3. INSPECTION/ADJUSTMENT

MXU 250

3

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

3

INSPECTION/ADJUSTMENT

__________________________________________________________________________________

SERVICE INFORMATION------------------------------------------------ 3- 1

MAINTENANCE SCHEDULE-------------------------------------------- 3- 2

FUEL LINE/THROTTLE OPERATION/AIR CLEANER ------------ 3- 3

AIR FILTER FOR DRIVE BELT ----------------------------------------- 3- 5

SECONDARY AUR SUPPLY SYSTEM/SPARK PLUG ------------- 3- 6

VALVE CLEARANCE----------------------------------------------------- 3- 7

CARBURETOR IDLE SPEED/IGNITION TIMING ------------------ 3- 8

CYLINDER COMPRESSION/ ENGINE OIL--------------------------- 3- 9

TRANSMISSION OIL REPLACEMENT ------------------------------- 3-11

DRIVE BELT/BRAKE PADS INSPECTION--------------------------- 3-12

BRAKE FLUID INSPECTION/ HEADLIGHT AIM------------------- 3-13

STEERING SYSTEM INSPECTION------------------------------------- 3-14

TOE-IN ADJUSTMENT --------------------------------------------------- 3-15

WHEELS/TIRES ------------------------------------------------------------ 3-16

DRIVE CHAIN SLACK ADJUSTMENT-------------------------------- 3-18

DRIVE SELECT LEVER ADJUSTMENT ------------------------------ 3-20

CABLE INSPECTION AND LUBRICATION-------------------------- 3-21

REAR SUSPENSION LUBRICATION---------------------------------- 3-21

COOLING SYSTEM-------------------------------------------------------- 3-22

SPARK ARRESTER CLEANING (OFF ROAD)----------------------- 3-23

3-0

3. INSPECTION/ADJUSTMENT

MXU 250

SERVICE INFORMATION

GENERAL

! WARNING

•Before running the engine, make sure that the working area is well-ventilated. Never run the

engine in a closed area. The exhaust contains poisonous carbon monoxide gas which may

cause death to people.

•Gasoline is extremely flammable and is explosive under some conditions. The working area

must be well-ventilated and do not smoke or allow flames or sparks near the working area or

fuel storage area.

SPECIFICATIONS

ENGINE

Throttle grip free play : 1~4 mm (0.04~0.16 in)

Spark plug gap : 0.6~0.7 mm (0.002~0.003 in)

Spark plug: Standard : DPR7EA-9

Valve clearance : IN: 0.1 mm (0.004 in)

EX: 0.1 mm (0.004 in)

Idle speed : 1500±100 rpm

Engine oil capacity:

At disassembly : 1.6 liter (1.4 lmp qt, 1.7 Us qt)

At change : 1.4 liter (1.23 lmp qt, 1.48 Us qt)

Gear oil capacity :

At disassembly : 400 cc (0.35 lmp qt, 0.42 Us qt)

At change : 300 cc (0.26 lmp qt, 0.32 Us qt)

Cylinder compression : 15±2 kg/cm²

Ignition timing : BTDC 5°±1°/2000 rpm

TIRE PRESSURE

Front 0.28 kgf/cm² (28 Kpa, 3.2 psi)

Rear 0.28 kgf/cm² (28 Kpa, 3.2 psi)

TIRE SIZE:

Front : 22*7-10

Rear : 22*10-10

TORQUE VALUES

Front wheel nut 4.5 kgf-m (45 Nm, 32 lbf-ft)

Rear wheel nut 4.5 kgf-m (45Nm, 32 lbf-ft)

3-1

1 Rider

3. INSPECTION/ADJUSTMENT

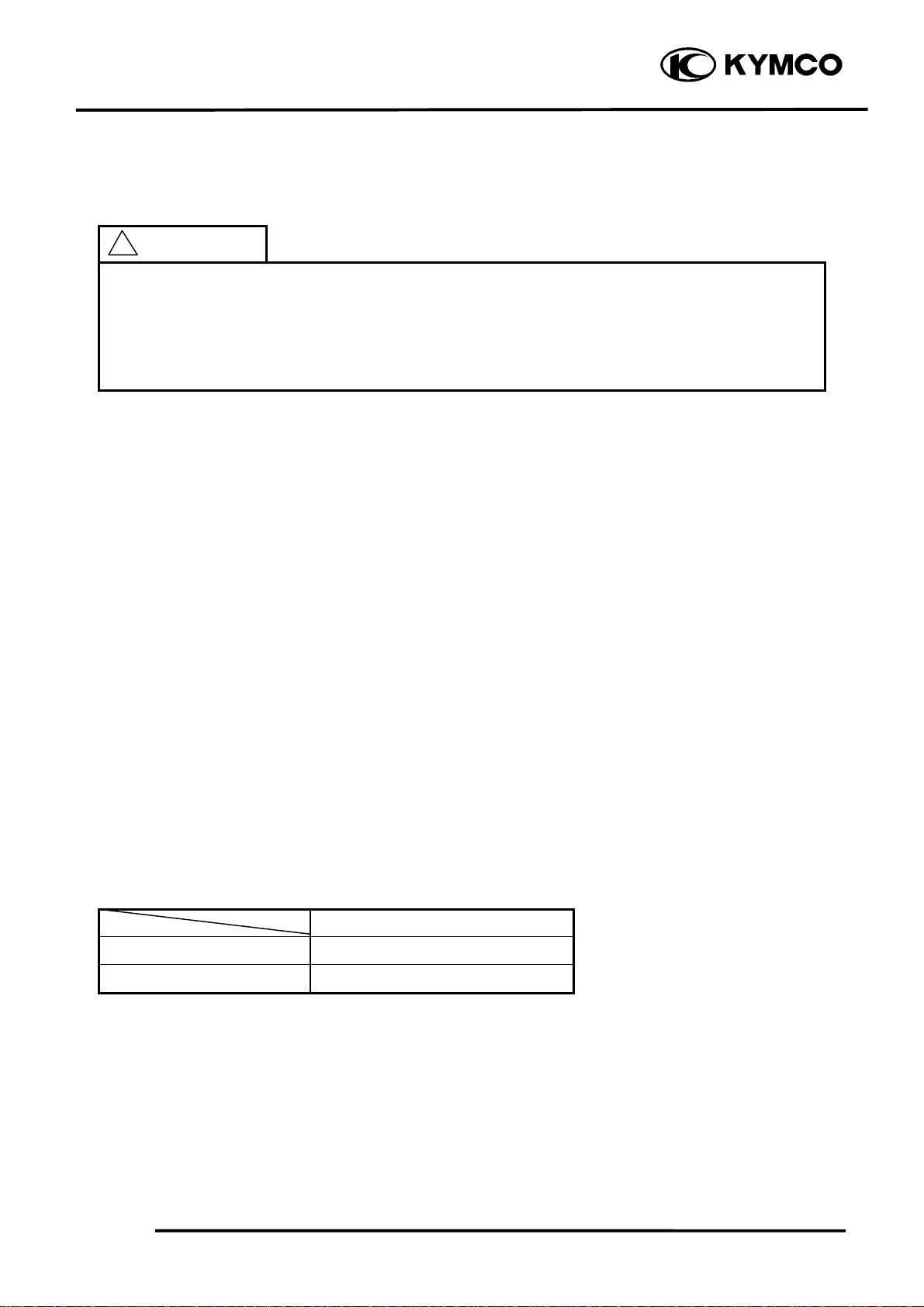

MAINTENANCE SCHEDULE

This chapter includes all information necessary to perform recommended inspections and

adjustments. These preventive maintenance procedures, if followed, will ensure more reliable

vehicle operation and a longer service life. The need for costly overhaul work will be greatly

reduced. This information applies to vehicles already in service ad well as new vehicles that are

being prepared for sale. All service technicians should be familiar with this entire chapter.

MXU 250

•In the interest of safety, we recommend these items should be serviced only by an authorized

KYMCO motorcycle dealer.

3-2

3. INSPECTION/ADJUSTMENT

r

t

r

FUEL LINE

Check the fuel tubes and replace any parts,

which show signs of deterioration, damage

or leakage.

*

Do not smoke or allow flames or sparks

in your working area.

MXU 250

Fuel Filte

Fuel tubes

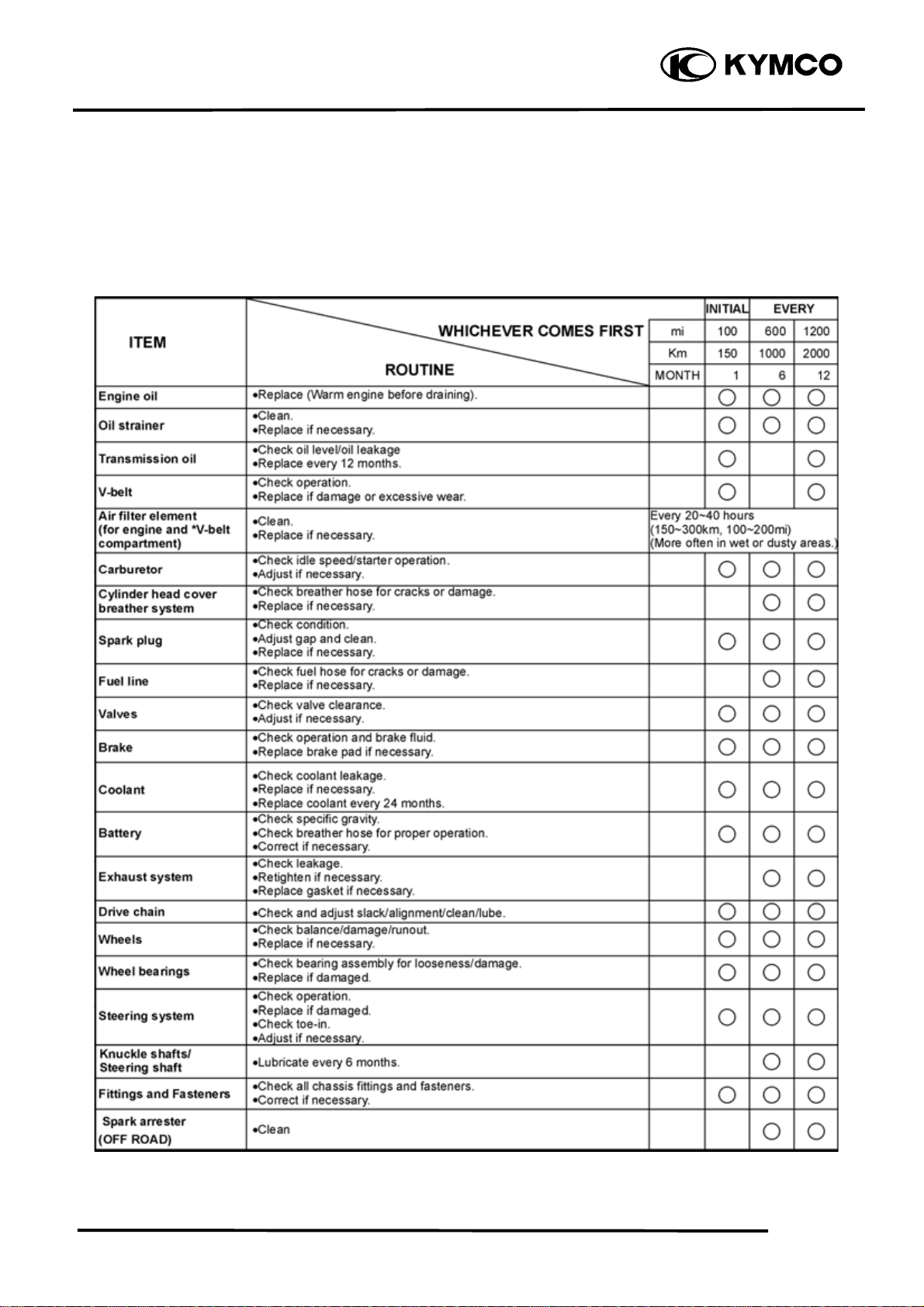

THROTTLE OPERATION

Check the throttle to swing for smooth

movement.

Measure the throttle to swing free play.

Free Play (A): 1~4 mm (0.04~0.16 in)

To adjust throttle free play:

Slide the rubber sleeve back to expose the

throttle cable adjuster.

Loosen the lock nut, then turn the adjuster

to obtain the correct free play. (1~4 mm or

0.04~0.16 in)

Tighten the lock nut and reinstall the sleeve.

AIR CLEANER

AIR CLEANER REPLACEMENT

Remove the seat. (See page 2-3)

Unlatch the four retainer clips (1) and

remove the air cleaner housing cover (2).

Lock nu

Rubber sleeve

Cable adjuste

3-3

3. INSPECTION/ADJUSTMENT

r

r

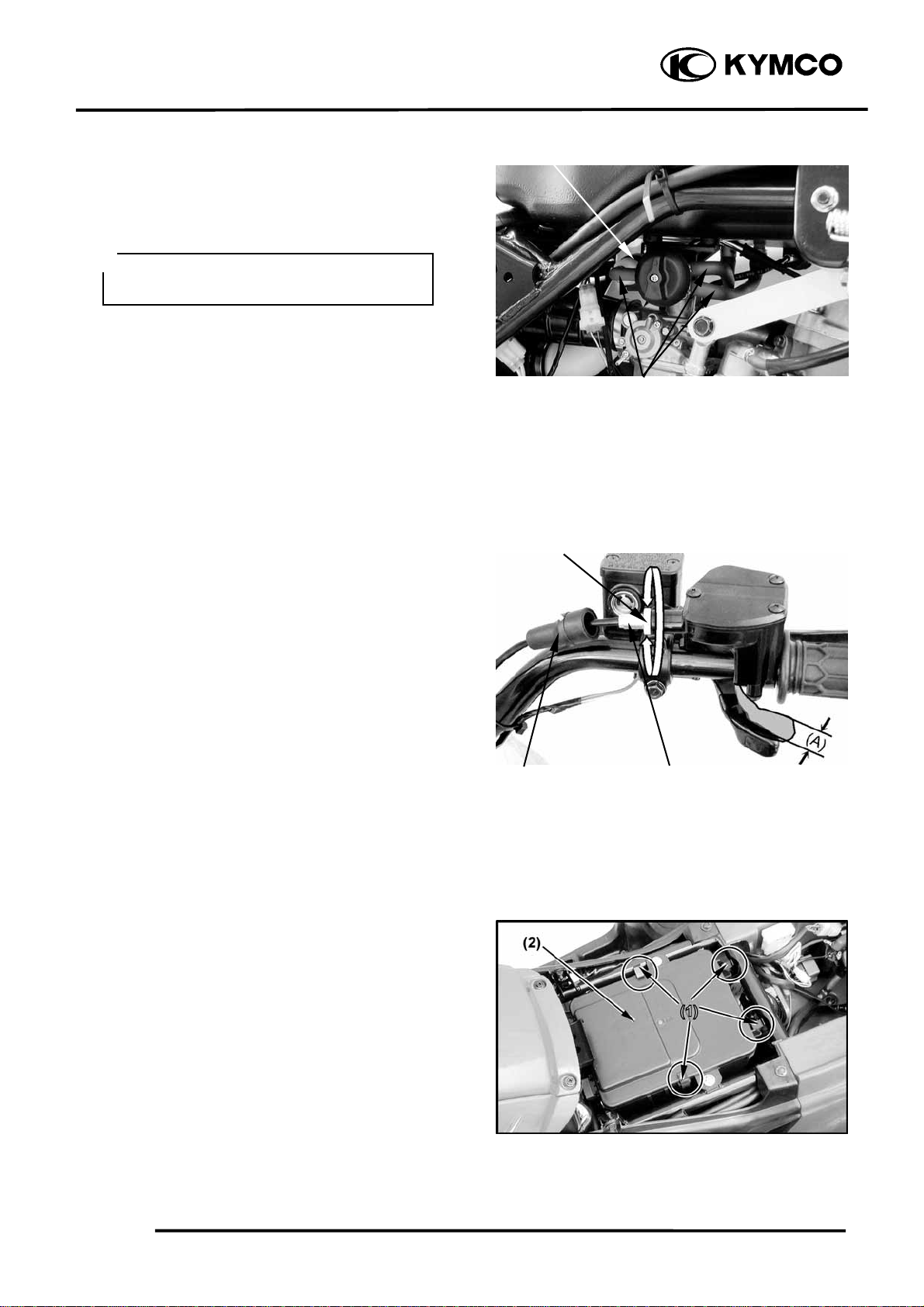

Unscrew (3) the clamp (5) and remove the

air cleaner assembly (4) from the air cleaner

housing.

MXU 250

Remove the screw and remove the air

cleaner assembly from the air cleaner

holder.

Remove the air cleaner and air cleaner

screen from the air cleaner body.

Remove the air cleaner net from the air

cleaner.

Screw Air Cleaner Holde

Air Cleane

Reassemble by reversing the disassembly

sequence.

Air Cleaner screen

Air Cleaner body

3-4

3. INSPECTION/ADJUSTMENT

r

m

r

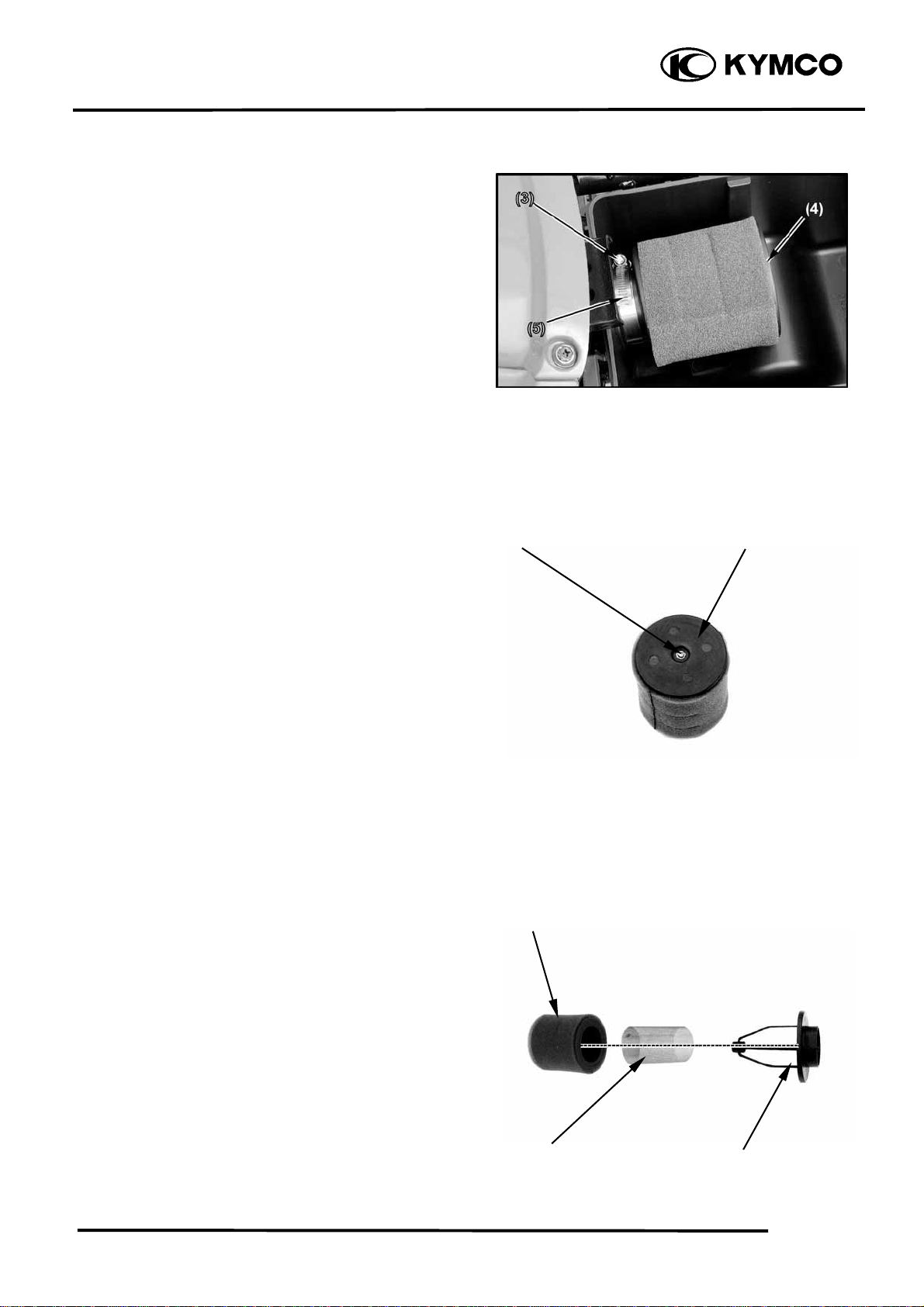

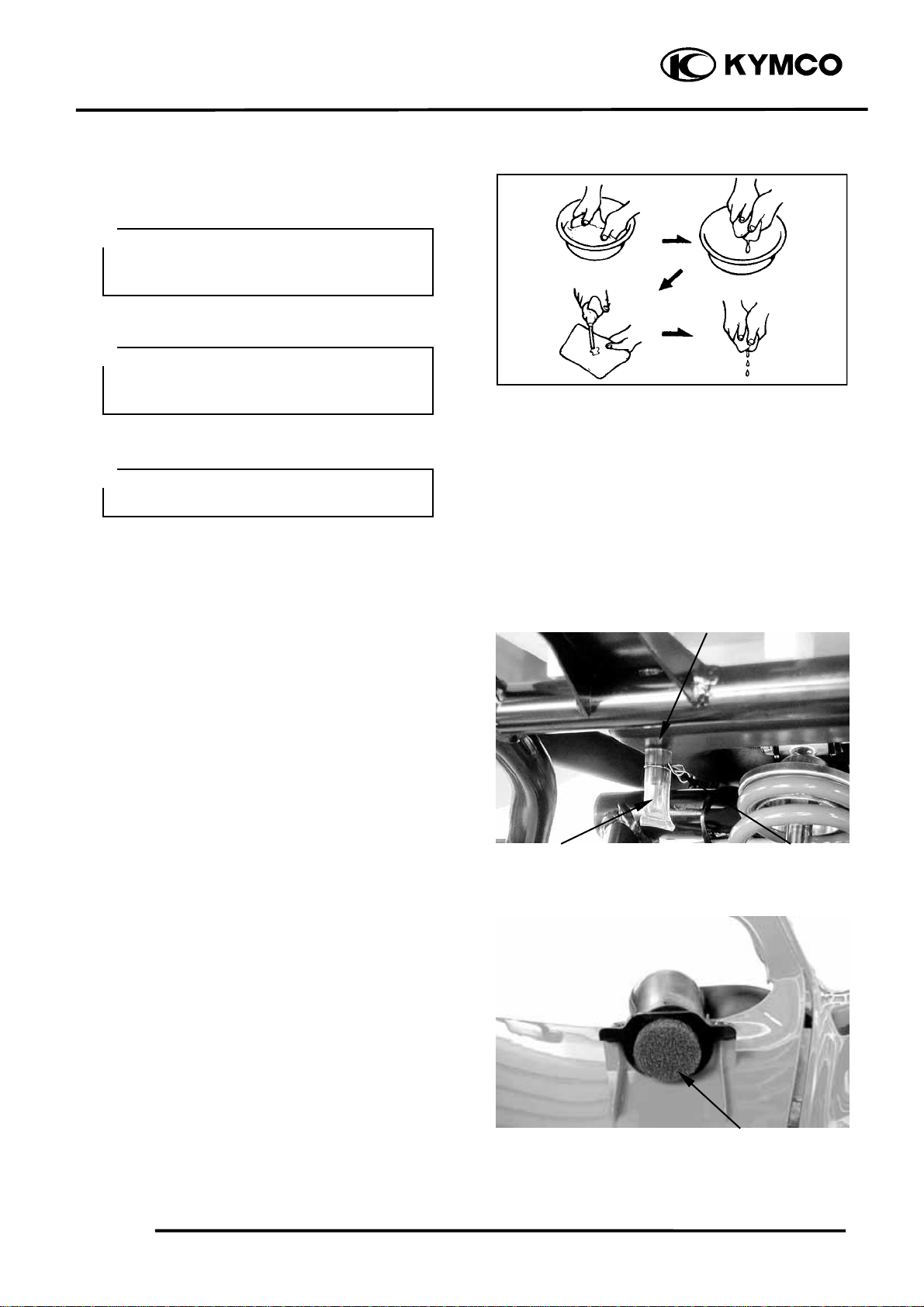

CLEAN AIR FILTER ELEMENT

Wash the element gently, but throughly in

solvent.

*

Use parts cleaning solvent only. Neve

use gasoline or low flash point solvents

which may lead to a fire or explosion.

Squeeze the excess solvent out of the

element and let dry.

*

Do not twist or wring out the foa

element. This could damage the foam

material.

Apply the engine oil.

Squeeze out the excess oil.

*

The element should be wet but not

dripping.

More frequent replacement is required when

riding in unusually dusty or rainy areas.

MXU 250

AIR CLEANER HOUSING DRAIN

Remove the drain tube (under air cleaner

case) by removing the clip.

Drain the deposits.

Reinstall the drain tube, securing it with the

clip.

AIR FILTER FOR DRIVE BELT

To clean the air filter:

Remove front center cover. (See page 2-7)

Remove air filter.

Tap the element lightly to remove most of

the dust and dirt.

Blow out the remaining dirt with

compressed air.

Drain Tube

Air Cleaner Housing

Clip

Installation is in the reverse order of

removal.

If necessary replace the air filter.

3-5

Air Filte

3. INSPECTION/ADJUSTMENT

MXU 250

SECONDARY AIR SUPPLY

SYSTEM

This model is equipped with a built-in

secondary air supply system. The pulse

secondary air supply system is located on

the cylinder head cover.

The secondary air supply system introduces

filtered air into exhaust gases in the exhaust

port. The secondary air is drawn into the

exhaust port whenever there is negative

pressure pulse in the exhaust system. This

charged secondary air promotes burning of

the unburned exhaust gases and changes a

considerable amount of hydrocarbons and

carbon monoxide into relatively harmless

carbon dioxide and water.

Check the PAIR (pulse secondary air

injection) hoses between the PAIR control

solenoid valve and cylinder head cover for

deterioration, damage or loose connections.

Make sure the hoses are not cracked.

If the hoses show any signs of heat damage,

inspect the PAIR check valve in the PAIR

reed valve cover damage.

Vacuum Hose

PAIR Control solenoid Valve

Air Supply HosePAIR Check Valve

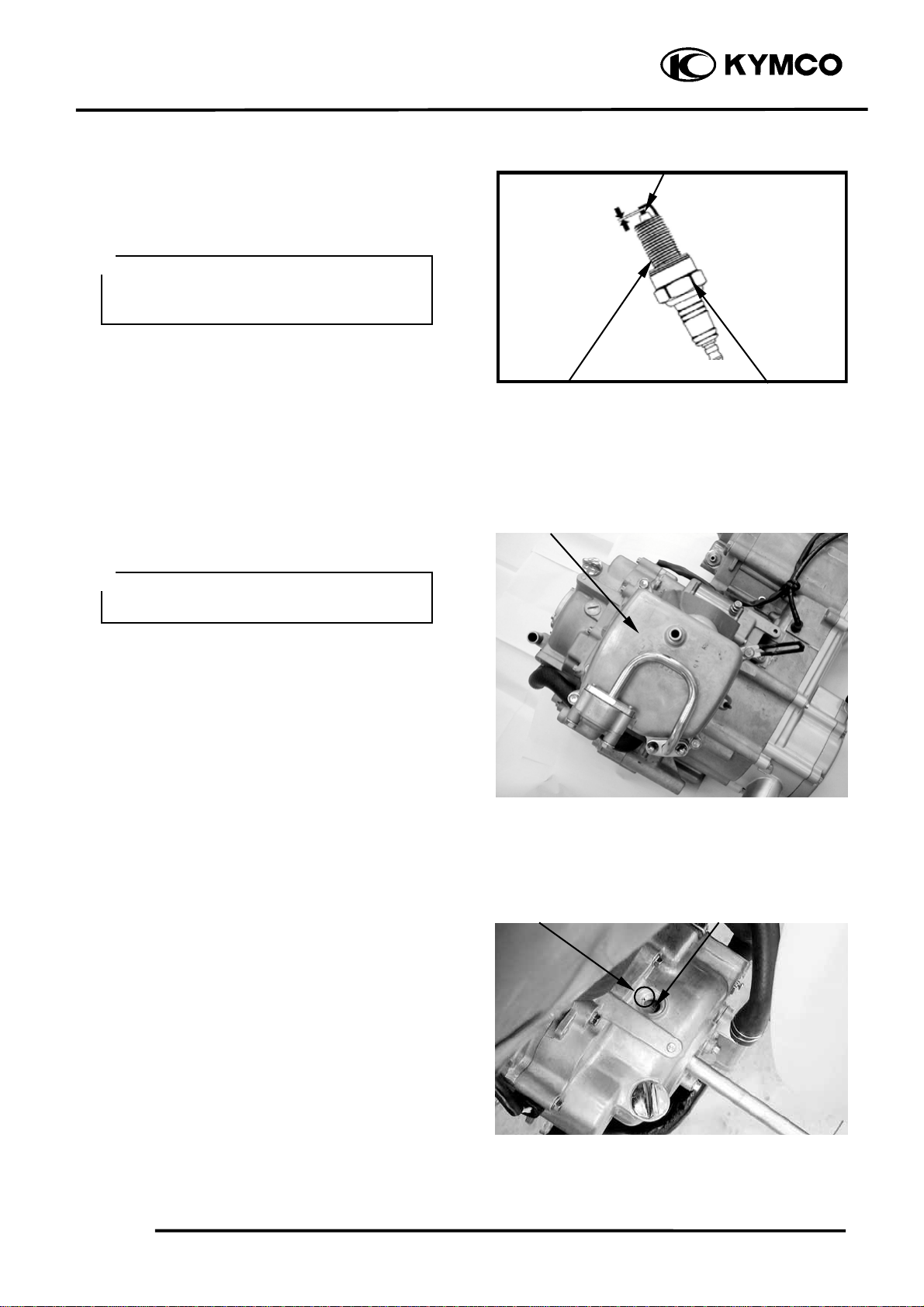

SPARK PLUG

Remove ignition coil cap and spark plug.

Check the spark plug for wear and fouling

deposits.

Clean any fouling deposits with a spark

plug cleaner or a wire brush.

Specified Spark Plug: DPR7EA-9

Ignition Coil Cap

Spark Plug

3-6

3. INSPECTION/ADJUSTMENT

k

r

MXU 250

Measure the spark plug gap.

Spark Plug Gap: 0.6~0.7 mm (0.002~

0.003 in)

*

When installing, first screw in the spar

plug by hand and then tighten it with a

spark plug wrench.

VALVE CLEARANCE

*

Inspect and adjust valve clearance while

the engine is cold (below 35℃).

Gap, Wear, and Fouling Deposits

Washer Deformation

Cylinder Head Cove

Cracks, Damage

Remove the cylinder head cover. (See

chapter 7)

Turn the flywheel clockwise so that the “T”

mark on the flywheel aligns with the index

mark on the right crankcase cover to bring

the round hole on the camshaft gear facing

up to the top dead center on the

compression stroke.

Inspect and adjust the valve clearance.

Valve Clearance: IN: 0.1 mm (0.004 in)

EX: 0.1 mm (0.004 in)

“T” MarkIndex Mark

3-7

3. INSPECTION/ADJUSTMENT

r

MXU 250

Loosen the lock nut and adjust by turning

the adjusting nut

Special

Tappet adjuster E012

*

• Check the valve clearance again afte

the lock nut is tightened.

CARBURETOR IDLE SPEED

*

• The engine must be warm for accurate

idle speed inspection and adjustment.

Valve Wrench

Round Hole

Warm up the engine before this operation.

Start the engine and connect a tachometer.

Turn the throttle stop screw to obtain the

specified idle speed.

Idle Speed: 1500±100 rpm

When the engine misses or run erratic,

adjust the air screw.

IGNITION TIMING

*

The ignition unit is not adjustable. If the

ignition timing is incorrect, check the

ignition system.

Remove the timing hole cap.

Check the ignition timing with a timing

light.

When the engine is running at idle speed,

the ignition timing is correct if the “F” mark

on the flywheel aligns with the index mark

on the right crankcase cover.

AirScrew

Timing Hole Cap

Throttle Stop Screw

Index Mark

Timing Hole

3-8

3. INSPECTION/ADJUSTMENT

CYLINDER COMPRESSION

Warm up the engine before compression

test.

Remove the spark plug.

Insert a compression gauge.

Open the throttle valve fully and push the

starter button to test the compression.

Compression: 15±2 kg/cm

If the compression is low, check for the

following:

- Leaky valves

- Valve clearance too small

- Leaking cylinder head gasket

- Worn piston rings

- Worn piston/cylinder

If the compression is high, it indicates that

carbon deposits have accumulated on the

combustion chamber and the piston head.

2

MXU 250

Compression Gauge

ENGINE OIL

OIL LEVEL

Place the machine on a level place.

Warm up the engine for several minutes and

stop it.

*

Run the engine for 2~3 minutes and

check the oil level after the engine is

stopped for 2~3 minutes.

Check the oil level through the inspection

window.

The oil level should be between the

maximum (H) and minimum (L) marks. If

the level is low, add oil to raise it to the

proper level.

Inspection Window

Upper Level

Lower Level

3-9

3. INSPECTION/ADJUSTMENT

g

p

ENGINE OIL REPLACEMENT

Place the machine on a level place.

Warm up the engine for several minutes and

stop it.

Place a container under the engine.

Remove the oil fill cap and drain plug to

drain the oil.

Reinstall the drain plug and tighten the

drain plug to specification.

Torque: 2.5 kgf-m (25 Nm, 15 lbf-ft)

MXU 250

Oil Fill Cap

Fill the engine with oil and install the oil fill

cap.

*

The engine oil will drain more easily

while the engine is warm.

Oil Capacity:

At disassembly: 1.6 liter (1.4 lmp qt,

1.7 Us qt)

At change: 1.4 liter (1.23 lmp qt, 1.48 Us

qt)

ENGINE OIL REPLACEMENT AND

OIL FILTER CLEANING

Place the machine on a level place.

Warm up the engine for several minutes and

stop it.

Place a container under the engine.

Remove the oil fill cap and oil filter cap to

drain the oil.

Drain Plu

Oil Filter Ca

3-10

3. INSPECTION/ADJUSTMENT

r

p

t

MXU 250

Clean the oil strainer with solvent.

Inspect the O-ring and replace if damaged.

Reinstall the O-ring, oil strainer,

compression spring and oil filter cap.

Tighten the oil filter cap to specification.

Torque: 1.5 kgf-m (15 Nm, 11 lbf-ft)

Fill the engine with oil and install the oil fill

cap.

Oil Capacity:

At disassembly: 1.6 liter (1.4 lmp qt,

1.7 Us qt)

At change: 1.4 liter (1.23 lmp qt, 1.48 Us

qt)

TRANSMISSION OIL

REPLACEMENT

Place the machine on a level place.

Place a container under the engine.

Remove the oil filler bolt and drain plug to

drain the oil.

Reinstall the drain plug and tighten to

specification.

Torque: 2.5 kgf-m (25 Nm, 18 lbf-ft)

Compression Spring

Oil Straine

Oil Filler Bol

O-ring

Oil Filter Ca

Fill the engine with oil and install the oil

filler bolt.

Oil Capacity:

At disassembly : 400 cc (0.35 lmp qt,

0.42 Us qt)

At change : 300 cc (0.26 lmp qt,

0.32 Us qt)

Start the engine and warm up for a few

minutes. While warming up, check for oil

leakage. If oil leakage is found, stop the

engine immediately and check for the cause.

*

Make sure that the sealing washer is in

good condition.

3-11

Drain Plug

3. INSPECTION/ADJUSTMENT

t

r

r

DRIVE BELT

Remove the left crankcase cover.

Inspect the drive belt for cracks, scaling,

chipping or excessive wear.

Measure the V-belt width

Service limit: 22 mm (0.88in)

Replace the drive belt if out of specification.

BRAKE PADS INSPECTION

A wear indicator is provided on each brake.

The indicators allows checking of brake

pads wear. Check the position of the

indicator. If the indicator reaches the wear

limit line, to replace the pads.

MXU 250

Drive Bel

Front Calipe

Rear Calipe

3-12

3. INSPECTION/ADJUSTMENT

MXU 250

BRAKE FLUID INSPECTION

Check if the fluid level is below the lower

level mark through the inspection window.

Inspection Window (R/L Brake Lever)

Inspection Window (Rear Brake Pedal)

HEADLIGHT AIM

Turn the ignition switch ON and start the

engine.

Turn on the headlight switch.

Adjust the headlight aim by turning the

headlight aim adjusting screw.

3-13

Adjust Screw

3. INSPECTION/ADJUSTMENT

STEERING SYSTEM

INSPECTION

Place the machine on a level place.

Check the steering column bushings and

bearings:

Move the handlebar up and down, and/or

back and forth.

Replace the steering column bushings and

or bearings if excessive play

MXU 250

Check the tie-rod ends

Turn the handlebar to the left and/or right

until it stops completely, then slightly move

the handlebar from left to right.

Replace the tie-rod ends if tie-rod end has

any vertical play.

Raise the front end of the machine so that

there is no weight on the front wheels.

Check ball joints and/or wheel bearings.

Move the wheels lately back and froth.

Replace the front arms and/or wheel

bearings if excessive free play.

Tie-rod Ends

3-14

3. INSPECTION/ADJUSTMENT

MXU 250

TOE-IN ADJUSTMENT

Place the machine on a level place.

Measure the toe-in

Adjust if out of specification.

Toe-in measurement steps:

Mark both front tire tread centers.

Raise the front end of the machine so that

there is no weight on the front tires.

Fix the handlebar straight ahead.

Measure the width A between the marks.

Rotate the front tires 180 degrees until the

marks come exactly opposite.

Measure the width B between the marks.

Calculate the toe-in using the formula given

below.

Toe-in = B-A

Toe-in: 0~15 mm (0~0.6 in)

If the toe-in is incorrect, adjust the toe-in

A

B

Adjust the toe-in step:

Mark both tie-rods ends.

This reference point will be needed during

adjustment.

Loosen the lock nuts (tie-rod end) of both

tie-rods

The same number of turns should be given

to both tie-rods right and left until the

specified toe-in is obtained, so that the

lengths of the rods will be kept the same.

Tighten the rod end locknuts of both tierods

Torque: 3 kgf-m (30 Nm, 22 lbf-ft)

3-15

Tie-rod

Tie-rod End Nuts

3. INSPECTION/ADJUSTMENT

t

MXU 250

*

• Be sure that both tie-rod are turned the

same amount. If not, the machine will

drift tight or left even though the

handlebar is positioned straight which

may lead to mishandling and accident.

• After setting the toe-in to specification,

run the machine slowly for some

distance with hands placed lightly on

the handlebar and check that the

handlebar responds correctly. If not,

turn either the right or left tie-rod

within the toe-in specification.

WHEELS/TIRES

Check the tires for cuts, imbedded nails or

other damages.

Check the tire pressure.

*

Tire pressure should be checked when

tires are cold.

Tie-rod End Nuts

Tie-rod

TIRE PRESSURE

1 Rider

Front 0.28 kgf/cm² (28 Kpa, 3.2 psi)

Rear 0.28 kgf/cm² (28 Kpa, 3.2 psi)

TIRE SIZE

Front: 22*7-10

Rear : 22*10-10

Check the front axle nut for looseness.

Front Axle Nu

3-16

3. INSPECTION/ADJUSTMENT

t

MXU 250

Check the rear axle nut for looseness.

If the axle nuts are loose, tighten them to the

specified torque.

Torque:

Front : 7 kgf-m (70 Nm, 50 lbf-ft)

Rear : 10 kgf-m (100 Nm, 72 lbf-ft)

RearAxle Nu

Inspect the tire surfaces.

Replace if wear or damage.

Tire wear limit: 3 mm (0.12 in)

*

It is dangerous to ride with a worn out

tire. When a tire wear is out of

specification, replace the tire

immediately.

WHEEL INSPECTION

Inspect the wheel.

Replace if damage or bends

Always balance the wheel when a tire or

wheel has been changed or replaced.

*

• Never attempt even small repairs to the

wheel.

• Ride conservatively after installing a

tire to allow it to seat itself properly on

the rim.

3-17

3. INSPECTION/ADJUSTMENT

t

t

DRIVE CHAIN SLACK

ADJUSTMENT

Before checking and/or adjusting, rotate the

rear wheels several revolutions and check

slack at several points to find the tightest

point. Check and/or adjust the chain slack

with the rear wheels in this “tightest”

position.

*

Too little of chain slack will overload the

engine and other vital parts; keep the

Place the machine on a level place.

*

Wheels should be on the ground without

Check drive chain slack.

Adjust if out of specification.

Drive chain slack (A):

30 ~ 40 mm (1.2 ~ 1.6 in)

MXU 250

Adjust drive chain slack:

Loosen the caliper holder bolt and two axle

hub holding bolt.

Provide a proper pin and pass the pin

through the axle hub and driven sprocket.

Bol

Bolts

Driven Sprocke

Pin

Axle Hub

3-18

3. INSPECTION/ADJUSTMENT

t

To tighten the chain, push the ATV

forward.

To loosen the chain, pull the ATV

backward.

MXU 250

Retighten the two axle hub holder bolt and

caliper holder bolt to the specification.

Torque:

Axle hub holding bolt:

4 kgf-m (40 Nm, 29 lbf-ft)

Caliper holder bolt:

1 kgf-m (10 Nm, 7.2 lbf-ft)

Pull out the pin.

Bolts

Bol

Pin

3-19

3. INSPECTION/ADJUSTMENT

r

m

r

MXU 250

DRIVE SELECT LEVER

ADJUSTMENT

Turn the ignition switch is ON and make

sure the engine stop switch in the OFF

position.

Loosen the lock nuts of rod.

Shift the gear to neutral by moving the shift

lever and/or turn the rod. (The neutral

indicator lamp comes on.)

Provide standard/phillips screwdriver and

pass the standard/phillips screwdriver

through the shift arm into the index hole at

the transmission case cover.

Turn the rod clockwise or counterclockwise

until the drive select lever into the "N"

position of the shift guide and tighten the

lock nuts, then pull out the standard/phillips

screwdriver.

After adjustment, start the engine and test to

ride the ATV to be sure the drive select

lever is operating properly.

Rod

Standard/Phillips Screwdrive

Lock Nuts

Shift Ar

Drive Leve

Index Hole

Rod

3-20

3. INSPECTION/ADJUSTMENT

N

CABLE INSPECTION AND

LUBRICATION

*

Damaged cable sheath may cause

corrosion and interfere with the cable

movement. An unsafe condition may

result so replace such cable as soon as

possible.

Inspect the cable sheath.

Replace if damage.

Check the cable operation.

Lubricate or replace if unsmooth operation.

*

Hold cable end high and apply several

drops of lubricant to cable.

MXU 250

LEVER LUBRICATION

Lubricate the pivoting parts of each lever.

REAR SUSPENSION

LUBRICATION

Inject grease into the nipples using a grease

gun until slight over flow is observed from

the thrust covers.

*

Wipe off the excess grease.

ipple

3-21

3. INSPECTION/ADJUSTMENT

t

MXU 250

COOLING SYSTEM

COOLANT LEVEL INSPECTION

Place the machine on the level ground.

Check the coolant level in the coolant

reservoir when the engine is cold as the

coolant level will vary with engine

temperature. The coolant level should be

between the maximum and minimum marks.

If the level is low, remove the coolant

reservoir cap, and then add coolant or

distilled water to raise it to the specified

level.

Recommended Coolant: SIGMA Coolant

(Standard Concentration 30%)

*

The coolant level does not change no

matter the engine is warm or cold. Fill to

the maximum mark.

COOLANT REPLACEMENT

*

Perform this operation when the engine

is cold.

Maximum Mark

Coolant Reservoir Cap

Minimum Mark

Remove the front fender. (Ö2-8)

Remove the radiator cap.

Remove the drain bolt to drain the coolant.

Drain the coolant in the reserve tank.

Reinstall the drain bolt.

*

The coolant freezing point should be 5

°C lower than the temperature of the

riding area.

Coolant capacity:

1400 cc (1232 lmp qt, 1484 Us qt)

Radiator capacity:

1100 cc (968 lmp qt, 1166 Us qt)

Reserve tank capacity:

300 cc (264 lmp qt, 318 Us qt)

Start the engine and check if there are no

bubbles in the coolant and the coolant level

is stable. Reinstall the radiator cap.

If there are bubbles in the coolant, bleed air

from the system.

Fill the reserve tank with the recommended

coolant up to the maximum mark.

Drain Bol

3-22

3. INSPECTION/ADJUSTMENT

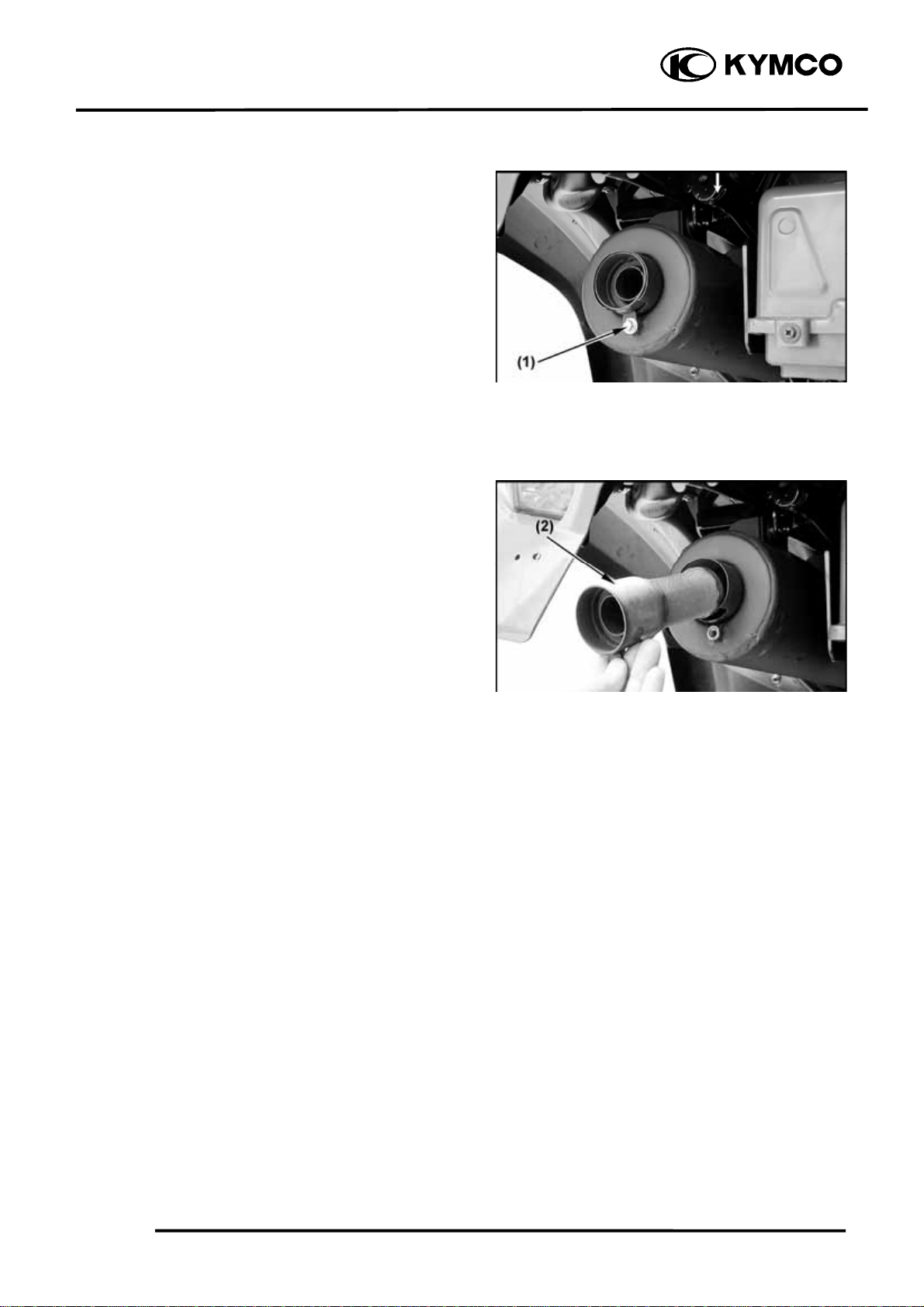

SPARK ARRESTER CLEANING

(OFF ROAD)

Be sure the exhaust pipe and muffler are

cool before cleaning the spark arrester.

1. Remove the bolt (1).

2. Remove the tailpipe (2) by pulling it out

of the muffler.

3. Tap the tailpipe lightly, then use a wire

brush to remove any carbon deposits

from the spark arrester portion of the

tailpipe.

4. Insert the tailpipe into the muffler and

align the screw holes.

5. Install the bolt and tighten it.

MXU 250

3-23

Loading...

Loading...