Page 1

en Service Manual Coffee Machine

EF 470

EF 471

Essenza

Page 2

Contents

Preface _____________________________ 3

Main Components__________________ 4

Overview ___________________________ 4

Overview of rating plates ______________ 5

Water circuit_________________________ 6

Technical data _______________________ 7

Operation___________________________ 8

Preparation _________________________ 8

Fill water system _____________________ 9

Making coffee ______________________ 10

Empty water system _________________ 11

Coffee machine status _______________ 12

Troubleshooting___________________ 13

Checking the machine on receipt ______ 13

Repair _____________________________ 15

General disassembly ________________ 15

Replacing thermoblock_______________ 16

Replacing NTC _____________________ 17

Replacing pump ____________________ 18

Replacing electronic control board with

button prints ________________________ 19

Replacing compact brewing unit (CBU) _20

Electronic control board, wiring diagram -

Europe (230V / 50 Hz) _______________ 21

Electronic control board, wiring diagram -

USA (UL, 120 V / 60 Hz) _____________ 22

Electronic control board, wiring diagram Japan (100 V / 50-60 Hz)_____________ 23

Descaling (1) _______________________ 24

Descaling (2) _______________________ 25

Measuring flow rate _________________ 26

Checking for leaks and pump

pressure (1) ________________________ 27

Checking for leaks and pump

pressure (2) ________________________ 28

Measuring coffee temperature ________ 29

Daily care and final cleaning __________ 30

Spare Parts ________________________ 31

Repair accessories __________________ 31

Spare parts EF 470__________________ 32

Spare parts EF 471__________________ 34

Notes ______________________________ 36

Service Manual EF 470 / EF 471 enVersion 1.1

2

Page 3

Preface

The purpose of this Service Manual is to

provide the service personnel with all

necessary information with regards to correct

handling, maintenance and repair of the coffee

machines EF 470 and EF 471.

This manual should be used by the

technicians as a valuable aid to guarantee the

permanent readiness for use of the machine.

In order to take full advantage of all the

functions, it is absolutely necessary to follow

the instructions in this manual.

Please keep this manual together with the

corresponding service documentation. This

way you are assured to have the necessary

information.

For fast access to information directly from the

PC or MAC monitor, this manual is also

available on CD-ROM. The required utility

(Adobe Acrobat), also on this CD-ROM, runs

on PC and MAC computers.

Service Manual EF 470 / EF 471 enVersion 1.1

3

Page 4

Main Components

Overview

1) Closing handle

2) Cover

3) Compact brewing unit (CBU)

4) Capsule inlet

5) Side panel

6) On/Off button

7) Coffee outlet

8) Coffee button, back lighted

9) Container for used capsules

10) Drip grid

11) Drip tray

12) Lower chassis

13) Thermoblock TB 2003

14) Electronic control board

15) Pump CP4-SP C2

16) Water tank connector

17) Upper chassis

18) Water tank

10

1

4

5

6

7

8

9

3

2

18

11

17

12

13

Service Manual EF 470 / EF 471 enVersion 1.1

4

14

15

16

Page 5

Main Components

Typ:

MAGIMIX

NESPRESSO

Turmix

MADE IN EUROPE

0042699

1260W

60Hz

MADE IN SWITZERLAND

0529 0074 7002 6100 018

FR.6

HOUSEHOLD COFFEE MAKER

Type C90

LISTED 39C5

A.C.only

120V

1260W 50Hz

Fabriqué en Suisse

0042728

ref 11238

0529 0064 7105 5100 011

M100

220-240V

0040133

1260W 50Hz

MADE IN SWITZERLAND

0529 0044 7105 1100 014

KOENIG

Capri 03161

220-240V~

KOENIG APPARATE AG ZÜRICH 17105

1260W 50Hz

MADE IN SWITZERLAND

0040624

TURMIX AG, 8645 Jona, Switzerland

0529 0084 7005 3100 019

220-240V~

TX100

17105

1260W50/60Hz

0040541

Type EN 90.R

0529 0014 7105 1100 011

220-240V~

P = 19 bar

Ser.Nr. 54213 S300075

1260W 50/60Hz

XN200610/1M0-4205

MADE IN SWITZERLAND

0042829

TYPE XN 2006

0529 0054 7005 6100 019

220-240V~

Overview of rating plates

The rating plate

- can be found at the underside of the coffee

machine,

- may be of varying design, depending on

the brand,

- carries the following information:

• Machine type

• Voltage and power rating

• Approval seal(s)

• Data matrix

• Serial number

• Bar code (Krups)

Serial number codification

Example: 0529 0074 7002 6100 018

05290 production date: 290th day of year 2005

07 machine partner codification

470 machine type

02 voltage / mains plug version

6 color version

1 production site

0001 incremental number per production day

8 checksum number

Service Manual EF 470 / EF 471 enVersion 1.1

5

Page 6

Main Components

Water circuit

1) Water tank

2) Water tank valve and connector

3) Pump

4) Thermoblock

5) Compact brewing unit (CBU)

6) Coffee outlet

5

6

1

2

4

Service Manual EF 470 / EF 471 enVersion 1.1

6

3

Page 7

Main Components

Technical data

EF 470

291 mm

166 mm

EF 471

291 mm

255 mm

Mains

EUR 230V / 50 Hz

USA /CAN 120 V / 60 Hz

JAP 100 V / 50-60 Hz

Approvals SEV, CENELEC, CE-conform,

UL, CUL, MITI

Cable length ~1,5 m

Pump data

Pump pressure

- max. permissible 17,5 bar ±1,5 bar

- during coffee preparation 9 -13 bar

(depending on brand of coffee)

Flow performance 120-240 ml/min. at 12 bar

Power consumption

(at all voltages and frequencies)

Thermoblock 1’200 W

Pump 60 W

Ratings

Preheating 8.5 Wh

1 small cup (55 ml) 6.5 Wh

1 large cup (110 ml) 10 Wh

Stand-by mode 9.5 Wh

(machine on) (in 1 hour)

Stand-by mode 0.45 Wh

(machine off) (in 1 hour)

Various data

Pre-heating time approx. 50 s

Safety temperature (thermal cut-off) 167° C

254 mm

Capacities

Coffee temperature at outlet 86° C ± 3° C

Water tank 0.9 l

Drip tray approx. 100 ml

Capsule container 10 - 14 pcs.

166 mm

Service Manual EF 470 / EF 471 enVersion 1.1

7

Weight of machine approx. 3 kg

(without water)

Page 8

Operation

Preparation

1. Fill tank with water.

2. Insert water tank in coffee machine.

3. Switch on machine by pressing the On/Off

button.

4. Position receptacle with a capacity of

min.100 ml under coffee outlet.

Do not insert a capsule yet.

)

5. Wait until machine is ready (coffee button

is lighted).

6. Press coffee button to rinse coffee outlet.

7. Press coffee button again when

receptacle is filled.

1

3

2

4

6

5

Service Manual EF 470 / EF 471 enVersion 1.1

8

7

Page 9

Operation

Fill water system

If the coffee machine cannot pump water

although there is water in the tank, the water

circuit may be empty.

Procedure to fill water system:

1. Perform steps 1 to 5 for preparation (see

page 8).

2. Open closing handle in vertical position.

3. Press coffee button.

4. Press and hold closing handle to rear end

position.

5. Observe capsule inlet for appearing

water.

6. Press down closing handle immediately

when first droplets are visible.

7. Press coffee button again to stop water

flow.

2

3

6

45

7

Service Manual EF 470 / EF 471 enVersion 1.1

9

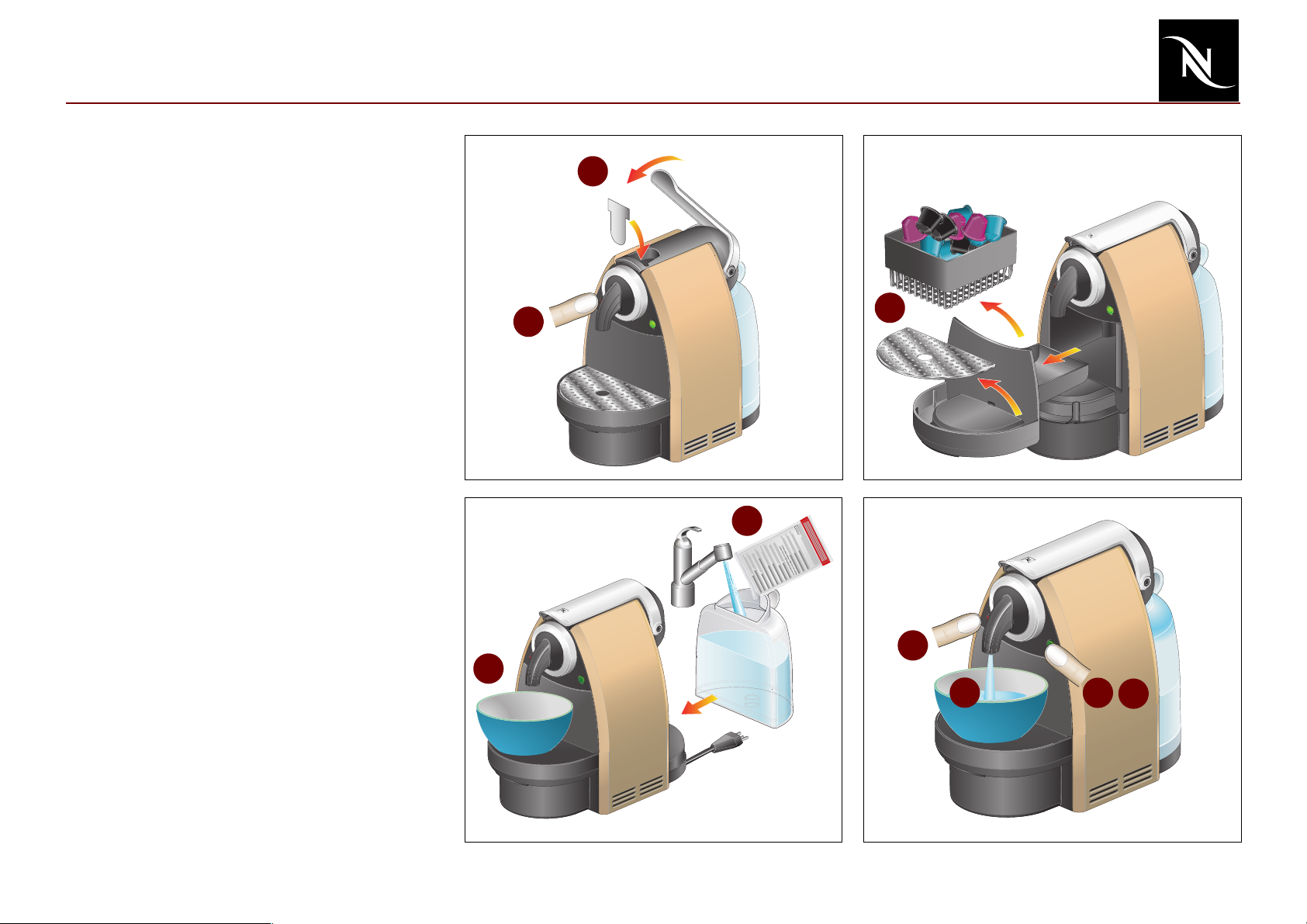

Page 10

Operation

Making coffee

1. Open closing handle.

2. Insert capsule.

3. Press down closing handle completely.

4. Position cup under coffee outlet.

5. Press coffee button.

6. Press button again to stop coffee flow

when cup is full.

7. Briefly open closing handle after coffee

preparation and eject capsule into capsule

container.

1

2

4

3

5

7

6

Service Manual EF 470 / EF 471 enVersion 1.1

10

Page 11

Operation

Empty water system

After operation, residual water remains in the

water circuit.

This residual water can be removed

- before a longer period of non-use,

- for frost protection,

- before repair and following shipping.

1. Empty water tank.

2. Press and hold On/Off button.

3. Simultaneously press coffee button three

times.

4. Release On/Off button.

The coffee button starts blinking fast and

the pump begins to empty the water

system.

5. Open closing handle and hold it in opened

position.

6. After coffee button stops blinking, press

down closing handle completely.

7. Empty drip tray.

5

1

2

4

3

3 x

6

7

After this procedure the machine is

)

Service Manual EF 470 / EF 471 enVersion 1.1

blocked for approx. 10 minutes (till

thermoblock temperature < 100° C).

11

Page 12

Operation

Coffee machine status

After pressing the On/Off button, an automatic

self test is performed to check if

- the NTC is connected,

- the NTC is short circuited,

- the thermoblock reaches the standby

temperature within 2 minutes in brewing

mode.

A detected failure is indicated by the

backlighted coffee button as well as the

operating modes listed in the following table.

Operating mode Coffee button LED signal

Off off

Heat up (coffee) blinking slow

Ready on

System too hot blinking fast

Brew coffee / rinse blinking slow

Heat up (descaling) blinking fast

Descaling ready blinking fast

Pump on (while descaling) blinking fast

Emptying water system blinking fast

Failure blinking three times fast

Service Manual EF 470 / EF 471 enVersion 1.1

12

Page 13

Troubleshooting

Checking the machine on receipt

The receipt check enables you to rapidly

locate faults on the machine and to initiate

appropriate repair action.

Check procedure Symptoms Action / repair work Further action / repair work

1 Check appliance for visible

damage

2 Check mechanical elements

3 Fill water tank 3.1 Water tank is leaking

4 Press On/Off button to perform

automatic self test

1.1 Parts of housing broken or damaged

1.2 Mains cable damaged

2.1 Closing handle works correctly

2.2 Is the capsule correctly ejected?

2.3 Is the capsule cage seal damaged?

(feel with a finger if the seal is damaged)

4.1 Machine is not working (no function)

Follow the check procedure.

Repair any faults found and check if the

machine is operating perfectly.

YES - Replace parts if necessary

NO - Go to point 1.2

YES - Replace mains cable

NO - Plug machine to the mains and go to point 2.1

YES - Go to point 2.2

NO - It is hard or impossible to close the closing handle

YES - Go to point 2.3

NO - Replace CBU

YES - Replace CBU

NO - Go to point 3

YES - Replace water tank

NO - Go to point 4

YES - a) Check if mains cable is functional

YES - b) Check if On/Off button is functional

YES - c) Check if pump is working (press coffee

button)

YES - d) Check if coffee button is functional

YES - e) Check if pump's fine wire fuse (128°C) is

defective

YES - f) Check if thermoblock’s fine wire fuse (167°C)

is defective

YES - Screw on closing handle screws at defined

torque and block them with Loctite 241 (see page

20) or replace CBU

NO - Replace the CBU

YES - Go to point b)

NO - Replace it

YES - Go to point c)

NO - Replace it

YES - Go to point f)

NO - Go to point d)

YES - Go to point e)

NO - Replace it

YES - Replace it

NO - Replace pump

YES - Replace it together with electronic control

board and if necessary the thermoblock

NO - Go to point g)

Service Manual EF 470 / EF 471 enVersion 1.1

13

Page 14

Troubleshooting

Check procedure Symptoms Action / repair work Further action / repair work

4.1 Machine is not working (no function)

4 Press On/Off button to perform

automatic self test - continued

5 Check coffee temperature while

preparing a coffee (see page 29)

6 Check for leaks and check flow

rate (see pages 26, 27 and 28)

7 Descaling process (if needed) 7.1 Machine scaled

8 Final cleaning (see page 30)

- continued

4.2 Backlighted coffee button blinks at irregular

intervals

5.1 No coffee outlet

5.2 Temperature is too low (less than 83°C)

5.3 Temperature is too high (more than 89°C)

6.1 Leakage at extraction system

6.2 Leakage at tubes connection

6.3 Flow rate out of range

YES - g) Check if electrical wires are functional

NO - Go to point 4.2

YES - Check if thermoblock heating element is func-

tional

NO - Self test ok. Go to point 5

YES - a) Water circuit is empty

YES - b) Pyramid plate is clogged

YES - c) Machine is blocked by scale YES - Descale machine (see page 24)

NO - Go to point 5.2

YES - Descale the machine (see page 24)

NO - Go to point 5.3

YES - Change NTC

NO - Go to point 6

YES - Replace CBU

NO - Go to point 6.2

YES - Replace defective tube and seal

NO - Go to point 6.3

YES - Machine is scaled

NO - No trouble found during the check procedure.

YES - Descale machine (see page 24)

NO - Go to point 8

YES - Replace electronic mainboard

NO - Replace defective(s) wire(s)

YES - Replace NTC

NO - Replace thermoblock

YES - Fill water circuit (see page 9)

NO - Go to point b)

YES - Replace CBU

NO - Go to point c)

YES - Descale machine (see page 24)

NO - Replace pump

Contact Nespresso Technical Correspondant for

further details in order to take decision.

End of check procedure

Service Manual EF 470 / EF 471 enVersion 1.1

14

Page 15

Repair

General disassembly

Tool:

- Oval screwdriver

Empty water system if necessary

)

Procedure:

(see page 11).

Unplug from the mains before

disassembling machine - appliance

must be isolated!

1. Remove water tank (33) and drip tray (8)

together with drip grid (7) and capsule

container (6).

2. Remove 2 screws (2) on the front side of

the machine.

3. Place machine on the repairing/service

holder device (see page 31).

4. Remove 6 screws (2) on the bottom of the

machine.

5. Swing out and remove both side panels

(5).

6. Remove lower chassis (22).

5

33

2

22

5

7 + 8 + 6

2

2

2

Service Manual EF 470 / EF 471 enVersion 1.1

15

Page 16

Repair

Replacing thermoblock

Tools:

- Torx screwdrivers T10, T30

- Open-ended spanner 10 mm AF

- Torque wrench

Procedure:

1. Follow general disassembly (see page 15).

2. Remove 3 screws (2) and separate thermoblock (40) with support (40) from chassis.

3. Remove screw M6 x 25 and separate

thermoblock from its support.

4. Remove screw (38) and separate fine wire

fuse (900) from thermoblock.

5. Remove electronic housing (28).

6. Unplug NTC connector from electronic

control board (28).

7. Remove NTC (43) from thermoblock.

8. Remove clips (13) and hose connectors

(16, 26) from thermoblock.

9. Remove ground wire and electrical

connections from thermoblock.

10. Replace thermoblock and nut M6.

11. Assemble in reverse sequence.

Use a torque wrench (90 - 110 Ncm)

)

)

to tighten NTC temperature sensor

(43) with spring washer.

Check that there is a clearance of

1-2 mm between thermoblock and

support after assemblage.

28

16

13

26

38

39

M6 x 25

900

38

40

40

2

43

M6

Service Manual EF 470 / EF 471 enVersion 1.1

16

Page 17

Repair

Replacing NTC

Tools:

- Torx screwdriver T10

- Open-ended spanner 10 mm AF

- Torque wrench

Procedure:

1. Follow general disassembly (see page 15).

2. Remove electronic housing (28).

3. Unplug NTC connector from electronic

control board (28).

4. Remove defective NTC temperature

sensor (43) from thermoblock (40) and

replace it with new one.

5. Assemble in reverse sequence.

Re-use spring washer and tighten

)

Service Manual EF 470 / EF 471 enVersion 1.1

new NTC temperature sensor (43)

with torque wrench (90 - 110 Ncm).

28

43

40

17

Page 18

Repair

Replacing pump

Tools:

- Torx screwdriver T10

- Long-nose pliers

- Blade screwdriver, no. 7

Procedure:

1. Follow general disassembly (see page 15).

2. Remove clip (14), hose (18) and o-ring

(15).

3. Remove angled hose (9).

4. Release pump (17) first from rubber strap

(12) at the side of the angled hose.

5. Remove electrical connections from pump.

6. Release pump from second rubber strap

(12).

7. Replace defective pump (17).

8. Attach new pump (17) to one rubber strap

with corner connector (20) first.

9. Plug in electrical connections on pump.

Check for correct wiring of pump.

)

10. Attach pump to second rubber strap.

11. Insert new seal (15), mount hose (18) and

clamp (14).

12. Mount angled hose (9).

12

18

15

9

N

T 128°C

9

L

14

17

20

Service Manual EF 470 / EF 471 enVersion 1.1

18

Page 19

Repair

Replacing electronic control board with button prints

Tools:

- Torx screwdriver T10

The service engineer must be

)

Procedure:

earthed using an earthing strap!

Only touch button prints with

dedicated gloves to avoid oxydation.

1. Follow general disassembly (see page 15).

2. Detach prints of On/Off button (30) and

coffee button (29) from upper chassis (1).

3. Remove housing (28) from electronic

control board (28).

4. Unplug NTC connector and all wires from

electronic control board (28).

5. Remove 2 screws (23) and replace defect

electronic control board with button prints

(29, 30).

6. Assemble in reverse sequence.

28

1

23

Check for correct wiring of electronic

)

Service Manual EF 470 / EF 471 enVersion 1.1

control board (see pages 21, 22 or

23).

19

30

29

Page 20

Repair

Replacing compact brewing unit (CBU)

Tools:

33

- Torx screwdrivers T10, T20

- Blade screwdriver no. 4

- Oval screwdriver

- Long-nose pliers

- Torque wrench

Procedure:

1. Remove water tank (33) and drip tray (8)

together with drip grid (7) and capsule

container (6).

2. Place machine on the repairing/service

holder device (see page 31).

3. Remove 4 screws (2) on the bottom of the

machine.

4. Swing out and remove both side panels (5).

5. Remove 2 screws (36) and pull off closing

handle (37).

6. Remove 2 screws (23) at the front and 1

screw (23) at the back to detach cover (35).

7. Unlatch coffee outlet (3) from compact

brewing unit (34) with a blade screwdriver.

8. Remove 4 screws (23) and detach

compact brewing unit (34).

9. Remove clip (14) and hose (32) with o-ring

(15) from compact brewing unit (34).

36

35

23

37

23

23

10. Assemble new compact brewing unit

together with new coffee outlet (3) in

reverse sequence.

Replace o-ring (15).

34

23

15

14+32

3

)

2

7+8+6

36

Tighten new (EFR nr. 39256) closing

handle screws (36) with a torque of

450 N/cm.

5

Service Manual EF 470 / EF 471 enVersion 1.1

20

Page 21

Repair

Electronic control board, wiring diagram - Europe (230V / 50 Hz)

1) Heat sink

2) Print for On/Off button

3) Print for coffee button with LED

4) NTC temperature sensor

5) Fine-wire fuse on thermoblock

6) Fine-wire fuse on pump

Electronic Main Board

1

J3

J7

L

J6 J1

L

J2

LN

J5

J4

ON/OFF Print

2

Thermoblock

4

NTC

GND

Coffee Button Print

3

T 167°C

5

Pump

T 128°C

6

Mains Plug

L N PE

Service Manual EF 470 / EF 471 enVersion 1.1

21

Page 22

Repair

Electronic control board, wiring diagram - USA (UL, 120 V / 60 Hz)

1) Heat sink

2) Print for On/Off button

3) Print for coffee button with LED

4) NTC temperature sensor

5) Fine-wire fuse on thermoblock

Electronic Main Board

1

J3

J7

L

J6 J1

L

J2

LN

J5

J4

ON/OFF Print

2

Thermoblock

4

NTC

Coffee Button Print

3

5

T 167°C

Pump

T 128°C

Mains Plug

Service Manual EF 470 / EF 471 enVersion 1.1

22

Page 23

Repair

Electronic control board, wiring diagram - Japan (100 V / 50-60 Hz)

1) Heat sink

2) Print for On/Off button

3) Print for coffee button with LED

4) NTC temperature sensor

5) Fine-wire fuse on thermoblock

6) Fine-wire fuse on pump

Electronic Main Board

1

J3

J7

L

J6 J1

L

J2

LN

J5

J4

ON/OFF Print

2

Thermoblock

4

NTC

Coffee Button Print

3

T 167°C

5

Pump

T 128°C

6

Mains Plug

L N

Service Manual EF 470 / EF 471 enVersion 1.1

23

Page 24

Repair

Descaling (1)

Only use Nespresso decalcifier -

Preparation:

)

Descaling:

never vinegar!

Decalcifier is aggressive to surfaces.

1. Switch off machine.

2. Eject capsule. Insert filter from descaling

kit in capsule inlet and close handle.

3. Empty drip tray and capsule container and

remove drip grid.

4. Re-insert drip tray and place a pot on it.

Carefully read safety instructions on

decalcifier package.

5. Fill water tank with 0.1 l descaling fluid

and 0.5 l water. Re-insert water tank.

6. Press On/Off button and coffee button

simultaneously for at least 3 seconds to

switch on machine and start descaling

mode (fast blinking coffee button).

7. Press coffee button to start pump.

8. Let entire descaling solution pass through

coffee outlet.

2

1

5

4

3

6

8

6

7

Service Manual EF 470 / EF 471 enVersion 1.1

24

Page 25

Repair

Descaling (2)

9. Fill water tank again with descaling

solution from pot.

10. Repeat descaling procedure one more

time: Press coffee button and let entire

descaling solution run through.

Rinsing:

11. Empty pot.

12. Remove filter from capsule inlet.

13. Rinse water tank thoroughly and fill it with

fresh water.

14. Place pot on drip tray.

15. Press coffee button to start pump.

Let complete content of water tank run

through coffee outlet.

16. Switch off machine.

Descaling is completed.

17. Insert drip grid.

18. Clean machine.

12

9

11

10

18

13

16

17

14

Service Manual EF 470 / EF 471 enVersion 1.1

15

25

Page 26

Repair

Measuring flow rate

Procedure:

1. Fill water tank.

2. Insert pressure plug in capsule inlet.

3. Press down closing handle lightly till

pressure plug fits in capsule cage.

4. Pull off holding device. The pressure plug

clamps itself to the capsule cage.

5. Position measuring beaker underneath

exit tube of pressure plug.

6. Switch on machine. Press coffee button

after heating-up.

7. Open valve fully till water begins to flow.

8. Close valve until 12 bar are indicated.

The manometer must be observed

)

continuously and the pressure

regulated using the valve if

necessary. With increasing

temperature the pressure also

increases, if necessary readjust the

pressure to 12 bar.

2

Notice:

- With a flow of < 60 ml the pump is defective

or there is a leak in the system.

- Large fluctuations in the pressure gauge

readings (± 4 bar) during measurement are

indicative of a defective pump.

1

3

4

7

9. Perform measurement for approx. 30 sec.

10. There must be at least 60-120 ml water in

the measuring beaker.

Service Manual EF 470 / EF 471 enVersion 1.1

26

8

5

6

6

Page 27

Repair

Checking for leaks and pump pressure (1)

The following components are checked for

leaks:

- Compact brewing unit

- Connections

- Thermoblock

-Pump

Preparation (unplug machine from mains):

1. Remove right side panel (pump is visible).

2. Insert pressure plug in capsule inlet.

3. Press down closing handle lightly till

pressure plug fits in capsule cage.

4. Pull off holding device. The pressure plug

clamps itself to the capsule cage.

5. Position pot underneath exit tube of

pressure plug.

6. Fill water tank.

7. Connect mains cable.

Dangerous voltage inside coffee

machine! - Do not touch any live part

while performing checks.

Hot, pressurized parts inside coffee

machine! - Do not touch any hot part

while performing checks. Wear

safety glasses during inspection.

2

1

5

4

3

6

7

Continued on next page.

Service Manual EF 470 / EF 471 enVersion 1.1

27

Page 28

Repair

Checking for leaks and pump pressure (2)

Procedure (continued):

8. Switch on machine. Press coffee button

after heating-up.

9. Open valve and leave water to run out for

approx. 10 s.

10. Fully close valve. The pressure will rise

rapidly initially and stabilise between

16 - 19 bar (check of pump pressure).

The pressure will rise slowly due to

)

11. Perform visual and acoustic checks on all

the temperature increase.

If the pressure exceeds 23 bar, the

machine has to be switched off and

pressure released through the

pressure valve.

pressurized connections.

9

10

8

8

13

The pump must not be in operation

12. Switch off machine.

13. Open valve to empty pressure gauge.

Service Manual EF 470 / EF 471 enVersion 1.1

for longer than 50 s without water

flow.

12

11

28

Page 29

Repair

Measuring coffee temperature

Procedure:

1. Press On/Off button to switch on machine.

2. Position measuring beaker underneath

coffee outlet.

3. After warming up, press coffee button and

preheat coffee outlet for 10 s with hot

water.

4. Insert a capsule (Cosi is the most suitable).

5. Press coffee button.

6. Wait until 20 ml coffee has flown in the

measuring beaker.

7. Measure the coffee temperature approx.

5 - 10 mm below the outlet opening.

Coffee temperature should be

)

approx. 86 °C ± 3 °C (187 °F ± 5.4 °F).

1

3

2

4

7

5

6

Service Manual EF 470 / EF 471 enVersion 1.1

29

Page 30

Repair

Daily care and final cleaning

Procedure:

1. Eject capsule.

2) Empty capsule container.

3) Empty water tank and drip tray.

4) Clean water tank and drip tray.

5) Fill tank with fresh water.

6) Reassemble coffe machine.

7) Press On/Off button.

8) Press coffee button and rinse coffe outlet

for 10 s.

9. Clean coffee machine.

1

2

3

5

7

4

Service Manual EF 470 / EF 471 enVersion 1.1

30

8

9

Page 31

Spare Parts

Repair accessories

0004878

Pos. EFR nr. Component

1 * Pressure gauge

2 * Repairing/service holder device A (for EF 470)

2 * Repairing/service holder device B (for EF 471)

3 0004872 Special screwdriver with oval bit

4 0004878 Oval bit for screwdriver

* Only available through Nespresso. Please contact the Nespresso club.

1

2

0004872

Service Manual EF 470 / EF 471 enVersion 1.1

31

Page 32

Spare Parts

Spare parts EF 470

3

5

6

7

8

9

10

38

38

39

11

12

13

14

15

16

15

17

11

18

12

15

19

23

14

20

Pos. EFR nr. Component

1 39166 Upper chassis EF 470

1

363736

23

35

23

34

33

23

15

32

14

31

30

29

2 24863 Safety screw 3,0 x 12 KST/PT

3 40686 Coffee outlet & front ring EF 470 (package)

5 39378 Side panel EF 470 titanium

5 39148 Side panel EF 470 ivory

5 42614 Side panel EF 470 orange

6 39170 Capsule container EF 470

7 39150 Drip grid EF 470

8 40477 Drip tray EF 470 printed : "Turmix"

8 40478 Drip tray EF 470 printed : "Krups"

8 40479 Drip tray EF 470 printed : "Nespresso"

9 39197 Hose water tank / pump

10 40691 Water tank connector assembled

11 39195 Pump attachment

12 39196 Pump fixation

13 37384 Clip D=5mm

14 5470 Clip to tube 770

15 24374 O-ring 3,4 x 1,9 silicon

16 37454 Angle connection for hoses

17 41029 Pump 230V

17 42530 Pump 120V

17 41030 Pump 100V

18 39199 Hose pump / thermoblock

21

22

22

40

21

23

5

28

23

27

15

14

26

13

24

41

4342

15

25

19 1565 O-ring 5,28 x 1,78 EPDM

20 36613 Angle connection for pump

21 13299 Elastic stop

22 39164 Lower chassis EF 470

23 16052 Screw 3,0 x 12 Torx 10

24 1053 Strain relief screwed

25 39369 Power cord Cebec 1,3m

25 39266 Power cord SEV 1,3m

25 40535 Power cord Israel 1,3m

25 39368 Power cord GB 1,3m

Service Manual EF 470 / EF 471 enVersion 1.1

32

Page 33

Spare Parts

Spare parts EF 470 (continued)

23

3

5

6

7

8

9

10

38

38

39

11

12

13

14

15

16

15

17

11

18

12

15

19

14

1

20

21

22

22

40

Pos. EFR nr. Component

25 42135 Power cord UL1,3m

363736

23

35

23

34

33

23

15

32

14

31

30

29

25 39271 Power cord Japan1,3m

26 38412 Angle connection for hoses

27 39188 Electronic base

28 40688 Electronic set 230V

28 40689 Electronic set 120V

28 40690 Electronic set 100V

29 39153 "Coffee" button EF 470

30 39152 "ON-OFF" button EF 470

31 26392 Silicon hose

32 39198 Hose thermoblock / CBU

33 39142 Water tank EF 470

34 40685 Compact brewing unit (CBU)

35 39168 Cover EF 470

36 39256 Screw M4 x 25 Torx 20

37 39162 Closing handle EF 470

38 19799 Screw M4 x 8 Torx 20

39 21542 Thermal cutoff clip

40 41436 Thermoblock complete 230V

40 41434 Thermoblock complete 120V

40 41435 Thermoblock complete 100V

41 40180 Bushing insulator electrical

42 5245 Spring washer M5

5

28

23

27

15

14

26

13

21

23

24

41

4342

15

25

43 40190 Temperature sensor 737

900 6328 Strand wire white 100mm

900 39263 Strand wire black 100mm

900 39264 Thermal cutoff 167°C

900 40606 Bushing insulator electrical

900 39630 Strand wire yellow/green 220mm

Service Manual EF 470 / EF 471 enVersion 1.1

33

Page 34

Spare Parts

Spare parts EF 471

3

5

6

7

8

9

10

38

38

39

11

12

13

14

15

16

15

17

11

18

12

15 19 14 20 21 2 22 2 21 23 24 25

23

1

363736

40 41 42 43

Pos. EFR nr. Component

1 39167 Upper chassis EF 471

2 24863 Safety screw 3,0 x 12 KST/PT

3 40687 Coffee outlet & front ring EF 471 (package)

5 39379 Side panel EF 471 silver

5 39157 Side panel EF 471 coral red

23

35

23

34

5 42613 Side panel EF 471 green

6 39171 Capsule container EF 471

7 39151 Drip grid EF 471

8 40480 Drip tray EF 471 printed : "Nespresso"

8 40481 Drip tray EF 471 printed : "Magimix"

8 40482 Drip tray EF 471 printed : "Koenig"

33

44

15

32

14

31

30

29

8 40483 Drip tray EF 471 printed : "DeLonghi"

9 39197 Hose water tank / pump

10 40691 Water tank connector assembled

11 39195 Pump attachment

12 39196 Pump fixation

13 37384 Clip D=5mm

14 5470 Clip to tube 770

15 24374 O-ring 3,4 x 1,9 silicon

16 37454 Angle connection for hoses

17 41029 Pump 230V

17 42530 Pump 120V

17 41030 Pump 100V

5

28

23

27

15

14

26

13

15

18 39199 Hose pump / thermoblock

19 1565 O-ring 5,28 x 1,78 EPDM

20 36613 Angle connection for pump

21 13299 Elastic stop

22 39165 Lower chassis EF 471

23 16052 Screw 3,0 x 12 Torx 10

24 1053 Strain relief screwed

25 39369 Power cord Cebec 1,3m

25 39266 Power cord SEV 1,3m

25 40535 Power cord Israel 1,3m

Service Manual EF 470 / EF 471 enVersion 1.1

34

Page 35

Spare Parts

Spare parts EF 471 (continued)

3

5

6

7

8

9

10

38

38

39

11

12

13

14

15

16

15

17

11

18

12

15 19 14 20 21 2 22 2 21 23 24 25

23

1

40 41 42 43

Pos. EFR nr. Component

25 39368 Power cord GB 1,3m

363736

25 42135 Power cord UL 1,3m

25 39271 Power cord Japan 1,3m

26 38412 Angle connection for hoses

23

35

23

34

27 39188 Electronic base

28 40688 Electronic set 230V

28 40689 Electronic set 120V

28 40690 Electronic set 100V

29 39154 "Coffee" button EF 471

30 39155 "ON-OFF" button EF 471

31 26392 Silicon hose

33

44

15

32

14

31

30

29

32 39198 Hose thermoblock / CBU

33 39143 Water tank EF 471

34 40685 Compact brewing unit (CBU)

35 39169 Cover EF 471

36 39256 Screw M4 x 25 Torx 20

37 39163 Closing handle EF 471

38 19799 Screw M4 x 8 Torx 20

39 21542 Thermal cutoff clip

40 41436 Thermoblock complete 230V

40 41434 Thermoblock complete 120V

40 41435 Thermoblock complete 100V

5

28

23

27

15

14

26

13

15

41 40180 Bushing insulator electrical

42 5245 Spring washer M5

43 40190 Temperature sensor 737

44 18904 Screw 3,0 x 16 Torx 10

900 6328 Strand wire white 100mm

900 39263 Strand wire black 100mm

900 39264 Thermal cutoff 167°C

900 40606 Bushing insulator electrical

900 39630 Strand wire yellow/green 220mm

Service Manual EF 470 / EF 471 enVersion 1.1

35

Page 36

Notes

Service Manual EF 470 / EF 471 enVersion 1.1

36

Loading...

Loading...