Kymco MO MXer50 Service Manual - chap 03 (manutenzione)

3. INSPECTION/ADJUSTMENT

3-0

MX’er 50

3

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

INSPECTION/ADJUSTMENT

__________________________________________________________________________________

SERVICE INFORMATION -------------------------------------------- 3- 1

MAINTENANCE SCHEDULE ---------------------------------------- 3- 2

FUEL LINE/THROTTLE OPERATION/AIR CLEANER ---------- 3- 3

SPARK PLUG/LUBRICATION SYSTEM---------------------------- 3- 5

CARBURETOR IDLE SPEED ----------------------------------------- 3- 7

CYLINDER COMPRESSION/FINAL REDUCTION GEAR OIL-- 3- 8

DRIVE BELT/BRAKE SHOE/BRAKE SYSTEM ------------------- 3- 9

HEADLIGHT AIM ------------------------------------------------------ 3-11

STEERING SYSTEM INSPECTION --------------------------------- 3-11

TOE-IN ADJUSTMENT------------------------------------------------ 3-12

WHEELS/TIRES -------------------------------------------------------- 3-13

DRIVE CHAIN SLACK ADJUSTMENT ----------------------------- 3-14

CABLE INSPECTION AND LUBRICATION ----------------------- 3-16

FRONT SUSPENSION LUBRICATION------------------------------ 3-16

3

3. INSPECTION/ADJUSTMENT

3-1

MX’er 50

SERVICE INFORMATION

GENERAL

°I WARNING

•Before running the engine, make sure that the working area is well-ventilated. Never run the

engine in a closed area. The exhaust contains poisonous carbon monoxide gas which may cause

death to people.

•Gasoline is extremely flammable and is explosive under some conditions. The working area

must be well-ventilated and do not smoke or allow flames or sparks near the working area or

fuel storage area.

SPECIFICATIONS

ENGINE

Throttle grip free play : 1_ 4mm

Spark plug gap : 0.6_ 0.7mm

Spark plug: Standard : NGK: BR8HAS

Idle speed : 2000±100rpm

Gear oil capacity :

At disassembly : 120cc

At change : 90cc

Cylinder compression : 12kg/cm_

Ignition timing : BTDC 22°/2000rpm

CHASSIS

Front brake free play: 10_ 20mm

Rear brake free play: 10_ 20mm

TIRE PRESSURE

1 Rider

Front

0.35kgf/cm_

Rear

0.35kgf/cm_

TIRE SIZE:

Front : 20*7-8

Rear : 22*10-8

TORQUE VALUES

Front wheel nut 6.0_ 8.0kgf-m

Rear wheel nut 6.0_ 8.0kgf-m

3. INSPECTION/ADJUSTMENT

3-2

MX’er 50

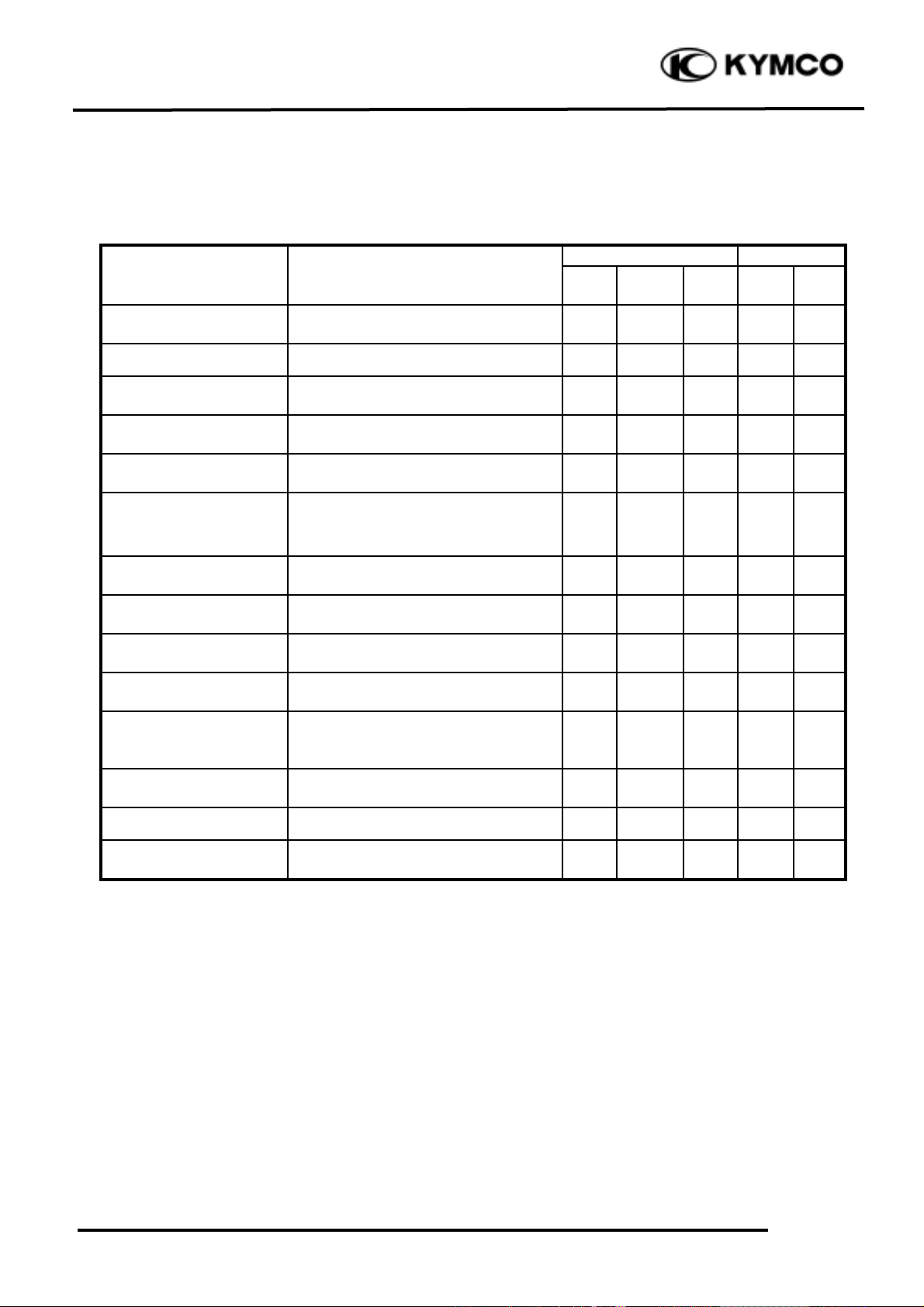

MAINTENANCE SCHEDULE

This chapter includes all information necessary to perform recommended inspections and

adjustments. These preventive maintenance procedures, if followed, will ensure more reliable

vehicle operation and a longer service life. The need for costly overhaul work will be greatly

reduced. This information applies to vehicles already in service ad well as new vehicles that are

being prepared for sale. All service technicians should be familiar with this entire chapter.

Initial

Every

Item

Remarks

1

month

3

month

6

month

6

month

1

year

Spark plug

Check condition. Clean or replace if

necessary.

°≥°≥°≥°≥°≥

Air clearance

Clean. Replace if necessary.

°≥°≥°≥

°≥

Carburetor

Check idle speed/starter operation.

Adjust if necessary.

°≥°≥°≥

°≥

Fuel line

Check fuel hose for cracks or

damage. Replace if necessary.

°≥°≥°≥

Engine oil

Replace (Warm engine before

draining).

°≥°≥°≥

°≥

Engine oil filter

screen

Clean. Replace if necessary.

°≥

°≥

Transmission oil

Check oil leakage. Replace every 12

months.

°≥

°≥

Brake system

Check operation. Adjust if

necessary.

°≥°≥°≥°≥°≥

Drive belt

Check operation/replace if damage

or excessive wear.

°≥

°≥

Wheels

Check balance/damage/runout.

Replace if necessary.

°≥°≥°≥

°≥

Wheel bearings

Check bearings assembly for

looseness/damage. Replace if

damaged.

°≥°≥°≥

°≥

Steering system

Check operation/replace if damage.

Check toe-in/adjust if necessary.

°≥°≥°≥°≥°≥

Knuckle shafts

Lubricate every 6 months.

°≥°≥°≥

Fitting/Fasteners

Check all chassis fittings and

fasteners. Correct if necessary.

°≥°≥°≥°≥°≥

• In the interest of safety, we recommend these items should be serviced only by an

authorized KYMCO motorcycle dealer.

3. INSPECTION/ADJUSTMENT

3-3

MX’er 50

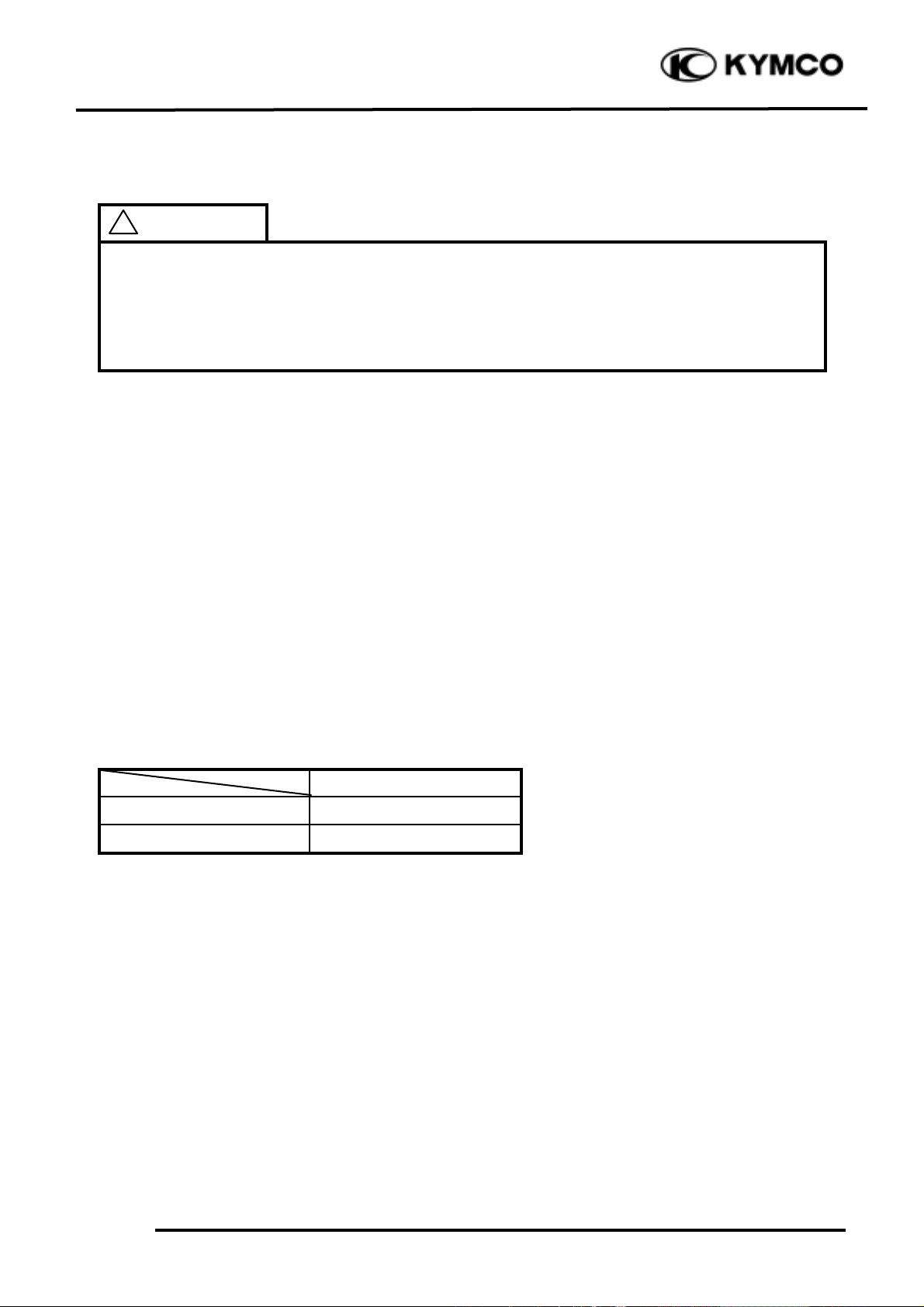

FUEL LINE

Check the fuel tubes and replace any parts,

which show signs of deterioration, damage

or leakage or leakage.

THROTTLE OPERATION

Check the throttle to swing for smooth

movement.

Measure the throttle to swing free play.

Free Play: 1_ 4mm

Minor adjustment is made with the

adjusting nut at the throttle to swing above.

Slide the rubber cover out and adjust by

loosening the lock nut and turning the

adjusting nut.

AIR CLEANER

AIR CLEANER REPLACEMENT

Remove five screws on the air cleaner case

cover and the cover.

Check the element and replace it if it is

excessively dirty or damaged.

Do not smoke or allow flames or sparks

in your working area.

°Ø

Lock Nut

Adjusting Nut

Fuel Filter

Fuel tube

Screws

Air Cleaner Case Cover

3. INSPECTION/ADJUSTMENT

3-4

MX’er 50

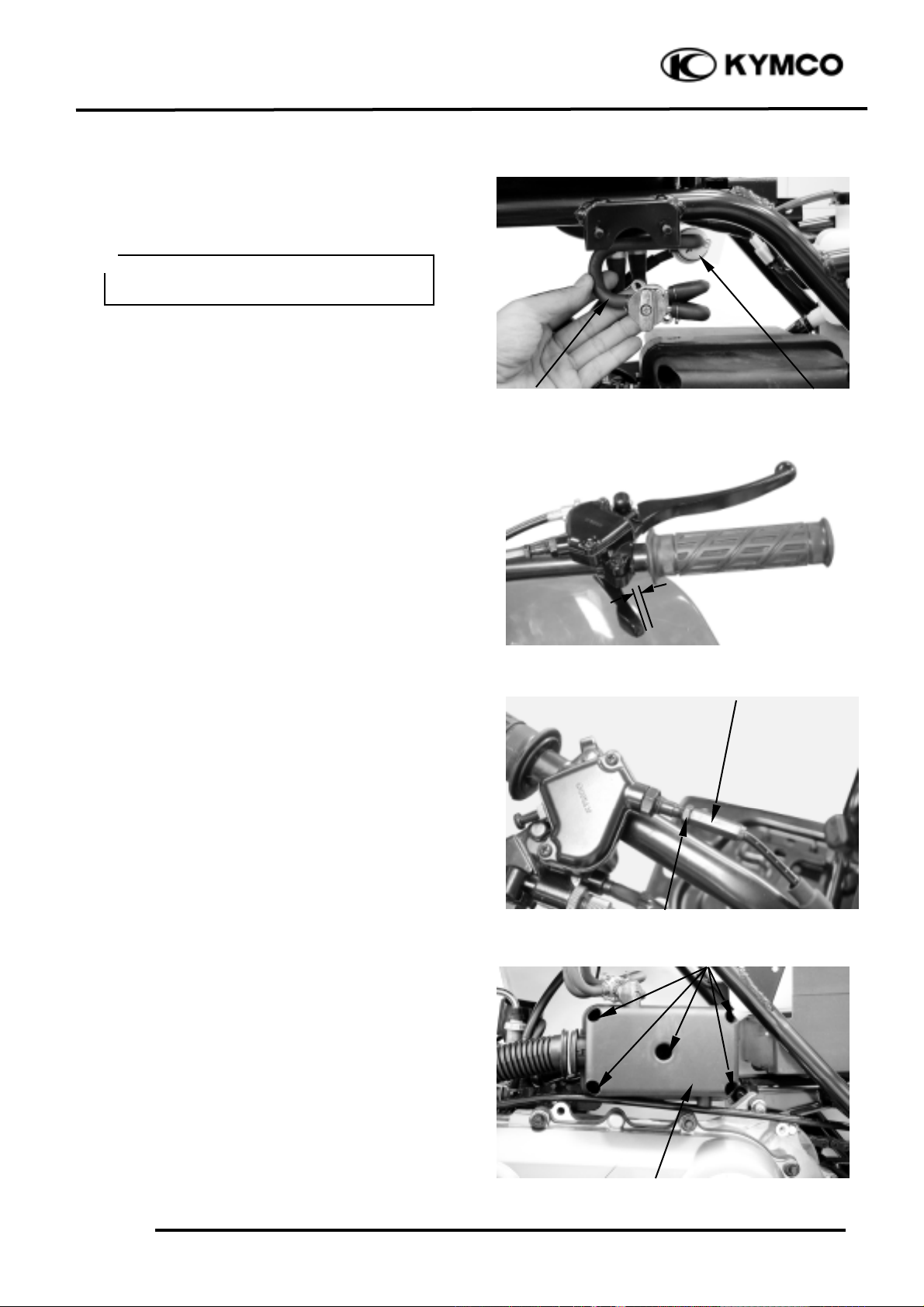

CLEAN AIR FILTER ELEMENT

Wash the element gently, but throughly in

solvent.

Squeeze the excess solvent out of the

element and let dry.

Apply the engine oil.

Squeeze out the excess oil.

CHANGE INTERVAL

More frequent replacement is required when

riding in unusually dusty or rainy areas.

Use parts cleaning solvent only. Never

use gasoline or low flash point solvents

which may lead to a fire or explosion.

°Ø

Do not twist or wring out the foam

element. This could damage the foam

material.

°Ø

The element should be wet but not

dripping.

°Ø

Air Cleaner Element

3. INSPECTION/ADJUSTMENT

3-5

MX’er 50

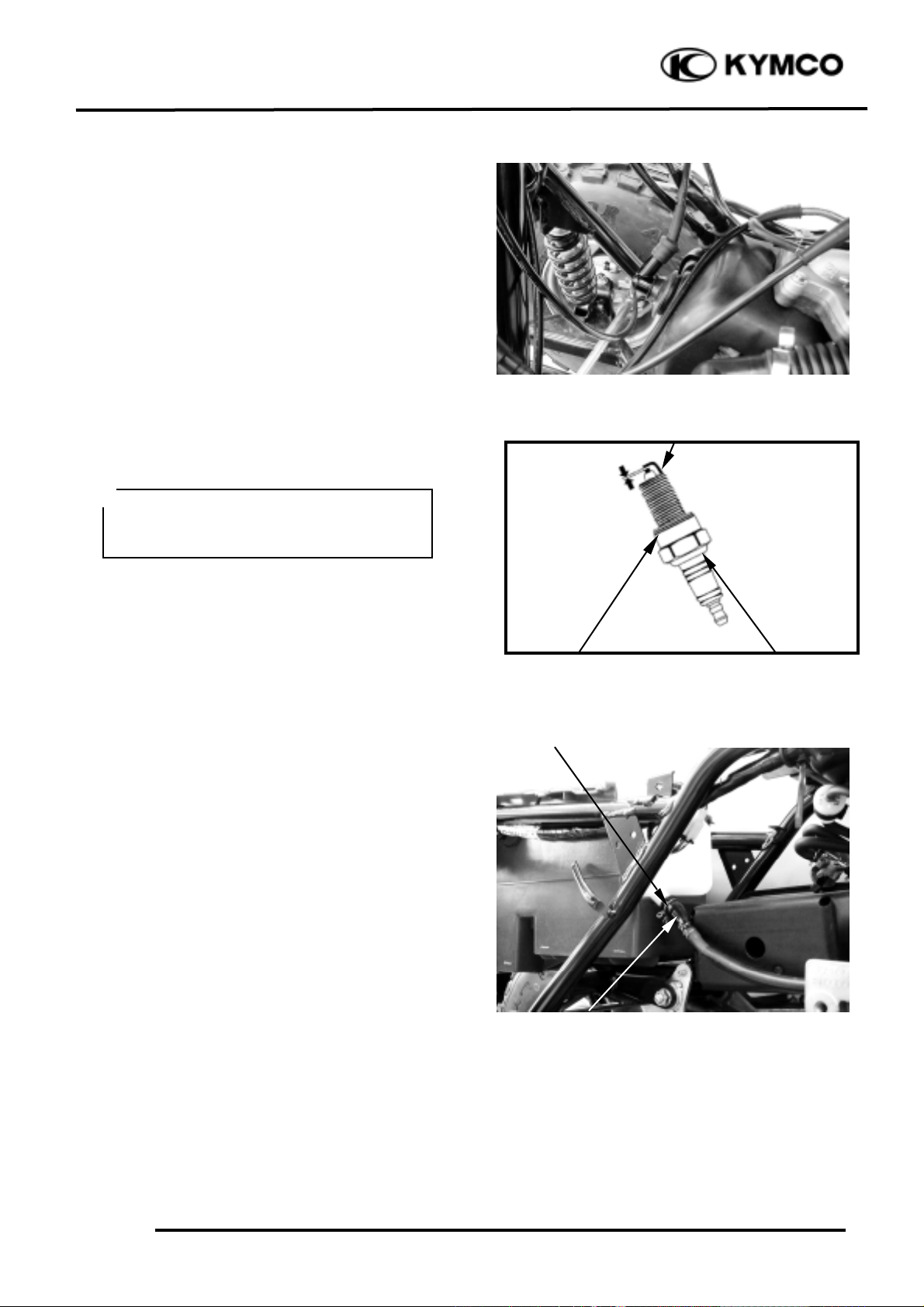

Gap, Wear, and Fouling Deposits

SPARK PLUG

Remove the spark plug

Check the spark plug for wear and fouling

deposits.

Clean any fouling deposits with a spark

plug

cleaner or a wire brush.

Specified Spark Plug: NGK: BR8HAS

Measure the spark plug gap.

Spark Plug Gap: 0.6_ 0.7mm

LUBRICATION SYSTEM

°mOil Filter Cltaning°n

Disconnect the oil tube at the oil pump side

and allow oil to drain into a clean container.

Remove the tube clip at the oil tank side and

disconnect the oil tube.

Remove the oil filter.

Cracks, Damage

Washer Deformation

When installing, first screw in the spark

plug by hand and then tighten it with a

spark plug wrench.

°Ø

Clip

Oil Filter

Loading...

Loading...