Page 1

09/97

Electromagnetic

flowmeters

for water and seewage

Installation

instructions

AQUAFLUX

• Primary head

• Compact flowmeters

CONTENTS

Storage and transport Pagesn 3-4

Installation in the pipeline Pages 4-5 and 7-8

AQUAFLUX F

Grounding Pagen 9

F

010 K

020 K

080 K

AQUAFLUX 010 K / 020 K AQUAFLUX 080 K

3.1M68EA1 099721 Order No. DIN size 7.02137.33.00

US size 7.02137.73.00

Page 2

Contents

System description 2

Product liability and warranty 2

Standards and approvals 2

Items included with supply 3

1 Important information for installation: PLEASE NOTE 4-5

2 Suggestions for installation 5

3 Instrument nameplate 6

4 Flowmeter versions 6

5 Installation in the pipeline 7

6 Torques 8

7 Grounding 9

8 Replacement of separate primary head 10

9 Technical data 10-11

10 Dimensions and weights 12-13

11 Limits 14

Printed form to accompany flowmeters returned to Krohne 15

System description

AQUAFLUX electromagnetic flowmeters are precision measuring instruments designed for the

linear flow measurement of process liquids.

The process liquids must be electrically conductive: ≥ 20 µS/cm for demineralized cold water

The full-scale range Q

AQUAFLUX 010 K / 020 K / 080 K: DN 10 - 1000 / 3/8” - 040” Q

AQUAFLUX F: DN 10 - 3000 /

can be set as a function of the meter size:

100%

3

/8” - 120” Q

= 0.1 - 033900 m3/hr = 0.02 - 1156640 USGPM

100%

= 0.1 - 305000 m3/hr = 0.02 - 1400000 US GPM

100%

This is equivalent to a flow velocity of 0.3 - 12 m/s, or 1 - 40 ft/s.

Product liability and warranty

AQUAFLUX electromagnetic flowmeters are designed solely for measuring the volumetric flowrate

of electrically conductive, liquid process products.

Flowmeters with AQUAFLUX primary heads are not certified for use in hazardous locations. Other

flowmeters series are available for such applications.

Responsibility as to suitability and intended use of these electromagnetic flowmeters rests solely

with the operator.

Improper installation and operation of the flowmeters (systems) may lead to loss of warranty.

In addition, the ”General conditions of sale” forming the basis of the purchase contract are

applicable.

If AQUAFLUX flowmeters need to be returned to Krohne, please note the information given on the

last-but-one page of this manual. Krohne regret that they cannot repair or check your flowmeter(s)

unless accompanied by the completed form sheet.

Standards and approvals

Please refer to the installation and operating instructions for the signal converter.

2

Page 3

Items included with supply

AQUAFLUX F

primary heads

• Primary head in the size as ordered

• Connecting wires for grounding, refer

to Section 7 ”Grounding”

• Certificate of calibration data

• Grounding rings (optional), if ordered

• Installation instructions

Fitting accessories (stud bolts, nuts, gaskets, etc.) are not supplied with the flowmeter,

to be provided by customer!

AQUAFLUX 010 K, 020 K and 080 K

compact flowmeters

• Compact flowmeter in the size as ordered

• Connecting wires for grounding, see

Section 7 ”Grounding”

• Certificate of calibration data

• Grounding rings (optional), if ordered

• Installation instructions

• Installation and operating instructions

for the signal converter

Do not lift flowmeter by the signal converter

housing or the terminal box.

PLEASE NOTE

the temperature limits for storage and transport, see Page 4.

Handling

Do not set flowmeter down on signal

converter housing or terminal box.

3

Page 4

1 Important information for installation: PLEASE NOTE !

• Use only solventless detergents to clean the signal converter housing (polycarbonate).

• Temperatures

Refer to Section 11 ”Limits” for operating pressure and vacuum load based on flange

standards and type of tube liner.

Ambient temperature Process temperature

Compact systems -25 to +60 °C (-13 to +140 °F) -25 to ≤ +60 °C (-13 to ≤ +140 °F)

-25 to +40 °C (-13 to +104 °F) -25 to ≤ +90 °C (-13 to ≤ +194 °F)

AQUAFLUX F -25 to +60 °C (-13 to +140 °F) -25 to > +60 °C (-13 to > +140 °F)

In storage -20 to +60 °C (-04 to +140 °F), kept immobile,

avoid moisture and sunlight.

Transport -05 to +50 °C (-04 to +140 °F),

avoid moisture and sunlight.

• Location and position as required,

but electrode axis X – • – • – • – X

Y

must be approximately horizontal in a

horizontal pipe run.

Y terminal box or converter housing

X

X

• Measuring tube must be completetly filled at all times.

• Direction of flow is arbitrary. Arrow on flowmeter can normally be ignored.

For exceptions, refer to Section ”Factory settings” in the installation and operating

instructions for the signal converter.

• Stud bolts and nuts: to fit, make sure there is sufficient room next to the pipe flanges.

• Vibration: support the pipeline on both sides of the compact flowmeter.

Level of vibration in conformity with IEC 068-2-34: below 2.2g for compact flowmeters

in the frequency range of 20-50 Hz with the IFC 010 K

/ IFC 020 K and 20-150 Hz

with the IFC 090 K.

• Do not expose to direct sunlight,

fit a sunshade if necessary, not included with flowmeter, to be provided by customer.

• Large meter sizes (≥≥DN 200 / ≥≥8”): use adapter pipes to allow axial shifting of the

counterflanges and to facilitate installation.

4

Page 5

• Strong electromagnetic fields, avoid in vicinity of flowmeter

• Straight inlet run minimum of 5 ××DN and outlet run minimum of 2 ××DN,

(DN = meter size), measured from the electrode axis.

• Vortex and corkscrew flow: increase length of inlet and outlet runs or install

flow conditioners.

• Mixing different process liquids: install flowmeter upstream of mixing point or at an

adequate distance downstream (minimum of 30 × DN), otherwise display may be unsteady.

• Plastic pipes and internally coated metal pipelines: grounding rings required,

see Section 7 ”Grounding”.

• Insulated pipeline: do not insulate flowmeter

• Zero setting not necessary. To check, it should be possible to set ”zero” flow velocity

in the completely filled measuring tube. Shutoff valves should therefore be provided

either downstream of the flowmeter or upstream and downstream of the flowmeter.

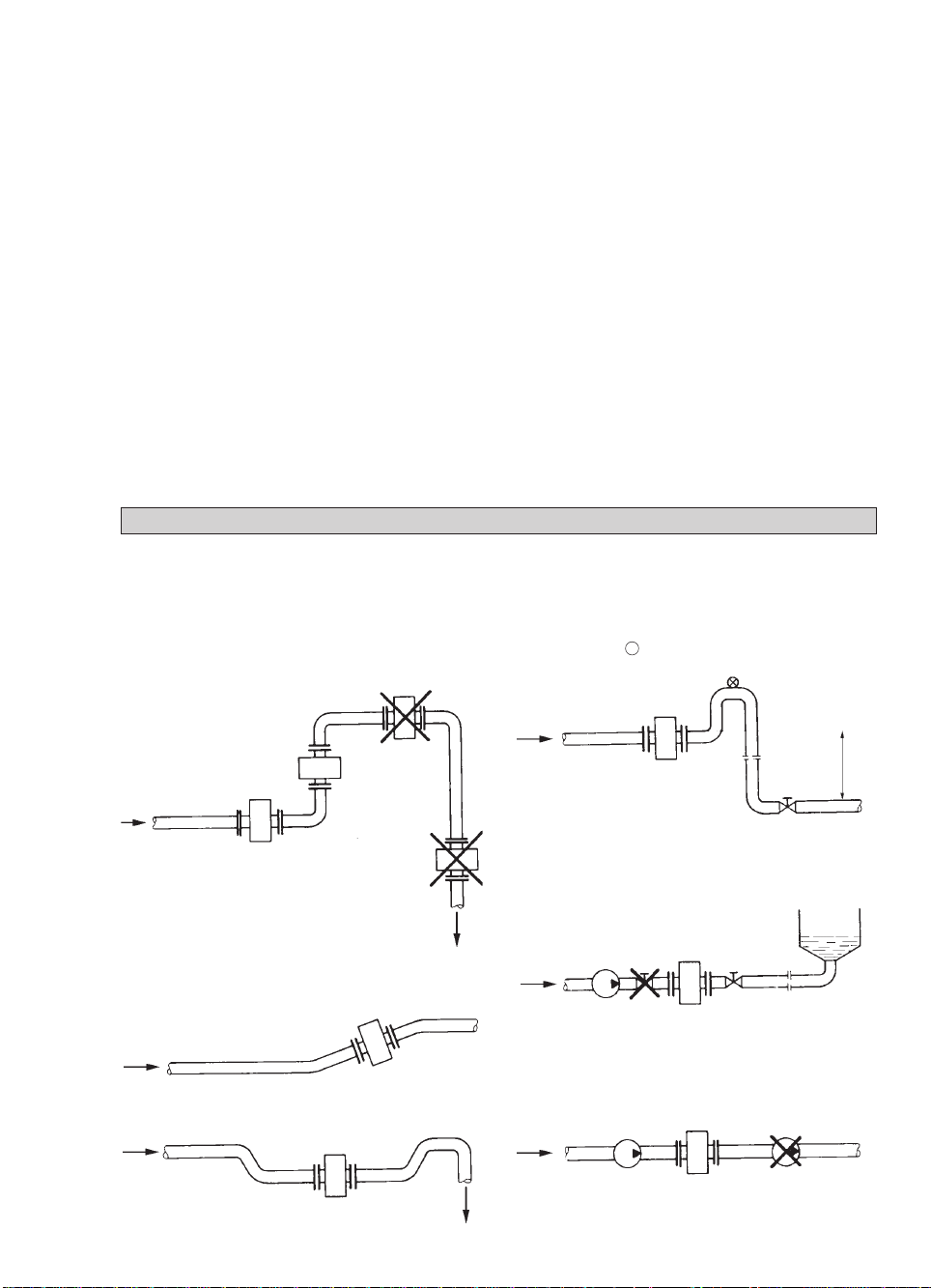

2 Suggestions for installation

To avoid measuring errors due to gas/air inclusion or to pipe running empty, please observe the

following:

Highest point of pipe run

(Air bubbles collect in measuring

tube - faulty measurements!)

Preferred

locations

Downpipe

”Zero” flow

velocity.

Line drained.

Faulty

measurements!

Horizontal pipe run

Install in slightly ascending pipe section. If not

possible, assure adequate velocity to prevent air,

gas or vapor from collecting in

uppper part of flow tube.

Open feed or discharge

Install meter in low section of pipe.

Downpipe over 5 m (16 ft) length

Install air valve X downstream of

flowmeter.

Long pipeline

Always install control and shutoff valves

downstream of flowmeter.

Pumps

Never install flowmeter on pump suction side.

> 5m

> 16 ft

open discharge

5

Page 6

3 Instrument nameplate

AQUAFLUX F

separate primary head

Altometer

Series No.

Primary head

constant

Meter size

DN in mm and

inch equivalent

A 97 00000

GK: 1.918

DN50/2”-H-HC PN 40 BAR

Liner

Teflon

Holland

®

PFA

Electrode material

Hastelloy C4

Type designation

AQUAFLUX F / 6

TAG: 1234567-89

ISO KL. H IP 67

Flange pressure rating

or flange class

Magnetic field frequency

(here 1/6 of power frequency)

Tag No.

Protection category

to IEC 529 / EN 60529

Insulation class

of field coils

Liner materials

H Hard rubber

T Teflon®-PTFE

Electrode materials

HC Hastelloy C4

TI Titanium

V4A Stainless steel 1.4571/ SS 316-Ti

Teflon®is a registered trademark of Du Pont

Instrument nameplate for compact flowmeters

see installation and operating instructions for the signal converter.

4 Flowmeter versions

AQUAFLUX F Separate primary head (F) , electrically connected to the signal

converter by signal and field current cables.

AQUAFLUX 010 K, Compact flowmeter (K), IFC 010 K or IFC 020 K signal converter mounted

AQUAFLUX 020 K direct on the primary head.

AQUAFLUX 080 K Compact flowmeter (K), IFC 090 K signal converter mounted direct

on the primary head.

6

Page 7

5 Installation in the pipeline

• Installation material not included, to be provided by customer (stud bolts,

nuts, gaskets, etc.)

• Pipe flanges and operating pressure: refer to tables on ”limits” in Section 11.

• Distance between pipe flanges

see fitting dimension ”a”, in Section 10 ”Dimensions and weights”.

• Position of flanges

Install flowmeter in line with the pipe

L

max

axis. Pipe flange faces must be

parallel to each other,

max. permissible deviation:

- L

min

≤≤

0.5 mm

L

max

≤ 0.02”

L

min

• Hard rubber liner

Please note the table on Page 4 for temperature limits of operation,

storage and transport.

• Teflon

®

-PTFE liner

Install at the lowest point of the pipe run to avoid an excessive vacuum condition at

the meter. Do not remove or damage liner, which is formed around the flange edges.

• Gaskets

Use gaskets suitable for the application and appropriate to the liner, not included

with flowmeter, to be provided by customer.

• Grounding rings / protective rings (option)

On plastic pipes and internally coated metal pipelines, grounding rings must form the

conductive connection with the fluid. Refer to Section 7 ”Grounding for electrical connection.

Groundin

g ring No. 1 Grounding ring, protective ring No. 2 Grounding ring, protective ring No. 3

3 mm/0.12” thick for flowmeters with Teflon®-PTFE with cylindrical neck, to protect the liner

liner, solidly fitted to the flanges, particularly at the inlet edge against

3 mm/0.12” thick abrasive products, 3 mm/0.12” thick.

Length: 130 mm/1.18”, for ≤ DN 300, ≤ 12“

100 mm/3.94”, for ≥ DN 350, ≥ 14“

Teflon®is a registered trademark of Du Pont.

7

Page 8

6 Torques

• Tighten stud bolts uniformly in diagonally opposite sequence, see table for number and type.

• Column A

®

Torques for Teflon

-PTFE liner.

• Column B

Torques for liner made of hard rubber.

• 10 Nm ~ 1.0 kpm ~ 7.23 ft ××lbf

Meter

size

DN

mm

10

15

20

25

32

40

50

65

65

80

100

125

150

200

200

250

250

300

300

350

400

450

500

600

700

800

900

1000

Pressure

rating

PN

40

40

40

40

40

40

40

16

40

25

16

16

16

10

16

10

16

10

16

10

10

10

10

10

10

10

10

10

Bolts

x

M 12

04

04 xM 12

04 xM 12

04 xM 12

04 xM 16

04 xM 16

x

04

M 16

04 xM 16

08 xM 16

08 xM 16

08 xM 16

08 xM 16

08 xM 20

x

08

M 20

12 xM 20

12 xM 20

12 xM 24

12 xM 20

12 xM 24

16 xM 20

x

M 24

16

20 xM 24

20 xM 24

20 xM 27

20 xM 27

24 xM 30

28 xM 30

x

28

M 35

003.5

003.5

014.8

Max. torque

Nm (ft xlbf)

003.6

(2.5)

003.6

(2.5)

014.8

(3.5)

014.4

012

023

039

031

051

069

079

104

093

091

143

127

180

161

259

269

269

Max. torque

Nm (ft x lbf)

AB A B

007.6

009.3

016

(5.5)

(6.7)

(11.6)

00

00

01

011

019

025

031

042

021

025

030

040

047

068

045

065

178

076

105

075

104

193

107

138

163

219

205

261

(3.3)

(4.1)

(6.9)

(8.0)

(13.0)

(18.1)

(22.4)

(30.4)

(15.2)

(18.1)

(21.7)

(28.9)

(34.0)

(49.2)

(32.5)

(47.0)

(56.4)

(54.9)

(75.9)

(54.2)

(75.2)

(67.2)

(77.4)

(99.8)

(117.8)

(158.3)

(148.2)

(188.7)

Meter

size

inch

3

/8

1

/2

3

/4

1

11/2

2

3

4

6

8

10

12

14

16

18

20

24

28

32

36

40

Body

pressure

rating

lb

580

580

580

580

580

580

360

230

230

145

145

145

145

145

145

145

145

145

145

145

145

Bolts

for ANSI

class 150

flanges

1

x

04

/2”

1

x

04

/2”

1

x

04

/2”

1

x

/2”

04

1

x

04

/2”

5

x

04

/8”

5

x

04

/8”

5

x

08

/8”

3

x

08

/4”

3

x

08

/4”

7

x

12

/8”

7

x

12

/8”

12 x1”

16 x1”

16 x11/8”

20 x11/8”

20 x11/4”

x

11/4”

28

28 x11/2”

32 x11/2”

36 x11/2”

Note: Process pressure must not exceed ANSI

flange rating. Refer to ANSI Standard B 16.5.

(2.6)

(2.6)

(3.5)

(3.2)

(8.7)

(16.6)

(28.2)

(22.4)

(36.9)

(49.9)

(57.1)

(75.2)

(76.2)

(65.8)

(103.4)

(91.8)

(130.1)

(116.4)

(187.3)

(194.5)

(194.5)

Teflon®is registered trademark of Du Pont

8

Page 9

7 Grounding

• All flowmeters must be properly grounded to avoid personnel shock hazard.

• The ground conductor should not transmit any interference voltages, therefore do not ground

any other electrical devices together with this conductor.

AQUAFLUX F separate primary head with terminal box

• An FE functional ground must always be connected.

• Signal converter with field power supply >125 mA / 60 V a PE protective conductor

must be connected to the primary head, because of the higher field current from the signal

converter. See grounding diagrams below.

AQUAFLUX 010 K, 020 K and 080 K compact systems

Supply power > 50 V AC

• Grounding is via the PE protective ground conductor incorporated in the power supply

cable, see also Section ”Connection to power” in the installation and operating instructions

for the signal converter.

• EXCEPTION:

Do not connect up the PE protective ground conductor in the terminal

box if e.g. compact units are operated in the proximity of electric furnaces, electrolysis

plants, etc., and large potential differences occur in the pipeline system. An FE functional

ground must simultaneously take over the function of the protective conductor (combined

protective/functional ground). Refer to appropriate national codes for specific requirements

for this type of installation, which may require the addition of a ground fault detection circuit

interrupter.

Power su

pply 24 V AC or DC

• Protective separation (PELV) must be ensured (VDE 0100 / VDE 0106 or

IEC 364 / IEC 536 or equivalent national regulations).

• An FE functional ground conductor must be connected for measurement reasons.

Grounding diagrams

Metal pipelines,

not internally coated

grounding without grounding rings

with or without internal coating,

Metal pipelines,

and plastic pipelines

grounding with grounding rings

YY

V1

RR

F

D3

FE

(PE)

D1, D2, D3 Gaskets, not included with supply, to be provided by customer.

E Grounding rings (option)

F Flowmeter flanges

FE

Functional ground, wire ≥ 4 mm2Cu (10 AWG), not included with flowmeter, to be provided by customer

PE Protective conductor required if the AQUAFLUX F is operated with a signal converter that supplies

a field current of > 125 mA / > 60 V .

Wire ≥ 4 mm2Cu (10 AWG), not included with flowmeter, to be provided by customer.

R Pipeline

RF Pipe flanges

V1, V2 Interconnecting wires, included with flowmeter

Y Terminal box or signal converter

V1 V2 V2

RR

F

RFRF

D3 D2 D1 D1

EE

FE

(PE)

FF

RFRF

D2

9

Page 10

8 Replacement of the separate primary head

Switch off power source before commencing work !

1) Note down terminal assignment before dismantling the ”old” primary head.

2) Install the new primary head as described in the supplied installation instructions.

3) Make electrical connection at the signal converter as described in the installation and

operating instructions for the signal converter.

4) Specific calibration data are defined during factory calibration for each primary head,

which are indicated on the instrument nameplate.

This includes the primary constant GK and the magnetic field frequency. These data

need to be reset in the signal converter.

5) If the size of primary head is also different from the old one, the full-scale range Q

100%

meter size will need to be reset.

6) After resetting the signal converter, carry out a zero point check.

7) If necessary, reset the internal electronic totalizer of the signal converter.

and the

10

Page 11

9 Technical data

Meter sizes

Compact systems DN 10 –1000 and 3/8” – 040”

AQUAFLUX F (separate) DN 10 –3000 and 3/8” – 120”

Pipe flanges

to DIN 2501 (= BS 4504) DN 10 – 50 and DN 80 / PN 40

DN 65 and DN 100 – 150 / PN 16

DN 200 – 1000 / PN 10

DN 1100 – 2000 / PN 6

DN 2200 – 3000 / PN 2.5

to ANSI B 16.5

3

/8” – 024” / Class 150 lb / RF

to AWWA 14” – 120” / Class B or D / FF

Electrical conductivity ≥ 20 µS/cm

Temperatures Ambient tem

perature Process temperature

Compact systems – 25 to + 060°C – 25 to ≤ + 060°C

– 13 to + 140°F + 23 to ≤ + 140°F

– 25 to + 140°C – 25 to ≤ + 290°C

– 13 to + 104°F + 23 to ≤ + 194°F

AQUAFLUX F (separate) – 25 to + 060°C – 25 to ≤ + 290°C

– 13 to + 140°F + 23 to ≤ + 194°F

Max. allowable operating data Process temperature, operating pressure and vacuum load

for the liner, refer to Page 3 “Limits”

Insulation class of field coils E

Electrode design

DN 010 – 3000 / 3/8” – 120’’ flat elliptical electrodes, solidly fitted,

surface-polished

Option DN 350 – 3000 / 14’’ – 120’’ field-replaceable electrodes WE

Protection category (EN 60 529 / IEC 529)

Standard IP 67, equivalent to NEMA 6

(with field replaceable electrodes WE: IP65,

equivalent to NEMA 4/4X)

Option IP 68, equivalent to NEMA 6

Grounding rings available as an option

Materials

Measurin

g tube stainless steel 1.4301 (or higher materials number),

equivalent to SS 304

Liner

DN 10– 0020 /3/8” – 3/4” Teflon®-PTFE

DN 25 – 3000 / 1’’ – 120’’ hard rubber

Electrodes

Standard Hastelloy C4

Option stainless steel 1.4571 or SS 316 Ti, titanium

Field replaceable WE stainless steel 1.4571 or SS 316 Ti

Connectin

g flanges*

DIN: DN 10 – 50, DN 80 (3/8” – 2’’, 3’’) steel 1.0402 (C 22) or AISI C 1020

DN 65, ≥ DN 100 (≥ 4’’) steel 1.0501 (RST 37.2) or AISI C 1035

ANSI steel ASTM A 105 N

g*

Housin

DN 10 – 40 / 3/8”–11/2” GTW-S 30 (malleable cast iron)

≥ DN 50 / ≥ 2’’ sheet steel

erminal box*

T

AQUAFLUX F (separate) die-cast aluminium

Groundin

g rings (option) stainless steel 1.4571 or SS 316 Ti

* with polyurethane coating

Teflon®is a registered trademark of Du Pont.

11

Page 12

10 Dimensions and weights

PLEASE NOTE

The total dimension for the height is obtained from dimension b (see table) plus the height

The total weight is made up of the weight of the signal converter (see table)

of the terminal box or the signal converter, see drawings.

plus the weight of the terminal box or signal converter, see below.

Terminal box

IFC 010 K and IFC 020 K

IFC 090 K signal converter

signal converters

Weight approx.

0.5 kg (1.1 lb)

Weight approx.

1.6 kg (3.6 lb)

Weight approx.

2.3 kg (5.1 lb)

Flange connections to ... Dimensions in mm (inch)

DIN 2501 DN 10-1300 PN 40, 16, 10 see table

(= BS 4504) DN 350-1000 PN 10 see table

DN 350-1000 PN 25 see table,

dimension ”a

standard

” + 200 mm

≥ DN 1200 PN 6, 2.5 information supplied on request

3

ANSI B 16.5

/8”-24” 150 lb / RF see table

≥ 300 lb / RF dimensions supplied on request

AWWA ≥ 14” Class B, D / FF dimensions supplied on request

• Dimension ”a” without flange gaskets:

not included with flowmeter, to be provided by customer.

• Meter size

3

/8”: flange connection 1/2”

Nominal size Dimensions in mm (inch)

DIN ANSI a (fitting length) b c dia.D in

DN PN inch Standard ISO 13359 ANSI DIN, ISO ANSI kg (lb)

1010 10/40 13/81150 0(5.91) – 150 7(5.91) 1146 7(5.75) 1121 4(4.76) 1190 2(3.54) 188.9 3(3.50) 883.5 88(7.7)

1015 10/40 1

1020 10/40 1

1025 10/40 1 1 1150 0(5.91) 200 7(7.87) 150 7(5.91) 1146 7(5.75) 1121 4(4.76) 1115 2(4.53) 108 3(4.25) 885.5 8(12.1)

1032 10/40 1 – 1150 0(5.91) 200 7(7.87) – 1161 7(6.34) 1139 4(5.47) 1140 2(5.51) – 886.5 88(15)

1040 10/40 1

1050 10/40 1 2 1200 0(7.87) 200 7(7.87) 200 7(7.87) 1199 7(7.83) 1160 4(6.30) 1165 2(6.50) 152 3(6.00) 887.5 88 (17)

1065 10/16 1 – 1200 0(7.87) 200 7(7.87) – 1209 7(8.23) 1173 4(6.81) 1185 2(7.28) – 812 88 (27)

1080 10/40 1 3 1200 0(7.87) 200 7(7.87) 200 7(7.87) 1216 7(8.50) 1173 4(6.81) 1200 2(7.87) 191 3(7.50) 812 88 (27)

1100 10/16 1 4 1250 0(9.84) 250 7(9.84) 250 7(9.84) 1267 (10.51) 1233 4(9.17) 1220 2(8.66) 228 3(8.98) 814 88 (31)

1125 10/16 1

1150 10/16 1 6 1300 (11.81) 300 (11.81) 300 (11.81) 1308 (12.13) 1257 (10.12) 1285 (11.22) 279 (10.98) 822 88 (49)

1200 10/16 1 8 1350 (13.78) 350 (13.78) 350 (13.78) 1366 (14.41) 1291 (11.46) 1340 (13.39) 343 (13.50) 845 8 (100)

1250 10/16 1 10 1400 (15.75) 450 (17.72) 400 (15.75) 1418 (16.46) 1331 (13.03) 1395 (15.55) 406 (16.00) 865 8 (144)

1300 10/16 1 12 1500 (19.69) 500 (19.69) 500 (19.69) 1481 (18.94) 1381 (15.00) 1445 (17.52) 533 (21.00) 895 8 (210)

1350 10/16 1 14 1500 (19.69) 550 (21.65) 700 (27.56) 1529 (20.83) 1428 (16.85) 1505 (19.88) 597 (23.50) 135 8 (298)

1400 10/16 1 16 1600 (23.62) 600 (23.62) 800 (31.50) 1587 (23.11) 1483 (19.02) 1565 (22.24) 635 (25.00) 170 8 (375)

1500 10/16 1 20 1600 (23.62) – 800 (31.50) 1632 (24.88) 1533 (20.98) 1670 (26.38) 699 (27.50) 230 8 (508)

1600 10/16 1 24 1600 (23.62) – 800 (31.50) 1801 (31.54) 1585 (23.03) 1780 (30.71) 813 (32.00) 315 8(695)

1700 10/16 1 28 1700 (27.56) – flanges 1918 (36.14) 1694 (27.32) 1895 (35.24) flanges 255 8 (565)*

1800 10/16 1 32 1800 (31.50) – to AWWA, 1039 (40.91) 1922 (36.30) 1015 (39.96) to AWWA, 335 8 (740)*

1900 10/16 1 36 1900 (35.43) – dimensions 1145 (45.08) 1026 (40.39) 1115 (43.90) dimensions 435 8(960)*

1000 10/16 1 40 1000 (39.37) – on request 1259 (49.57) 1132 (44.57) 1230 (48.43) on request 520 (1150)*

1

/21150 0(5.91) 200 7(7.87) 150 7(5.91) 1146 7(5.75) 1121 4(4.76) 1195 2(3.74) 188.9 3(3.50) 883.5 88(7.7)

3

/41150 0(5.91) 200 7(7.87) 150 7(5.91) 1146 7(5.75) 1121 4(4.76) 1105 2(4.13) 198.6 3(3.88) 885.5 8(12.1)

1

1

/21150 0(5.91) 200 7(7.87) 150 7(5.91) 1161 7(6.34) 1139 4(5.47) 1150 2(5.91) 127 3(5.00) 886.5 88(15)

– 1250 0(9.84) 250 7(9.84) – 1278 (10.94) 1233 4(9.17) 1250 2(9.84) – 819 88 (42)

Approx. weight

* weight with DIN flanges

12

Page 13

DN 10 - 40 /

160 (6.30”)

136 (5.35”)

3

/8” - 11/2”

98 (3.86”)

208 (8.19”)

140 (5.51”)

78 (3.07”)

Dimensions in mm (inch)

Tolerance details

for fitting length dimension ”a”

to DIN 2501 and ANSI B 16.5

DN ≤ 300 / ≤ 12”: ± 0.5 %,

min. ± 1 mm / ± 0.04”

DN ≥ 350 / ≥ 14”: ± 0.5 %

dia. D

a

DN 50 - 300 / 2” - 12”

160 (6.30”)

136 (5.35”)

98 (3.86”)

dia. D

c

208 (8.19”)

140 (5.51”)

78 (3.07”)

71 (2.80”)

b

71 (2.80”)

165 (6.50”)

105 (4.13”)

165 (6.50”)

105 (4.13”)

b

to ISO DIS 13 359

DN ≤ 200 / ≤ 08”: +0 / -3

DN ≥ 250 / ≥ 10”: +0 / -5

a

DN 350 - 2000 / 14” - 80”

dia. D

a

c

b

Øc

13

Page 14

11 Limits

PLEASE NOTE!

The limits specified in the table for process temperature and operating pressure make allowance

•

for the tube liner and the flange standard. Refer also to the footnotes.

•

At

ambient temperatures of +40 to +60 °C or +104 to +140 °F the product temperature

may not be higher than +60 °C or +140 °F.

Limits for pressure and temperature

Liner Connection flange Max. operating pressure in bar (psig)

Meter size Flange Pressure rating S = Standard

PTFE DN 10 – 20 DIN 2501 PN 40 S 40 (580) 40 (580) 40 (580) 40 (580)

3

/8” – 3/4” ANSI B 16.5 150 lb S 19.0* (275)* 18.9* (274)* 17.9* (259)* 17.1* (248)*

Hard

DN 25 – 50, DN 80 DIN 2501 PN 40 S 40 (580)(580) 40 (580)(580) 40 (580)(580) 40 (580)(580)

rubber

DN 65, DN 100 – 150 DIN 2501 PN 16 S 16 (230) 16 (230) 16 (230) 16 (230)

DN 200 – 600 DIN 2501 PN 10 S 10 (150) 10 (150) 10 (150) 10 (150)

DN 700 – 1000 DIN 2501 PN 10 S <10

≥ DN 1200 DIN 2501 PN 6/2.5 S/O on request on request on request on request

1” – 40” ANSI B 16.5 150 lb S 19.0

≥ 14” AWWA B S 06 0(90) 06 0(90) 06 0(90) 06 0(90)

with gaskets made of Neoprene or similar material

***

dependent on meter size

***

with gaskets made of Neoprene or similar material, dependent on meter size.

***

Note: Calculated operating pressures to DIN 2505 are much lower than the values in the table above.

***

standard or flange class O = Option ≤ 20 °C (≤ 68 °F) ≤40 °C (≤ 105 °F) ≤ 60 °C (≤ 140 °F) ≤ 90 °C (≤ 194 °F)

300 lb O 40 (580) 40 (580) 40 (580) 40 (580)

PN 40 O 40 (580) 40 (580) 40 (580) 40 (580)

PN 16 O 16 (230) 16 (230) 16 (230) 16 (230)

PN 25 O 25 (360) 25 (360) 25 (360) 25 (360)

PN 16 O <13.8

300 lb O 40 (580) 40 (580) 40 (580) 40 (580)

D O 10 (150) 10 (150) 10 (150) 10 (150)

at product temperature of ...

**.8 (<150)** <9.9**0 (<144)** <9.5**0 (<138)** on request

***(<200)*** <128*** (<185)*** <12.5*** (<181)*** on request

*< (275)* 18.9*< (274)* 17.9* (259)* 17.1* (248)*

Vacuum load

Liner Meter size Max. allowed vacuum load in mbar abs. (psia)

DN mm inch ≤ 20 °C (≤ 68 °F) ≤ 40 °C (≤ 105 °F) ≤60 °C (≤ 140 °F) ≤ 80 °C (≤ 176 °F)

PTFE DN 10 – 20

Hard DN 25 – 300 01 – 12 250 (3.6) 250 (3.6) 400 (5.8) 400 (5.8)

rubber DN 350 – 1000 14 – 40 500 (7.3) 500 (7.3) 600 (8.7) 600 (8.7)

≥ DN 1200 ≥ 48” on request on request on request on request

3

/8” – 3/4” 000 0.(0) 000 0.(0) 000 0.(0) 000 0.(0)

at product temperature of ...

14

Page 15

If you need to return flowmeters for testing

or repair to Krohne

Your electromagnetic flowmeter

• has been carefully manufactured and tested by a company

with ISO 9001 certification

• and volumetrically calibrated in one of the world’s most

accurate test rigs.

If installed and operated in accordance with these operating

instructions, your flowmeter will rarely present any problems.

Should you nevertheless need to return a flowmeter for

checkout or repair, please pay strict attention to the following

:

points

Due to statutory regulations concerning protection of the envi-

ronment and the health and safety of our personnel, Krohne

may only handle, test and repair returned flowmeters that

have been in contact with liquids if it is possible to do so without risk to personnel and environment. This means that

Krohne can only service your flowmeter if it is accompanied

by a certificate in line with the following model confirming that

the flowmeter is safe to handle.

If the flowmeter has been operated with toxic, caustic,

flammable or water-endangering liquids, you are kindly

requested

• to check and ensure, if necessary by rinsing or neutralizing, that all cavities in the flowmeter are free from such

dangerous substances.

(Directions on how you can find out whether the primary

head has to be opened and then flushed out or neutralized

are obtainable from Krohne on request.)

• to enclose a certificate with the flowmeter confirming that

the flowmeter is safe to handle and stating the liquid used.

Krohne regret that they cannot service your flowmeter unless

accompanied by such a certificate.

SPECIMEN certificate

Company: Address:

Department: Name:

Tel. No.:

The enclosed electromagnetic flowmeter

Type: Krohne Order No. or Series No.:

has been operated with the following liquid:

Because this liquid is

water-endangering * / toxic * / caustic * / flammable *

we have

– checked that all cavities in the flowmeter are free from such substances *

– flushed out and neutralized all cavities in the flowmeter *

(* delete if not applicable)

We confirm that there is no risk to man or environment through any residual liquid contained in this flowmeter.

Date: Signature:

Company stamp:

15

Loading...

Loading...