Page 1

PC3x

Service Manual

©2008 All rights reserved. Kurzweil® is a product line of Young Chang Co., Ltd. Young Chang®,

Kurzweil®, and PC3® are trademarks of Young Chang Co., Ltd. All other products and brand

names are trademarks or registered trademarks of their respective companies. Product features and

specifications are subject to change without notice.

Part Number: 910515-001 Ver. 1.0

Page 2

The lightning flash with the arrowhead symbol,

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

within an equilateral triangle, is intended to alert

the user to the presence of uninsulated

"dangerous voltage" within the product's

enclosure that may be of sufficient magnitude

to constitute a risk of electric shock to persons.

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE THE COVER

NO USER SERVICEABLE PARTS INSIDE

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL

The exclamation point within an equilateral

triangle is intended to alert the user to the

presence of important operating and

maintenance (servicing) instructions in the

literature accompanying the product.

IMPORTANT SAFETY & INSTALLATION INSTRUCTIONS

INSTRUCTIONS PERTAINING TO THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS

WARNING: When using electric products, basic precautions should

always be followed, including the following:

1. Read all of the Safety and Installation Instructions and Explanation

of Graphic Symbols before using the product.

2. This product must be grounded. If it should malfunction or break

down, grounding provides a path of least resistance for electric

current to reduce the risk of electric shock. This product is equipped

with a power supply cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged into an

appropriate outlet which is properly installed and grounded in

accordance with all local codes and ordinances.

DANGER: Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. Do not modify the

plug provided with the product - if it will not fit the outlet, have a

proper outlet installed by a qualified electrician. Do not use an

adaptor which defeats the function of the equipment-grounding

conductor. If you are in doubt as to whether the product is properly

grounded, check with a qualified serviceman or electrician.

3. WARNING: This product is equipped with an AC input voltage

selector. The voltage selector has been factory set for the mains

supply voltage in the country where this unit was sold. Changing

the voltage selector may require the use of a different power supply

cord or attachment plug, or both. To reduce the risk of fire or electric

shock, refer servicing to qualified maintenance personnel.

4. Do not use this product near water - for example, near a bathtub,

washbowl, kitchen sink, in a wet basement, or near a swimming

pool, or the like.

5. This product should be used only with a stand or cart that is

recommended by the manufacturer.

6. This product, either alone or in combination with an amplifier and

speakers or headphones, may be capable of producing sound

levels that could cause permanent hearing loss. Do not operate for

a long period of time at a high volume level or at a level that is

uncomfortable. If you experience any hearing loss or ringing in the

ears, you should consult an audiologist.

7. The product should be located so that its location or position does

not interfere with its proper ventilation.

8. The product should be located away from heat sources such as

radiators, heat registers, or other products that produce heat.

9. The product should be connected to a power supply only of the type

described in the operating instructions or as marked on the product.

10. This product may be equipped with a polarized line plug (one blade

wider than the other). This is a safety feature. If you are unable to

insert the plug into the outlet, contact an electrician to replace your

obsolete outlet. Do not defeat the safety purpose of the plug.

11. The power supply cord of the product should be unplugged from the

outlet when left unused for a long period of time. When unplugging

the power supply cord, do not pull on the cord, but grasp it by the

plug.

12. Care should be taken so that objects do not fall and liquids are not

spilled into the enclosure through openings.

13. The product should be serviced by qualified service personnel

when:

A. The power supply cord or the plug has been damaged;

B. Objects have fallen onto, or liquid has been spilled into the

product;

C. The product has been exposed to rain;

D. The product does not appear to be operating normally or

exhibits a marked change in performance;

E. The product has been dropped, or the enclosure damaged.

14. Do not attempt to service the product beyond that described in the

user maintenance instructions. All other servicing should be

referred to qualified service personnel.

WARNING: Do not place objects on the product’s power supply

15.

cord, or place the product in a position where anyone could trip

over, walk on, or roll anything over cords of any type. Do not allow

the product to rest on or be installed over cords of any type.

Improper installations of this type create the possibility of a fire

hazard and/or personal injury.

RADIO AND TELEVISION INTERFERENCE

WARNING: Changes or modifications to this instrument not expressly

approved by Young Chang could void your authority to operate the

instrument.

IMPORTANT: When connecting this product to accessories and/or other

equipment use only high quality shielded cables.

NOTE: This instrument has been tested and found to comply with the

limits for a Class B digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This instrument

generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If

this instrument does cause harmful interference to radio or television

reception, which can be determined by turning the instrument off and on,

the user is encouraged to try to correct the interference by one or more

of the following measures:

SAVE THESE INSTRUCTIONS

ii

• Reorient or relocate the receiving antenna.

• Increase the separation between the instrument and the receiver.

• Connect the instrument into an outlet on a circuit other than the one

to which the receiver is connected.

• If necessary consult your dealer or an experienced radio/television

technician for additional suggestions.

NOTICE

This apparatus does not exceed the Class B limits for radio noise

emissions from digital apparatus set out in the Radio Interference

Regulations of the Canadian Department of Communications.

AVIS

Le present appareil numerique n’emet pas de bruits radioelectriques

depassant les limites applicables aux appareils numeriques de la

class B prescrites dans le Reglement sur le brouillage radioelectrique

edicte par le ministere des Communications du Canada.

Page 3

Important Safety Instructions

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with dry cloth.

7. Do not block any of the ventilation openings. Install in accordance with the manufacturer’s

instructions.

8. Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus

(including amplifiers) that produce heat.

9. Do not defeat the safety purpose of the polarized or grounding-type plug. A polarized plug has

two blades with one wider than the other. A grounding type plug has two blades and a third

grounding prong. The wide blade or the third prong are provided for your safety. If the

provided plug does not fit into your outlet, consult an electrician for replacement of the obsolete

outlet.

10. Protect the power cord from being walked on or pinched, particularly at plugs, convenience

receptacles, and the point where they exit from the apparatus.

11. Only use attachments/accessories specified by the manufacturer.

12. Use only with a cart, stand, tripod, bracket, or table specified by the

manufacturer, or sold with the apparatus. When a cart is used, use

caution when moving the cart/apparatus combination to avoid

injury from tip-over.

13. Unplug this apparatus during lightning storms or when unused for

long periods of time.

14. CAUTION: Danger of explosion if battery is incorrectly replaced. Replace only with the same or

equivalent type (CR2032).

15. Refer all servicing to qualified service personnel. Servicing is required when the apparatus has

been damaged in any way, such as power supply cord or plug is damaged, liquid has been

spilled or objects have fallen into the apparatus, the apparatus has been exposed to rain or

moisture, does not operate normally, or has been dropped.

Warning - To reduce the risk of fire or electric shock, do not expose this apparatus to rain or moisture.

Do not expose this equipment to dripping or splashing and ensure that no objects filled with liquids,

such as vases, are placed on the equipment.

To completely disconnect this equipment from the AC Mains, disconnect the power supply cord plug

from the AC receptacle.

iii

Page 4

Kurzweil International Contacts

Contact the Kurzweil office listed below to locate your local Kurzweil representative.

Kurzweil Music Systems

19060 S. Dominies Hills Drive

Rancho Dominguez

California 90220 USA

Telephone: (310) 637-2000

Fax: (310) 637-2025

http://www.kurzweilmusicsystems.com

Kurzweil Co., LTD

iPark Building #102, Floor 9

Jeongja-Dong 9, Bundang-Gu

Soungnam-Shi, Gyeonggi-Do 463-859

South Korea

http://www.ycpiano.co.kr

http://www.youngchang.com

Page 5

Kurzweil PC3x Service Manual

Chapter 1 Introduction

Notes, Cautions, Warnings ............................................................................................................................................ 1-1

Rear Panel Features......................................................................................................................................................... 1-1

PC3x Front Panel............................................................................................................................................................. 1-3

Front Panel Features................................................................................................................................................ 1-3

Wheels Assembly (not shown)........................................................................................................................ 1-5

Chapter 2 Diagnostics

Diagnostic Tests ............................................................................................................................................................... 2-1

Entering Diagnostics....................................................................................................................................................... 2-1

LCD and Front Panel Buttons ................................................................................................................................ 2-2

Test Results................................................................................................................................................................ 2-2

Diagnostic Test Modes.................................................................................................................................................... 2-3

Run ............................................................................................................................................................................. 2-3

Loop ........................................................................................................................................................................... 2-3

Continuous................................................................................................................................................................ 2-3

Burn-in loop.............................................................................................................................................................. 2-3

Description of Tests......................................................................................................................................................... 2-4

SDRAM Refresh ....................................................................................................................................................... 2-4

Flash Memory........................................................................................................................................................... 2-4

MARA Validity Check ............................................................................................................................................. 2-4

MARA Communications......................................................................................................................................... 2-4

Expansion DIMM Check......................................................................................................................................... 2-5

MIDI UART............................................................................................................................................................... 2-5

External Card............................................................................................................................................................ 2-6

MARA Delay RAM.................................................................................................................................................. 2-6

MARA Sound ROM................................................................................................................................................. 2-6

Audio Output ........................................................................................................................................................... 2-7

Diagnostic Version 0.20 or earlier................................................................................................................... 2-7

Sine Wave Test................................................................................................................................................... 2-8

Chapter 3 Disassembly/Assembly

Introduction ..................................................................................................................................................................... 3-1

Notes, Cautions, Warnings ..................................................................................................................................... 3-1

Cables, Connectors................................................................................................................................................... 3-1

Cables ................................................................................................................................................................. 3-1

Cable Routing.................................................................................................................................................... 3-1

Required Tools and Materials................................................................................................................................. 3-1

Opening the PC3x ........................................................................................................................................................... 3-2

PC3x Bottom ............................................................................................................................................................. 3-2

Removing the Top Enclosure.................................................................................................................................. 3-3

Replacing the Top Enclosure .................................................................................................................................. 3-5

Closing the PC3x ...................................................................................................................................................... 3-6

Top Enclosure................................................................................................................................................................... 3-7

Removing the Enclosure Support Wall................................................................................................................. 3-8

Replacing the Enclosure Support Wall.................................................................................................................. 3-8

Removing the Connector Board............................................................................................................................. 3-9

Replacing the Connector Board ........................................................................................................................... 3-10

Removing the Slider Board....................................................................................................................................3-11

Replacing the Slider Board ................................................................................................................................... 3-12

i

Page 6

Kurzweil PC3x Service Manual

Removing the LCD Board..................................................................................................................................... 3-13

Replacing the LCD Board ..................................................................................................................................... 3-14

Removing the Front Panel Board......................................................................................................................... 3-14

Replacing the Front Panel Board ......................................................................................................................... 3-16

Removing the Engine Board................................................................................................................................. 3-17

Replacing the Engine Board ................................................................................................................................. 3-18

Removing the USB/xD Daughtercard................................................................................................................ 3-18

Replacing the USB/xD Daughtercard................................................................................................................. 3-18

Removing the Wheels Assembly ......................................................................................................................... 3-19

Replacing the Wheels Assembly.......................................................................................................................... 3-19

PC3x Keyboard Assembly............................................................................................................................................ 3-20

Removing the PC3x Keyboard Assembly........................................................................................................... 3-20

Replacing the PC3x Keyboard Assembly........................................................................................................... 3-21

Removing Keys ...................................................................................................................................................... 3-22

Natural/White Key ........................................................................................................................................ 3-22

Removing Natural/White Keys........................................................................................................................... 3-23

Removing Sharp/Black Keys ............................................................................................................................... 3-23

Replacing a Sharp Key .......................................................................................................................................... 3-23

Replacing a Natural/White Key.......................................................................................................................... 3-24

Servicing the Keyboard Contact Boards............................................................................................................. 3-24

Removing the Treble Contact Board ............................................................................................................ 3-24

Replacing the Treble Contact Board............................................................................................................. 3-24

Removing the Bass Contact Board ............................................................................................................... 3-24

Replacing the Bass Contact Board................................................................................................................ 3-25

Connecting the Keyboard Contact Boards ......................................................................................................... 3-25

Removing the Keyboard Contact Strips ............................................................................................................. 3-25

Replacing the Keyboard Contact Strips.............................................................................................................. 3-25

Chapter 4 Troubleshooting & Maintenance

Introduction ..................................................................................................................................................................... 4-1

Cables, Connectors................................................................................................................................................... 4-1

Cables ................................................................................................................................................................. 4-1

Cable Routing.................................................................................................................................................... 4-1

Surface-Mount Devices ........................................................................................................................................... 4-1

Required Tools and Materials................................................................................................................................. 4-1

Boot Loader...................................................................................................................................................................... 4-2

Entering the Boot Loader........................................................................................................................................ 4-2

Resets................................................................................................................................................................................. 4-2

Hard Reset................................................................................................................................................................. 4-2

Soft Reset ................................................................................................................................................................... 4-2

Saving User Data............................................................................................................................................................. 4-3

Saving to an xD Card............................................................................................................................................... 4-3

Saving to a Computer.............................................................................................................................................. 4-3

Software Updates ............................................................................................................................................................ 4-4

Updating with an xD Card ..................................................................................................................................... 4-4

Updating via Computer.......................................................................................................................................... 4-5

Rebuilding the Internal NAND Flash Memory.......................................................................................................... 4-6

Rebuilding with an xD Card .................................................................................................................................. 4-6

Rebuilding via a Computer .................................................................................................................................... 4-7

Boot EPROM .................................................................................................................................................................... 4-9

Removing the EPROM ............................................................................................................................................ 4-9

ii

Page 7

Kurzweil PC3x Service Manual

Replacing the EPROM............................................................................................................................................. 4-9

Replacing the Battery.................................................................................................................................................... 4-10

Accessing the Battery............................................................................................................................................. 4-10

Removing the Battery............................................................................................................................................ 4-10

Installing the Battery ............................................................................................................................................. 4-10

Scanner Tests...................................................................................................................................................................4-11

Front Panel Buttons ................................................................................................................................................4-11

Alpha Wheel ........................................................................................................................................................... 4-12

Front Panel Sliders................................................................................................................................................. 4-12

Right Main Output................................................................................................................................................. 4-12

Switch Pedals 1, 2, and 3 ....................................................................................................................................... 4-12

Continuous Control Pedal 1 and 2 ...................................................................................................................... 4-12

Wheels ..................................................................................................................................................................... 4-13

Adjusting the Pitch Wheel Center................................................................................................................ 4-13

Keyboard ................................................................................................................................................................. 4-13

Adjusting Key Pressure Sensitivity.............................................................................................................. 4-13

Power Problems............................................................................................................................................................. 4-14

Dead: LEDs, LCD backlight, and xD Card socket not lit ................................................................................. 4-14

Audio Problems............................................................................................................................................................. 4-14

No Audio................................................................................................................................................................. 4-14

Front Panel Problems.................................................................................................................................................... 4-15

LCD not lit............................................................................................................................................................... 4-15

LCD lit, no characters ............................................................................................................................................ 4-15

Buttons, Sliders or Controllers not working ...................................................................................................... 4-15

Keyboard Problems....................................................................................................................................................... 4-16

Dead Keyboard....................................................................................................................................................... 4-16

Dead Note(s) or no velocity sensitivity .............................................................................................................. 4-16

One or More in a Section................................................................................................................................ 4-16

PC3x Interconnect Diagram......................................................................................................................................... 4-17

Converting the Voltage................................................................................................................................................. 4-18

Accessing the Fuses ............................................................................................................................................... 4-18

The Fuse Holder..................................................................................................................................................... 4-19

Using 5 mm X 20 mm Fuses .......................................................................................................................... 4-21

Replacing the Fuse Holder ................................................................................................................................... 4-21

Chapter 5 Parts Lists

PCB & Sub Assemblies............................................................................................................................................ 5-1

Engine Board............................................................................................................................................................. 5-1

Connector Board ...................................................................................................................................................... 5-4

Front Panel Board..................................................................................................................................................... 5-6

Slider Board............................................................................................................................................................... 5-7

Engine Board–USB/xD Daughtercard.................................................................................................................. 5-7

Button Board............................................................................................................................................................. 5-8

Wheels Assembly..................................................................................................................................................... 5-8

Keyboard Assembly................................................................................................................................................. 5-8

Miscellaneous ........................................................................................................................................................... 5-9

Chapter 6 Schematics

Engine Board Assembly–SH7705 CPU and Memory (1 of 9) ................................................................................... 6-3

Engine Board Assembly–MARA 2 (2 of 9)................................................................................................................... 6-4

iii

Page 8

Kurzweil PC3x Service Manual

Engine Board Assembly–MARA 1 (3 of 9)................................................................................................................... 6-5

Engine Board Assembly–MARA Clocks, Delay Memory Interface (4 of 9)............................................................ 6-6

Engine Board Assembly–Sound ROM (5 of 9)............................................................................................................ 6-7

Engine Board Assembly–ROM DIMMs, SmartMedia Interface, LCD, etc. (6 of 9)............................................... 6-8

Engine Board Assembly–DAC, Main Outs (7 of 9) .................................................................................................... 6-9

Engine Board Assembly–Aux and Headphone Outs (8 of 9) ................................................................................. 6-10

Engine Board Assembly–Mictors, CPLD, Power (9 of 9) .........................................................................................6-11

Connector Board–M38869 Scanner (1 of 4)................................................................................................................ 6-12

Connector Board–MIDI, Pedals, Ribbon, LCD Contrast (2 of 4)............................................................................ 6-13

Connector Board–Power Supply, Audio (3 of 4)....................................................................................................... 6-14

Connector Board–Sample Rate Converter (4 of 4).................................................................................................... 6-15

Front Panel Board–Front Panel Misc. Buttons And LEDs (1 of 2).......................................................................... 6-16

Front Panel Board–Front Panel Bank & Program Buttons & LEDs (2 of 2) .......................................................... 6-17

Slider Board.................................................................................................................................................................... 6-18

Wheels Board–Wheels & AT........................................................................................................................................ 6-19

Engine Board–USB/xD Daughtercard....................................................................................................................... 6-20

i

v

Page 9

Chapter 1

Introduction

This chapter provides the service technician with a layout of the front and rear panel features, as

well as a brief explanation of their functions. For in-depth descriptions of the many features the

PC3x includes, consult the Getting Started Guide .

Warning : If possible, save all user programs and setups before disassembly. For instructions,

refer to the Boot Loader in Chapter 4, page 4-2 .

Notes, Cautions, Warnings

Please pay special attention to all Notes, Cautions, and Warnings used throughout this manual

as they not only point out specific instructions, but also alert you to variations between

manufactured units.

A brief description of these symbols follows:

Note : Provides additional information, indicates differences between models, and emphasizes

specific instructions.

Caution : Highlights areas to instruct you to proceed cautiously so that damage does not occur

to the unit or individual components.

Warning : Alerts you so that damage does not occur to yourself, others, or external equipment

and devices.

Rear Panel Features

Storage —Use this slot to insert an xD memory card to update software, back up, and share files.

USB Port —Use the USB Port to send and receive MIDI or to connect to a computer for file

transfer.

Storage

Figure 1-1 PC3x rear panel, left end

USB Port

1-1

Page 10

Introduction

Rear Panel Features

MIDI Select Switch —Slide switch to select the operation of the MIDI Thru/Out port. This

switch is recessed into the rear panel so that it cannot be accidentally changed.

MIDI Ports —In, Thru/Out, and Out ports to connect the PC3x to other MIDI devices to receive,

pass, and send MIDI data.

Display —Rotary potentiometers to adjust the brightness and contrast of the LCD for the best

visibility.

MIDI

Select

Switch

MIDI

Ports

Display

Bright,

Contrast

Sync In

Digital Out

Breath

Input

Switch

Pedals

Continuous

Control Pedals

Ribbon

Input

Balanced

Analog Outputs

Headphones

Power Entry

Module

Figure 1-2 PC3x rear panel, right end

Sync In —This RCA jack allows the PC3x to receive digital clock signals when it is slaved to

another device.

Digital Out —RCA jack to connect to another device with an AES or S/PDIF input via a 75 !

coaxial cable.

Switch Pedals —Three 1/4” jacks to connect switch pedals that can be assigned to control

operations such as sustain, sostenuto, etc. (use 1/4” tip/sleeve).

1-2

Continuous Control Pedals —Two 1/4” jacks to connect pedals that can be assigned to control

operations such as volume, expression, etc. (use 10K ! linear taper potentiometer, 1/4”

tip/ring/sleeve, wiper to tip).

Breath Input —A 3.5mm jack to connect a standard breath controller to send standard MIDI

Breath messages.

Ribbon Input —Modular jack to connect the Kurzweil Ribbon Controller option.

Balanced Analog Outputs —Four 1/4” balanced audio output jacks. Use the Main outputs, left

(mono) and right, to connect to an amplifier, mixer or sound system. Use the Aux outputs for

monitoring or other operations. They duplicate the Main outputs, but are always in stereo.

Headphones —Standard 1/4” jack to connect headphones.

Power Entry Module —includes the power switch, AC receptacle, and the fuse holder/voltage

select compartment. (See Chapter 4, page 4-18 for instructions to change the voltage setting.)

Page 11

PC3x Front Panel

V

y

p

Front Panel Features

Introduction

PC3x Front Panel

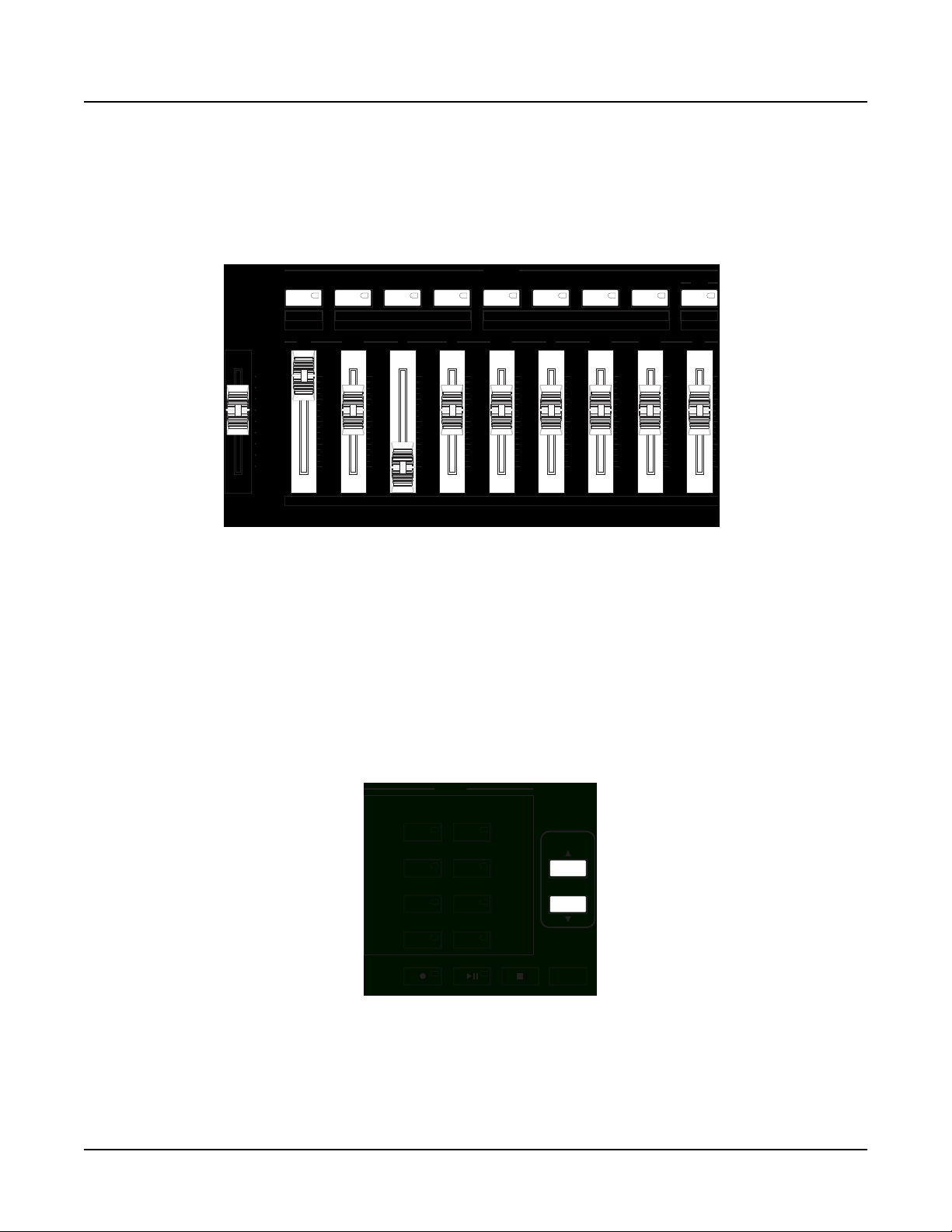

MASTER

OLUME

BANKS

StringsOrchestraClassic KeysBase 1 Base 2 Exp 1 UserExp 2

Rotary

16' 5 1/3' 8' 4' 2 2/3' 2' 1 3/5' 1 1/3' 1'

A B IEC G HFD

Data MIDI 1 3 MIDI 22 MI DI 23 MIDI 24

Vibrato

DepthOn/Off Chor/VibFast/Slow

Loud/Soft Decay F/S Pitch H/L

On /Off

Percussion Enable

MIDI 25 MIDI 26 MIDI 27 MIDI 28

KB3

On /Off

Figure 1-3 Master Volume, Bank buttons, Sliders

Master Volume —Slider to adjust the overall volume.

Bank buttons—Use these buttons to select different banks of programs, then select an individual

program using the Category and Program buttons. The labeling above the button indicates the

program. In KB3 mode, these buttons have different functions. Their labeling is below the Bank

buttons.

Sliders —The operation of the sliders depends on which mode is active. In KB3 mode, these

sliders emulate the drawbars of an organ. They are labeled as follows: above each slider for KB3

mode, and below when used for data and MIDI controllers.

MODE

MIDIProgram

Mute 1

Setup Master

Q Access Song

Solo Mute Active

Effect Storage

FX Bypass Compare

Record Pla

Mute 2

Mute 4Mute 3

/ Pause Sto

Chan / Layer

Edit

Figure 1-4 Mode, Edit, Chan/Layer and record function buttons

Mode buttons—use these buttons to select one of the eight available operating modes. The

additional labeling of these buttons indicate that they function differently depending on the

current mode or editor.

1-3

Page 12

Introduction

PC3x Front Panel

Chan/Layer buttons—depending on the current editor, use these buttons to scroll through

layers, presets, values, and zones.

Record , Play/Pause , and Stop buttons—use these buttons to activate the sequencer to record

and playback songs.

Edit button—use this button to enter the editor or the current mode to modify a selected object

or parameter.

ExitExit

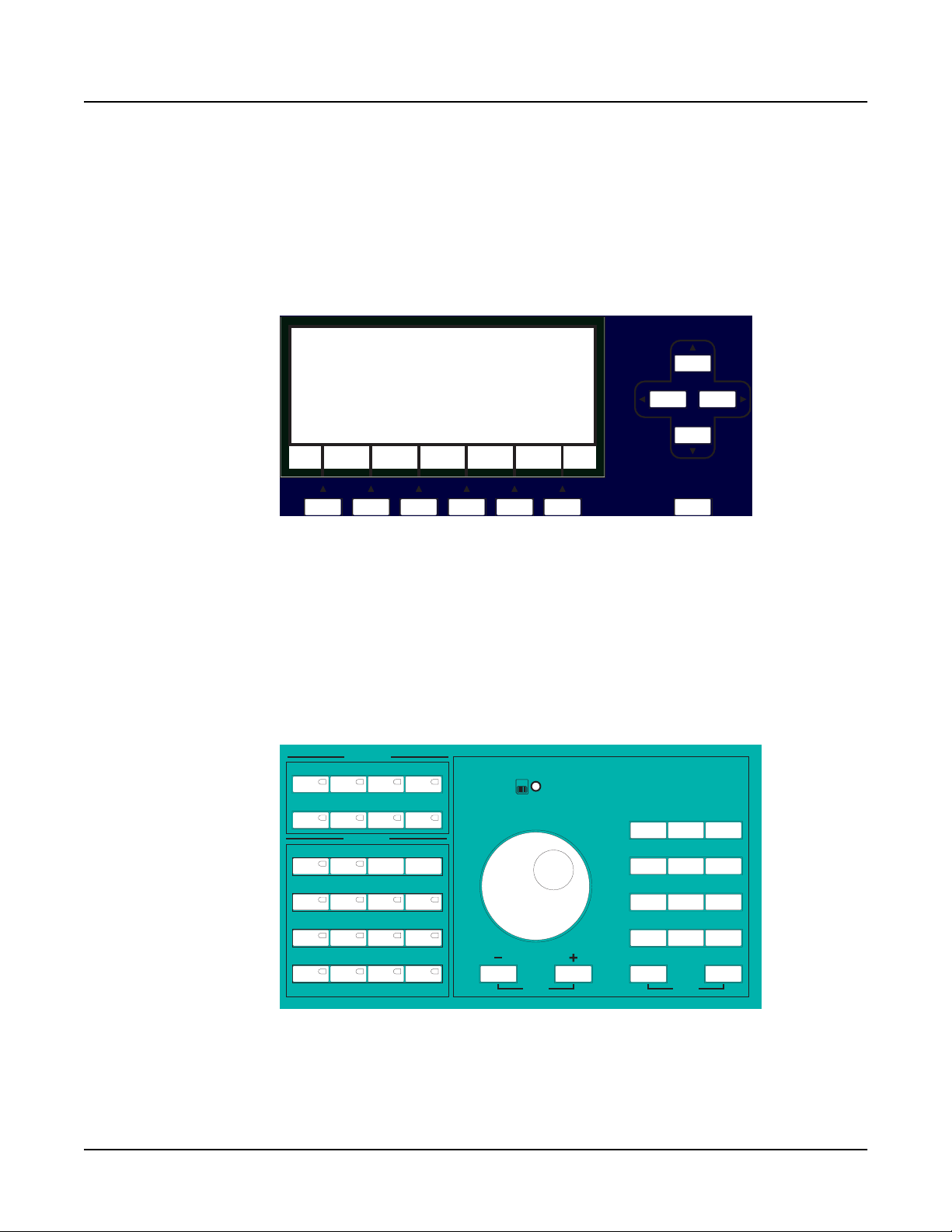

Figure 1-5 LCD and Soft, Cursor, and Exit buttons

Display —Angled 240 x 64, backlit graphic LCD.

Soft buttons — use these buttons to select an action or item shown directly above the button in

the bottom line of the display.

Cursor buttons — use these buttons navigate the cursor in the display.

Exit button—press this button to leave the current editor.

PROGRAM

1 432

CATEGORY

E Piano 1Piano 2Piano 1 E Piano 2

8765

BrassOrganClavierPop Keys

PadsSynthsVoicesStrings

PercussionDrumsBassGuitar

Jump

Storage

Active

1 2 3

4 5 6

STU YZVWX

-

/

+

Shift 0-9

Cancel Enter

GHIDEFABC

PQRMNOJKL

8 97

0 Clear

Space

PANIC

1-4

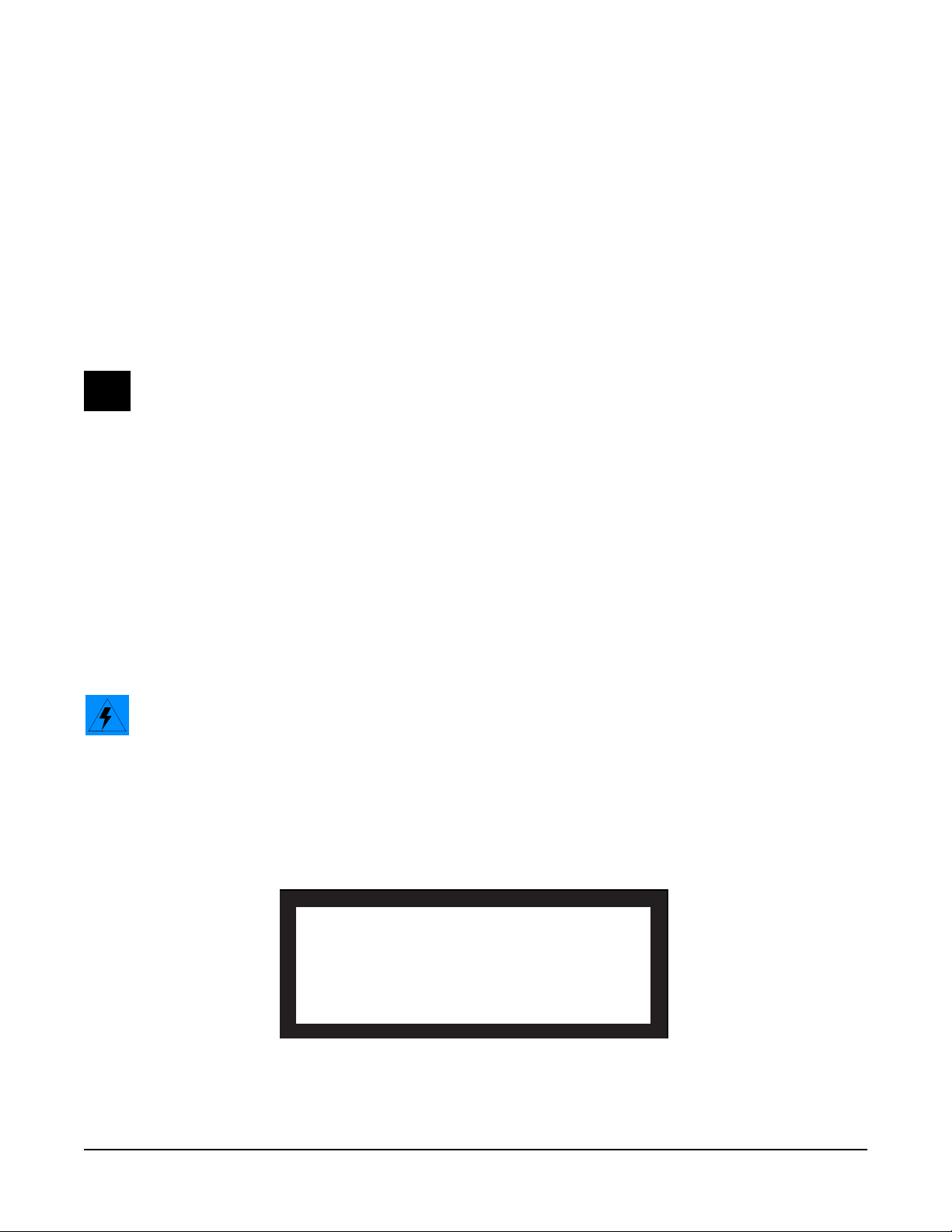

Figure 1-6 Program, Category, Alpha wheel and Alphanumeric buttons

Category and Program buttons—use these buttons to first select a Category , then select one of

the eight

Program buttons.

Page 13

PC3x Front Panel

Alpha Wheel— use the Alpha Wheel to increase or decrease a value by one or several

increments.

Plus ( + ) and Minus ( – ) buttons —these buttons operate similar to the Alpha Wheel. Pressing the

Plus (+) or Minus (-) button allows you to increase or decrease a value by one. Pressing these

buttons simultaneously, selects the Jump function.

Alphanumeric Keypad—use these buttons to enter characters (both uppercase and lowercase),

numbers, and spaces. Pressing these buttons simultaneously, selects the Panic button. Select the

Panic button to send an All Notes/All Controllers Off message on all 16 channels.

Storage Active LED—this blue LED is lit when an xD daughter card is installed and there is

activity. (Do not remove the xD card when the blue LED is lit.)

Wheels Assembly (not shown)

Pitch and Mod Wheels—use these wheels to vary modulation and pitch. In some programs, the

Mod Wheel can be used for other functions.

Introduction

ARP button—use this button to active the Arpeggiator.

SW button—this button can be programmed for a variety of functions.

1-5

Page 14

Introduction

PC3x Front Panel

1-6

Page 15

Chapter 2

Diagnostics

Diagnostic Tests

The following lists the diagnostic tests available for the PC3x.

Note: Throughout this manual many references are made to the MARA 1 and MARA 2 ICs. For

service personnel unfamiliar with the PC3x, MARA is the name given to the two Kurzweil

Custom Sound ICs.

• SDRAM Refresh

• Flash Memory

• MARA Validity Check

• MARA Communications

• Exp DIMM Check

• MIDI UART

• External Card

• MARA Delay RAM

• MARA Sound ROM

• Audio Output

Warning: If possible, save all user programs and setups before entering diagnostics or

performing maintenance or repair. For instructions, refer to Saving User Data in Chapter 4,

page 4-2.

Entering Diagnostics

1. Apply power to the unit. When the ****Welcome to the Kurzweil PC3**** message appears in

the LCD, quickly press and release the Exit button. The LCD should display the following:

PC3 Boot Loader Version X.XX

RUN UPDATE RUN SYSTEM FILE

PC3 IMAGE DIAGS RESET UTILITIES

Figure 2-1 LCD example, Boot Loader

2. Press the soft button below RUN DIAGS in the LCD.

2-1

Page 16

Diagnostics

Entering Diagnostics

3. The LCD flashes the message: Running ROM-based diagnostics.

4. The LCD displays the following:

Running SDRAM refresh test

RAM Test Passed

OK

Figure 2-2 LCD example, diagnostic main menu

5. The bottom line in the display shows the four test modes. Press the soft button below the

test mode to run the tests.

LCD and Front Panel Buttons

The LCD displays the list of tests, test modes, actions, and test results.

Press the Left, Right, Up, or Down cursor buttons or turn the Alpha Wheel to navigate through

the available tests.

Use the soft buttons located below the LCD to select different test modes or actions.

Press the Exit button to return to the Boot Loader.

Test Results

At the completion of an individual test, the LCD displays the results of the test. Figure 2-3 shows

an example of the display for the SDRAM refresh test.

Figure 2-3 LCD example, SDRAM refresh test

Running SDRAM refresh test

RAM Test Passed

OK

2-2

Page 17

Diagnostic Test Modes

Run

The run test mode allows you to select an individual test, or to step through and run each

available test. To step through the different tests, use the Left, Right, Up, or Down cursor

buttons or turn the Alpha Wheel. Press the soft button below RUN to select the test.

At the completion of a test, whether pass or fail, press the OK soft button to exit the test and

return to the test menu.

To exit diagnostics, press the Exit button to return to the Boot Loader.

Loop

Loop continuously runs an individual test. The number of tests performed and the result is

displayed continuously in the LCD. The test continues to run until you press the Exit button.

Continuous

Continuous is the same as Loop, but stops if a failure is detected.

Diagnostics

Diagnostic Test Modes

Burn-in loop

Burn-in continuously runs the following sequence of tests.

• SDRAM Refresh

• Flash Memory

• MARA Validity Check

• MARA Delay RAM

• MARA Communications

• MARA Sound ROM

If a failure is detected, the test stops and displays the result.

To exit Run Burn-in and return to the Boot Loader, press and hold the Exit button.

2-3

Page 18

Diagnostics

Description of Tests

Description of Tests

SDRAM Refresh

This test verifies the write/read functionality and accuracy of the SDRAM chip (U3) attached to

the microprocessor, SH7705 (U1).

A failure of this test indicates a problem with the SDRAM chip or associated circuitry on the

Engine Board.

Flash Memory

This test verifies the manufacturer ID and the size of the NAND Flash installed. The test then

writes and reads back one or more blocks not occupied by the file system. This test also indicates

if the NAND Flash is formatted or unformatted.

A failure of this test may indicate a problem with the with the microprocessor (U1), NAND

Flash (U2), Fin CPLD (U45), or related circuitry on the Engine Board.

MARA Validity Check

Note: Throughout this manual many references are made to the MARA 1 and MARA 2 ICs. For

service personnel unfamiliar with the PC3x, MARA is the name given to the two Kurzweil

Custom Sound ICs.

This tests verifies the proper content of certain read-only registers and the read/write accuracy

of certain read/write registers on both MARAs. It also writes and reads back the various register

blocks in both MARAs that are implemented as RAM cells.

A failure of this test may indicate a problem with the with the microprocessor (U1), MARA 1

(U11) or MARA 2 (U10), or related circuitry on the Engine Board.

MARA Communications

This test transfers data from one MARA to the other via the SMOOCH interface and checks the

accuracy of the data received. All four SMOOCH inputs and outputs are exercised.

This test will likely fail if the MARA Validity Test fails. However if the MARA Validity Test

passes and this test fails, it may indicate a bad solder joint underneath one or both MARAs.

2-4

Page 19

Expansion DIMM Check

This test checks to see if a DIMM module is installed in J10 or J11 and confirms the type.

Running Exp DIMM check test

CHECK READ WRITE PLAY

DIMMS DIMMS DIMMS DIMMS EXIT

Figure 2-4 LCD example, Exp DIMM check test

Note: There are two types of DIMM modules—one with all four NOR Flash chips present and

the other with only two out of the four chips populated. The J10 DIMM socket on the Engine

Board can only support the half-populated DIMM version.

Each DIMM module has an upper and lower bank. The half-populated DIMM module has Flash

chips installed in the upper bank only. Therefore, this diagnostic will only report results for

DIMM 0, High Bank; but will report results for both the High and Low Bank of DIMM 1.

Diagnostics

Description of Tests

A failure of this test may indicate a problem with the DIMM(s), their installation, soldering of

the socket(s), or related circuitry on the Engine Board.

MIDI UART

The MIDI test performs a loop-back of the serial port by sending a 23-byte pattern over the

external MIDI link. This test requires a MIDI loop (a MIDI cable that connects two MIDI jacks).

The test will fail if a MIDI cable is not connected between two MIDI jacks. Be sure to run this test

with MIDI cables connected as follows:

1. Connect a MIDI cable to the MIDI In and MIDI Out jacks and run the test.

2. Connect a MIDI cable to the MIDI In and MIDI Out/Thru jacks and set the MIDI select

A failure of this test could be caused by failure of the serial port, other MIDI circuitry, or a

problem on the Engine Board.

On the Engine Board check the signal paths from U1, pins 172, 174, 177, and 179 to connector J5.

switch on the rear panel to Out. Run the test.

2-5

Page 20

Diagnostics

Description of Tests

External Card

This test checks the hardware interface for the xD Card. The test first checks to see if a card is

installed; and if so, reads and reports the identifying data.

Note: This test is safe to run on an xD Card that has data on it.

A failure of this test indicates a problem with USB/xD Daughtercard, related circuitry or the

Engine Board.

MARA Delay RAM

This is a write/read test to check the Delay RAM connected to MARA 1. The Delay RAM test

first checks address and databus connectivity and then reports which bits are not functioning to

aid troubleshooting.

Error reporting for this test identifies whether the error is likely to have occurred during writing

or during reading. Data value mismatch errors are reported in hexadecimal values starting with

“0x” followed by 8 hex digits. If the data value that was ReadBack differs greatly from the value

Wrote, it could mean there was an address bit error, or one or more of the control signals are bad.

A failure of this test would indicate a problem with the DDR SDRAM (U13), MARA 1 (U11), or

the Engine Board.

MARA Sound ROM

This test calculates and verifies the checksum for each 16 MB section of the on-board Sound

(Sample) ROM. It also tests the data and address lines from both MARAs to the Sound ROMs.

This test may also report errors when the MARA Validity Test fails. If MARA Validity Test only

fails on one of the MARAs, then the other MARA may still pass this test.

Running MARA sound ROM test

MARA 1 Sound ROM checksums are correct

MARA 1 Sound ROM data lines are correct

MARA 1 Sound ROM addr lines are correct

MARA 2 Sound ROM checksums are correct

MARA 2 Sound ROM data lines are correct

OK

Figure 2-5 LCD example, MARA Sound ROM test

A failure of this test may indicate a problem with a Sound ROMs (U20, U21, U22, or U23), or the

Engine Board.

Use the Down cursor button

or the Alpha wheel to scroll

down to the next line of the

test result.

2-6

Page 21

Audio Output

This is not a test that fails. It is an interactive test for the entire audio chain. However for this test

to pass reliably, the MARA Validity and MARA Delay RAM tests should pass. The software

creates waveforms (sine and sawtooth) and stores them in the Delay RAM. Therefore, MARA 1

and its Delay RAM need to be functioning for this test to produce a clean audio waveform.

When you select this test, the LCD displays the following:

Figure 2-6 LCD example, Audio output test

Note: If the diagnostic version is earlier than 0.20, this test is only useful to check the polarity of

the Main Output audio signals. Use the Sine Wave Test on page 2-8 for audio level and distortion

tests. If the diagnostic version is 0.20 or later, follow the on-screen instructions for use.

Diagnostics

Description of Tests

Running Audio output test

Frequency = 220 Hz

Output = Main outputs

PLAY PLAY SAMPLE

SINE SAWTOOTH LOOP EXIT

Warning: This test produces loud sine waves. Before beginning this test, turn the volume slider

on the PC3x and your sound system down to minimum.

Diagnostic Version 0.20 or earlier

To use diagnostic Version 0.19 or earlier to check amplitude, polarity, and frequency response

flatness; an oscilloscope is needed.

1. Move the Volume slider to maximum, then press the Play Sawtooth soft button.

2. A 275 Hz sawthooth with a peak amplitude of +/-0.30V will appear on the Main Left and

Main Right Outputs.

If the polarity is correct, the sawtooth ramp will be positive-going at the Tip contact of

each jack and negative-going at the Ring contact.

If the frequency response is flat, the ramp will be perfectly straight except for three tiny

ripples just before and after the flyback part of the signal.

The volume slider does not act normally during the test so leave it set to maximum. Only the

Main outputs will be driven. When finished checking the Main Output signals, press the Exit

soft button to exit the diagnostic.

The Play Sine soft button will produce a sine wave, also 0.30V peak amplitude, but it is not

pure and thus unsuitable for distortion measurements. Use the Sine Wave Test that follows.

Do not press the Sample Loop soft button. It will hang and require a power cycle to recover.

2-7

Page 22

Diagnostics

Description of Tests

Sine Wave Test

For a pure sine wave that exercises the full dynamic range of the PC3x, press the Run PC3 soft

button to exit diagnostics and return to normal operation. In Program mode, use the numeric

keypad and select program 1000, Sine Wave.

Warning: This test can produce a very high level (20-30dB higher than normal which can be

damaging), and must be activated in order to play. Follow Steps 1–5 to activate and run the test.

1. Position the volume slider and sliders 1-9 to minimum.

2. Use the numeric keypad and select program 1000, Sine Wave.

3. Press the SW1 button located directly above the Mod Wheel.

4. Play C4 (Middle C) to produce a 261 Hz sine wave at all of the outputs.

5. Move the volume slider up slowly.

Note: Do not touch Slider 1 or the amplitude may change.

\

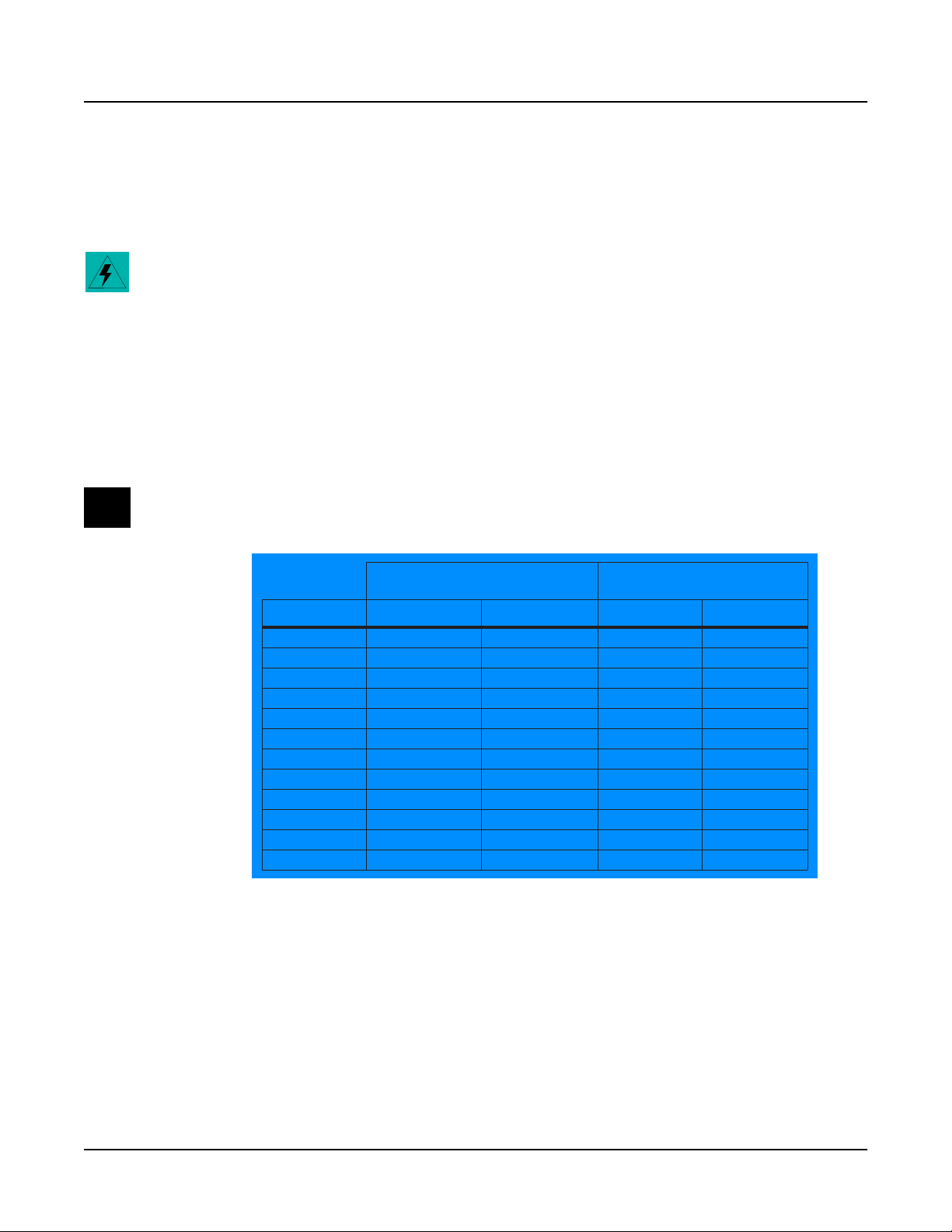

FREQUENCY

NOTE Hz Vrms Vp-p dBm

D2

F#2

C3

F#3

C4

F#4

C5

F#5

C6

F#6

C7

D7

20.6

32.7

65.4

130.8

261.6

523.2

1046.5

2092.8

4186.0

8371.2

16744.0

21096.1

3.08

3.21

2.80

2.80

2.80

2.80

2.77

2.80

2.80

2.81

3.00

2.77

Table 2-1 Frequency and Amplitude Values

AMPLITUDE

(Tip or Ring to Sleeve)

4.35

4.54

3.95

3.95

3.95

3.95

3.92

3.95

3.95

3.97

4.24

3.92

+12.0

+12.3

+11.2

+11.2

+11.2

+11.2

+11.1

+11.2

+11.2

+11.2

+11.8

+11.1

2-8

Page 23

Diagnostics

Description of Tests

Notes

1. Slider 1 is a fine amplitude adjustment. It has a range from 63% of the values listed in

Table 2-1 to beyond clipping.

2. Clipping level is specified to be 4.25 Vrms, 6.00Vp-p, +14.8 dBm unbalanced, +20.8 dBm

balanced at the Main and Aux Outputs.

3. The Headphones Output level is twice that of the Line Outputs. Clipping is

approximately 7.0 Vrms or 20.0Vp-p.

4. The keys are not velocity sensitive.

5. Keys not in the table produce other frequencies from a minimum of 6.49 Hz (E1) to a

maximum of 21096 Hz (D7).

6. The frequency ratio from one key to the next is 1.122462.

2-9

Page 24

Diagnostics

Description of Tests

2-10

Page 25

Chapter 3

Disassembly/Assembly

Introduction

This chapter contains all the procedures for the disassembly and reassembly of the PC3x. There

are three main sections: Opening the PC3x, Top Enclosure, and the PC3x Keyboard Assembly.

Warning: If possible, save all user programs and setups before disassembly. For instructions,

refer to Boot Loader in Chapter 4, page 4-2.

Notes, Cautions, Warnings

Please pay special attention to all Notes, Cautions, and Warnings as they not only point out

specific instructions, but also alert you to variations between manufactured units.

Cables, Connectors

Cables

All cables with connectors are keyed, and therefore cannot be reversed.

Warning: Some units may have a small PC board installed on the flat ribbon cable connected to

J202 on the Front Panel Board. Neither the socket nor the pins on this board are keyed. See

page 3-14 and page 3-16 for further information.

Cable Routing

In some cases, tape fastens cables to printed circuit boards or the top and bottom enclosures.

When disconnecting cables, always peel back the tape from one side so that the tape remains

properly positioned.

Required Tools and Materials

• No. 1 Phillips head screwdriver

• No. 2 Phillips head screwdriver

• Small flat screwdriver

• Dowel (3mm diameter)

• Needle-nose pliers

• Small blunt-end tool (Q-Tip, toothpick, etc.)

• USB cable

• xD Card

• Foam blocks

3-1

Page 26

Disassembly/Assembly

Opening the PC3x

Opening the PC3x

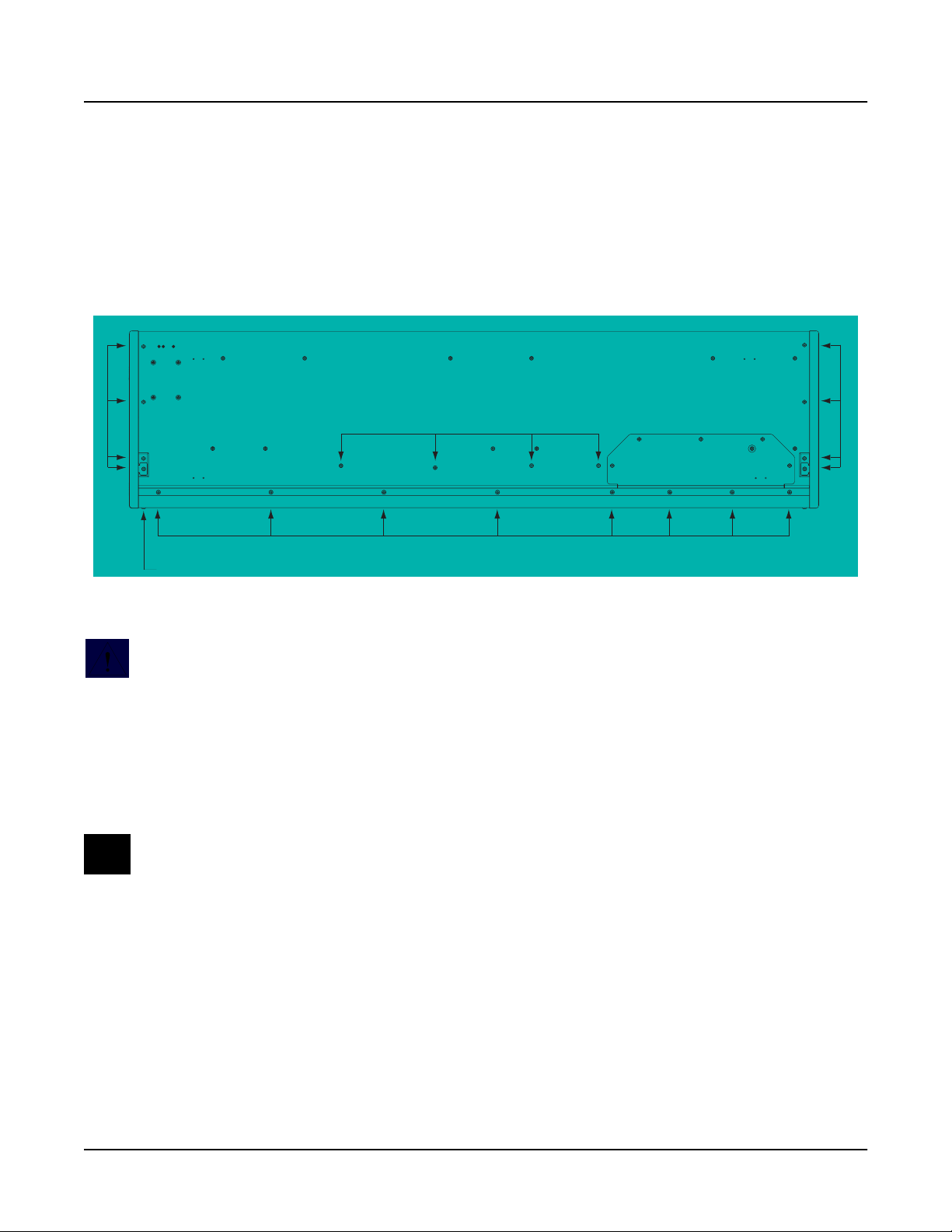

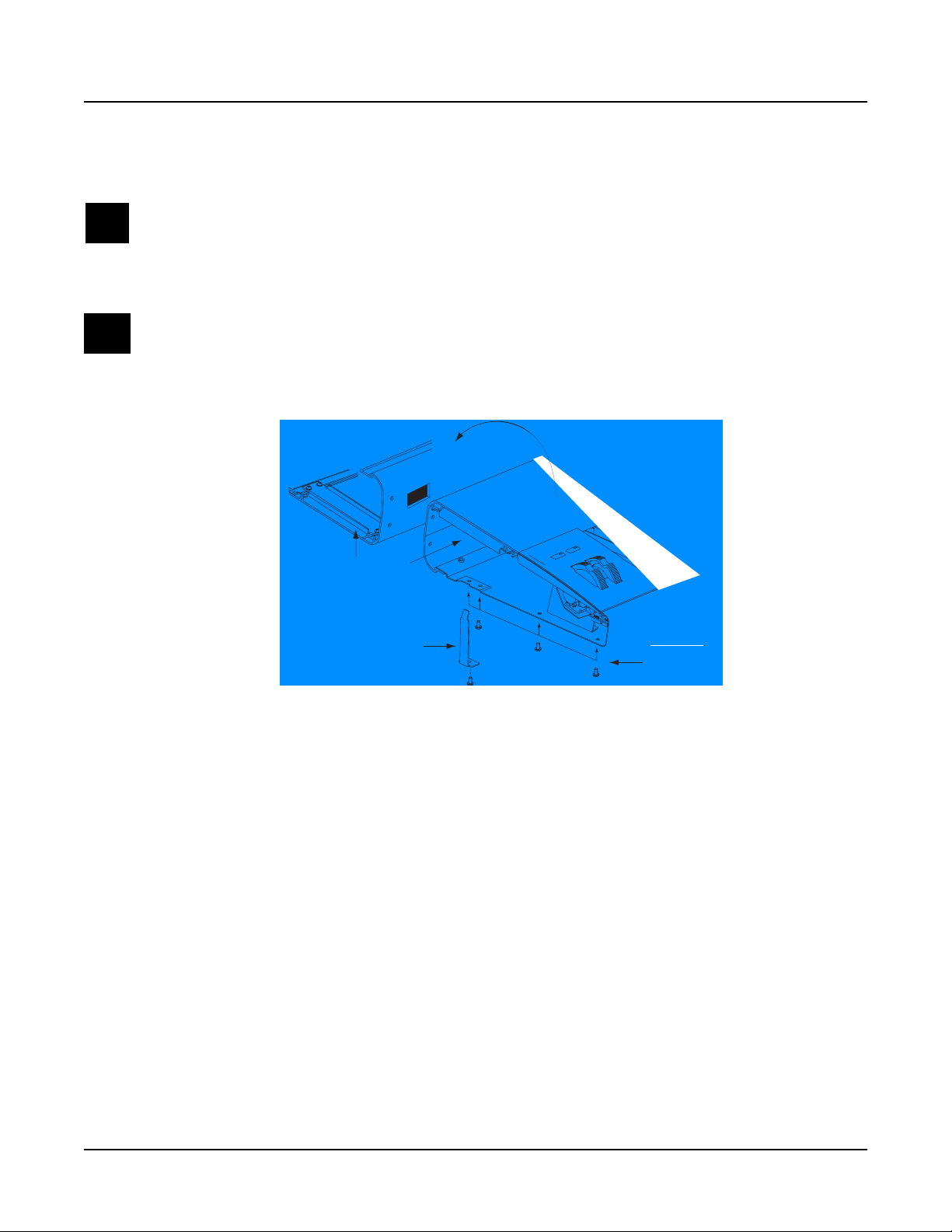

PC3x Bottom

Refer to Figure 3-1. Arrows indicate the locations of the enclosure support wall, endcap and rear

panel screws.

Keyboard

Endcap screws

Enclosure support wall screws

Access panel

*

Rear panel screws

Rear panel

*Endcap locking bracket screws

Endcap screws

*

Figure 3-1 PC3x bottom enclosure

Caution: Do not remove the endcap or rear panel screws at this point of the procedure.

1. Tilt the PC3x up and remove the four enclosure support wall screws.

2. Place the unit flat on your work surface.

3. Move the unit so that the rear panel portion of the unit hangs over the edge of your work

surface. This gives you access to the eight screws that secure the rear panel portion of the

top enclosure to the bottom enclosure. Remove the eight screws.

Note: Two of these screws also secure the rear panel portion of the access panel. It is not

necessary to remove the five remaining access panel screws.

3-2

4. Slide the unit back onto the work surface.

Page 27

Removing the Top Enclosure

The following procedure assumes that you have completed Steps 1–4 in PC3x Bottom.

Removing the top enclosure requires removing the left and right endcaps. Each endcap includes

the endcap, endcap side bracket and endcap locking bracket.

Endcap

Endcap Side Bracket

Endcap Locking Bracket

Figure 3-2 Endcap assembly

Disassembly/Assembly

Opening the PC3x

1. Refer to Figure 3-3.

2. Remove the four screws that secure the endcaps to the rear panel.

Endcap screws

Endcap screws

Figure 3-3 PC3x rear panel

3. Refer to Figure 3-1. Move the unit so that one end hangs over the edge of your work

surface.

4. Remove the endcap locking bracket screw from the bottom enclosure.

Caution: When you remove the endcap locking bracket screw, the endcap locking bracket may

remain loosely in the endcap. However, it can come out of the endcap. When you remove the

screw securing the endcap locking bracket, hold it in position so that it does not fall out of the

endcap and become lost or damaged.

5. Remove the remaining three screws and set the endcap safely aside.

6. Repeat for the other endcap.

3-3

Page 28

Disassembly/Assembly

Opening the PC3x

7. Refer to Figure 3-4. The bottom edge of the rear panel and back edge of the bottom

enclosure connect to form a lip. The rear panel screws secure the lip.

Transformer

Rear panel screw locations

Enclosure

Support Wall

Lip

Figure 3-4 Top and bottom enclosures

Warning: Be sure to have your work surface prepared. This includes

placing foam blocks behind the unit. When the top enclosure is removed,

place it on the foam blocks to avoid damaging the Alpha Wheel, control

panel buttons, and sliders. The following procedure requires enough room

behind the rear of the unit to place the top enclosure face down on your

work surface.

8. Grip each end of the top enclosure and rotate it back approximately two inches. This

separates the bottom edges of the top enclosure and bottom enclosure.

9. Lift the top enclosure straight up.

10. Turn the top enclosure over and place it face down onto your work surface.

Caution: Table 3-1 lists the cables, by board location, from the top enclosure to the assembly

they connect to on the bottom enclosure. You do not need to disconnect these cables.

3-4

Page 29

Top cover Assembly Bottom Enclosure

Connector Board, Bass Keyboard Assembly, Bass

Connector Board, Treble Keyboard Assembly, Treble

Slider Board Button Board/Wheels Assembly

Connector Board Wheels Assembly

Table 3-1 Top and bottom enclosure cables

Replacing the Top Enclosure

1. Position the top enclosure behind the bottom enclosure.

2. Move the top enclosure so that the bottom edge of the rear panel is positioned under the

bottom enclosure edge. See Figure 3-4 on page 3-4.

Note: Verify that the cables listed in Table 3-1 are lying flat on the bottom enclosure. Be sure that

all other cables are tucked between the top enclosure and the enclosure support wall.

Disassembly/Assembly

Opening the PC3x

3. Hold the top enclosure safely in place and move the unit so that one end of the rear panel

edge hangs over the edge of your work surface and install the rear panel screw at that end.

Slide the unit back onto your work surface. Repeat for other end.

Warning: Perform Steps 3 and 4 separately. Combining these steps could cause the top

enclosure to flip away from the bottom enclosure or drop off of your work surface.

4. Move the unit so that the rear panel edge of the unit hangs over the edge of your work

surface and install the remaining screws.

3-5

Page 30

Disassembly/Assembly

s

Opening the PC3x

Closing the PC3x

Warning: The following procedure assumes that you have completed Steps 3 and 4 in Replacing

the Top Enclosure. If you have not completed these steps, do so before continuing.

1. Refer to Figure 3-1. Tilt the unit up and install the four enclosure support wall screws.

Note: In addition to the rear panel screws, the endcap locking bracket secures the endcap to the

top enclosure. When the endcap locking bracket is in position, it rests against the endcap

clamping bracket located on the underside of the top enclosure. See Figure 3-5.

Endcap Clamping Bracket

Endcap Locking Bracket

Endcap Screw

Figure 3-5 Top enclosure, endcap locking and clamping brackets

2. Slide one side of the unit off of your work surface and hold the appropriate endcap and

endcap locking bracket in position.

3. Install the endcap locking bracket screw in the bottom enclosure.

4. Install the three remaining endcap screws in the bottom enclosure.

5. Repeat for the other endcap.

6. Refer to Figure 3-3. Install the four endcap screws in the rear panel.

3-6

Page 31

Top Enclosure

The top enclosure includes six boards: Connector, Front Panel, LCD, Slider, Engine, and

USB/xD Daughtercard. The enclosure support wall, transformer and AC recptacle are also

included on the top enclosure. Figure 3-6 shows the placement of the enclosure support wall on

the top enclosure. Figure 3-7 shows the placement of the boards, transformer, and AC recptacle

with the enclosure support wall removed.

Disassembly/Assembly

Top Enclosure

USB

Engine Board

Figure 3-6 Top enclosure, enclosure support wall location

Enclosure

Support Wall

Front Panel

LCD

Connector Board

Slider Board

Transformer

Figure 3-7 Top enclosure, board locations, transformer, and AC recptacle

3-7

Page 32

Disassembly/Assembly

Top Enclosure

Removing the Enclosure Support Wall

The shielded cable bundle connecting J302 on the Connector Board to J18 on the Engine Board is

routed and taped along the front of the enclosure support wall. Tape also secures the cable

bundle to the Slider and Front Panel Boards. Always peel back the tape from one side so that the

tape remains properly positioned.

Note: The routing of this cable is important to minimize noise and hum. Be sure to note the

placement of the cable so that you position it properly when you reinstall the enclosure support

wall.

1. Peel back the tape from one side to free the cable bundle from the enclosure support wall

and the Slider Board.

2. Disconnect the cable bundle from J302 on the Connector Board and move the cable bundle

away from the enclosure support wall.

3. Remove the seven screws that secure the enclosure support wall to the top enclosure, and

remove the enclosure support wall.

Replacing the Enclosure Support Wall

1. Align the center screw holes of the three-hole groupings in the enclosure support wall

with the thread marks in the extrusion.

2. Install the seven screws that secure the enclosure support wall to the top enclosure.

3. Secure the cable bundle to the front of the enclosure support wall with the tape.

4. Connect the shielded cable bundle to J302 on the Connector Board and secure it to the

Slider Board with the tape.

Note: The routing of this cable is important to minimize noise and hum. Be sure to note the

placement of the cable so that you position it properly when you reinstall the enclosure support

wall.

3-8

Page 33

Removing the Connector Board

1. Follow the procedure described on page 3-8 to remove the enclosure support wall.

2. Following Steps 3–5, disconnect the cables listed in Table 3-2.

Ref. Name Cable Type Destination

J301 PC3 Power stranded wire Engine Board

J303 MIDI/CPU stranded wire Engine Board

J304 Front Panel flat ribbon Front Panel Board

J305 Slider stranded wire Slider Board

J306 Treble flat ribbon Keyboard Assembly

J307 Bass flat ribbon Keyboard Assembly

J308 Wheels stranded wire Wheels Assembly

J324 AC power stranded wire Transformer

J325 Digital Audio Out stranded wire Engine Board

Table 3-2 Connector Board cables

Disassembly/Assembly

Top Enclosure

3. Disconnect the stranded wire cables from J301, J303, and J325 on the Connector Board.

Note: The cables used throughout the PC3x are bundled and routed so that their locations and

destinations seem obvious. However, to avoid reversing the Bass and Treble cables when

reconnecting, mark one or both cables designating B for Bass and T for Treble.

4. Disconnect the flat ribbon cables from J304, J306, and J307.

Connector Board

AC Power

J301

PC3 Power

Figure 3-8 Cable locations

5. Disconnect the stranded wire cables from J305, J308, and J324.

Dig.

Audio Out

MIDI & CPU

J303 J305

Slider Wheels

J308J325J324

Treble

J306

Bass Front Panel

J307

J304

Audio Out

J302

3-9

Page 34

Disassembly/Assembly

Top Enclosure

*

*

*

longer screws with spacers

Figure 3-9 Rear panel hardware locations

6. Remove the eight screws that secure the Connector Board to the rear panel. Two screws

are longer than the others and have spacers located between the screw and the rear panel.

See Figure 3-9 for the locations of the screws and spacers.

Note: Do not remove any other hardware from this portion of the rear panel.

7. Remove the Connector Board.

Replacing the Connector Board

Refer to Figure 3-10. The Connector Board is designed to work with a number of different

keyboards. This is determined by the position of a diode(s) on the Connector Board. There are

four diode locations, D19 through D22, located between J306 and J307 on the Connector Board.

If you are replacing the Connector Board with a new one, determine the location of the diode(s)

and be sure the new board matches the board you are removing.

3-10

Treble

J306

D19

OPT 1

D21

OPT 2

D20OPT 3

D22

OPT 4

Bass

J307

Figure 3-10 Connector Board, diode configuration

1. Hold the Connector Board and position it so that the rear panel jacks, potentiometers, and

switches are correctly positioned through the rear panel portion of the top enclosure.

2. Install the eight screws that secure the Connector Board to the rear panel. Be sure to place

a spacer and use one of the longer screws at the locations noted in Figure 3-9.

Page 35

Disassembly/Assembly

Top Enclosure

3. Connect the stranded wire cable from the Slider Board to J305 on the Connector Board.

4. Connect the stranded wire cable from the Transformer to J324 on the Connector Board.

5. Connect the stranded wire cable from the Wheels Assembly to J308.

6. Connect the flat ribbon cables from the Keyboard Assembly to J306 and J307 on the

Connector Board.

7. Connect the flat ribbon cable from the Front Panel Board to J304 on the Connector Board.

Warning: If you are replacing the Connector Board with a new board, check the flat ribbon cable

at location J202 on the Front Panel Board. Some earlier units have a small PC board attached to

the flat ribbon cable. If the unit has this small PC Board, check the value of RN10 and RN12 on

the new Connector Board. If a 6.8K resistor network is installed in RN10 and RN12, disconnect

the flat ribbon cable from J202, remove the small PC Board, and reconnect the cable directly to

the Front Panel Board.

8. Connect the stranded wire cables from the Engine Board to J301, J303, and J325 on the

Connector Board.

9. Follow the procedure on page 3-8 to install the enclosure support wall.

Removing the Slider Board

1. Follow the procedure described on page 3-8 to remove the enclosure support wall.

2. Follow the procedure described on page 3-9 to remove the Connector Board.

3. Tilt the top enclosure up and remove the ten slider knobs, then lay it flat on your work

surface.

4. Following Steps 5 and 6, disconnect the cables listed in Table 3-3.

Ref. Name Cable Type Destination

J303 Slider Bridge flat ribbon Front Panel Board

J304 IBBB stranded wire Button Board/Wheels Assembly

Table 3-3 Slider Board cables

5. Disconnect the flat ribbon cable from J303.

6. Disconnect the shielded wire cable from J304.

Note: The stranded wire cable connected to location J302 was disconnected following the

procedure to remove the Connector Board. It is not necessary to disconnect it from the Slider

Board. However, if you are replacing the Slider Board with a replacement board, be sure to

disconnect the cable and connect it to the replacement board.

7. Remove the four screws that secure the front panel edge of the Slider Board.

3-11

Page 36

Disassembly/Assembly

Top Enclosure

8. Remove the four screws that secure the two PC board clamps (two screws per clamp).

9. Remove the Slider Board.

1

J303

FP Bridge

Slider

Board

Figure 3-11 Slider Board, screw locations

These screws also secure the rear panel edge of the Board.

J304

J302

Caution: Each switch button cap uses a set of small pegs to mount the cap to a board. The

button caps on the Slider Board are mounted individually. If a cap becomes separated from the

board, be careful that a peg is not inadvertently broken.

Replacing the Slider Board

1. Position the Slider Board onto the top enclosure.

2. Raise the top enclosure up to verify that the switch button caps and slider shafts are

correctly positioned through their openings in the top enclosure.

3. Align the center screw hole on the front panel edge with the thread marks in the extrusion

and install the four screws that secure the front panel edge.

4. Place a PC board clamp in position. Align the center screw holes of the clamp with the

thread marks in the extrusion and install the two screws that secure the clamp. Repeat for

the other clamp.

5. Tilt the top enclosure up and install the ten slider knobs, then lay it flat on your work

surface.

Caution: To avoid damaging a slider, move the slider shaft to either the top or bottom end of its

travel to install a knob.

6. Connect the stranded wire cable from the Button Board on the Wheels Assembly to J304

on the Slider Board.

3-12

7. Connect the flat ribbon cable from the Front Panel Board to J303 on the Slider Board.

8. If you have disconnected the cable from J302, reconnect it.

9. Follow the procedure on page 3-10 to install the Connector Board.

10. Follow the procedure on page 3-8 to install the enclosure support wall.

Page 37

Removing the LCD Board

1. Follow the procedure described on page 3-8 to remove the enclosure support wall.

2. Follow the procedure described on page 3-9 to remove the Connector Board.

3. Disconnect the flat ribbon cable from J15 on the Engine Board. This cable is bundled with

other cables routed along the rear panel portion of the top enclosure. They are secured

with tie wraps to cable mounts. Removing the LCD requires cutting the tie wraps and

separating the flat ribbon cable from the other cables routed along the rear panel.

4. The LCD is mounted onto a bezel that is secured to the Front Panel Board. Remove the

four screws that secure the LCD to the front panel bezel.

Disassembly/Assembly