Page 1

K2600 Series

Service Manual

©2003 All rights reserved. Kurzweil is a product line of Young Chang Co.; Kurzweil is a

trademark of Young Chang Co. All other products and brand names are trademarks or

registered trademarks of their respective companies. Product features and specifications

are subject to change without notice.

Part Number: 910396 Rev. A

Page 2

t

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

The lightning flash with the arrowhead symbol,

within an equilateral triangle is intended to aler

the user to the presence of uninsulated

"dangerous voltage" within the product's

enclosure that may be of sufficient magnitude

to constitute a risk of electric shock to persons.

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE THE COVER

NO USER SERVICEABLE PARTS INSIDE

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL

The exclamation point within an equilateral

triangle is intended to alert the user to the

presence of important operating and

maintenance (servicing) instructions in the

literature accompanying the product.

IMPORTANT SAFETY & INSTALLATION INSTRUCTIONS

INSTRUCTIONS PERTAINING TO THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS

WARNING: When using electric products, basic precautions should

always be followed, including the following:

1. Read all of the Safety and Installation Instructions and Explanation

of Graphic Symbols before using the product.

2. Do not use this product near water—for example, near a bathtub,

washbowl, kitchen sink, in a wet basement, or near a swimming

pool, or the like.

3. This product should be used only with a stand or cart that is

recommended by the manufacturer.

4. This product, either alone or in combination with an amplifier and

speakers or headphones, may be capable of producing sound

levels that could cause permanent hearing loss. Do not operate for

a long period of time at a high volume level or at a level that is

uncomfortable. If you experience any hearing loss or ringing in the

ears, you should consult an audiologist.

5. The product should be located so that its location or position does

not interfere with its proper ventilation.

6. The product should be located away from heat sources such as

radiators, heat registers, or other products that produce heat.

7. The product should be connected to a power supply only of the type

described in the operating instructions or as marked on the product.

8. This product may be equipped with a polarized line plug (one blade

wider than the other). This is a safety feature. If you are unable to

insert the plug into the outlet, contact an electrician to replace your

obsolete outlet. Do not defeat the safety purpose of the plug.

9. The power supply cord of the product should be unplugged from the

outlet when left unused for a long period of time. When unplugging

the power supply cord, do not pull on the cord, but grasp it by the

plug.

10. Care should be taken so that objects do not fall and liquids are not

spilled into the enclosure through openings.

11. The product should be serviced by qualified service personnel

when:

A. The power supply cord or the plug has been damaged;

B. Objects have fallen onto, or liquid has been spilled into the

product;

C. The product has been exposed to rain;

D. The product does not appear to be operating normally or

exhibits a marked change in performance;

E. The product has been dropped, or the enclosure damaged.

12. Do not attempt to service the product beyond that described in the

user maintenance instructions. All other servicing should be

referred to qualified service personnel.

13. WARNING: Do not place objects on the product’s power supply

cord, or place the product in a position where anyone could trip

over, walk on, or roll anything over cords of any type. Do not allow

the product to rest on or be installed over cords of any type.

Improper installations of this type create the possibility of a fire

hazard and/or personal injury.

RADIO AND TELEVISION INTERFERENCE

WARNING: Changes or modifications to this instrument not expressly

approved by Young Chang could void your authority to operate the

instrument.

IMPORTANT: When connecting this product to accessories and/or other

equipment use only high quality shielded cables.

NOTE: This instrument has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference when the instrument is used in a commercial

environment. This instrument generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this instrument in a residential area is

likely to cause harmful interference, in which case the user will be

required to correct the interference at his or her own expense.

Changes and modifications not expressly approved by the manufacturer

SAVE THESE INSTRUCTIONS

ii

or registrant of this instrument can void the user’s authority to operate

this instrument under Federal Communications Commission rules.

In order to maintain compliance with FCC regulations, shielded cables

must be used with this instrument. Operation with unapproved

equipment or unshielded cables is likely to result in harmful interference

to radio and television reception.

NOTICE

This apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus set out in the Radio Interference

Regulations of the Canadian Department of Communications.

AVIS

Le present appareil numerique n’emet pas de bruits radioelectriques

depassant les limites applicables aux appareils numeriques de la

class A prescrites dans le Reglement sur le brouillage radioelectrique

edicte par le ministere des Communications du Canada.

Page 3

Young Chang Distributors

Contact the nearest Young Chang office listed below to locate your local Young Chang/Kurzweil

representative.

A N D Music Corp.

P.O. Box 99995

Lakewood, WA 98499-0995

Tel: (253) 589-3200

Fax: (253) 984-0245

Young Chang Akki Co., Ltd.

178-55 Gajwa-Dong

Seo-Ku, Inchon

Korea 404-250

Tel: 011-82-32-570-1380

Fax: 011-82-32-570-1218

Young Chang America, Inc. (Canadian Division)

P.O. Box 61515

9350 Yonge Street

Richmond Hill, Ontario

Canada L4C 3N0

Tel: (905) 508-0531

Fax: (905) 508 1308

iii

Page 4

Page 5

Kurzweil K2600 Series Service Manual

Contents

Young Chang Distributors ............................................................................................................................................... iii

Chapter 1 Introduction

Models ....................................................................................................................................................................... 1-1

Notes, Cautions, Warnings ..................................................................................................................................... 1-1

K2600/X Rear Panel........................................................................................................................................................ 1-2

K2600R Rear Panel .......................................................................................................................................................... 1-2

Rear Panel Features......................................................................................................................................................... 1-3

All Models................................................................................................................................................................. 1-3

Keyboard Models only............................................................................................................................................ 1-3

Rack Models only..................................................................................................................................................... 1-3

K2600/X Front Panel ...................................................................................................................................................... 1-4

Front Panel Features ....................................................................................................................................................... 1-5

All Models................................................................................................................................................................. 1-5

Keyboard Models only............................................................................................................................................ 1-5

K2600R Front Panel......................................................................................................................................................... 1-6

Rack Models only..................................................................................................................................................... 1-6

Contents

Chapter 2 Diagnostics

Diagnostic Tests ............................................................................................................................................................... 2-1

Saving User Data............................................................................................................................................................. 2-1

Entering Diagnostics....................................................................................................................................................... 2-2

LCD and Front Panel Buttons ................................................................................................................................ 2-2

Test Results................................................................................................................................................................ 2-3

Diagnostic Test Menus.................................................................................................................................................... 2-3

Main Menu................................................................................................................................................................ 2-3

Burn-In Menu ........................................................................................................................................................... 2-3

Forever....................................................................................................................................................................... 2-3

Description of Tests......................................................................................................................................................... 2-4

LCD ............................................................................................................................................................................ 2-4

Engine Blk (Engine Block) ...................................................................................................................................... 2-4

Object Blk (Object Block)......................................................................................................................................... 2-4

RAM/PRAM............................................................................................................................................................. 2-5

I/O Port ..................................................................................................................................................................... 2-5

FDD Init (Floppy Disk Drive Initialize)................................................................................................................ 2-6

Scanner ...................................................................................................................................................................... 2-6

MIDI Uart.................................................................................................................................................................. 2-6

FDD R/W (Floppy Disk Drive Read/Write) ....................................................................................................... 2-6

SCSI ............................................................................................................................................................................ 2-7

VLSI & ZRAM .......................................................................................................................................................... 2-7

Hobbes................................................................................................................................................................ 2-7

Janis..................................................................................................................................................................... 2-7

Lisa...................................................................................................................................................................... 2-8

Sampling Opt (Sampling Option).......................................................................................................................... 2-8

Test access to sampling option........................................................................................................................ 2-8

Test analog-sampling circuitry........................................................................................................................ 2-8

Test digital-sampling circuitry........................................................................................................................ 2-9

i

Page 6

Kurzweil K2600 Series Service Manual

Contents

Sine Wave .................................................................................................................................................................. 2-9

Sound ROM ............................................................................................................................................................ 2-10

Sound RAM ............................................................................................................................................................ 2-10

1st NVRAM..............................................................................................................................................................2-11

2nd NVRAM............................................................................................................................................................2-11

Digital IO..................................................................................................................................................................2-11

Chapter 3 K2600R Disassembly/Assembly

Introduction ..................................................................................................................................................................... 3-1

Saving User Data...................................................................................................................................................... 3-1

Cables, Connectors................................................................................................................................................... 3-1

Tools Required.......................................................................................................................................................... 3-1

Opening the K2600R ....................................................................................................................................................... 3-2

Removing the Top Cover ........................................................................................................................................ 3-2

Replacing the Top Cover......................................................................................................................................... 3-2

Removing the Audio Board.................................................................................................................................... 3-3

Replacing the Audio Board..................................................................................................................................... 3-3

Removing the Digital I/O Option Board.............................................................................................................. 3-3

Replacing the Digital I/O Option Board .............................................................................................................. 3-4

Removing the Small Digital I/O Board ................................................................................................................ 3-4

Replacing the Small Digital I/O Board................................................................................................................. 3-5

Removing the DSP Board........................................................................................................................................ 3-5

Replacing the DSP Board ........................................................................................................................................ 3-6

Removing the CPU Board....................................................................................................................................... 3-6

Replacing the CPU Board ....................................................................................................................................... 3-8

Removing the Power Supply Board...................................................................................................................... 3-9

Replacing the Power Supply Board....................................................................................................................... 3-9

Removing the Transformer..................................................................................................................................... 3-9

Replacing the Transformer.................................................................................................................................... 3-10

Removing the Backlight Board ............................................................................................................................ 3-10

Replacing the Backlight Board ............................................................................................................................. 3-10

Removing the Fan ...................................................................................................................................................3-11

Replacing the Fan....................................................................................................................................................3-11

Front Panel Assembly................................................................................................................................................... 3-12

Removing the Front Panel Cover......................................................................................................................... 3-12

Replacing the Front Panel Cover ......................................................................................................................... 3-12

Removing the Front Panel Mounting Bracket ................................................................................................... 3-12

Replacing the Front Panel Mounting Bracket.................................................................................................... 3-14

Removing the Front Panel/Scanner Board ........................................................................................................ 3-15

Replacing the Front Panel/Scanner Board......................................................................................................... 3-15

Removing the LCD Board..................................................................................................................................... 3-16

Replacing the LCD Board ..................................................................................................................................... 3-16

Removing the AC Entry Module......................................................................................................................... 3-16

Replacing the AC Entry Module.......................................................................................................................... 3-17

Removing the Floppy Disk Drive........................................................................................................................ 3-17

Replacing the Floppy Disk Drive......................................................................................................................... 3-17

Removing the Hard Disk Drive ........................................................................................................................... 3-18

Replacing the Hard Disk Drive............................................................................................................................ 3-18

Removing the Sampling Board ............................................................................................................................ 3-18

Replacing the Sampling Board............................................................................................................................. 3-19

ii

Page 7

Kurzweil K2600 Series Service Manual

Chapter 4 K2600/K2600X Disassembly/Assembly

Introduction ..................................................................................................................................................................... 4-1

Saving User Data...................................................................................................................................................... 4-1

Notes, Cautions, Warnings ..................................................................................................................................... 4-1

Cables, Connectors................................................................................................................................................... 4-1

Tools Required.......................................................................................................................................................... 4-1

Opening the K2600/K2600X.......................................................................................................................................... 4-2

K2600 Bottom............................................................................................................................................................ 4-2

K2600X Bottom......................................................................................................................................................... 4-3

Removing the Top Enclosure.................................................................................................................................. 4-4

Replacing the Top Enclosure .................................................................................................................................. 4-5

Closing the K2600/K2600X .................................................................................................................................... 4-5

Top Enclosure................................................................................................................................................................... 4-6

Removing the Audio Board.................................................................................................................................... 4-7

Replacing the Audio Board..................................................................................................................................... 4-7

Removing the Disk Drive ....................................................................................................................................... 4-7

Replacing the Disk Drive ........................................................................................................................................ 4-7

Removing the Digital I/O Option Board.............................................................................................................. 4-8

Replacing the Digital I/O Option Board .............................................................................................................. 4-8

Removing the Small Digital I/O Board ................................................................................................................ 4-8

Replacing the Small Digital I/O Board................................................................................................................. 4-9

Removing the Sampling Board .............................................................................................................................. 4-9

Replacing the Sampling Board............................................................................................................................... 4-9

Removing the Slider Board................................................................................................................................... 4-10

Replacing the Slider Board ................................................................................................................................... 4-10

Removing the LCD Board......................................................................................................................................4-11

Replacing the LCD Board ......................................................................................................................................4-11

Removing the Backlight Board ............................................................................................................................ 4-12

Replacing the Backlight Board ............................................................................................................................. 4-12

Removing the Control Panel Board..................................................................................................................... 4-13

Replacing the Control Panel Board ..................................................................................................................... 4-13

Bottom Enclosure .......................................................................................................................................................... 4-15

Removing the Keyboard Scanner Board............................................................................................................. 4-15

Replacing the Keyboard Scanner Board ............................................................................................................. 4-15

Removing the DSP Board...................................................................................................................................... 4-15

Replacing the DSP Board ...................................................................................................................................... 4-16

Removing the CPU Board..................................................................................................................................... 4-16

Replacing the CPU Board ..................................................................................................................................... 4-17

Removing the Power Supply Board.................................................................................................................... 4-17

Replacing the Power Supply Board..................................................................................................................... 4-18

Removing the Transformer................................................................................................................................... 4-18

Replacing the Transformer.................................................................................................................................... 4-18

Removing the Fan .................................................................................................................................................. 4-18

Replacing the Fan................................................................................................................................................... 4-19

Removing the Hard Disk Drive ........................................................................................................................... 4-19

Replacing the Hard Disk Drive............................................................................................................................ 4-19

Removing the Mod Wheel Assembly.................................................................................................................. 4-19

Replacing the Mod Wheel Assembly .................................................................................................................. 4-20

K2600 Keyboard Assembly.......................................................................................................................................... 4-21

Removing the K2600 Keyboard Assembly......................................................................................................... 4-21

Replacing the K2600 Keyboard Assembly.......................................................................................................... 4-22

Disconnecting the K2600 Keyboard .................................................................................................................... 4-23

Contents

iii

Page 8

Kurzweil K2600 Series Service Manual

Contents

Connecting the Keyboard ..................................................................................................................................... 4-23

Removing Keys ...................................................................................................................................................... 4-24

Natural/White Key ........................................................................................................................................ 4-24

Natural/White Keys.............................................................................................................................................. 4-25

Sharp/Black Keys .................................................................................................................................................. 4-25

Replacing a Key...................................................................................................................................................... 4-26

Servicing the Keyboard Contact Boards............................................................................................................. 4-26

Removing the Treble Contact Board ............................................................................................................ 4-26

Replacing the Treble Contact Board............................................................................................................. 4-26

Removing the Bass Contact Board ............................................................................................................... 4-26

Replacing the Bass Contact Board................................................................................................................ 4-26

Removing the Keyboard Contact Strips ............................................................................................................. 4-27

Replacing the Keyboard Contact Strips.............................................................................................................. 4-27

K2600X Keyboard Assembly ....................................................................................................................................... 4-28

Removing the K2600X Keyboard Assembly ...................................................................................................... 4-28

Replacing the K2600X Keyboard Assembly....................................................................................................... 4-29

Removing Keys ...................................................................................................................................................... 4-29

Natural/White Key ........................................................................................................................................ 4-30

Natural/White Keys.............................................................................................................................................. 4-30

Sharp/Black Keys .................................................................................................................................................. 4-31

Replacing a Key...................................................................................................................................................... 4-32

Servicing the Keyboard Contact Boards............................................................................................................. 4-32

Removing the Treble Contact Board ............................................................................................................ 4-32

Replacing the Treble Contact Board............................................................................................................. 4-32

Removing the Bass Contact Board ............................................................................................................... 4-32

Replacing the Bass Contact Board................................................................................................................ 4-32

Removing the Keyboard Contact Strips ............................................................................................................. 4-33

Replacing the Keyboard Contact Strips.............................................................................................................. 4-33

Removing a Key Weight........................................................................................................................................ 4-34

Replacing a Key Weight ........................................................................................................................................ 4-34

Chapter 5 Troubleshooting

Introduction ..................................................................................................................................................................... 5-1

Surface-Mount Devices ........................................................................................................................................... 5-1

Cables, Connectors................................................................................................................................................... 5-1

Using the Disk Drive ...................................................................................................................................................... 5-1

Formatting Floppy Disks ........................................................................................................................................ 5-1

Saving User Data...................................................................................................................................................... 5-2

Loading Saved Data................................................................................................................................................. 5-2

Boot Loader...................................................................................................................................................................... 5-3

Entering the Boot Loader........................................................................................................................................ 5-3

Hard Reset................................................................................................................................................................. 5-3

Soft Reset ................................................................................................................................................................... 5-4

Installing the Operating System ............................................................................................................................ 5-4

Installing Objects...................................................................................................................................................... 5-4

Replacing the Battery...................................................................................................................................................... 5-5

Removing the Battery.............................................................................................................................................. 5-5

Installing a Battery................................................................................................................................................... 5-5

Scanner Diagnostics ........................................................................................................................................................ 5-6

K2600R Rack Models ............................................................................................................................................... 5-6

Front Panel Buttons ................................................................................................................................................. 5-6

iv

Page 9

Kurzweil K2600 Series Service Manual

Contents

Alpha Wheel ............................................................................................................................................................. 5-6

K2600 Keyboard Models......................................................................................................................................... 5-7

Front Panel Sliders................................................................................................................................................... 5-7

Wheels ....................................................................................................................................................................... 5-7

Small Ribbon............................................................................................................................................................. 5-8

Large Ribbon............................................................................................................................................................. 5-8

Keyboard ................................................................................................................................................................... 5-8

Switch Pedals 1, 2, 3, and 4 ..................................................................................................................................... 5-8

CC Pedals 1 and 2 .................................................................................................................................................... 5-8

Power Up Problems ........................................................................................................................................................ 5-9

Dead, No Power ....................................................................................................................................................... 5-9

Blue Screen................................................................................................................................................................ 5-9

Locks Up, Freezes .................................................................................................................................................. 5-10

‘Running System…’ or Fails VLSI/ZRAM test in diagnostics:................................................................ 5-10

‘Waking up Scanner’ ...................................................................................................................................... 5-10

‘V.A.S.T.’ Sign Wave on boot-up or Fails Sound ROM, Sound RAM or VLSI diagnostic tests ........... 5-10

“Please Wait…” when trying to load from floppy disk: ........................................................................... 5-10

“Please Wait…” when trying to load from SCSI: ....................................................................................... 5-10

Fails Sound RAM Diagnostic test ........................................................................................................................ 5-10

Front Panel Problems.....................................................................................................................................................5-11

Boots up with three Flashes...................................................................................................................................5-11

LCD not lit................................................................................................................................................................5-11

Buttons, Sliders or Controllers Not Working......................................................................................................5-11

Audio Problems............................................................................................................................................................. 5-12

Intermittent or No Audio...................................................................................................................................... 5-12

No Audio, Distortion, or Noisey Outputs.......................................................................................................... 5-12

Right Channel.................................................................................................................................................. 5-12

Left Channel .................................................................................................................................................... 5-12

Full volume static distortion after 10-15 minutes of warm-up then locks-up: ...................................... 5-12

Different clicks and pops on each effect or consistent ‘thumping’ noise in all outputs:...................... 5-12

Boots up normally but has no sound,.......................................................................................................... 5-12

Keyboard Problems....................................................................................................................................................... 5-13

Keyboard velocity problems................................................................................................................................. 5-13

Dead Keyboard....................................................................................................................................................... 5-13

Dead Note(s), One or More in a Section...................................................................................................... 5-13

Mechanical Noise............................................................................................................................................ 5-13

K2600/K2600X Interconnect Diagram ....................................................................................................................... 5-14

K2600R Interconnect Diagram..................................................................................................................................... 5-15

Chapter 6 Parts Lists

Introduction ..................................................................................................................................................................... 6-1

K2600R, K2600RS ..................................................................................................................................................... 6-1

K2600, K2600S, K2600X, K2600XS, K2600 AES.................................................................................................... 6-2

K2600 Series ..................................................................................................................................................................... 6-3

CPU Board, N012305411 ......................................................................................................................................... 6-3

DSP Board, N012305413.......................................................................................................................................... 6-5

K2600R/K2600RS............................................................................................................................................................ 6-6

Audio Board, N012305605 ...................................................................................................................................... 6-6

Backlight Board, N012104325................................................................................................................................. 6-7

FLoppy Disk Drive Assembly, N012104665 ......................................................................................................... 6-7

LCD Board, N012103796 ......................................................................................................................................... 6-7

v

Page 10

Kurzweil K2600 Series Service Manual

Contents

Phone & Volume Assembly, N012401127.............................................................................................................. 6-8

AC Entry Module Assembly, N012104121 ........................................................................................................... 6-8

Power Supply Board, N012304340 ........................................................................................................................ 6-8

Front Panel/Scanner Board, N012305417........................................................................................................... 6-10

Final Assembly, N012000134 .................................................................................................................................6-11

K2600 Series Keyboard Models................................................................................................................................... 6-13

Audio Board, N012305611..................................................................................................................................... 6-13

Button Board, N012304344.................................................................................................................................... 6-14

Control Panel Board, N012104341 ....................................................................................................................... 6-14

Floppy Disk Drive Assembly, N012104666 ........................................................................................................ 6-15

Backlight Board, N012104311 ............................................................................................................................... 6-15

Super Ribbon Assembly, N044011513 ................................................................................................................. 6-16

Pitch & Mod Wheel Assembly, N012304338 ...................................................................................................... 6-16

Player Control Board, N012104337...................................................................................................................... 6-16

AC Entry Module, N012104111............................................................................................................................ 6-17

Power Supply Board, N012304339 ...................................................................................................................... 6-17

Keyboard Scanner Board, N012305415 ............................................................................................................... 6-19

Slider Board, N012104345 ..................................................................................................................................... 6-20

K2600/K2600S ............................................................................................................................................................... 6-21

LCD Board, N012103794 ....................................................................................................................................... 6-21

Final Assembly, N012002131 ................................................................................................................................ 6-21

Keyboard Assembly, N215040311........................................................................................................................ 6-23

K2600X/K2600XS/K2600 AES .................................................................................................................................... 6-24

LCD Board, N012103798 ....................................................................................................................................... 6-24

Final Assembly, N012000133 ................................................................................................................................ 6-24

Keyboard Assembly, N215040413........................................................................................................................ 6-26

Chapter 7 Schematics

CPU Board–CPU, Sampler Interface (1 of 8)............................................................................................................... 7-3

CPU Board–Flash, SRAM, Expansion PRAM (2 of 8)................................................................................................ 7-4

CPU Board–FDD, LCD, MIDI Interface (3 of 8).......................................................................................................... 7-5

CPU Board–SCSI Interface (4 of 8)................................................................................................................................ 7-6

CPU Board–JANIS, DAC Interface (5 of 8).................................................................................................................. 7-7

CPU Board–Sound Memory Interface (6 of 8) ............................................................................................................ 7-8

CPU Board–Sound Memory (7 of 8)............................................................................................................................. 7-9

CPU Board–Connectors and Decoders (8 of 8)......................................................................................................... 7-10

DSP Board–Vast Chain (1 of 5) .....................................................................................................................................7-11

DSP Board–FX LISAs, DITHER (2 of 5) ..................................................................................................................... 7-12

DSP Board–DRAM 3/5V Addr/Data Buffers (3 of 5).............................................................................................. 7-13

DSP Board–FX Delay RAM (4 of 5)............................................................................................................................. 7-14

DSP Board–System Init, Dig IO Int, Decode, Clock (5 of 5).................................................................................... 7-15

Backlight Inverter Board .............................................................................................................................................. 7-17

Audio Board (rack models)–A DACs, B DACs, Filters (1 of 4)............................................................................... 7-18

Audio Board (rack models)–C DACs, D DACs, Filters (2 of 4).............................................................................. 7-19

Audio Board (rack models)–A, B, C, D Balanced Outs (3 of 4) .............................................................................. 7-20

Audio Board (rack models)–Mix Output, Phones Output (4 of 4)......................................................................... 7-21

Front Panel/Scanner Board (rack models)–Scanner, Front Panel I/F................................................................... 7-22

Audio Board (keyboard models)–A DACs, B DACs, Filters (1 of 4) ..................................................................... 7-23

Audio Board (keyboard models)–C DACs, D DACs, Filters (2 of 4)..................................................................... 7-24

Audio Board (keyboard models)–A, B, C, D Balanced Outs (3 of 4) ..................................................................... 7-25

Audio Board (keyboard models)–Mix Output, Phones Output (4 of 4)................................................................ 7-26

vi

Page 11

Kurzweil K2600 Series Service Manual

Contents

Front Panel Board (keyboard models)–Buttons and LEDs ..................................................................................... 7-27

Slider Board (keyboard models) ................................................................................................................................. 7-28

Scanner Board (keyboard models)–Scanner Kybd I/F, Play I/F (1 of 2) .............................................................. 7-29

Scanner Board (keyboard models)–Power, Dig I/O (2 of 2)................................................................................... 7-30

Player Control Board (keyboard models)–Player Control Interface...................................................................... 7-31

Itty Bitty Button Board (keyboard models) ............................................................................................................... 7-32

Digital I/O Board–Relays, AES Encoding, KDS Encoding (1 of 3)........................................................................ 7-33

Digital I/O Board–KDS & AES In/Out connectors (2 of 3).................................................................................... 7-34

Digital I/O Board–KDS In (3 of 3) .............................................................................................................................. 7-35

ROM Expansion Daughter Board–Sound Memory Control, Connectors............................................................. 7-36

Sampling Option Board (SMP-2)–Analog A/D (1 of 4)........................................................................................... 7-37

Sampling Option Board (SMP-2)–System Interface (2 of 4).................................................................................... 7-38

Sampling Option Board (SMP-2)–Digital Interface (3 of 4)..................................................................................... 7-39

Sampling Option Board (SMP-2)–Analog Input (4 of 4) ......................................................................................... 7-40

vii

Page 12

Kurzweil K2600 Series Service Manual

Contents

viii

Page 13

Chapter 1

Introduction

This chapter provides the service technician with a layout of the front and rear panel features, as

well as a brief explanation of their functions. For in-depth descriptions of the many features the

K2600 Series instruments include, consult the Musician’s Guide.

This chapter also includes a description of the models available in the K2600 Series and a

description of the symbols used throughout this manual.

Note: If possible, all user data should be saved prior to opening the unit, entering the Boot

Loader to run diagnostics or to perform a hard reset. For instructions to save all user data, refer

to Chapter 5, Saving User Data on page 5-1.

Models

There are seven models in the K2600 Series. The available models are listed below.

• K2600, 76-note keyboard

• K2600S, 76-note keyboard with built-in sampler

• K2600X, 88-note keyboard

• K2600XS, 88-note keyboard with built-in sampler

• K2600R, Rack-mount

• K2600RS, Rack-mount with built-in sampler

• K2600 AES, 88-note keyboard with built-in sampler, digital I/O, DMTI, and sample libraries

Notes, Cautions, Warnings

Please pay special attention to all Notes, Cautions, and Warnings used throughout this manual

as they not only point out specific instructions, but also alert you to differences between the

K2600R rack units, the 76-note K2600 keyboard, and the 88-note K2600X keyboard. Certain

chapters and sections are solely for the keyboard or rack unit. Other chapters combine both the

keyboard and rack units.

A brief description of these symbols follows:

Note: Provides additional information, indicates differences between models, and emphasizes

specific instructions.

Caution: Highlights areas to instruct you to proceed cautiously so that damage does not occur

to the unit or individual components.

Warning: Alerts you so that damage does not occur to yourself, others, or external equipment

and devices.

Page 14

Introduction

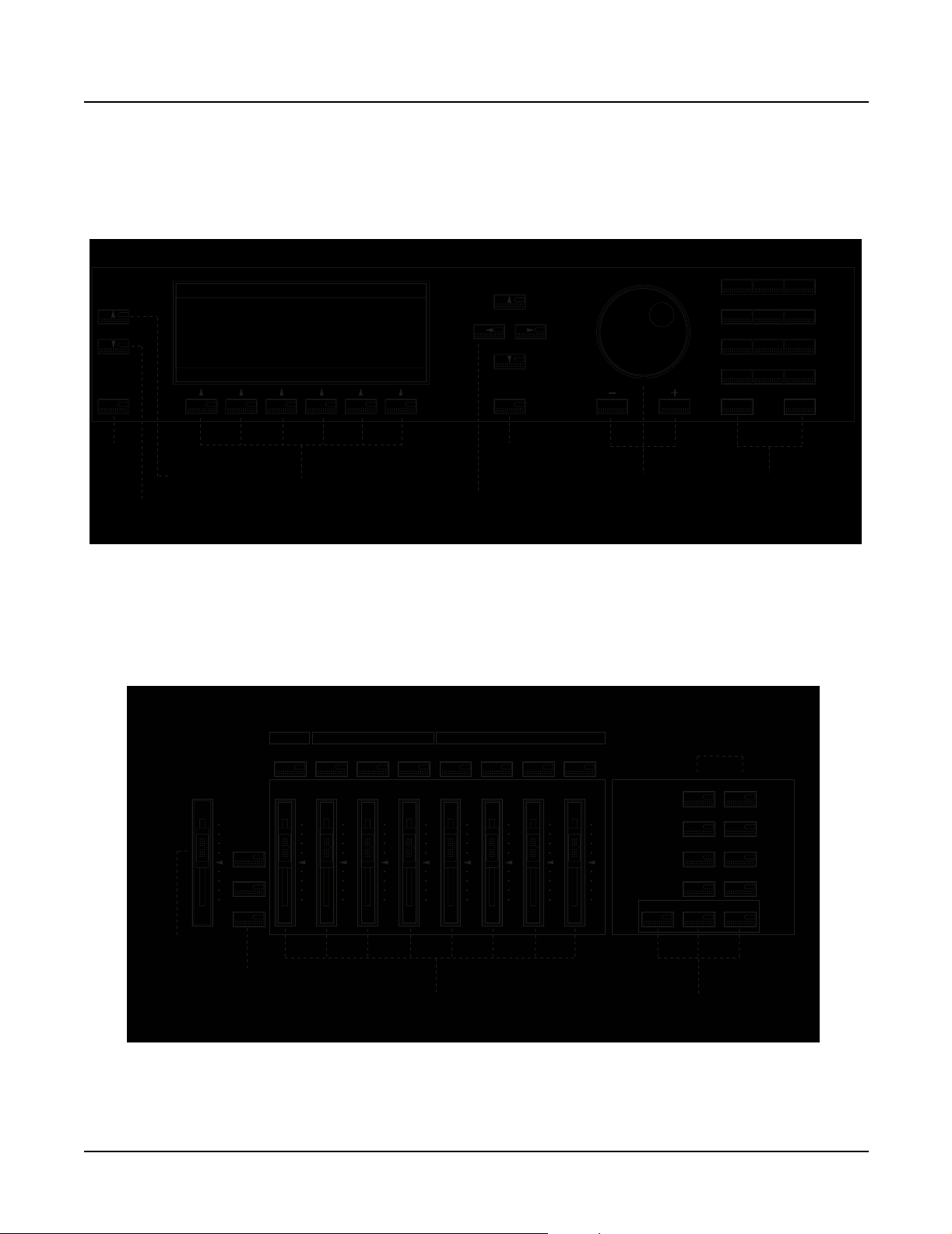

K2600/X Rear Panel

K2600/X Rear Panel

100/120V ~ F2.0A 250V slow-blow

230/240V ~ F1.0A 250V slow-blow

100/120/230/240V ~ AC

1.5/.75 A

50-60 Hz

WARNING

ATTENTION

FOR CONTINUED PROTECTION AGAINST

UTILISER UN FUSIBLE DE

THE RISK OF FIRE, REPLACE ONLY WITH

RECHANGE DE MEME TYPE.

THE SAME TYPE AND RATING OF FUSE.

Power

Entry Module

Figure 1-1 K2600/X rear panel

K2600R Rear Panel

Analog Outputs

Bal/Unbal

SCSI Termination

Auto / Disable

SCSI

Termination

Switch

SCSI

SCSI

Ports

SCSI Thru

Optical

MIDI

In Thru / Out Out

MIDI

Ports

Mix

Outputs

Inputs

In

Analog

Analog Inputs

Optical

In

Lo ZLeft RightLo Z

MIDI Select

Thru / Out

MIDI

Select Switch

Kurzweil

Kurzweil I/O

Left

Right

Hi Z

LCD Contrast

LCD

Contrast

Optical

I/O

KDS Out DMTi In

CC Pedals / Breath

Breath12or

CC Pedals/

Breath

Out

Digital

Digital I/O

Optical

Out

Out In

Switch Pedals

1234

Switch

Pedals

Analog Outputs

I/O

Analog Outputs

Bal/Unbal

Bal/Unbal

Left

BDCA

Right

Headphones

Mix

Outputs

(mono)

Mix

Headphones

Power

Entry Module

1-2

Bal/UnbalAnalog Outputs

A

LR

Kurzweil I/O

KDS Out DMTi In

Auto/Disable

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES. OPERATION IS SUBJECT TO THE FOLLOWING TWO CONDITIONS:

(1) THIS DEVICE MAY CAUSE HARMFUL INTERFERENCE, AND (2) THIS DEVICE MUST ACCEPT ANY INTERFERENCE

RECEIVED, INCLUDING INTERFERENCE THAT MAY CAUSE UNDESIRED OPERATION.

SCSI

B

LR

Optical

Out

SCSI Thru

SCSI

Termination

Switch

Kurzweil

I/O

SCSI

Ports

Figure 1-2 K2600R rear panel

C

LR

Digital I/O

Out In

Optical

Out

D

LR

MIDI

In Thru / Out Out

Digital

I/O

Mix

(mono)

LR

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

ATTENTION

RISQUE DE CHOC ELECTRIQUE

NE PAS OUVRIR

MIDI

Ports

WARNING:

WHEN TRANSPORTING

RACK-MOUNTED K2600R,

SUPPORT REAR OF UNIT

TO PREVENT DAMAGE.

WARN ING:

TO REDUCE RISK OF FIRE AND

ELECTRIC SHOCK, DO NOT

EXPOSE THIS PRODUCT TO

RAIN OR MOISTURE.

Mfr: Young Chang Akki, Co., LTD

Made in Korea

Serial No.

MIDI SelectSCSI Termination

Thru / Out

MIDI

Select Switch

WARNING:

FOR CONTINUED PROTECTION AGAINST THE RISK

OF FIRE, REPLACE ONLY WITH THE SAME TYPE AND RATING OF FUSE.

ATT ENTION:

UTILISER UN FUSIBLE DE RECHANGE DE MEME TYPE.

100/120/230/240V ~ AC

1.5/.75 A

48-65 Hz

100/120V ~ F2.0A 250V slow-blow

230/240V ~ F1.0A 250V slow-blow

Page 15

Rear Panel Features

All Models

• Mix Outputs, use these two 1/4” jacks (Left is mono) to connect either T/S or T/R/S cables.

• Analog Outputs Bal/Unbal, configure these 1/4” jacks (four pairs, A–D) as stereo pairs of

individual mono outputs.

• SCSI ports, use these two ports to connect a hard drive or other SCSI devices.

• SCSI Termination switch, a slide switch to select either Auto or Disable for SCSI termination.

• MIDI ports, In, Thru/Out, and Out, to use with other MIDI devices to receive, pass, and

send MIDI data.

MIDI Select switch, a slide switch to select the operation of the Thru/Out port.

•

• Kurzweil I/O, use these serial ports to send or receive the Kurzweil KDS format.

• Digital I/O, use these XLR jacks to send or receive digital information.

• Optical Out, use this jack to send or receive digital information from external devices with

an optical in jack.

Introduction

Rear Panel Features

Keyboard Models only

• Power Entry Module, includes the power switch, AC connector, fuse holder, and voltage

select switch.

• LCD Contrast, turn this potentiometer to adjust the LCD for the best visibility.

• CC Pedals/Breath, use these two 1/4” jacks to connect external control pedals (10kΩ linear

taper potentiometer, ring/tip/sleeve). Use the 3.5mm jack to connect a breath controller.

• Switch Pedals, use these four 1/4” jacks to connect footswitches.

• Inputs, this section is covered by a plate if the sampling option is not installed.

• For units with the sampling option, use either the two Lo Z XLR or the Hi Z 1/4”

(tip/ring/sleeve) jacks for sampling from an analog source.

• Optical In, If sampling from a digital source with an optical out jack, use this input.

• Headphones: use this 1/4” jack to connect headphones.

Rack Models only

• Power Entry Module, includes the AC connector, fuse holder, and voltage select switch.

1-3

Page 16

Introduction

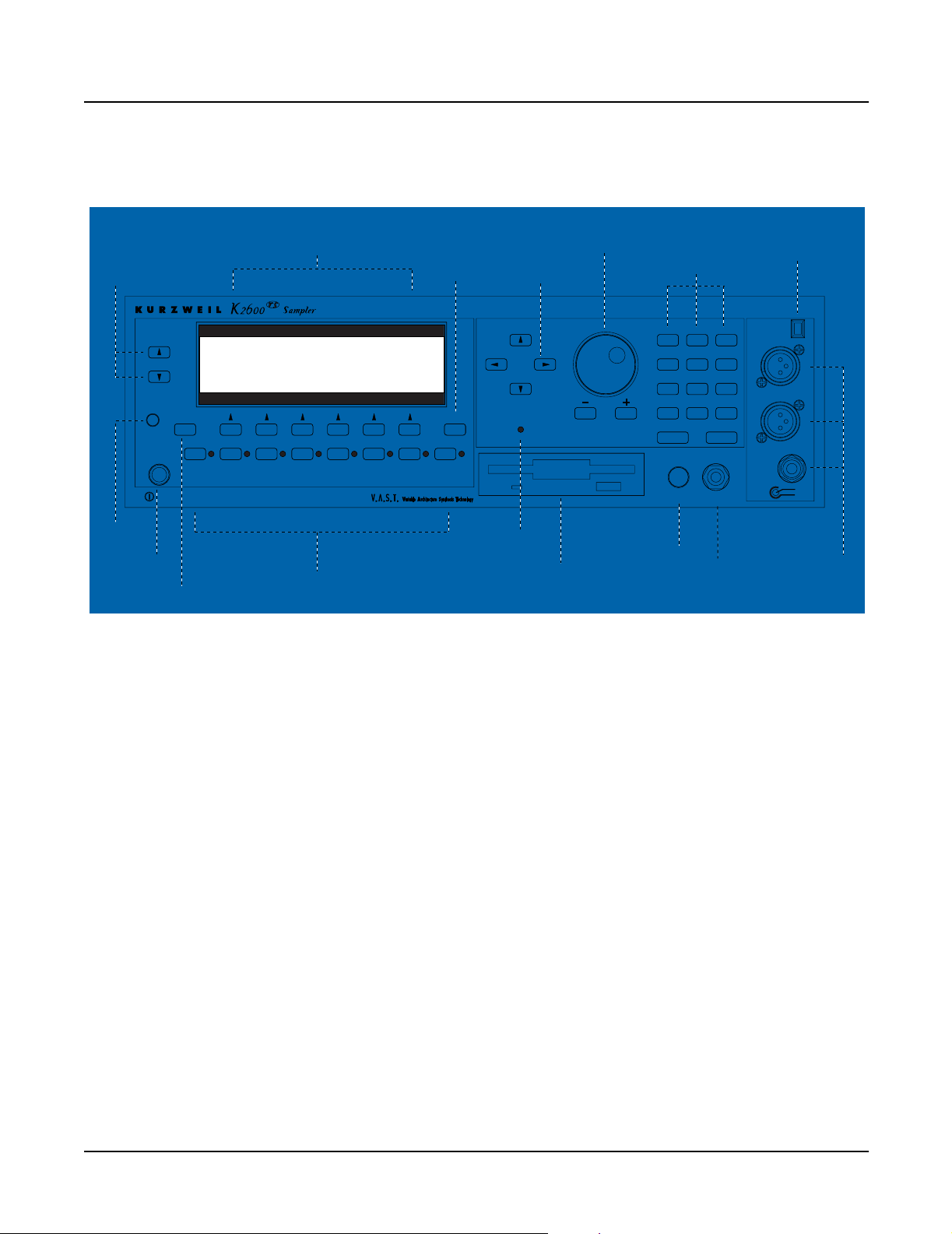

K2600/X Front Panel

K2600/X Front Panel

Data Entry

Chan/Bank

Layer/Zone

Edit

123

ABC DEF GHI

456

JKL MNO PQR

789

STU VWX YZ

+ / - 0 Clear

Exit

Cancel Enter

Space0-9UPPER/lower

Exit

button

Layer/Zone

button

Chan/Bank

button

LCD,

soft buttons

Figure 1-3 Data Entry Section

Assignable Controllers

Master Volume

Solo

Mixdown

MIDI Faders

Rotary Vibrato Percussion

Fast / Slow On / Off

12345678

ABCDEF GH

Chorus /

Vibrato

KB3 Controllers

Depth

1 / 2 / 3

On / Off

Cursor

buttons

Volume

Loud / Soft

Exit

button

Decay

Fast / Slow

Pitch

High / Low

Alpha Wheel,

Minus, Plus

buttons

Mode

Mute 1

Zoom - Gain -

Mute 2

Zoom +

Mute 3

Samp/Sec

Record Play/Pause Stop

Mode

buttons

Program MIDI

Setup Master

Q Access

Song

Effects Disk

Alphanumeric

buttons

Previous Pg

Mark

Gain +

Jump

Link

CompareFX Bypass

1-4

Master

Volume

slider

Solo,

Mixdown,

MIDI Faders

buttons

Assignable

and KB3 controllers

Figure 1-4 Assignable Controllers and Mode Sections

Record,

Play/Pause,

Stop buttons

Page 17

Front Panel Features

All Models

• LCD, backlit graphic display

• Soft buttons, use these buttons to select an action or item shown directly above a button in

the LCD.

• Cursor buttons, use these buttons to navigate through the LCD.

• Alpha Wheel, use the Alpha Wheel to increase or decrease a value by one or several increments.

• Plus (+) and Minus (–) buttons, these buttons operate similar to the Alpha Wheel. Pressing

the Plus (+) or Minus (-) button allows you to increase or decrease a value by one.

Alphanumeric Keypad, use these buttons to enter characters (both uppercase and

•

lowercase), numbers, and spaces.

• Mode buttons, use these buttons to select one of the eight operating modes.

• Chan/Bank and Layer/Zone buttons, depending on the current editor, use these buttons to

scroll through layers, presets, values, and zones.

• Exit button, press this button to leave the current editor.

• Edit button, use this button to modify a selected object or parameter.

Introduction

Front Panel Features

Keyboard Models only

• Master Volume slider, adjusts the overall volume of the mixed audio outputs and the

headphone jack.

• Assignable and KB3 Controllers, use these buttons to define the functions of these sliders

for zones or KB3 organ programs.

• Record, Play/Pause, and Stop buttons, use these buttons in Song mode.

• Solo button, this button mutes all but the current zone.

• Mixdown button, press this button to enter the Mixdown page to select the functions of the

physical controllers during MIDI mixdown.

• MIDI Faders button, press this button to enter the MIDI Faders page to define the functions

of the sliders.

• Ribbon Controller (not shown), define the parameters for the ribbon controller to respond

to finger positions and pressure. It can be programmed to control one section or up to three

sections.

• Disk Drive (not shown), use the disk drive to load, save, and copy data to a floppy disk.

• Mod/Pitch Wheel Assembly (not shown)

• Mod and Pitch wheels, use these wheels to vary modulation and pitch.

• Small Ribbon Controller, use this controller to add expression such as vibrato.

• SW1 and SW2 buttons, assignable buttons for use in the Setup Editor.

1-5

Page 18

Introduction

K2600R Front Panel

K2600R Front Panel

Chan/Bank,

Layer/Zone

buttons

LCD

Contrast

Chan/Bank

Layer/Zone

Edit

LCD

Contrast

Program MIDISetup Master SongEffects DiskQ Access

Mute 1 JumpMute 2 Mute 3 CompareFX Bypass MarkPrevious Pg

Power

Power

Edit

button

Figure 1-5 Front panel, K2600RS rack model

LCD and

Soft buttons

(below)

MIDI LEDMIDI LED

Mode

buttons

Alpha wheel,

Minus (–) and

Plus (+) buttons

Exit

button

Exit

LinkSamp/SecZoom +Zoom - Gain - Gain +

Cursor

buttons

MIDI

Alphanumeric

buttons

123

ABC DEF GHI

456

JKL MNO PQR

789

STU VWX YZ

+ / - 0 Clear

Cancel Enter

Volume

Space0-9UPPER/lower

Headphone

InputsData Entry

Optical

Lo Z

Hi Z

Optical

In

Left

Right

Left

Right

MIDI LED

Disk Drive

Volume

Headphone

Inputs

Rack Models only

• Power switch, push switch to turn the unit on and off.

• MIDI LED, this LED flashes when receiving data from a MIDI controller.

• Headphone jack, use this 1/4” jack to connect headphones.

• Volume potentiometer, adjusts the overall volume of the mixed audio outputs and the

headphone jack.

• LCD Contrast, turn this potentiometer to adjust the LCD for the best visibility.

• Disk Drive, use the disk drive to load, save, and copy data to a floppy disk. Use formatted

double-sided, double density (DSDD—720K or high-density (HD—1.4M) disks.

Inputs, this section is covered by a plate if the sampling option is not installed.

•

• For units with the sampling option, use either the two Lo Z XLR or the Hi Z 1/4”

(tip/ring/sleeve) jacks for sampling from an analog source.

• Optical In, If sampling from a digital source with an optical out jack, use this input.

1-6

Page 19

Chapter 2

Diagnostics

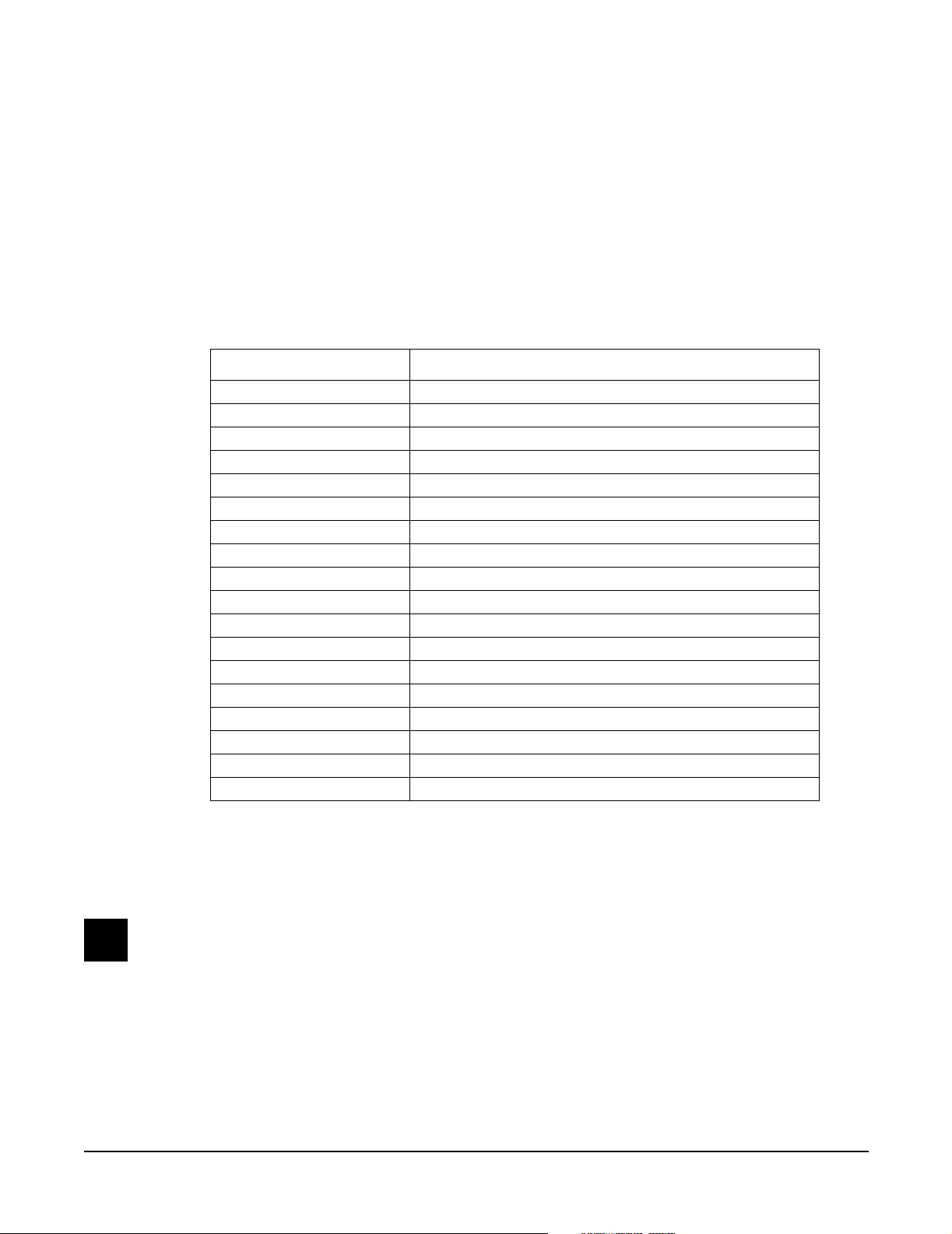

Diagnostic Tests

Test Name Description

LCD Tests the LCD

Engine Blk Tests the Operating System (installed in FlashROM)

Object Blk Tests the Setups (installed in FlashROM)

RAM/PRAM Tests the RAM (volatile, non-volatile and expansion)

I/O Port Tests the Microcontroller’s port pins

FDD Init Tests the Floppy Disk Drive controller

Scanner Tests the Scanner communications

MIDI Uart Tests MIDI In and Out

FDD R/W Tests the Floppy Disk Drive

SCSI Tests drive(s) on the SCSI bus

VLSI & ZRAM Tests Janis, Hobbes, and Lisa (not Lisa option)

Sampling Opt Tests the Sampling Option

Sine Wave Tests the sound hardware with sine waves

Sound ROM Tests the Sound ROM

Sound RAM Tests the Sound RAM

1st NVRAM Writes to the Non-Volatile and Expansion RAM

2nd NVRAM Checks the pattern written by the 1st NVRAM test

Digital IO Tests the Lisa Option

Table 2-1 Diagnostic Tests

Saving User Data

Warning: Be sure to save all user data and remove any user disk from the disk drive before

entering diagnostics.

To save user data, insert a formatted floppy disk into the disk drive and press the Disk button.

In Disk Mode, use the

in the LCD. Press the soft button under OK and follow the instructions displayed in the LCD.

See Saving User Data on page 5-2 for additional information.

Down cursor button to scroll through the list until Everything appears

Page 20

Diagnostics

Entering Diagnostics

Entering Diagnostics

1. Apply power to the unit. When the Please wait... message appears in the LCD,

quickly press and release the Exit button. The LCD shows the following:

------ K2600 Boot Loader v1.00 ------

Install System Hard Reset

Install Objects Run Diags

Run System Fixed Diags

OK

Figure 2-1 LCD example, boot loader menu

2. Use the cursor buttons or turn the Alpha Wheel until Run Diags is highlighted. Press the

soft button under OK.

3. The LCD briefly shows a message that the integrity of the operating system is being

checked and then displays a message warning you that some diagnostic tests will erase

data stored in user RAM.

Warning: If you have not saved the data stored in user RAM and wish to do so before

proceeding, turn the unit off to exit the diagnostic tests, power up and save the data. If

you need instructions, refer to Saving User Data on page 5-2.

4. If you have already saved data stored in user RAM, press any button to continue.

5. The LCD shows the following:

------ K2600 Diagnostic Ver 1.03 -----LCD Scanner Sine Wave

Engine Blk MIDI Uart Sound ROM

Object Blk FDD R/W Sound RAM

RAM/PRAM SCSI 1st NVRAM

I/O Port VLSI & ZRAM 2nd NVRAM

FDD Init SamplingOpt Digital IO

BurnIn Forever OK

Figure 2-2 LCD example, K2600 diagnostic menu

LCD and Front Panel Buttons

The LCD displays the list of tests, test modes, actions, and test results.

Press the Left, Right, Up, or Down cursor buttons or turn the Alpha Wheel to navigate through

the available tests.

2-2

Use the soft buttons located below the LCD to select different test modes or actions.

Page 21

Test Results

At the completion of an individual test, the LCD displays the results of the test. Figure 2-3 shows

an example of the display for the Engine Blk test.

Test Item : Engine Blk

Please wait. Testing...Success

Press any key to continue...

Figure 2-3 LCD example, Engine Blk test

Diagnostic Test Menus

After following the steps described in Entering Diagnostics, you’ll see the main diagnostic menu

in the LCD. The following describes the steps required to run the tests in the three menus.

Diagnostics

Diagnostic Test Menus

Main Menu

To run an individual test, press Left, Right, Up, or Down cursor buttons or turn the Alpha

Wheel to highlight the test name, then press the soft button below OK to execute the test. When

the test has completed, whether pass or fail, press any button to return to the main menu and

use the cursor buttons or Alpha Wheels to select another test.

Burn-In Menu

Burn-In continuously runs the sequence of tests listed in Figure 2-4.

Figure 2-4 LCD example, Burn-In tests

Press the soft button below Burn-In in the LCD to begin running the tests. The tests continue to

run until you press the Exit button.

LCD : PASS Scanner : PASS

Engine Blk : PASS FDD R/W : PASS

Setup Blk : PASS Sound ROM : PASS

RAM/PRAM : PASS Sound RAM : PASS

I/O port : PASS

FDD Init : PASS

EXIT-Stop Diags. Total-0000 Fail-0000

Forever

Forever continuously runs an individual test. The test continues to run until you press the Exit

button. The number of tests performed and the result is displayed in the LCD. You can return to

the diagnostic main menu by pressing the soft button below EXIT-Stop Diag. in the LCD.

2-3

Page 22

Diagnostics

Description of Tests

Description of Tests

LCD

This test writes a group of characters to the LCD and verifies that the same characters can be

read back again. The LCD Test includes four test phases that run automatically. The four steps

include the following:

1. Data test phase for the LCD character display memory

2. Address test phase for the LCD character display memory

3. Data test phase for the LCD graphics display memory

4. Address test phase for the LCD graphics display memory

The data test phase repeatedly writes the following 17-byte data pattern to the LCD:

0x00, 0xFF, 0x00, 0x0F, 0xF0, 0xCC, 0x33, 0xAA, 0x55, 0x11, 0xEE, 0x22, 0xDD, 0x44, 0xB, 0x88, 0x77

After the pattern is written, it is read back. If a difference is detected, the test fails.

The address test phase writes consecutive values to consecutive locations in the LCD. Then

these values are read back. If a difference is detected, the test fails.

A failure of this test indicates a problem with the LCD, Engine Board, connections between the

two boards or related circuitry.

Engine Blk (Engine Block)

This test computes an observed 32-bit check value of the setup area of the Flash ROMs (U4 and

U5) on the Engine Board. This value is then compared to the expected value, which is stored in

the flash itself. If the values differ, an error is reported.

If this test fails, install the latest Operating System and run the test again.

A failure of this test indicates a problem with the microcontroller, Flash ROMs, or related

circuitry on the Engine Board.

Object Blk (Object Block)

This test computes an observed 32-bit check value of the setup area of the Flash ROMs (U4 and

U5) on the Engine Board. The value is then compared to the expected value, stored in the Flash

ROMs. If the values differ, the test fails.

If this test fails, install the latest Operating System and Objects and run the test again.

A failure of this test indicates a problem with the Flash ROMs or related circuitry on the Engine

Board.

2-4

Page 23

RAM/PRAM

Caution: This test destroys all non-volatile user RAM! If you haven’t already saved user data,

power cycle the unit and save the data now. If you need instructions, refer to Saving User Data on

page 5-2.