Konica Minolta DRYPRO SIGMA Installation Manual

KONICA MINOLTA DRYPRO SIGMA Laser Imaging System

Film Types

The DRYPRO SIGMA Laser Imager prints on KONICA MINOLTA Medical Imaging Film.

Intended Use

The DRYPRO SIGMA Laser Imaging System is intended to provide hard copy images

from digital imaging source output signals onto KONICA MINOLTA MEDICAL IMAGING

FILM SD-S. The device is intended for use with a variety of digital modalities,

including, but not limited to, CR (Computed Radiology), DR (Digital Radiology), CT

(Computerized Tomography) and MRI (Magnetic Resonance Imaging). The images

are to be used for medical diagnosis and referral to physicians and their patients.

This device is not intended to be used with Full Field Digital Mammography units or

Computed Radiography units supporting digital mammography.

Getting Started

Your laser imager comes with several publications to help you get started quickly and

safely. Locate the following publications:

• SafetyManual(9G7565):Reviewthismanualrsttounderstandhowtopositionandwork

with the laser imager safely and within regulations.

• Pre-Installation Manual (9G7563): Ensure that your site is ready for the installation.

• Installation Manual (9G7567): Learn how to install the laser imager.

• Operation Manual (9G7564): See this guide for a product overview, use instructions, and

troubleshooting tips.

• Quick Reference Card (9G7566): Keep this card in a convenient place and reference it as

needed.

Pub history:

A: 2011-03-31. First release.

B: Updated the company name.

Pub No. 9G7571_en, Rev. B, 2013-04-01

© KONICA MINOLTA, INC., 2013

KONICA MINOLTA and DRYPRO are trademarks of KONICA

MINOLTA, INC.

KONICA MINOLTA, INC.

1 Sakura-machi, Hino-shi, Tokyo, 191-8511, Japan

Installation Manual

CAUTION:

Requirements to install the laser imager

The laser imager weighs approximately 54 kg (120 lb). Two

people must use safe lifting techniques to move the laser

imager. One person can complete the remaining steps. The

installation must be performed by qualified personnel.

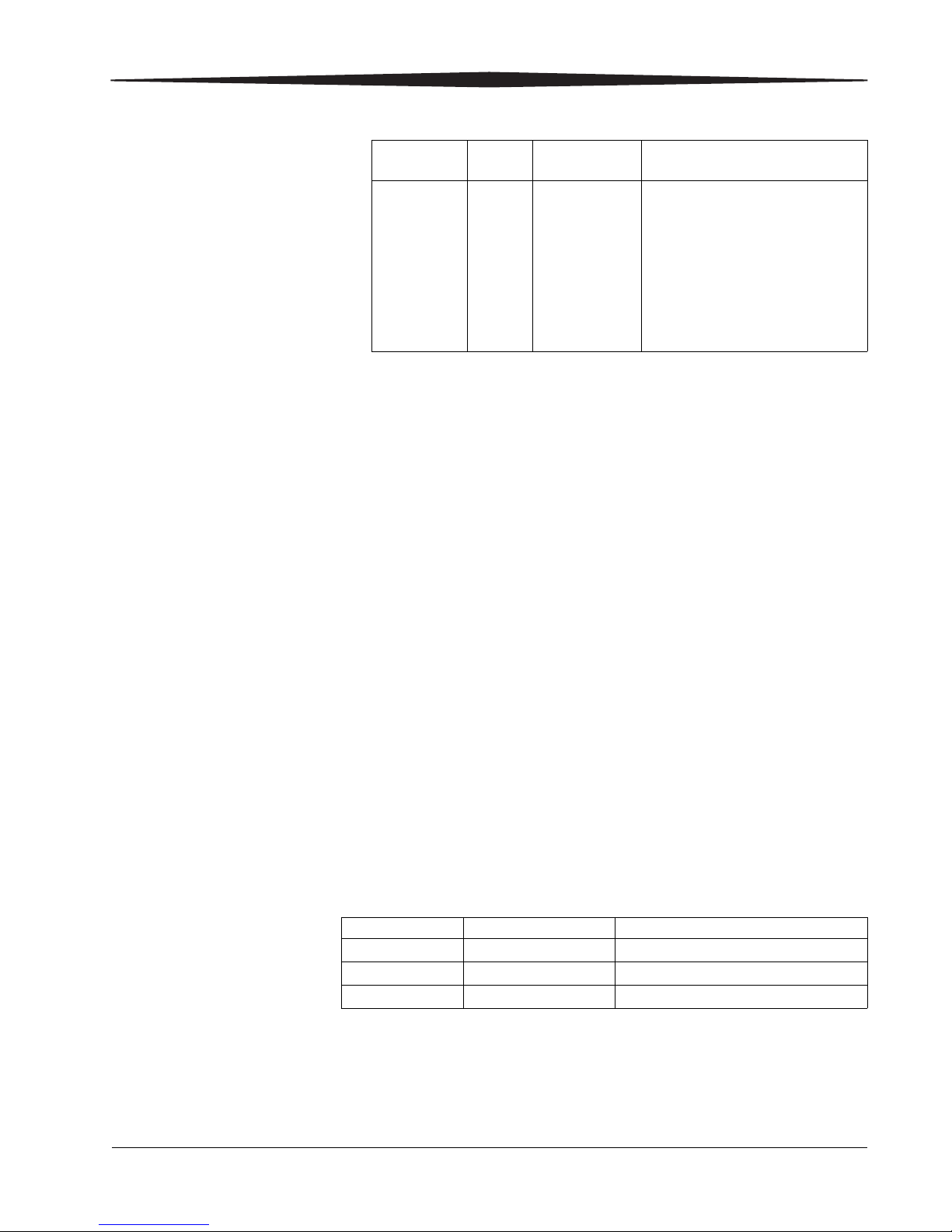

Task Recommended Skill or Knowledge

Unpack the laser imager. Ability to use common hand tools.

Use a personal computer to view the documentation on

the publications disc supplied with the laser imager.

Connect a personal computer to the laser imager and

enter the network information.

Configure the laser imager to print from a modality. Familiarity with DICOM protocol.

Make a backup disk of the configuration. Understand personal computer file name

Basic personal computer skills.

Familiarity with TCP/IP network addressing

conventions.

conventions.

Required tools • Phillips screwdriver

• Scissors

• Straight blade screwdriver

• Crossover cable (not shown)

Required information You will need:

2015-04-17 9G7567_en 1

• IP Address and related network information for the laser imager

• Configuration information for each modality that will print to the laser

imager

This information should have been previously collected and recorded in

the Pre-Installation Manual that was provided to your site.

If you do not have the Pre-Installation Manual, contact your dealer or

qualified service provider.

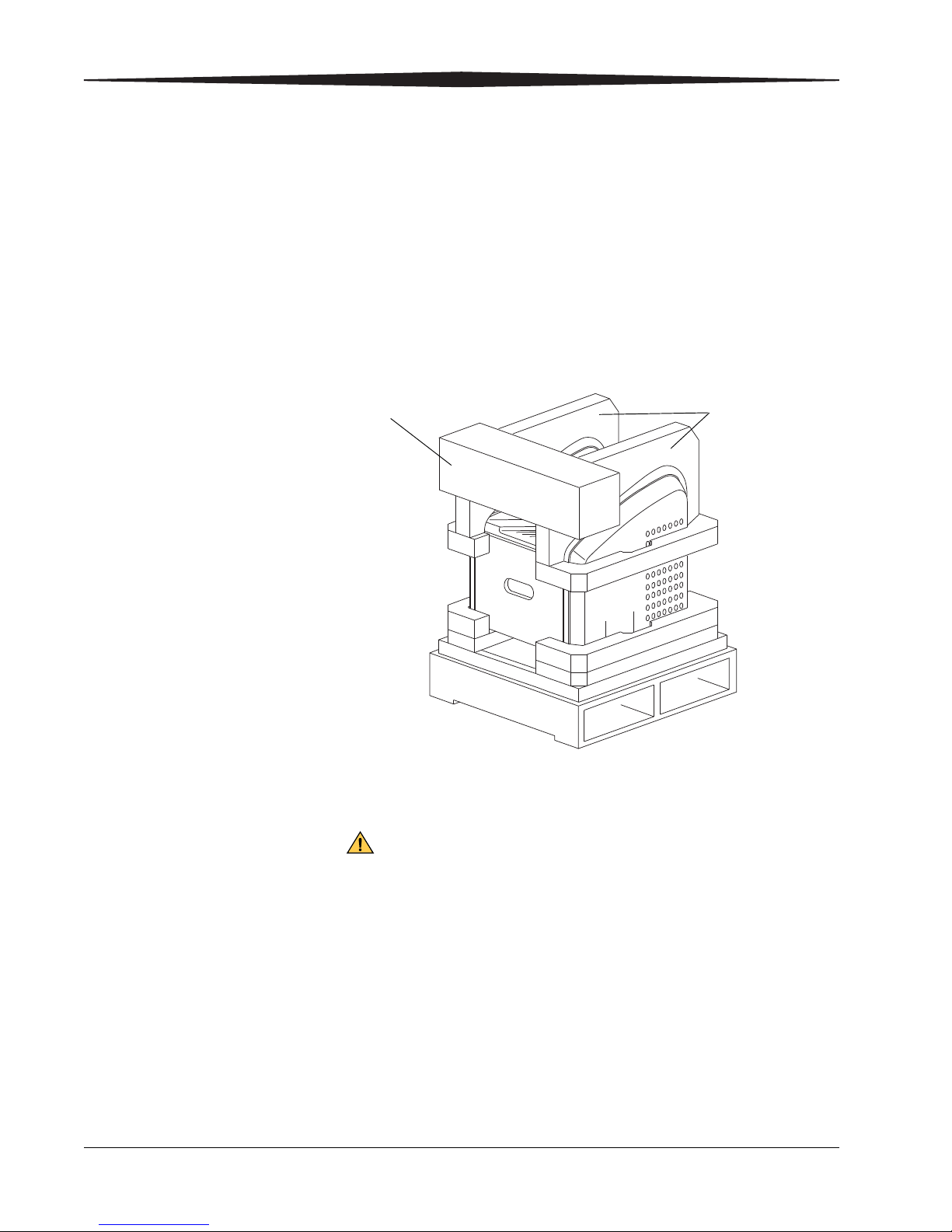

Unpacking the laser imager

CAUTION:

Foam Assemblies

Accessories

Box

Checking the

accessories

Check that the following items are included in the accessories box:

• Power cord

• Network cable

• Deodorant filter

• Publications kit

IMPORTANT: Please read the Safety Manual before you proceed to

install or operate the laser imager.

2 9G7567_en 2015-04-17

1. Remove the two foam assemblies.

2. Open the bag that covers the laser imager.

Use safe lifting techniques and two people to move the laser

imager.

3. Lift the laser imager from the carton and set it on a flat surface.

Position the laser imager temporarily so there is a space of at least

1 m (39 in.) at the back of the laser imager.

Moving the shipping

Shipping Brackets

Shipping Brackets reattached

brackets and retainer

Shipping brackets are fastened inside the la ser imager to keep the parts

safe during shipment. You must remove them, and then reinstall them in

a different location (as shown) inside the laser imager. This prevents the

shipping brackets from becoming lost. You must also remove the rollback

retainer.

NOTE: If it is necessary to ship the laser imager again, you must return

the shipping brackets to the shipping locations.

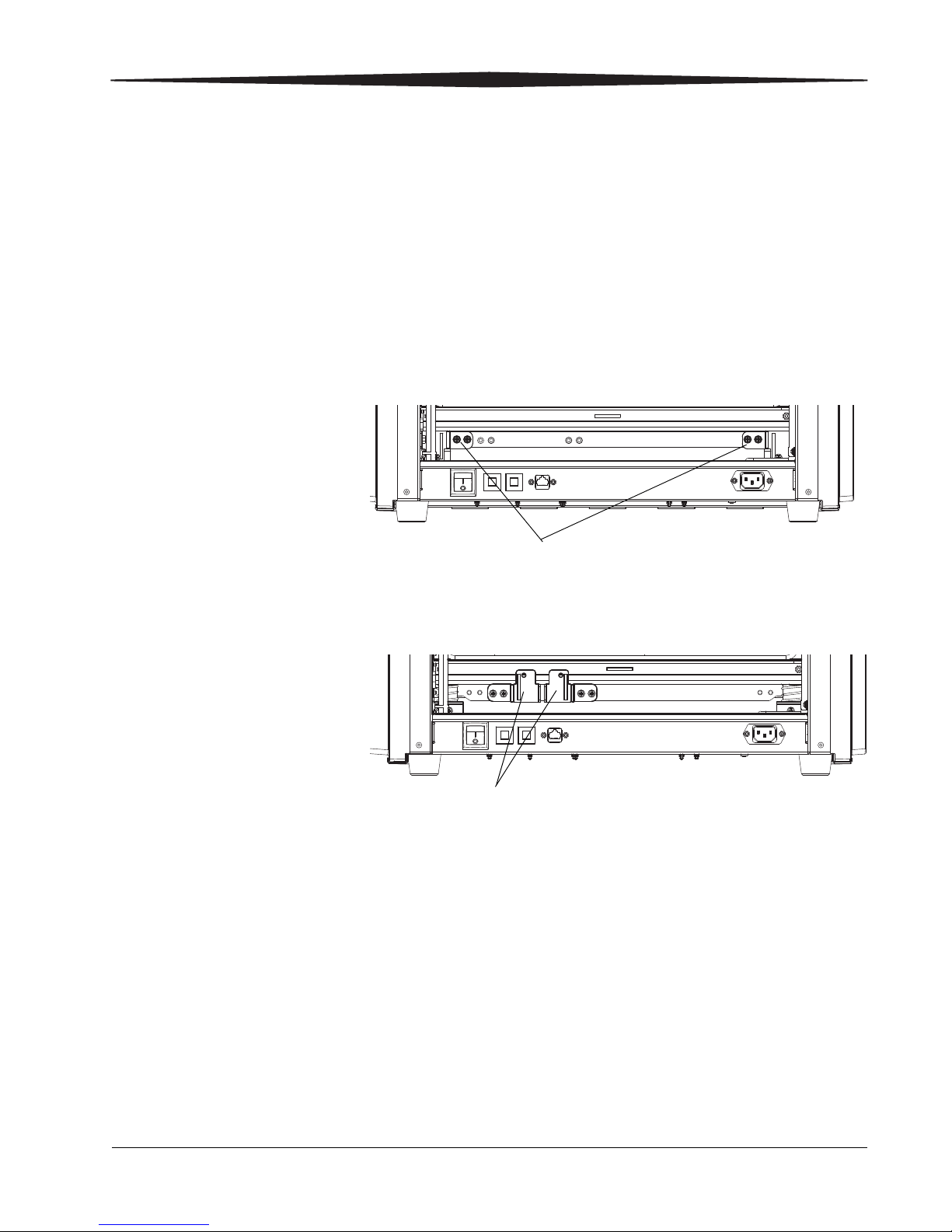

1. To move the back shipping brackets, remove:

a. Back cover

b. 4 screws that fasten the 2 shippin g brackets

Back view of laser imager

2. Rotate the shipping brackets and reattach them in the alternate set

of holes on the rail.

3. Retain the other 2 bracket screws: Install the screws into any of the

empty holes where the bracket was attached earlier.

4. Replace the back cover.

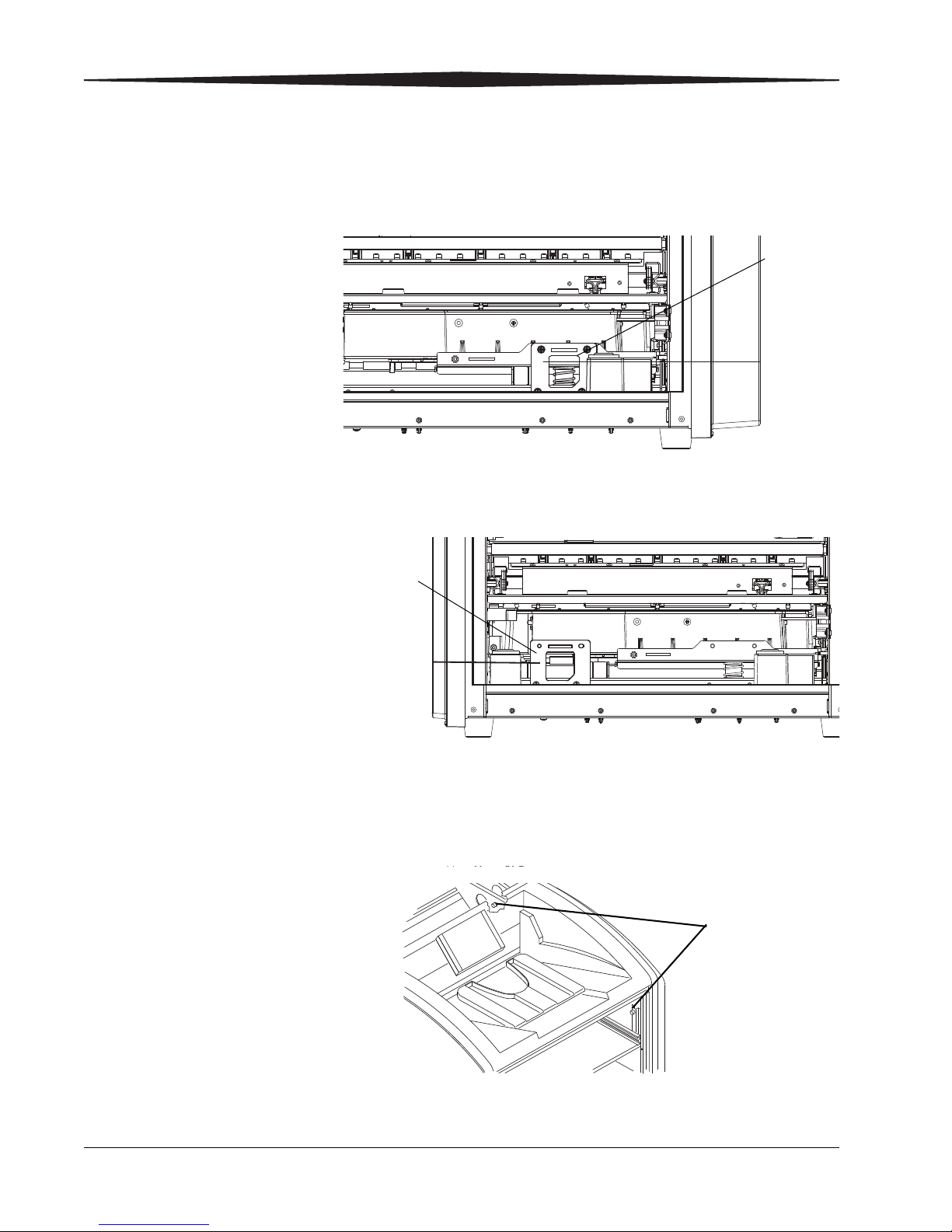

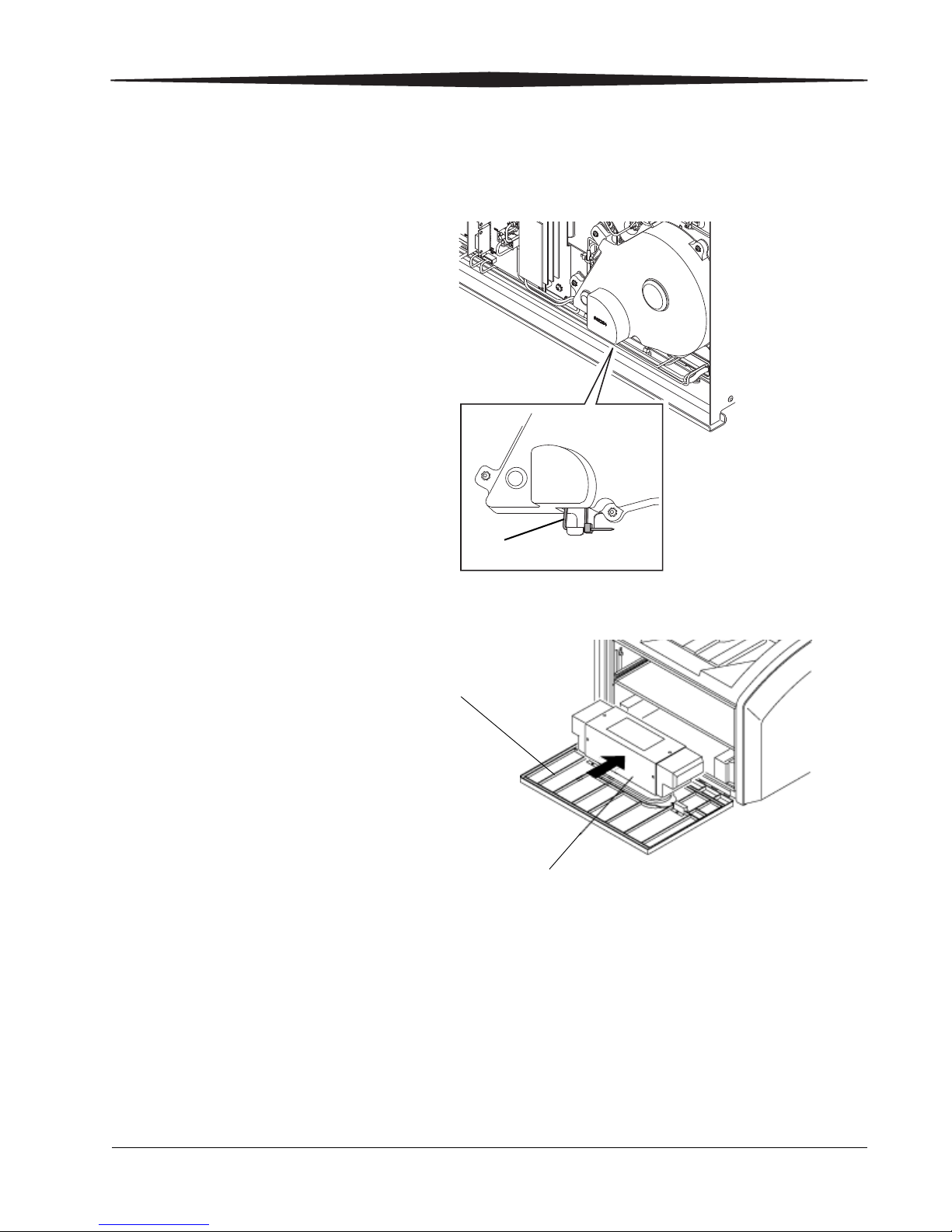

5. At the front of the imager, open the film supply. Reach in and

remove the foam rollback retainer.

2015-04-17 9G7567_en 3

6. To move the front shipping bracket, remove 4 screws that fasten the

FRONT SHIPPING

BRACKET

(FILTER REMOVED

Shipping

Bracket

Front Shipping

Bracket in

Storage

Shipping

Bracket

reattached

H221_6003AC

2 screws

shipping bracket.

Front view of laser imager

7. Use 2 of the screws to reattach the shipping bracket in the alternate

set of holes on the left side of the rail.

4 9G7567_en 2015-04-17

8. Retain the other 2 bracket screws: Install the screws into any of the

empty holes where the bracket was attached earlier.

9. Remove the right cover:

a. Remove the top cover. (Leave the film supply open.)

b. Remove 2 screws that attach to the right cover standoffs.

10. Behind the right cover, locate the tie wrap that fastens the exposure

H221_6030GC

Tie Wrap

Film Supply

Filter

transport belt. The tie wrap removes tension from the belt during

shipping. Cut and remove the tie wrap from the belt.

11. Install the deodorant filter.

12. Reinstall the right and top covers.

13. Close the film supply.

2015-04-17 9G7567_en 5

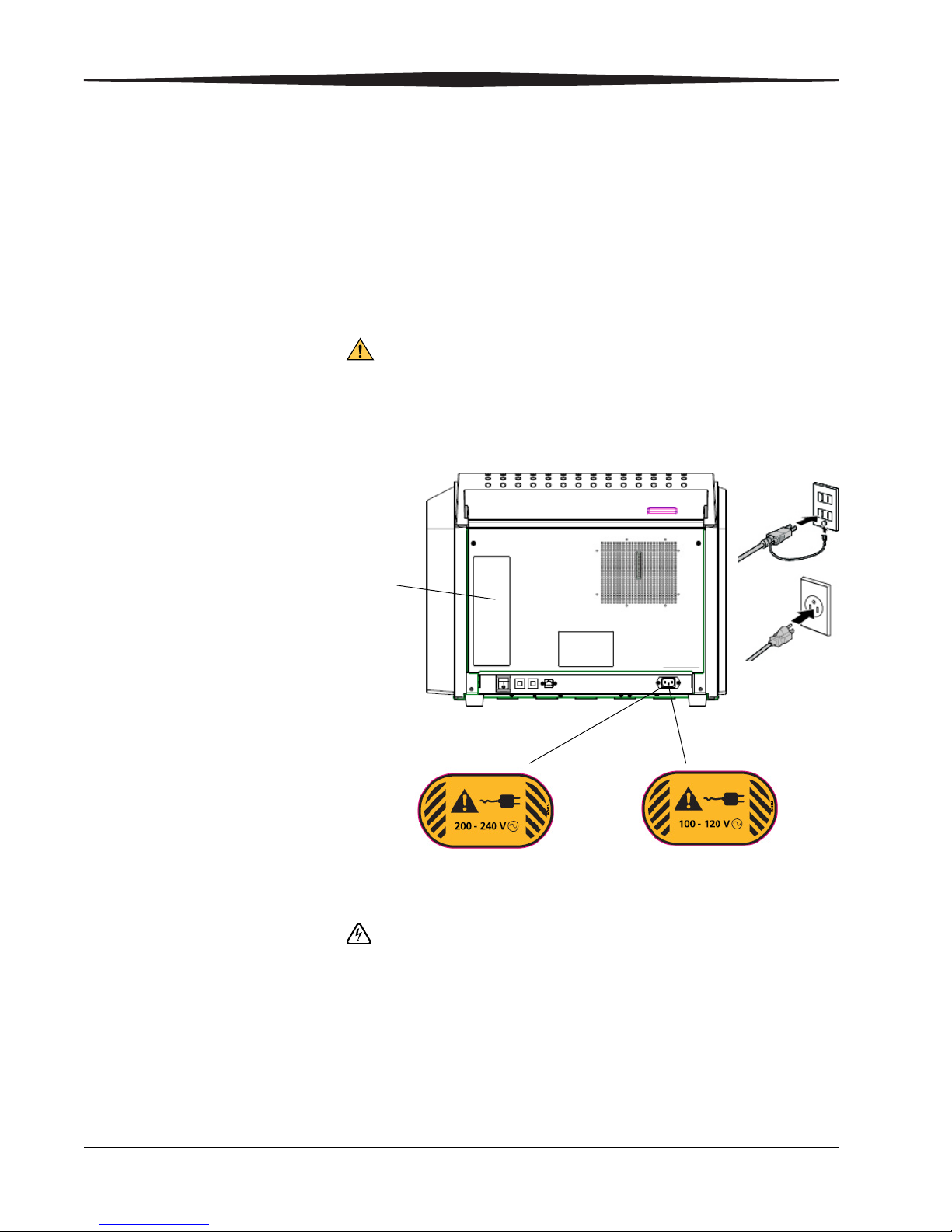

Connecting to electrical power

CAUTION:

RISK OF ELECTRIC SHOCK:

OR

Laser

Imager

Back

Panel

1. Locate the power cord. The power cord must match the AC power

outlets at your site.

If you cannot use the power cord that is provided, obtain a suitable

power cord locally. You must use an agency-approved power cord

rated for adequate amperage with a plug type suitable for your

location. Contact your dealer if you need assistance.

2. Check that the voltage on the label over the power cord inlet

matches the AC voltage at your site.

If the voltage on the label does not match the AC voltage at

your site, do not continue with the installation. Contact your

dealer or qualified service provider.

Power cord inlet labels and connectors

6 9G7567_en 2015-04-17

3. Remove the power cord inlet label.

Dangerous voltage!

4. Connect the power cord to the:

• AC power connector on the laser imager.

• Building AC power outlet.

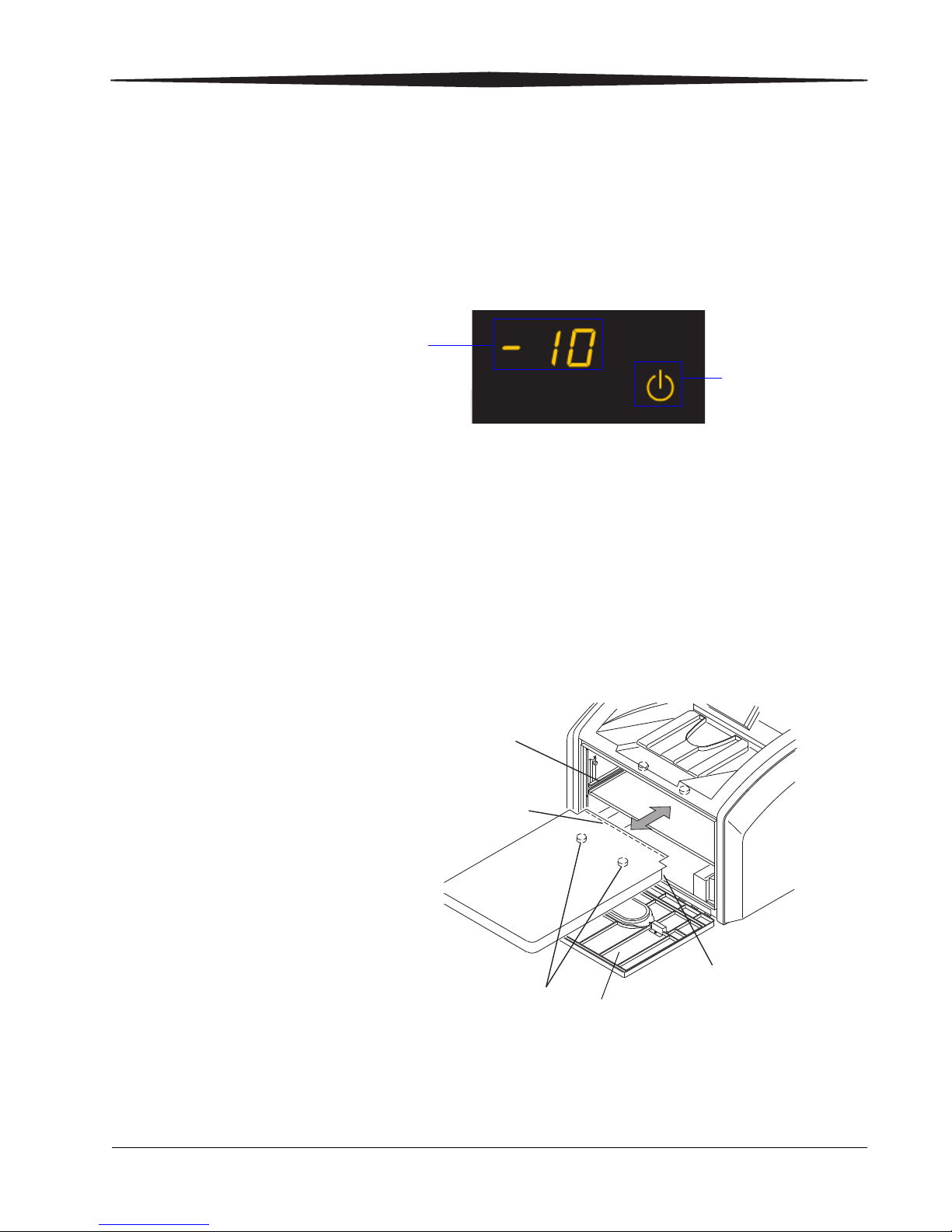

Applying power

The power symbol is

yellow and flashing

while the laser

imager warms up

A countdown to zero (0) indicates

how soon the laser imager will be

ready to print

Film Supply

1. Check that the film supply is closed.

2. To start the laser imager, press the power switch on the back of the

Warming up

NOTE: If the laser imager does not start, see “Troubleshooting” on page

Inserting a film cartridge

1. Open the film supply.

2. Insert the film cartridge. Align the cartridge with the label facing up

laser imager to on (|). Wait as the laser imager warms up. The

warm-up period might last up to 30 minutes. The display screen

shows the progress as the laser imager becomes ready to print.

The warm-up period varies depending on how long the laser imager

has been off and the ambient temperature.

12.

and the perforations to the front. Set the leading edge on the

cartridge guides, then slide the film cartridge into the laser imager to

engage the detents in the bottom of the cartridge.

Cartridge

Guide

Perforations

Leading Edge

Detents

H210_1020ACA

H210_1020AC

3. Close the film supply.

4. Check that the film count appears on the display screen.

NOTE: If a film count does not appear, see the Operation Manual for

2015-04-17 9G7567_en 7

help.

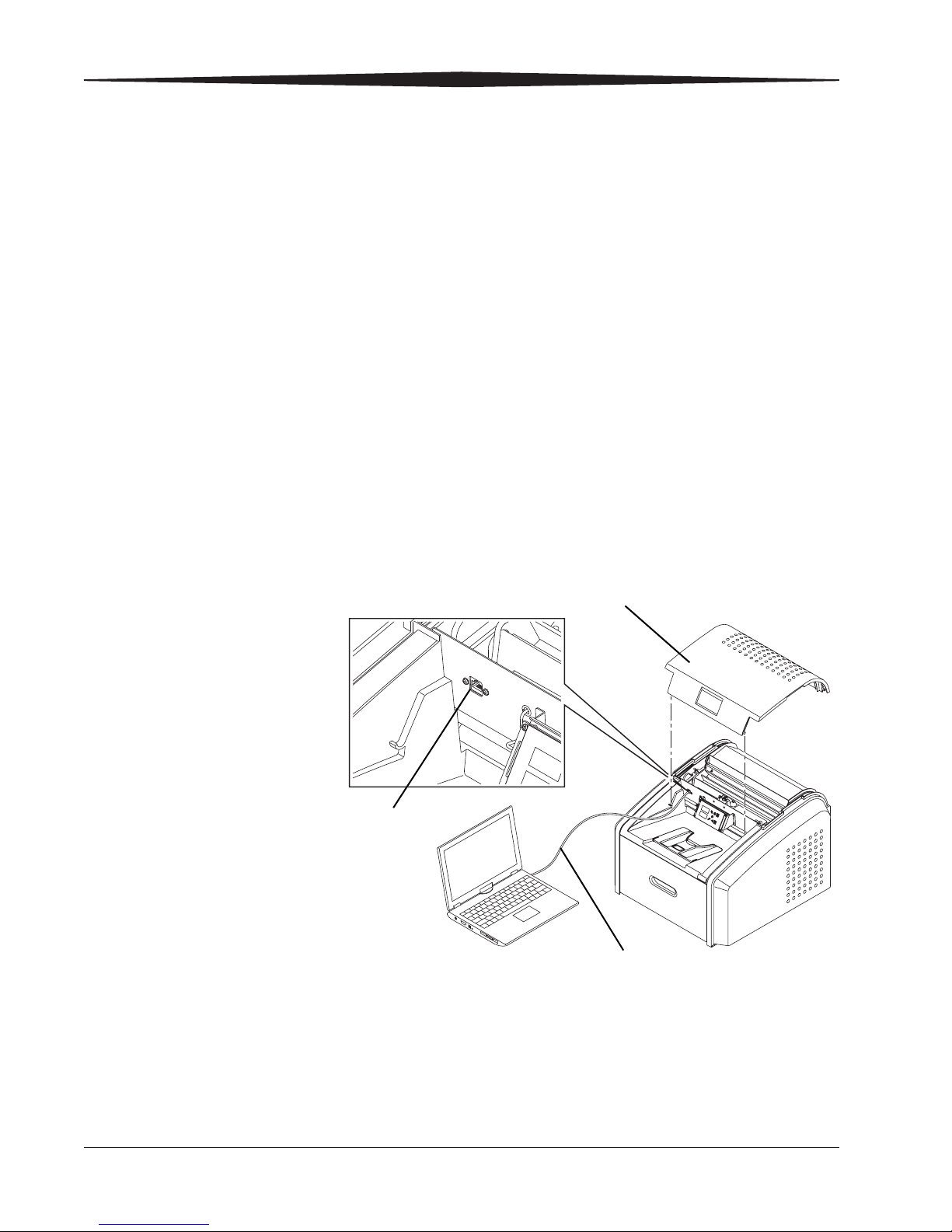

Configuring the laser imager

Service

Port

Top Cover

Crossover Cable

Setting up your

computer to

communicate with the

laser imager

Connecting your

computer to the laser

imager

Do this procedure at your computer.

1. Select Start>Settings>Network Connections.

NOTE: Depending on your operating system, this might be

Start>Settings>Network and Dial-up Connections.

2. Right-click Local Area Connection.

3. Select Properties.

4. Select Internet Protocol (TCP/IP).

5. Click Properties.

IMPORTANT: Remember or write down your current settings, as you

will reset your computer to these settings near the end of

the installation.

6. Select the option button next to Obtain an IP address

automatically.

7. Click OK.

8. Click OK.

8 9G7567_en 2015-04-17

H221_6031HC

1. Remove the laser imager’s top cover.

2. Using a crossover cable, connect your computer to the service port

on the laser imager.

3. Route the crossover cable so that it does not interfere with the top

cover when it is installed.

4. Reinstall the top cover.

Configuring

site-specific information

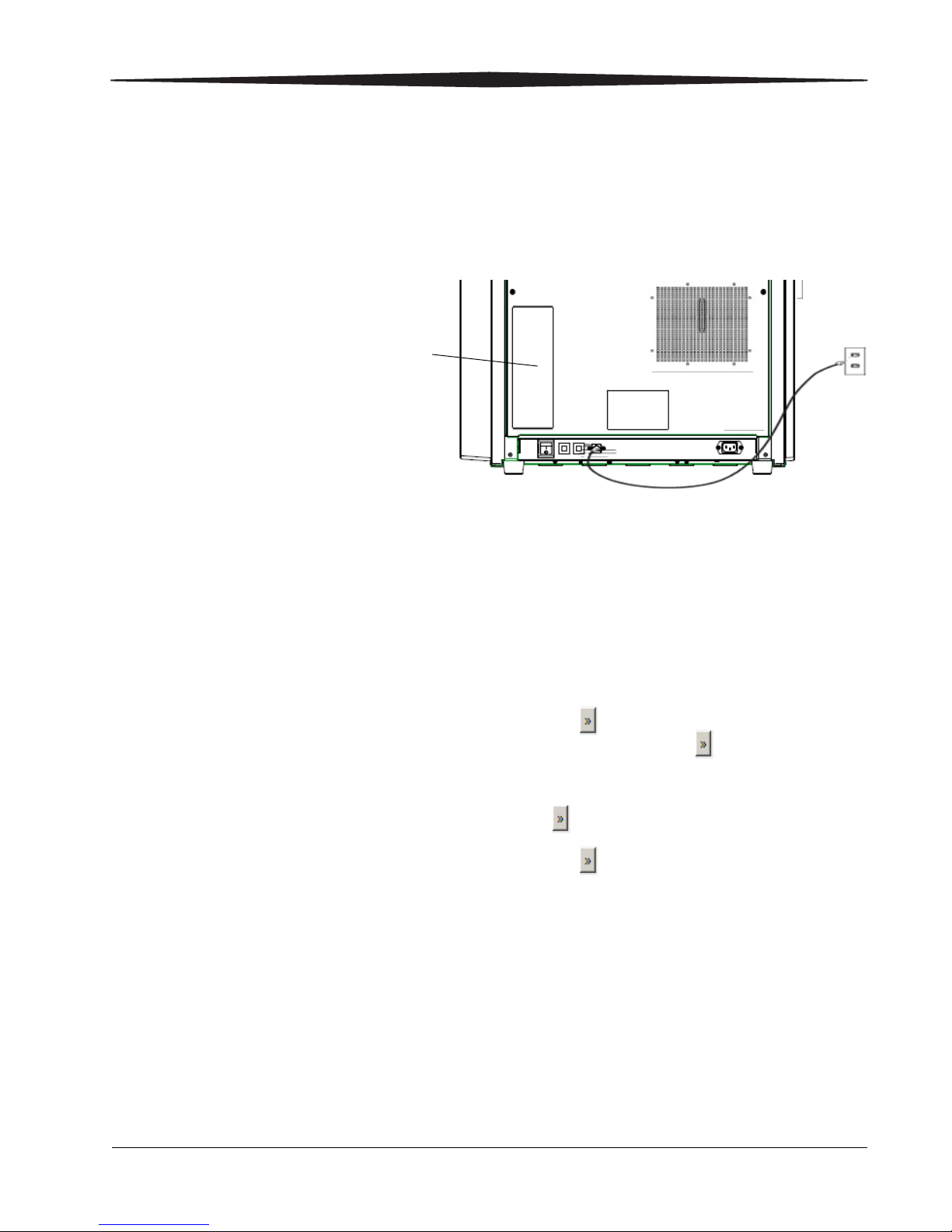

1. Start MICROSOFT INTERNET EXPLORER.

2. In the Address box, type: 192.168.0.1

3. Click Go. The main screen for the Web Portal appears.

4. If you are using INTERNET EXPLORER 8, set the IE8 window to

compatibility view. Click the Compatibility View toolbar button. This

will correct some potential viewing issues with IE8. If the icon is not

on the toolbar, select Compatibility View from the Tools menu.

5. Select your language:

6. Select Wizards > Installation Assistant.

7. Click at the bottom of the screen. The Network Configuration

screen appears.

8. Enter:

•Host Name

• IP Address

• Subnet Mask

• Default Gateway

2015-04-17 9G7567_en 9

NOTE: This information should have been gathered in the

Pre-Installation Manual. If you need help, see your network

administrator.

9. Click Save.

10. Click . The Clock Configuration screen appears.

IMPORTANT: The system clock is set before the laser imager is

shipped to you. If the time zone is not correct, change it.

When you change the time zone, the time and date

display correctly.

11. Are the time zone, date, and time correct?

Ye s N o

Advance to step 13. Continue with the next step.

12. Will you set the clock manually, or does the site use a time server

for synchronization?

Manually Synchronization

Select the time zone.

a.

b. Edit the time if

needed.

c. Click Save.

a. Select the Enable Time

Synchronization check box.

b. In the IP Address field, type the

address of the time server to be

used for synchronization.

c. In the Period field, select the

synchronization period (how often

the clock is synchronized) from the

drop-down menu.

d. Select the time zone.

e. Click Save.

13. Click . The System Identification screen appears.

NOTE: Completing this screen is optional.

14. Enter the following information:

• Country Code

•Postal Code

• Hospital Name

• Department Name

• Device Location

15. Click Save.

16. Click to return to the main screen.

17. Select Utilities > Session, and then click Restart.

NOTE: Make sure to restart using these steps or the network

parameters will not be saved.

10 9G7567_en 2015-04-17

Wait for the laser imager to restart. The laser imager requires approximately

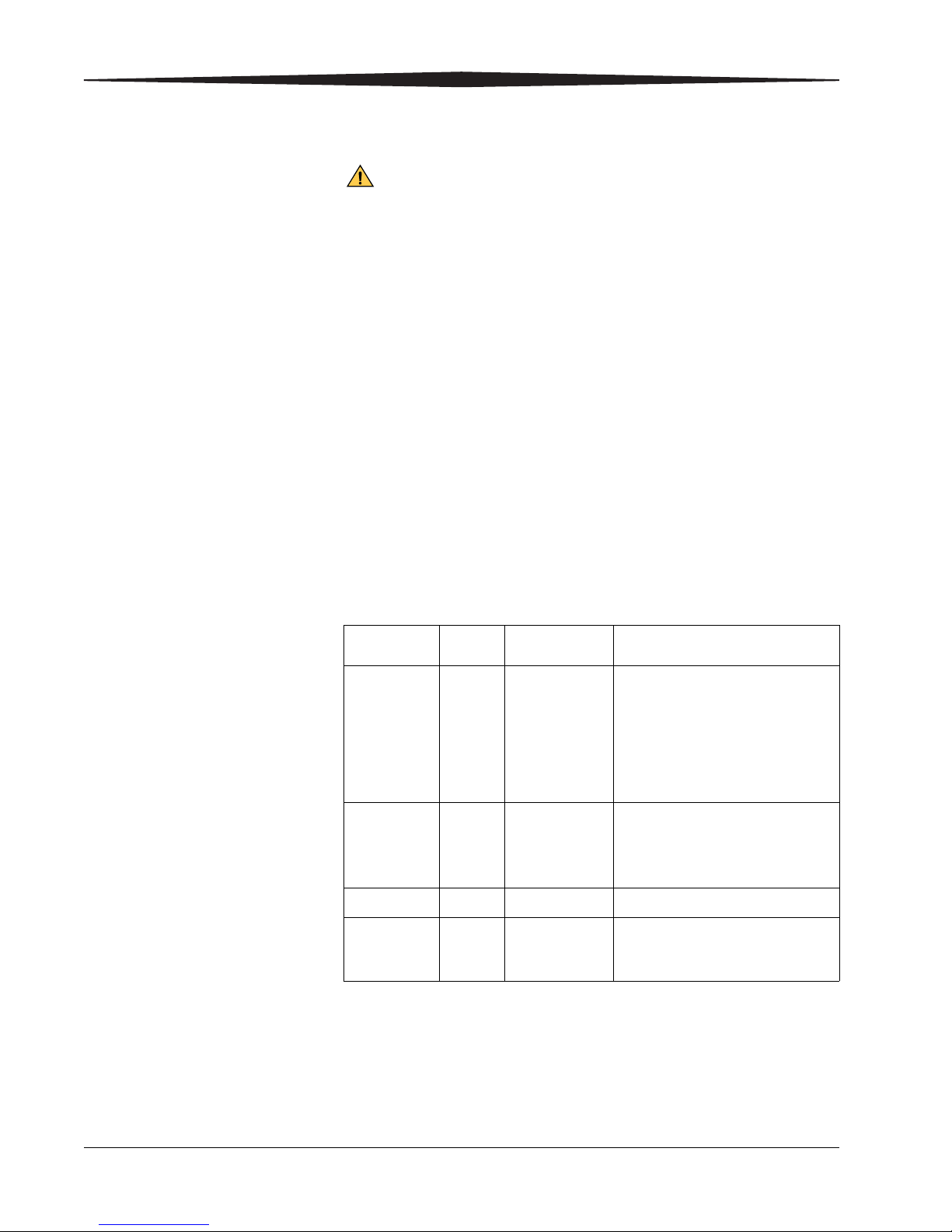

Laser Imager

Back Panel

30 minutes to warm up. After completing the warm-up cycle, the laser imager

may print a calibration film if the film cartridge requires it. While the laser

imager is warming up, continue with the next step.

Completing the installation

1. Connect the network cable to the:

• Network connector on the laser imager.

• Nearest building network connector.

2. After the laser imager has completed the warm-up cycle, send an image from

each modality that will print to the laser imager.

3. If the image quality must be improved for a modality, optimize the images

from that modality:

a. From the main screen, select Wizards > Image Quality.

b. Cancel all pending print jobs OR wait until all print jobs are printed.

c. Under Optimization Steps, click .

d. Send an image from the modality, and then click .

NOTE: The image does not print until you click the button.

NOTE: If none of the images are optimal for your site, call a qualified service

4. Disconnect the crossover cable and restore the settings to your computer if

Discarding excess material

2015-04-17 9G7567_en 11

When you are finished and the laser imager is operational, discard all excess

shipping materials in a manner suitable to local ordinances.

e. View the test print and visually select the optimal image.

f. Under Image Number, click to select the number of your optimal

image.

g. Under Optimization Steps, click again to continue.

h. Check for a “Passed” status near the bottom of the screen.

i. Send another image from the modality and check the print.

provider.

necessary.

Troubleshooting

CAUTION:

Laser imager does not

start

Never pull on the cord to disconnect the plug from the wall

outlet. Grasp the plug and pull to disconnect.

1. Press the power switch on the back of the laser imager off(0), and

then on (|), to restart the laser imager.

If this does not solve the problem, continue with step 2.

2. Disconnect the power cord from the wall outlet.

3. Check that the power cord is properly connected to the AC power

connector on the laser imager.

4. Plug the power cord into the wall outlet.

5. Check that the wall outlet is energized.

6. If the laser imager still does not start, contact your qualified service

provider.

Error codes The following codes might appear during the installation. If so, see the

table to resolve them. For a complete list of error codes, see the

Operation Manual.

NOTE: As shown in the table, the same code appears as a 3-digit

number on the display screen and as a 5-digit number at the

Web Portal. See the Operation Manual for more information.

Display

Screen

Web

Portal

Web Portal

Message

Action

006 20006 Disconnected

or faulty

network cable

Check and reconnect the

network cable on both ends.

Try a different cable. Check

that the network is functioning

at your site.

If the error persists, call for

service.

209 20209 Laser Imager

Opened

During Self

Test

Close the cover. Restart the

laser imager.

If the error persists, call for

service.

701 20701 none Close the cover.

704 20704 none The network connection to the

laser imager has been lost.

Restart the laser imager.

12 9G7567_en 2015-04-17

Display

Screen

Web

Portal

Web Portal

Message

Action

175 21175 Rollback

Failed to

Engage

Cartridge

If the Pause symbol is on, press

it to cover the film cartridge.

When the Pause symbol stops

flashing, remove the film

cartridge from the laser imager.

Insert a different film cartridge

into the laser imager.

If the error persists, call for

service.

Publication History

2015-04-17 9G7567_en 13

Revision Date Reason for Change

A 2011-03-31 First release

B 2013-04-01 Updated the company name

C 2015-04-17 Added the rollback retainer

KONICA MINOLTA, INC.

1 Sakura-machi, Hino-shi, Tokyo, 191-8511, Japan

KONICA MINOLTA, INC., 2015

©

Pub No. 9G7567_en

Rev C

Operation Manual

Publication No. 9G7564_en

2013-04-01

All rights reserved. No part of this manual may be reproduced or copied in

any form by any mean graphic, electronic, or mechanical, including

photocopying, typing, or information retrieval systems without written

permission.

Contents

1Overview

How the Imager Works ................................................................................................................. 1-4

Print Sequence ......................................................................................................................... 1-4

Film Sizes .................................................................................................................................. 1-5

Automatic Image Quality and Processing ..............................................................................1-5

Configure and Monitor the System (Using the Web Portal) ................................................. 1-5

Agency Compliance ................................................................................................................. 1-6

Operation Manual Conventions ............................................................................................. 1-6

2 Basic Operating Tasks

Understanding the Display Screen ...............................................................................................2-2

Turning the Power On and Off .....................................................................................................2-4

Emergency Shutdown or Power Loss ........................................................................................... 2-4

Restarting the Imager ................................................................................................................... 2-5

Film Cartridge Information ...........................................................................................................2-6

Insert a New Film Cartridge ..........................................................................................................2-7

Load a Different Film Size to Match a Print Request ..................................................................2-8

Delete Pending Jobs ...................................................................................................................... 2-9

Make a Test Print ........................................................................................................................... 2-9

Calibrate the Imager for the Installed Film ................................................................................2-10

Open or Remove a Cover ............................................................................................................2-11

Additional Functionality with the Web Portal .......................................................................... 2-12

Access the Web Portal ........................................................................................................... 2-12

3 Maintenance and Troubleshooting

Overview: Status and Error Messages and Codes ........................................................................ 3-1

Preventive Maintenance ............................................................................................................... 3-2

About the Filter ....................................................................................................................... 3-2

Replace the Filter .....................................................................................................................3-2

550 Code and Maintenance Symbol ....................................................................................... 3-3

Error Indicators on the Display Screen .........................................................................................3-4

Using the Web Portal to Gain More Information on Errors ....................................................... 3-5

Subsystem Error Codes and Messages .......................................................................................... 3-6

DICOM (Digital Imaging and Communications in Medicine) ................................................ 3-6

Printer ....................................................................................................................................... 3-7

Film Cartridge .......................................................................................................................... 3-8

Job Manager ............................................................................................................................ 3-9

9G7564_en | 2013-04-01 i

Condition Codes .......................................................................................................................... 3-10

Film Jam Indication and Areas .................................................................................................... 3-16

Clear Film Jam Code 116 / Jam in Area 1 .............................................................................3-18

Clear Film Jam Code 323 / Jam in Area 2 .............................................................................3-18

Clear Film Jam Code 324 or 325 / Jam in Area 2 ..................................................................3-19

Clear Film Jam Code 326 / Jam in Area 2 or 3 ...................................................................... 3-20

Clear Film Jam Code 543 or 544 / Jam in Area 3 ..................................................................3-21

Display Screen is Not Functional .................................................................................................3-21

Call for Support ...........................................................................................................................3-21

4 Film Technical Information

Spectral Sensitivity .........................................................................................................................4-1

Image Quality ................................................................................................................................4-1

Environmental Impact ................................................................................................................... 4-2

Undeveloped Film Handling and Storage ....................................................................................4-2

Developed Film Handling and Archival ........................................................................................4-3

Exposing Film to Moisture ............................................................................................................ 4-3

Odor Dissipation ............................................................................................................................ 4-4

Heat Dissipation ............................................................................................................................. 4-4

Film Recycling ................................................................................................................................4-4

5 Specifications

Equipment Specifications .............................................................................................................. 5-1

Operating Space Requirements .................................................................................................... 5-1

Environmental Requirements ....................................................................................................... 5-1

Environmental Effects .............................................................................................................5-2

Power Requirements ............................................................................................................... 5-2

Network Requirements ...........................................................................................................5-2

6 Publication History

ii 9G7564_en | 2013-04-01

1

Important

Overview

The Laser Imaging System is a continuous-tone laser imager with an internal

photothermographic film processor. Heat, rather than photo chemicals, is used to

develop the film. This easy-to-use and reliable imager provides high quality prints. Use

the prints from this system for:

• Diagnostic purposes to determine patient treatments

• Referral, sharing, or educational purposes

The system receives and prints from image sources such as medical electrical equipment

(modalities) and workstations over the network. You can send print jobs simultaneously

from multiple image sources. The open design lets you connect to modalities of all types

and vendors.

Install the printing system in a secure location to protect patient privacy rights if required by local

regulations.

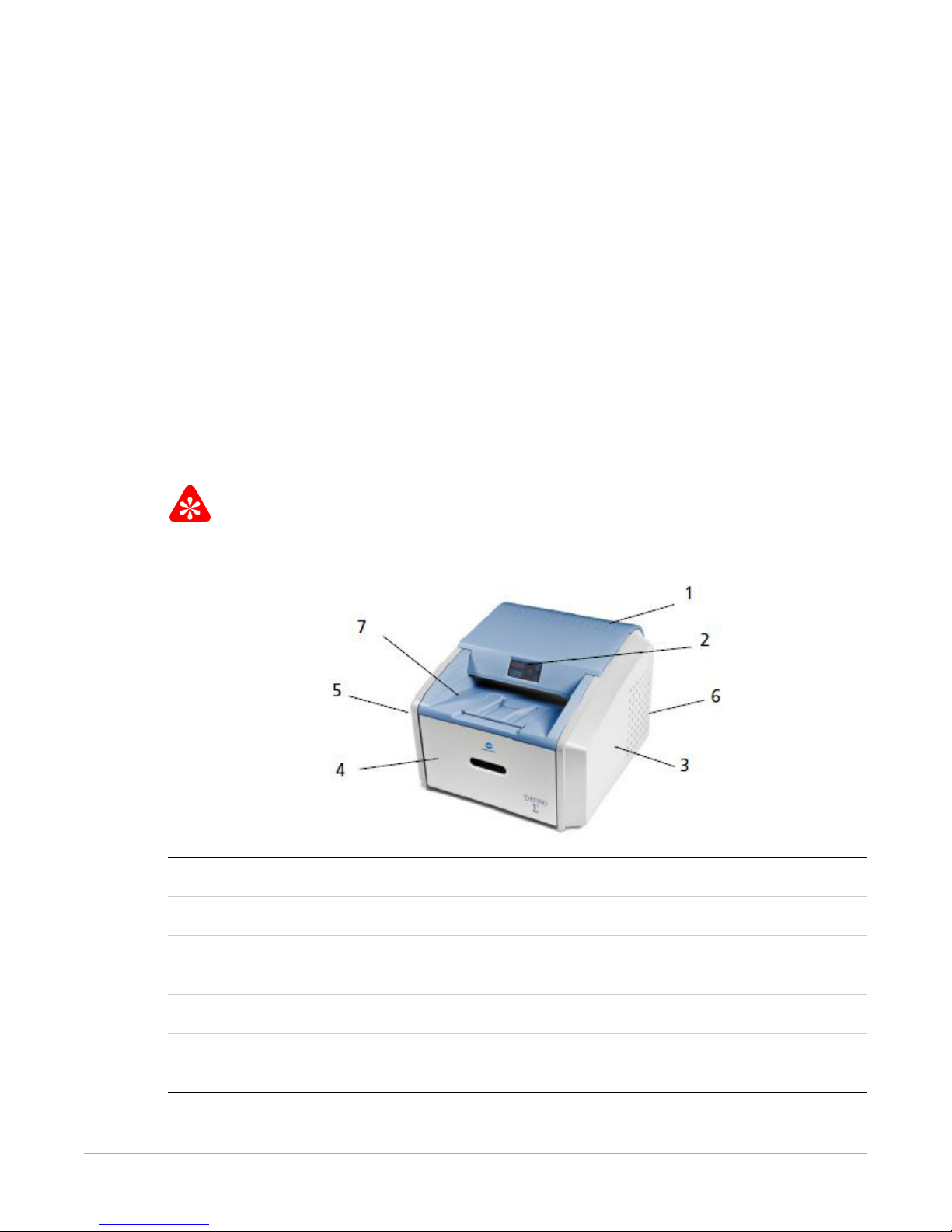

1 Top cover. Covers the processor rollers. The top cover is interlocked.

2 Display screen. Your interface to the imager. Provides status and error information.

3 Right cover. Protects sensitive electronic equipment. The right cover is only accessed by

service personnel.

4 Film supply cover. Covers the film supply, which supports four film sizes.

5 Left cover. You might remove the left cover to clear an occasional film jam. The left

cover is interlocked.

9G7564_en | 2013-04-01 1–1

Overview

6 Power switch. The power switch is on the back.

7 Exit tray. Extend the exit tray to hold large film (35 x 43 cm, or 14 x 17 in.) as it finishes

printing. It can hold up to 50 processed sheets of film.

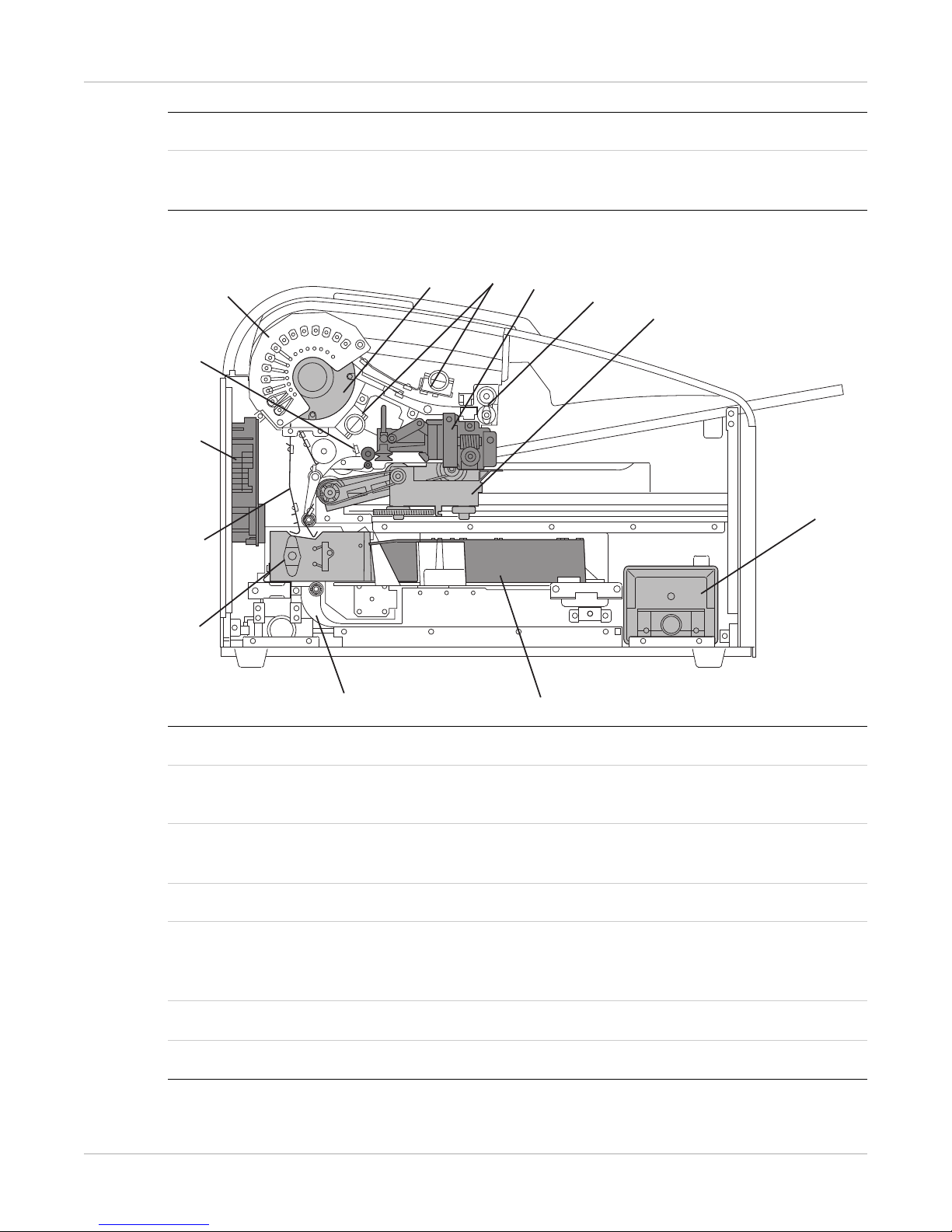

Major Internal Assemblies

5

6

4

3

2

1

13

7

8

12

9

10

11

H210_1012HC

1 Exposure transport. Moves the film past the scanning laser beam.

2 Transport guides. Orient and center the film while moving the film from the supply to

the imaging portion of the imager.

3 DICOM Raster Engine (DRE). A computer board that receives, processes, and man-

ages the images.

4 Feed rollers. Move the film through the imager.

5 Processor rollers. The processor uses heat to develop the image written onto the film

by the laser in the optics module. The rollers move the film through the processor

assembly, holding the film against the processor drum.

6 Processor drum. Provides the heat that processes the image on the film.

7 Airflow manifolds. Remove heat and processing odors from the processor assembly.

1–2 9G7564_en | 2013-04-01

Overview

8 Pickup assembly. Lifts a single sheet of film from the supply cartridge and feeds it into

the rollers.

9 Exit rollers. Moves the film from the processor area to the exit tray.

10 Rollback assembly. Rolls the film cartridge cover back so the pickup assembly can lift

the film. When the imager is not printing, the cover is closed over the film cartridge to

protect the film from light.

11 Deodorant filter. Absorbs the odors caused by heat processing.

12 Optics module. Writes the image onto the film while the film is moved through the

exposure transport.

13 Accumulator. The film feeds into the accumulator as it is imaged. When imaging is

complete, the film is sent from the accumulator up to the processor assembly where the

heat is applied to process the image.

9G7564_en | 2013-04-01 1–3

Overview

How the Imager Works

The imager receives, processes, manages, and prints the images on film. The imager has

limited storage to hold a small number of digital images. As images are received for

printing, they are stored in memory, placed in a sequential print queue, and are printed

in order. The imager can continue to accept incoming print jobs even if temporarily

unable to print (if the film supply is empty, etc.).

During normal operation, the imager requires very little attention. It prints automatically

in response to print requests from the configured image sources. Information sent with

the images by the image source, such as film type and size and image quality settings, is

applied unless you set the imager to override information that comes from the image

source.

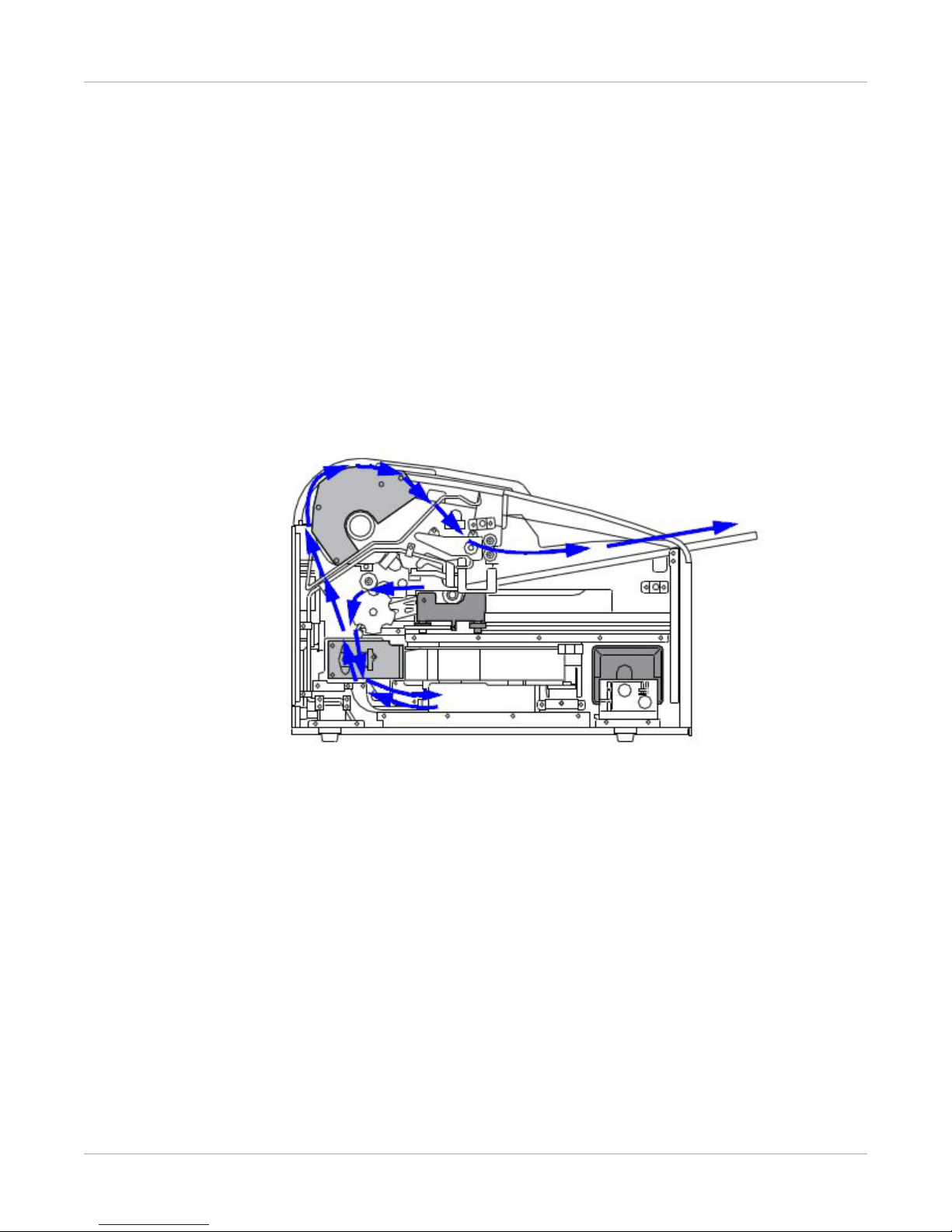

Print Sequence

Each time the imager receives a print request, the following print sequence occurs. The

blue arrows show the film path.

1. Suction cups in the pickup area lift a single sheet of film out of the supply ca

and

feed the film into the transport rollers.

2. The transport rollers move the film down into the exposure transport area.

3. The film moves down during imaging (as the optics module writes the image on

film),

reverses direction at the conclusion of imaging, and then the film moves up

the processor.

4.

As the film passes over the processor drum, the heat generate

the film.

5.

The exit rollers move the developed film to the

1–4 9G7564_en | 2013-04-01

rtridge

to

into

d by the drum develops

exit tray.

Film Sizes

The imager supports four sizes:

• 35 x 43 cm (14 x 17 in.)

• 28 x 35 cm (11 x 14 in.)

• 25 x 30 cm (10 x 12 in.)

• 20 x 25 cm (8 x 10 in.)

For the specific films that are supported, see the Publications Cover Page.

Automatic Image Quality and Processing

An internal densitometer enables the imager to automatically adjust image processing

parameters (Automatic Image Quality Control, or AIQC) to produce an optimal image.

The imager adjusts these parameters each time it prints a calibration film.

A calibration film is printed when:

• The film tray is inserted in the imager with film of a new lot number.

• You request a calibration film at the display screen or the Web Portal.

Overview

• A film cartridge is inserted into the imager for which a current calibrat

stored.

Related topics

Calibrate the Imager for the Installed Film

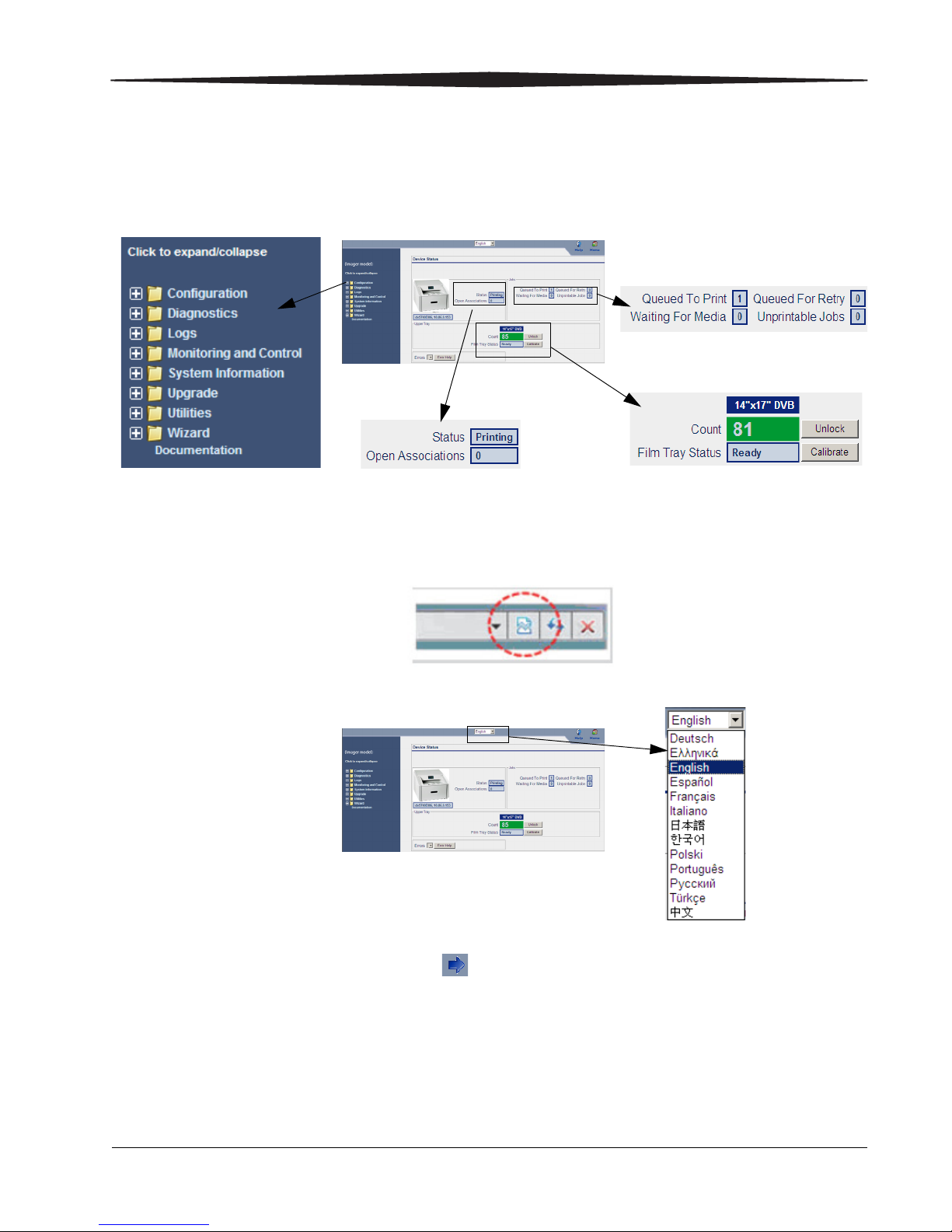

Configure and Monitor the System (Using the Web Portal)

The Web Portal is your interface to additional features. In addition to the installation and

setup of your system, you can view and manage the imager's connections over the

network, configure features, view error messages, and access general status information

at the Web Portal. You can also check film count, film size, and film type.

Related topics

Access the Web Portal

ion is not

9G7564_en | 2013-04-01 1–5

Overview

Note

Important

Caution

DANGER

Note

Agency Compliance

See the Safety Manual.

Operation Manual Conventions

The following special messages emphasize information or indicate potential risks to

personnel or equipment.

Notes provide additional information, such as expanded explanations, hints, or reminders.

Important notes highlight critical policy information that affects how you use this guide and this

product.

Cautions point out procedures that you must follow precisely to avoid damage to the system or

any of its components, loss of data, or corruption of files in software applications.

Danger identifies procedures that you must follow precisely to avoid injury to yourself or others.

Laser warnings warn personnel that access to laser radiation is possible and all personnel must

avoid direct exposure to the beam.

1–6 9G7564_en | 2013-04-01

2

Basic Operating Tasks

During normal operation, the imager receives and automatically prints images sent by

modalities over a network. Very little interaction is required. You may do the following:

• Turn the power on (|) and off (0).

• Load film cartridges.

• Monitor the display screen for status and operating conditions.

Sometimes it will be necessary to perform preventive maintenance, filter replacement,

and other corrective actions such as a restart.

You also may access the Web Portal to perform additional configuration, optimize image

quality, or do troubleshooting tasks.

Related topics

Maintenance and Troubleshooting

Additional Functionality with the Web Portal

9G7564_en | 2013-04-01 2–1

Basic Operating Tasks

Note

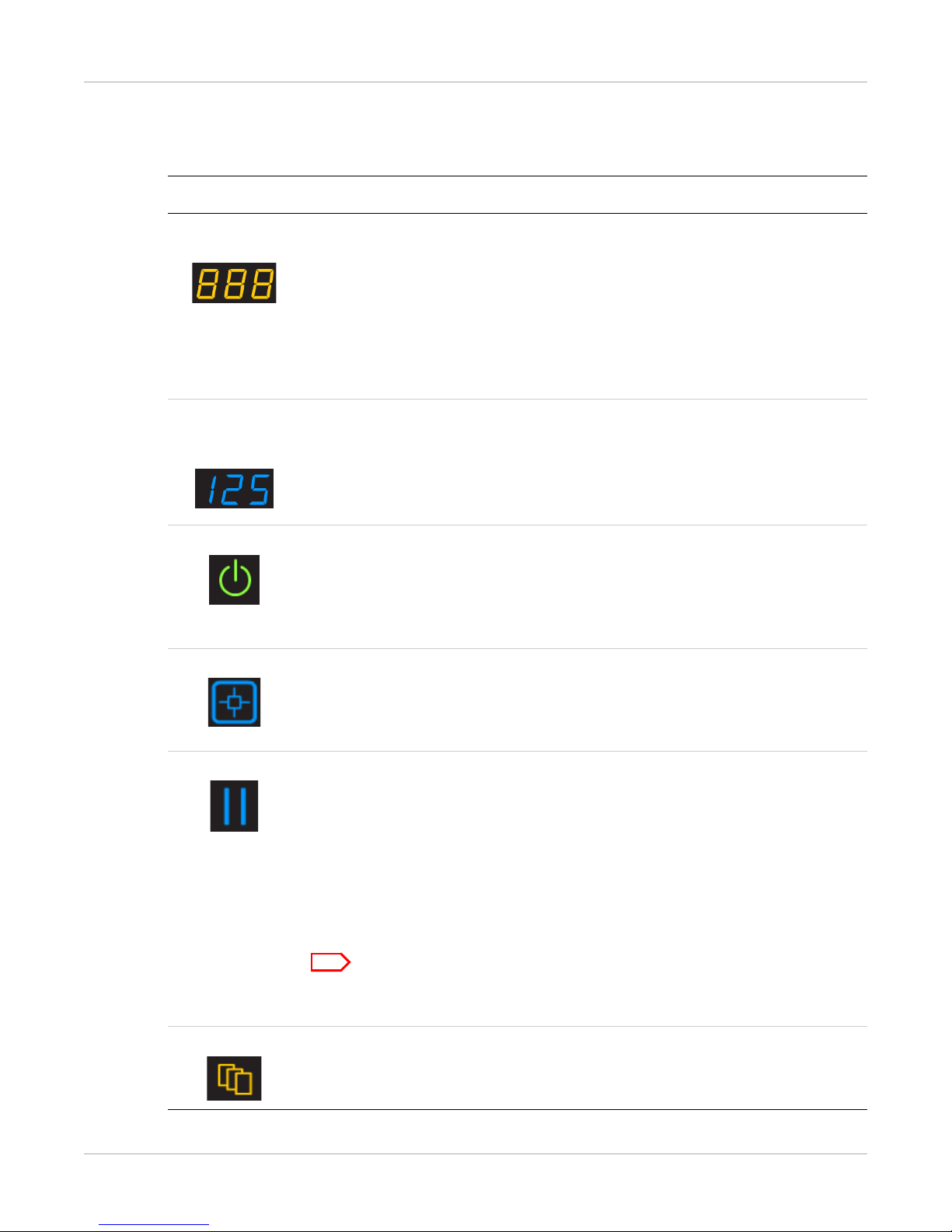

Understanding the Display Screen

The display screen communicates the status of the imager.

Symbol or code Description

Top left of the

display screen:

Error or status code. The 3-digit code displays when the error or status condition is present. If the imager is on and a 3-digit code does not display, the

imager is operating normally.

If a different film size has been requested than what is installed, the

requested film size displays.

When the imager is starting, a countdown displays the number of minutes

until the imager will be ready to print (for example, -4 means 4 minutes

until the imager will be ready to print).

Lower left of

the display

screen:

Film count. Displays the number of films that are remaining in the film cartridge.

The loaded film size also displays in this location.

If a blue number does not display while the imager is powered on, the film

cartridge is not inserted (or not fully inserted) into the imager.

Power When the symbol is green, the power is on and the imager is ready to print.

The symbol flashes while the imager is while processing, calibrating, or

making a test print.

When the symbol is yellow, the imager is not ready to print. Examples are

when the imager is warming up or when the film cartridge is empty.

Calibrate Press to initiate film calibration. The symbol flashes while the calibration is

in process.

Calibration might be needed if the symbol is on and code 624, 631, or 632

appears.

Pause During normal operation, the symbol is off. (See exceptions in the note

below.) When the film cartridge cover is open, the symbol is on. To avoid

exposing the film to light, do not open the film supply until the symbol is

off.

If the Pause symbol is on, you can press the symbol to temporarily pause

printing. Any jobs in progress finish printing, then the film cartridge cover

closes.

Wait until the Pause symbol is off for cartridge replacement, etc.

The Pause symbol is on while the imager is processing images or test prints

and during calibration.

Film Size When the symbol appears, the requested job requires a different film size.

You can also cancel all pending print jobs that require an unavailable media

size.

2–2 9G7564_en | 2013-04-01

Basic Operating Tasks

Symbol or code Description

Restart Restart the imager. An error code also displays.

Film Jam Film is jammed. The error code confirms the film jam and gives direction on

where to find the film inside the imager.

Maintenance Preventive maintenance is required. Check the error code to learn what

action to take.

Related topics

Maintenance and Troubleshooting

Load a Different Film Size to Match a Print Request

Calibrate the Imager for the Installed Film

Delete Pending Jobs

Restarting the Imager

Film Jam Indication and Areas

Preventive Maintenance

9G7564_en | 2013-04-01 2–3

Loading...

Loading...