Page 1

4/2001

V

)

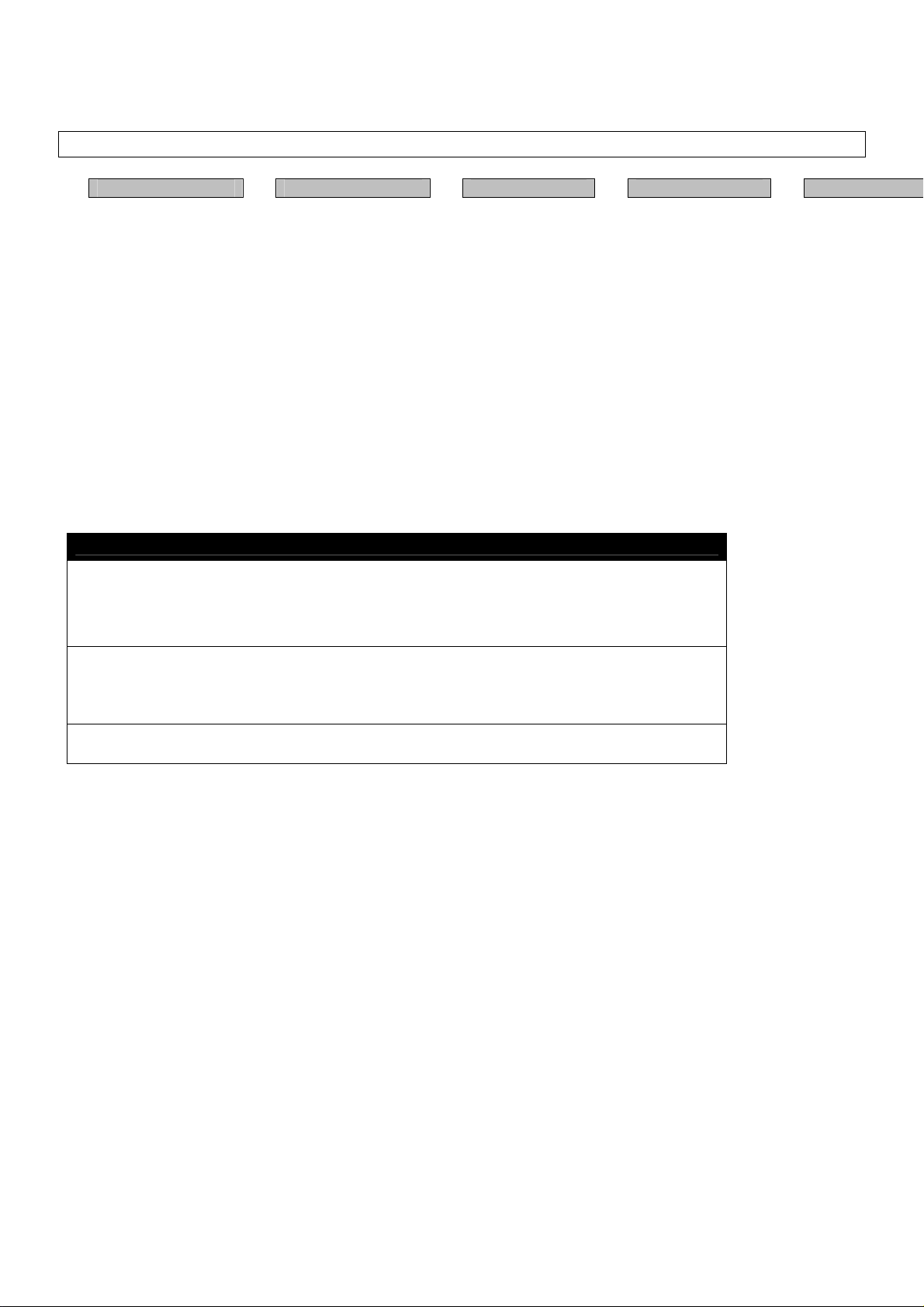

Vortex flowmeter

Installation and

operating

Instructions

FM 5090 (I

Page 2

Part A System installation and Start-up

1. Description 1

2. Installation in the pipeline 1

2.1 General

2.2 Sandwich type to DIN 19205 / ANSI

2.3 Flanged type to DIN 2501 / ANSI B16.5 (SCH-40)

2.4 Temperature and Pressure measurements

2.4.1 Temperature measurement 4

2.4.2 Pressure measurement with built-in sensor 5

2.4.3 Pressure measurement by external means 5

3. Electrical connection 5

3.1 Installation location and cable diameter

3.2 Connection to power

3.3 Outputs

3.3.1 Abbreviations 6

3.3.2 Current (analog) output I 6

3.3.3 Frequency (pulse) output F 6

3.3.4 Connection diagram for outputs j to m 7-8

4. Start-up 8

Contents

1-3

4

4

4

5

5

6

Part B Signal converter VFC 090

5. Operation of the signal converter 9

5.1 General

5.1.1 Starting up signal converter 9

5.1.2 Measurement mode 9

5.1.3 Programming or menu mode 9

5.1.4 Error handling 9

5.2 Operating elements

5.3 Program organization and programming chart

5.3.1 Menu levels 11

5.3.2 Programming chart 12

5.3.3 Description of keys 13

5.4 Programming and function of keys

5.5 Error Messages

5.5.1 Error Messages in Measurement mode 16

5.5.2 Error Messages in Programming mode 17

5.5.3 Other Error Messages 17

5.6 Plausibility Checks

5.7 Options available with VFM 5090(I)

5.7.1 METER TYPE 18-19

5.7.2 OUTPUT TYPE 20-24

9

10

11

14-15

16

17

18

Page 3

(I)

6. Description of program functions 25

6.1 Numerical order description

6.1.1 Program function description 25-39

6.1.2 Program function description for AGA supported software 39

6.2 Functional order description

6.2.1 Physical units 40-41

6.2.2 Numerical format 42

6.2.3 Display 42

6.2.4 Flow range and meter size 43

6.2.5 Primary information 43

6.2.6 Application information 43

6.2.7 Internal Electronic Totalizer 43

6.2.8 Current (analog) output I 44

6.2.9 Frequency (pulse) output F 45-46

6.2.10 Languages of display text 46

6.2.11 Coding desired for entry into programming mode 46

6.2.12 Behaviour of outputs during programming 46

25

40

Part C Functional checks and Trouble shooting hints

7. Functional checks 47

7.1 Primary head functional checks

7.1.1 Vortex Sensor 47

7.1.2 Temperature Sensor 47

7.2 Signal converter functional checks

7.2.1 Self diagnostics 47

7.2.2 Display check 48

7.2.3 Current output check 48

7.2.4 Frequency output check 48

8. Trouble shooting hints 48-49

Part D VFM 5000

9. Description of the system 50

9.1 VFM 5090(I)Ex Earthing connections

9.2 Electrical connection

10. Process pressure and temperature 50

11. Replacement of the electronics in signal converter 50-51

12. Nameplates of VFM 5090(I)Ex 52

Ex

47

47

50

50

Part E TECHNICAL DATA

53-76

Page 4

p

r

m

d

y

Part A System installation and Start-u

1. Description

KHRONE MARSHALL Vortex Flowmete

operate on the Karman vortex street principle to

measure volumetric flow rate of gases / stea

and liquids. VFM computes normalize

volumetric and mass flow rates from operating

DF Max. allowable difference between inside

diameters of primary head and pipeline.

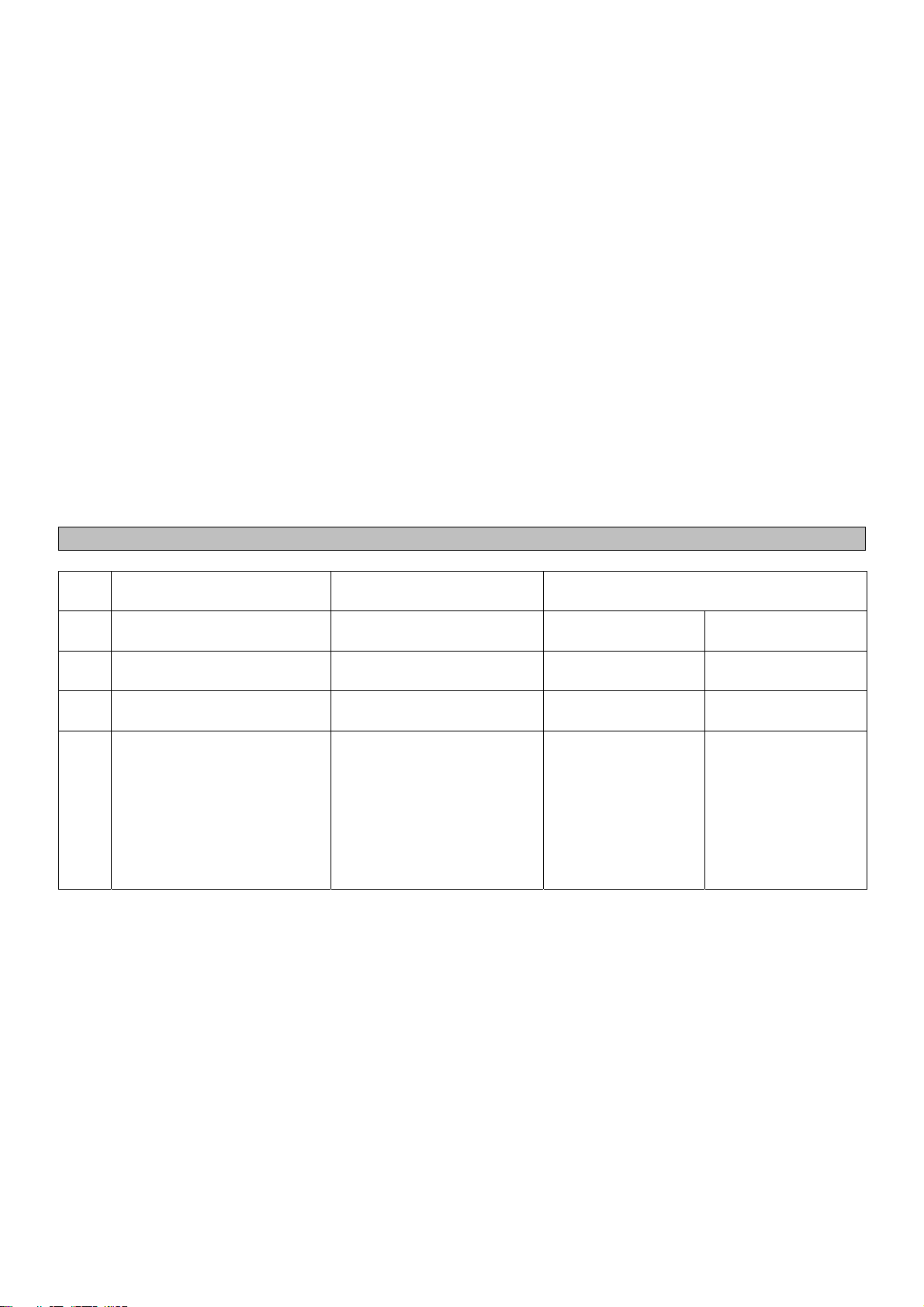

SIZE f Df SIZE f Df

DN

(mm)

mm

(inch)

10S 8.9

Pressure and Temperature values, or from densit

values. Temperature sensor is standard &

pressure sensor is optional to provide an on-line

P&T compensation.

Items included with shipment

·

Compact Vortex Flowmeter

·

Installation and operating instructions

·

Mounting bolts, washers, nuts

·

Plastic cover wrench for electronic housing

· Optional upstream & downstream pipes

10 12.6

15 14.9

20 20.9

25 28.5

40 43.1

· Programming chart indicating factory

configuration settings.

·

Gaskets between primary head and pipeline.

Provided by customer

· All cables for electrical connections.

50 54.5

80 82.5

100 107.1

150 159.3

200 206.5

2. Installation in the pipeline

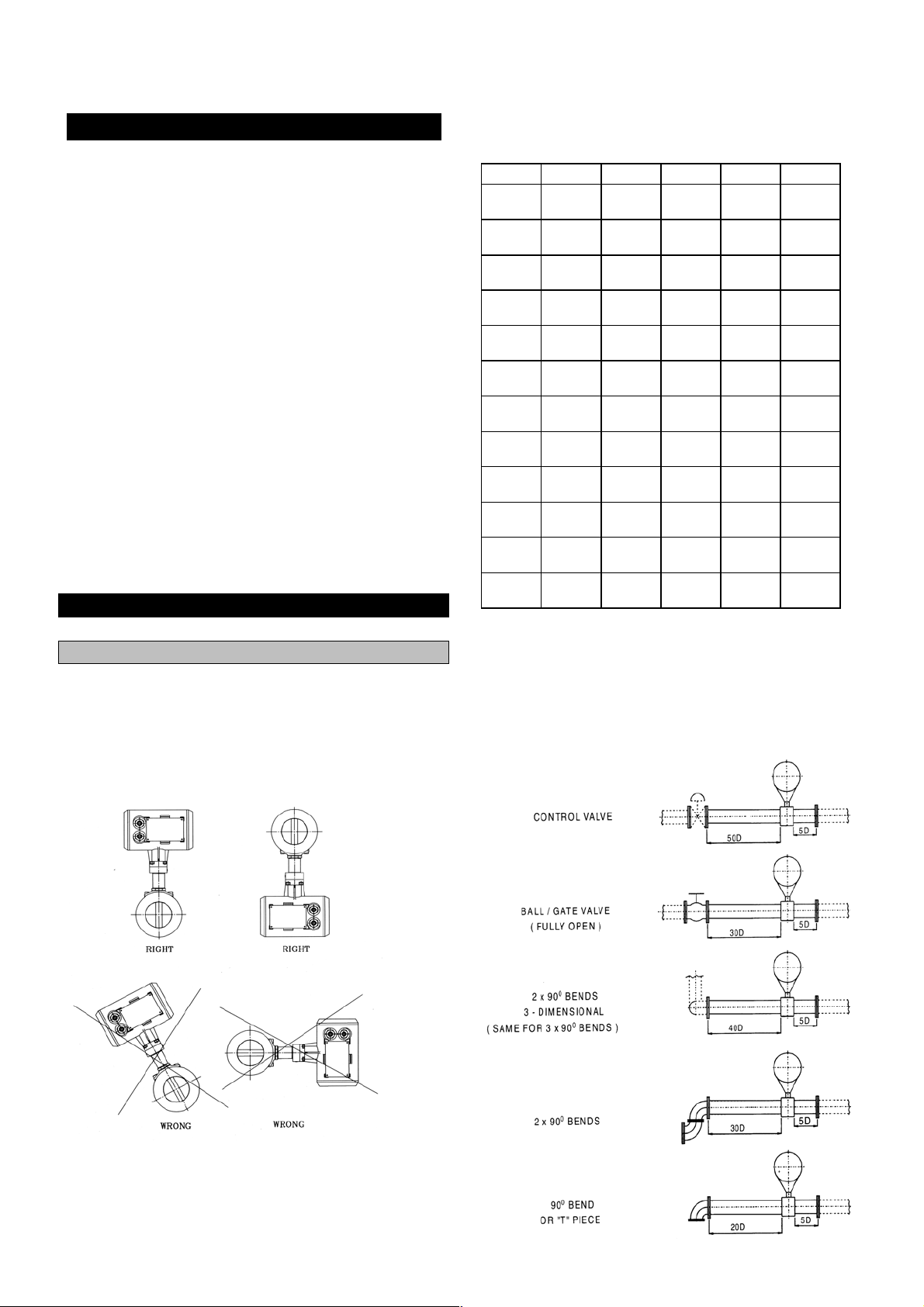

2.1 General

Ensure that the bore of locating pipes are smooth and without

deposits or scaling of welding beads.

3. Straight, unimpeded inlet and outlet runs

mm

(inch)

0.4

(0.35)

(0.50)

(0.59)

(0.82)

(1.12)

(1.70)

(2.15)

(3.25)

(4.22)

(6.27)

(8.13)1 (0.039)

(0.016)

0.4

(0.016)

0.4

(0.016)

0.4

(0.016)

0.4

(0.016)

0.4

(0.016)

0.6

(0.024)

0.6

(0.024)

0.6

(0.024)

0.8

(0.031)

DN

(inch)

3/8"S 8.9

mm

(inch)

3/8" 12.6

1/2" 14.9

3/4" 20.9

1" 26.7

1/5" 40.9

2" 52.6

3" 78

4" 102.4

6" 154.2

(6.07)

8" 202.7

mm

(inch)

0.4

(0.35)

(0.50)

(0.59)

(0.82)

(1.05)

(1.61)

(2.07)

(3.07)

(4.03)

(7.98)1(0.039)

(0.016)

0.4

(0.016)

0.4

(0.016)

0.4

(0.016)

0.4

(0.016)

0.4

(0.016)

0.6

(0.024)

0.6

(0.024)

0.6

(0.024)

0.8

(0.031)

1.

·

Flow direction and meter position

Flow must always be in the direction of arrow,

bluff side of vortex-shedding body facing

incoming flow i.e. upstream side.

·

Vertical pipe run : upward flow direction

·

Horizontal pipe run : see below

2.

Difference between inside diameter of primary

head and pipeline

D=Meter size (Nominal Dia. DN)

INLET OUTLET

DN F Meter size of primary head in mm or inches.

Inside diameter of primary head in mm or inches.

1

Page 5

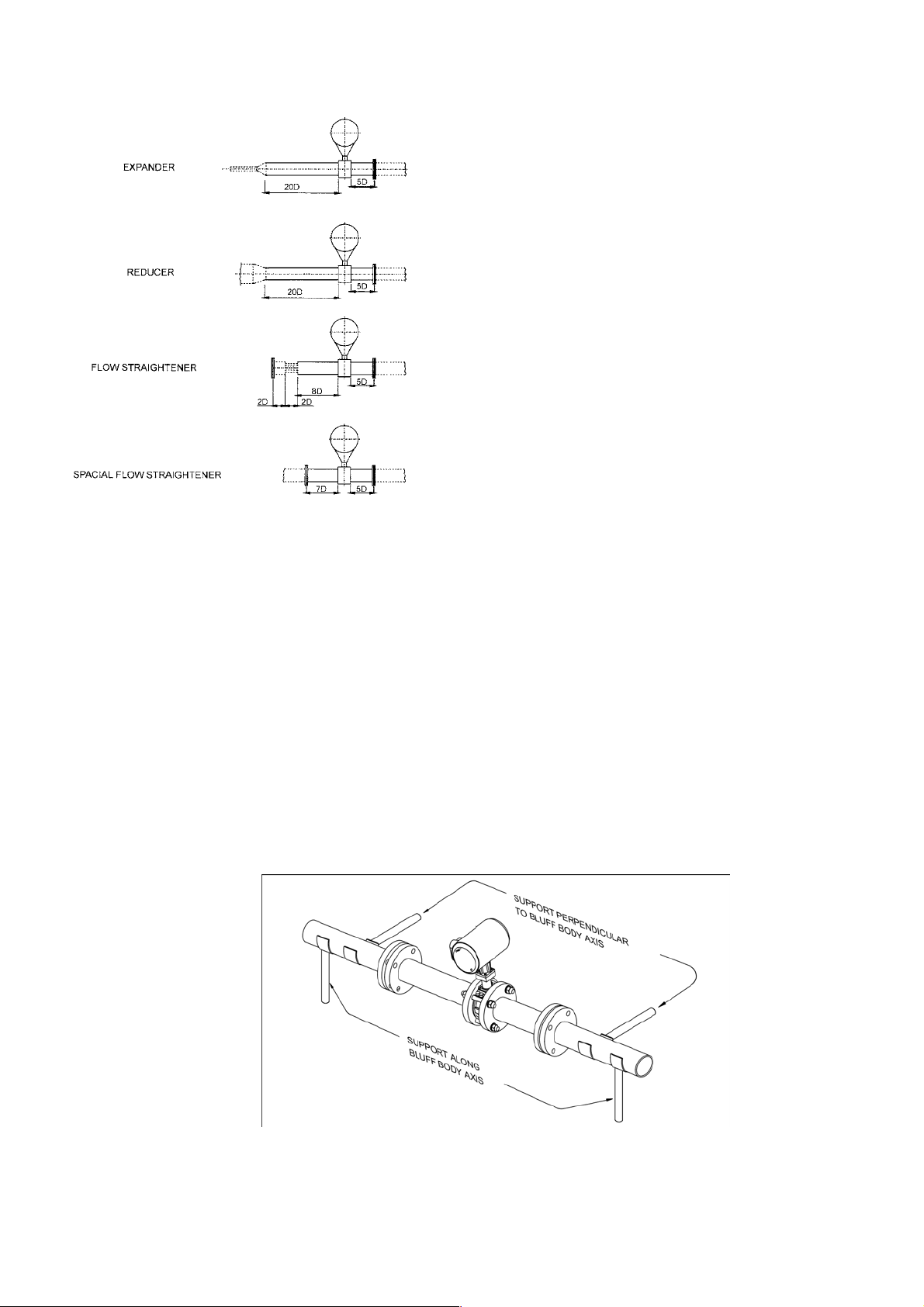

With flow straightener the inlet pipe length may be

halved e.g. for a control valve the inlet length is 25D

instead of 50D. The minimum inlet pipe length

including flow straightner must always be 12 D.

4. Pipe vibration

Pipe Vibration caused, for example, by the action of

pumps, valves, etc., will falsify measurements

particularly at low flow velocities. Support the

pipeline on both sides of the flowmeter, in the

direction perpendicular to both the pipeline & bluff

body axis.

INLET OUTLET

· Pipe vibration limit is 0.2g _peak to peak upto

8-500 Hz crossover frequency..(which equals

0.75 mm)

5. Pipeline along a wall

Where possible, the distance between the pipe

centerline and wall should be greater than 0.5 m(20”).

If it is less, first connect all cables to terminals in the

connection compartment (power supply and outputs)

and run them via an intermediate connection box (see

also Section 3) before installing the flowmeter.

6. Orientation

Turn the display board through ±90° or 180° to

·

obtain horizontal positioning of the display.

·

Turn the signal converter housing through ±90°

should that be more suitable for the location of the

installation.

7. State of Medium

·

Ensure single phase flow. Liquid droplets in gas/

vapour, solid particles in gas/liquid & gas bubbles

in liquid are not permitted.

In Liquid application e.g. water, to prevent

cavitation, minimum D/S pressure is given by the

relation:

Pds(bar _g) > =(2.9*DP) + (1.3*Ps)-1.013

where

DP= pr. drop of VFM in Bar from sizing program

Ps=Sat.pr. in Bar at op.temp.

·

In case of steam or compressed gas, a moisture

separator may be used 50D upstream of the meter

if the dryness fraction is less than 95%.

·

For any fluid, a filter or strainer may be used to

remove solid particles. This is specially important

for meter sizes below 1” where a filter or strainer

is a must.

2

Page 6

Sandwich Version

Flanged Version

3

Page 7

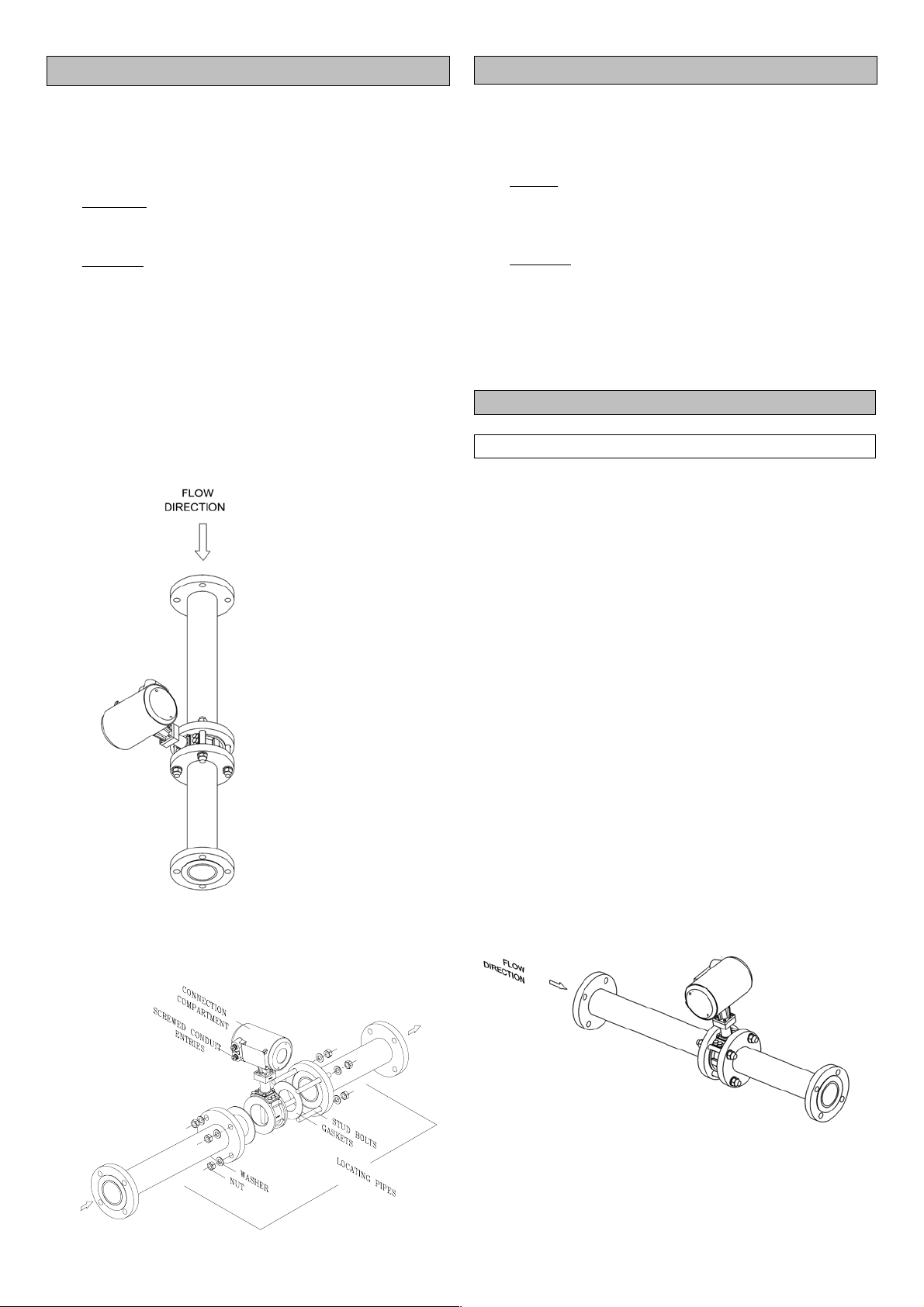

2.2 Sandwich type to DIN19205 / ANSI

·

Meter sizes DN 25, 40, 50, 80,100 and 150 (1”to

6”)

·

Pipe flanges

(Pressure ratings

to DIN

DN50/PN40, 64, 100; DN80/PN40, 64, 100;

DN100/PN16, 40, 64 and DN 150 / PN16, 40

to ANSI

·

Gaskets inside diameter must be greater than the

inside diameter f of the primary head. e.g. use flat

gaskets to DIN 2690. Gaskets must not project into

the effective pipe cross sectional area.

·

Bolts, nuts and washers are supplied.

·

Check flange connections for leak-tightness after

flowmeter installation.

Installation in Vertical Pipe Run

Assembly Diagram of Sandwich Units

:- DN25/PN40, 100; DN40/PN40, 100;

: 1” to 6”/ # 150, 300 SORF)

2.3 Flanged type to DIN 2501/ANSI B 16.5(SCH40)

Meter sizes DN 10S, 10, 15, 20, 25, 40, 50, 80 100,

·

150 and 200 (3/8”S to 8”)

· Pipe flanges

to DIN

DN 50/PN 40, 64, 100; DN 80/PN 40, 64, 100; DN

100/PN 16, 40, 64; DN 150/PN 16, 40; DN 200/PN

10, 16 and

to ANSI

Gaskets are supplied by us with flanged units.

Center the flowmeter by sight. ·

: DN 25/PN 40, 100; DN 40/PN 40, 100;

: 1/2” to 8” / # 150, 300 SORF)

· Check flange connections for leak-tightness after

flowmeter installation.

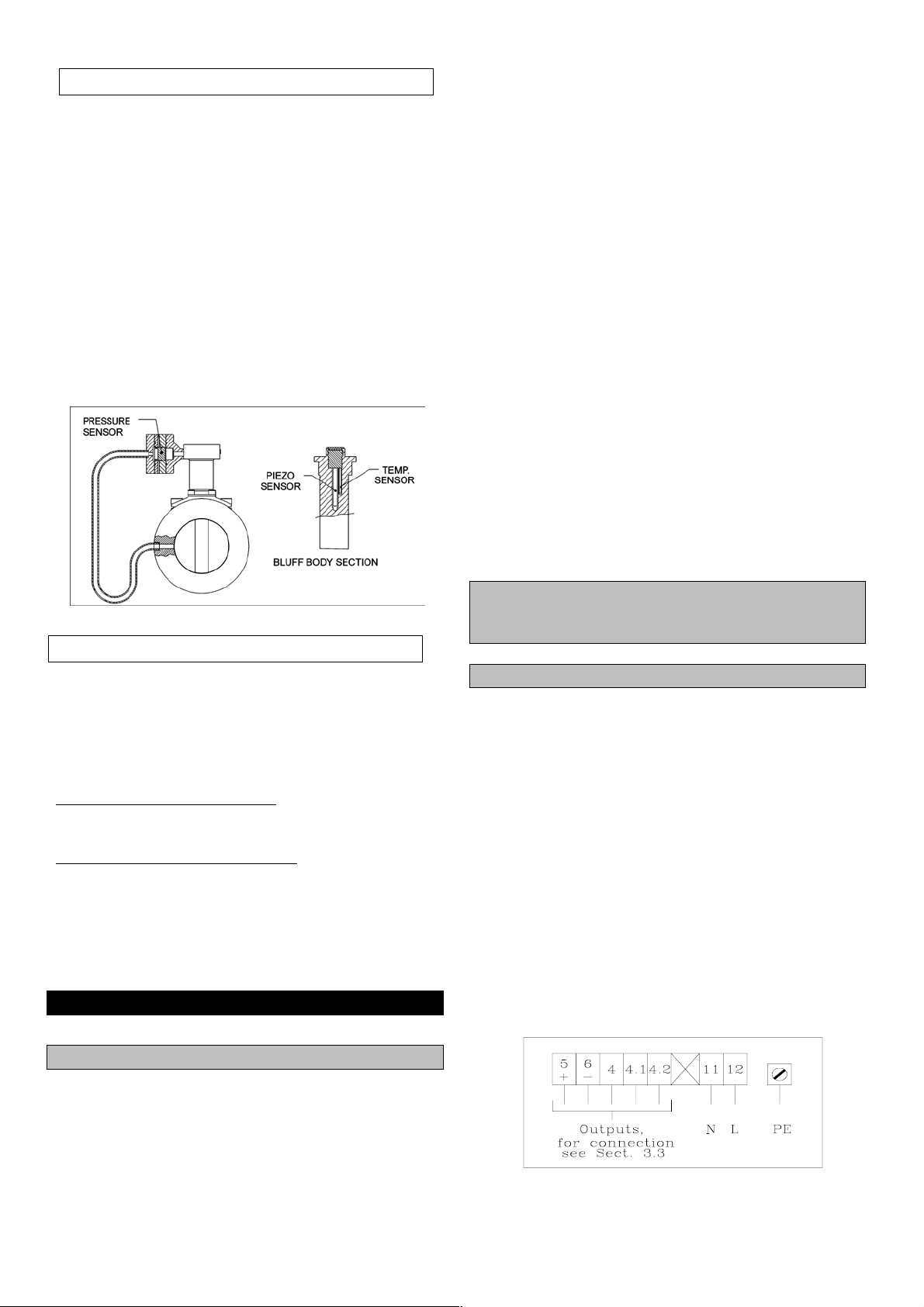

2.4 Temperature and pressure measurements

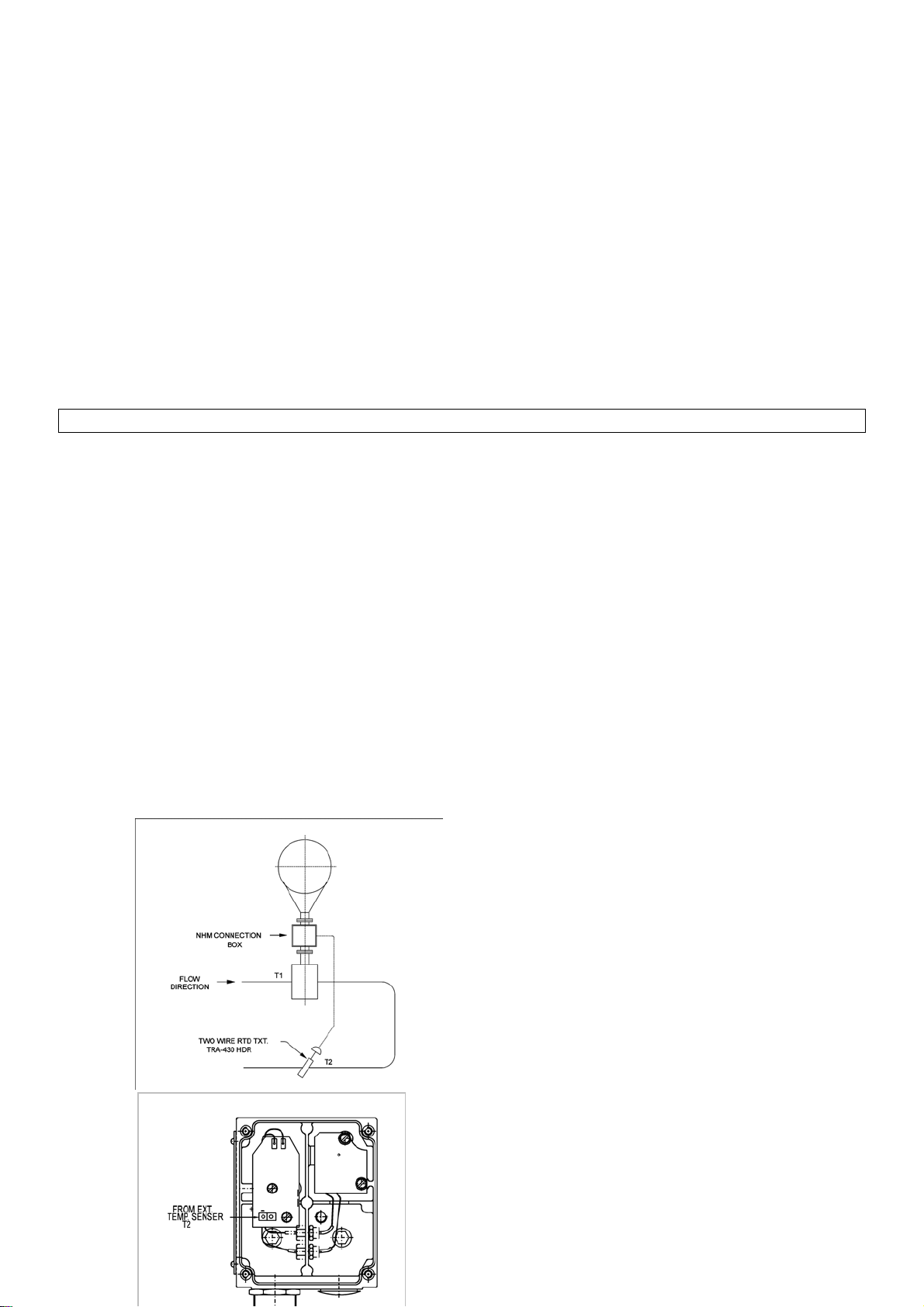

2.4.1 Temperature measurement

VFM 5090(I) is always supplied with a temperature

sensor. This sensor is RTD (PT1000 type) and is

located within the Vortex bluff body. See figure given

for location of Temperature sensor. This sensor

provides an accurate measurement of temperature of the

medium at the vortex sensor.

Flowmeter will continuously measure medium

temperature -

To display medium temperature ·

·

To provide on-line T compensation for mass and

normalized flow computations.

·

To monitor whether the medium temperature

remains within the user specified operating

temperature limits.

Installation in Horizontal Pipe Run

4

Page 8

2.4.2 Pressure measurement with built-in sensor

VFM 5090(I) may be supplied with an optional

pressure sensor. This sensor is typically a strain gauge

type and located in the primary assembly as shown in

the figure below. Thus the sensor also provides an

accurate measurement of pressure of the process fluid.

Flowmeter will continuously measure medium

pressure -

·

To display the medium pressure value

·

To provide an on-line P&T compensation along

with T sensor for mass and normalized volumetric

flow computation.

·

To monitor whether the medium pressure is within

the user specified operating pressure limits.

2.4.3 Pressure measurement by external means

To determine the pressure of the medium (e.g. to feed

the pressure value in VFM for an off-line P&T

compensation for mass or normalized flow

computations), suitable measuring point must be

provided near the flowmeter.

Location upstream of flowmeter

Min. distance : 20*DN (DN = meter size)

Location downstream of flowmeter

Min. distance : 5*DN (DN = meter size)

Allowance must be made for the pressure drop in the

flowmeter as correction value for operating conditions

prevailing upstream of the flowmeter.

3. Electrical connection

3.1 Installation location and cable diameter

Location

·

The rotating design of the housing makes it easier

to connect the two cables for power and outputs to

the terminals in the rear terminal box.

Cable diameter

To conform to protection category requirements,

observe the following recommendations

·

Cable diameter : 8 to 13 mm (0.31” to 0.51”)

·

Enlarge the inside diameter of the Screwed conduit

entry by removing the appropriate onion ring(s)

from the seal,only if cables have extremely tight

fit.

·

Fit blanking plug PG 16 and apply sealant to

unused cable entries.

·

Do not kink cables at conduit entries.

·

Provide water drip point (U bend in cable).

Conduit Installation, general wiring considerations

·

When electrical codes require conduit, it must be

installed in such a manner that the meter

connection compartment remains dry at all times.

·

Power and output wiring should be run in a

separate conduit.

·

Use twisted pair for output wiring.

WARNING Power wiring should utilize a grounded

conductor to avoid possible shock hazard and damage

to component parts.

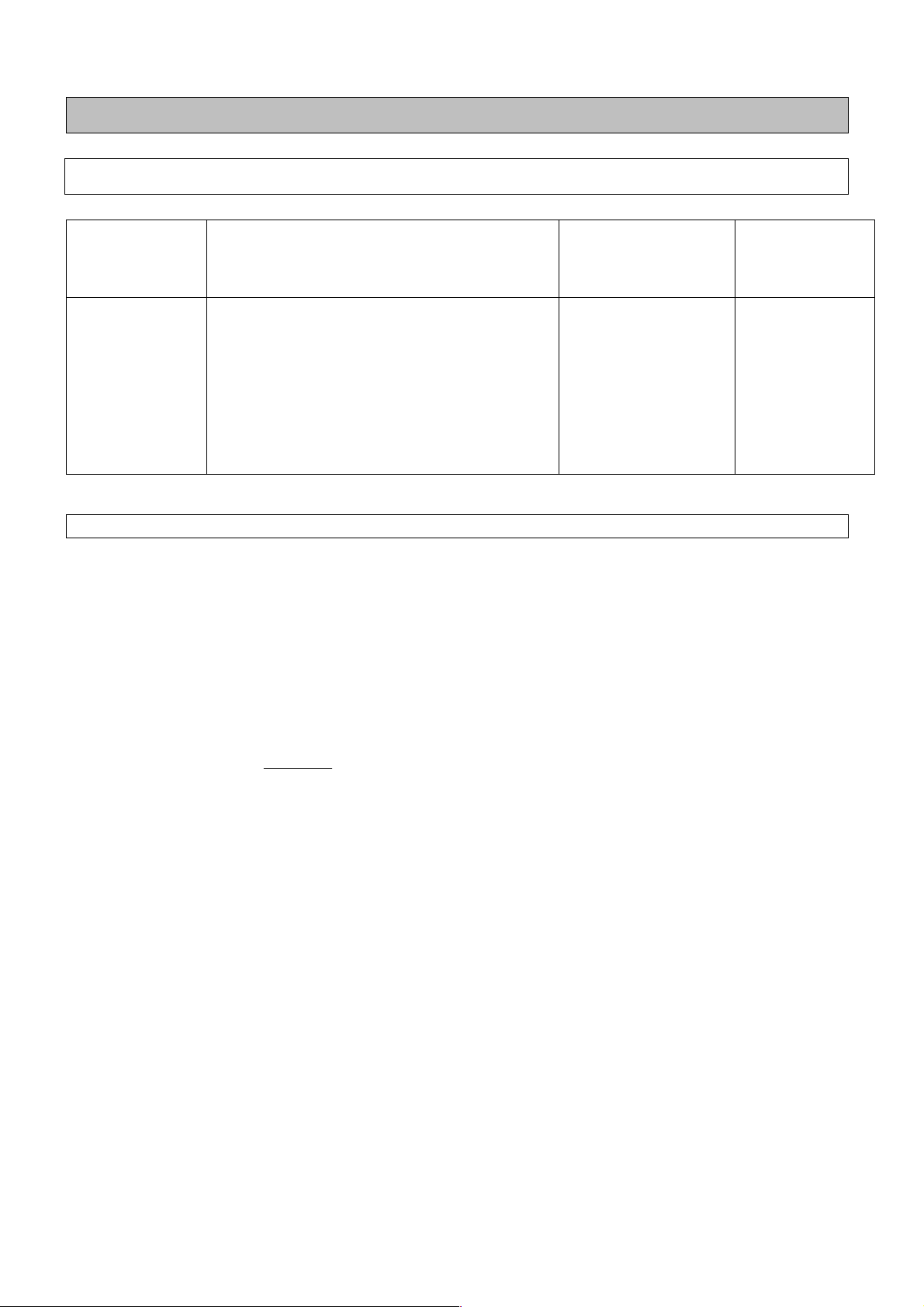

3.2 Connection to power

Note information given on the instrument name

·

plate (voltage, frequency)!

·

Electrical connection in conformity with VDE

0100 “Regulations governing heavy-current

installations with rated voltages up to 1000V” or

equivalent national standard.

·

The PE protective ground conductor for supply

power must be connected to the separate U-clamp

terminal in the terminal box of the signal

converter.

·

Do not cross or loop cables in the terminal box of

the signal converter. Use separate PG or NPT

screwed conduit entries for power and output

cables.

·

Ensure that the screw thread of the round cover

on the terminal box is well greased at all times.

·

Connection to power, VFM 5090(I)

·

Do not expose the compact flowmeter to direct

sunlight. Install a sunshade if necessary.

·

Do not expose to intense vibration. If necessary

support the pipeline to the left & right of the flow

meter.

5

Page 9

I

3.3 Outputs

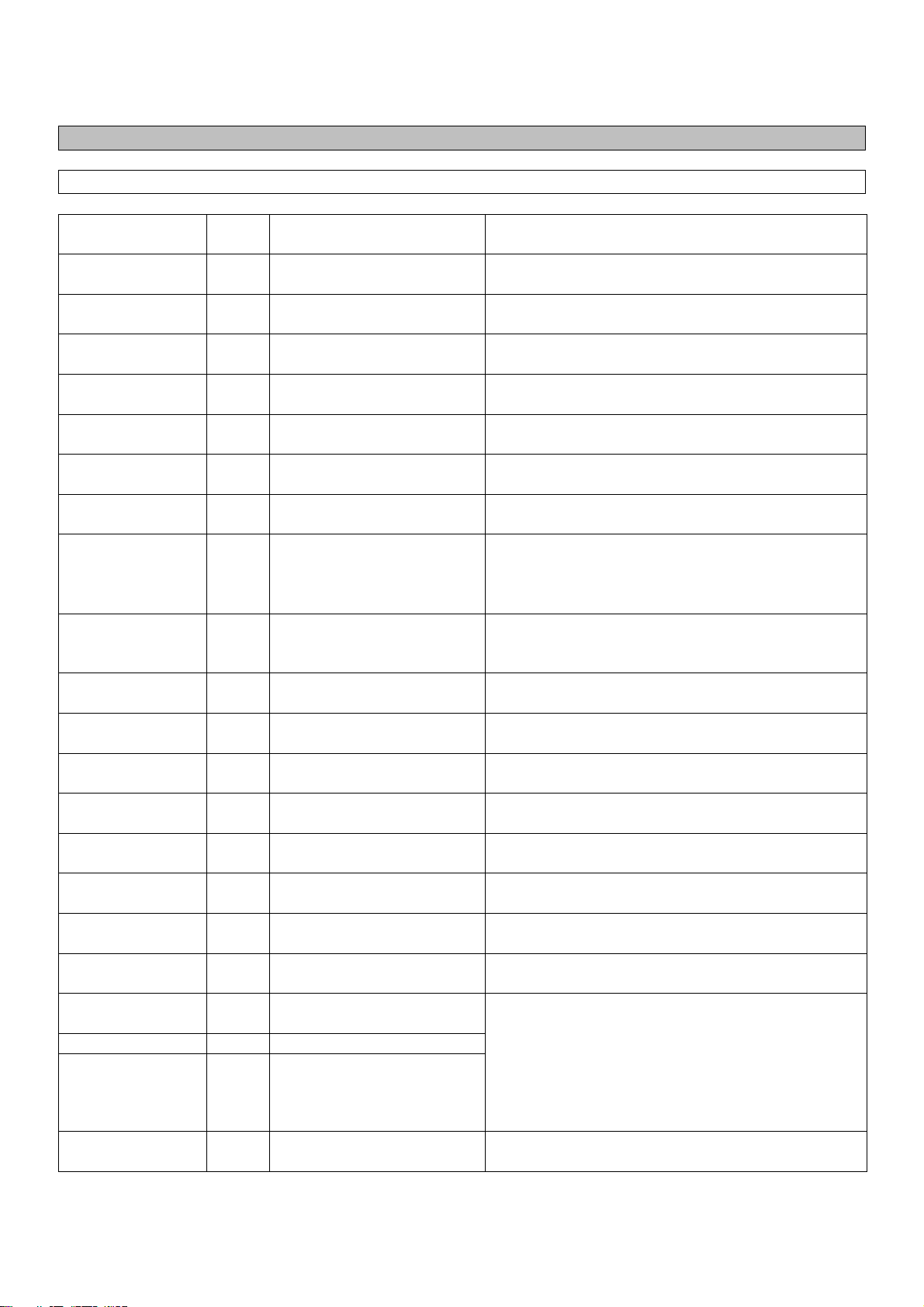

3.3.1 Abbreviations

Abbreviation Stands for

EC

EMC

F

F

100%

I

I

0%

I

100%

Q

0%

Q

100%

Electronic counter

Electro-mechanical counter

Frequency (Pulse) output

Pulses for Q = 100 % flow rate or pulse value

Current (analog) output

Current at 0/4 mA flow

Current at 20 mA flow

0% flow rate

Full - Scale range, 100 % flow rate.

Programming

via Fct. No...

---

---

1.4.X

1.4.2

1.3.X

1.3.3

1.3.4

1.1.2

Description

See Sect....

---

---

6.1 + 6.2.9

6.1 + 6.2.9

6.1 + 6.2.8

6.1 + 6.2.8

6.1 + 6.2.8

-

6.1 + 6.2.4

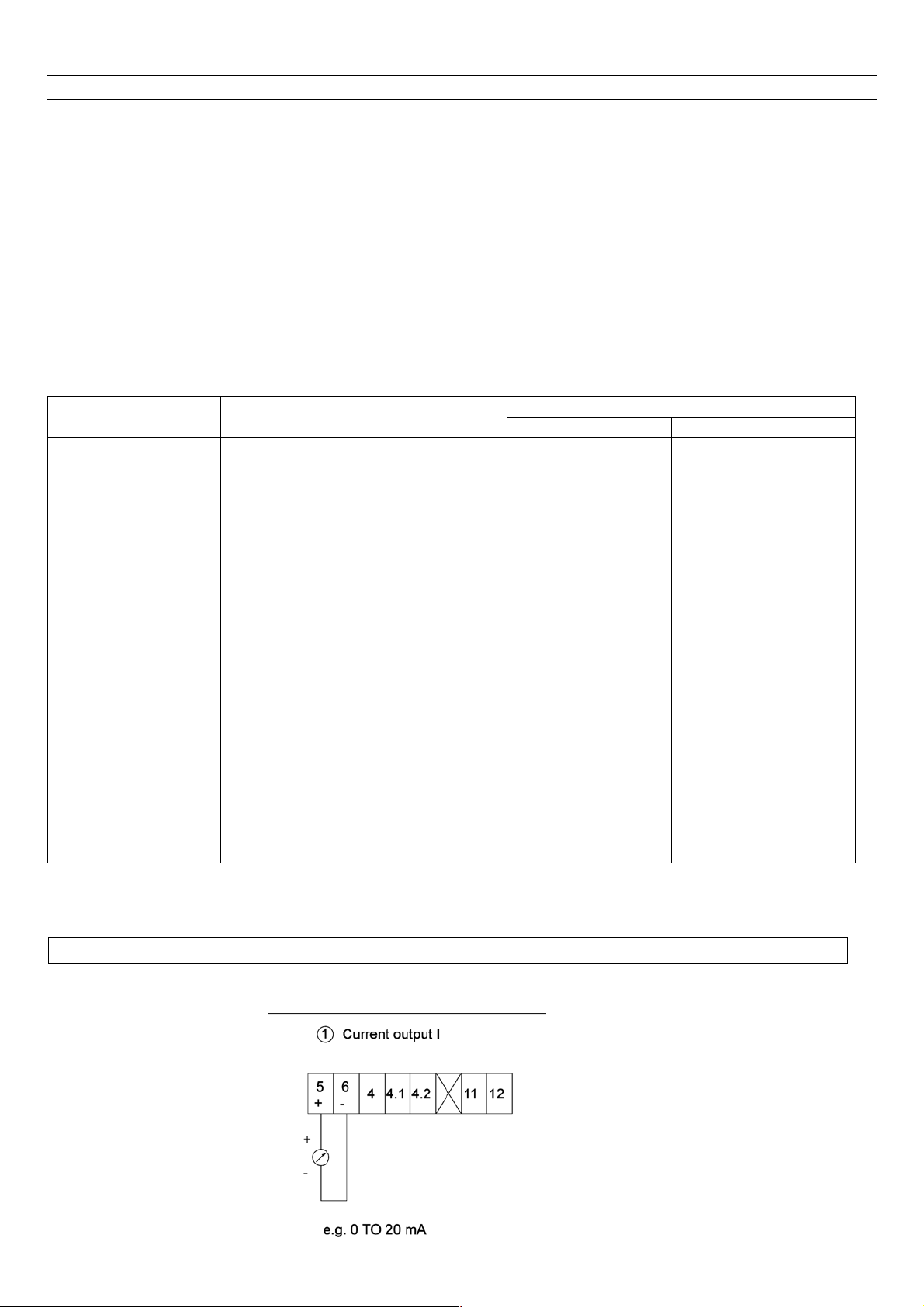

3.3.2 Current (analog) output I

The current output is galvanically isolated from all input and output circuits but not from frequency

·

output F. Therefore only one grounded receiver instrument may be connected to either current output I or

frequency output F.

·

All functions and operating data are programmable, see sections 5, 6.1 & 6.2.8.

·

Factory-set data and functions are listed in the enclosed ‘Configuration Sheet’ on settings.

This can also be used to record any changes made to the operating parameters.

·

Max load at terminals 5/6 for I

(Fct. 1.3.4) :

100%

V

Max. load Kohms =

[

14

%100

(e.g. 0.7 K ohms for I

]

][

mA

Error annunciation programmable to 2 mA or 22 mA (Fct. 1.3.2) ·

· Connection diagram Refer to Section 3.3.4

= 20 mA)

100%

6

Page 10

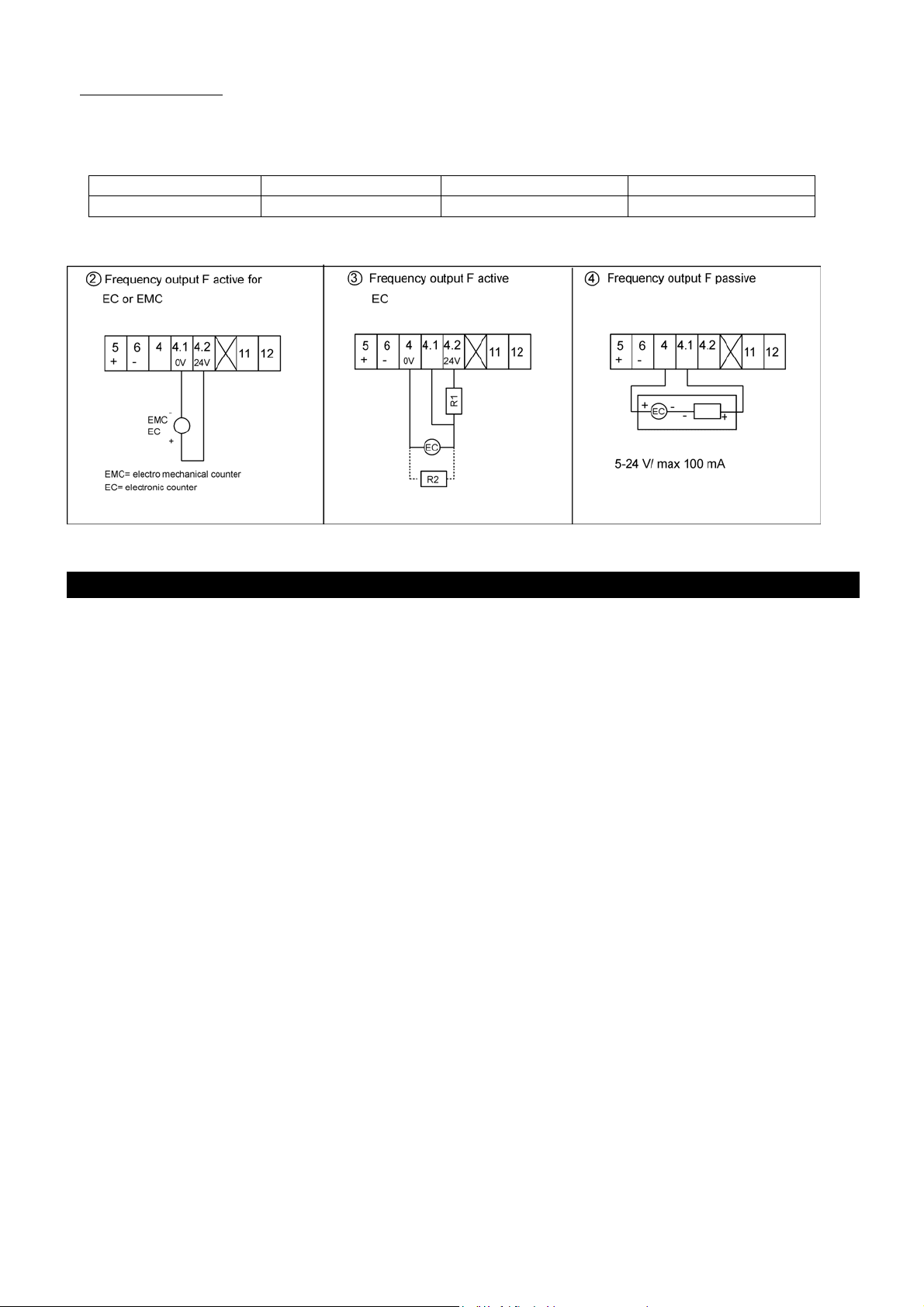

3.3.3 Frequency (pulse) output F

The frequency output is galvanically isolated from all input and output circuits but not from current output I.

·

Therefore only one grounded receiver instrument may be connected to either frequency output F or current output

I.

·

All functions and operating data are programmable, see Section 5, 6.1 & 6.2.9.

·

Factory - set data and functions are listed in the enclosed report on settings. This can also be used to record any

changes made to the operating parameters.

·

Active frequency output for electromechanical totalizers EMC (terminals 4.1/4.2) or for electronic totalizers EC

(terminals 4.1/4.2 or 4/4.1/4.2), 10 to 36000000 pulses/hr (0.0028 to 10000 Hz), amplitude max. 30 V, selectable

pulse widths and load rating see below.

·

Passive frequency output, open collector for connection of active electronic counters EC or switchgear, input

voltage 5 to 30V, load current max. 100 mA, R

·

Pulse width (Fct. 1.4.3) as a factor of frequency f (pulse rate) and maximum permissible load for active output

= 100 ohms, selectable pulse widths see below.

i

(term. 4.1/4.2 or 4/4.1/4.2), see also Sect. 6.2.9.

Pulse width Frequency f = F

500 ms 0.0028 Hz < f

Load rating of active output

100%

Load current Load

1 Hz < 150 mA ³160 Ohm

£

200 ms 0.0028 Hz < f

2 Hz < 150 mA ³160 Ohm

£

100 ms 0.0028 Hz < f

3 Hz < 150 mA ³160 Ohm

£

100 ms 3 Hz < f

5 Hz < 60 mA ³400 Ohm

£

50 ms 0.0028 Hz < f

5 Hz < 150 mA ³160 Ohm

£

50 ms 5 Hz < f

10 Hz < 60 mA ³400 Ohm

£

30 ms 0.0028 Hz < f

6 Hz < 150 mA ³160 Ohm

£

30 ms 6 Hz < f

10 Hz < 80 mA ³300 Ohm

£

Pulse duty cycle 1:1* 10 Hz < f £ 1000 Hz < 25 mA ³1000 Ohm

160 µs* 1000 Hz < f £ 2547 Hz < 25 mA ³1000 Ohm

50 µs* 2547 Hz < f £ 10000 Hz < 25 mA ³1000 Ohm

* fixed pulse width, independent of programming in Fct. 1.4.3

Refer connection diagrams k, l and m. Refer to Section 3.3.4 ·

·

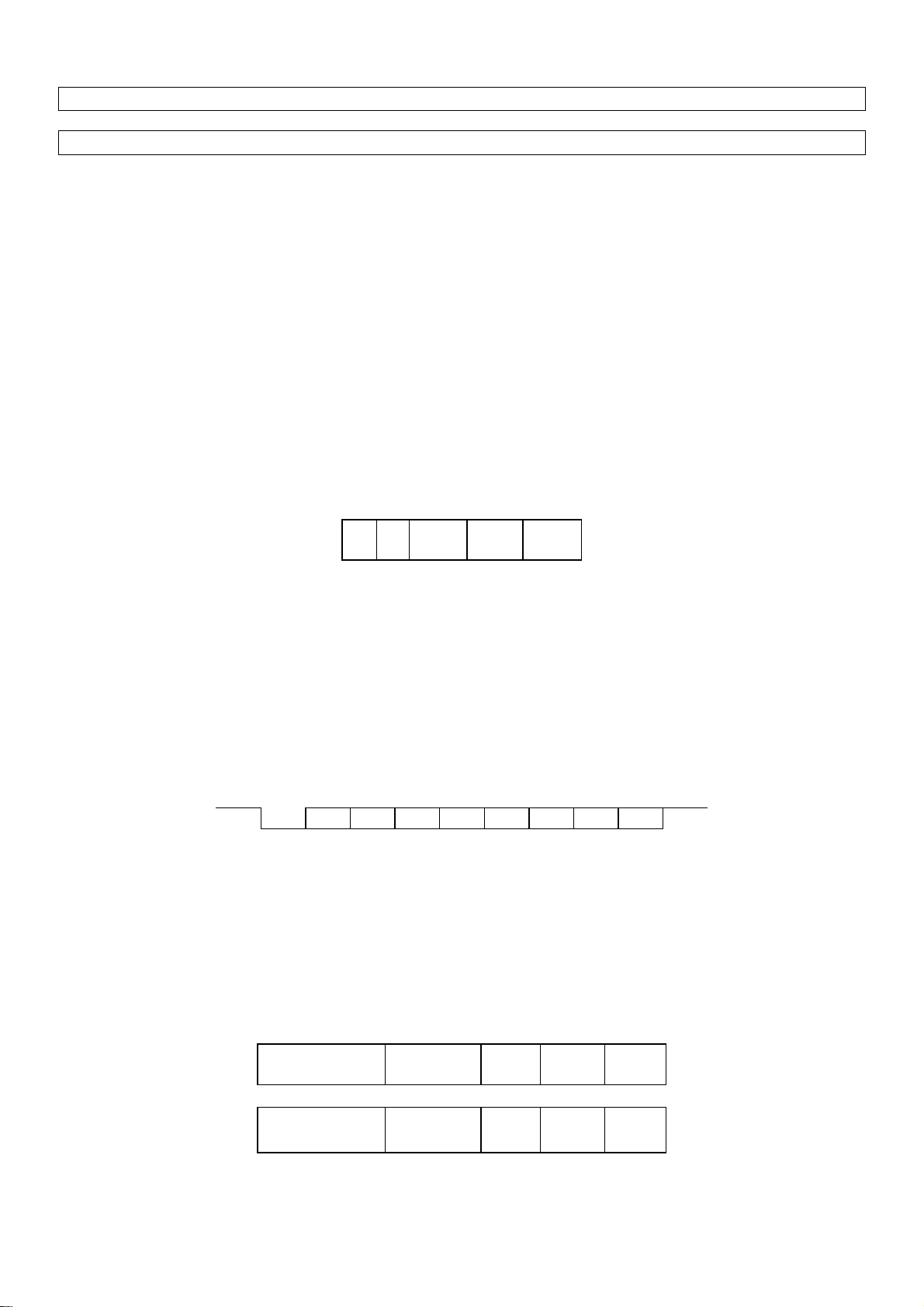

3.3.4 Connection diagram for outputs j to m

Output characteristics

Current output I:

Diagrams I1 in Section 6.2.8

7

Page 11

3. Frequency output F: Diagram F1 in Section 6.2.9

R1 & R2 when electronic counter is connected to terminals 4/4.1/4.2 connection diagram l

R1 = 1 Kohm , 1W

R2 needed only for totalizer with input voltage Umax < 30 Volts.

Umax 24 V 12 V 5 V

R2 3.9 Kohm 680 ohm 180 ohm

4. Start-up

Check that the system has been correctly installed as described in Sect. 1, 2 and 3. ·

·

Before initial start-up check that the following details on the nameplate agree with the data specified in the

report of settings for the signal converter. If not, reprogramming will be necessary.

Meter size Fct. 3.1.1 Sect. 6.1, 6.2.5.

K-Factor Fct. 3.1.2 Sect. 6.1, 6.2.5.

·

The flowmeter is ready for service 15 minutes (waiting time) after switching on the power source. Increase

flow velocity slowly and steadily.

·

Avoid abrupt changes in pressure in the pipeline.

·

If the process product is steam, condensate may form initially and cause faulty measurements when the system

is started up for the first time.

·

When powered, the signal converter normally operates in the measurement mode. The power-on sequence to

measurement mode is as follows :

‘TEST’ is displayed for approx. 3 seconds followed by

‘VFM 5090’ the instrument type followed by

‘Ver x.xx’ the software version of the instrument.

Then instrument operates in measurement mode where it displays the parameter being measured or ‘FATAL

ERROR ’ if there are one or more critical errors detected (For description on errors refer Sect 5.5)

8

Page 12

Part B Signal Converter VFC 090

5. Operation of the signal converter

5.1 General

5.1.1 Starting up signal converter

When power is switched ON to signal convertor it displays TEST, VFM 5090 & Ver x.xx and then goes to

measurement mode. In this initial sequence VFM 5090(I) carries out self diagnostics to check its own

functional elements and loads the configuration data from non-volatile memory. If any error(s) are detected in

power-ON diagnostics, the converter displays FATAL.ERROR since instrument has critical error(s) and is not

able to carry out normal measurements. If no start-up errors are detected the first measured parameter displayed

is the one being displayed when power supply was removed last time.

5.1.2 Measurement Mode

In measurement mode, the parameters that the converter measures/computes are shown on the display in the

appropriate units. (See Sect. 5.2 for display details). As per the configuration, display can be either in noncyclic/cyclic mode. In non cyclic mode of display, use é key to see the next parameter on display. In cyclic

mode display shows all the parameters one after another, wherein each parameter is displayed for about 6

seconds.

5.1.3 Programming or menu mode

All the configurations/settings/test functions are grouped in the form of menu tree structure (see Sect. 5.3.1 for

details) and are accessible in the programming mode. Operator can view or alter the present settings and data

values by the use of functions available in this mode.

All changes made in the programming mode are stored temporarily until the operator quits to the

·

measurement mode and responds YES to an ‘UPDATE’ prompt. Only then the new changes are saved in

non-volatile memory and have appropriate effect on the operation of signal converter.

· Even in the programming mode the converter “keeps working” as per present configuration. Simply stated,

the converter continues to measure (flow rate, totalizing of flow, P, T etc.) and control outputs (current and

frequency outputs) while in the programming mode.

5.1.4 Error handling

Converter can detect errors during power-on diagnostics as well as when in normal measurement mode. Errors

are divided into two main categories viz. fatal errors and non-fatal errors. Fatal errors cause measurement to

stop since they are serious in nature. Non-fatal errors do not affect functionality of the converter.

If one or more errors are present, display (in the measurement mode) starts blinking. If programmed so, error

information is shown on display, interleaved between the display of two parameters.

9

Page 13

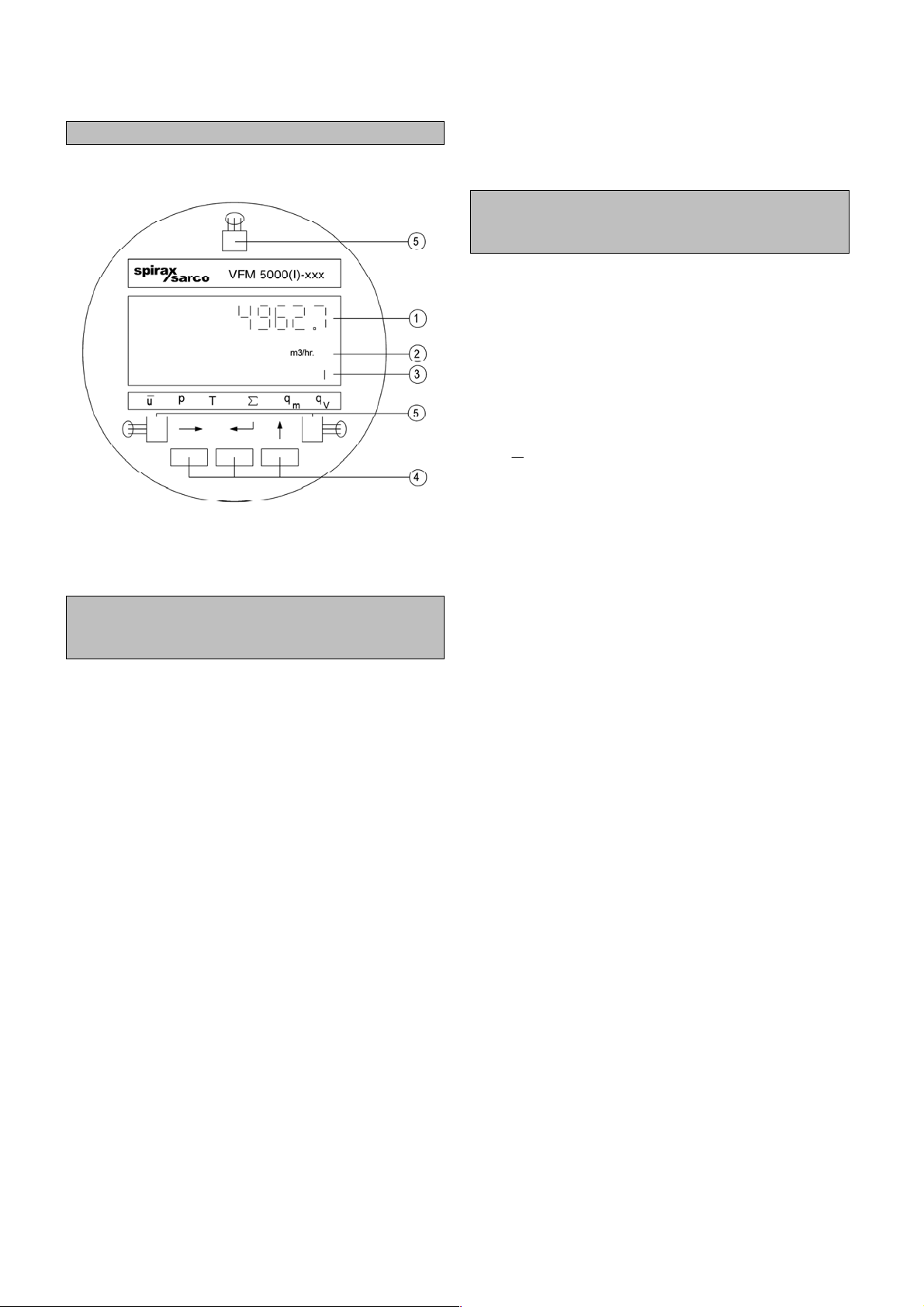

5.2 Operating elements

CAUTION To avoid damage to electronics, be

certain that the area around the meter is dry before

removing the electronics compartment cover.

The operating elements are accessible after

removing the cover of the electronics section using

the special wrench.

CAUTION Do not damage screw thread, never

allow dirt to accumulate, and make sure it is well

greased at all times.

Display, 1

Display, 2

Display, 3

st

line

nd

line

rd

line

Cursor symbols described below

q

Volumetric flow rate

v

q

Mass flow rate

m

Totalizer value

S

Measured / Set temperature value

T

Measured / Set pressure value

P

Velocity of medium

u

Keys for programming the Signal Converter, refer

to Sect. 5.4 for the functions of keys.

Magnetic Sensors to program the converter by

means of a hand-held bar magnet without having

to open the housing, refer to Sect. 6.3. Function

of sensors is same as keys . Hold the bar

magnet by the cap. Apply other end of the magnet

(north pole) to the glass pane above the magnetic

sensors. Sensor or key response is acknowledged

by symbols appearing in 1

6

xxx on the display is used to describe the type of

o

the meter. It can be :

st

line of display.

1. AGA - Natural Gas Meter (AGA)

2. FAD - Free Air Delivery

3. HM - Heat Meter

4. NHM - Net Heat Meter

5. STD - Standard

10

Page 14

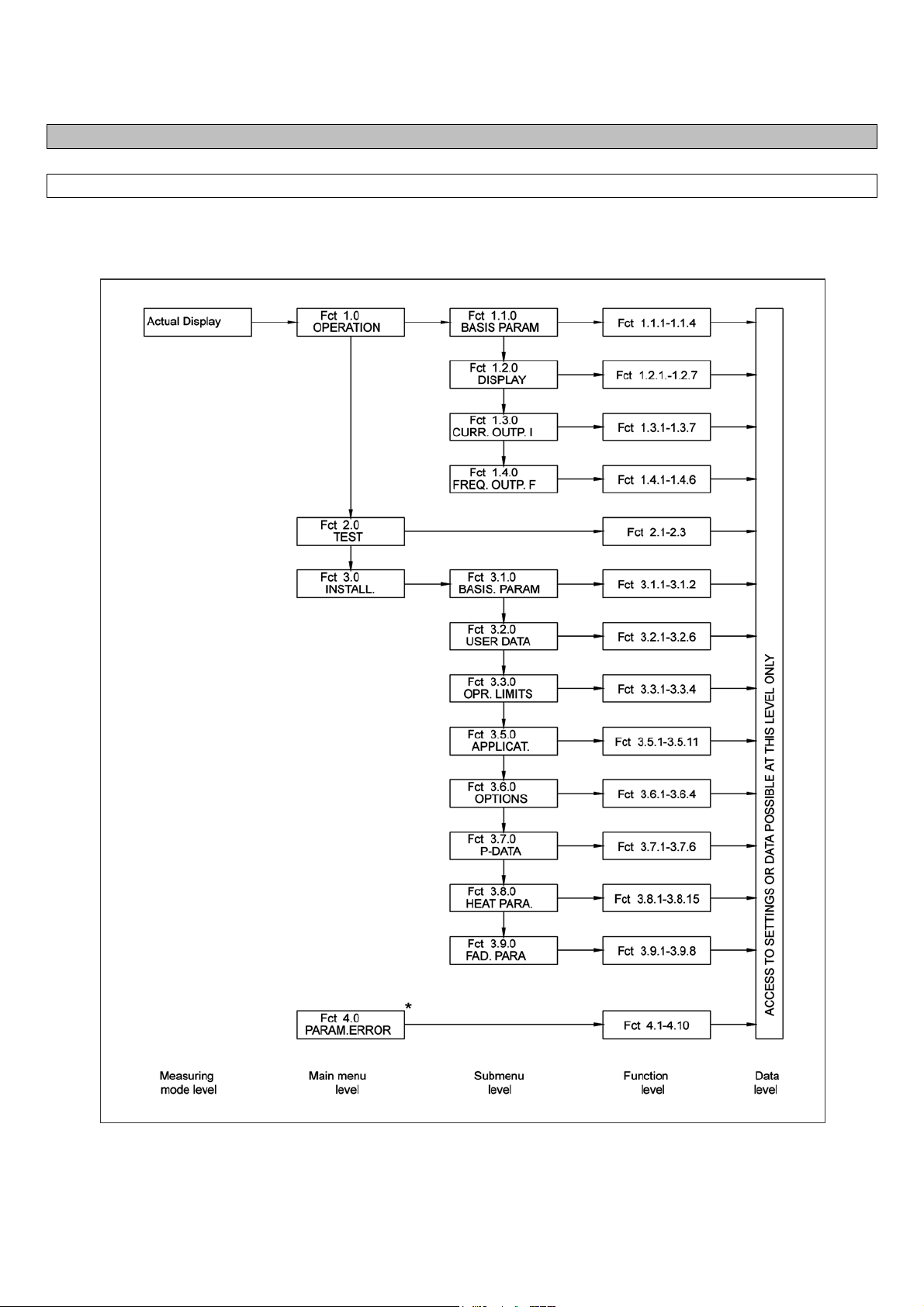

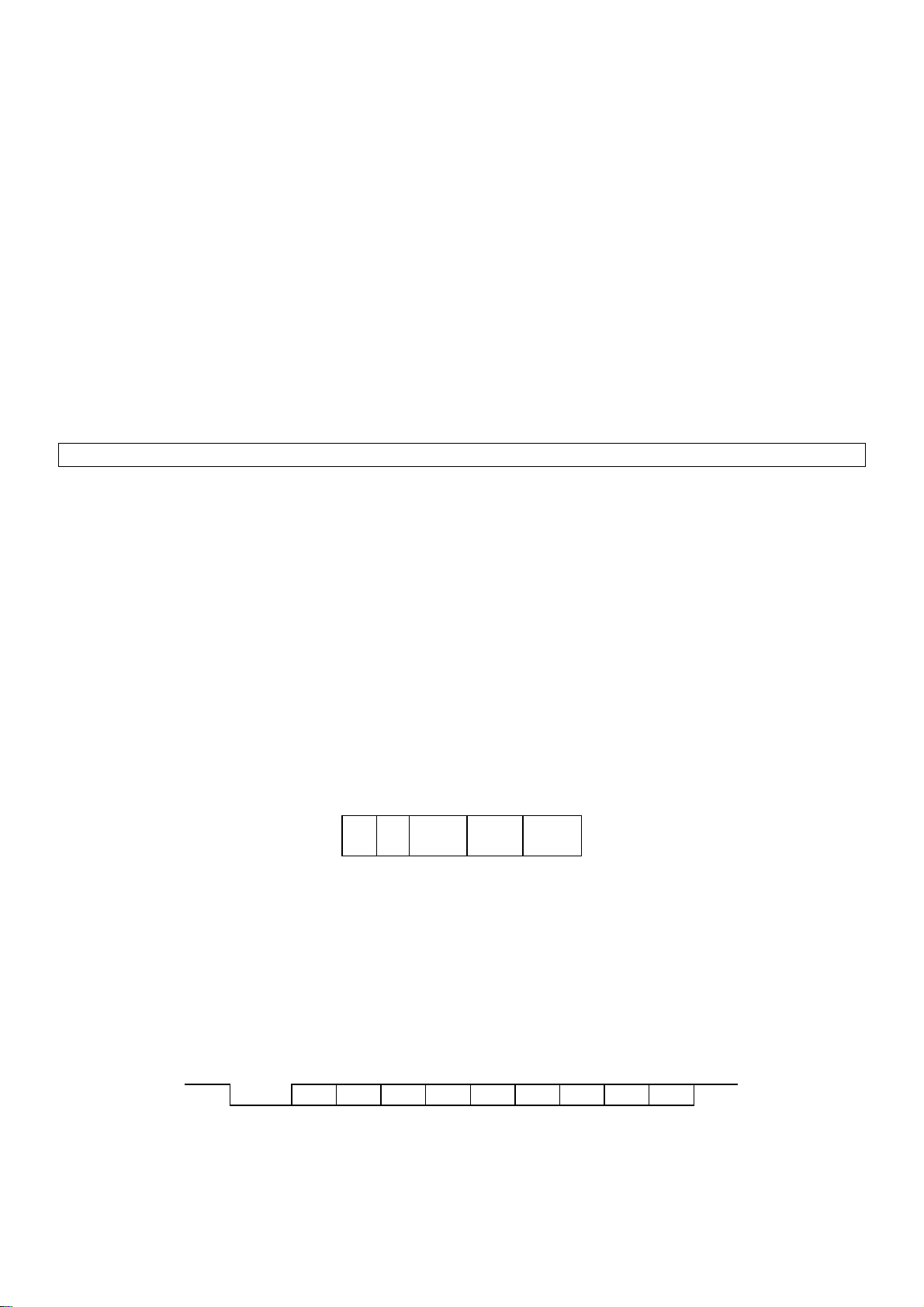

5.3 Program organization & programming chart

5.3.1 Menu Levels

The program for the signal converter consists of 5 levels. The 1st line of display will identify the menu level during

programming.

11

* Function 4.0 is not accessible in usual manner and is explicitly generated due to errors detected by

Page 15

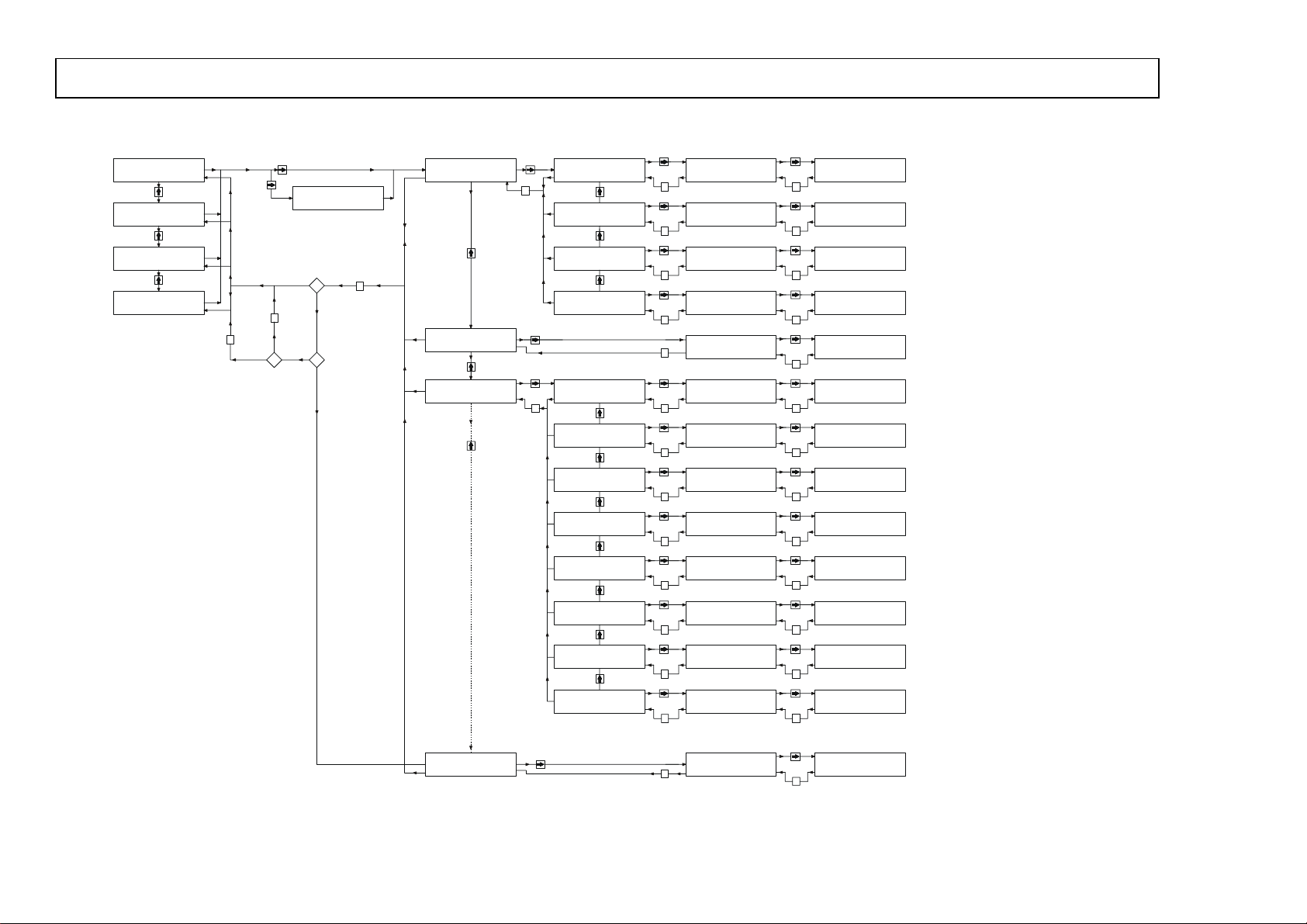

5.3.2 Programming chart

A

A

O

MEASURED

PARA MET ER

-

-

Error Msg DISPLAY

NEXT MEASURED

PAR AMET ER

-

-

-

Next Error Msg

n Err

n Err

-

-

-

-

-

-

settings

not

Saved

E

YES

NO

UPDATE NO?

E

Fct 3.2.2 as N

ENTRY.CODE.1

CODE 1(9 keys)

Password

Fct 3.2.2 as YES

ENTRY.CODE.1

Settings changed?

NO

?

YES

settings

saved

Plausibility

YES

checks OK?

??

NO

Fct 1.0

OPERATION

E

Fct 2.0

TEST

Fct 3.0

INSTALL.

During

plausibility

corrections

E

Fct 1.1.0

BASIS PARAM

Fct 1.2.0

Fct 1.3.0

CURR. OUTP. I

Fct 1.4.0

FREQ. OUTP. F

Fct 3.1.0

BASIS. PARAM

E E

Fct 3.2.0

USER DATA

Fct 3.3.0

OPR. LIMITS

Fct 3.5.0

APPLICAT.

Fct 3.6.0

OPTIONS

Fct 3.7.0

P-DATA

Fct 3.8.0

HEAT PARA.

Fct 3.9.0

FAD. PARA

Fct 1.1.1 TO

E E

E

E

E

E

E

E

E

E

E

E

E

Fct 1.1. 4

Fct 1.2.1 TO

Fct 1.2. 7

Fct 1.3.1 TO

Fct 1.3. 7

Fct 1.4.1 TO

Fct 1.4. 6

Fct 2.1 TO

Fct 2.3

Fct 3.1.1 TO

Fct 3.1. 2

Fct 3.2.1 TO

Fct 3.2. 6

Fct 3.3.1 TO

Fct 3.3. 4

Fct 3.5.1 TO

Fct 3.5.11

Fct 3.6.1 TO

Fct 3.6. 4

Fct 3.7.1 TO

Fct 3.7. 6

Fct 3.8.1 TO

Fct 3. 8.15

Fct 3.9.1 TO

Fct 3.9. 8

E

E

E

E

E

E

E

E

E

E

E

E

Actual 1.1.X

FUNCTIONS

Actual 1.2.X

FUNCTIONS

Actual 1.3.X

FUNCTIONS

Actual 1.4.X

FUNCTIONS

ctual 2.X

FUNCTIONS

Actual 3.1.X

FUNCTIONS

Actual 3.2.X

FUNCTIONS

Actual 3.3.X

FUNCTIONS

Actual 3.5.X

FUNCTIONS

Actual 3.6.X

FUNCTIONS

Actual 3.7.X

FUNCTIONS

Actual 3.8.X

FUNCTIONS

Actual 3.9.X

FUNCTIONS

Fct 4.0

PARAM.ERROR

Fct 4.1 TO

E

Fct 4.10

E

ctual 4.X

FUNCTIONS

12

Page 16

13

s

e

p

5.3.3 Description of keys

u

Measuring mode level

é

display measured

parameters /error

messages

Enter programming

E

mode

v

é

è

E

Main menu level

Go to main menu

Enter main menu

displayed

Return to measuring

mode level

w

Submenu level

é

Go to submenu

è

Enter submenu

displayed

Return to main

E

menu level

x

Function level

é

Go to Function Units/Options

è

Enter/execute

function displayed.

Then continue as

under y data level

y

Data level

é

Go to next propo

è

Return to submenu

E

level or main menu

level

Important

1. All changes made in programming mode are stored temporarily and do not affect

operation of the signal converter until operator leaves menu mode and responds with

UPDATE YES. Exceptions: all 2.X test functions.

2. Main menu level 4.0 PARAM.ERROR is automatically created if the plausibility

checks on the new configuration detects invalid values entered.

(See section 5.6 for details)

3. VFM 5090(I) continues to function even when in programming mode.

Temporarily sav

E

roposal then

with further data

any, or return

function level

Page 17

5.4 Programming and function of keys

Function of keys in measurement mode :

After power - on, the signal converter enters the normal measuring mode. Display shows the actual measured

value of the parameter, units and arrow markers to identify parameter. A steady (non - blinking) display indicates

that there are no errors in measuring mode. Use the é key to get the next parameter on display. If display is in

cyclic mode (Fct. 1.2.7 CYCLE DISP as YES) the next parameter is displayed after every 6 seconds and é has no

function.

Use the è key to go to the programming mode. If Fct. 3.2.2 ENTRY.CODE.1 is YES then converter will ask for

the code 1 password. Password is the sequence of 9 keys as given under Fct. 3.2.3 CODE 1. A wrong password

generates a set of unfamiliar characters on display. Press E key to go back to normal display.

Using the E key results in prompt for Code 2 password when converter is in measuring mode. Code 2 password is

predefined and reserved for KHRONE MARSHALL service person. Operator should not use E key at normal

display. If used by accident then give any arbitrary key sequence to Code 2 prompt until display gets back to

normal.

Using keys in measuring mode

KEY FUNCTION

è

è Followed by 9 keys

é

E followed by é è Resets LINE INTR error.

Function of keys in programming mode :

Programming and other functions are grouped in a menu tree structure. To navigate in the menu tree use keys as

follows :

è

To go into the branch i.e. from main menu level to submenu level or submenu level to function level. If you

were already at function level then that function will be executed.

é

Selects other options/branches at the same level.

Takes you one level back. If you were already at main menu level then this key takes you back to

E

measurement mode.

Programming functions involve one or more of the following types of data.

1. Selecting an option from option list - initially present option is displayed in second line of display and

display blinks to indicate that there are other choices. Use the é key to scroll through all options one by one.

Using E will cause that option to be selected and also completes selection process.

2. Entering a numeric value-Entering numeric data is very flexible in VFM 5090(I). You can enter +ve or -ve

number in floating point with /without exponent notation.

Formats : ddd.ddddd floating point e.g.

1.2345678, -12.34567

dd. dddEdd exponent e.g.

1.00000E6, -1.2345E-3

Method of entry : Initially the present value is displayed (in floating point format as far as possible) in the

first line of display. A flashing digit will change by using é key. è selects next digit position in sequence

and E terminates entry of the number.

With

}

without

Display next parameter measured or next error message

coding, dependent on programming of

Fct. 3.2.2

Go to programming mode.

(Fct. 1.2.6 as YES for error messages)

If in non cyclic mode ( Fct. 1.2.7 as NO)

In cyclic mode the key has no function.

14

Page 18

Notes

a) When you use è to move cursor and all digits start flashing then it means that you are at the decimal

point position. At this time use of é moves decimal point across the number.

b) Usually digits cycle through 0-9 values. At certain relevant position they cycle through 0, 1, 2, . . . 9,

-/E for -ve number or exponent notation.

c) When you enter a value beyond its limit then you get message dddd.dddd (MIN.VALUE) or

dddd.dddd (MAX.VALUE). Press E after you have noted limit and then correct value to be in valid

limits.

d) If you don’t want to change value press E at the beginning itself!

3.

Entering string (alphanumeric value) - This type of data input is required by a few functions. Present string is

displayed in the 2

é

to scroll through characters 0 - 9, A - Z, a - z and some other punctuation characters.

è

Change flashing (cursor) position

Terminate data entry.

E

nd

line and as usual 1st column blinks. Use :

Note :

Since scroll list (using é key) is far too long, an autorepeat function to keys is enabled. This allows you to press

and hold down é key to quickly reach the target character.

Using keys in programming mode

Key Main menu level Submenu level

Data level

Function level

Option/Units Numerical

values/strings

é

Go to main menu Go to submenu or function Select next proposal Change flashing

digit or character

è

E

Enter displayed main menu Enter displayed submenu or

(execute) function

Quit Programming mode and

go back to measurement

Return to main menu or

submenu

mode

Shift flashing digit

or character position

Select displayed

proposal and return

to function level if

no further data entry

is required by the

function

Enter the displayed

numerical value or

alphanumerical

string. Then returns

to function level if

no further data input

is required by that

function.

VFM 5090(I) continues to perform measurement functions even when you are in the programming mode as per the

configuration stored in non-volatile memory. Newly entered data will be saved in non-volatile memory and

accepted by measuring program only after termination of programming mode as described below :

Pressing the E key at main menu level quits the programming mode. Software then checks whether one has altered

existing settings (refered to as configuration). If no changes are detected, then converter goes back to measurement

mode. If configuration has been changed, converter displays options UPDATE NO or UPDATE YES prompting

you, if you really want to change existing configuration. When you say yes to update, then plausibility of the new

configuration is checked. If there are no errors in plausibility checks, then only the new configuration is saved in

nonvolatile memory and converter reverts to measurement mode as per the newly programmed configuration. (If

any errors are detected in the plausibility checks then a new main menu level Fct 4.0 PARAM.ERROR is

automatically created for you to correct for plausibility errors. The converter goes to programming mode at Fct 4.0

(See Sect. 5.6 for details of plausibility checks).

15

Page 19

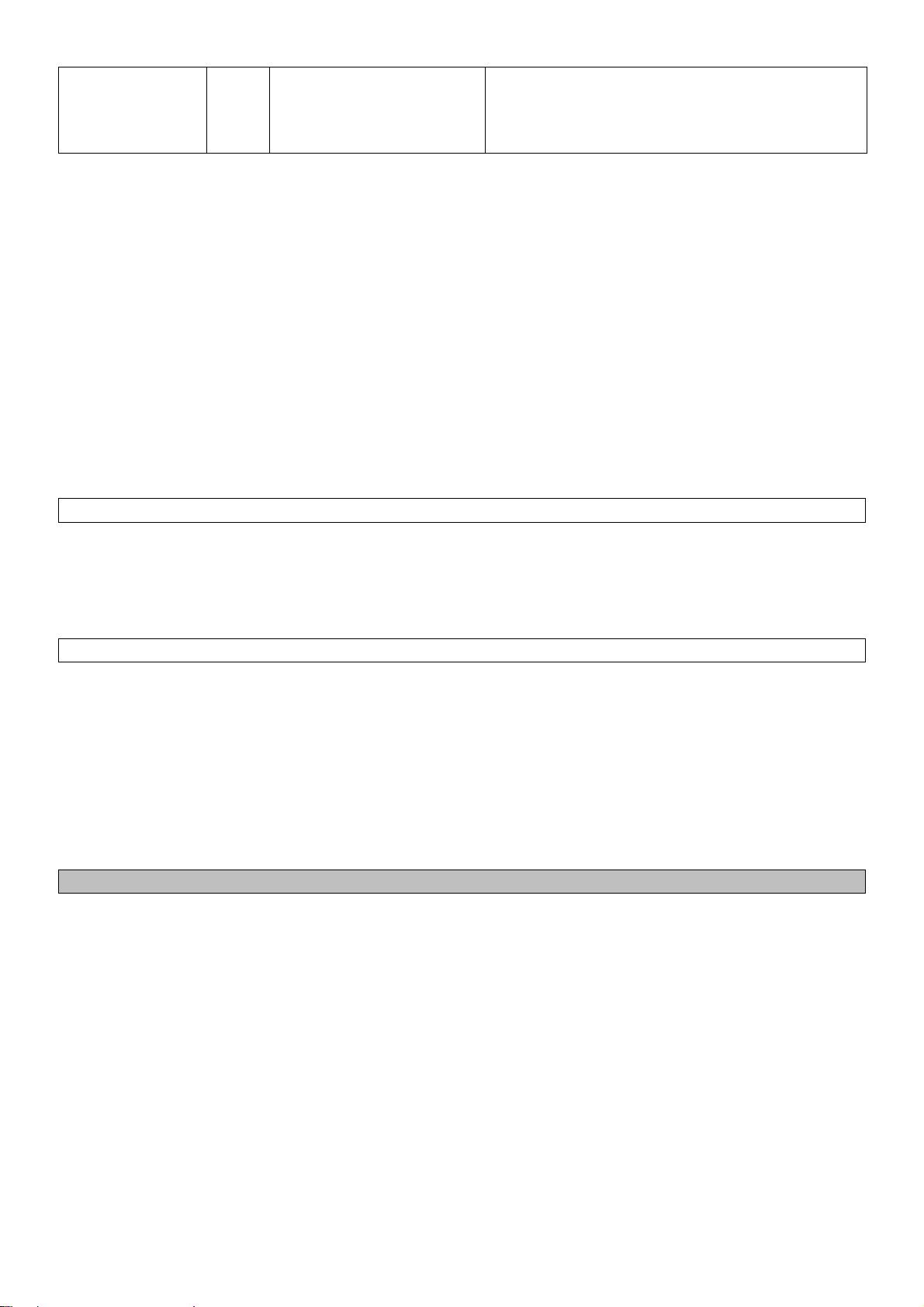

5.5 Error messages

5.5.1 Error messages in measurement mode

Error message

(display 2

nd

line)

INTL.ERR.nn * Internal error in converter

NO SIGNAL N No signal from the vortex

CHECK INST N Vortex sensor signal quality

LOW SIGNAL N Vortex signal amplitude too

HIGH SIGNAL N Vortex sensor signal

Type Description Corrective action required

Switch off the power and try again. If the problems

operation

persists contact KHRONE MARSHALL service.

No flow through the primary or Vortex sensor

sensor

problem

Check that 1. Flow rate > q min if OK. 2. Check for

is bad

excessive pipe vibration & proper installation.

Check that 1. Flow rate > q min if OK contact

low.

KHRONE MARSHALL Service.

This occurs very rarely. Check 1. Flow rate < q max

amplitude too high

if OK contact KHRONE MARSHALL Service.

LOW.FREQ. N Vortex frequency too low Check 1. Flow rate > q min else call KHRONE

MARSHALL Service.

HIGH.FREQ. N Vortex frequency too high check 1. Flow rate < q max else call KHRONE

MARSHALL Service.

LOW.FLOW N Flow rate lower than

minimum flow rate q min.

Converter will continue to display actual flow rate.

However, accuracy of measurement may suffer. If

flow rate reduces further, then other errors such as

CHECK INSTALL,LOW SIGNAL will be generated

HIGH.FLOW N Actual flow rate higher than

q max.

Corrective action depends on application process. If

flow rate exceeds too much further it may damage

entire instrument physically !

LOW.TEMP. OPR N Operating temp. lower than

Corrective action depends on the process.

limit.

HIGH.TEMP.OPR N Operating temp. higher than

Corrective action depends on the process.

limit

LOW.PRES. OPR N Operating pressure lower

Take corrective action depending on the process.

than limit.

HIGH.PRES. OPR N Operating pressure higher

Corrective action is process dependent.

than limit.

LOW.TEMP. PHY. N Operating temp. lower than

Take corrective action depending on the process.

physical limit.

HIGH.TEMP.PHY F Operating temp. higher than

physical limit.

LOW.PRES.PHY. N Operating pressure lower

Will cause damage to primary as well as signal

converter !

Take corrective action depending on process.

than physical limit.

HI.PRES.PHY F Operating pressure higher

Will cause damage to primary and signal converter!

than physical limit.

T.SENS.SHORT N Temp. sensor / wires short

circuit.

T.SENS.OPEN N Temp. sensor open circuit.

P.SENS.OPEN N Pressure sensor open

circuited

Indicates fault in temperature/pressure sensor.

Contact KHRONE MARSHALL Service. You may

use signal converter with temperature or pressure

compensation offline in the mean time till you get

the service. P&T values entered through menu are

used.

INV. CONFIG F Configuration data in non-

volatile memory is not valid.

Check entire configuration again. If error persistscall for service

16

Page 20

LINE.INTR N Mains power to the

instrument was interrupted.

This error is generated only when totalizer is on to

indicate that internal totalizer could not totalize flow

during period of the power failure.

Acknowledge & reset the error by keying in E é è

* This text is displayed for a wide variety of errors and most of them are Fatal in nature. The nature of error is

beyond the scope of user (failure of IC or other hardware inside converter electronics etc.) We therefore

suggest the user to switch OFF power and then try again. If error message continues, call KHRONE

MARSHALL service.

nn = internal error number.

Type N indicates non fatal errors whereas F indicates fatal errors. ·

·

Measurement stops if any Fatal error is encountered. This means flow rate q = 0, current output to minimum

value 0/4 mA or to error value 2/22 mA (as per programming of current output), frequency output = 0Hz.

·

When errors are displayed during the measuring mode, “n Err” (n = number of errors) will appear in the 1st

line. n gives the number of momentarily occuring errors that are displayed alternately with the actual measured

value.

·

Error messages disappear when their cause disappears.

5.5.2 Error messages in programming mode

Error in programming mode can only occur while entering any numerical value. When you enter numerical value

outside possible limits you get message “ nnnn.nnnn ” in 1

st

line and MIN. VALUE or MAX. VALUE in the 2nd

line (“MIN. VALUE ” if entered value is less than lower limit and “MAX. VALUE” if higher limit is crossed).

Note the message indicating permissible limit; then press the E key to continue.

5.5.3 Other Error messages

VFM 5090(I) signal converter does lot of mathematical computations to calculate various physical parameters and

other quantities. Math functions of the instrument software will generate errors for cases such as divide by zero,

square root of a -ve number etc. Such errors are never expected to occur in VFM 5090(I). If ( due to corruption of

memory data or in the unlikely event of a software ‘bug’) any math error occurs, instrument cannot function since

there is no simple recovery and it annunciates errors such as - HALTED - RUN.TIME.ERR then DEVIDE.BY O

or other math error message. All measurement functions are stopped, display continuously annunciates the same

message. In such a case switch OFF the mains supply and then switch ON again. If the same error occurs again

contact KHRONE MARSHALL Service.

5.6 Plausibility checks

These checks are carried out when operator leaves programming mode and desires to save the new configuration in

non-volatile memory. These checks detect whether the configuration as a whole is plausible or not. If any error(s)

are detected in plausibility checks, a new main menu level Fct. 4.0 PARAM.ERROR is automatically created. The

functions under PARAM.ERROR enable you to correct parameters which caused plausibility checks to fail. To

understand the concept, consider the following example :

Fct 3.1.1 NOMINAL.DIA is DN 50 & Fct. 3.1.2 K-FACTOR is 6250. Then operator changes Fct. 3.1.2

NOMINAL.DIA as DN 80 and attempts to save the configuration. Now the limits for K factor are 1740 to 2730

for DN 80 which are dependent on nominal diameter of primary. Since the K factor lies outside valid limits,

plausibility check will fail. Operator should then change the K factor under Fct. 4.1 K-FACTOR.. Thus when the

operator changes a menu function without changing other functions whose validity depended on the changed

function, the error gets trapped by the plausibility checks. Plausibility checks are designed to resolve all such

interdependencies, to ensure that the configuration as a whole is plausible to work with.

17

Page 21

5.7 Options available with VFM5090(I)

5.7.1 METER TYPE

1. Heat Meter

VFM-5090(I), supports thermal power and energy calculations for Steam and Water. Thermal power is calculated

on line from the mass flow and specific enthalpy, at the operating P&T and thermal energy is calculated by time

integrating (totalizing) thermal power. An energy totalizer is provided to accumulate the thermal energy.

The thermal power can be displayed in one of the following units -

KJ/hr, MJ/hr, GJ/hr, BTU/hr, KCal/hr, KW and MW.

Corresponding units for energy display are - KJ, MJ, GJ, BTU, KCal, KWh and MWh.

2. FAD Meter

An air compressor sucks in air from the atmosphere and delivers it compressed to the required pressure. Since

atmospheric air contains water vapour, what the compressor actually sucks in is a mixture of air and water vapour.

Under these conditions the Free Air Delivery specification of the compressor is not directly and easily known.

Almost all manufacturers specify FAD at standard suction conditions only. What the user gets to use as eventual

plant air or process air needs to be found out and hence metered with ease and a reasonable accuracy of at least

±1%.

VFM 5090(I) FAD-METER can measure FAD on-line, compensated for humidity and RPM apart from its use as

STD FLOWMETER.The software built into the meter evaluates the FAD automatically on line. The menu driven

user friendly software prompts the user for information like ambient temperature, pressure and relative humidity,

design & actual RPM, and discharge pressure. The steam tables and compressibility data are programmed into the

memory as a standard feature. There is a temperature sensor which measures on line discharge temperature. The

meter is also available with an optional pressure sensor which measures the discharge pressure on-line eliminating

the need to feed in the value manually.

3. AGA Natural Gas Meter

The special version software is made with added capability for density computation according to American Gas

Association (AGA) standards.

AGA Natural Gas Meter - This software is made with the purpose of using VFM5090(I) Meter as a Natural Gas

meter which accurately calculates the density value of the gas mixture at given temperature and pressure so that

the mass flow and normalized mass flow calculations will be very much accurate. Please note that this is a special

version and supports only natural gas and gas mixture applications.

Heat Meter - The same software can be used to calculate the thermal power and energy for natural gas

applications. Heat value of the gas mixture is also available. Thermal power at the operating P&T is calculated on

line using the composition of natural gas. Thermal energy is calculated by time integrating (totalizing) thermal

power. An energy totalizer is provided to accumulate the thermal energy.

Heat value, compressibility factor and thermal power at the operating P & T is calculated on line using the

composition of natural gas.

18

Page 22

Heat vale of the mixture can be displayed in one of the following units -

N

N

y

KJ/m3, MJ/m3, GJ/m3, BTU/ft3, BTU/in3, KCal/m3

The thermal power can be displayed in one of the following units -

KJ/hr, MJ/hr, GJ/hr, BTU/hr, KCal/hr, KW and MW.

Corresponding units for energy display are - KJ, MJ, GJ, BTU, KCal, KWh and MWh.

The gas components supported are

l

Methane

l

Ethane

l

Hydrogen Sulfide

l

Oxygen

l

i-Pentane

l

n-Heptane

l

n-Decane

4. Net Heat Meter

l

Nitrogen

l

Propane

l

Hydrogen

l

i-Butane

l

n-Pentane

l

n-Octane

l

Helium

l

Carbon Dioxide

l

Water

l

Carbon Monoxide

l

n-Butane

l

n-Hexane

l

n-Nonane

l

Argon

VFM-5090(I) supports net thermal power and net energy calculations for saturated steam and water.

Thermal power is calculated on line from mass flow and specific enthalpy both at the inlet of the process

and at the outlet. The difference between these two values is the net thermal power. The net thermal

energy is calculated by time integrating (totalizing) the net thermal power. The mass flow is measured

by the VFM along with the temperature at that point. The temperature at the exit of the process is also

measured and transmitted (4 to 20 mA) to the VFM through an additional junction box. The mass flow

rate at the inlet and outlet of the process is assumed to be the same.

et or external thermal power can be displayed in any one of the following units.

KJ/hr, MJ/hr, GJ/hr, BTU/hr, KCAL/hr, KW, MW.

et thermal energy units may be displayed in one of the following units.

KJ, MJ, GJ, BTU, KCAL, KWH, MWH.

For external temperature sensing, 2 wire RTD transmitter can be used. This should have current output

4 to 20 mA.& Accurac

better than +/- 0.25% of full scale .

19

Page 23

5.7.2 OUTPUT TYPE

1. RS-232 OUTPUT

The RS-232 output option provides a means for communication of measured values to remote system. At present,

this communication is in one direction only [from VFM 5090(I) to remote system]. Measured values as well as

Error Messages which appear on the instrument display in the normal measurement mode are output on RS-232

line. When the RS-232 output option is present, the usual frequency output function cannot be used.

1.1 RS-232 OUTPUT

The RS-232 output is galvanically isolated from all inputs and output circuits but not from current output.

·

Therefore, only one grounded receiver may be connected to either RS-232 output or current output. Note that

connecting RS-232 to IBM PC/compatibles will ground the RS-232 output.

·

Operating data for RS-232 output is not programmable as in case of current or frequency output. VFM

5090(I) always uses the following operating data : 1 Start bit, 8 Data bits, No Parity, 1 Stop bit at a baud rate of

1200 bits/sec.

·

Connection diagram for RS-232 output is given below. Please note that the RS-232 output uses the same

terminals as used by the Frequency output. Consequently, when the RS-232 option is present, frequency output

function can not be used.

5 + 6 - 4

RXD

4.1

TXD

4.2

GND

1.2 CHARACTER FORMAT

Measured values or Error messages which appear on instrument display in normal measuring mode are coded as

series of 8-bit characters or “bytes”. These are transmitted serially, using a conventional UART (Universal

Asynchronous Receiver/Transmitter) function to serialize each byte. As in RS-232 or other asynchronous

communication, a start bit and stop bit are added to each byte. This allow the receiving UART to identify the start

of each character.

A single 8-bit byte is sent as the following sequence of 1’s and 0’s.

0 DO D1 D2 D3 D4 D5 D6 D7 1

Start bit <---------------------8 Data Bits -----------------------> Stop bit

Baud Rate is 1200 bits/sec. All characters are encoded in ASCII character format.

1.3 DATA FORMAT

Format for transmitting Measured values or Error messages is as follows :

Measured

Value

<SP>

<SP>

unit <CR> <LF>

#nn Err#

<SP>

<SP>

error

mesg.

<CR> <LF>

20

Page 24

where,

Measured Value Numeric value of measured parameter as displayed in numeric field.

<SP> ASCII space character.

unit Unit of the measured value.

<CR> <LF> ASCII carriage return and line-feed sequence.

#nn Err# nn is the number of errors detected by the instrument.

error mesg. Error message as appears in the alphanumeric line of display.

examples -

1234.56 <SP> <SP> m3/hr <CR> <LF>

# 1 Err# <SP> <SP> LOW FLOW <CR> <LF>

Note that the actual number of characters in each format is not fixed and depends on the contents of Measured

Value, unit and error mesg. fields. The user system may use the 2 space characters and CR, LF characters as

delimiters for fields.

2. RS-485 OUTPUT

The RS-485 output option provides a means for communication of measured values to remote system such as

steam flow indicator. At present, this communication is in one direction only [from VFM5090(I) to remote

system]. Measured Values as well as Error Messages which appear on the instrument display in the normal

measurement mode are output on RS-485 line. When the RS-485 output option is present; the usual frequency

output function cannot be used.

2.1 RS-485 OUTPUT

The RS-485 output is galvanically isolated from all inputs and output circuits but not from current output.

·

Therefore, only one grounded receiver may be connected to either RS-485 output or current output.

·

Operating data for RS-485 output is not programmable as in case of current or frequency output. VFM

5090(I) always uses the following operating data : 1 Start bit, 8 Data bits, Odd Parity, 1 Stop bit at a baud rate

of 1200 bits/sec.

·

Connection diagram for RS-485 output is given below. Please note that the RS-485 output uses the same

terminals as used by the Frequency output. Consequently, when the RS-485 option is present, frequency output

function can not be used.

5 + 6

4

-

TX+

4.1

TX-

4.2

GND

2.2 CHARACTER FORMAT

Measured values or Error messages which appear on instrument display in normal measuring mode are coded as

series of 8-bit characters or “bytes”. These are transmitted serially, using a conventional UART (Universal

Asynchronous Receiver/Transmitter) function to serialize each byte. As in RS-485 or other asynchronous

communication, a start bit and stop bit are added to each byte. This allow the receiving UART to identify the start

of each character.

A single 8-bit byte is sent as the following sequence of 1’s and 0’s.

0 DO D1 D2 D3 D4 D5 D6 D7 P 1

Odd

Start bit <------------------------ 8 Data Bits ------------------- > Parity Stop bit

Baud Rate is 1200 bits/sec.

All characters are encoded in ASCII character format.

21

Page 25

2.3 FORMAT

Format for transmitting Measured values or Error messages is as follows :

If there are no Fatal Errors detected by 5090(I) :

:QV<QVval><sp><sp><QVunits><sp><sp>

:QN<QNval><sp><sp><QNunits><sp><sp>

:QM<QMval><sp><sp><QMunits><sp><sp>

:TV<TVval><sp><sp><TVunits><sp><sp>

:TN<TNval><sp><sp><TNunits><sp><sp>

:TM<TMval><sp><sp><TMunits><sp><sp>

:PR<PRval><sp><sp><PRunits><sp><sp>

:TR<TRval><sp><sp><TRunits><sp><sp>

:VE<VEval><sp><sp><VEunits><sp><sp>

:FR<FRval><sp><sp><FRunits><sp><sp>

:TP<TPval><sp><sp><TPunits><sp><sp>

:TE<TEval><sp><sp><TEunits><sp><sp>

:QF<QFval><sp><sp><QFunits><sp><sp>

:XT<XTval><sp><sp><XTunits><sp><sp>

:XP<XPval><sp><sp><XPunits><sp><sp>

:NP<NPval><sp><sp><NPunits><sp><sp>

:NE<NEval><sp><sp><NEunits><sp><sp>

:H<ID>E# nn Err#<sp><sp>

:m<mesg m><cr><lf>

If there are Fatal Errors detected by 5090(I) then measurement is not made and transmitted :

:FEFATAL.ERROR<cr><lf>

:H<ID>E# nn Err#<sp><sp>

:<mesg m><cr><lf>

where,

QVval Numeric value of measured volumetric flowrate.

QVunit Unit of the volumetric flowrate value.

QNval Numeric value of measured normalised flowrate.

QNunit Unit of the normalised flowrate value.

QMval Numeric value of measured mass flowrate.

QMunit Unit of the mass flowrate value.

TVval Numeric value of computed totalised volumetric flow.

TVunit Unit of the totalised volumetric flow value

TNval Numeric value of computed totalised normalised flow.

TNunit Unit of the totalised normalised flow value

TMval Numeric value of computed totalised mass flow.

TMunit Unit of the totalised mass flow value

PRval Numeric value of the operating pressure.

PRunit Unit of the operating pressure

TRval Numeric value of operating temperature.

TRunit Unit of the operating Temperature.

VEval Numeric value of flow velocity.

VEunit Unit of the flow velocity.

FRval Numeric value of measured vortex frequency

FRunit Unit of measured vortex frequency

TPval Numeric value of computed thermal power

TPunit Unit of thermal power

TEval Numeric value of computed thermal energy

TEunit Unit of thermal energy

QFval Numeric value of computed FAD

QFunit Unit of FAD

XT val Numeric value of measured external temperature

22

Page 26

XT units Unit of external temperature

XP val Numeric value of computed external thermal power.

XP units Unit of external thermal power.

NP val Numeric value of computed net thermal power.

NP units Unit of net thermal power.

NE val Numeric value of computed net thermal energy.

NE units Unit of net thermal energy.

<ID> Optional meter identifier. Value between 00 to 99

#nn Err# nn is the number of errors detected by the instrument.

error mesg. Error message as appears in the alphanumeric line of display.

<sp> ASCII space character.

<cr> <lf> ASCII carriage return and line-feed sequence.

Note : Either QV, QN or QM is transmitted at a time. Similarly for TV, TN and TM.

For all transmitted parameters, the user selected unit is used.

After all parameters <cr><lf> is send instead of <sp><sp>

Example -

:QM1234.56 <sp> <sp>kg/hr <sp> <sp>

:TM1000.00<sp><sp>kg<sp><sp>

:PR1.00<sp><sp>atm<sp><sp>

:TR100.0<sp><sp>Deg.C<CR><lf>

:HE# 1 Err# <sp> <sp> LOW FLOW <cr> <lf>

Note that the actual number of characters in each format is not fixed and depends on the contents of Measured

Value, unit and error mesg. fields. The user system may use the 2 space characters and CR, LF characters as

delimiters for fields.

2.4 RS-485 OUTPUT (FOR AGA NATURAL GAS METER)

RS485 option given for AGA supported software is same except for some transmitted values.These values are as

follows :

:CF<CFval><sp><sp><CFunits><sp><sp>

:TH<THval><sp><sp><THunits><sp><sp>

:HE# nn Err#<sp><sp>

:m<mesg m><cr><lf>

If there are Fatal Errors detected by 5090(I) then measurement is not made and transmitted :

:FEFATAL.ERROR<cr><lf>

:HE# nn Err#<sp><sp>

:<mesg m><cr><lf>

where

CFval Numeric value of computed compressibility factor

CFunit Unit of computed compressibility factor

THval Numeric value of computed thermal heat value

THunit Unit of the computed thermal heat value

#nn Err# nn is the number of errors detected by the instrument.

error mesg. Error message as appears in the alphanumeric line of display.

<sp> ASCII space character.

<cr> <lf> ASCII carriage return and line-feed sequence.

Note : Either QV, QN or QM is transmitted at a time. Similarly for TV, TN and TM.

For all transmitted parameters, the user selected unit is used.

Only those parameters selcted in the display cycle are transmitted.

After all parameters, <cr><lf> is sent instead of <sp><sp>

23

Page 27

Example -

:QM1234.56 <sp> <sp>kg/hr <sp> <sp>

:TM1000.00<sp><sp>kg<sp><sp>

:PR1.00<sp><sp>atm<sp><sp>

:TR100.0<sp><sp>Deg.C<CR><lf>

:HE# 1 Err# <sp> <sp> LOW FLOW <cr> <lf>

Note that the actual number of characters in each format is not fixed and depends on the contents of Measured

Value, unit and error mesg. fields. The user system may use the 2 space characters and CR, LF characters as

delimiters for fields.

Note : In this software QFval computed FAD value is not applicable.

24

Page 28

6. Description of program functions

+

6.1 Numerical order description

6.1.1 Program function description

Program functions are given in numeric order as

follows

·

Function number and title

·

DESCRIPTION of the function

·

LIMITS - Applicable limits for numerical input.

·

APPEARS - Conditions when the function

appears. When any function does not

appear it is because it is not required

Fct. 1.0 OPERATION

This is the first main menu level. Submenus and their

functions grouped under Fct. 1.0 (1.x.x functions)

control the operation of the instrument in the

following areas.

- Range of flow measurement

- Display settings of measured values, units, errors

- Current and frequency output programming.

APPEARS - always

Fct. 1.1.0 BASIS.PARAM

Fct. 1.1.2 MAX.FLOW maximum flow rate

Enter the maximum flow rate desired. Max. flow

should be within the measuring range for the given

primary data (3.1.x functions) and application data

(3.5.x functions).

The frequency output range value directly

corresponds to max. flow. If flow rate exceeds max.

flow an error condition (HIGH FLOW) is generated

which may affect current output depending on

programming of Fct. 1.3.2 RANGE I.

The following units are available to choose from

depending on programing of Fct. 1.1.1 MEAS.INST.

for volumetric flow -

l

m3/hr

l

Litre/hr

l

ft3/hr

l

cft/hr

l

cuft/hr

l

US Gal/hr

l

UK Gal/hr

for normalized volumetric flow -

l

Norm.m3/hr

l

Norm.L/hr

l

Sft3/hr

l

Scft/hr

l

m3/min

l

Litre/min

l

ft 3/min

l

cft/min

l

cuft/min

l

US Gal/min

l

UK Gal/min

l

Norm.m3/ min

l

Norm.L/min

l

Sft3/min

l

Scft/min

l

m3/sec

l

Litre/sec

l

ft3/sec

l

cft/sec

l

cuft/sec

l

US Gal/sec

l

UK Gal/sec

l

Norm.m3/ sec

l

Norm.L/sec

l

Sft3/sec

l

Scft/sec

The submenu groups the functions that do

- Setting of basic flow measurement type

(volumetric/normalized-volumetric/mass flow

measurement).

- flow range (minimum & maximum flow) to

measure.

- time constant for flow rate.

APPEARS - Always.

Fct. 1.1.1 MEAS. INST. measuring instrument

type

Set instrument to measure volumetric or normalized

volumetric or mass flow rate as per the options -

l VOLUME l NORM.VOLUME lMASS

Usually, this function is used once initially. If you

need to change the basic measurement type later on,

you should check/reprogram all flow rate and totalizer

related functions such as - MAX.FLOW,

MIN.FLOW, FLOW UNITS, TOTAL.UNITS,

0/4mA FLOW, 20mA FLOW, RANGE F, TOT.

VALUE

LIMITS - Not applicable

APPEARS - Always

for mass flow -

l

Kg/hr

l

T/hr

l

Lb/hr

LIMITS. - 1 to 10,000,000,000 Practically no limit

when entering max. flow. Real check on this

parameter is done during plausibility test. For

reference see Fct. 4.5 MAX. FLOW.

APPEARS - Always

Fct. 1.1.3 MIN. FLOW minimum flow rate Enter

the minimum flow rate in the same units as for

max.flow above. Min. flow should be within the

measuring range for the given primary data (3.1.X

functions) and application data (3.5.X functions). If

flow is below min. flow then an error condition (LOW

FLOW) will be generated. Note that this value cannot

be zero for vortex flowmeters.

LIMITS - > 0 to (0.5* max flow). Higher limit is the

50% of the value entered in Fct. 1.1.2 MAX. FLOW.

Real check on this parameter is done during

plausibility test. For reference see Fct. 4.6

MIN.FLOW.

APPEARS – Always

l

kg/min

l

T/min

l

Lb/min

l

l

l

kg/sec

T/sec

Lb/sec

25

Page 29

Fct. 1.1.4 TIMECONST. time constant for flow rate

Fct. 1.2.2 TOTAL.UNITS totalizer unit for display

Enter a low-pass filter time constant in seconds to be

applied to flow rate. A value of zero indicates that

low-pass filter is not to be applied. With this function

it is possible to compromise between a steady

indication (on display/current output) and response

time (to flow changes).

LIMITS - 0 to 20 seconds.

APPEARS - Always.

Fct. 1.2.0 DISPLAY

This submenu groups the display functions which

- Allow selection of units for all measured parameters.

- Select what parameters to include in display cycle.

- Select display mode (cyclic/non-cyclic) and error

messages to appear or not to appear in display cycle.

APPEARS - Alwayss

Fct. 1.2.1 FLOW UNITS for display

Select a unit in which flow rate is to be displayed

from the following list of the available units,

depending on programming of Fct.1.1.1MEAS.

INST.

for volumetric flow -

l

m3/hr

l

Litre/hr

l

ft3/hr

l

cft/hr

l

cuft/hr

l

US Gal/hr

l

UK Gal/hr

l

% MAX. FLOW

l

m3/min

l

Litre/min

l

ft 3/min

l

cft/min

l

cuft/min

l

US Gal/min

l

UK Gal/min

l

m3/sec

l

Litre/sec

l

ft3/sec

l

cft/sec

l

cuft/sec

l

US Gal/sec

l

UK Gal/sec

for normalized volumetric flow -

Totalized flow may be displayed in one of the

following units.

For volumetric flow -

l

m3

l

cft

l

UK Gal

l

Litre

l

cuft

l

NO DISPLAY

l

l

ft3

US Gal

For normalized volumetric flow -

l

Norm.m3

l

Scft

l

Norm.L

l

NO DISPLAY

l

Sft3

For mass flow -

l

kg

l

NO DISPLAY

l

T

l

Lb

Use NO DISPLAY to exclude totaliser for display

cycle.

LIMITS - Not applicable.

APPEARS - Always.

Fct. 1.2.3 TEMP. UNITS for display

The following options exist for temperature unit

l

Deg. C

l

NO DISPLAY

l

Deg. F

l

KELVIN

Use NO DISPLAY to exclude temperature for

display cycle.

LIMITS - Not applicable.

APPEARS - Always.

Fct. 1.2.4 PRES. UNITS pressure unit for display

l

Norm.m3/hr

l

Norm.L/hr

l

Sft3/hr

l

Scft/hr

l

% MAX. FLOW

l

Norm.m3/ min

l

Norm.L/min

l

Sft3/min

l

Scft/min

l

Norm.m3/ sec

l

Norm.L/sec

l

Sft3/sec

l

Scft/sec

For mass flow -

l

Kg/hr

l

T/hr

l

Lb/hr

l

% MAX. FLOW

l

l

l

kg/min

T/min

Lb/min

l

l

l

kg/sec

T/sec

Lb/sec

Note that the list is same as for Fct. 1.1.2 except for

an additional unit % MAX. FLOW (to display flow

rate as a percentage of max. flow).

LIMITS - Not applicable.

APPEARS - Always.

The following options exist for pressure. Unit with the

suffix _g are gauge pressure units and those without

the same are absolute pressure units.

l

Pa

l

Bar

l

Lbf/ft2

l

mm Hg

l

KPa_g

l

mBar_g

l

Kg/cm2_g

l

mm Water_g

l

KPa

l

mBar

l

Kg/cm2

l

mm Water

l

atm_g

l

PSI_g

l

In. Hg_g

l

NO DISPLAY

l

atm

l

PSI

l

In. Hg

l

pa_g

l

Bar_g

l

Lbf/ft2_g

l

mm Hg_g

Use NO DISPLAY to exclude pressure from display

cycle.

LIMITS - Not applicable.

APPEARS - If Fct. 3.5.1 FLUID is not LIQUID.

26

Page 30

Fct. 1.2.5 VELO. UNITS velocity unit for display

You can choose one of the following

l

m/Sec

l

ft/Sec

l

NO DISPLAY

Select NO DISPLAY if you don’t want this parameter

to be displayed.

Fct. 1.2.6 ERROR MSG. display of error messages.

If you want error messages to appear between display

of parameters in normal measuring mode, choose YES

otherwise select NO.

error output if any error(s) are present in the

instrument. Range options are listed below.

l

0-20

l

4-20/22=E

l

4-20

l

4-20/2=E

l

0-20/22=E

LIMITS - Not applicable.

APPEARS - If Fct. 1.3.1 FUNCTION I is YES.

Fct. 1.3.3 0/4mA FLOW

Enter the flow value at which you want current output

at its minimum 0mA (for 0-20 and 0-20/22=E ranges)

or 4mA (for other range options).

LIMITS - Not applicable

APPEARS - Always.

Fct. 1.2.7 CYCLE DISP. cyclic/non-cyclic display.

YES means display will cycle automatically. This

means a measured parameter is shown in selected

units for about 6 seconds and then the next parameter

in the display cycle is shown for 6 seconds and so on.

NO (non-cyclic display) means the parameter is

continuously shown on the display (to see other

parameters or to change setting use the é key). You

may see error messages in between changeover from

one parameter to next if error(s) are present and Fct.

1.2.6 ERROR MSG. is YES.

LIMITS - Not applicable.

APPEARS - Always.

Fct. 1.3.0 CURR.OUTP. I

This submenu groups current output related functions.

APPEARS - Always.

Fct. 1.3.1 FUNCTION I current output function

Choose YES - to make current output active as per

functions Fct. 1.3.2 to Fct. 1.3.4 NO makes current

output inactive (0 mA).

LIMITS - Not applicable.

APPEARS - Always.

Fct. 1.3.2 RANGE I current output range selection

Here one selects one of the five possible range

options. To set current output as 0-20mA or 4-20mA

with/without error indication on current output. When

a range with suffix of 22=E or 2=E is selected then it

means that current output will give 22mA or 2mA

LIMITS- 0 to (max_flow-(max_flow-min_flow)* 0.2)

Value is programmable from 0 upto below max_flow

by 20% of span.

APPEARS - if Fct. 1.3.1 FUNCTION I is YES

Fct. 1.3.4 20mA FLOW

Enter the flow value at which you want current output

at its maximum (20mA). This function and Fct.1.3.3

above define the current output with respect to flow

rate. Note that both the points that you define are

programmable and don’t have to correspond to min.

flow (Fct. 1.1.3) and max. flow (Fct. 1.1.2).

LIMITS - (iqmin + (max_flow-min_flow)*0.2) to 5*

max_flow. Where iqmin is the value entered in Fct.

1.3.3 0/4mA FLOW Lower limit ensures a minimum

of 20% flow span. Higher limit allows you exceed

max_flow by 5 times for current output.

APPEARS : If Fct.1.3.1 FUNCTION I is YES.

Fct. 1.3.5 VARIABLE I Current Output selection

function

Selects any one of the three options available for

current output.

Options are listed below :

· FLOW

· POWER

· NET POWER

LIMITS : Not applicable

APPEARS – If meter type is HEAT METER or NET

HEAT METER. For meter type HEAT METER ,

only flow and power options are available. For meter

type NET HEAT METER, all three options are

available.

27

Page 31

Fct. 1.3.6 0/4 mA POWER

Enter the power value at which you want current

output at its minimum 0 mA or 4 mA.

LIMITS : No limits

APPEARS : If meter type is HEAT METER or NET

HEAT METER and Fct. 1.3.5. VARIABLE I is

POWER or NET POWER.

Fct. 1.3.7 20 mA POWER

Enter the power value at which you want current

output at its minimum 20 mA.

LIMITS : No limits

APPEARS : If meter type is HEAT METER or NET

HEAT METER and Fct. 1.3.5. VARIABLE I is

POWER or NET POWER

Fct. 1.4.0 FREQ. OUTP. F

This submenu groups frequency output related

functions.

APPEARS – Always (Not when output type is RS

485 or RS 232)

Fct. 1.4.1 FUNCTION F frequency output

Choose YES - to make frequency output active as per

functions Fct. 1.4.2 to Fct. 1.4.4 NO makes frequency

output inactive (0 Hz)

LIMITS - Not applicable.

APPEARS - Always. (Not when output type is RS

485 or RS 232)

For volumetric flow -

l

PULSE/hr

l

PULSE/m3

l

PULS/cft

l

PULS/UK. Gal

l

PULSE/min

l

PULS/Litre

l

PULS/cuft

l

PULSE/sec

l

PULS/ft3

l

PULS/US.Gal

For normalized volumetric flow -

l

PULSE/hr

l

PUL

l

PULS/Scft

/NormM3

l

PULSE/min

l

PULS/

NormL

l

PULSE/sec

l

PULS/Sft3

Or mass flow -

l

PULSE/hr

l

PULS/Kg

l

PULSE/min

l

PULS/t

l

PULSE/sec

l

PULS/Lb

LIMITS - 0.0028 Hz TO 10,000 Hz. These limits are

also applied when programming in pulses per unit

flow units. All the necessary conversions for the same

are done internally.

APPEARS - If Fct. 1.4.1 FUNCTION F is YES.

Fct. 1.4.3 PULS.WIDTH pulse width

You can limit the duration of maximum active pulse

width of the frequency output for frequencies less

than or equal to 10 Hz. All options that may appear

are listed below. Only the possible options that are

available (depending on programming of Fct. 1.4.2

RANGE F) to choose are displayed during actual

programming.

l

500 mSec

l

50 mSec

l

200 mSec

l

30 mSec

l

100 mSec.

l

50 %

This function helps to minimize the overheating of

electro-mechanical counter coils.

Fct. 1.4.2 RANGE F frequency output range value

The frequency output range value is the frequency

that corresponds to max. flow (Fct. 1.1.2). The other

point is always 0 Hz for 0 flow because frequency

output is designed for use with external totalizers. It is

also possible to define range f in terms of pulses/unit

flow.

Example -

Assume max. flow (Fct. 1.1.2) = 1000 Kg/hr then

range f = 10000 pulses/hr (at max. flow) and

range f = 10 pulses/Kg are identical. The latter

method is better because it is easy to infer that

totalizer will have a least count of 0.1 Kg (10 pulses

per Kg = 1pulse per 0.1 Kg) and totalizer

programming will be independent of max. flow. The

various options of units for RANGE F are given

below.

LIMITS - Not applicable.

APPEARS - if Fct. 1.4.1 FUNCTION F is YES.

Fct. 1.4.4 VARIABLE F frequency output selection

function

Selects any one of the three options available for

frequency output.

Options are listed below :

· FLOW

· POWER

· NET POWER

LIMITS : Not applicable

APPEARS – If meter type is HEAT METER or NET

HEAT METER. For meter type HEAT METER ,

only flow and power options are available. For meter

type NET HEAT METER, all three options are

available.

28

Page 32

Fct. 1.4.5 F.S. POWER

Enter full scale power value at which you want to

have max. frequency programmed.

LIMITS : No limits

APPEARS : If meter type is HEAT METER or NET

HEAT METER and Fct. 1.3.5. VARIABLE F is

POWER or NET POWER.

Fct. 1.4.6 F.S.FREQ.

Enter maximum frequency required for maximum

power programmed in Fct. 1.4.5 F.S. POWER

LIMITS : Maximum 10,000 Hz.

APPEARS : If meter type is HEAT METER or NET

HEAT METER and Fct. 1.3.5. VARIABLE I is

POWER or NET POWER

Fct. 2.0 TEST.

Place current meter in series with current loop then

select one of the following values.

l

l

0 mA

10 mA

l

l

2 mA

20 mA

l

l

4 mA

22 mA

Selecting any value will cause that current to flow so

that you can check on meter. Select CONT. YES to

test other current value or CONT.NO to end. When

the menu function finishes, normal current value

depending on flow rate and programming of current

output function will be restored.

LIMITS - Not applicable.

APPEARS – Always

Fct. 2.3 TEST F frequency output test

CAUTION: During this test frequency output will

change to test values so you should take

appropriate actions depending on how you are

using frequency output

This second main menu level groups test functions

for display, current output and frequency output.

There are no sub-menus under 2.0. Since these are test

functions, when executed they have an immediate

effect on the signal converter for the duration the test

function is executed. When using all the other menu

functions, the changes made are stored temporarily

and have no effect on the operation of signal

converter unless you quit menu and respond with YES

to update changes.

APPEARS - Always

Fct. 2.1 TEST DISP. display test

All segments of the display are tested in the following

sequence. Alphanumeric field, numeric field, arrow

and key markers. You can press the E key at any time

to terminate display test. Executing display test does

not affect the normal operation of the signal

converter.

LIMITS - Not applicable

APPEARS - Always.

Fct. 2.2 TEST I current output test

CAUTION: During this test, current output will

change to test values so you should take

appropriate actions depending on how you are

using current output.

Connect frequency meter to frequency output. Select

one of the following test values.

l

1 Hz

l

1000 Hz

l

10 Hz

l

10000 Hz

l

100 Hz

Selecting any value will cause that frequency to

output so that you can check on meter. Select