Konica Minolta DRYPRO Model 793 Operation Manual

LASER IMAGER

DRYPRO MODEL 793

OPERATION MANUAL

CODE NO.

0792 (UL), 0791 (CE)

No. 26-2, Nishishinjuku 1-chome, Shinjuku-ku, Tokyo 163-0512, Japan

Table of Contents

Foreword.............................................................. 1

About This Manual .............................................. 3

Ch.1 Safety Precautions & Warnings ................ 7

Ch.2 Product Outline .......................................... 17

2-1 Name of Each Component ................................. 18

2-2 Internal Structure ................................................ 25

Ch.3 Operation .................................................... 27

3-1 Operation Panel.................................................. 28

3-2 Startup ................................................................ 30

3-3 Shutdown............................................................ 31

3-4 Film Loading ....................................................... 35

3-5 Sleep Mode......................................................... 40

3-6 Changing the Film Size and Film Type............... 42

Ch.4 Maintenance Mode ..................................... 47

4-1 Maintenance Mode Overview ............................. 48

4-2 Switching to the Menu Mode .............................. 50

4-3 Switching to the Maintenance Mode................... 52

4-4 Operation of Each Menu..................................... 56

4-4-1 PRINT QUEUE INFO............................... 56

4-4-2 PREVIOUS PRINT................................... 57

4-4-3 QUEUE CLEAR ....................................... 61

4-4-4 TEST PRINT ............................................ 62

4-4-5 CALIBRATION ......................................... 64

4-4-6 MAMMO QC PRINT................................. 66

4-4-7 PRINT CONDITION ................................. 68

4-4-8 LUT SETUP ............................................. 73

4-4-9 FILM DATA .............................................. 78

4-4-10 FILM SETUP............................................ 80

4-4-11 START TIMER......................................... 82

4-4-12 TIME SET ................................................ 84

4-4-13 TOUCH PANEL ....................................... 86

4-4-14 SLEEP MODE.......................................... 88

4-4-15 SORTER SETUP..................................... 90

4-4-16 FRONT COVER OPEN............................ 93

4-4-17 SYSTEM RESET..................................... 94

4-4-18 DUST CLEANING.................................... 95

Ch.5 Web Maintenance Mode ............................ 99

5-1 Overview of Web Maintenance Mode................. 100

5-2 Startup/Shutdown of Web Maintenance Mode ... 103

5-3 Menu Items of Web Maintenance Mode ............. 107

5-3-1 STATUS................................................... 107

5-3-2 QUEUE LIST............................................ 108

5-3-3 PREVIOUS PRINT................................... 109

5-3-4 QUEUE CLEAR ....................................... 110

5-3-5 PRINT CONDITION ................................. 111

5-3-6 LUT SETUP ............................................. 113

5-3-7 FILM DATA .............................................. 115

5-3-8 FILM SETUP............................................ 116

5-3-9 START TIMER ......................................... 117

5-3-10 TIME SET ................................................ 118

5-3-11 SLEEP MODE.......................................... 119

5-3-12 SORTER SETUP..................................... 120

5-3-13 SYSTEM RESET..................................... 121

Ch.6 Troubleshooting ......................................... 123

6-1 Error Message and Reaction .............................. 124

6-2 Error Reset ......................................................... 126

6-3 Resolving the Film Jam ...................................... 128

6-3-1 Film Jam in Cooling Unit .......................... 129

6-3-2 Film Jam in the Descent Transport Unit... 132

6-3-3 Film Jam in the Elevator Transport Unit... 136

6-3-4 Film Jam in the Supply Tray .................... 138

6-3-5 Film Jam in the Sorter Transport unit....... 139

Ch.7 Care & Maintenance ................................... 139

7-1 Periodic Maintenance and Inspection................. 140

7-2 Maintenance/Inspection Schedule...................... 146

7-3

Display and Check of the Maintenance & Inspection

.. 147

Specifications...................................................... 149

< 1 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

We would like to thank you for purchasing Laser Imager DRYPRO Vstage MODEL 793

(hereinafter referred to as DRYPRO 793).

DRYPRO MODEL 793 is a laser imager which realized a complete dry process, devel-

oped by considering the environment and operability, while maintaining high perfor-

mance and high image quality.

In this manual, safety precautions and operational procedures are described to allow the

users of the DRYPRO 793 to be fully familiarized with the potential of the device. The

manual should be at all times be kept in a readily accessible place for easy reference.

Should you loose this manual, please contact your Service Representative for a new

one.

Foreword

Foreword

< 2 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

Features

DRYPRO MODEL 793 is a laser imager which realized a complete dry process, developed by consid-

ering the environment and operability, while maintaining high performance and high image quality.

High-quality Image

1) Realizing super-sharpened images with the pixel size of 43.75 µm and 25µm as well as

capability of mammography.

2) Films that are most suitable for the imager and CR are newly developed.

3) Supporting 12-bit image input

4) Rendering high-quality images with advanced image interpolation processing technology

5) Built-in auto density control function for stabled image output.

Operation environment

1)Shortening waiting time for output by high-speed processing capability. (120 sheets / hour)

2) Maximum 3 CH of input tray, including 8"x10" and 10"x12".

Imaging environment

Capability of direct connection to diagnostic devices with DICOM communications secures

expandability on the open network even in the future.

Notes

(1) Unauthorized reproduction of this manual in whole or in part is prohibited.

(2) The content of this manual is subject to change without prior notice.

(3) Should any discrepancies, errors or omissions be discovered, KONICA MINOLTA should be contacted.

(4) Notwithstanding item(3) above, KONICA MINOLTA shall accept no responsibility of any claims made against loss or

loss of profits arising from use of the product.

Be sure to observe the following in order to prevent any danger.

1.NEVER remove the external and internal covers with a screwdriver, and others.

2.NEVER perform any operations, adjustments, or actions other than the specified in this Operation Manual; other-

wise, you may be exposed to dangerous radiation.

3.If any problem occurs in this device, contact your Service Representative. NEVER use the troubled device as it is

dangerous. Note that a laser tube is incorporated in this device, and direct exposure of eye or skin to the laser beam

may result in injury. Also the device contains an assembly using a high voltage. Due case should be taken not to

suffer from electrocution by touching this assembly.

< 3 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

About This

Manual

Be sure to read this chapter before using this

manual so that the manual can be fully utilized.

About This Manual

< 4 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

Chapter1 Safety Precautions & Warnings

When using the DRYPRO 793, the cautions detailed in this chap-

ter must be strictly followed in order to safely use the device.

Chapter2 Product Outline

The product outline of DRYPRO 793 is described in this chapter.

Chapter3 Operation

The operation of DRYPRO 793 is described in this chapter.

Chapter4 Maintenance Mode

This chapter describes the Maintenance Mode of the DRYPRO

793.

Chapter5 WEB Maintenance Mode

This chapter describes the WEB Maintenance Mode with which

the DRYPRO 793 can be maintenanced from external PC.

Chapter6 Troubleshooting

This chapter describes typical methods of trouble shooting and

the error message list displayed on DRYPRO 793.

Chapter8 Care & Maintenance

This chapter details the procedure for care and maintenance of

the DRYPRO 793.

Specifications Specifications of the DRYPRO 793 are described in this para-

graph.

Index The index describes special terminology used in the DRYPRO

793 Operation Manual.

Structure of this manual

This manual consists of the chapters listed below.

How to use this manual

About This Manual

< 5 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

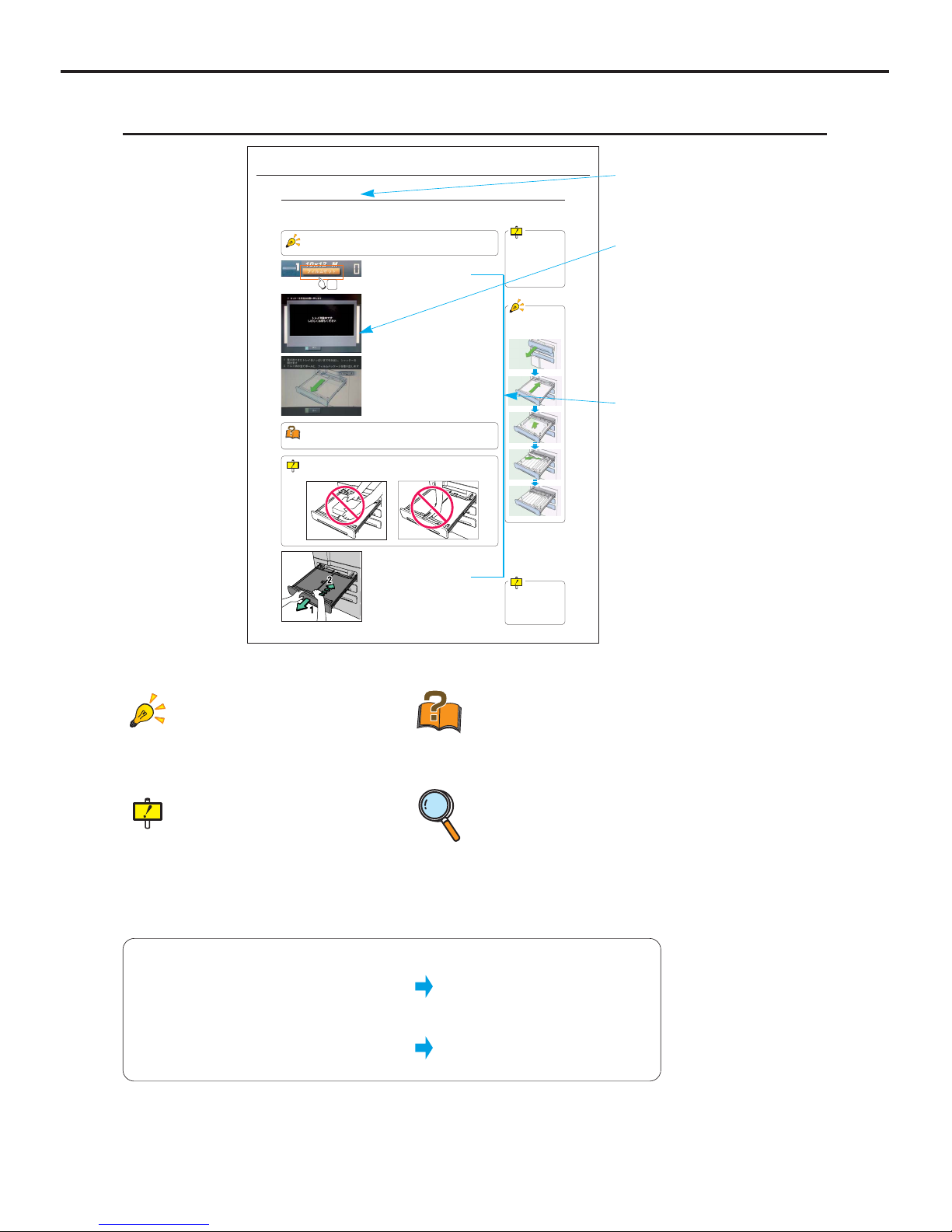

Parenthesis in a sentence.

The word in this mark shows that it is displayed in the touch panel of the CS-2

operation unit.

The word in this mark shows that it is the

name of the button to be pushed or

touched.

Ex. "Ready"

Ex. [Complete] Button

Ch.3 Operation

< 35 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.0.01 2004.10

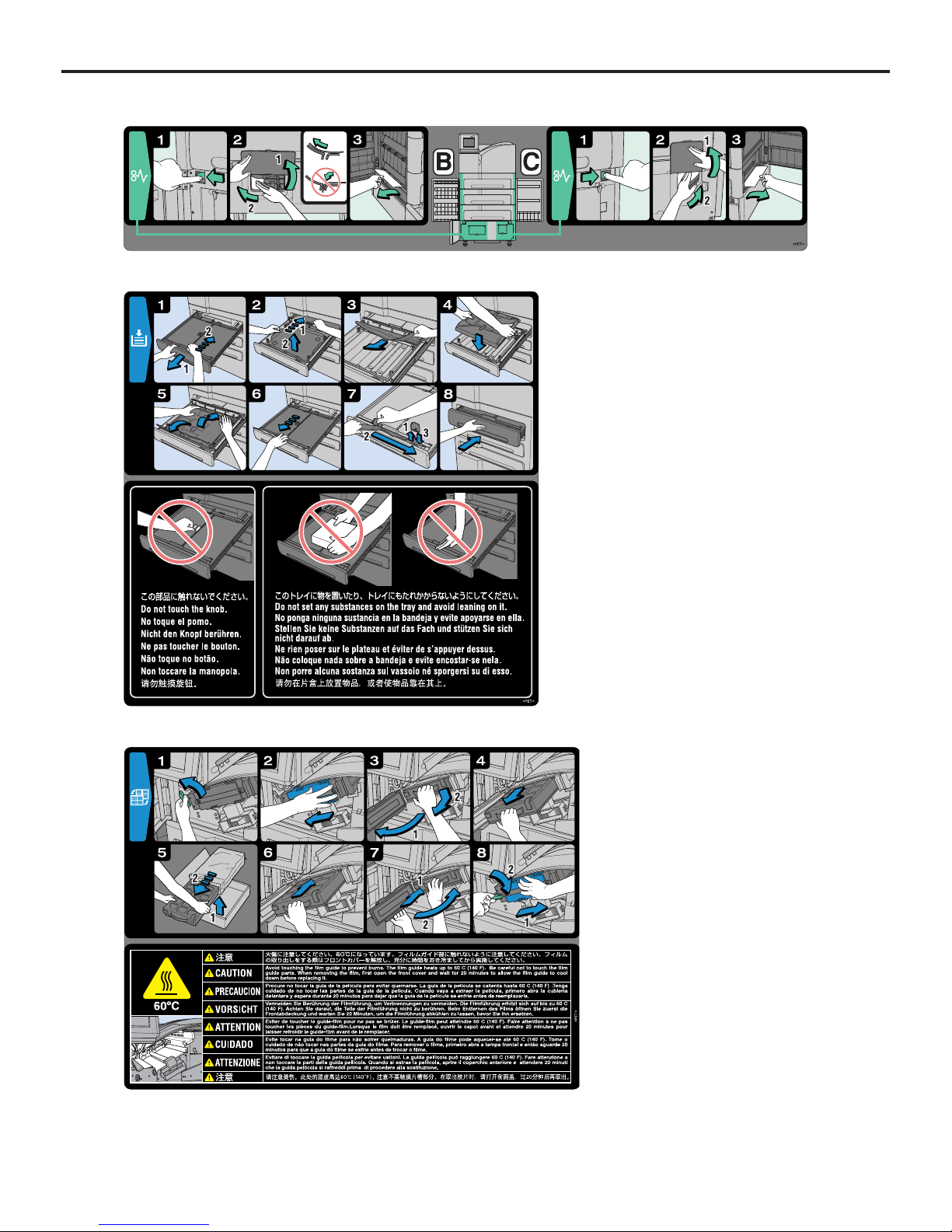

3-4 Film Loading

When the supply tray becomes empty, a beep sound is released, followed by the [Film Set] button that is newly displayed in the

message column of the Operation Panel. (Beep sound can be selected from "Silent", "Single" and "Continuous" at the time of

installation) When this button is displayed, follow the procedures shown below to load the film package in the supply tray.

The DRYPRO 793 can receive the print data from the diagnostic device while it is in

film loading operation. The print data received during film loading will be printed after

the film loading is completed.

When a film is in printing process, Supply

Tray cannot be pulled

out until that film has

been printed. This may

take maximum 95 sec.

1 Touch the [Film Set] button.

- A message indicating that the tray is being pulled out.

- Supply tray pops out a few centimeters, and the animation

showing how to load the film package (pull out of the tray

~ removal of the sandwich paper and light-proof package)

will be displayed.

Do not put anything or lean on the Supply Tray while it is pulled out. Doing so will

damage the Supply Tray.

1

2 Gently and fully pull out the Supply Tray to its

end. (1 in the left fig.)

3 Fully open the Supply Shutter. (2 in the left fig.)

Shutter cannot be

opened if the Supply

Tray is not fully pulled

out.

Animation for "pull out

of the tray ~ removal of

the sandwich paper"

Sandwich Paper

One sheet of sandwich paper is always contained in a film package, and helps protect

the films from folding.

Hint

Points to be noted.

Technical Term

Technical terms are

explained.

Reference

Shows reference pages or

sections.

See the page for more

details.

Title

This title stands for the

general meanings for

the descriptions.

Display

Display with the operational procedure is

shown.

Operation Procedure

Operation procedure is

explained in order.

Caution

Cautions for operating the

machine.

Details should be carefully

noted.

Page Layout

About This Manual

< 6 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

< 7 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

When using the DRYPRO 793, the cautions

detailed in this chapter must be strictly followed in

order to safely use the device.

Safety

Precautions &

Warnings

1

Chap.

Ch.1 Safety Precautions & Warnings

< 8 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

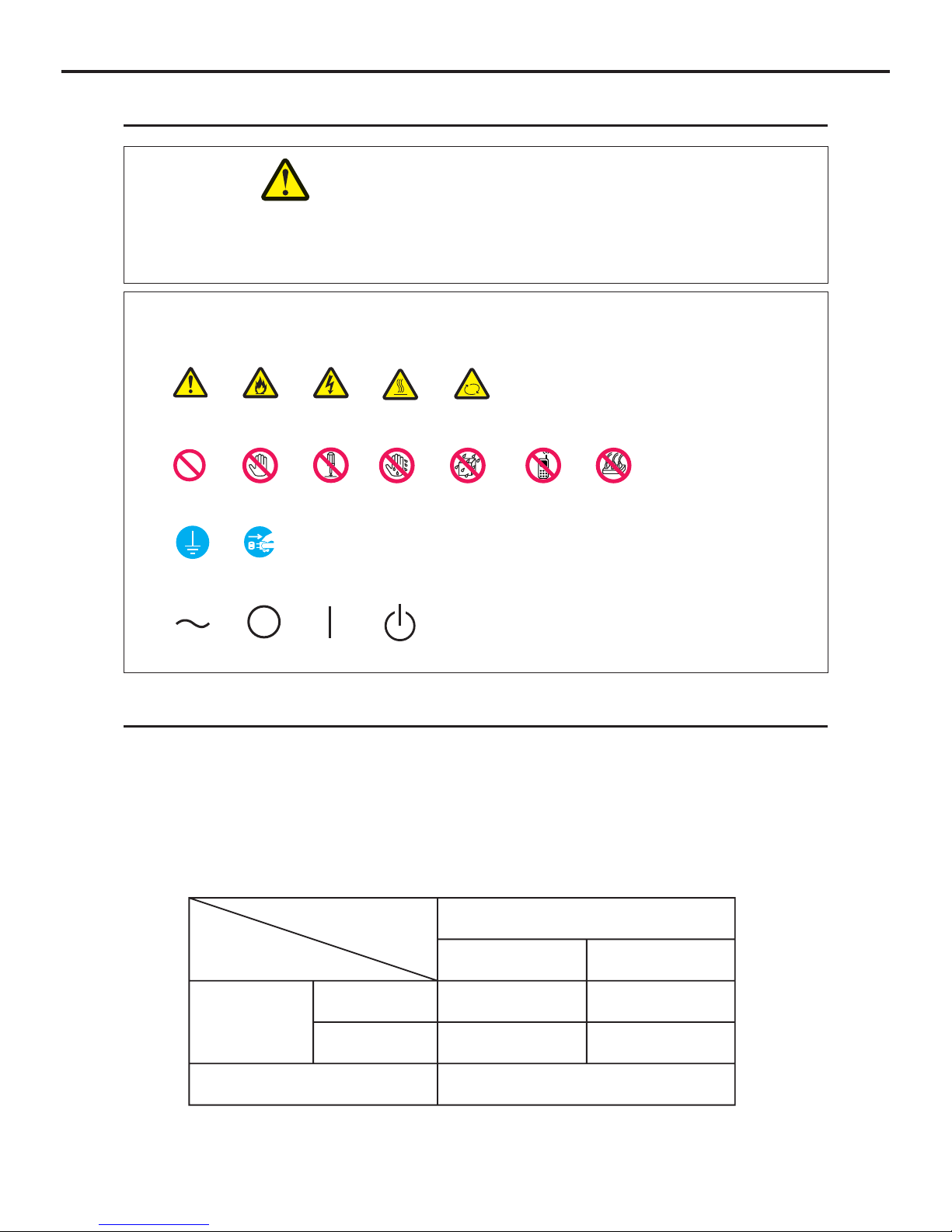

This is the safety alert symbol and is intended to draw the attention of the user to potential dangers to the user

him/herself or to others that may arise during the use or operation of this system.

These messages must be read thoroughly and strictly observed.

All safety related precautions should be carefully read and fully understood before proceeding with assembly or

usage of this system.

Safety Alert Symbol

●

Symbols indicating the need for caution (including danger and warnings)

● Symbols indicating prohibited acts

● Symbols indicating essential acts (compulsory or indicated acts)

● Other Symbols

Description of Graphic Symbols

Normal Caution Danger of Fire

Prohibited

AC Voltage

(Power Supply)

Ground

Danger of High

Temperature

Danger of

Rotation

Main Power

Supply OFF

Main Power

Supply ON

Main Power

Standby

Remove the plug from

the power outlet

Do not touch Do not disassemble Do not touch

with wet hand

Mobile

Prohibited

Multi-Leads

Prohibited

Do not expose

to moisture

Danger of

Electrocution

Alert and Symbol Marks

Warning Text (Signal Word)

Signal words indicate the degree of potential hazards in the product.

There are 3 degrees of caution labels, and each is used depending on the level of risk and damage caused by

incorrect use and mishandling.

DANGER

: Failure to observe the caution will produce high risk of serious or fatal injury.

WARNING

: Failure to observe the caution will produce moderate risk of serious or fatal injury.

CAUTION

: Failure to observe the caution will produce risk of moderate or light injury.

Risk of the damage

Bodily injury

(and damage to property)

Damage to property only

Loss of life or serious injury

(Damage is serious)

High Low

DANGER WARNING

WARNING

CAUTION

CAUTION

CAUTION

Moderate damage or light injury

(Damage is light)

or

NOTE : If the contents of this page are not legible, order a new manual.

Ch.1 Safety Precautions & Warnings

< 9 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

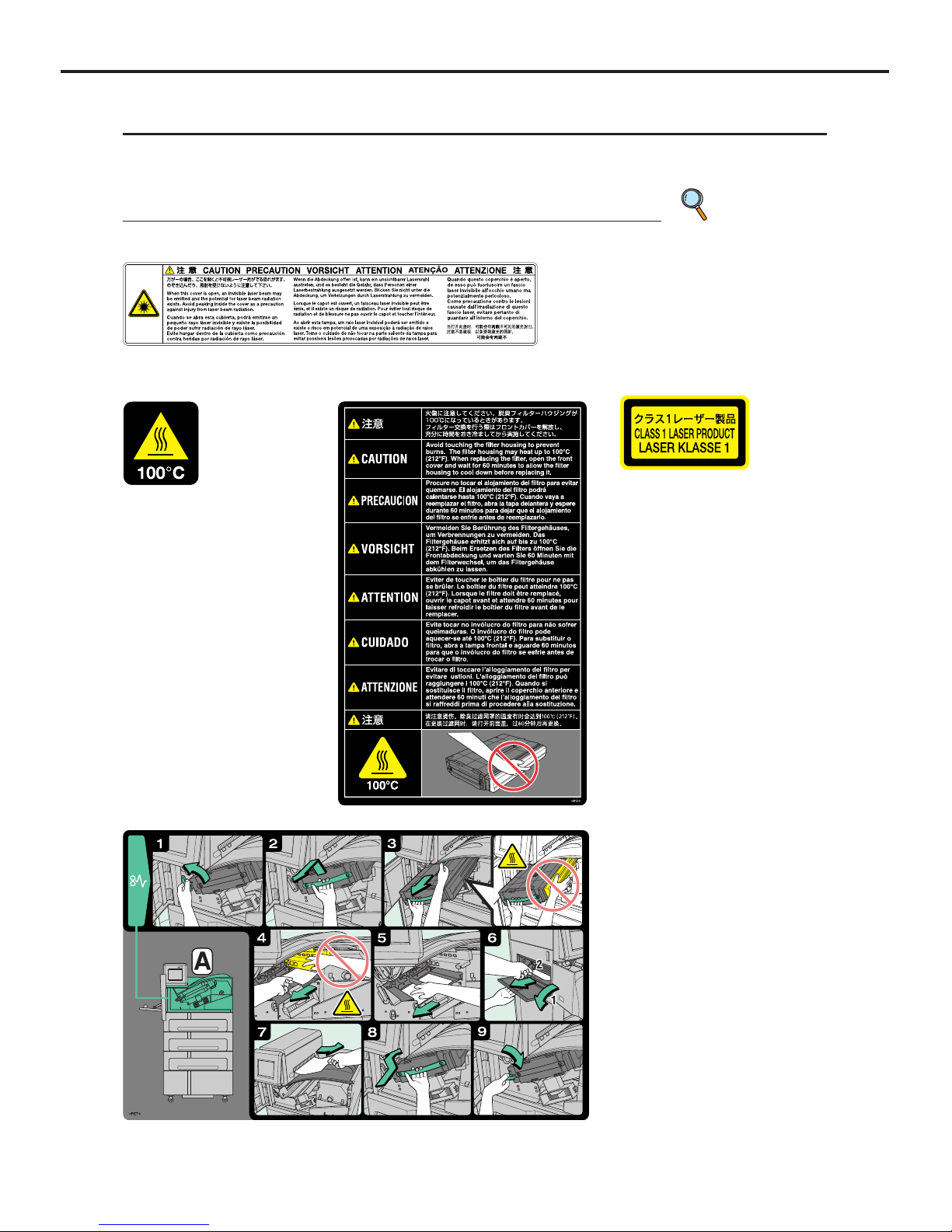

Warning Labels

Warning labels on the DRYPRO 793 are affixed at the locations shown below, and indicate the possible dan-

ger to the user.

NOTE : If the contents of this page are not legible, order a new manual.

(1) Laser Caution Label

(2) High Temp. 100

: Label-1

(4) Class1 Laser Product Label

(5) Jam Release Label-A

Description of Warning Labels

p.12 Locations of

Warning

Labels

(3) High Temp. 100: Label-2

Ch.1 Safety Precautions & Warnings

< 10 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

(7) Film Loading Label

(8) Deodorant Filter Change Label

NOTE : If the contents of this page are not legible, order a new manual.

(6) Jam Release Label-B•C

Ch.1 Safety Precautions & Warnings

< 11 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

(9) Cleaning Roller Cleaning Label

NOTE : If the contents of this page are not legible, order a new manual.

Ch.1 Safety Precautions & Warnings

< 12 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

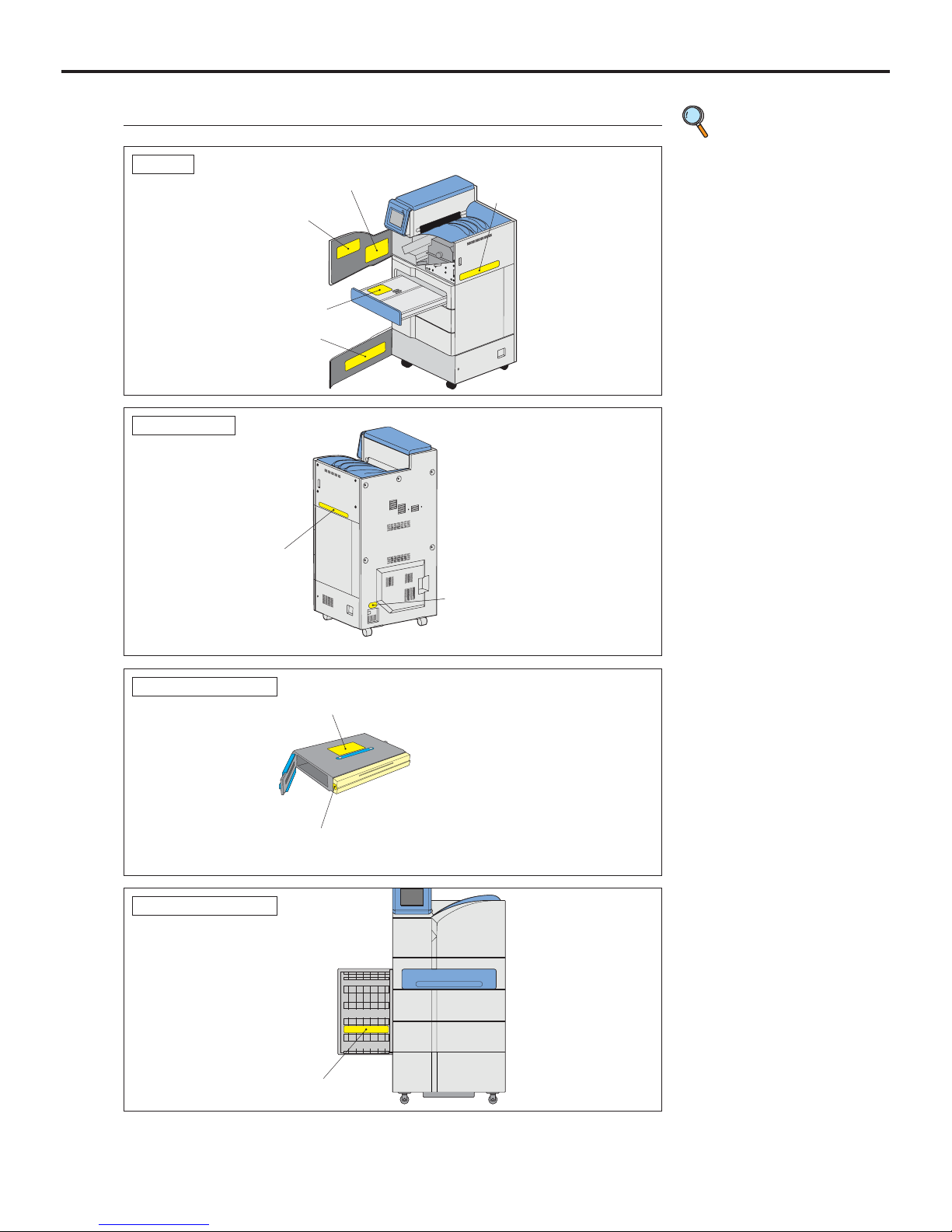

Locations of Warning Labels

NOTE : If the contents of this page are not legible, order a new manual.

p.9 Description

of Warning

Labels

(6) Jam Release Label B¥C

(5) Jam Release Label

(8) Deodorant Filter Change Label

(1) Laser Caution Label

(7) Film Loading Label

(1) Laser Caution Label

(4) Class1 Laser Product Label

Internal

Rear • Left Side

(9) Cleaning Roller Cleaning Label

Cleaning Roller

(3) Deodorant Filter Housing High Temp. 100: Label

(2) High Temp. 100: Label

Deodorant Filter Case

Ch.1 Safety Precautions & Warnings

< 13 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

NOTE : If the contents of this page are not legible, order a new manual.

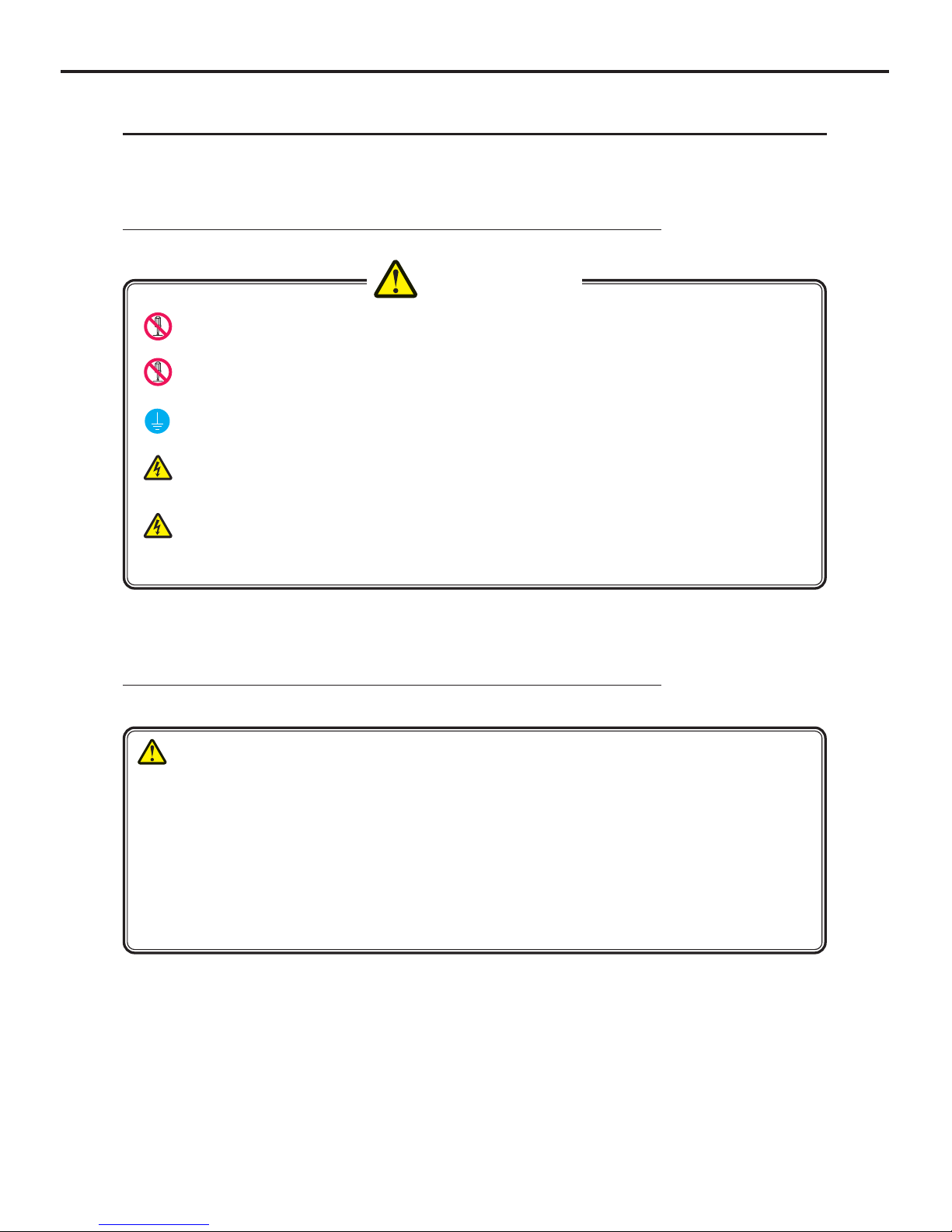

Cautions for Safety

Thoroughly read the Cautions for Safety before use, and use the device correctly. Strictly observe all cau-

tions detailed here because they are quite important to secure the safe use of the device.

Cautions for Installation

• Never attempt to modify the device.

If you modify the device, this may cause a breakdown, electric shock, or fire.

• For installation, contact a sales office where you purchased this device or your Technical

Representative.

If you install the device and there are any problems in installation, this may cause an electric

shock or a fire.

• Be sure to ground the device well.

Never connect the grounding cable to the gas pipe, water supply pipe, lighting rod, or the grounding cable for telephone.

• As for the electrical work (including grounding and communications cable work) follow the

local regulations on the technical standards.

If the work is not done properly, this may cause an electric shock or breakdown.

• Use the power supply with sufficient capacities according to the specifications.

If you use any power supply other than the specifications, or the power supply with insufficient

capacities, this may result in heating the electrical components or cause a fire.

WARNING

Cautions for Reinstallation, Storage and Repair

CAUTION

• In the event of detection of smoke, unusual odors or sounds, the power should be switched off

immediately and the power plug disconnected from the power outlet. Then contact your Konica Service Representative. Continued use under such circumstances could result in fire.

Continued use of the device despite of such abnormality may result in damage, electric shock or fire.

• Contact your Technical Representative as to the reaction to the errors other than those listed in this

manual.

If the repair is done by the user with some failure, it may cause electric shock or fire.

• For reinstallation, storage and repair, contact a sales office where you purchased this device or your

Technical Representative.

If the device is relocated, reinstalled by the user with some failure, it may cause electric shock or fire.

Ch.1 Safety Precautions & Warnings

< 14 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

Cautions for Usage

• Never open or close any covers other than the specified in this Operation Manual.

High voltage may be applied on some units in the device. If you touch them accidentally, you may

suffer burns or an electric shock.

• When replacing FILTER or removing film jams in the discharge unit, follow the procedure in

this Operation Manual;

otherwise, a fire may be caused.

• Plug the power cable completely.

If dust is accumulated on the power plug, or the power cable is not plugged properly, this may

cause an electric shock or a fire.

• Be sure to use the power cable supplied with this device. Do not use an extension cord or

do not connect another device to the same wall outlet;

otherwise, a fire or heating may be caused.

• Be careful not to trip over the power cable to damage it.

If you continue using the damaged power cable, this may cause an electric shock or fire.

• Do not block the air inlet or the air outlet of this device;

otherwise, a breakdown may be caused.

• Do not start up or shut off the device by plugging or unplugging the power cable;

otherwise, an electric shock or breakdown may be caused.

• If it is likely that lightning may occur, stop operating the device, and unplug the power

cable.

A breakdown may occur depending on the degree of lightning.

• Do not use this device for any purpose other than printing image data;

otherwise, a breakdown may be caused.

• Do not operate the switches with wet hands;

otherwise, you may suffer an electric shock.

• When unplugging the power cable, do not pull it;

otherwise, the inner cable may be broken, and this may cause heating or a fire.

• Do not let this device exposed to water by cleaning the device with a wet cloth or placing

the vase containing water on the device, etc;

otherwise, you may suffer an electric shock due to a leakage of currents.

• Before you clean the device, be sure to stop operating it, and unplug the power cable or turn

the breaker OFF;

otherwise, you may suffer injury or the device may be broken down as the fan rotates at the high

speed in the device.

• If the device is not going to be used for an extended period of time, unplug the power cable

for safety purpose;

otherwise, dust may be accumulated, resulting in heating or a fire.

• When the failure occurs on the device, contact your Technical Representative.

NEVER use the troubled device as it is dangerous.

Note that a laser tube is incorporated in this device, and direct exposure of eye or skin to the laser

beam may result in injury. Also the device contains an assembly using a high voltage. Due case

should be taken not to suffer from electrocution by touching this assembly.

WARNING

NOTE : If the contents of this page are not legible, order a new manual.

Ch.1 Safety Precautions & Warnings

< 15 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

CAUTION

• As for any servicing other than "Servicing by User" described in this Operation Manual, contact a service person as they require an expert technology.

If you perform any service other than "Servicing by User" by yourself, and there are any problems on it, this may

cause an electric shock or fire.

• If the smell is unpleasant, install a ventilating fan in a room where this device is installed.

(Please determine the size and capacity of the fan according to the structure of a room.)

Although a chemical substance is discharged during operation, the amount of emissions is within acceptable limits.

NOTE : If the contents of this page are not legible, order a new manual.

Cautions for Installation Location

CAUTION

Be sure to observe the following conditions for the installation location of this device.

By installing this device in the Radiology Department, you could make the work flow smooth.

1)Install the device in a location where it is not exposed to water.

2)Install the device in a location where it is not exceed the temperatures or atmospheric pressure described in

the specifications.

3)Install the device in a location where it is not exposed to direct sunlight.

4)Install the device in a flat place.

5)Install the device where there is no likelihood of being given by vibration or impact.

6)Install the device in a location where there is no likelihood of being adversely affected by chemical agents,

or air containing gas, dust, salt or sulfur, etc.

7)Install the device where the air inlet or exhaust outlet is not blocked.

Cautions for Disposal

CAUTION

When disposing of the DRYPRO 793 main unit [ including lithium button battery (free from lead, hexavalent

chromium, cadmium, mercury, PBB, PBDE), fluorescent tubes (contained in the LCD module) ], accessories,

options, and films, accept the regulations of each local government.

p.00

Maintenance Proce-

dures to be Carried

out by the Customer

Ch.1 Safety Precautions & Warnings

< 16 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

< 17 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

Product Outline

2

Chap.

Product outline of the DRYPRO 793 is detailed in

this chapter.

Ch.2 Product Outline

< 18 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

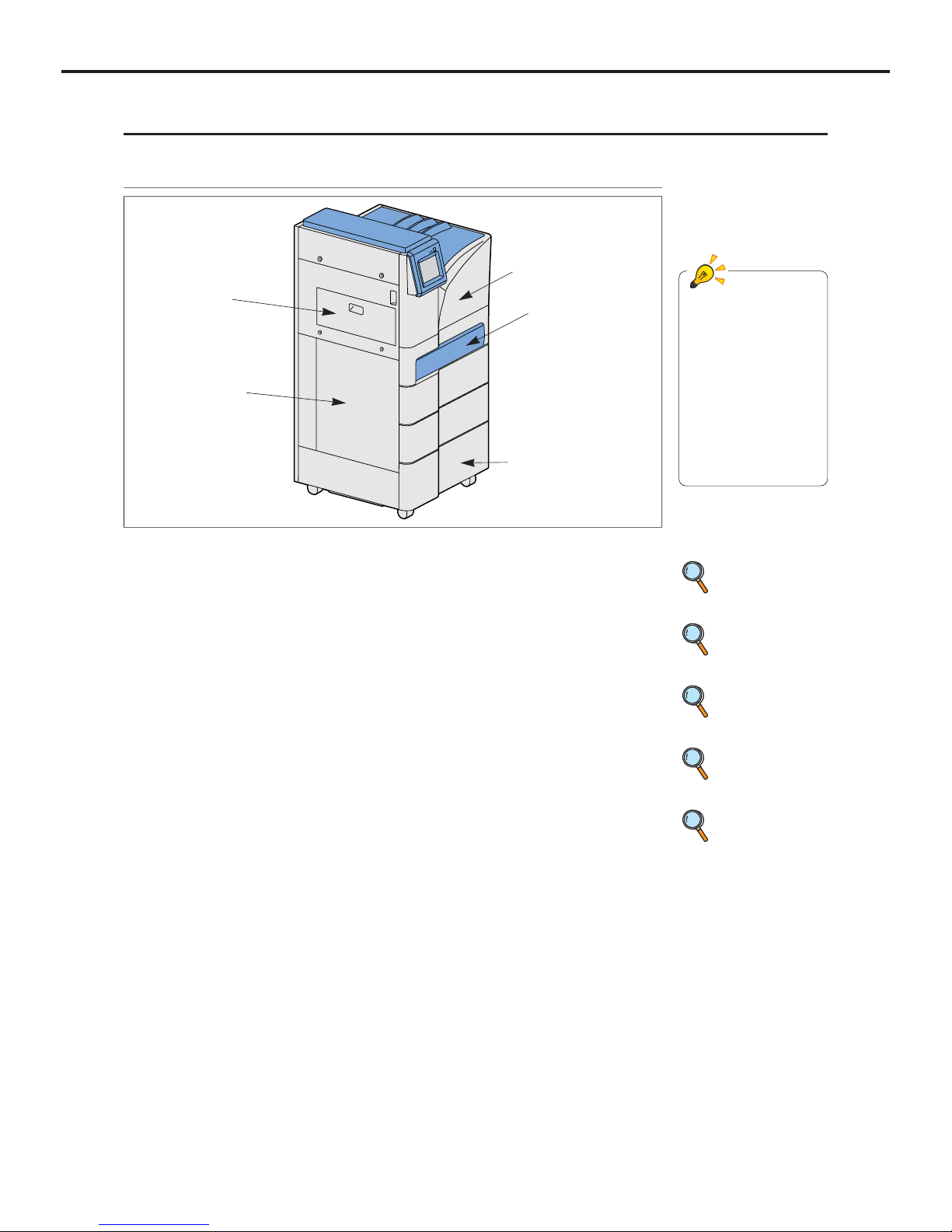

2-1 Name of Each Component

Each component and its function of the DRYPRO 793 is detailed below.

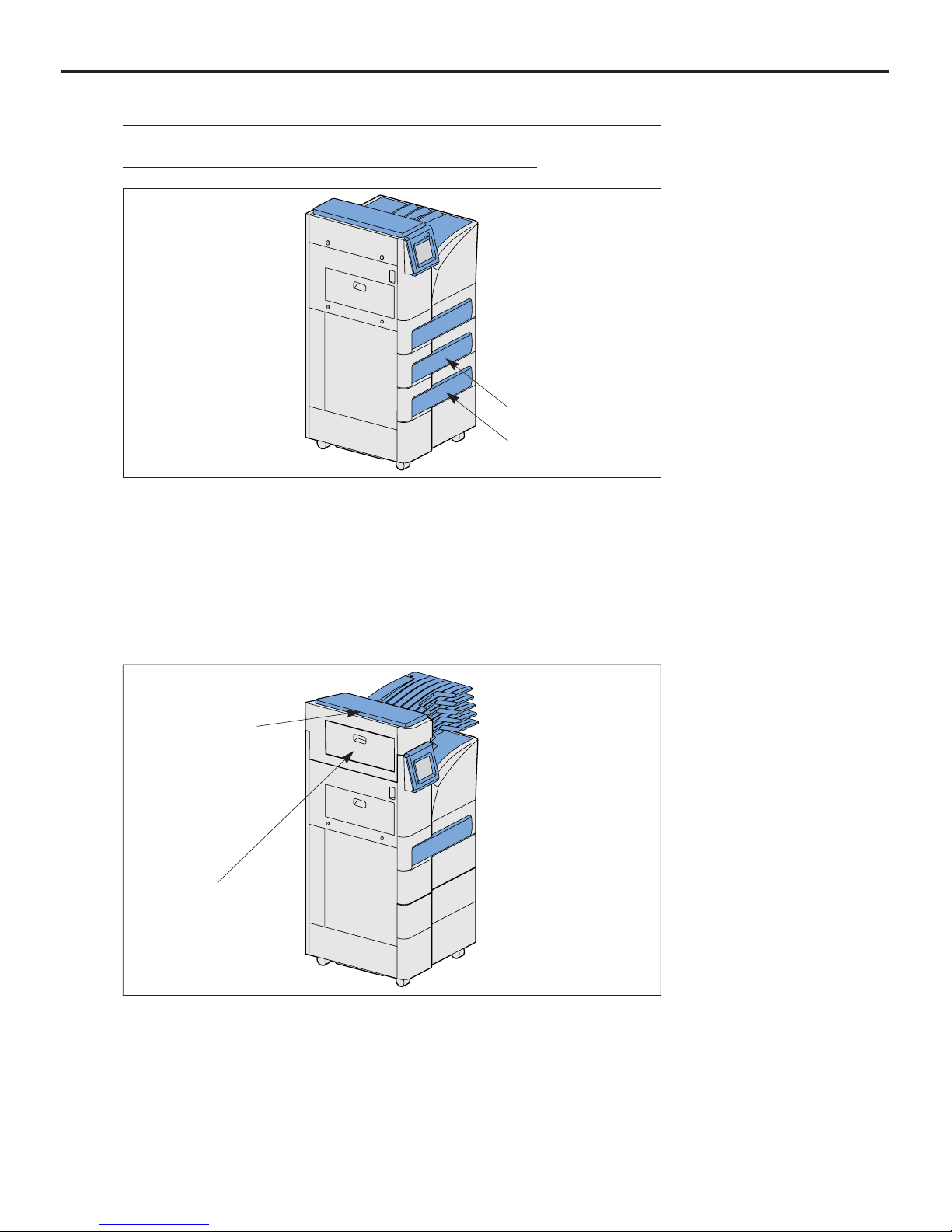

2-1-1 Front and Left Side View

Film size for the

DRYPRO 793 can be

selected from 14"x17",

14"x14", 11"x14",

10"x12", 8"x10". Set up

of the film size selected

by the facility will be

made by the service

representative at the

time of installation of the

DRYPRO 793.

1) Front Upper Cover

3) Front Lower Cover

2) Supply Tray 1

1) Front Upper Cover

When a film jam occurs in HPRO(Hear Processing Unit) - Cooling Unit, open this

cover and take the jammed film out. Also

open when the deodorant filter is replaced.

2) Supply1

(Standard : 1 trays, with option : max. 3 trays)

Load films in these trays.

3) Front Lower Cover

When a film jam occurs in Descent or Elevator transport unit, or Film Justification

unit, open this cover and take the jammed

film out. Also it is possible to send the

jammed film to the left cover or right cover

accessing through this opening.

4) Exit Cover

When a film jam occurs in Ejection Unit,

open this cover and take the jammed film

out.

5) Left Cover

When a film jam occurs in Descent Transport unit, open this cover and take the

jammed film out. Also open when cleaning

of the cleaning roller is performed.

p.19 Operation

Panel

p.93 Front Cover

Open

p.24 Supply Tray

& Cutter

4) Exit Cover

5) Left Cover

p.132 Film Jam in

the Descent

Transport Unit

p.95 Dust

Cleaning

Ch.2 Product Outline

< 19 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

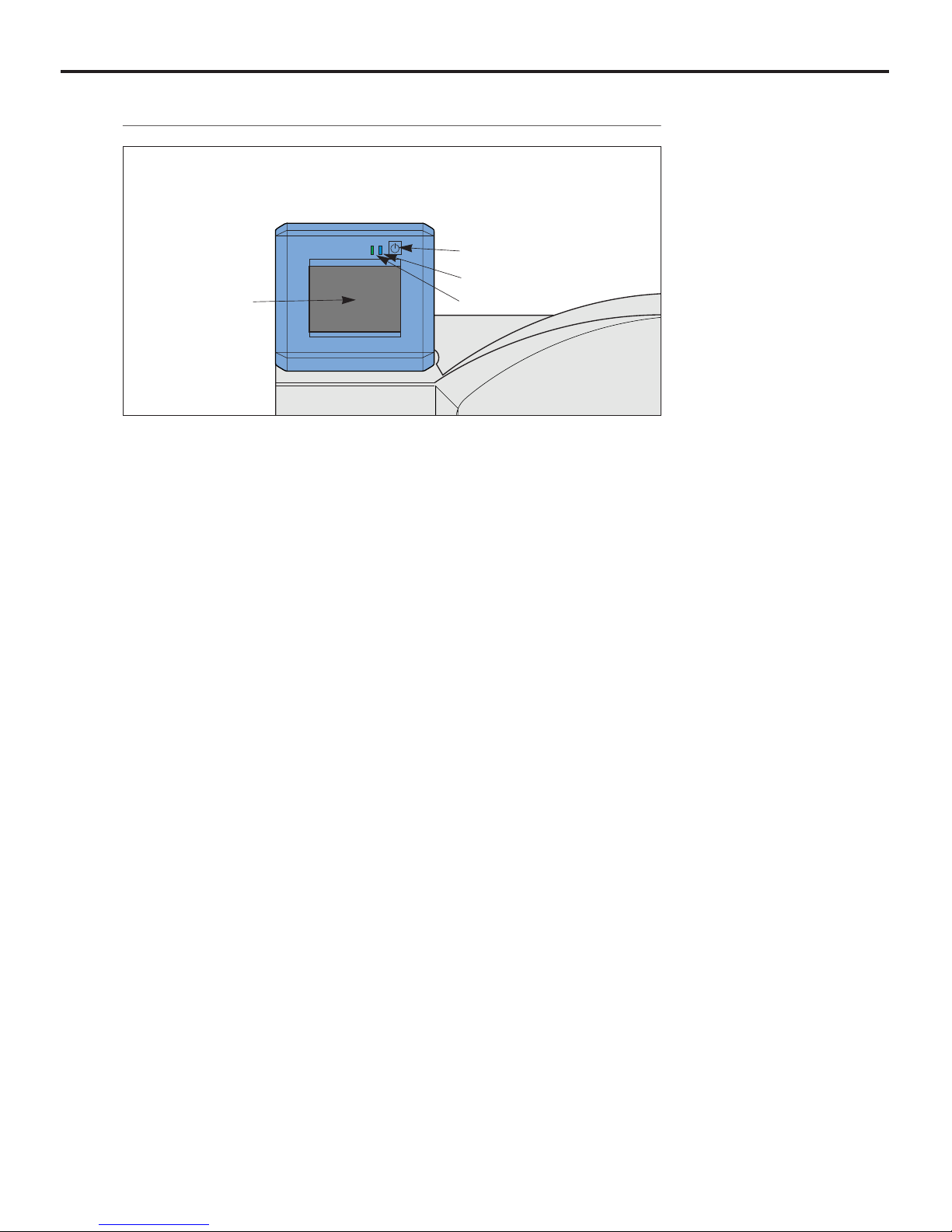

1) Operation Button

Start up or shut down the DRYPRO

793.

2) Operation Lamp(blue/orange)

Operating : Lights in blue

Start Timer ON : Lights in blue

Shutdown Process : Blinks in blue

Power OFF

(Breaker ON) : Lights in orange

Power OFF

(Breaker OFF): Extinguished

3) Timer Lamp

(green)

Lights when the Start Timer is ON.

4) Operation Panel

Operates and performs various settings

for the DRYPRO 793. Also displays various messages.

2-1-2 Operation Panel

1) Operation Button

2) Operation Lamp

3) Timer Lamp

4) Operation Panel

Ch.2 Product Outline

< 20 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

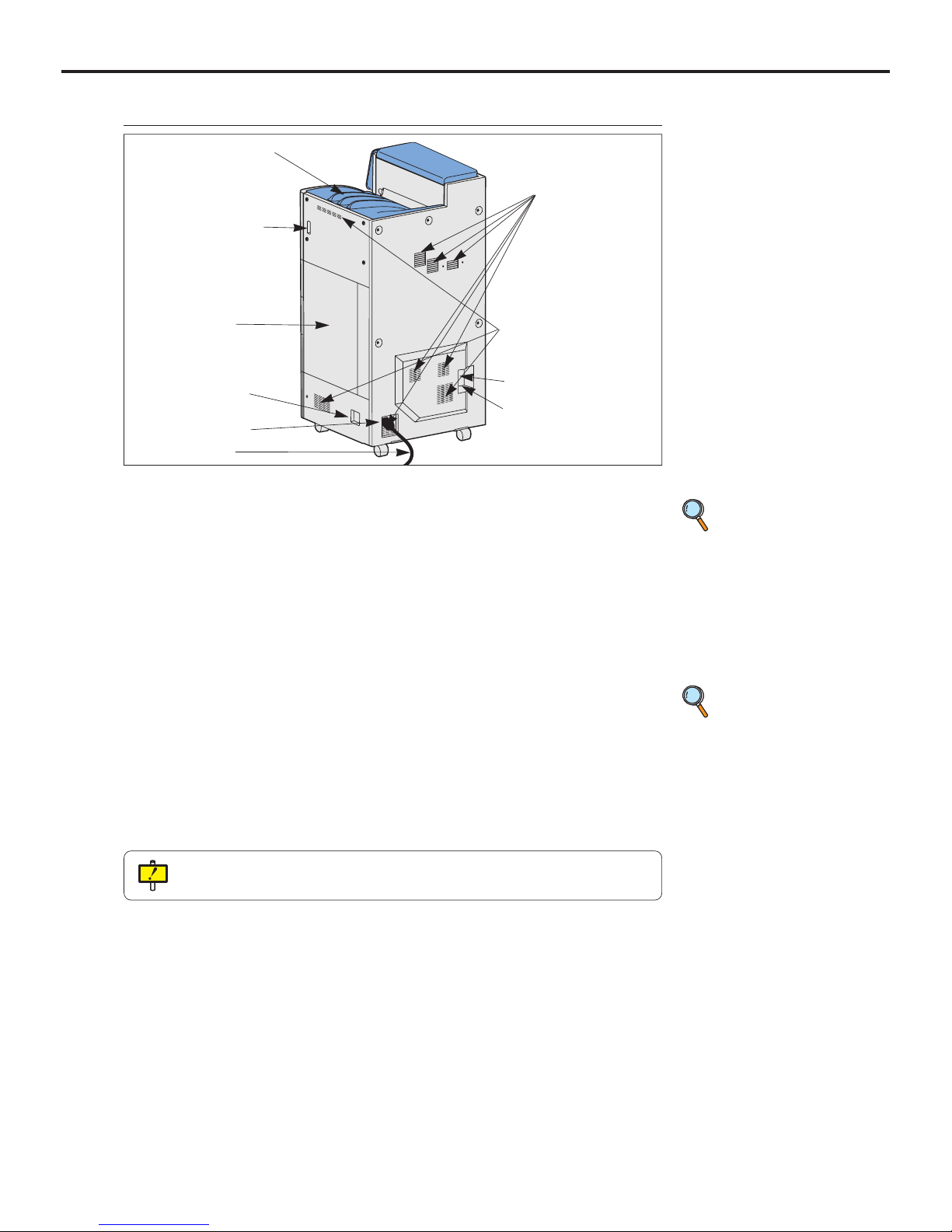

6) Power Cable

7) Outlet

9) Ethernet Port

5) Power Cable

Connector

1) Film Exit Tray

Printed films are output to this tray.

When an optional "6ch Sorter" is

installed, films are output to the sorter.

2) Front Upper Cover Release Lever

Releases the lock of the Front Upper

Cover when it is necessary to open.

3) Right Cover

When a film jam occurs in the Elevator

Transport unit, open this cover and take

the jammed film out.

4) Power Breaker

Turns ON/OFF the main power.

5) Power Cable Connector

Plug in the Power Cable.

6) Power Cable

Connects the DRYPRO793 to the

power outlet of the facility.

7) Outlet (6 locations)

Air used to cool inside of the unit is

exhausted from this slot.

8) Inlet (2 on the right side, 1 on the rear

side)

Takes in the air to cool inside of the

unit.

9) Ethernet Port

Connects to the network.

10) Serial Port

When a backup battery is used, connect

the cable of the backup battery to this

port.

2-1-3 Rear, Right Side, Top View

10) Serial Port

8) Inlet

p.139 Film

Jam in the Sorter

Transport Unit

4) Power Breaker

3) Right Cover

2) Front Upper Cover

Release Lever

p.136 Film

Jam in the Elevator

Transport Unit

1) Film Exit Tray

Do not leave films equivalent to one package (= 125 sheets) or more on the Film Exit

Tray.

Ch.2 Product Outline

< 21 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

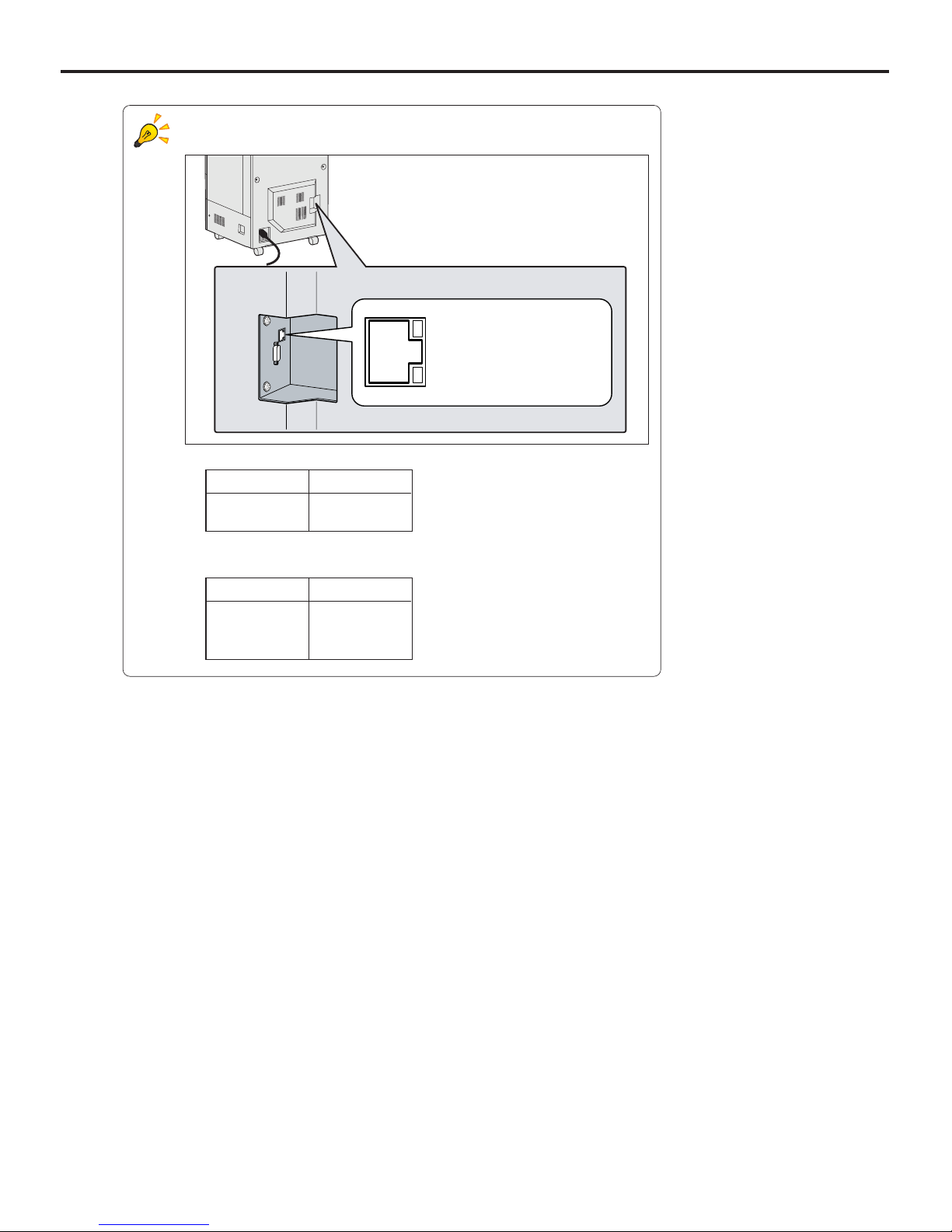

LEDs at the Ethernet Port.

Two LEDs at the Ethernet Port indicate the following.

- Link/Activity LED (upper)

- Com. Speed LED (lower)

Com. Speed LED

10Mbps Extinguished

100Mbps Lights in orange

1000Mbps Lights in green

Com. Status LED

Link Lights in orange

Activity Lights in green

Link / Activity LED

Com. Speed LED

Lower right of the rear

Ch.2 Product Outline

< 22 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

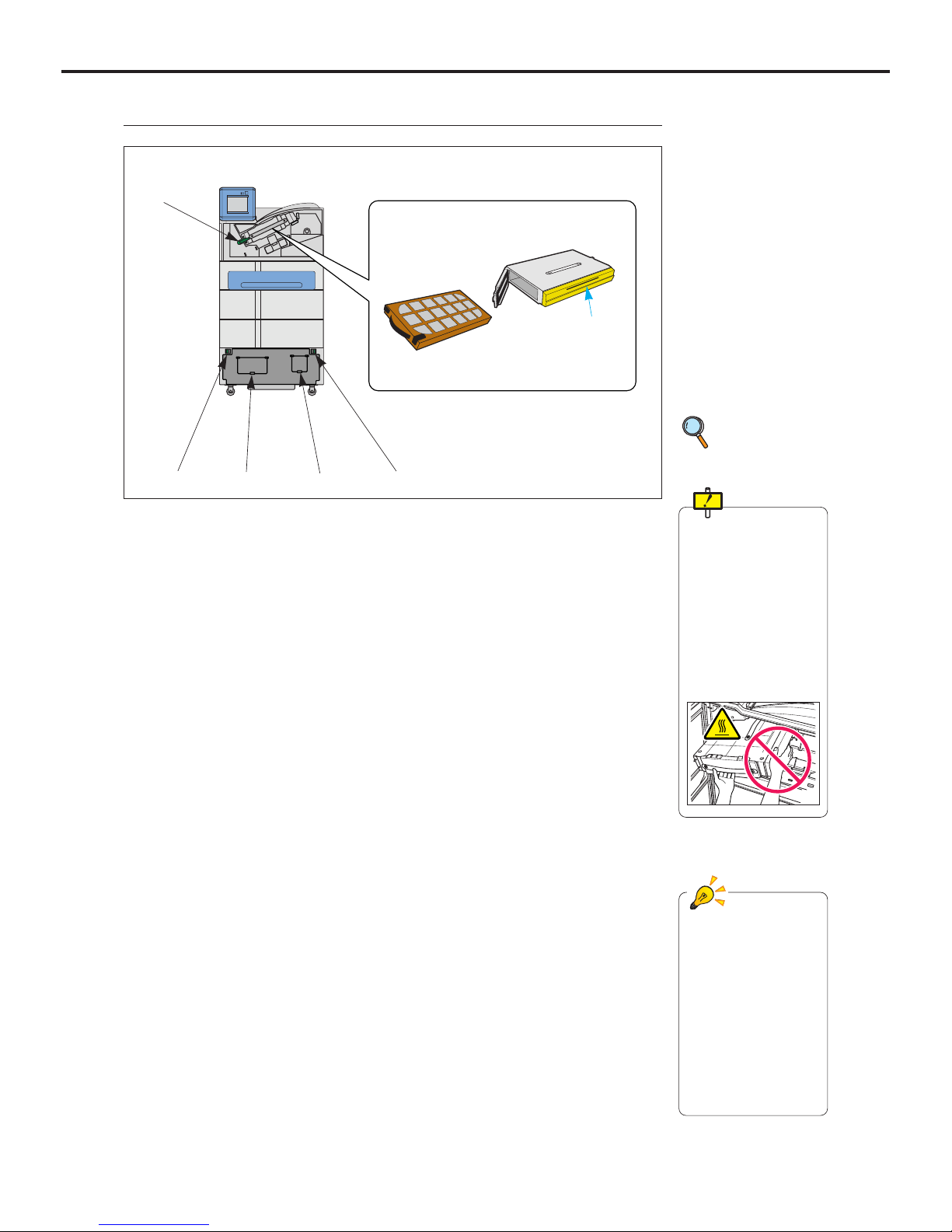

2-1-4 Main Unit without Outer Covers

p.128 Resolving

the Film Jam

Be careful not to touch

the Deodorant filter

Housing (yellow) when

pulling out the Deodor-

ant Filter Case.

Deodorant Filter Hous-

ing is heated above

100:, and touching it

may cause burn.

1) Lever-A (green)

Locks the Deodorant Filter Case.

2) Lever-B (green)

Unlock this lever when opening the Left

Cover.

3) Lever-C (green)

Unlock this lever when opening the

Right Cover.

4) Cover-B

When a film jam occurs in the path

between the Descent Transport unit and

the Justification unit, open this cover to

send the jammed film to the Descent

Transport unit.

5) Cover-C

When a film jam occurs in the path

between the Justification unit and the

Elevator Transport unit , open this cover

to send the jammed film to the Elevator

Transport unit.

6) Deodorant Filter

Removes the odor that is generated

during Heat Processing. It is necessary

to regularly change the Deodorant Filter.

7) Deodorant Filter Case

Contains the Deodorant Filter. To

change the Deodorant Filter, open the

cover for the Deodorant Filter Case.

When a film jam occurs in the HPRO ~

Film Discharge unit, remove the

Deodorant Filter Case to take the

jammed film out.

7) Deodorant Filter Case

6) Deodorant Filter

1) Lever-A

Housing (yellow)

2) Lever-B 3) Lever-C

4) Cover-B 5) Cover-C

Levers and knobs in the

DRYPRO 793 are

painted in different col-

ors depending on the

purpose of use.

Blue : For mainte-

nance and

inspection

Green : For removal of

jam films.

Ch.2 Product Outline

< 23 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

1) Supply 2, 3 Tray

(2nd, 3rd tray)

Load the film.

2-1-5 Options

1) Supply 3 Tray

1. Supply 2, 3 Tray

1) Lis-793

Printed films are output to five bins of

the sorter and to the Film Exit Tray

depending on the setup.

2) Sorter Cover

When a film jam occurs in the Sorter

Transport unit, open this cover to

remove the jammed film.

1) Lis-793

2) Sorter Cover

2. Lis-793

1) Supply 2 Tray

Ch.2 Product Outline

< 24 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

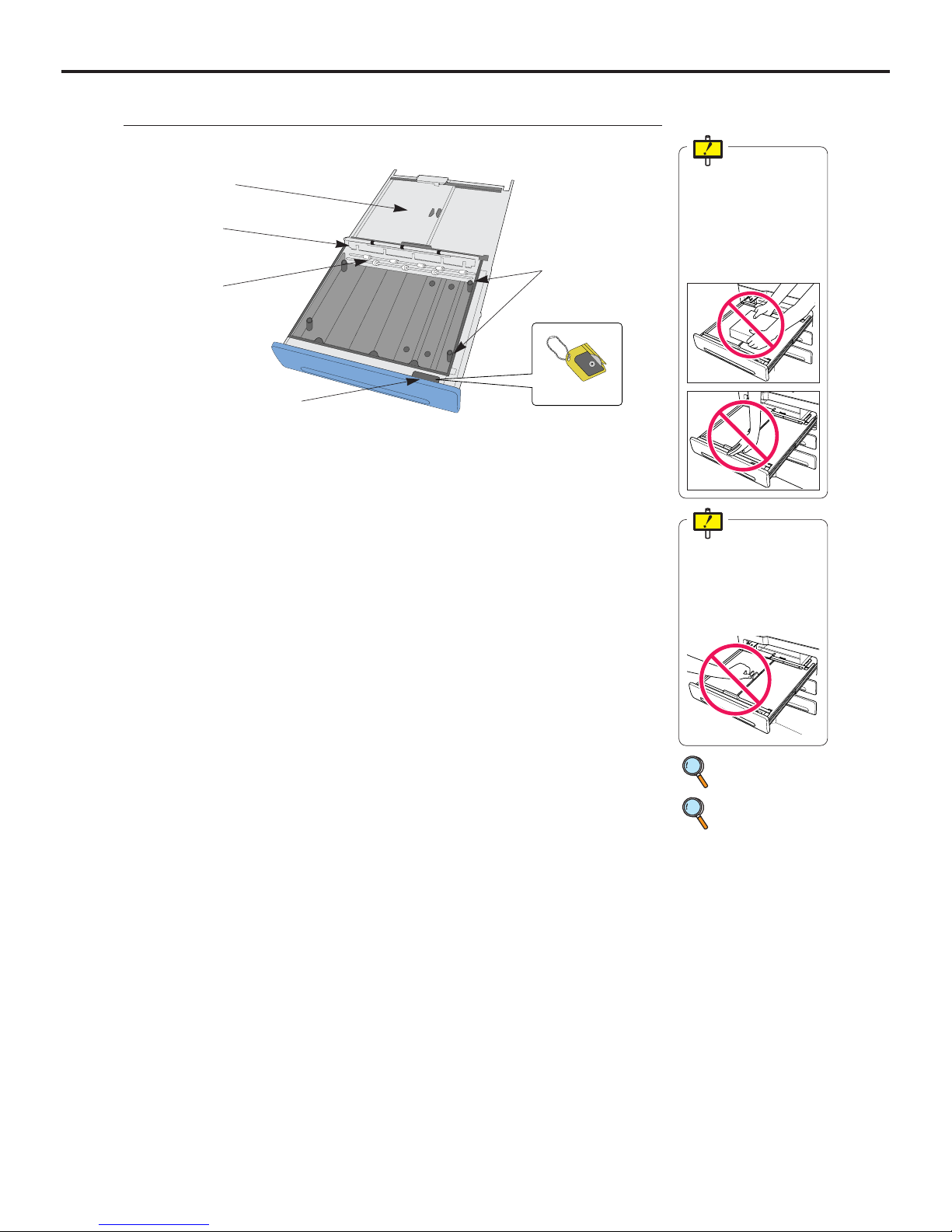

1) Shutter

2) Holding Plate

3) Winding Shaft

4) Cutter Pocket

5) Cutter

2-1-6 Supply Tray & Cutter

1) Shutter

Protect the film from being exposed to

the external light.

2) Holding Plate

Press and hold the edge of the film

package when loading the film.

3) Winding Shaft

Wind the film package when it is loaded.

Next time when a new film package is

loaded, unwind and remove the previous film package before the new film

package is loaded.

4) Cutter Pocket

Holds the cutter.

5) Cutter

Use this cutter to cut the film package

when it is newly loaded.

6) Side Stopper

Replace the position of Side Stoppers

when the film size is changed.

p.35 Film Loading

Do not place anything

or lean on the Supply

Tray when it is pulled

out from the DRYPRO

793. It may cause damage to the device.

Do not touch the shutter knob, otherwise it

may cause an accidental exposure of the film.

p.42 Changing the

Film Size and

Film Type

6) Side Stoppers

Ch.2 Product Outline

< 25 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

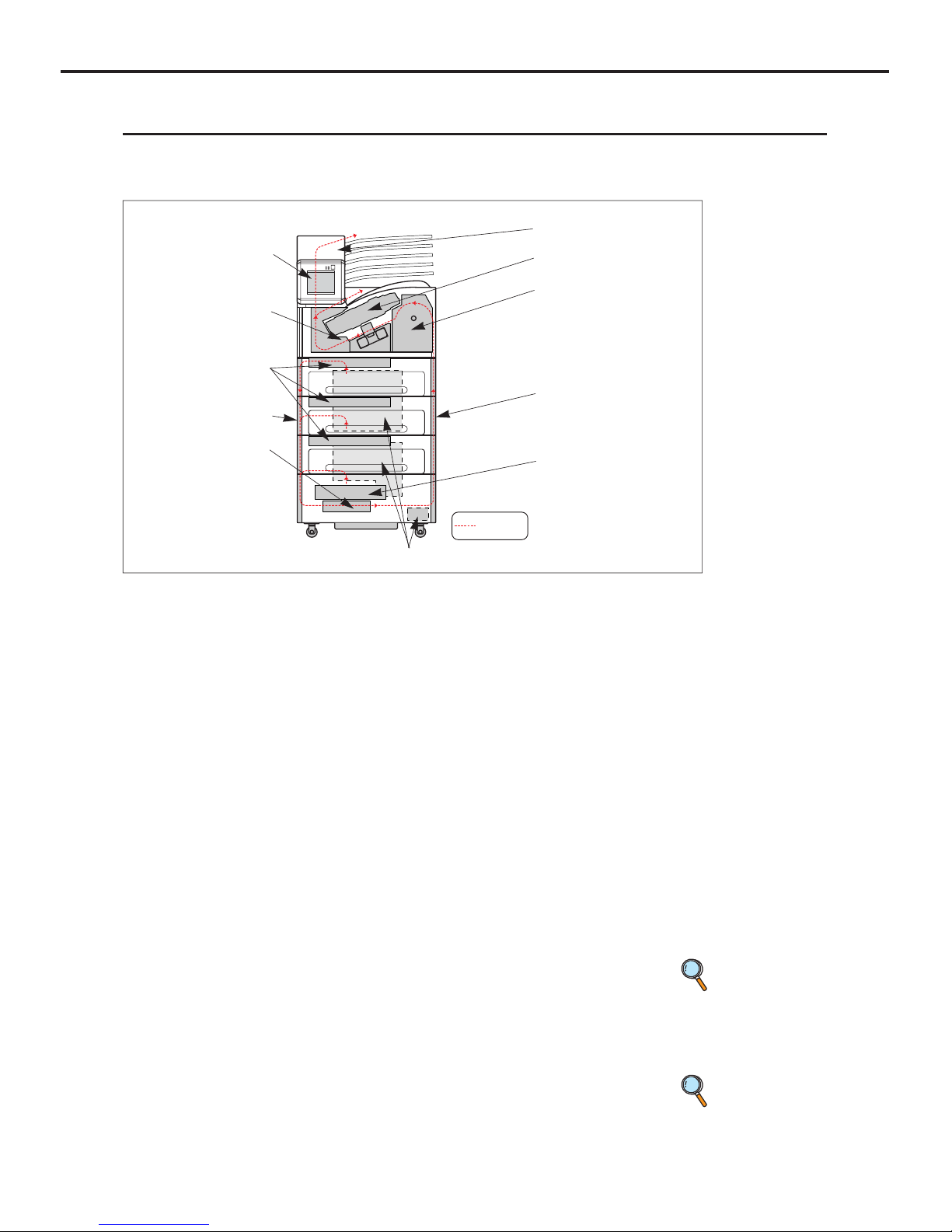

2-2 Internal Structure

Internal structure of the DRYPRO 793 is outlined below.

A film is transported from 1) through 7) in sequence in print process.

1) Supply Unit (available to each Supply Tray)

Picks up films in the Supply Tray unit one by one, and sends it to the Descent Transport unit.

2) Descent Transport Unit

Sends a film picked up at the Supply unit to the Justification unit.

3) Justification Unit

Aligns the right and left edge of the film sent from the Descent Transport unit, and

sends to the Exposure unit.

4) Exposure Unit (a: Sub-Scan Unit, b: Main Scan Unit)

Performs a laser scanning in synchronization with the film transport and prints an

image on the film.

5) Elevator Transport Unit

Sends the film to the HPRO (Heat Processing) unit after the exposure.

6) HPRO Unit

Processes the exposed film by heating.

7) Cooling/Discharge Unit

Cools the heat-processed film and discharges it.

8) Deodorant Filter

Removes the odor generated in heat processing. It is necessary to regularly change

the Deodorant Filter.

9) Electrical Components Unit

Consists of the power supply unit for supplying the power to the device and the control

unit for controlling the entire device, communicating with the diagnostic devices, and

processing / controlling images.

10) Operation Panel

Operates and makes settings of the DRYPRO 793.

11) Lis-793 (option)

Discharges the film discharged from the main body into the specified bin.

Film Pass

1) Supply Unit

2) Descent Transport

Unit

4) Exposure Unit

5) Elevator Transport

6) H-PRO Unit

7) Cooling/Discharge

Unit

8) Deodorant Filter

9) Electrical Unit (rear)

10) Operation Panel

p.19 Operation

Panel

p.142

Replacement

of Deodorant

Filter

3) Justification Unit

11) Lis-793

Ch.2 Product Outline

< 26 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

< 27 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

Operation

3

Chap.

How to operate the DRYPRO 793 is detailed in

this chapter.

Ch.3 Operation

< 28 >

DRYPRO Vstage MODEL 793 Operation Manual Ver.1.01 2005.1

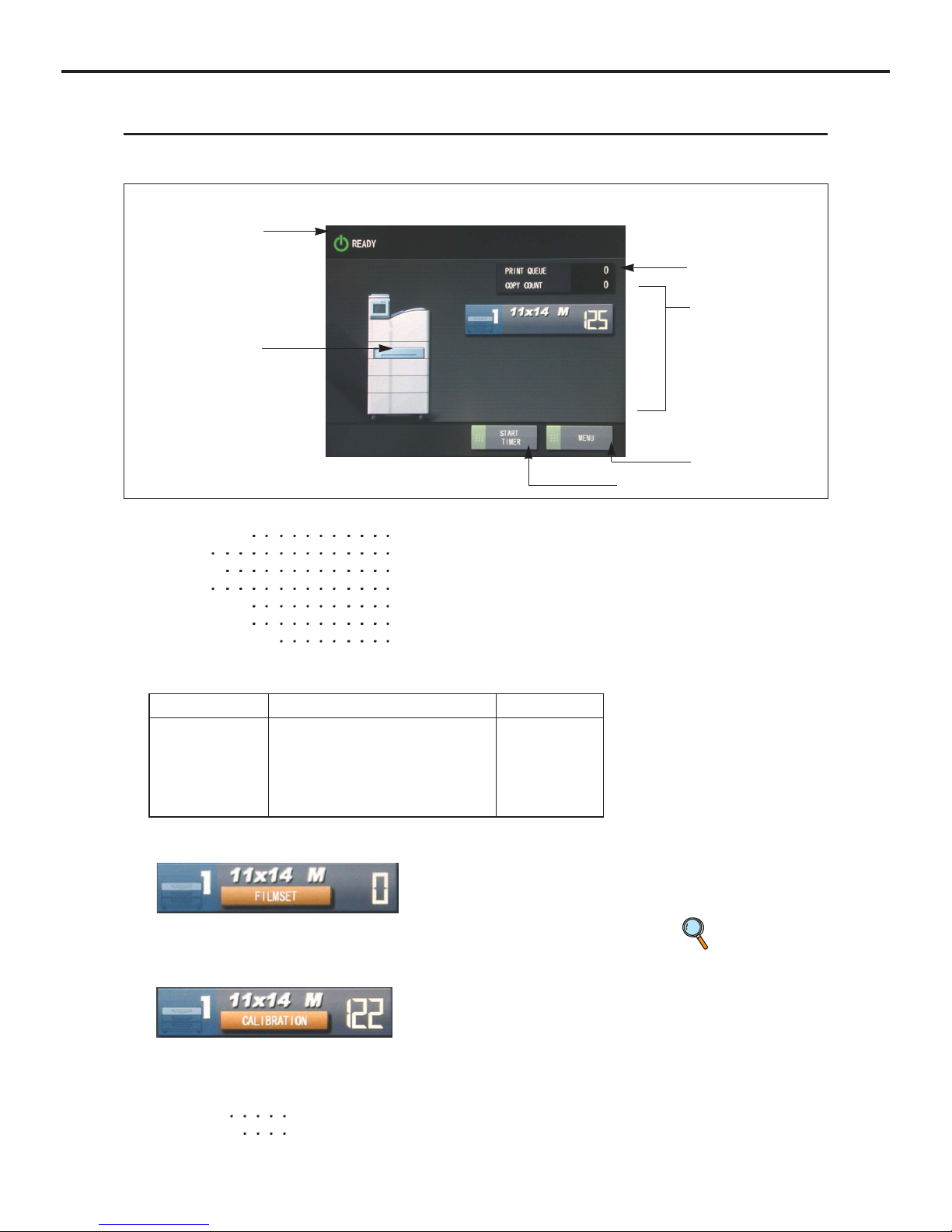

3-1 Operation Panel

The operation, control and settings of this device can be made by using the control panel located on the main unit.

The following shows the operating procedures.

1) Message Column

3) Job Info.

2) Loaded Film Info.

4) Status Info.

6) [Menu] Button

5) [Start Timer] Button

1) Message Column : Displays the status of the DRYPRO 793.

Warming Up

Warming up

Ready

Ready for print

Printing

In printing process

Error

Error occurred

Error Reset

Error in reset process

Maintenance

Servicing in Maintenance Mode

Web User Busy

Accessed by Web user

2) Displays film type, size, number of remaining films in the Tray 1, 2, 3.

Display changes as follows when the film is empty.

Touching the area where "Film Set" is displayed initiates the film loading sequence.

Display changes as follows when the density calibration is required.

(Note : depending on the calibration settings)

Touching the area where "Calibration" is displayed initiates the automatic density

calibration.

3) Job Info. : Copy Count at present waiting for printout.

Queues

The number of jobs waiting for printout.

Print Count

Count of jobs in printing and unprinted.

p.35 FILM

LOADING

Size Film Type Remaining

14x17 B (blue) SD-P) 0-126

14x14 C (clear) (SD-PC)

11x14 M (mammo) (SD-PM)

10x12

8x10

Loading...

Loading...