Kymco MO MXU250 Service Manual - chap05 (imp alimentazione)

5. FUEL SYSTEM

MXU 250

5

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

5

FUEL SYSTEM

__________________________________________________________________________________

SERVICE INFORMATION------------------------------------------------ 5- 2

TROUBLESHOOTING----------------------------------------------------- 5- 3

FUEL TANK ----------------------------------------------------------------- 5- 4

FUEL VALVE --------------------------------------------------------------- 5- 4

THROTTLE VALVE---------------------------------------------------------- 5- 7

CARBURETOR-------------------------------------------------------------- 5- 9

AIR CLEANER HOUSING------------------------------------------------ 5-15

PAIR SOLENOID VALVE ------------------------------------------------ 5-16

5-0

5. FUEL SYSTEM

MXU 250

5-1

5. FUEL SYSTEM

MXU 250

SERVICE INFORMATION

GENERAL INSTRUCTIONS

Gasoline is very dangerous. When working with gasoline, keep sparks and flames away

from the working area.

Gasoline is extremely flammable and is explosive under certain conditions. Be sure to

work in a well-ventilated area.

• Do not bend or twist control cables. Damaged control cables will not operate smoothly.

• When disassembling fuel system parts, note the locations of O-rings. Replace them with new

ones during reassembly.

• Before float chamber disassembly, loosen the drain screw to drain the residual gasoline into a

clean container.

• After the carburetor is removed, plug the intake manifold side with a clean shop towel to prevent

foreign matters from entering.

• When cleaning the carburetor air and fuel jets, the O-rings and diaphragm must be removed first

to avoid damage. Then, clean with compressed air.

• When the motorcycle is not used for over one month, drain the residual gasoline from the float

chamber to avoid erratic idling and clogged slow jet due to deteriorated fuel.

SPECIFICATIONS

Item Standard

Type PTG

Venturi dia. φ22

Float level 14.8mm

Main jet No. 98

Adjust method Piston

Idle speed 1500±100rpm

Throttle grip free play 1~4mm

Air screw opening 11/8±1/2

5-2

5. FUEL SYSTEM

SPECIAL TOOL

Float level gauge

MXU 250

TROUBLESHOOTING

Engine cranks but won’t start Engine lacks power

• No fuel in tank • Clogged air cleaner

• No fuel to carburetor • Faulty carburetor

• Cylinder flooded with fuel • Faulty ignition system

• No spark at plug

• Clogged air cleaner Lean mixture

• Intake air leak • Clogged carburetor fuel jets

• Improper throttle operation • Float level too low

• Intake air leak

Engine idles roughly, stalls or runs poorly • Clogged fuel tank cap breather hole

• Excessively used choke • Kinked or restricted fuel line

• Ignition malfunction

• Faulty carburetor Rich mixture

• Poor quality fuel • Float level too high

• Lean or rich mixture • Clogged air jets

• Incorrect idle speed • Clogged air cleaner

Misfiring during acceleration

• Faulty ignition system

• Faulty carburetor

Backfiring at deceleration

• Float level too low

• Incorrectly adjusted carburetor

• Faulty exhaust muffler

5-3

5. FUEL SYSTEM

g

N

MXU 250

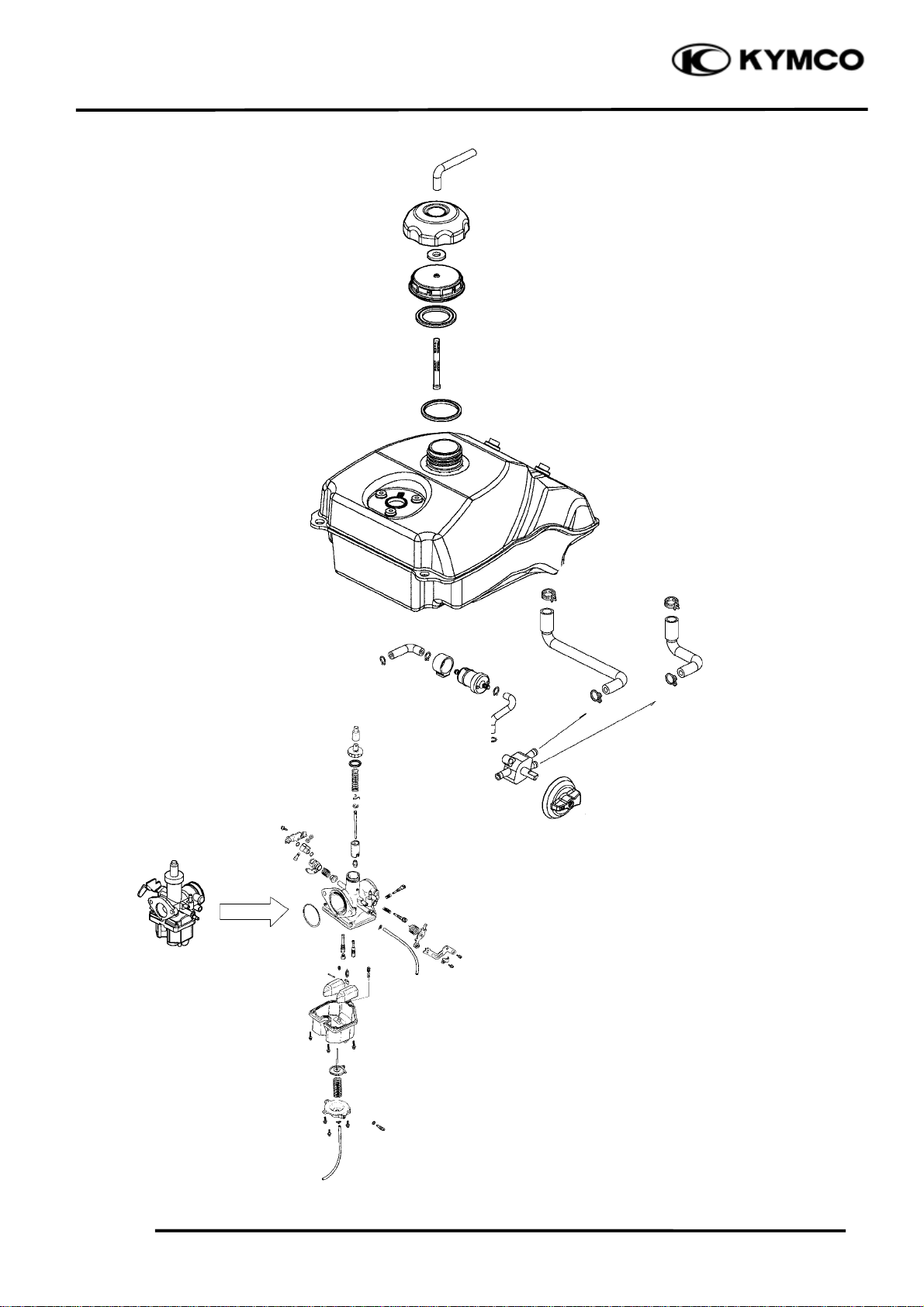

FUEL TANK

REMOVAL

Warnin

• Keep sparks and flames away from the

work area.

• Wipe off any spilled gasoline.

Remove the seat (See page 2-3), right and

left side frame cover (See page 2-6) and fuel

tank cover (See page 2-5).

Switch the fuel valve “OFF”.

Disconnect the fuel tube from carburetor.

Disconnect the fuel unit connectors.

Remove the two bolts and two nuts from the

fuel tank, then remove the fuel tank.

Fuel Valve

Fuel Tube

Bolts

INSTALLATION

Reverse the “FUEL TANK REMOVAL”

procedures.

FUEL VALVE

REMOVAL

*

• Keep sparks and flames away from the

work area.

• Drain gasoline into a clean container.

Remove the screw and then remove control

switch.

Disconnect all fuel tubes and remove the two

screws, then remove fuel valve.

Screw

uts

Control Switch

Fuel Unit Connectors

Fuel Valve

Fuel Tube

Screws

Fuel Tubes

5-4

5. FUEL SYSTEM

t

t

r

t

MXU 250

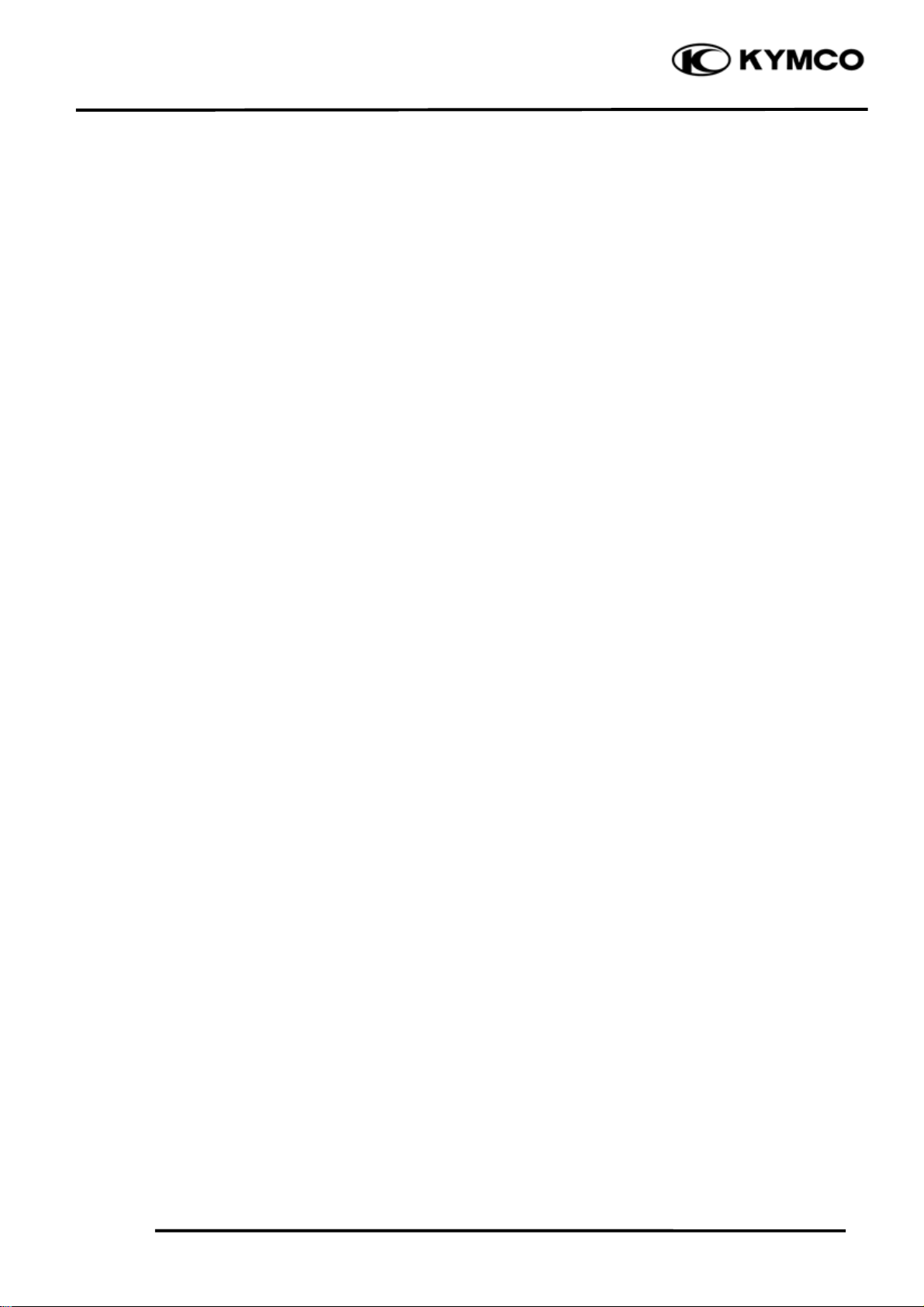

DISASSEMBLY

Remove the two screws on the retaining ring

and then remove retaining ring.

Remove the washer and control shaft.

Remove the rubber gasket from the fuel

valve body.

Screws

Retaining Ring

Rubber Gaske

Control Shaf

Fuel Valve Body

Washe

INSPECTION

Inspect the fuel valve body for dirt and clog.

Clean if necessary.

Replace the rubber gasket with new ones if

they are damaged or deteriorated.

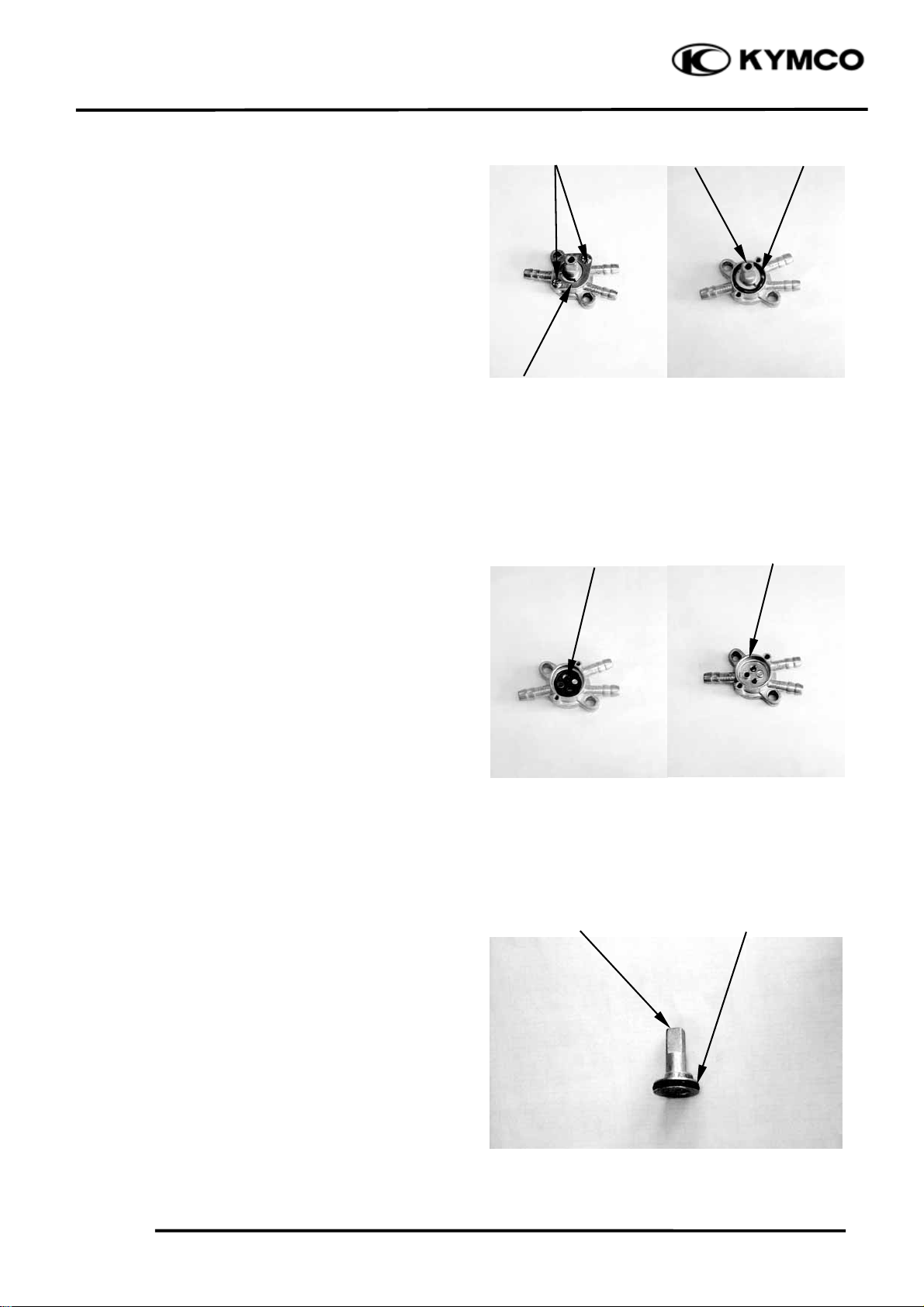

Replace the O-rings with new ones if they

are damaged or deteriorated.

Control Shaf

O-ring

5-5

Loading...

Loading...