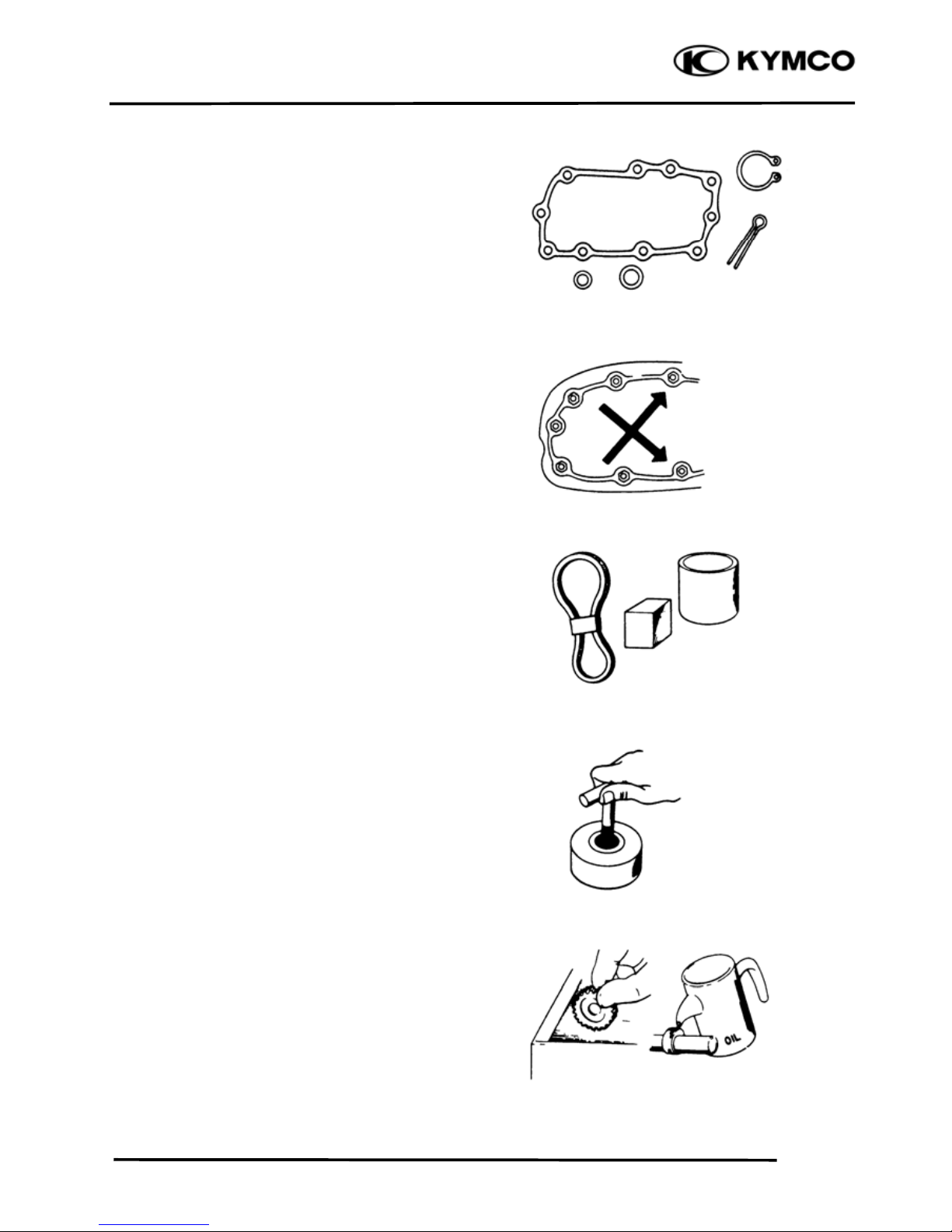

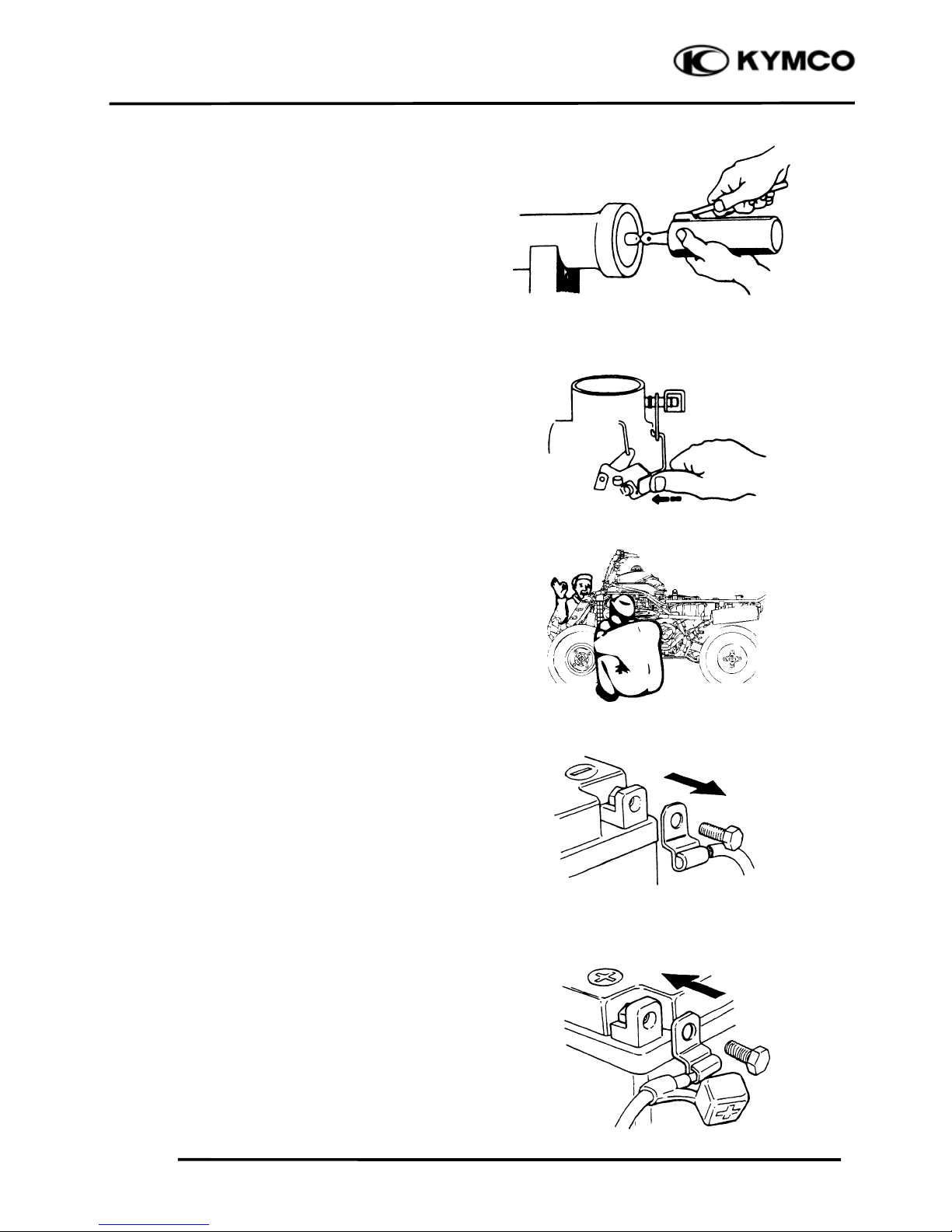

Make sure to install new gaskets, O-rings,

circlips, cotter pins, etc. when

reassembling.

When tightening bolts or nuts, begin with

larger-diameter to smaller ones at several

times, and tighten to the specified torque

diagonally.

Use genuine parts and lubricants.

When servicing the motorcycle, be sure

to use special tools for removal and

installation.

After disassembly, clean removed parts.

Lubricate sliding surfaces with engine oil

before reassembly.

Page 10

1. GENERAL INFORMATION

1-7

Apply or add designated greases and

lubricants to the specified lubrication

points.

After reassembly, check all parts for

proper tightening and operation.

When two persons work together, pay

attention to the mutual working safety.

Disconnect the battery negative (-)

terminal before operation.

When using a spanner or other tools,

make sure not to damage the motorcycle

surface.

After operation, check all connecting

points, fasteners, and lines for proper

connection and installation.

When connecting the battery, the positive

(+) terminal must be connected first.

After connection, apply grease to the

battery terminals.

Terminal caps shall be installed securely.

Page 11

1. GENERAL INFORMATION

1-8

If the fuse is burned out, find the cause

and repair it. Replace it with a new one

according to the specified capacity.

After operation, terminal caps shall be

installed securely.

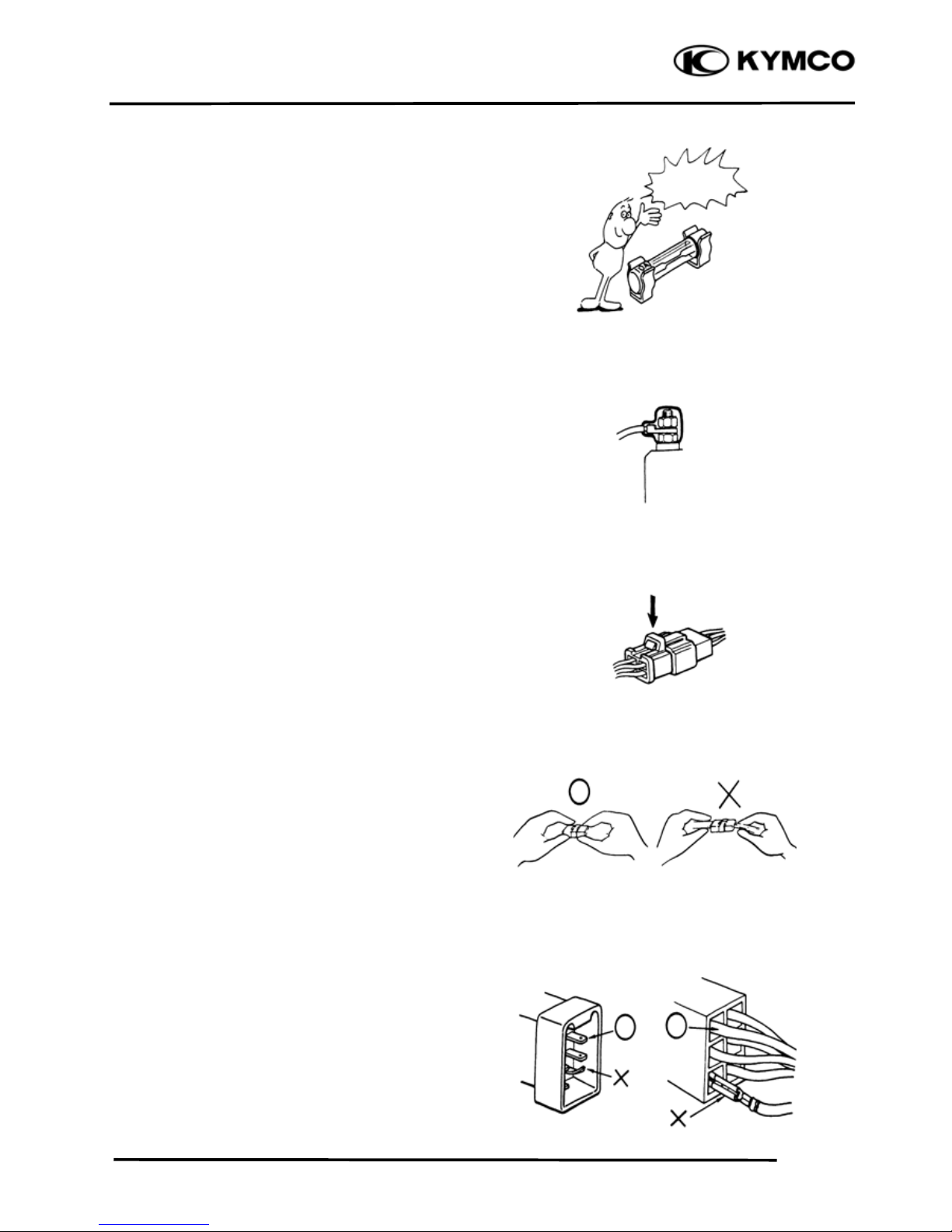

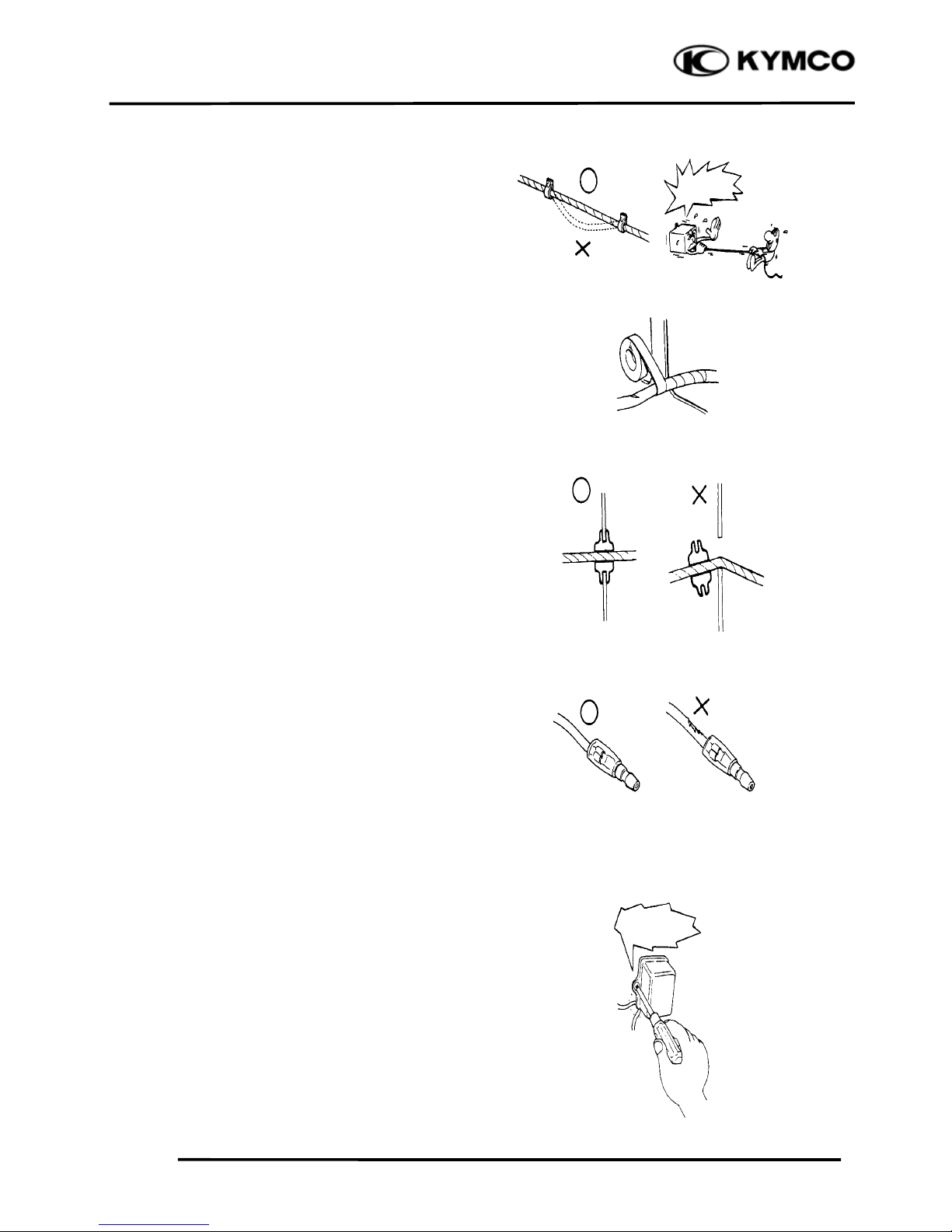

When taking out the connector, the lock

on the connector shall be released before

operation.

Hold the connector body when

connecting or disconnecting it.

Do not pull the connector wire.

Check if any connector terminal is

bending, protruding or loose.

Confir

m

Capacity

Page 12

1. GENERAL INFORMATION

1-9

The connector shall be inserted

completely.

If the double connector has a lock,

lock it at the correct position.

Check if there is any loose wire.

Before connecting a terminal, check

for damaged terminal cover or loose

negative terminal.

Check the double connector cover for

proper coverage and installation.

Insert the terminal completely.

Check the terminal cover for proper

coverage.

Do not make the terminal cover opening

face up.

Secure wire harnesses to the frame with

their respective wire bands at the

designated locations.

Tighten the bands so that only the

insulated surfaces contact the wire

harnesses.

Snapping!

Page 13

1. GENERAL INFORMATION

1-10

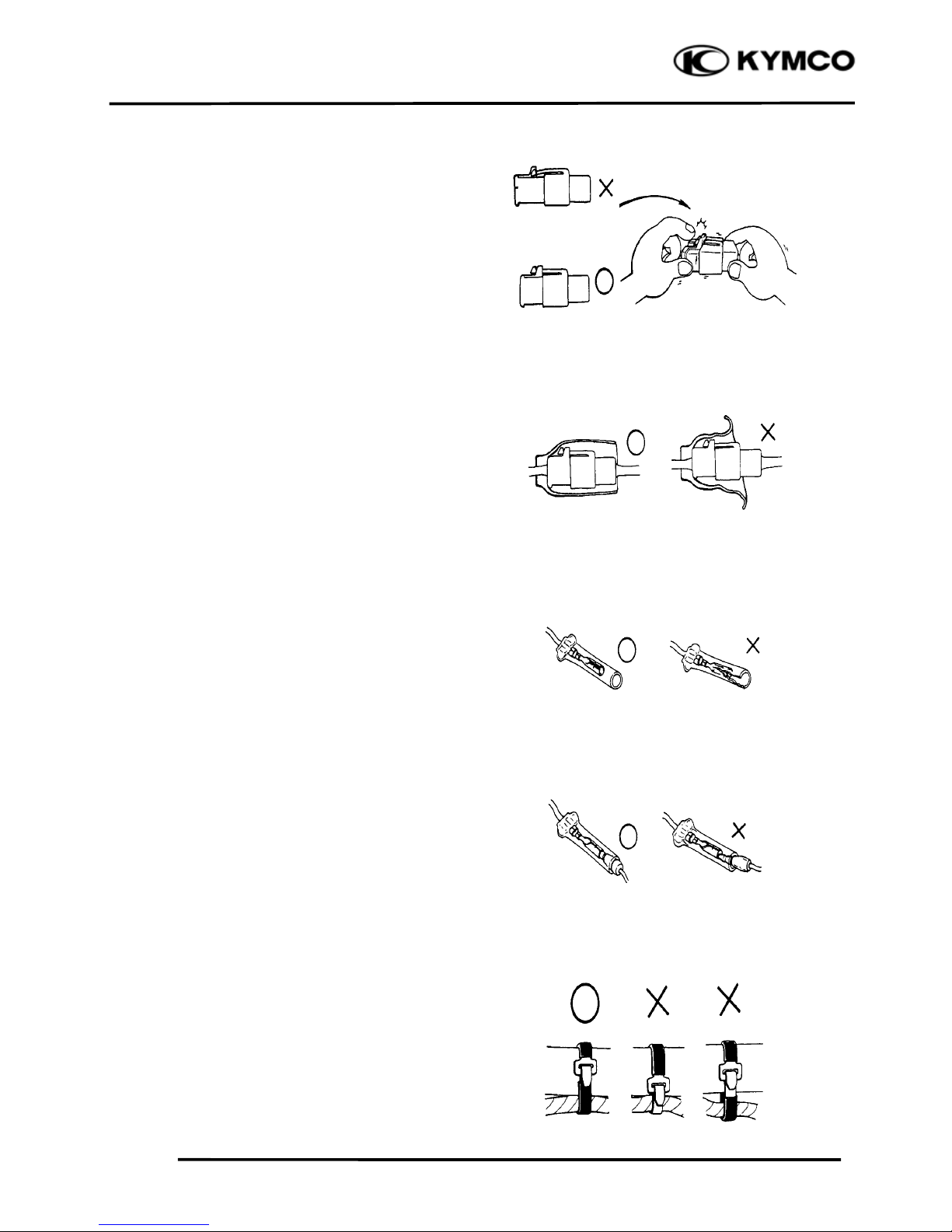

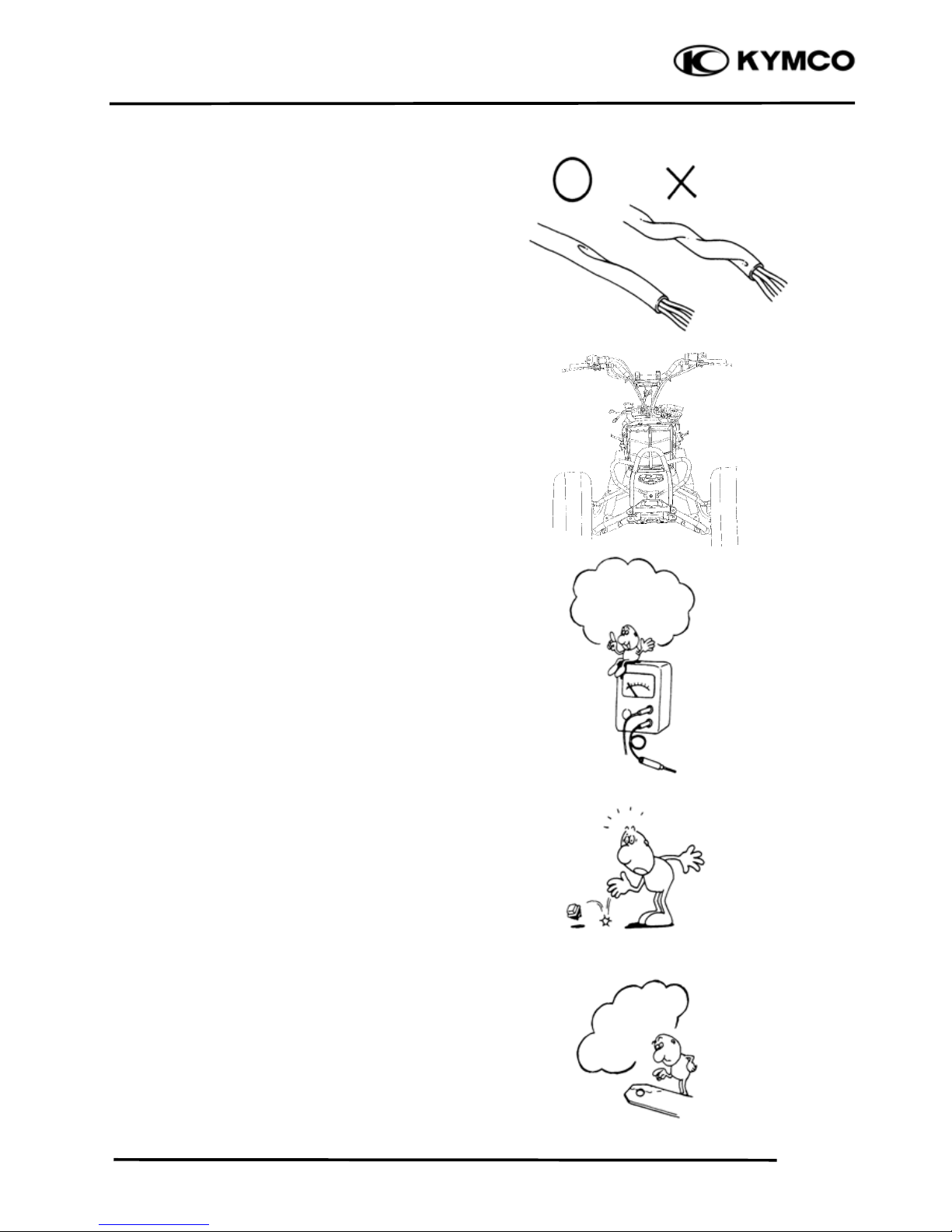

After clamping, check each wire to make

sure it is secure.

Do not squeeze wires against the weld or

its clamp.

After clamping, check each harness to

make sure that it is not interfering with

any moving or sliding parts.

When fixing the wire harnesses, do not

make it contact the parts which will

generate high heat.

Route wire harnesses to avoid sharp

edges or corners. Avoid the projected

ends of bolts and screws.

Route wire harnesses passing through the

side of bolts and screws. Avoid the

projected ends of bolts and screws.

N

o Contact !

Page 14

1. GENERAL INFORMATION

1-11

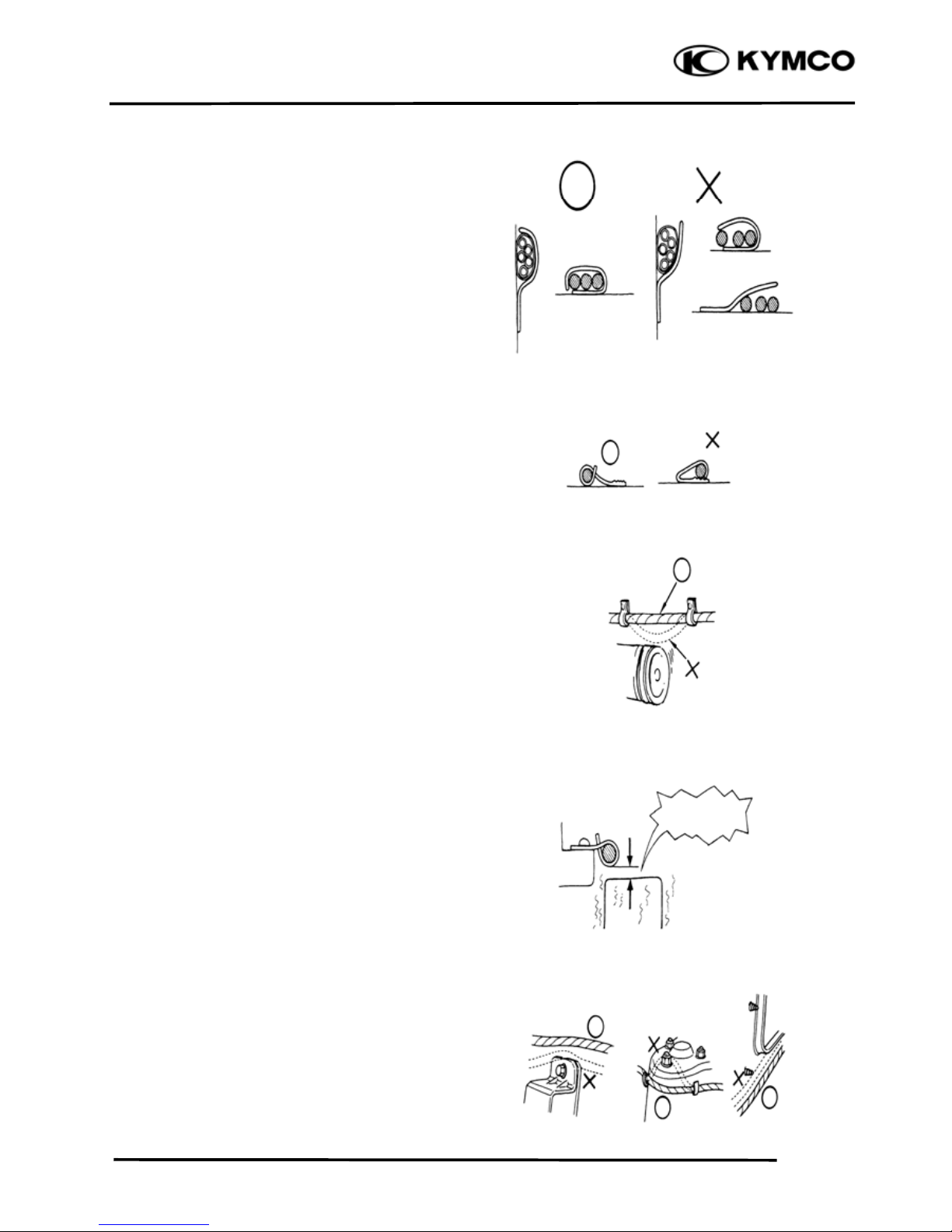

Route harnesses so they are neither

pulled tight nor have excessive slack.

Protect wires and harnesses with

electrical tape or tube if they contact a

sharp edge or corner.

When rubber protecting cover is used to

protect the wire harnesses, it shall be

installed securely.

Do not break the sheath of wire.

If a wire or harness is with a broken

sheath, repair by wrapping it with

protective tape or replace it.

When installing other parts, do not press

or squeeze the wires.

Do not pull

too tight!

Do not press or

squeeze the wire.

Page 15

1. GENERAL INFORMATION

1-12

After routing, check that the wire

harnesses are not twisted or kinked.

Wire harnesses routed along with

handlebar should not be pulled tight, have

excessive slack or interfere with adjacent

or surrounding parts in all steering

positions.

When a testing device is used, make sure

to understand the operating methods

thoroughly and operate according to the

operating instructions.

Be careful not to drop any parts.

When rust is found on a terminal, remove

the rust with sand paper or equivalent

before connecting.

Do you understand

the instrument? Is

the instrument set

correctly?

Remove Rust !

Page 16

1. GENERAL INFORMATION

1-13

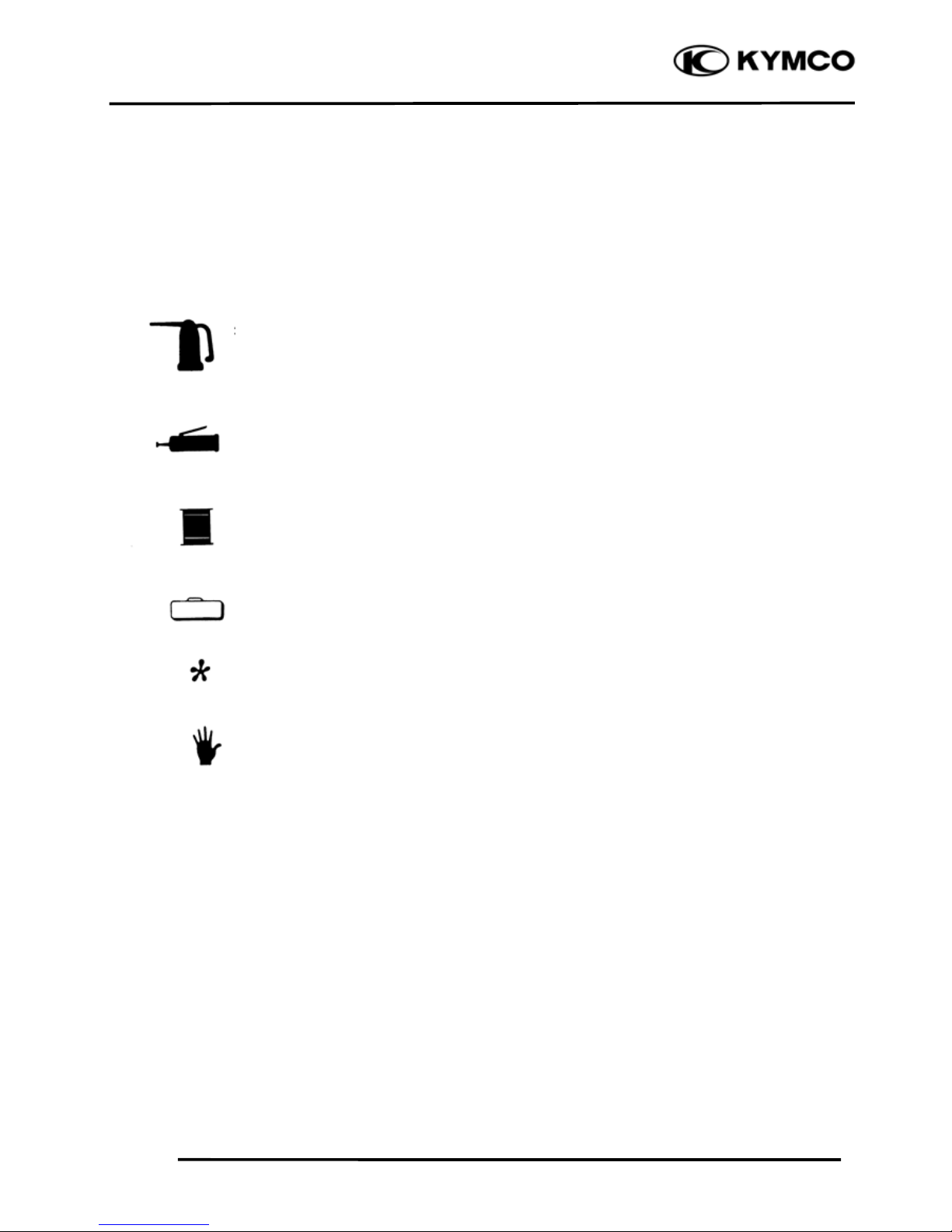

Symbols:

The following symbols represent the

servicing methods and cautions included

in this service manual.

: Apply engine oil to the

specified points. (Use

designated engine oil for

lubrication.)

: Apply grease for

lubrication.

: Transmission Gear Oil

(90#)

: Use special tool.

: Caution

: Warning

Engine Oil

Grease

Gear Oil

Special

Page 17

1. GENERAL INFORMATION

1-14

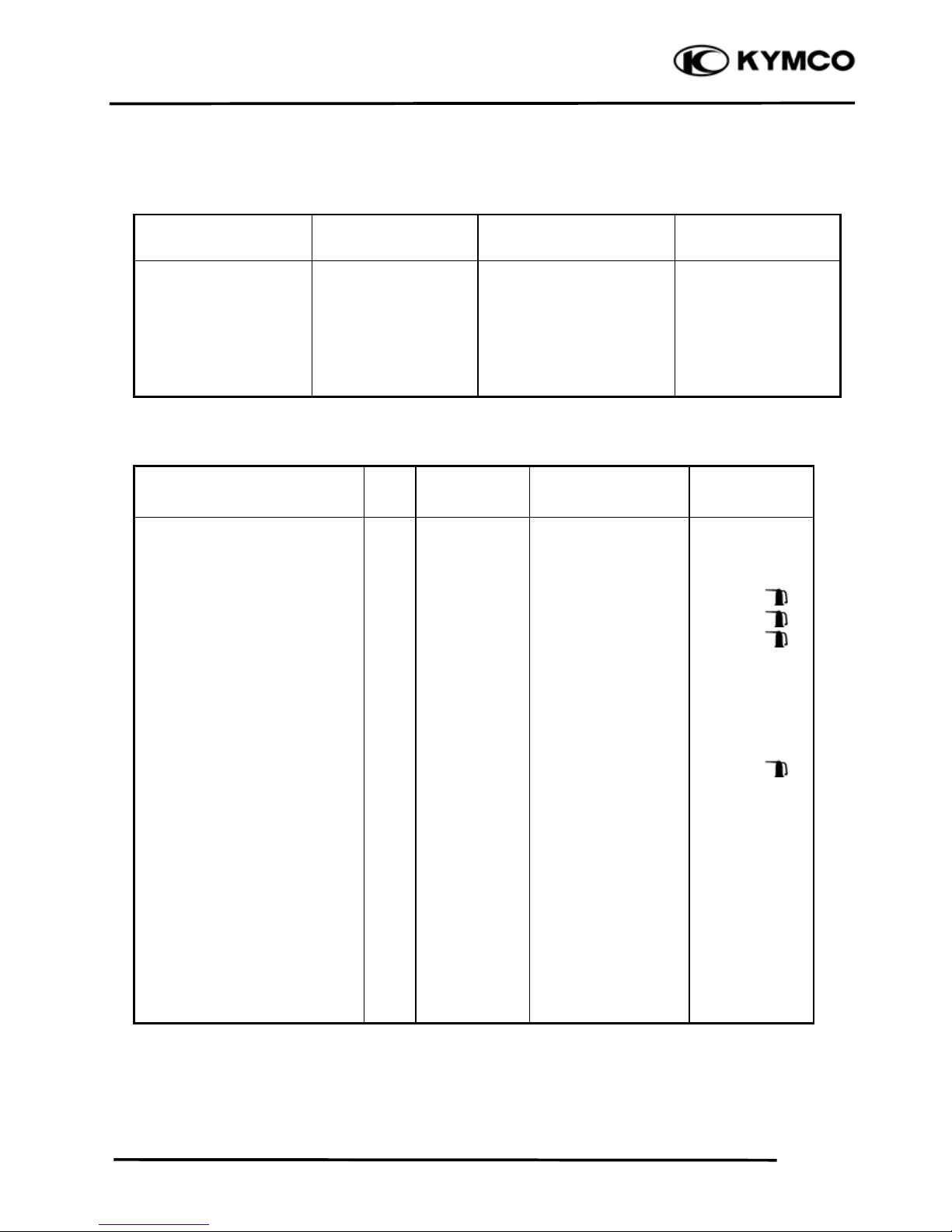

TORQUE VALUES

STANDARD TORQUE VALUES

Item

Torque

N•m (kgf•m, lbf•ft)

Item

Torque

N•m (kgf•m, lbf•ft)

5mm bolt and nut

6mm bolt and nut

8mm bolt and nut

10mm bolt and nut

12mm bolt and nut

14mm bolt and nut

5(0.5, 4)

10 (1, 7)

22 (2.2, 16)

35 (3.5, 25)

55 (5.5, 40)

70 (7, 50)

4mm screw

5mm screw

6mm screw, SH bolt

6mm flange bolt and nut

8mm flange bolt and nut

10mm flange bolt and nut

3 (0.3, 2)

4 (0.4, 3)

9 (0.9, 6.5)

12 (1.2, 9)

27 (2.7, 20)

40 (4, 29)

Torque specifications listed below are for important fasteners.

ENGINE (90cc/70cc/50cc-4T)

Item Q‘ty

Thread dia.

(mm)

Torque

N•m (kgf•m, lbf•ft)

Remarks

Stud bolt

Oil filter screen cap

L cover

Cam shaft holder nut (90cc)

Cam shaft holder nut

Tappet ADJ nut

Pivot tensioner bolt

Lifter tensioner bolt

Lifter tensioner cap

Mission case bolt

Mission fill bolt

Driver face nut

Clutch outer nut

Drive plate nut

Oneway clutch nut (90&70 cc)

ACG flywheel nut

Spark plug

Drain plug

Oil pump screw

Head CYL stud bolt (IN pipe)

Head CYL stud bolt (EX pipe)

A.C.G Startor

Fan

4

1

8

4

4

2

1

2

1

7

1

1

1

1

1

1

1

1

1

2

2

3

4

8

30

6

8

7

5

6

6

6

8

8

12

10

28

24

10

10

10

3

6

8

5

6

9 (0.9, 6.5)

15 (1.5, 11)

12 (1.2, 9)

20 (2, 14)

14 (1.4, 10)

9 (0.9, 6.5)

10 (1, 7)

12 (1.2, 9)

4.5 (0.45, 3)

27 (2.7, 19)

18 (1.8, 13)

60 (6, 43)

40 (4, 29)

55 (5.5, 40)

55 (5.5, 40)

40 (4, 29)

12 (1.2, 9)

25 (2.5, 18)

2 (0.2 1.4)

9 (0.9, 6.5)

9 (0.9, 6.5)

10 (1, 7)

8 (0.8, 5.8)

Apply oil

Apply oil

Apply oil

Apply oil

Page 18

1. GENERAL INFORMATION

1-15

ENGINE (50cc-2T)

Item Q‘ty

Thread dia.

(mm)

Torque

N•m (kgf•m,

lbf•ft)

Remarks

Cylinder head bolt

Clutch drive plate nut

Drive face nut

Clutch outer nut

ACG flywheel nut

Mission fill bolt

Drive plate nut

Spark plug

4

1

1

1

1

1

1

1

6

28

10

10

10

8

28

14

10 (1, 7)

55 (5.5, 40)

40 (4, 29)

40 (4, 29)

40 (4, 29)

15 (1.5, 11)

55 (5.5, 40)

15 (1.5, 11)

FRAME

Item Q‘ty

Thread dia.

(mm)

Torque

N•m (kgf•m,

lbf•ft)

Remarks

Steering stem nut

Front Swing arm nut

Front wheel nut

Rear wheel nut

Front wheel hub nut

Rear wheel hub nut

Front shock absorber upper mount bolt

Front shock absorber lower mount bolt

Rear shock absorber upper mount bolt

Rear shock absorber lower mount bolt

Rear swing arm axle hub bolt

Rear axle hub bolt

Front engine mounting bolt

Rear engine mounting bolt

Rear caliper bolt

Brake oil bolt

M/C holder

Exhaust muffler lock bolt

Exhaust muffler lock nut (90&70 cc)

Exhaust muffler lock nut (50 cc)

Rod-end nut

1

4

8

8

2

2

2

2

1

1

1

4

2

2

2

2

2

4

2

2

4

14

10

10

10

12

14

10

10

10

10

14

12

10

8

8

10

6

8

8

6

8

70 (7, 50)

45 (4.5, 32)

45 (4.5, 32)

45 (4.5, 32)

60 (6, 43)

80 (8, 58)

40 (4, 29)

40 (4, 29)

40 (4, 29)

40 (4, 29)

70 (7, 50)

70 (7, 50)

45 (4.5, 32)

32 (3.2, 23)

32 (3.2, 23)

35 (3.5, 25)

12 (1.2, 9)

35 (3.5, 25)

22 (2.2, 16)

10 (1, 7)

35 (3.5, 25)

Page 19

1. GENERAL INFORMATION

1-16

SPECIAL TOOLS

90cc/70cc/50cc-4T

Tool Name Tool No.

Remarks Ref. Page

Clutch spring compressor A120E00034

Bearing puller A120E00037

Valve spring compressor A120E00040

Oil seal & bearing installer A120E00014

Tappet adjuster A120E00012

Long socket wrench A120E00015

Start clutch puller A120E00006

Flywheel puller A120E00001

Universal holder A120E00017

50cc-2T

Tool Name Tool No. Remarks Ref. Page

Flywheel puller A120E00001

Oil seal and bearing install A120E00014

Universal holder A120E00017

Clutch spring compressor A120E00034

Bearing puller A120E00037

Crankshaft install A120E00016

Crankshaft & crankcase install A120E00024

Crankcase puller A120E00026

Crankshaft Bearing puller A120E00030

Page 20

1. GENERAL INFORMATION

1-17

LUBRICATION POINTS

ENGINE (90cc/70/50-4T)

Lubrication Points Lubricant

Valve guide/valve stem movable part

Cam lobes

Valve rocker arm friction surface

Cam chain

Cylinder lock bolt and nut

Piston surroundings and piston ring grooves

Piston pin surroundings

Cylinder inside wall

Connecting rod/piston pin hole

Connecting rod big end

Crankshaft right side oil seal

Crankshaft one-way clutch movable part

Oil pump drive chain

Balance gear

A.C. generator

Starter one-way clutch

Bearing movable part

O-ring face

Oil seal lip

•Genuine KYMCO Engine Oil (SAE15W-40)

•API SG Engine Oil

Transmission gear and movable parts Gear oil: SAE90#

ENGINE (50cc-2T)

NO. Lubrication Points Lubricant

1 Crankcase sliding & movable KYMCO 2-STROKE OIL or QUIVALENT

2 Cylinder movable parts KYMCO 2-STROKE OIL or QUIVALENT

3 Transmission gear (final gear) SAE-90#

4 Kick starter spindle bushing Grease

5 Drive pulley movable parts Grease

6 Starter pinion movable parts Grease

Page 21

1. GENERAL INFORMATION

1-18

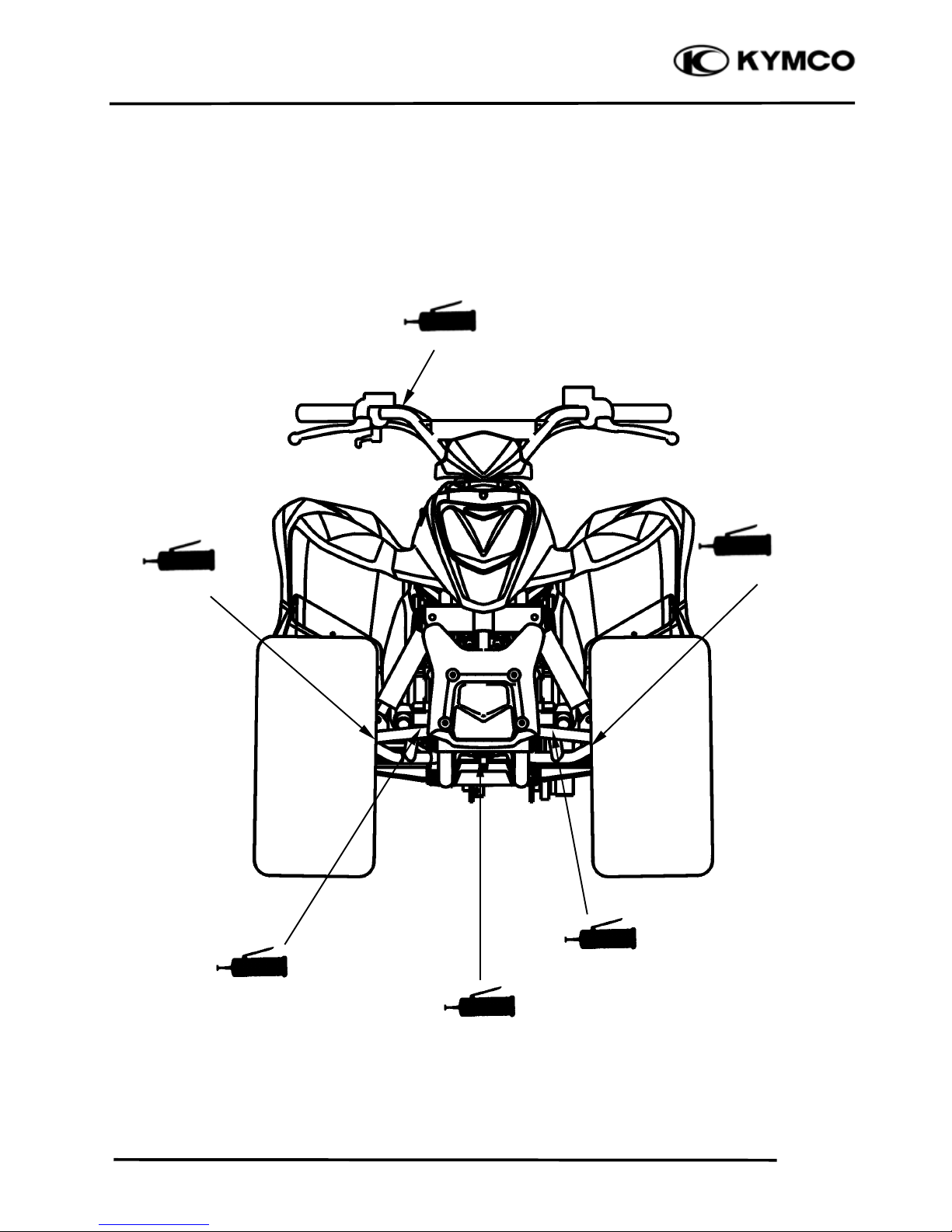

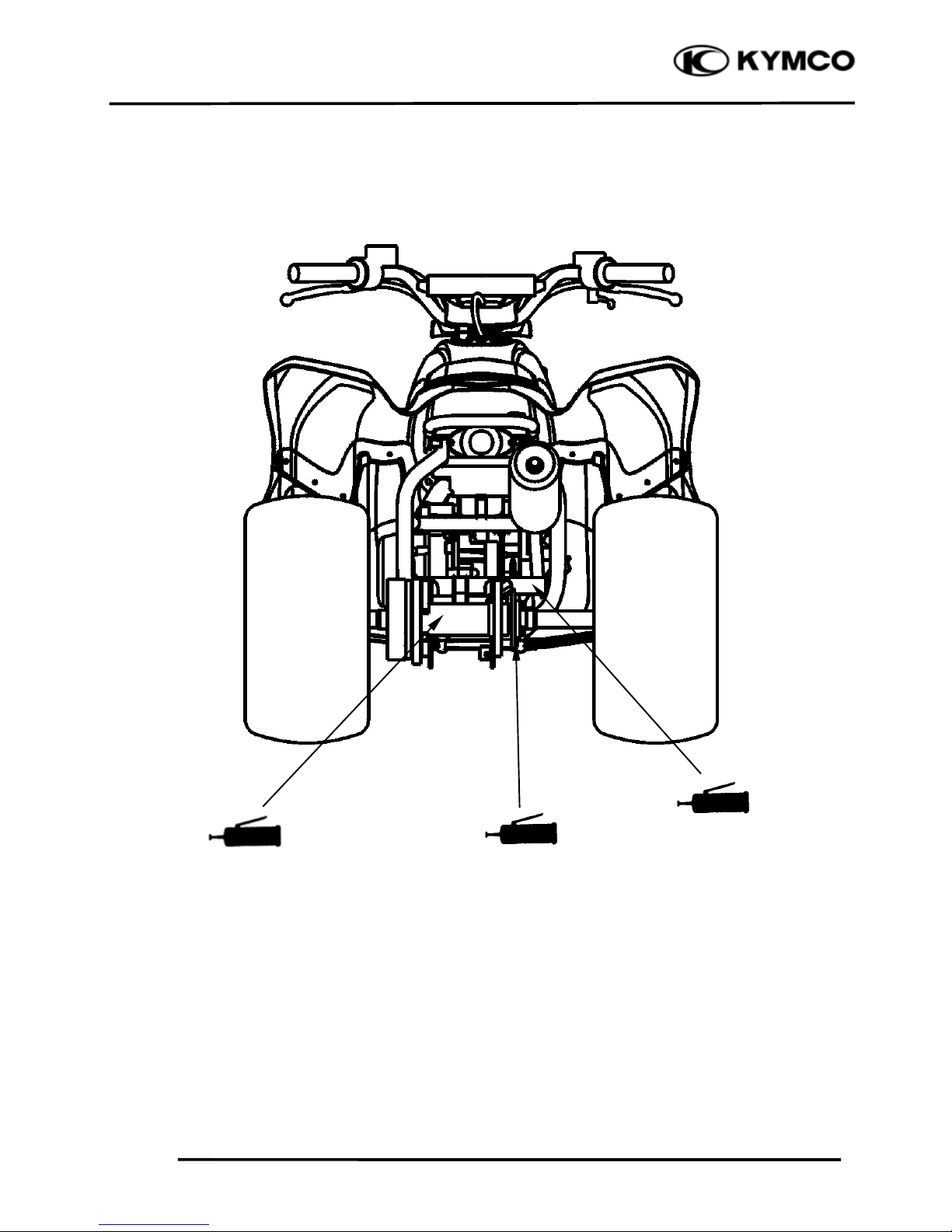

FRAME

The following is the lubrication points for the frame.

Use general purpose grease for parts not listed.

Apply clean engine oil or grease to cables and movable parts not specified. This will avoid

abnormal noise and rise the durability of the ATV.

Throttle Cable

Steering Column Lowe

r

Front Swing Arm Bush

Front Swing Ar

m

Steering knuckle

Steering knuckle

Page 22

1. GENERAL INFORMATION

1-19

Rear Axle Hub

Collar/Oil

Seal/Bearing

Driven Sprocket

Rear Swing Arm Axle

Page 23

1. GENERAL INFORMATION

1-20

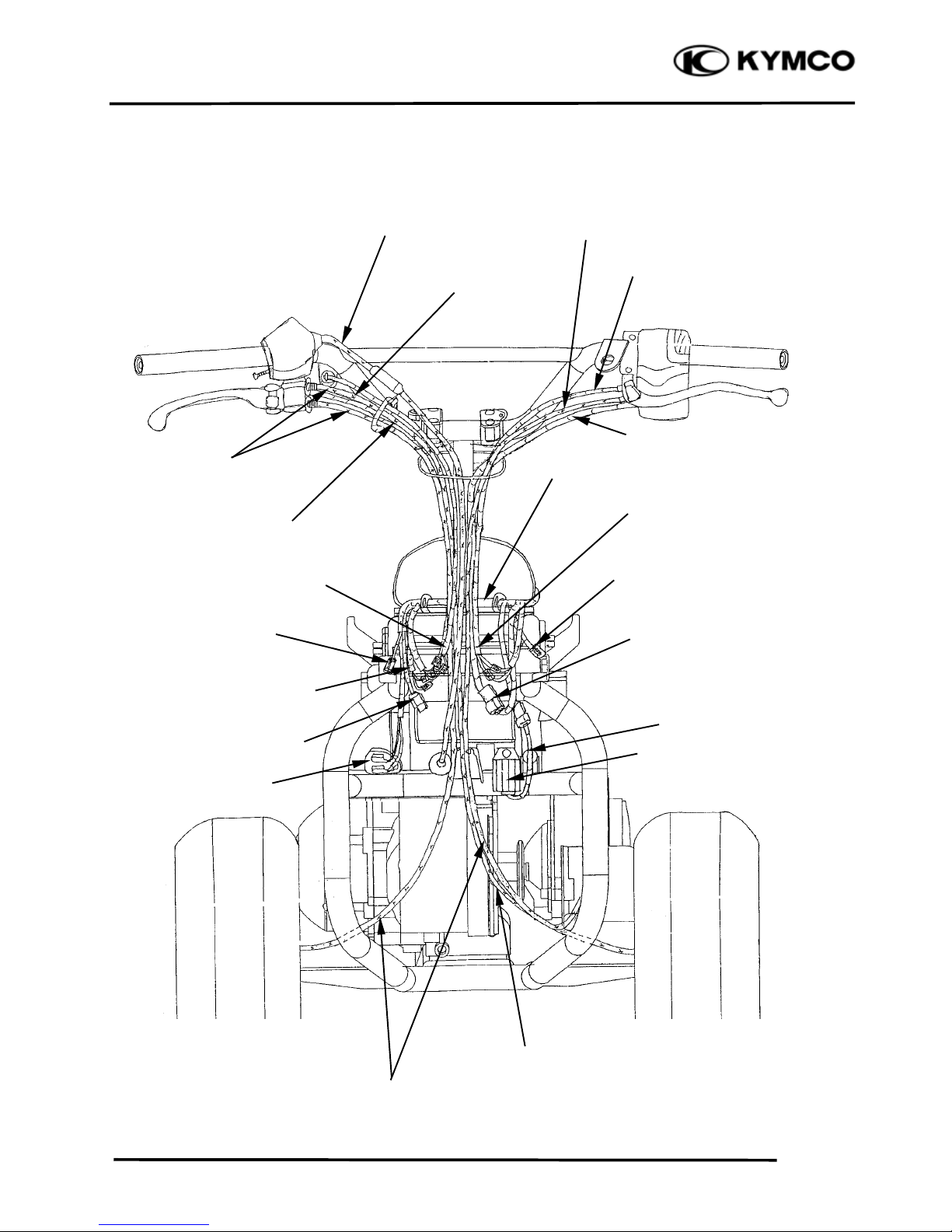

CABLE & HARNESS ROUTING

Headlight Wire Couple

r

Rear Brake Cable/Fluid Hose

Handlebar Switch Couple

r

Ignition Switch Couple

r

Harness Wire

Ignition Coil

Kill Switch (Safety)

Front Brake Cable

Front Stop Switch Wire

Throttle Cable

REG.REC Wire

Pilot Leads

(50cc-2T)

Rear Stop Switch Wire

Handlebar Switch Wire

Rear Stop Switch Wire

Kill Switch (Safety)

Front Stop Switch Wire

Front Brake Cable

Rear Brake Cable/Fluid Hose

REG.REC

Page 24

1. GENERAL INFORMATION

1-21

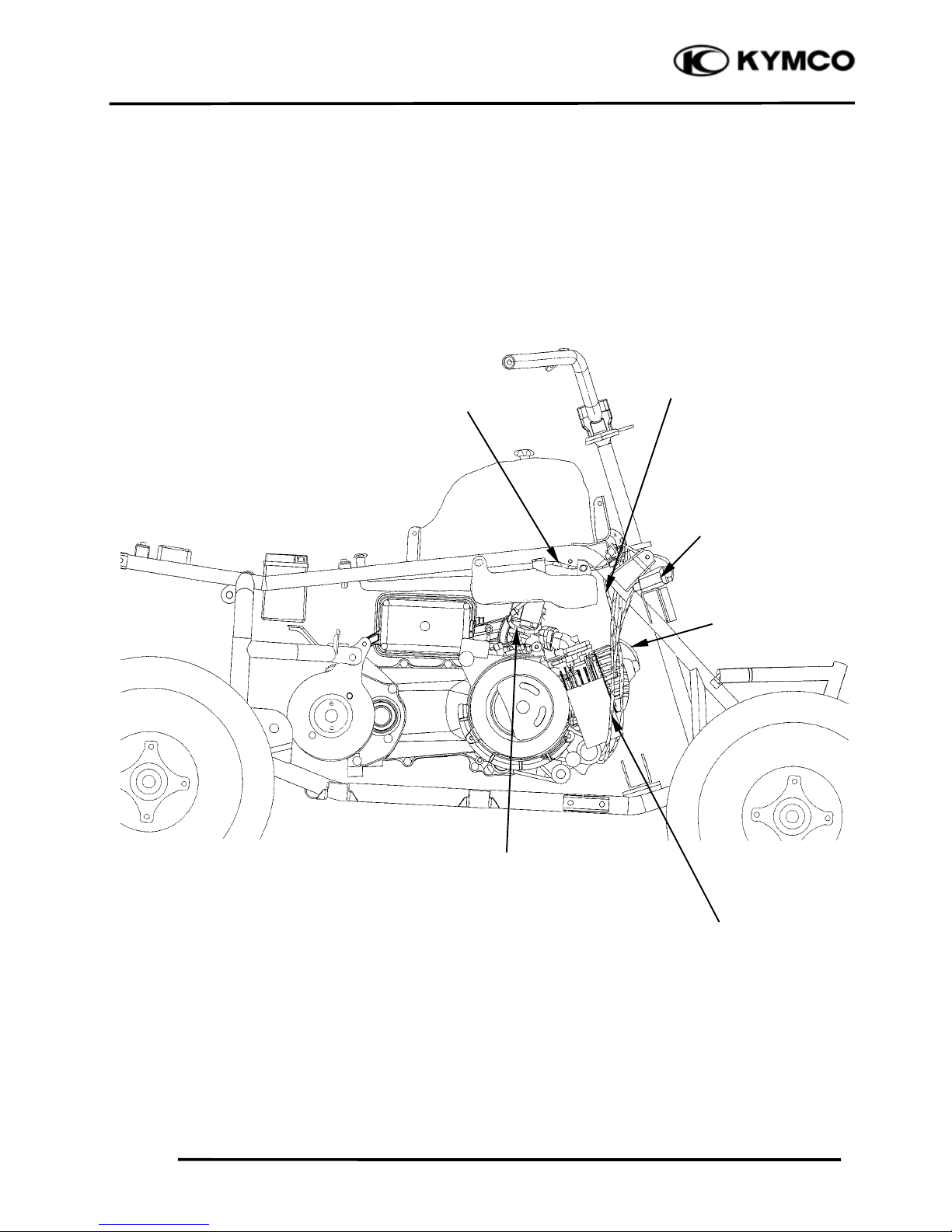

Oil Outlet Tube

(50cc-2T)

Oil Level Switch Wire

(50cc-2T)

A.C.G. Wire

Ignition Coil

Ignition Coil Wire

Starter Motor Wire

Page 25

1. GENERAL INFORMATION

1-22

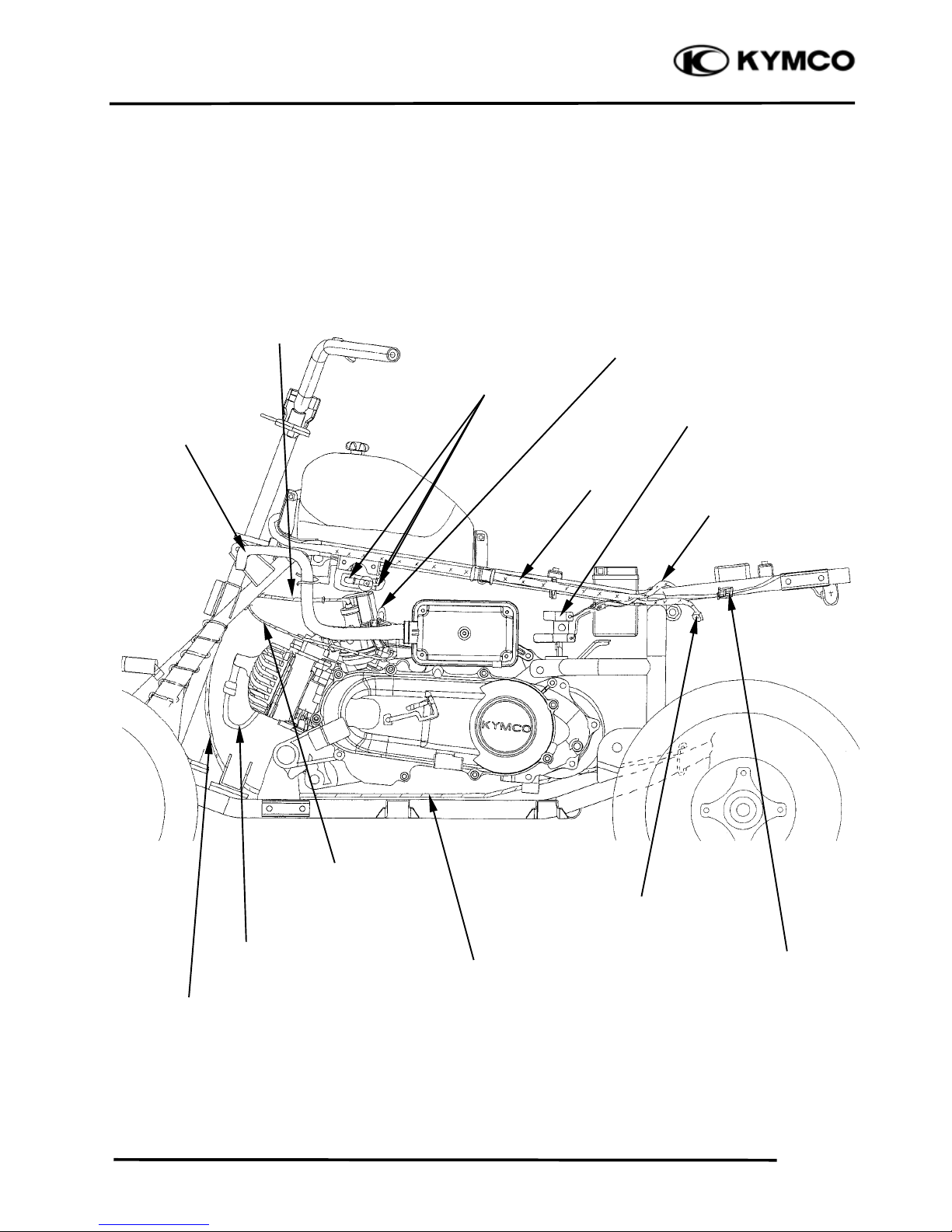

Taillight Couple

r

Battery Positive (+)

Battery Negative (-)

Oil Pump Control Cable

(50cc-2T)

Ignition Coil Wire

Rear Brake Cable/Fluid Hose

Air Inlet Hose

Throttle Cable

Fuel Tube

Autobystarter Wire

Harness Wire

Resisto

r

Page 26

1. GENERAL INFORMATION

1-23

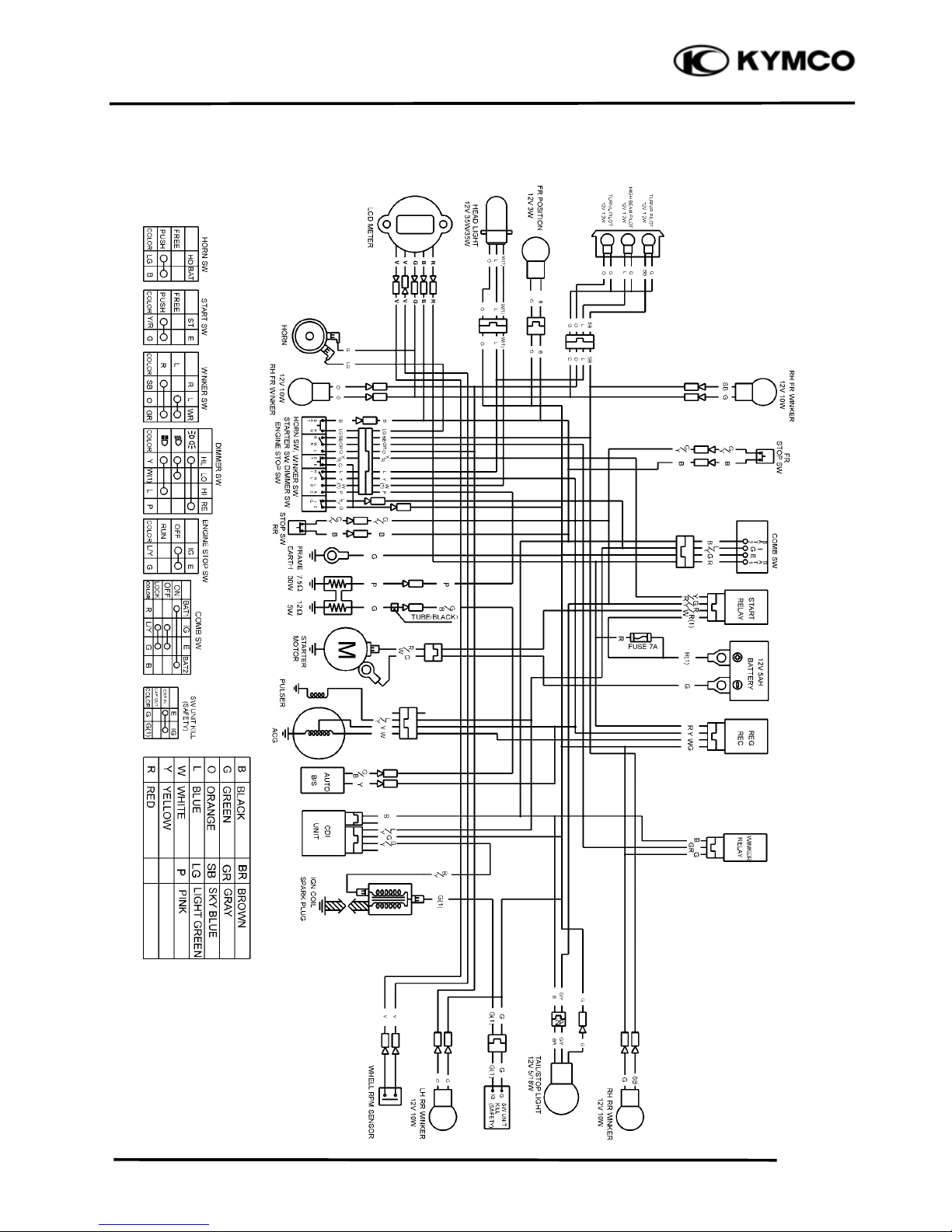

WIRING DIAGRAMS

Mongoose 90/MXER 90R/Mongoose 50-4T OFF ROAD

G

Page 27

1. GENERAL INFORMATION

1-24

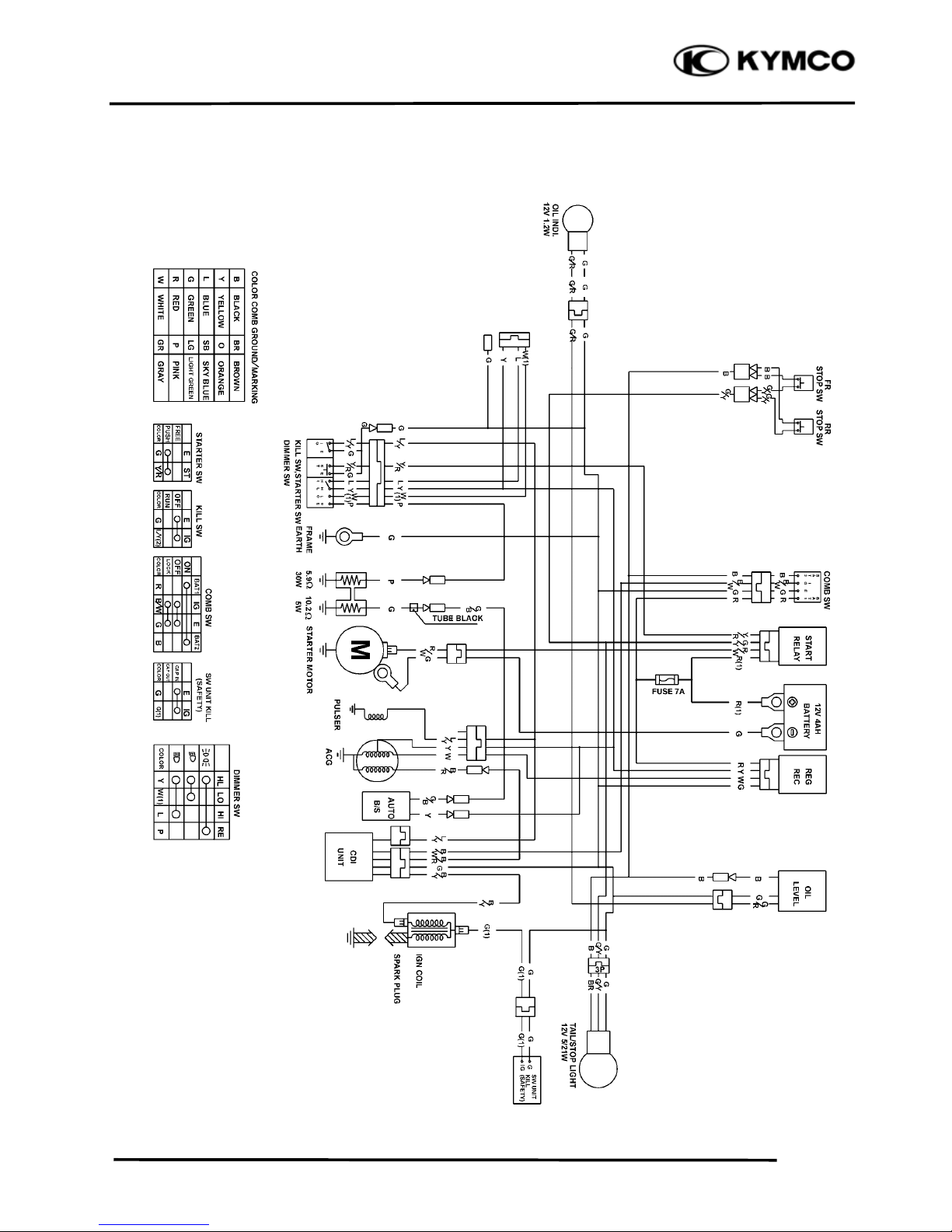

MXER 90R ON ROAD

Page 28

1. GENERAL INFORMATION

1-25

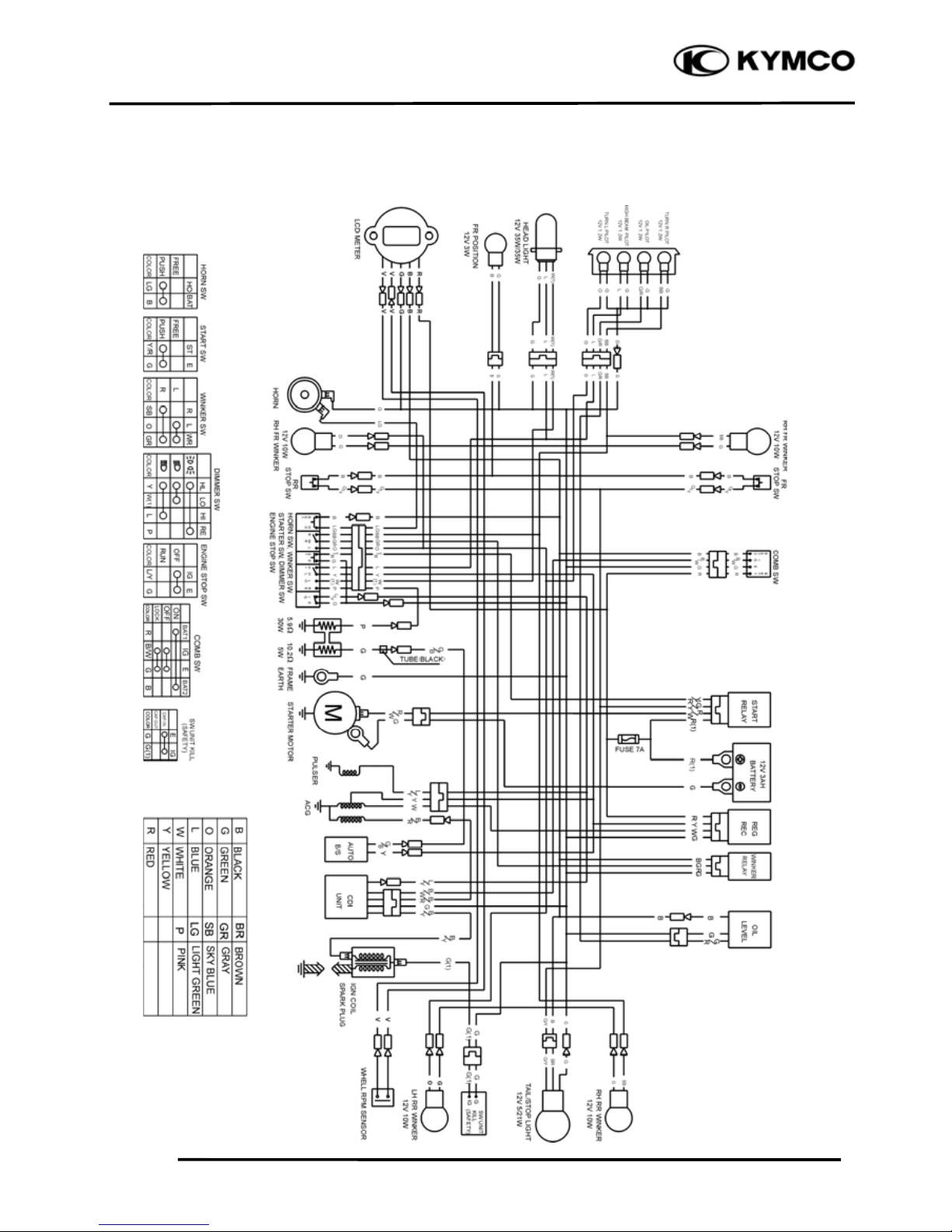

Mongoose 70

Page 29

1. GENERAL INFORMATION

1-26

Mongoose 50-2T/MXER 50R-2T OFF ROAD

Page 30

1. GENERAL INFORMATION

1-27

MXER 50R-2T ON ROAD

Page 31

1. GENERAL INFORMATION

1-28

TROUBLESHOOTING

ENGINE WILL NOT START OR IS HARD TO START

Empty fuel tank

Clogged fuel line between fuel

tank and carburetor

Clogged float oil passage

Clogged fuel tank cap breather

hole

Clogged fuel filter

Clogged fuel valve passage

Faulty spark plug

Fouled spark plug

Faulty ignition unit

Faulty pulser coil

Broken or shorted ignition coil

Broken or shorted exciter coil

Faulty ignition switch

Weak or dead battery

Faulty starter clutch

Valve clearance too small

Valve stuck open

Worn cylinder, piston and piston

rings

Leaking cylinder head gasket

Air leaking through intake pipe

Leaking intake manifold

Incorrect ignition timing

Incorrectly adjusted air screw

Flooded carburetor

Clogged air cleaner

Throttle valve excessively open

Check if fuel reaches

carburetor by loosening

drain screw

Remove spark plug and

install it into spark plug

cap to test spark by

connecting it to engine

ground

Inspection/Adjustment

Probable Cause

Spark jumps

Normal

compression

Engine does no

t

fire

Weak or no spark

Low or no

compression

Engine fires bu

t

does not start

Test cylinde

r

compression

Start engine by following normal starting

p

rocedure

Remove spark plug and

inspect again

Symptom

Fuel reaches

carburetor

Fuel does no

t

reach carburetor

Wet spark plug

Dry spark plug

Page 32

1. GENERAL INFORMATION

1-29

ENGINE LACKS POWER

Clogged air cleaner

Restricted fuel flow

Clogged fuel tank cap breather hole

Clogged exhaust muffler

Carburetor fuel level too low

Faulty ignition unit

Faulty pulser coil

Improper valve clearance

adjustment

Excessively worn valve seat

(protruded valve stem)

Improper valve and seat contact

Worn cylinder and piston rings

Leaking cylinder head gasket

Improper valve timing

Clean and unclog

Fouled spark plug

Incorrect heat range plug

Oil level too high

Oil level too low

Oil not changed

Clogged oil line

Faulty oil pump

Worn cylinder and piston rings

Mixture too lean

Poor quality fuel

Excessive carbon build-up in

combustion chamber

Ignition timing too early

Excessive carbon build-up in

combustion chamber

Poor quality fuel

Clutch slipping

Mixture too lean

Ignition timing too early

Start engine and

accelerate lightly for

observation

Inspection/Adjustment

Symptom

Probable Cause

Engine speed

Correct timin

g

Engine speed does no

t

increase sufficientl

y

Incorrect timin

g

Check ignition timing

(using a timing light)

Test cylinder compression

Check carburetor fo

r

clogging

Rapidly accelerate or run

at high speed

Remove spark plug and

inspect

Check if engine overheats

Check valve clearance

Correc

t

Incorrec

t

N

ormal

com

p

ression

Abnormal

compression

Remove oil dipstick and

check oil level and condition

Remove cylinder head oil

pip

e bolt and inspec

t

Engine overheats

Engine does no

t

overheats

Plug not fouled o

r

discolored

Plug fouled o

r

discolored

Correct and no

t

contaminated

Incorrect o

r

contaminated

Valve train lubricated

prop

erl

y

Valve train no

t

lubricated properl

y

Engine does not knock

Engine knocks

Not clogged

Clogged

Page 33

1. GENERAL INFORMATION

1-30

POOR PERFORMANCE (ESPECIALLY AT IDLE AND LOW SPEEDS)

Faulty ignition unit

Faulty pulser coil

Mixture too rich (turn screw

out)

Mixture too lean (turn screw in)

Deteriorated O-ring

Carburetor not securely

tightened

Damaged insulator rubber

Faulty or fouled spark plug

Faulty CDI unit

Faulty A.C. generator

Faulty ignition coil

Broken or shorted spark plug

wire

Faulty ignition switch

Remove spark plug and

install it into spark plug

cap to test spark by

connecting it to engine

g

round

Inspection/Adjustment Symptom Probable Cause

Check ignition timing

Check carburetor gaske

t

for air leaks

Check carburetor ai

r

screw adjustment

Correct timing

Incorrect timing

Correctly adjusted

No air leak

Air leaks

Good spark

Weak or inter-

mittent spark

Incorrectly adjusted

Page 34

1. GENERAL INFORMATION

1-31

POOR PERFORMANCE (AT HIGH SPEED)

Faulty CDI unit

Faulty pulser coil

Improperly adjusted valve

clearance

Worn valve seat

Empty fuel tank

Clogged fuel tube or filter

Clogged Fuel tank cap breather

hole

Clean and unclog

Cam timing gear aligning marks

not aligned

Faulty spring

Inspection/Adjustment Symptom Probable Cause

Check ignition timing

Check carburetor jets

for clogging

Check fuel pump fo

r

fuel supply

Correct timing

Incorrect timing

Check valve spring

tension

Check valve clearance

Fuel flows freely

Fuel flow restricted

Correc

t

Incorrec

t

Not clogged

Clogged

Correctly adjusted

Incorrectly adjusted

Not weakened

Weak spring

Check valve timing

Page 35

1. GENERAL INFORMATION

1-32

POOR CHARGING (BATTERY OVER DISCHARGING OR OVERCHARGING)

Undercharging

Dead battery

Faulty battery

Faulty A.C. generator coil

Broken yellow wire

Shorted white and yellow

wires

Broken red wire

Faulty regulator/rectifier

Poorly connected coupler

Faulty A.C. generator

Overcharging

Broken green wire

Poorly connected coupler

Faulty regulator/rectifier

Start engine and tes

t

limit voltage of battery

terminals

Connect battery (+) wire

to regulator/rectifier

coupler red wire and

battery (-) wire to engine

ground and test voltage

Inspection/Adjustment

Inspection/Adjustment

Symptom

Symptom

Probable Cause

Probable Cause

Normal voltage

B

attery has voltage

with ignition

switch “ON”

Normal

Voltage does no

t

B

attery has no

voltage with ignition

switc

h

“ON”

Resistance too high

Normal voltage No voltage

Measure resistance

between AC generator

coil terminals

Normal

Abnormal

Check regulator/rectifier

coupler for loose

connection

Normal

Abnormal

Connect battery (+) wire

to regulator/rectifier

coupler green wire and

battery (-) wire to engine

ground and test voltage

Check regulator/rectifier

coupler for loose

connection

Page 36

1. GENERAL INFORMATION

1-33

NO SPARK AT SPARK PLUG

Faulty spark plug

Loose spark plug cap

Poorly connected coupler

Faulty ignition switch

Weak battery

Faulty pulser coil

Faulty ignition coil

Faulty charging system

Broken wire harness

Poorly connected coupler

Faulty CDI unit

Faulty ignition coil

Replace with a new

spark plug and inspect

a

g

ain

Check CDI unit coupler

for looseness

Inspection/Adjustment Symptom

Probable Cause

Normal

Abnormal

Normal

Abnormal

Normal

Abnormal

Abnormal

Measure resistance

between terminals of

CDI unit cou

pler

Check related parts

Check ignition coil with

a CDI unit tester

Weak or no spark

Not loose

Good spark

Loose

Good

Good

Check spark plug cap

and high-tension wire

for looseness

Check CDI unit with a

CDI unit tester

Page 37

2. FRAME COVERS/EXHAUST MUFFLER

2-0

2

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

FRAME COVERS/EXHAUST MUFFLER

__________________________________________________________________________________

SERVICE INFORMATION------------------------------------------------ 2- 2

FRAME COVERS----------------------------------------------------------- 2- 3

EXHAUST MUFFLER REMOVAL-------------------------------------- 2- 7

TAILLIGHT BULB --------------------------------------------------------- 2- 8

2

Page 38

2. FRAME COVERS/EXHAUST MUFFLER

2-1

Page 39

2. FRAME COVERS/EXHAUST MUFFLER

2-2

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• When removing frame covers, use special care not to pull them by force because the cover joint

claws may be damaged.

• Make sure to route cables and harnesses according to the Cable & Harness Routing.

TORQUE VALUES

Exhaust muffler lock bolt 35 N-m (3.5 kgf-m, 25 lbf-ft)

Exhaust muffler lock nut (90cc/70cc/50cc-2T) 20 N-m (2 kgf-m, 15 lbf-ft)

Exhaust muffler lock nut (50cc-4T) 10 N-m (1 kgf-m, 7 lbf-ft)

TROUBLESHOOTING

Noisy exhaust muffler

• Damaged exhaust muffler

• Exhaust muffler joint air leaks

Lack of power

• Caved exhaust muffler

• Exhaust muffler air leaks

• Clogged exhaust muffler

Page 40

2. FRAME COVERS/EXHAUST MUFFLER

2-3

FRAME COVERS

HANDLEBAR COVER REMOVAL

Remove the two screws attaching the

handlebar cover.

Disconnect the oil level indicator leads.

Remove the handlebar cover.

INSTALLATION

Reverse the “HANDLEBAR COVER

REMOVAL” procedures.

SEAT REMOVAL

To remove the seat, pull upward the seat

lock lever and pull up the seat at the rear.

To install the seat, align the tabs on the seat

with the grommets on the frame and press

the seat down until it locks.

HANDLEBAR REMOVAL

Remove handlebar cover. (See page 2-3)

Remove the rear brake master cylinder

attaching bolts (disk brake).

Disconnect the rear brake cable (drum

brake).

Disconnect the handlebar switch coupler

and lead (under front fender).

Bolts

Handlebar Cove

r

Seat Lock Leve

r

Sea

t

Make sure that the seat is securely fitted.

*

Bolts

Handlebar Switch Coupler and Lead

Page 41

2. FRAME COVERS/EXHAUST MUFFLER

2-4

Disconnect the front brake cables.

Disconnect the remote stop switch and front

brake stop switch leads.

Remove the two screws and speed limiter

cover.

Disconnect the throttle cable.

Remove the two bolts and handlebar cover

holder.

Remove the four bolts and upper handlebar

holders.

Remove the handlebar.

INSTALLATION

Reverse the “HANDLEBAR REMOVAL”

procedures (refer to the “STEERING

SYSTEM” section in the chapter 12).

Refer to the “BRAKE LEVER FREE

PLAY” section in the chapter 3 to adjust

brake lever free play.

*

Front Brake Cables

Remote Engine Stop

Switch Leads

Front Brake Stop

Switch Leads

Screws

Throttle Cable

Bolts

Bolts

Page 42

2. FRAME COVERS/EXHAUST MUFFLER

2-5

FRONT FENDER REMOVAL

Remove the seat. (See page 2-3)

Remove the handlebar. (See page 2-3)

Remove the six screws and nuts attaching

the front fender and right/left foot boards.

Remove the four screws and two nuts

attaching the front fender and rear fender at

the right/left side.

Remove the two bolts attaching front fender

at the right/left side.

Remover the fuel filler cap.

Remove the front fender and disconnect the

ignition switch coupler.

During removal, do not pull the joint

claws forcedly to avoid damage.

*

After remove, be sure to tighten the fuel

filler cap.

*

Screws

Screws

Screws

Screws

Bolts

Fuel Filler Cap

Ignition Switch Couple

r

Page 43

2. FRAME COVERS/EXHAUST MUFFLER

2-6

INSTALLATION

Reverse the “FRONT FENDER

REMOVAL” procedures.

REAR FENDER REMOVAL

Remove the front fender. (See page 2-5)

Remove the battery. (See chapter 14)

Remove the starter relay and CDI unit.

Remove the ten screws attaching the rear

fender and foot boards at the right/left side.

Remove the two screws attaching the rear

fender at the rear.

Remove the three bolts attaching the rear

fender at the center and then remove the

rear fender.

After remove, be sure to tighten the fuel

filler cap.

*

Starter Relay Ignition Uni

t

Screws

Screws

Screws

Bolts

Page 44

2. FRAME COVERS/EXHAUST MUFFLER

2-7

FOOT BOARD REMOVAL

Remove front fender. (See page 2-5)

Remover rear fender. (See page 2-6)

Remove the four bolts attaching the

right/left foot board.

FRONT CARRIER REMOVAL

Remove the four bolts attaching front

carrier at the right/left side.

EXHAUST MUFFLER

REMOVAL

Remove the two nuts attaching the exhaust

pipe and cylinder head.

Remove the three bolts attaching the

exhaust muffler, then remove the exhaust

muffler.

Bolts

Bolts

N

uts

Bolts

Page 45

2. FRAME COVERS/EXHAUST MUFFLER

2-8

Inspect the gasket.

If the exhaust gas leaks, the gasket should

be replaced.

Install by reversing the removal sequence.

Torque:

Exhaust muffler lock bolt

35 N-m (3.5 kgf-m, 25 lbf-ft)

Exhaust muffler lock nut (90cc/70cc/50cc-

2T)

20 N-m (2 kgf-m, 15 lbf-ft)

Exhaust muffler lock nut (50cc-4T)

10 N-m (1 kgf-m, 7 lbf-ft)

TAILLIGHT BULB

REMOVAL

Remove the two screws and taillight lens.

Turn bulb and remove it.

Be sure to install a new exhaust gasket.

*

Gaske

t

Screws

Bulb

Page 46

3. INSPECTION/ADJUSTMENT

3-0

3

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

INSPECTION/ADJUSTMENT

__________________________________________________________________________________

SERVICE INFORMATION------------------------------------------------ 3- 1

MAINTENANCE SCHEDULE-------------------------------------------- 3- 3

FUEL LINE/THROTTLE OPERATION--------------------------------- 3- 4

AIR CLEANER -------------------------------------------------------------- 3- 5

SPARK PLUG/CYLINDER COMPRESSION-------------------------- 3- 7

VALVE CLEARANCE (90cc/70cc/50cc-4T) --------------------------- 3- 8

CARBURETOR IDLE SPEED -------------------------------------------- 3- 8

ENGINE OIL (90cc/70cc/50cc-4T) --------------------------------------- 3- 9

TRANSMISSION OIL------------------------------------------------------ 3-11

DRIVE BELT/BRAKE SHOES/BRAKE PADS/BRAKE FLUID --- 3-12

BRAKE LEVER FREE PLAY (DRUM BRAKE) ---------------------- 3-13

STEERING SYSTEM INSPECTION------------------------------------- 3-14

TOE-IN ADJUSTMENT --------------------------------------------------- 3-15

WHEELS/TIRES ------------------------------------------------------------ 3-16

DRIVE CHAIN SLACK ADJUSTMENT-------------------------------- 3-17

CABLE INSPECTION AND LUBRICATION-------------------------- 3-19

SUSPENSION LUBRICATION------------------------------------------- 3-19

HEADLIGHT BEAM ADJUSTMENT (ON ROAD ONLY)---------- 3-20

BRAKE PEDAL ADJUSTMENT (ON ROAD ONLY)---------------- 3-20

BRAKE FULID -------------------------------------------------------------- 3-21

3

Page 47

3. INSPECTION/ADJUSTMENT

3-1

SERVICE INFORMATION

GENERAL

! WARNING

•Before running the engine, make sure that the working area is well-ventilated. Never run the

engine in a closed area. The exhaust contains poisonous carbon monoxide gas which may

cause death to people.

•Gasoline is extremely flammable and is explosive under some conditions. The working area

must be well-ventilated and do not smoke or allow flames or sparks near the working area or

fuel storage area.

SPECIFICATIONS

ENGINE

Throttle grip free play : 1~4 mm (0.04~0.16 in)

Spark plug gap : 0.6~0.7 mm (0.024~0.028 in)

Spark plug: Standard : 90 cc: NGK: CR7HSA

: 70 cc: NGK: CR7HAS

: 50 cc-4T: NGK: CR7HAS

: 50 cc-2T: NGK: R8HAS

Valve clearance : 90 cc: IN: 0.1mm (0.004 in)

EX: 0.1mm (0.004 in)

: 70 cc IN: 0.04mm (0.0016 in)

EX: 0.04mm (0.0016 in)

: 50 cc-4T IN: 0.04mm (0.0016 in)

EX: 0.04mm (0.0016 in)

Idle speed : 90 cc 1800±100rpm

: 70 cc 2000±100rpm

: 50 cc-2T 2000±100rpm

: 50 cc-4T 2000±100rpm

Engine oil capacity (90cc/70cc/50cc-4T):

At disassembly : 0.8 L (0.7 lmp qt , 0.85 US qt)

At change : 0.7 L (0.62 lmp qt , 0.74 US qt)

Gear oil capacity :

At disassembly : 0.12 L (0.11 lmp qt , 0.13 US qt)

At change : 0.11 L (0.1 lmp qt , 0.12 US qt)

Cylinder compression : 90 cc 16kg/cm²(1600kpa, 227.2psi)

: 70 cc 14kg/cm²(1400kpa, 198.8psi)

: 50 cc-4T 14kg/cm²(1400kpa, 198.8psi)

: 50 cc-2T 12kg/cm²(1200kpa, 170.4psi)

Page 48

3. INSPECTION/ADJUSTMENT

3-2

Ignition timing : 90 cc BTDC 13°/1800rpm

: 70 cc BTDC 13°/1800rpm

: 50 cc-4T BTDC 13°/2000rpm

: 50 cc-2T BTDC 15°/1700rpm

CHASSIS

Front brake free play: 10~20 mm (0.4~0.8 in)

Drive chain slack: 10~20 mm (0.4~0.8 in)

TIRE PRESSURE

1 Rider

Front 25 kPa (0.25 kgf/cm², 3.6 psi)

Rear 25 kPa (0.25 kgf/cm², 3.6 psi)

TIRE SIZE: 90 cc:

Front: 18*7-8

Rear: 18*9-8

: 70cc/50cc-4T/50cc-2T:

Front: 16*8-7

Rear: 16*8-7

TORQUE VALUES

Front wheel nut 45 N-m (4.5 kgf-m, 32 lbf-ft)

Rear wheel nut 45 N-m (4.5 kgf-m, 32 lbf-ft)

Page 49

3. INSPECTION/ADJUSTMENT

3-3

MAINTENANCE SCHEDULE

This chapter includes all information necessary to perform recommended inspections and

adjustments. These preventive maintenance procedures, if followed, will ensure more reliable

vehicle operation and a longer service life. The need for costly overhaul work will be greatly

reduced. This information applies to vehicles already in service ad well as new vehicles that are

being prepared for sale. All service technicians should be familiar with this entire chapter.

Initial Every

Item Remarks

1

month3month6month6month

1

year

Valves (except 50cc-2T)

Check valve clearance. Adjust if

necessary.

○○○○

Spark plug

Check condition. Clean or

replace if necessary.

○○○○○

Air clearance Clean. Replace if necessary. ○○○○

Carburetor

Check idle speed/starter

operation. Adjust if necessary.

○○○○

Fuel line

Check fuel hose for cracks or

damage. Replace if necessary.

○○○

Engine oil (except 50cc2T)

Replace (Warm engine before

draining).

○○○○

Engine oil filter

screen(except 50cc-2T)

Clean. Replace if necessary.

○○

Transmission oil

Check oil leakage. Replace

every 12 months.

○○

Brake system

Check operation. Adjust if

necessary.

○○○○○

Drive belt

Check operation/replace if

damage or excessive wear.

○○

Wheels

Check balance/damage/runout.

Replace if necessary.

○○○○

Wheel bearings

Check bearings assembly for

looseness/damage. Replace if

damaged.

○○○○

Steering system

Check operation/replace if

damage. Check toe-in/adjust if

necessary.

○○○○○

Knuckle shafts Lubricate every 6 months. ○○○

Fitting/Fasteners

Check all chassis fittings and

fasteners. Correct if necessary.

○○○○○

Spark arresterl

Clean

○○○

• In the interest of safety, we recommend these items should be serviced only by an authorized

KYMCO motorcycle dealer.

Page 50

3. INSPECTION/ADJUSTMENT

3-4

FUEL LINE

Check the fuel tubes and replace any parts,

which show signs of deterioration, damage

or leakage.

THROTTLE OPERATION

Check the throttle to swing for smooth

movement.

Measure the throttle to swing free play.

Free Play: 1~4 mm (0.04~0.16 in)

To adjust throttle free play:

1. Slide the rubber sleeves back to expose

the throttle cable adjuster.

2. Loosen the lock nut, then turn the

adjuster to obtain the correct free play.

(1~4 mm or 0.04~0.16 in)

3. Tighten the lock nut and reinstall the

sleeve.

OIL PUMP ADJUSTMENT (50cc-4T

only)

Open the throttle valve fully and check that

the index mark on the pump body aligns

with the aligning mark on the oil pump

control lever.

Reference tip alignment within 1mm of

index mark on open side is acceptable.

Start and idle the engine, then slowly open

the throttle to increase engine rpm and

check the operation of the oil pump control

lever.

If adjustment is necessary, adjust the oil

pump control cable by loosening the control

cable lock nut and turning the adjusting nut.

After adjustment, tighten the lock nut.

Fuel Filte

r

Fuel Tubes

Rubber Sleeves

Lock Nu

t

Cable Adjuste

r

Throttle Leve

r

Adjust oil pump control cable after the

throttle grip free play is adjusted.

*

Control Lever Aligning Mark

Lock NutAdjusting Nu

t

Do not smoke or allow flames or sparks

in your working area.

*

Page 51

3. INSPECTION/ADJUSTMENT

3-5

If the oil pump is not synchronized properly,

the following will occur:

• Excessive white smoke or hard starting

due to pump control lever excessively

open

• Seized piston due to pump control lever

insufficiently open

AIR CLEANER

AIR CLEANER

REPLACEMENT/CLEANING

(90cc/70cc/50cc-4T)

To replace the air cleaner

1. Remove the seat. (See page 2-3.)

2. Remove the five screws and then remove

air filter case cover.

3. Remove the air filter element, and

separate it from the box.

Screws

Air Filter Case Cove

r

Air Filter Elemen

t

Reference tip alignment within 1mm of

index mark on open side is acceptable.

However, the aligning mark on the

control lever must never be on the

closed side of the index mark, otherwise

engine damage will occur because of

insufficient lubrication.

*

Page 52

3. INSPECTION/ADJUSTMENT

3-6

To replace the air cleaner (50cc-2T)

1. Remove the five screws and air filter case

cover.

2. Remove the air filter element, and

separate it from the box.

To clean the air filter element:

1. Wash the element gently but thoroughly

in solvent.

2. Squeeze the excess solvent out of the

filter and let it dry.

3. Inspect the element. If damaged, replace

it.

4. Apply quality foam air filter oil to the

element. If foam air filter oil is not

available, motor oil may be used.

5. Reinstall the element to the air filter case.

6. Reinstall the element assembly and parts

removed for access.

Apply the engine oil.

Squeeze out the excess oil.

CHANGE INTERVAL

More frequent replacement is required when

riding in unusually dusty or rainy areas.

Use parts cleaning solvent only. Neve

r

use gasoline or low flash point solvents

which may lead to a fire or explosion.

*

Do not twist or wring out the foa

m

element. This could damage the foam

material.

*

The element should be wet but not

dripping.

*

Air Filter Elemen

t

Screws

Air Filter Case Cove

r

Page 53

3. INSPECTION/ADJUSTMENT

3-7

Gap, Wear, and Fouling Deposits

SPARK PLUG

Remove the ignition coil cap and spark

plug.

Check the spark plug for wear and fouling

deposits.

Clean any fouling deposits with a spark

plug cleaner or a wire brush.

Specified Spark Plug:

90cc/70cc/50cc-4T: NGK: CR7HSA

50cc-2T: NGK: BR8HAS

Measure the spark plug gap.

Spark Plug Gap:

0.6~0.7 mm (0.024~0.028 in)

CYLINDER COMPRESSION

Warm up the engine before compression

test.

Remove the spark plug.

Insert a compression gauge.

Open the throttle valve fully and push the

starter button to test the compression.

Compression:

90 cc: 16 kgf/cm²(1600 kPa, 227.2 psi)

70 cc: 14 kgf/cm²(1400kPa, 198.8 psi)

50 cc-4T: 14 kgf/cm²(1400kPa, 198.8 psi)

50 cc-2T: 12 kgf/cm²(1200kPa, 170.4 psi)

If the compression is low, check for the

following:

- Leaky valves

- Valve clearance too small

- Leaking cylinder head gasket

- Worn piston rings

- Worn piston/cylinder

If the compression is high, it indicates that

carbon deposits have accumulated on the

combustion chamber and the piston head.

Cracks, Damage

Washer Deformation

Ignition Coil Cap/Spark Plug

When installing, first screw in the spar

k

plug by hand and then tighten it with a

spark plug wrench.

*

Compression Gauge

Page 54

3. INSPECTION/ADJUSTMENT

3-8

VALVE CLEARANCE

(90cc/70cc/50cc-4T)

Disconnect the oil recycle tube at the

cylinder head cover.

Remove the four bolts and cylinder head

cover.

Remove the two screws and two bolts, then

remove the fan cover.

Turn the cooling fan clockwise so that the

“T” mark on the flywheel aligns with the

index mark on the crankcase to bring the

round hole on the camshaft gear facing up

to the top dead center on the compression

stroke.

Inspect and adjust the valve clearance.

Valve Clearance:

90cc: IN: 0.1mm (0.004 in)

EX: 0.1mm (0.004 in)

70cc/50cc-4T: IN: 0.04mm (0.0016 in)

EX: 0.04mm (0.0016 in)

Loosen the lock nut and adjust by turning

the adjusting nut

Special tool:

Tappet adjuster A120E00012

CARBURETOR IDLE SPEED

Warm up the engine before this operation.

Start the engine and connect a tachometer.

Turn the throttle stop screw to obtain the

specified idle speed.

Idle Speed:

90 cc: 1800±100rpm

70 cc/50 cc-4T/50 cc-2T: 2000±100rpm

When the engine misses or run erratic,

adjust the air screw.

Inspect and adjust valve clearance while

the engine is cold (below 35°C).

*

• Check the valve clearance again afte

r

the lock nut is tightened.

*

Cylinder Head Cove

r

Bolts

Cooling Fan Cove

r

Screws

Bolts

Round Hole

Punch Marks

Tappet Adjuste

r

Throttle Stop Screw

Air Screw

• The engine must be warm for accurate

idle speed inspection and adjustment.

*

Page 55

3. INSPECTION/ADJUSTMENT

3-9

ENGINE OIL (90cc/70cc/50cc-4T)

OIL LEVEL

Remove the two bolts and right side cover.

Place the machine on a level place.

Warm up the engine for several minutes and

stop it.

Remove the dipstick and wipe it off with a

clean rag. Insert the dipstick in the filler

hole without screwing it in.

Remove the dipstick and inspect the oil

level.

The oil level should be between the

maximum and minimum marks. If the level

is low, add oil to raise it to the proper level.

ENGINE OIL REPLACEMENT

Place the machine on a level place.

Warm up the engine for several minutes and

stop it.

Place a container under the engine.

Remove right side cover.

Remove the oil filler cap and drain plug to

drain the oil.

Reinstall the drain plug and tighten the

drain plug to specification.

Torque: 25 N-m (2.5 kgf-m, 18 lbf-ft)

Fill the engine with oil and install the oil

filler cap.

Warm up the engine for several minutes at

idle speed. Check for oil leakage while

warming up.

Oil Capacity:

At disassembly:

0.8 L (0.7 lmp qt , 0.85 US qt)

At change:

0.7 L (0.62 lmp qt , 0.74 US qt)

Maximum Level Mark

Dipstick/Oil Filler Cap

Minimum Level Mark

Dipstick/Oil Filler Cap

Drain Plug

Be sure no foreign material enters the

crankcase.

*

Run the engine for 2~3 minutes and

check the oil level after the engine is

stopped for 2~3 minutes.

*

Right Side Cove

r

Bolts

Page 56

3. INSPECTION/ADJUSTMENT

3-10

ENGINE OIL REPLACEMENT AND

OIL FILTER CLEANING

A. Place the machine on a level place.

B. Warm up the engine for several minutes

and stop it.

C. Place a container under the engine.

D. Remove the oil filler cap and oil filter

cap to drain the oil.

E. Clean the oil strainer with solvent.

F. Inspect the O-ring and replace if

damaged.

G. Reinstall the O-ring, oil strainer,

compression spring and drain plug.

Tighten the drain plug to specification.

Torque: 15 N-m (1.5 kgf-m, 11 lbf-ft)

Oil Capacity:

At disassembly:

0.8 L (0.7 lmp qt , 0.85 US qt)

At change:

0.7 L (0.62 lmp qt , 0.74 US qt)

Oil Filter Cap

.Be sure no foreign material enters the

crankcase.

.When removing the drain plug, the

compression spring, oil strainer and

O-ring will fall out. Take care not to

lose these parts.

*

Before reinstalling the drain plug, be sure

to install the O-ring, compression spring

and oil strainer.

*

Oil Filter Cap

Compression Spring

Oil Straine

r

O-ring

Page 57

3. INSPECTION/ADJUSTMENT

3-11

TRANSMISSION OIL

TRANSMISSION OIL

MEASUREMENT

Place the machine on a level place.

Remove the oil filler bolt and check the oil

level. It should be up to the brim of the hole.

If the level is low, add oil to raise it to the

proper level.

Reinstall the oil filler bolt and tighten to

specification.

Torque: 18 N-m (1.8 kgf-m, 13 lbf-ft)

TRANSMISSION OIL REPLACEMENT

Place the machine on a level place.

Place a container under the engine.

Remove the oil filler bolt and drain plug to

drain the oil.

Reinstall the drain plug and tighten to

specification.

Torque: 18 N-m (1.8 kgf-m, 13 lbf-ft)

Fill the engine with oil and install the oil

filler bolt.

Torque: 18 N-m (1.8 kgf-m, 13 lbf-ft)

Oil Capacity:

At disassembly:

0.12 L (0.11 lmp qt , 0.13 US qt)

At change:

0.11 L (0.1 lmp qt , 0.12 US qt)

Start the engine and warm up for a few

minutes. While warming up, check for oil

leakage. If oil leakage is found, stop the

engine immediately and check for the cause.

Oil Filter Bolt/Measurement Hole

Drain Plug

Be sure no foreign material enters the

crankcase.

*

Page 58

3. INSPECTION/ADJUSTMENT

3-12

DRIVE BELT

Remove the left crankcase cover.

Inspect the drive belt for cracks, scaling,

chipping or excessive wear.

Measure the V-belt width

Service limit:

90cc: 16.5 mm (0.66 in)

70cc: 16.5 mm (0.66 in)

50cc-4T: 17 mm (0.68 in)

50cc-2T: 17.5 mm (0.7 in)

Replace the drive belt if out of specification.

BRAK SHOES

The checking of brake shoes wear will

disassemble the brake. If the lining

thickness below to the wear limit (A) 2 mm

(0.08 in), to replace the shoes as a set.

BRAKE PADS

A wear indicator is provided on each brake.

The indicators allows checking of brake

pads wear. Check the position of the

indicator. If the indicator reaches the wear

limit line, to replace the pads.

BRAKE FLUID

Check if the fluid level is below the lower

level mark through the inspection window.

Drive Bel

t

Inspection Window

Page 59

3. INSPECTION/ADJUSTMENT

3-13

BRAKE LEVER FREE PLAY

(DRUM BRAKE)

The brake lever free play (A) should be

adjusted to 10~20 mm (0.4~0.8 in) at the tip

of the brake lever.

FRONT BRAKE FREE PLAY

ADJUSTMENT

Loosen the upper lock nut and fully turn in

the adjusting bolt.

Loosen the lower lock nut.

Turn the lower adjusting bolt until specified

free play is obtained.

Tighten the lower lock nut.

While applying the front brake, turn out the

upper adjusting bolt until the upper and

lower cable lengths (A) are equal. The cable

joint will become vertical.

Tighten the upper lock nut.

REAR BRAKE FREE PLAY

ADJUSTMENT

Turn the adjusting nut on the brake hub in

direction A to decrease play, and in

direction B to increase play.

Lock Nuts

Adjusting Bolts

Page 60

3. INSPECTION/ADJUSTMENT

3-14

STEERING SYSTEM

INSPECTION

Place the machine on a level place.

Check the steering column bushings and

bearings:

Move the handlebar up and down, and/or

back and forth.

Replace the steering column bushings and

or bearings if excessive play

Check the tie-rod ends

Turn the handlebar to the left and/or right

until it stops completely, then slightly move

the handlebar from left to right.

Replace the tie-rod ends if tie-rod end has

any vertical play.

Raise the front end of the machine so that

there is no weight on the front wheels.

Check ball joints and/or wheel bearings.

Move the wheels lately back and froth.

Replace the front arms and/or wheel

bearings if excessive free play.

Tie-rod Ends

Make sure the cut-out on the adjusting

nut Is seated on the brake arm pin after

making final free play adjustment.

*

Arm Pin

Adjusting Nu

t

Page 61

3. INSPECTION/ADJUSTMENT

3-15

TOE-IN ADJUSTMENT

Place the machine on a level place.

Measure the toe-in

Adjust if out of specification.

Toe-in measurement steps:

Mark both front tire tread centers.

Raise the front end of the machine so that

there is no weight on the front tires.

Fix the handlebar straight ahead.

Measure the width A between the marks.

Rotate the front tires 180 degrees until the

marks come exactly opposite.

Measure the width B between the marks.

Calculate the toe-in using the formula given

below.

Toe-in = B-A

Toe-in: 0~15mm

If the toe-in is incorrect, adjust the toe-in

Adjust the toe-in step:

Mark both tie-rods ends.

This reference point will be needed during

adjustment.

Loosen the lock nuts (tie-rod end) of both

tie-rods

The same number of turns should be given

to both tie-rods right and left until the

specified toe-in is obtained, so that the

lengths of the rods will be kept the same.

Torque: 30 N-m (3 kgf-m, 22 lbf-ft)

• Be sure that both tie-rod are turned the

same amount. If not, the machine will

drift tight or left even though the

handlebar is positioned straight which

may lead to mishandling and accident.

• After setting the toe-in to specification,

run the machine slowly for some

distance with hands placed lightly on

the handlebar and check that the

handlebar responds correctly. If not,

turn either the right or left tie-rod

within the toe-in specification.

*

A

B

Tie-rod

Tie-rod End Nuts

Tie-rod

Tie-rod End Nuts

Page 62

3. INSPECTION/ADJUSTMENT

3-16

WHEELS/TIRES

Check the tires for cuts, imbedded nails or

other damages.

Check the tire pressure.

TIRE PRESSURE

1 Rider

Front 25kPa(0.22kgf/cm²,3.6psi)

Rear 25kPa(0.22kgf/cm²,3.6psi)

90 cc:

Front: 18*7-8

Rear: 18*9-8

70cc/50cc:

Front: 16*8-7

Rear: 16*8-7

Check the front wheel hub nut for

looseness.

Check the rear wheel hub nut for looseness.

If the axle nuts are loose, tighten them to the

specified torque.

Torque:

Front: 60 N-m(6 kgf-m, 43 lbf-ft)

Rear : 70 N-m(7 kgf-m, 50 lbf-ft)

WHEEL INSPECTION

Inspect the tire surfaces.

Replace if wear or damage.

Tire wear limit: 3 mm (0.12 in)

Front Axle Nu

t

Tire pressure should be checked when

tires are cold.

*

RearAxle Nu

t

It is dangerous to ride with a worn out

tire. When a tire wear is out of

specification, replace the tire

immediately.

*

Page 63

3. INSPECTION/ADJUSTMENT

3-17

Inspect the wheel.

Replace if damage or bends

Always balance the wheel when a tire or

wheel has been changed or replaced.

DRIVE CHAIN SLACK

ADJUSTMENT

Before checking and/or adjusting, rotate the

rear wheels several revolutions and check

slack at several points to find the tightest

point. Check and/or adjust the chain slack

with the rear wheels in this “tightest”

position.

Place the machine on a level place.

Check drive chain slack (A).

Adjust if out of specification.

Drive chain slack:

Approximately 10~20 mm (0.4~0.8 in)

Adjust drive chain slack:

Elevate the rear wheels by placing a suitable

stand under the rear of frame.

Loosen the upper and lower axle holding

bolts.

Bolts

• Never attempt even small repairs to the

wheel.

• Ride conservatively after installing a

tire to allow it to seat itself properly on

the rim.

*

Too little of chain slack will overload the

engine and other vital parts; keep the

*

Wheels should be on the ground without

*

Support the machine securely so there is

*

Hub Stopper Nu

t

Page 64

3. INSPECTION/ADJUSTMENT

3-18

Turn the adjusting nut, to decrease or

increase chain slack.

Retighten the upper and lower axle holding

bolts.

Torque: 70 N-m (7 kgf-m, 50 lbf-fi)

Drive chain cleaning and lubrication

The drive chain is equipped with rubber O-

rings between the chain plates. Steam

cleaning, high-pressure washes, and certain

solvents can damage these O-rings. Use

only kerosene to clean the drive chain. Wipe

it dry, and thoroughly lubricate it with SAE

30~50 motor oil. Do not use any other

lubricants on the drive chain. They may

contain solvents that could damage the Orings.

Adjusting Nu

t

O-ring

Page 65

3. INSPECTION/ADJUSTMENT

3-19

CABLE INSPECTION AND

LUBRICATION

Inspect the cable sheath.

Replace if damage.

Check the cable operation.

Lubricate or replace if unsmooth operation.

LEVER LUBRICATION

Lubricate the pivoting parts of each lever.

SUSPENSION LUBRICATION

Inject grease into the nipples using a grease

gun until slight over flow is observed from

the thrust covers.

Front Swing

Arm Nipple

Damaged cable sheath may cause

corrosion and interfere with the cable

movement. An unsafe condition may

result so replace such cable as soon as

possible.

*

Wipe off the excess grease.

*

Hold cable end high and apply several

drops of lubricant to cable.

*

Rear Swing

Arm Nipple

Page 66

3. INSPECTION/ADJUSTMENT

3-20

HEADLIGHT BEAM

ADJUSTMENT (ON ROAD

ONLY)

Vertical adjustment:

Turn the ignition switch ON and start the

engine.

Turn on the headlight switch.

Adjust the headlight aim by turning the

headlight aim adjusting screw.

BRAKE PEDAL ADJUSTMENT

( ON ROAD ONLY)

The brake pedal free play should be

adjusted to 5~10 mm (0.2~0.4 in) at the

brake pedal pivot. If the free play is

incorrect, adjust as follows:

Adjust:

1. Keep front brake lever free play at 10~20

mm (0.4~0.8 in).

2. Loosen the locknuts. (R/L front lower

brake cables)

3. Turn the adjusting bolts until the front

lower brake cables is tensed.

4. Apply the front brake lever and check

front brake cam lever to make sure that

the brake does not drag after adjusting.

5. While remove the cable joint case cover

and applying the brake pedal, make sure

the left and right front lower cable

lengths (A and B) are equal. The cable

joint will become vertical.

6. Tighten the locknuts. (R/L front lower

brake cables)

Headligh

t

Adjusting screw

Adjusting Bolts

Locknuts Brake Cam Leve

r

R/L Front Lower Cable

Cable Joint Case Cove

r

Bolts

Cable Join

t

Page 67

3. INSPECTION/ADJUSTMENT

3-21

7. Loosen the locknut. (Brake pedal cable)

8. Turn the adjusting bolt until the specified

free play is obtained.

9. Tighten the locknut. (Brake pedal cable)

BRAKE FLUID

Check if the fluid level is below the lower

level mark through the inspection window.

Locknu

t

Adjusting Blo

t

Brake Pedal Cable

Page 68

4. LUBRICATION SYSTEM

4-0

4

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

LUBRICATION SYSTEM

__________________________________________________________________________________

SERVICE INFORMATION (90cc/70cc/50cc-4T)---------------------- 4- 3

SERVICE INFORMATION (50cc-2T)----------------------------------- 4- 4

ENGINE OIL/OIL FILTER (90cc/70cc/50cc-4T)----------------------- 4- 5

OIL PUMP (90cc) ----------------------------------------------------------- 4- 5

OIL PUMP (70cc/50cc-4T)------------------------------------------------- 4- 9

OIL PUMP BLEEDING (50cc-2T)---------------------------------------- 4-15

OIL TANK (50cc-2T)------------------------------------------------------- 4-16

OIL PUMP (50cc-2T) ------------------------------------------------------- 4-17

OIL FILTER CLEANING (50cc-2T) ------------------------------------- 4-18

4

Page 69

4. LUBRICATION SYSTEM

4-1

LUBRICATION SYSTEM (90cc/70cc/50cc-4T)

Oil Pump

Oil Filter Screen

Crankshaft

Rocker Arm Shaft

Page 70

4. LUBRICATION SYSTEM

4-2

LUBRICATION SYSTEM (50cc-2T)

Page 71

4. LUBRICATION SYSTEM

4-3

SERVICE INFORMATION (90cc/70cc/50cc-4T)

GENERAL INSTRUCTIONS

• The maintenance of lubrication system can be performed with the engine installed in the frame.

• Use care when removing and installing the oil pump not to allow dust and foreign matters to

enter the engine and oil line.

• Do not attempt to disassemble the oil pump. The oil pump must be replaced as a set when it

reaches its service limit.

• After the oil pump is installed, check each part for oil leaks.

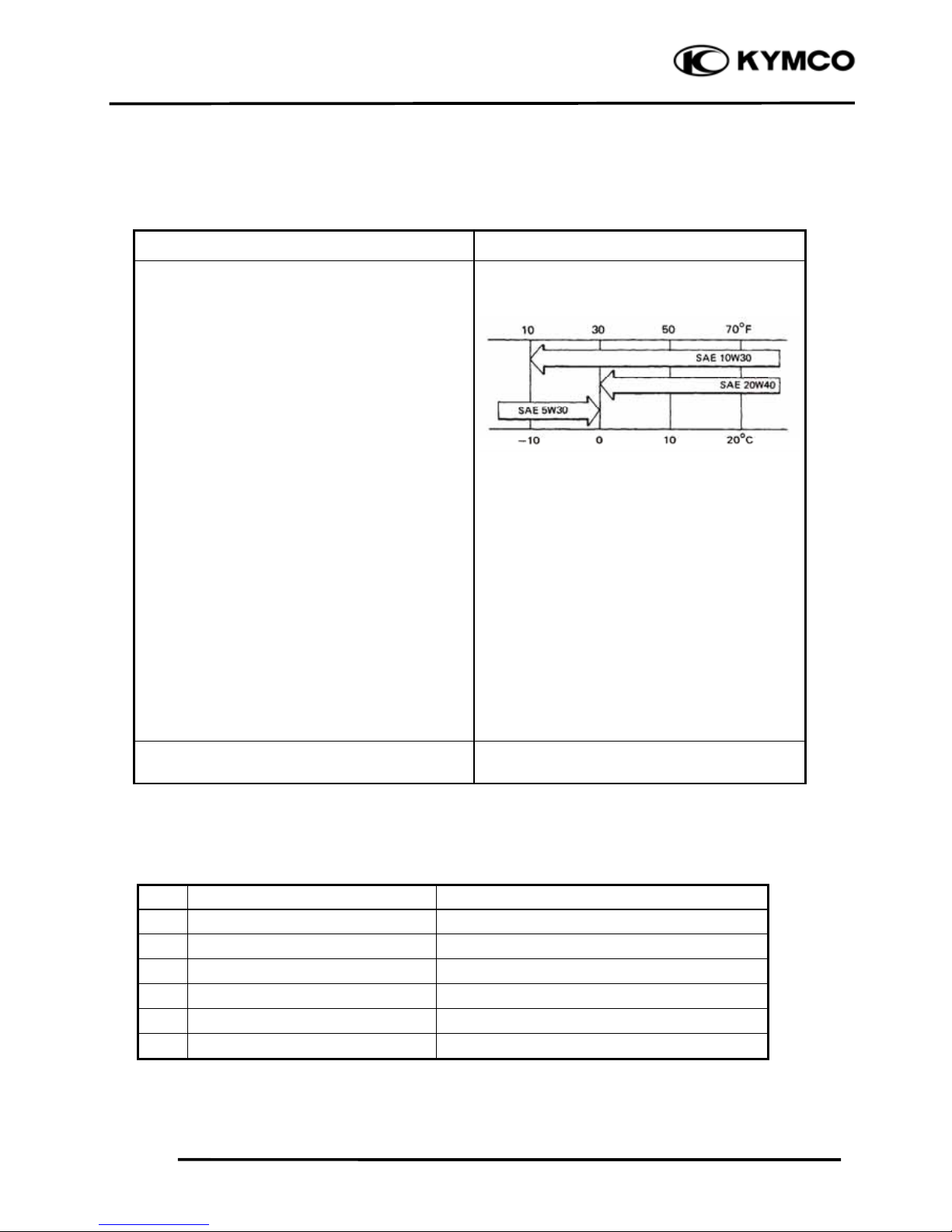

SPECIFICATIONS mm (in)

Item Standard Service Limit

Inner rotor-to-outer rotor clearance 0.15 (0.006) 0.2 (0.008)

Outer rotor-to-pump body clearance 0.15~0.2 (0.006~0.008) 0.25 (0.01)

Oil

pump

Rotor end-to-pump body clearance 0.04~0.09 (0.0016~0.0036) 0.12 (0.0048)

TROUBLESHOOTING

Oil level too low Poor lubrication pressure

• Natural oil consumption • Oil level too low

• Oil leaks • Clogged oil filter or oil passages

• Worn or poorly installed piston rings • Not use the specified oil

• Worn valve guide or seal

Page 72

4. LUBRICATION SYSTEM

4-4

SERVICE INFORMATION (50cc-2T)

GENERAL INSTRUCTIONS

• Use care when removing and installing the oil pump not to allow dust and dirt to enter the engine

and oil line.

• Do not attempt to disassemble the oil pump.

• Bleed air from the oil pump if there is air between the oil pump and oil line.

• If the oil is disconnected, refill the oil line with motor oil before connecting it.

SPECIFICATIONS

• Recommended Motor Oil: SAE20W20# 2-stroke Motor Oil

• Oil Capacity : 1 liter (0.88 lmp qt, 1.06 US qt)

Light comes on : 0.25 liter (0.22 lmp qt, 0.265 US qt)

TROUBLESHOOTING

Excessive white smoke or carbon deposits on spark plug

• Oil pump not properly synchronized (excessive oil)

• Poor quality oil

Engine overheating

• Oil pump not properly adjusted (insufficient oiling)