Page 1

Certified AutoCAD Driver

KIP Unattend

Operator Guide

Page 2

KIP Unattend Operator Guide

Contents

KIP Unattend ................................................................................................................................................................. 1

Configuration Menu .................................................................................................................................................... 4

KIP 7.2 File Shredding (Overwriting) ........................................................................................................................ 14

KIP Windows Unattend Configuration ..................................................................................................................... 15

Print Queue ............................................................................................................................................................ 1

KIP Code ................................................................................................................................................................. 1

Requester ............................................................................................................................................................... 1

Job Name/Number .............................................................................................................................................. 2

Description ............................................................................................................................................................. 2

Media ...................................................................................................................................................................... 2

# of Orig. ................................................................................................................................................................ 2

# of Sets .................................................................................................................................................................. 2

Color Codes ........................................................................................................................................................... 3

Set Monitor Paths .................................................................................................................................................. 4

Request Dir Path .................................................................................................................................................... 4

Configure Monitored Directory........................................................................................................................... 5

Monitor Path Selection Arrows ............................................................................................................................ 5

Save ........................................................................................................................................................................ 5

Cancel .................................................................................................................................................................... 5

Miscellaneous Setup ............................................................................................................................................. 5

Units ......................................................................................................................................................................... 6

Media Selection .................................................................................................................................................... 6

Rotation .................................................................................................................................................................. 6

Password ................................................................................................................................................................ 6

Copy Density ......................................................................................................................................................... 6

Feeder Size ............................................................................................................................................................. 6

Feeder Media ........................................................................................................................................................ 7

Separator Media ................................................................................................................................................... 7

Log file Directory ................................................................................................................................................... 7

Print Configs ........................................................................................................................................................... 7

Cold Sleep Settings ........................................................................................................... .................................... 7

Copy mode delay ................................................................................................................................................ 8

Unattended delay ................................................................................................................................................ 8

Default DPI ............................................................................................................................................................. 8

Print Separator Sheet ............................................................................................................................................ 8

Deck Info ................................................................................................................................................................ 8

Save ........................................................................................................................................................................ 8

Cancel .................................................................................................................................................................... 8

Check Your M-files ................................................................................................................................................ 9

Reset Current Job ................................................................................................................................................. 9

Quit Configuration ................................................................................................................................................ 9

Exit Program ......................................................................................................................................................... 10

Manager Mode ................................................................................................................................................... 10

Managing the Current Job ............................................................................................................................... 11

Managing Subsequent Jobs ............................................................................................................................. 12

Printing to the KIP 9000 Sheet Feed .................................................................................................................. 13

Page 3

KIP Unattend Operator Guide

KIP Unattend

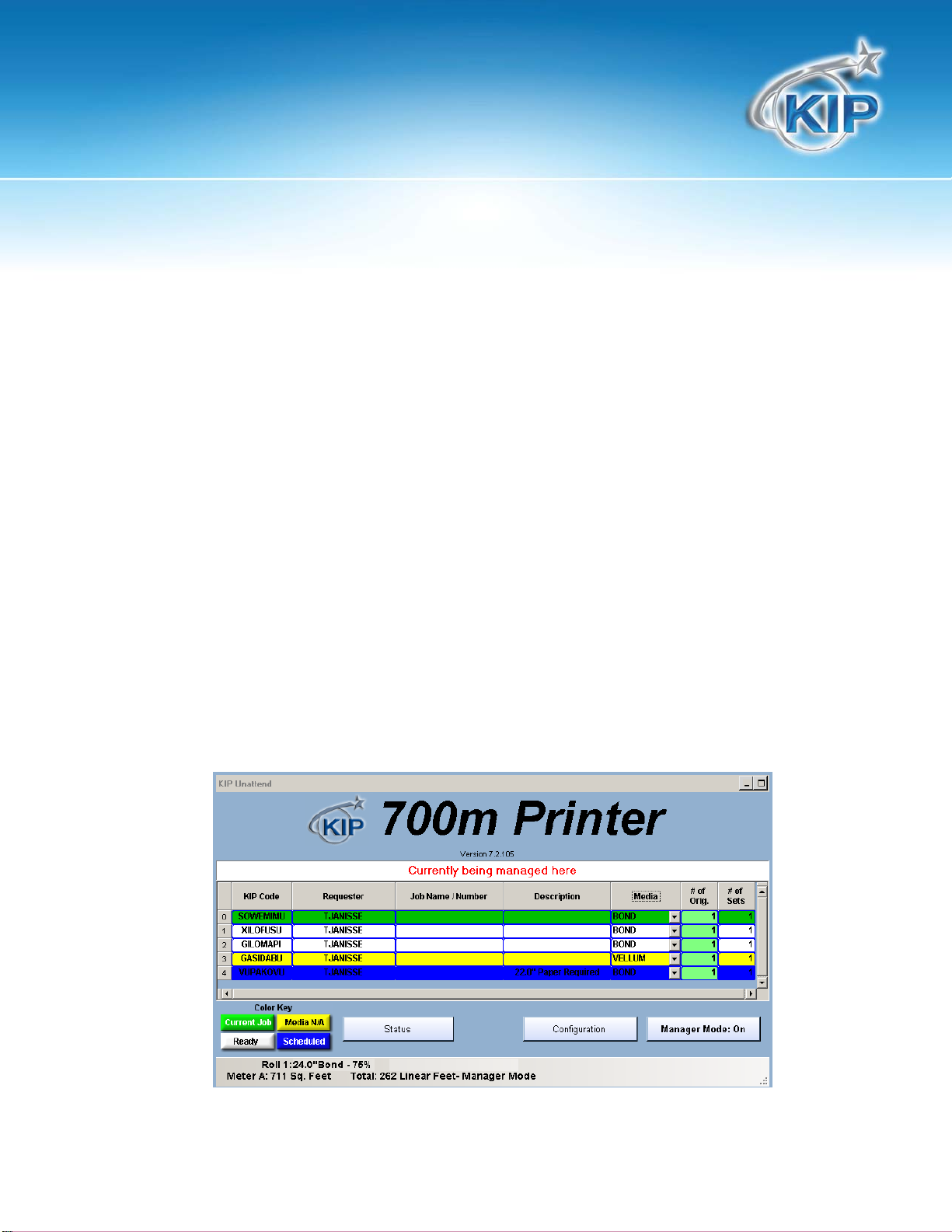

The KIP Unattend software is used as the KIP print queue with local print management features. The

model of the KI P Print engine is displayed at the top of the KIP Unattend screen. The print queue of the

requested print jobs or files within the queue is displayed here.

Print Queue

The print queue is divided into columns of information regarding the files in queue. These are:

KIP Code

When files are requested from the KIP Request software, the software helps in identifying the job ticket in

print by generating the KIP code. When files are simply dropped into the monitor path(s) the file name is

displayed in this column.

Requester

User information identifying person or location of the file’s requester. (This information is derive d from the

KIP Request software.)

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 1 -

Page 4

KIP Unattend Operator Guide

Job Name/Number

User information identifying job name/number of the job(s) in print. (This information is derived from the

Request software.)

Description

Additional user information identifying the job(s) in print. (This information is derived from the Request

software.) When files are simply dropped into the monitor path(s) the files path is displayed in this

column. File sent via LPR will show the file name in this field.

Media

This column will show the media type of the job(s) in print. If user(s) have requested a file using the

Request software, the media type requested will be shown.

# of Orig.

This column will show the number of originals of the job(s) in print.

# of Sets

This column will show the number of sets requested of the job(s) in print.

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 2 -

Page 5

KIP Unattend Operator Guide

Color Codes

When jobs are received in the Unattend print queue they will be assigned one of the four different col or

codes, the definition of these four color codes is conveniently displayed in a color key at the bottom left

corner of the KIP Unattend interface.

a) GREEN: This displays the current job being printed.

b) WHITE: This displays a subsequent job in queue, ready for print.

c) YELLOW: This displays the job with a warning that the job requested requires a different media

than what is available in the print engine.

d) BLUE: This displays the job with a wait state: either the controller’s time or time zone setting is not

in synchronization with the computer it was requested from, or the user has requested this job to

be printed at a later time. Jobs that are sent with a specific size (Forced) will show BLUE until the

applicable size media is installed in the printer.

Note: When the # of Originals column shows the number of originals displays green this means that

these files have already been preprocessed and are ready to be printed.

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 3 -

Page 6

KIP Unattend Operator Guide

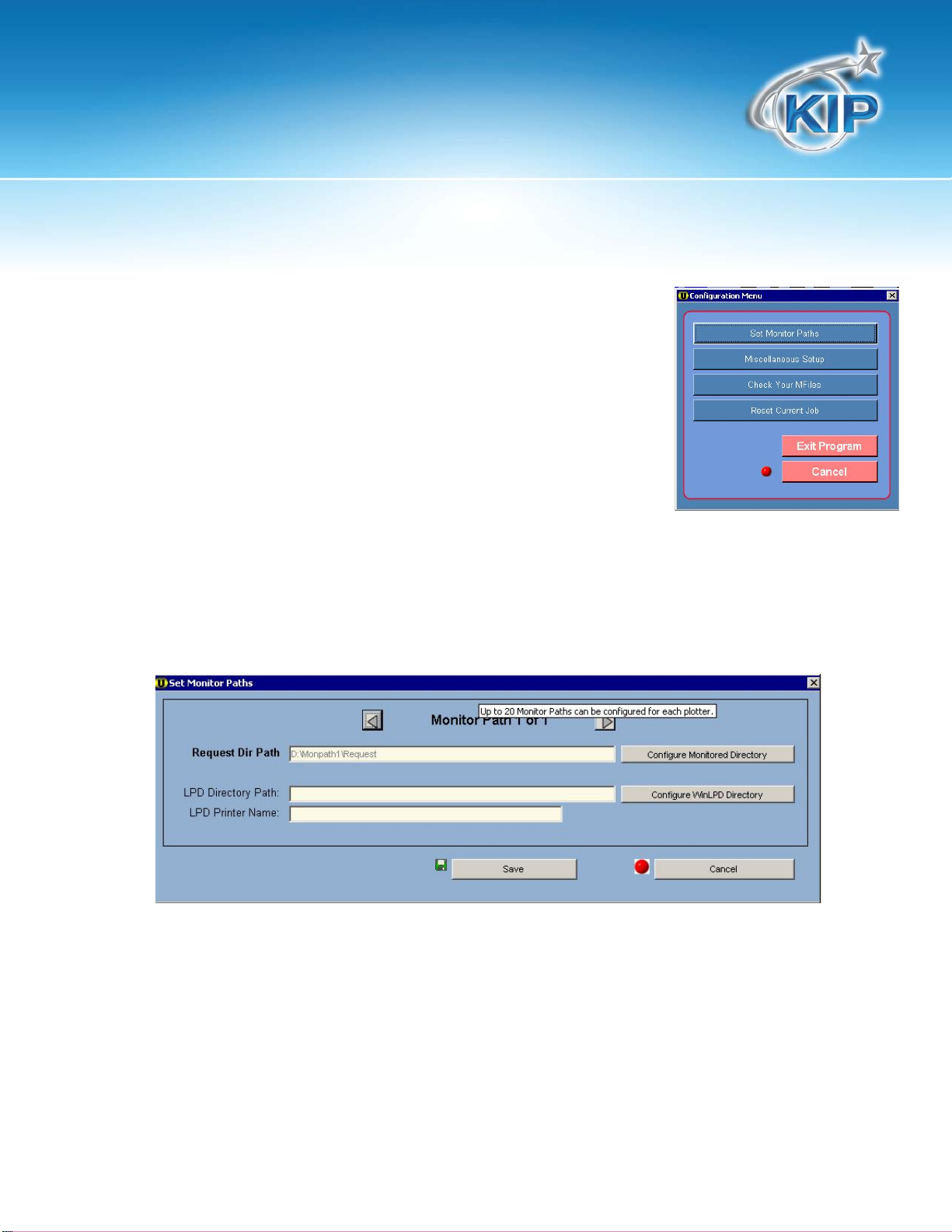

Configuration Menu

The first selection displayed underneath the print queue, the

configuration button will call up a dialog box with six (6) selections,

which are:

Set Monitor Paths

Allows the user to set up to different paths for the KIP Unattend software to monitor for incoming

print jobs.

Request Dir Path

This field contains the path statement KIP Unattend will monitor for print Requests.

‘D:\Monpath1\Request’ is the fir st request path and should not be removed or modified.

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 4 -

Page 7

KIP Unattend Operator Guide

Configure Monitored Directory

Files that are sent to the configured monitored directory

will have the parameters that are defined within the miniRequest as shown to the right. With this, it is possible to

create custom paths that can enlarge / reduce a file,

apply custom pen settings or change the media type. This

is helpful if sending LPR data that has no embedded

information within the printable image.

Monitor Path Selection Arrows

These arrows allow the user to toggle between the monitor paths currently setup on the controller.

Save

Allows the u se r to save monitor pat h s cr e ated in the set monitor path screen.

Cancel

Allows the user to exit the s et monitor path screen and return to the configuration menu.

Miscellaneous Setup

Allows the user to set up custom configurations of media defaults, copy density, password protection,

etc. Variables within the miscellaneous configuration include:

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 5 -

Page 8

KIP Unattend Operator Guide

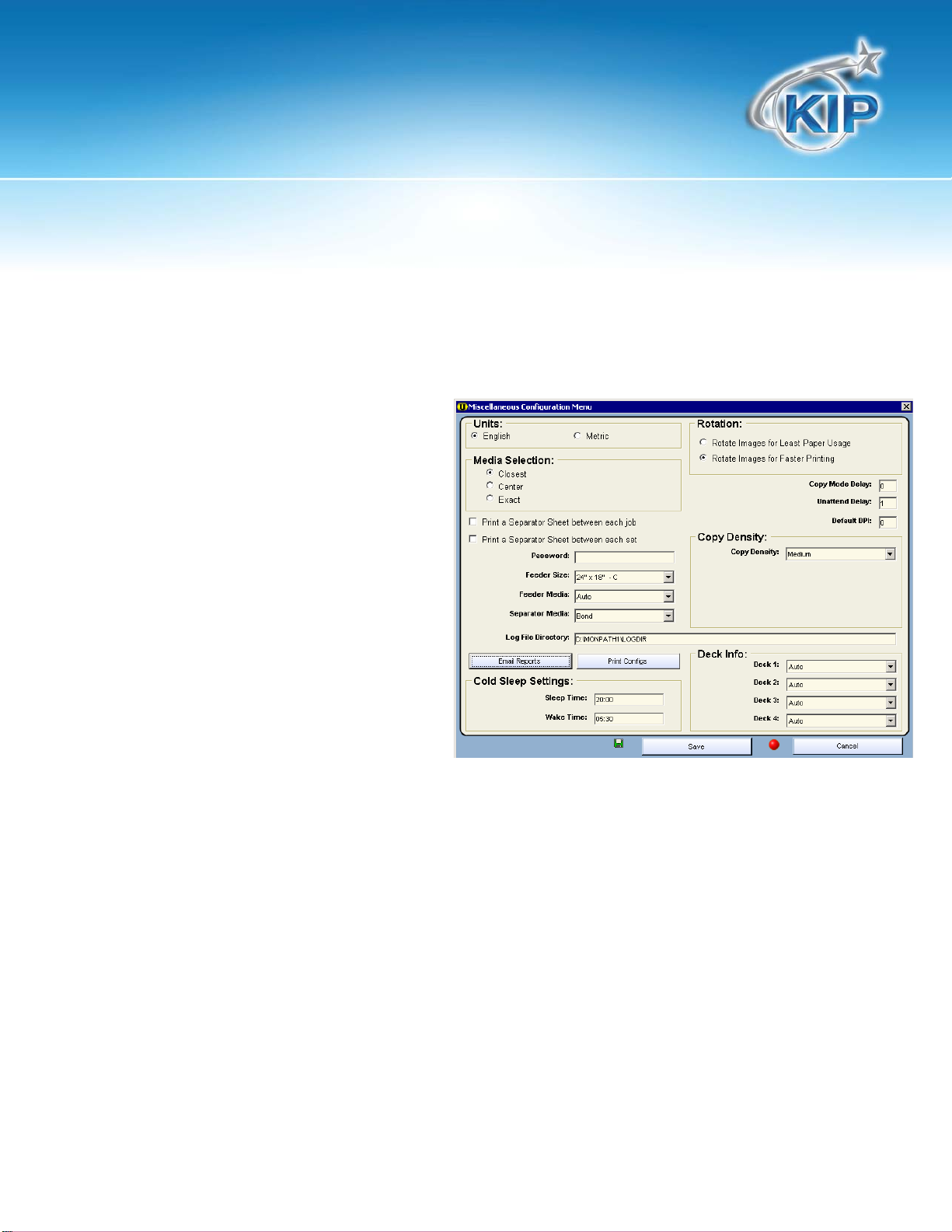

Units

Allows the user to set the controller to read either Eng lish or Metric standards of measurement.

Media Selection

Allows the user to print their documents on the closest size media loaded in the machine, or to the

‘Exact size’ media. If the user has this

option set to exact, the job will not print out

until the correct size media is loaded into

the machine.

Rotation

Rotate for least paper usage will place the

printed image on the smallest roll saving

the most paper.

Rotate for faster printing will rotate the

printed image to allow for least drum

rotation. This may use more paper.

Password

Allows the user to set a password in the Unattend mode, so that no configuration changes can be

made without entering a password. This password is not encrypted.

Copy Density

Allows the u se r to change the amoun t of toner (density) th at is being applied to printed files.

Feeder Size

Specific to the KIP 8000. Users must pre-select the size of the sheets in the sheet feed deck. The

corresponding roll size must not be installed when using the sheet feed.

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 6 -

Page 9

KIP Unattend Operator Guide

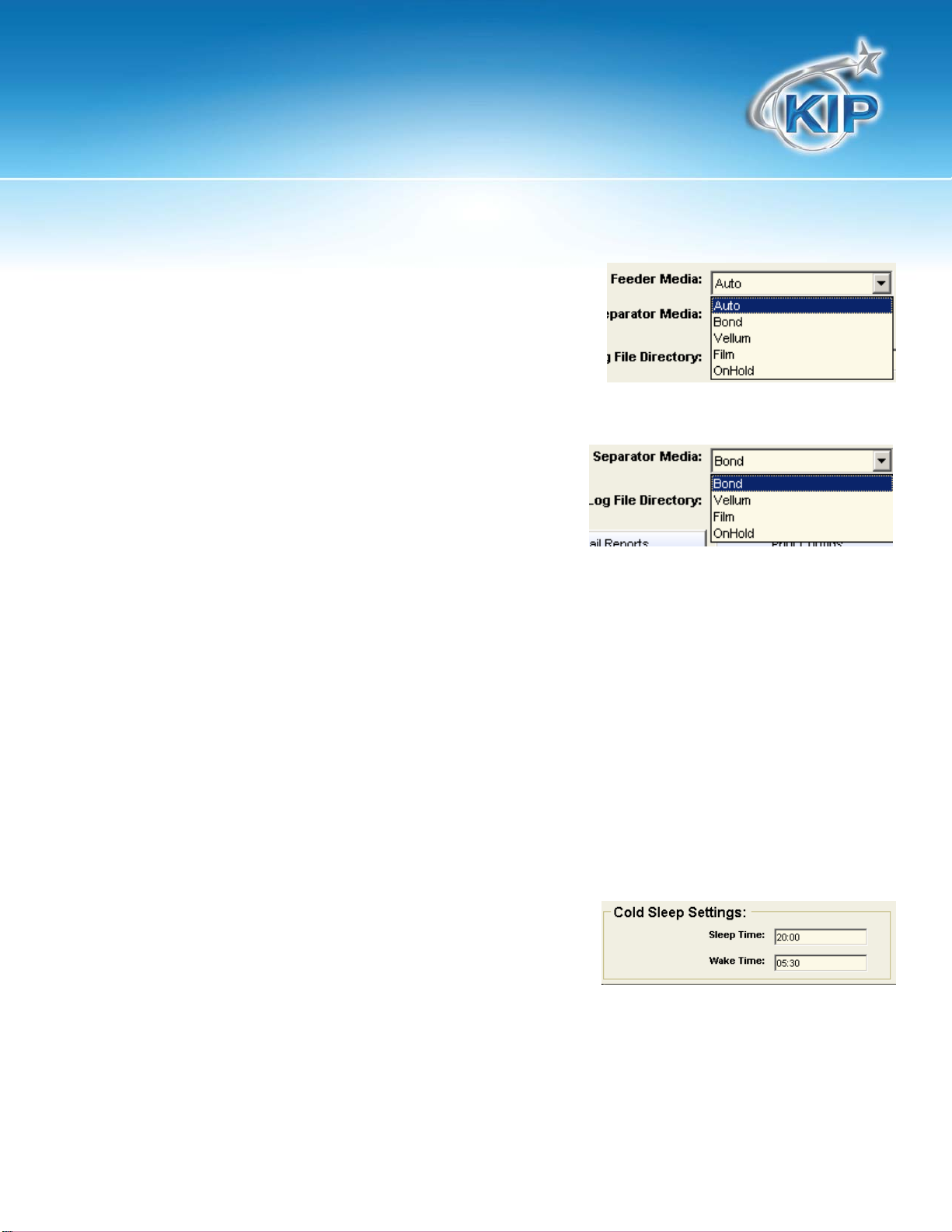

Feeder Media

Type of media (bond, vellum, film, on hold) in the feeder

(Starprint 8000) can be specified here.

Separator Media

Type of media on which the separator sheet should print can

be specified here.

Log file Directory

Allows the user to set a directory in which the Printer status and accounting data should be stored. This

can be input as a UNC path to a server location. Note: The KIP controller must have access to this

location. The default path of c:\monpath1\logdir will continue to receive the print logs.

Print Configs

Allows the user to print all configuration files (.INI files) on the e mbedded controller with the touch of a

button.

Cold Sleep Settings

Sleep time and wake up time are intuitive for power saving.

Users can set up time for sleep when there’s no apparent

printing that’s needed, or can set up time for the printer to

wake up. By default, the printer will start warming back up

anytime a Job / file arrives at a monitored path for printing. It will resume cold sleep 15 minutes later. This

can be set to 24 hour time or 12 hour time. Please check the time zone for proper settings.

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 7 -

Page 10

KIP Unattend Operator Guide

Copy mode delay

Allows the user to adjust the interval (in seconds) the machine will use when interrupting the print queue

for copy mode. It can also be set to zero for infinity and will require a ke y stroke to escape out of Copy

mode. This is not used on HDP printers.

Unattended delay

Allows the user to adjust the time interval (in seconds) in which the KIP Controller will seek the monitor

paths for files to be printed. The default should be set to 2 seconds.

Default DPI

Allows a user to set a conversion DPI if not specified in a submitted file or job ticket.

Print Separator Sheet

Users can choose to print a separator sheet between

each job, or between each set. This feature has been

found to be very useful for users of KIP folding and finishing

systems.

Deck Info

Allows the user to override the media in a specific drawer of the printer, or the print er can be set to

automatically detect the media loaded into a drawer. It is also possible to adjust the winuntd.ini file for

custom paper types, such as BBOND or TRANS. Please see the [PaperTypes] sections of the winuntd.ini

file.

Save

Allows the user to save changes made to the miscellaneous setup.

Cancel

Allows the user to exit the miscellaneous setup screen and return to the configura tion menu.

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 8 -

Page 11

KIP Unattend Operator Guide

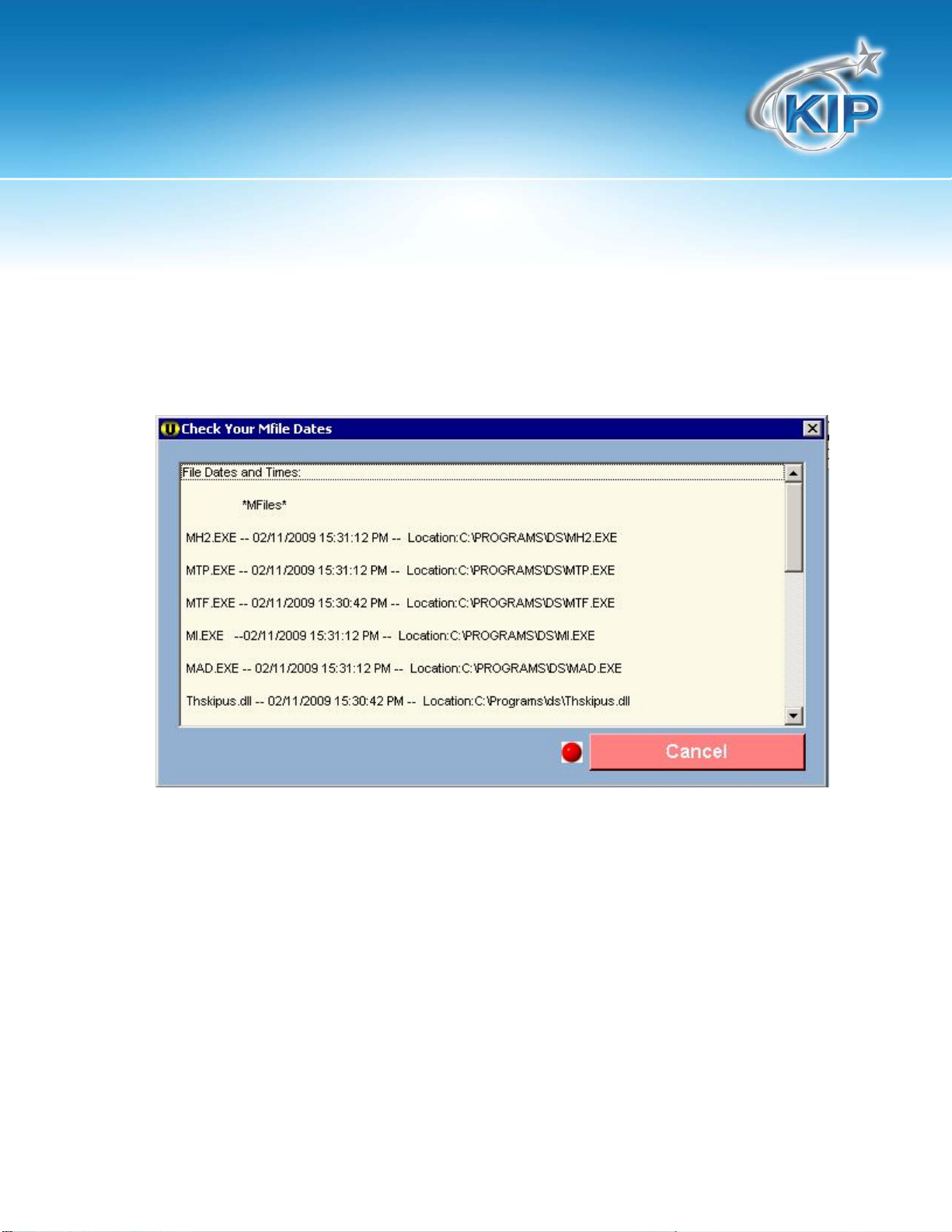

Check Your M-files

The “Check your M-files” button allows a technician to quickly see what conversion files are being used

on the KIP printer. These are the files that are responsible for the conversion of the files sent into a

printable format.

Reset Current Job

Clicking on Reset Current Job will stop any print job that is currently processing on the KIP controller. It

will stop / kill any process (conversion file / M-File) that is running and place the offending print job into a

“problem folder” for later review. This information can then be gathered using the KIP 6.5 Request

software using the Transfer Æ Get Problem Files option. Please see the KIP 6.5 Request documentation

for further information.

Quit Configuration

Allows the user to quit the configuration mode.

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 9 -

Page 12

KIP Unattend Operator Guide

Exit Program

Allows the user to exit Unattend.

Note: Exiting the KIP Unattend will stop all printing. KIP Unattend MUST be opened for printing to occur.

Manager Mode

The Manager Mode button will allow the user the option of manually controlling the print queue.

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 10 -

Page 13

KIP Unattend Operator Guide

Managing the Current Job

By selecting the Manager Mode button, the mouse

cursor will change from an arrow to a crosshair. The

Manager Mode icon will illuminate in Bold and pause all

printing. The operator can manage a print job by

double-clicking the “job count” list along the left side.

The user is given six selections to choose from:

1. Update Copy Count – This will allow the user to update the copy count if more or less copies are

needed.

2. Remove Job- this will allow the user to remove the Job before conversion begins.

3. Pause After Job- this will allow the user to pause Unattend after the current Job in queue is printed.

4. Pause After Set- this will allow the user to pause Unattend after the current set in queue is printed

5. Cancel- this will allow the user to cancel the manager mode.

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 11 -

Page 14

KIP Unattend Operator Guide

Managing Subsequent Jobs

By placing the crosshair over job count on the left side of the screen and double-clicking on subsequent

jobs in the print queue (not job 0 shown in Green) the user is given the ability to manually control the

order, number of sets printed, type of media used and SEND JOB to ANOTHER KIP PRINTER. (For instance,

the job(s) in the queue are printing and you have a job you need printed NOW to another KIP printer.

Double click on the job in the queue you need right away and the Manager Screen will appear with a

number of variables. They are:

1. Remove Job button - this allows the customer to remove the job they have just highlighted from the

print queue

2. Job name - this is the KIP Code information generated by Request. This field is not available for

change.

3. Number of Originals - this is the number of originals requested. This field is not available for change.

4. Format - this is the format information as explained earlier in Section I (The Print Queue) either

“Request”, “Raster” or “Vector”. This field is not available for change.

5. Number of Sets - this is the number of sets requested, this is modifiable in Manager Mode

6. Media - whichever is the type of media requested, this is modifiable in Manager Mode.

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 12 -

Page 15

KIP Unattend Operator Guide

7. Time - this i s the time of the request

8. Requestor - this is Requestor information input in Request

9. Distribution - this is Distribution information input in Request

10. Description - this is Description information input in Request

11. Move Job buttons - these four buttons will allow the customer to move jobs within the queue and

prioritize them. These four buttons are:

• Move to Top - (remember our example? You need a job NOW!). Highlight the job you need by

double clicking it in the queue, click the “Move to Top” button and the job you need will be

moved to the next job in the queue.

• Move Up One - Highlight the job you need by double clicking it in the queue, click the “Move Up

One” button and the job you need will be moved up one position in the queue.

• Move Down One - Highlight the job you need by double clicking it in the queue, click the “Move

Down One” button and the job you need will be moved down one position in the queue.

• Move to Bottom - Highlight the job you need by double clicking it in the queue, click the “Move

to Bottom” button and the job you need will be moved to the bottom position in the queue.

12. Send Job – This allows the user to send jobs from one network configured KIP printer to another

network configured KIP printer. This helps with load sharing in multiunit installations.

By right clicking on a job (current or subsequent) you are offered 5 items to choose from. These are the

same functionality as outlined above. Move job, Schedule, Remove, and Send To. There is also a

selection for changing media. The job list can be modified by clicking and dragging a single job t o any

spot in the list.

Printing to the KIP 9000 Sheet Feed

When Printing to the KIP 9000 sheet feed the tray can hold up to 50 sheets of media (C size or less) for

auto mode pr i nting. If larger than C s i z e me d ia is to be used only one sheet may be loaded at a time.

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 13 -

Page 16

KIP Unattend Operator Guide

KIP 7.2 File Shredding (Overwriting)

KIP 7.2 Software includes the Department of Defense NISPOM specifications to securely delete (overwrite) all

image data after a print, copy or scan job has been completed. KIP7.2 File Shredding (overwriting) processes

and scheduling is configurable using KIP PrintNET.

The KIP PrintNET File Shredding configuration allows administrators or key operators to select one or both of the

following file shredding processes:

1. After each copy, print or scan job, KIP 7.2 software will remove all remnants of file image data.

2. 7.2 Software may also be configured via KIP PrintNET to shred all blank hard disk drive space on a daily,

weekly or monthly basis.

Organizations using file shredding software may wish to use both processes. That is they wish to shred image

data after each print, copy or scan job plus shred blank hard drive space on a daily, weekly or monthly basi s.

The shredding process time can vary depending on the amount of data or empty hard drive space to be

overwritten.

NISPOM (National Industrial Security Program Operating Manual) paragraphs 5-704 and 5-705 set out

requirements for the destruction of classified data that is no longer required. The appropriate file shredding

procedure to be used is based on the classification of sensitivity of the information and the type (size, capacity

and coercivity) of the media.

NISPOM outlines the clearing and sanitizing of data with a matrix. This matrix outlines the method of clearing

and sanitization of hard disk drives (Rigid Disks). In order to comply with NISPOM standards for rigid disks, KIP 7.2

software removes all image data and temporary image data used during the copy, print and scan process.

The KIP three pass file shredding process complies with the NISPOM specification which consists of overwriting all

image data locations with a character, its compliment and a random character. This method ensures that all

image data can no longer be accessed using a data recovery device.

KIP 7.2 File Shredding (Overwriting) Technical Details

Overwriting is a process whereby unclassified data are written to storage locations that previously held sensitive

data. To satisfy the DoD (Department of Defense) clearing requirement, it is sufficient to write any character to

all data locations in question. To purge AIS (Automa ted Information Systems) storage media, the DoD requires

overwriting with a pattern, then its comple ment, and finally with another pattern; e.g., overwrite first with 0011

0101, followed by 1100 1010, then 1001 0111. The number of times an overwrite must be accomplished depends

on the storage media, sometimes on its sensitivity, and sometimes on differing DoD component requirements. In

any case, a purge is not complete until a final overwrite is made using unclassified data.

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 14 -

Page 17

KIP Unattend Operator Guide

KIP Windows Unattend Configuration

WindowsUnattendVersion=7.1.x

The current version of KIP Unattend. The value is automatically entered by the Unattend program.

Primarily used for diagnostic purposes.

Language=1

Current Language being used.

LastLanguage=1

Last Language used.

MachineID=

Machine Serial Number

DealerName=

If Entered in the IPS User Interface this information will show up here also.

DealerNumber=

If Entered in the IPS User Interface this information will show up here also.

MachineType=9900

The defined Printer Model. Choices are listed in the top paragraph. This line is usually modified after a

system re-ghost. An incorrect entry would force Unattend to see incorrect paper roll information, or

none at all.

DisplayPrinterName=9900~9900~4

Allows for customization of the Unattend header displayed on the main screen

Units=METRIC

Defines ENGLISH or METRIC mode.

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 15 -

Page 18

KIP Unattend Operator Guide

Password=

When a password is defined in Unattend, the user must know the password before the program will

allow them into Unattend Manager Mode, or the Configuration menu. Note that the Unattend

password is not encrypted in the winuntd.ini, and offers minimal security.

SCSIScanner=True

Set to Tru e if the printer is attached to a 2050, 2080, 20120, or 2160 SCSI Scanner.

BypassBoard=False

Used With KIP Legacy units.

UnattendedDelay=1

The Interval in which the KIP Queue Vi ew will look for printable files in the designated folder locations.

Used with Unattend 6.5. Unattend 7.1 automatically looks for a job when files are sent to the monitored

locations.

JobReadDelay=30

CopyModeDelay=0

Utilized with KIP Legacy units.

AFolderDelay=0

Folder Delay used for printing smaller (A Size) sheets.

OtherFolderDelay=0

Additional delay for folder

LandscapeFolderDelay=0

Folder Delay used for printing smal ler landscape sheets.

ShutDownDelay=0

SleepWarmDelay=840

Value is a number of seconds. If Unattend does not receive a print within this number of seconds, it

lowers the fuser temperature to a ‘power-save’ state. Value 0 disables Warm Sleep mode.

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 16 -

Page 19

KIP Unattend Operator Guide

SleepColdDelay=5340

Value is a number of seconds. If the engine is in a “Warm Sleep” state, and a print is not received within

this number of seconds, the fuser temperature is lowered even further to room temperature. Value 0

disables Cold Sleep mode.

SleepColdStandBy=False

Puts the KIP IPS into Standby Mode.

ColdStartTime=

The information entered under ‘Windows Unattend – Configuration – Misc settings’ in the screen below is

duplicated in the Winuntd.ini for ColdStartime and ColdStoptime. ColdStartime refers to the time when

the software will s ignal the printer to go into Cold slee p mode. Coldstoptime refers to Wake t ime that

sends the printer to ‘warm up’. Users can normally put the Sleep time at 20:00 (8PM) and Wake time at

06:00 (6AM).

ColdStopTime=

See above

Advanced Sleep=

Feeder5Paper=6

Utilized with the KIP 8000, KIP 9000 & KIP 9900

IdleWait=0

MeterPeriod=

MeterDate=

MeterDay=

MeterTime=

MeterReportDate=12:00:00 AM

This section is used for the Print Reports Setting utilized in KIP PrintNet

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 17 -

Page 20

KIP Unattend Operator Guide

CurrentLogPath=C:\MONPATH1\LOGDIR

Normally selected in Unattend’s CONFIG/MISC menu, this is the defined path that Unattend uses to

write its Log and Roll information. Unattend creates an ASCII-based print log using the naming

convention MonthYear.l og (i.e. Jan03.log). It also writes roll information files (rollinfo.dat) to this location.

This path can be defined to point to another

computer on the network, but the KIP Controller will need rights in order to create and modify files on

another computer.

LogFileName=

Some users prefer their own naming structure instead of the MonthYear.log format that Unattend uses to

write the print log. User can define another filename and extension (i.e. printlog.txt). This file will be

written in the Current Log Path as defined in the CurrentLogPath= line. The new Log File does not create

a new file every month, but appends a single file. Note that the MonthYear.log file is still written in

addition to the custom Log Filename.

TempDir=C:\TU

The Directory location where all conversion of files takes p lace.

LPDSpoolDirectory=

EnhancedWinLPDRead=F

HistoryGB=0

The amount of hard drive space designated for the storing of History Jobs.

MinDoneFileSize=1

MinCutLength=8.5

Allows the technician to set the minimum number of inches for the cut length that will be produced by

the controller when printing. Especially helpful for printing longer Trim Sheets or Error Pages, that may

jam the printer when the curl of the media causes problems. (Suggested MINCUTLENGTH=17)

DefaultMedia=Bond

SepMedia=BOND

LastPen=C:\PROGRAM FILES\KIP\REQUEST\PENS\DEFAULT.PEN

The last pen table used for printing.

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 18 -

Page 21

KIP Unattend Operator Guide

DefaultDPI=0

Rarely changed (0 by default) when set to 0 this tells the KIP to read and use the dpi of the file as it was

sent.

PrinterDPI=600

DPI capability of the KIP Unit.

SwitchSelect=4

TextPos=0

TextSize=.1

ExtraGap=0

AmountCutOff=500

If the original being printed exceeds the Maximum print width this setting will strip pixels off of the sides.

AddHpglCmd=-: 6

Switches may be added to this location to assist with specific printing requirements (contact KIP for

assistance).

AddRasterCmd=

Switches may be added to this location to assist with specific printing requirements (contact KIP for

assistance).

AddPrintCmd=

Switches may be added to this location to assist with specific printing requirements (contact KIP for

assistance).

AddOutputCmd=-j 75

Switches may be added to this location to assist with specific printing requirements (contact KIP for

assistance).

AddCGMCmd=

Switches may be added to this location to assist with specific printing requirements (contact KIP for

assistance).

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 19 -

Page 22

KIP Unattend Operator Guide

AddDWFCmd=-lt 6

Switches may be added to this location to assist with specific printing requirements (contact KIP for

assistance).

AddPSCmd=-dNOTRANSPARANCY

Switches may be added to this location to assist with specific printing requirements (contact KIP for

assistance).

LeadingSpace=0

IgnoreExt=

CopyDensity=2

CyanCopyDensity=0

Utilized with the KIP KC80 Printer.

MagentaCopyDensity=0

Utilized with the KIP KC80 Printer.

YellowCopyDensity=0

Utilized with the KIP KC80 Printer.

MaximumRollSize=36.75

Allows the technician to set the Maximum Roll size the printer will utilize. This can be set a bit larger to

allow off size files to print.

FoldBypass=01

This sets the Folder Bypass to either on (1) or off (0) this is set in KIP PrintNet.

DefaultFileType=V

DefaultJamCopies=2

Value is a number of prints. If a jam occurs, and if Internal Controller=False, Unattend displays a popup

window asking how many copies to reprint. This value is the default number, unless the user changes it. If

Internal Controller=True, the program uses the ReprintJamInches= value to automatically reprint copies.

ReprintJamInches=24

Sets the amount of inches the printer will go back and print after a Jam.

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 20 -

Page 23

KIP Unattend Operator Guide

DelayBetweenSets=0

MaxImageSize=600

Sets the Max imum Print length of the KIP (in inches)

WireCleanTime=12:00

Value is in military time. A Wire Cleaning will be performed every day on the engine at this defined time,

based on the computer clock.

WireCleanAmount=0

Value is a linear feet total. Once FeetSinceWireClean= counts up to this total, a Wire Cleaning will be

performed, in addition to the time established in WireCleanTime=. Automatic wire cleaning is only

available on certain printer models. Other models sh ould have this feature disabled by changing the

value to 0.

FeetSinceWireClean=166.5468

Value is a counter that keeps track of the number of linear feet printed since the last Wire Cleaning.

Once the WireCleanAmount= is reached, a Wire Cleaning will be performed at the time defined in

WireCleanTime=.

RasterMultiplier=1

This value will be multiplied by the –G value in Request Job Tickets or in the

AddHpglCmd= line, whichever applies. It is used to darken the grayscale level of light HP-RTL data.

KipNumberOfRolls=0

KeyCode=

BackupConfigFile=C:\Program Files\KIP\Unattend\WinUntd.Ini-Bak

SCPFilterDir=C:\SCP\Db

JISTolerance=0

Japanese Image Standard, this is a tolerance that will match non-standard sizes and print them to

Japanese Image Standard sizes.

UseKipFinishResponse=True

ExternalJamReprint=False

WaitASCIIJobs=False

IgnoreKeyCardError=True

KipStatDelay=False

AutoTrimPaper=False

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 21 -

Page 24

KIP Unattend Operator Guide

When set to True, Unatte nd will automatically cut a trim sheet from a new roll once it is inserted.

PreloadPaper=True

MultPlotCopies=True

UseRigoliFold=False

When set to True, Unatte nd will attempt communication with a Rigoli Folder.

IgnoreFoldPresets=False

UseKipFold=False

When set to True, Unattend will attempt communication with a KIP Folder.

UseEsteFold=False

When set to True, Unatte nd will attempt communication with a Este Folder.

UseKipFold500=False

When set to True, Unattend assumes a KIP 500 Fan Folder is present. This statement is not dependent

upon UseKipFold (stated above)

InternalController=True

PrintSeparatorSheetJob=False

PrintSeparatorSheetSet=False

FoldSeparatorSheet=True

ScaleSeparatorSheet=True

ReverseMultipageRaster=False

PrintLocalSeparator=False

When set to True, and if PrintSeparaterSheet=True, the Separator Sheet will print to the KIP Controller’s

default Windows printer instead of the KIP Printer engine.

NewInterface=False

DontEmailErrors=False

CalcompParams=True

ForceTextOn=False

TextOn=False

DontPrintMultipleRaster=False

KeepMultipleSets=True

HardwareConnect=False

Rarely altered. Only set to False if Unattend is being used in Demo mode, or diagnostic mode.

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 22 -

Page 25

KIP Unattend Operator Guide

MCC8BoardTest=False

IgnoreTime=True

When set to False, Unattend sorts jobs by the times created within the Job Ticket. But since these Job

Tickets are created on the user workstations and copied to the KIP Controller, this can lead to jobs being

scheduled for moments or hours later, if the workstation clocks (and workstation Time Zones) are not

synchronized with the KIP Controller. When set to True, IgnoreTime= simply prints the jobs in the order

they were received by Unattend, ignoring any perceived ‘scheduled’ times.

ReprintMultiple=True

KipCopier=False

MultiPagePDF=True

ReverseCGM=False

RedPrinter=False

StampInRed=False

HeaderInRed=False

PowerScriptInstalled=True

Used to define a method of PDF file conversion. In previous versions of KIP, more than one PDF

conversion option was available, and this legacy setting was used to enable PowerScript. In KIP 5,

Powerscript is the only available conversion option. This setting should be set to True even if the

Powerscript Hardware Key has not been attached.

LPDDisplay=True

ViewOutput=True

Used in troubleshooting. If HardwareConnect=False, then Unattend is running in demo mode.

ViewOutput= determines whether a job sent to Unattend ‘prints to screen’, or simply disappears from

the queue.

QuickView=True

Determines if quickview will be used to display output, else ultraview

OutputPaperSquareFootage=True

Will use paper dimensions when set to true to calculate print logging information. Will use image

dimension to calculate print logging information when set to False

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 23 -

Page 26

KIP Unattend Operator Guide

PreconvertSets=False

Must be set to True for Starprint 1020 printers. Can be set to true for other printers if the controller has

trouble printing at full speed during the first collated set. When set to True, the controller will pre-convert

the complete set of images before any printing takes place. This allows the printer to work at full speed

during the first collated set of printing.

CheckHardwareLockMultiple=False

When set to True will check for KIP Online and/or Powerscript 3 hardware lock multiple times before

rejection.

DontCheckHardwareLock=False

When set to Tru e t h i s wi ll tell the printer not to look for a Hardware lock.

AlwaysUseConfiguredMedia=False

When set to True, will use a configured path setting for Media Type when KIPJL based plot files are

presented to KIP0 via LPR or port copy. When set to False, will use KIPJL based media call.

RotateToSavePaper=False

DontUseCalcompData=False

ReadStatusFile=True

JISStandardCut=False

This will turn on (1) or turn off (0) the use of Japanese Image Standard

RightJustifyFolds=False

AbacusEnabled=True

If Abacus is being used this will be set to True

PrintDriverUnifiedAccounting=False

Turns on the Unified Accounting for the KIP Windows Driver. This can also be turned on through KIP

PrintNet.

WaitForceSize=False

If True will hold a force size job in the queu e when media runs out allowing other jobs to print.

DisableFoldReprints=False

IgnoreHDIBorders=False

Ignores existing borders that are on by defaul from within AutoCAD.

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 24 -

Page 27

KIP Unattend Operator Guide

CardReaderEnabled=False

True enables the use of a card reader; False disable the use of a card reader. Used in Europe.

MultiSheetFeederEnabled=False

Used in conjunction with a feeder drawer on the KIP 700M and 7100 systems.

Embedded=True

MultiThreadPDF=True

Uses the multithread (Dual Core) capabilities of the IPS for processing multi-page pdf files.

ExpandedMagenta=False

Used in conjunction with the KIP KC80

FolderPort=0

Used when connecting a KIP Controller to a Folding Unit. Value is a Com Port (serial port) number.

Correct number will depend on the unique configuration and the number of serial ports on the KIP

Controller. Controllers not connected to a Folding Unit should use a value of 0.

SerialDisplayPort=-1

Used when connecting an internal KIP Controller to an LCD Display Window on KIP 4000 and 5000

models. Value is a Com Port (serial port) number. Correct number will depend on the unique

configuration and the number of serial ports on the KIP Controller. Also, InternalController= must be set

to True, and the Unattend program must be running, for the LCD Display to function. Controllers not

connected to an LCD Display should use a value of -1.

FormTop=1170

FormLeft=6165

FormHeight=11085

FormWidth=14625

FormState=0

ShowColorKey=TRUE

Debug=-1

Used for diagnostic purposes only

PrintExe=C:\PROGRAMS\KIPPRNT.EXE

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 25 -

Page 28

KIP Unattend Operator Guide

StatusExe=C:\PROGRAMS\KIPSTAT.EXE

VectorInExe=C:\PROGRAMS\DS\MH2.EXE

RasterInExe=C:\PROGRAMS\DS\MTF.EXE

TlcPrintExe=C:\PROGRAMS\DS\MTP.EXE

ViewExe=

TiffViewExe=

QuickViewExe=C:\PROGRAM FILES\KIP\REQUEST\QV.EXE

RequestExe=C:\PROGRAM FILES\KIP\REQUEST\WINREQ.EXE

MergeExe=C:\PROGRAMS\DS\MI.EXE

ColorExe=C:\SCP\KC80_COLOR_ENGINE.EXE

AutoRecognizeExe=C:\PROGRAMS\DS\MAD.EXE

PowerScriptExe=C:\PROGRAMS\DS\PSCRIPT.EXE

NestImageExe=C:\PROGRAMS\MPACK.EXE

KipPortExe=C:\PROGRAMS\KAWPDFT.EXE

DWFExe=C:\PROGRAMS\DS\DWFCONVERT.EXE

BlankPrint=C:\PROGRAMS\TRIMSHT.TLC

ExternalCommandLine=

ExternalDirectory=

[PDFDefaults]

UseImageSize=True

PDFImageSizeX=0

PDFImageSizeY=0

ReverseOrder=False

EnhancedColor=False

PSUsePageSize=True

The above lines refer to default handling of PDF/PS documents if presented through KIP0 using Port

based transfer methods. If using the 6.5 KIP Windows Printer driver, PSUsePageSize must be set to True.

[RasterScaling]

RasterThreshold1=0

RasterThreshold2=0

RasterSetting1=

RasterSetting2=

RasterSetting3=

Added Enhancements to full and half Size Printing of Raster Data – designed to improve full and half size

printing of heavy Raster data. The INI settings allow the technician to specify at what “Raster Density”

the KIP software applies a Dither Pattern and Density Setting. This is very similar to applying a Dither

Pattern and Density Setting to RTL data, but this now applies for Raster Data.

Here’s how the features work:

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 26 -

Page 29

KIP Unattend Operator Guide

a. Below RasterThreshold1, it is best to apply a no setting command, (EG:

RasterSetting1=“blank”). Leave blank. Most “line” images fall under 2.8, these don’t need

any further settings.

b. Between RasterThreshold1 and RasterThreshold2; RasterSetting2 will be used.

c. Above RasterThreshold2; RasterSetting3 will be used.

Switches

These five switches must be used i n conjunction with each other .

Z - Photo Mode ON

W 100 - Raster Density, lower numbers will “ li ghten” data.

u 0 - Raster Dither Pattern, values include 0,4,6, or 8. Same as RTL Density values. These two switches must

be used in conjunction with each other and BOTH must be used together.

q 1 – utilizes a “random” dither pattern, better for non-continuous tone images.

W 75 - Raster Density, lower numbers will “lighten” data.

[FoldPresets2.0]

ESizePortraitPreset=6

ESizeLandscapePreset=6

E2SizePortraitPreset=2

E2SizeLandscapePreset=2

E3SizePortraitPreset=2

E3SizeLandscapePreset=2

DSizePortraitPreset=6

DSizeLandscapePreset=6

D2SizePortraitPreset=2

D2SizeLandscapePreset=2

CSizePortraitPreset=2

CSizeLandscapePreset=2

C2SizePortraitPreset=2

C2SizeLandscapePreset=2

C3SizePortraitPreset=2

C3SizeLandscapePreset=2

BSizePortraitPreset=2

BSizeLandscapePreset=2

B2SizePortraitPreset=2

B2SizeLandscapePreset=2

ASizePortraitPreset=2

ASizeLandscapePreset=2

[MetricFoldPresets]

A0SizePortraitPreset=27

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 27 -

Page 30

KIP Unattend Operator Guide

A0SizeLandscapePreset=27

A02SizePortraitPreset=27

A02SizeLandscapePreset=27

A1SizePortraitPreset=28

A1SizeLandscapePreset=28

A12SizePortraitPreset=28

A12SizeLandscapePreset=28

A2SizePortraitPreset=29

A2SizeLandscapePreset=29

A3SizePortraitPreset=30

A3SizeLandscapePreset=30

A4SizePortraitPreset=31

A4SizeLandscapePreset=31

[PaperSettings]

Roll1Paper=Auto

Roll2Paper=Auto

Roll3Paper=Auto

Roll4Paper=Auto

Roll5Paper=Auto

[FolderPaperSettings3.0]

FolderPaperSizeE=36

FolderPaperSizeE2=34

FolderPaperSizeE3=30

FolderPaperSizeD=24

FolderPaperSizeD2=22

FolderPaperSizeC=18

FolderPaperSizeC2=17

FolderPaperSizeC3=15

FolderPaperSizeB=12

FolderPaperSizeB2=11

FolderPaperSizeA=11

FolderPaperSizeDPortrait=24

FolderPaperSizeD2Portrait=22

FolderPaperSizeCPortrait=18

FolderPaperSizeC2Portrait=17

FolderPaperSizeC3Portrait=15

FolderPaperSizeBPortrait=12

FolderPaperSizeB2Portrait=11

FolderRotationSizeEPortrait=0

FolderRotationSizeE2Portrait=0

FolderRotationSizeE3Portrait=0

FolderRotationSizeDPortrait=0

FolderRotationSizeD2Portrait=0

FolderRotationSizeCPortrait=0

FolderRotationSizeC2Portrait=0

FolderRotationSizeC3Portrait=0

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 28 -

Page 31

KIP Unattend Operator Guide

FolderRotationSizeBPortrait=0

FolderRotationSizeB2Portrait=0

FolderRotationSizeAPortrait=0

FolderRotationSizeELandscape=3

FolderRotationSizeE2Landscape=3

FolderRotationSizeE3Landscape=3

FolderRotationSizeDLandscape=3

FolderRotationSizeD2Landscape=3

FolderRotationSizeCLandscape=3

FolderRotationSizeC2Landscape=3

FolderRotationSizeC3Landscape=3

FolderRotationSizeBLandscape=3

FolderRotationSizeB2Landscape=3

FolderRotationSizeALandscape=3

ESizeWidthMax=1500

ESizeWidthMin=47.5

ESizeLengthMax=36.5

ESizeLengthMin=35.5

E2SizeWidthMax=1500

E2SizeWidthMin=43.5

E2SizeLengthMax=34.5

E2SizeLengthMin=32.5

E3SizeWidthMax=1500

E3SizeWidthMin=41

E3SizeLengthMax=30.5

E3SizeLengthMin=29.5

DSizeWidthMax=1500

DSizeWidthMin=35.5

DSizeLengthMax=24.5

DSizeLengthMin=23.5

D2SizeWidthMax=1500

D2SizeWidthMin=33.5

D2SizeLengthMax=22.5

D2SizeLengthMin=21.5

CSizeWidthMax=1500

CSizeWidthMin=23.5

CSizeLengthMax=18.5

CSizeLengthMin=17.5

C2SizeWidthMax=1500

C2SizeWidthMin=21.5

C2SizeLengthMax=17.5

C2SizeLengthMin=16.5

C3SizeWidthMax=1500

C3SizeWidthMin=20.5

C3SizeLengthMax=15.5

C3SizeLengthMin=14.5

BSizeWidthMax=1500

BSizeWidthMin=17.5

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 29 -

Page 32

KIP Unattend Operator Guide

BSizeLengthMax=12.5

BSizeLengthMin=11.5

B2SizeWidthMax=1500

B2SizeWidthMin=16.5

B2SizeLengthMax=11.5

B2SizeLengthMin=10.5

ASizeWidthMax=1500

ASizeWidthMin=10.5

ASizeLengthMax=9.5

ASizeLengthMin=7.5

[MetricFolderPaperSettings]

FolderPaperSizeA0=841

FolderPaperSizeA02=0

FolderPaperSizeA1=594

FolderPaperSizeA12=0

FolderPaperSizeA2=420

FolderPaperSizeA3=297

FolderRotationSizeA0Portrait=0

FolderRotationSizeA02Portrait=0

FolderRotationSizeA1Portrait=0

FolderRotationSizeA12Portrait=0

FolderRotationSizeA2Portrait=0

FolderRotationSizeA3Portrait=0

FolderRotationSizeA4Portrait=0

FolderRotationSizeA0Landscape=1

FolderRotationSizeA02Landscape=1

FolderRotationSizeA1Landscape=1

FolderRotationSizeA12Landscape=1

FolderRotationSizeA2Landscape=1

FolderRotationSizeA3Landscape=1

FolderRotationSizeA4Landscape=2

A0SizeWidthMax=6000

A0SizeWidthMin=1170

A0SizeLengthMax=864

A0SizeLengthMin=812

A02SizeWidthMax=0

A02SizeWidthMin=0

A02SizeLengthMax=0

A02SizeLengthMin=0

A1SizeWidthMax=6000

A1SizeWidthMin=812

A1SizeLengthMax=625

A1SizeLengthMin=560

A12SizeWidthMax=0

A12SizeWidthMin=0

A12SizeLengthMax=0

A12SizeLengthMin=0

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 30 -

Page 33

KIP Unattend Operator Guide

A2SizeWidthMax=6000

A2SizeWidthMin=550

A2SizeLengthMax=440

A2SizeLengthMin=400

A3SizeWidthMax=6000

A3SizeWidthMin=400

A3SizeLengthMax=320

A3SizeLengthMin=270

A4SizeWidthMax=6000

A4SizeWidthMin=270

A4SizeLengthMax=220

A4SizeLengthMin=200

[MonitorPaths]

RasterMonitorPath1=

VectorMonitorPath1=

RequestMonitorPath1=C:\Monpath1\Request

[WinLpd]

WinLpdMonitorPath1=

WinLpdName1=

[PriorityPaths]

PriorityRequestPath=C:\MonPath1\PRequest

This defined path is used only for jobs coming from KIP Scan’s or KIP CopyMaker’s “Concurrent Print”

mode. When “Concurrent Print” is enabled, the Scan program places a file called prequest.kip in the

root of the Monpath1 folder. When Unattend sees t h is file, it pauses the normal print queue, and displays

the message “Priority Plots – Idle.” “Concurrent Print” then sends jobs via this defined folder. Unattend

gives priority to these jobs, and remains in this mode until “Concurrent Print” is disabled in the Scan

/CopyMaker program.

[CopyDensityValues]

Dark=12

MediumDark=10

Medium=8

MediumLight=6

Light=5

Printer strobe-timing values. Numbers vary per printer model. Smaller numbers lay down less toner. If

these values are set too high, Unattend will appear to convert the file, but then it will disappear from the

queue. For HDP models (2000, 6000, 7000, 8000), this value cannot exceed 48. For KIP 3000 models, these

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 31 -

Page 34

KIP Unattend Operator Guide

values cannot exceed 13. These values are usually matched to the Copy Density Values in the backup

data mode of the print engine.

[RedCopyDensityValues]

Dark=19

MediumDark=14

Medium=11

MediumLight=9

Light=7

[CyanCopyDensityValues]

Dark=12

MediumDark=10

Medium=8

MediumLight=6

Light=5

[MagentaCopyDensityValues]

Dark=12

MediumDark=10

Medium=8

MediumLight=6

Light=5

[YellowCopyDensityValues]

Dark=12

MediumDark=10

Medium=8

MediumLight=6

Light=5

[PaperTypes]

Paper0=Bond

Paper1=Vellum

Paper2=Film

Paper3=OnHold

List of available paper types. This section should match the [PaperTypes] section in the winreq.ini. Once

configured, the user can force Unattend to use the custom typ e in Unattend’s C ONFIG/MISC/ROLL INFO

pulldown section. This feature is used to override the paper-type signals coming from the print engine

drawer selections. Custom types may be manually added following this format: Papern=(6 characters or

less) i.e. Paper3=BluBnd

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 32 -

Page 35

KIP Unattend Operator Guide

It is also possible to set the same values for the KIP 6.5 Request software so that a user can select the

same paper types from within the Request user interface. Please see [PaperType] in c:\program

files\kip\request\winreq.ini to make the same setting changes.

[OpaquePens]

[ConvertTypes]

Type1=ASCII TXT A

Type2=INI INI A

Type3=OUT OUT A

Type4=LOG LOG A

This information is solely for use of KIP Personnel and KIP Authorized Dealers. No part of this publication may be copied,

reproduced or distributed in any form without express written permission from KIP America, Inc. © 2011 KIP America, Inc.

- 33 -

Loading...

Loading...