Komatsu PC490-11, PC490LC-11 Operation Manual

Operation &

Maintenance Manual

UENAM01105

PC490

PC490LC

HYDRAULIC EXCAVATOR

SERIAL NUMBERS

PC490-11 - 85006

-11

-11

and up

PC490LC-11 - 85006

PC490-11 - K70001

PC490LC-11 - K70001

WARNING

Unsafe use of this machine may cause serious injury or

death. Operators and maintenance personnel must read

this manual before operating or maintaining this

machine. This manual should be kept inside the cab for

reference and periodically reviewed by all personnel who

will come into contact with the machine.

and up

and up

and up

ORIGINAL INSTRUCTIONS

FOREWORD

Komatsu recommends that any service parts used for maintenance, repair or

replacement of emission control systems be genuine new Komatsu or Komatsu approved rebuilt parts or assemblies or others parts of equivalent

quality, and that the engine be serviced by an authorized Komatsu distributor. Failure to follow these recommendations could result in ineffective service, damage to the product or safety risks (including personal injury or

death).

1-1

READ THIS MANUAL FOREWORD

READ THIS MANUAL

This manual gives details of the operation and methods of inspection and maintenance for this machine that

must be obeyed in order to use the machine safely. Most accidents are caused by the failure to follow fundamental safety rules for the operation and maintenance of machines.

Read, understand and follow all precautions and warnings in this manual and on the machine before performing

operation and maintenance. Failure to do so may result in serious injury or death.

Komatsu cannot predict every circumstance that might involve a potential hazard when the machine is used.

Therefore, the safety messages in this manual and on the machine may not include all possible safety precautions.

If you perform any operation, inspection, or maintenance under conditions that are not described in this manual,

understand that it is your responsibility to take the necessary precautions to ensure safety. In no event should

you or others engage in the prohibited uses or actions described in this manual. It is dangerous to perform improper operation and maintenance of the machine. It may cause serious injury or death.

If you sell the machine, be sure to give this manual to the new owner together with the machine.

Always keep this Operation and Maintenance Manual in the indicated location so that all relevant personnel can

read it at any time.

Keep it in the magazine box on the left side of the operator's

seat.

If this manual is lost or damaged, contact Komatsu or your Komatsu distributor and tell them about the machine

model name and the serial No. immediately to arrange for its replacement.

For details regarding the machine model name and the serial No., see the machine serial No. plate. In order to

arrange the proper Operation and Maintenance Manual, you will need to provide the machine model name and

the serial No.

This manual uses the International System of Units (SI) for units of measurement. For reference, units that have

been used in the past are given in { }.

The explanations, values, and illustrations in this manual have been prepared based on the latest information

available as of the date of its publication. Continuing improvements in the design of this machine may lead to

additional changes that are not reflected in this manual. If there is any question or suggestion, consult your Komatsu distributor.

The numbers in the illustrations correspond to the numbers in ( ) in the text. (Example: 1 → (1))

Komatsu delivers machines that comply with all applicable regulations and standards of the country to which it

has been shipped. If this machine has been purchased in another country, it may lack certain safety devices and

specifications that are necessary for use in your country. If there is any question about whether your product

complies with the applicable standards and regulations of your country, consult your Komatsu distributor before

operating the machine.

1-2

FOREWORD SAFETY INFORMATION

SAFETY INFORMATION

To enable you to use the machine safely, and to prevent personal injury to operators, service personnel or bystanders, the precautions and warnings included in this manual and the safety signs attached to the machine

must always be observed.

To identify important safety messages in the manual and on the machine labels, the following signal words are

used.

The "Safety Alert Symbol" identifies important safety messages on machines, in manuals, and elsewhere. When

you see this symbol, be alert to the risk of personal injury or death. Follow the instructions in the safety message.

This signal word indicates an imminently hazardous situation which, if not avoided, will result

in death or serious injury.

This signal word indicates a potentially hazardous situation which, if not avoided, could result

in death or serious injury.

This signal word indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury. It may also be used to alert against unsafe practices that may

cause property damage.

The following signal words are used to alert you to information that must be followed to avoid damage to the

machine.

If precautions described are not observed, the machine may be damaged or the service life

may be reduced.

This word is used for information that is useful to know.

1-3

SAFETY LABELS FOREWORD

SAFETY LABELS

Safety labels are affixed to the machine to inform the operator or maintenance worker on the spot when carrying

out operation or maintenance of the machine that may involve hazard.

This machine uses "Safety labels using pictograms" to indicate safety procedures.

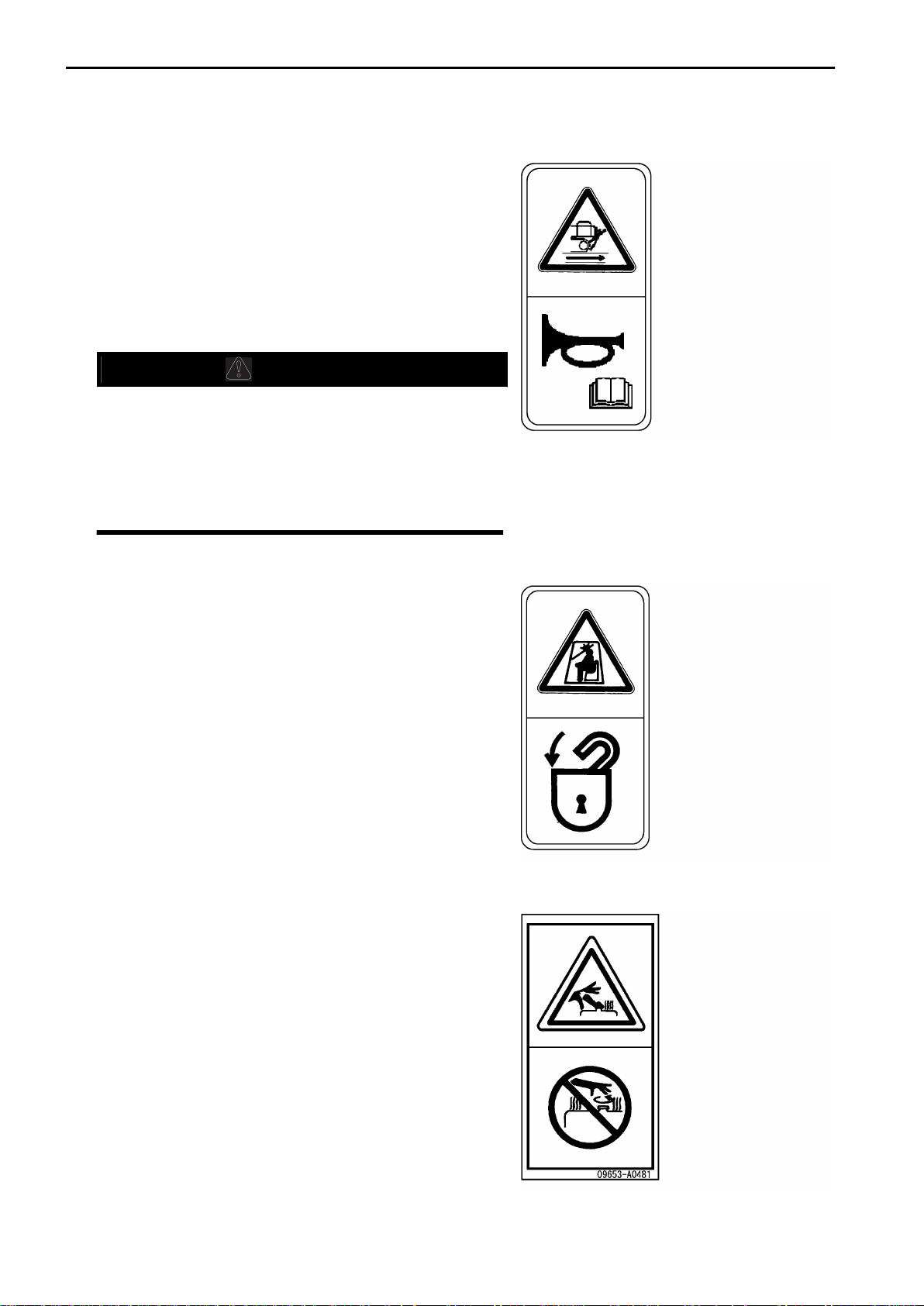

SAFETY LABELS USING PICTOGRAMS

Safety pictograms use a picture to express a level of hazardous

condition equivalent to the signal word. These safety pictograms use pictures in order to let the operator or maintenance

worker understand the level and type of hazardous condition at

all times. Safety pictograms show the type of hazardous condition at the top or left side and the method of avoiding the hazardous condition at the bottom or right side. In addition, the

type of hazardous condition is displayed inside a triangle and

the method of avoiding the hazardous condition is shown inside

a circle.

Komatsu cannot predict every circumstance that might involve

a potential hazard in operation and maintenance. Therefore,

the safety messages in this manual and on the machine may

not include all possible safety precautions.

If any procedures or actions not specifically recommended or

allowed in this manual are used, it is your responsibility to take

the necessary steps to ensure safety

In no event should you engage in prohibited uses or actions described in this manual.

The explanations, values, and illustrations in this manual were prepared based on the latest information available at that time. Continuing improvements in the design of this machine can lead to changes in detail which may

not be reflected in this manual

Consult Komatsu or your Komatsu distributor for the latest available information of your machine or for questions regarding information in this manual.

The numbers in the illustrations correspond to the numbers in ( ) in the text.

1-4

107

FOREWORD NOISE

NOISE

Two labels indicating the machine noise level are affixed on the machine.

• Sound pressure level at the operator’s station, measured

according to ISO 6396 (Dynamic test method, simulated

working cycle).

The maximum value of the standard deviation of the measured time-averaged A-weighted emission sound pressure

level at the operator’s position is 2.5dB, in accordance with

ISO 11201

• Sound power level emitted by the machine, measured according to ISO 6395 (Dynamic test method, simulated

working cycle). This is the guaranteed value as specified in

European directive 2000/14/EC.

This value includes an uncertainty of 0.7 dB.

1-5

VIBRATION LEVELS FOREWORD

VIBRATION LEVELS

When used for its intended purpose, levels of vibration for the earth-moving machine transmitted from the operator's seat are lower than or equal to the tested vibrations for the relative machinery class in compliance with

ISO 7096.

For PC490-11, PC490LC-11

The actual acceleration value for the hands and arms is less than or equal to 2.5 m/s2 , the uncertainty for this

value is 0.25 m/s2 according to EN12096:1997.

The actual acceleration value for the body is less than or equal to 0.5 m/s2, the uncertainty for this value is 0.10

m/s2 according to EN12096:1997.

These values were determined using a representative machine and measured during the typical operating con-

dition indicated below according to the measurement procedures that are defined in the standards ISO 2631/1

and ISO 5349.

VIBRATION - OPERATING CONDITION

Excavating (Digging-loading-rotating-unloading-rotating)

GUIDE TO REDUCE VIBRATION LEVELS ON MACHINE

The following guides can help an operator of this machine to reduce the whole body vibration levels:

1.

Use the correct equipment and attachments.

2.

Maintain the machine according to this manual

• Tension of crawler (for crawler machines)

• Brake and steering systems

• Controls, hydraulic system and linkages

3.

Keep the terrain where the machine is working and travelling in good condition

• Remove any large rocks or obstacles

• Fill any ditches and holes

• Site manager should provide machine operators with machine and schedule time to maintain terrain

conditions

4.

Use a seat that meets ISO 7096 and keep the seat maintained and adjusted

• Adjust the seat and suspension for the weight and size of the operator

• Wear seat belt

• Inspect and maintain the seat suspension and adjustment mechanisms

5.

Steer, brake, accelerate, and move the attachment levers and pedals slowly so that the machine moves

smoothly

6.

Adjust the machine speed and travel path to minimize the vibration level

• When pushing with bucket or blade, avoid sudden loading; load gradually

• Drive around obstacles and rough terrain conditions

• Slow down when it is necessary to go over rough terrain

• Make the curve radius of travelling path as large as possible

• Travel at low speed when travelling around sharp curves

7.

Minimize vibrations for long work cycle or long distance travelling

• Reduce speed to prevent bounce

• Transport machines long distances between worksites

8.

The following guidelines can be effective to minimize risks of low back pain

• Operate the machine only when you are in good health

• Provide breaks to reduce long periods of sitting in the same posture

1-6

FOREWORD VIBRATION LEVELS

• Do not jump down from the cab or machine

• Do not repeatedly handle and lift loads

1-7

kk

INTRODUCTION FOREWORD

INTRODUCTION

MAIN USE OF MACHINE

This Komatsu machine is designed to be used mainly for the following work:

• Digging work

• Ditching work

• Loading work

• Levelling work

For details of work procedure, see MACHINE OPERATIONS AND CONTROLS “RECOMMENDED APPLICATIONS (3-205)”.

DEMOLITION WORK

WARNING

• A demolition machine is a machine based on earth

moving machinery (see EN ISO 6165) and including

equipment and attachment (working tool - e.g. processor or breaker) specifically designed to demolish,

cut, loosen, separate, pick up, transport and distribute

component parts of buildings or civil engineering

structures.

• This machine is not prepared for use in Demolition.

• Using this machine in demolition work gives an increased risk of serious injury or death.

• All Komatsu machines that are specifically designed,

and can be used for demolition work, will display the

Komatsu demolition decal.

• If the machine does not display this decal and it is

necessary to carry out demolition work, contact your

distributor for information on demolition machinery compliant with the applicable standards.

DIRECTIONS OF MACHINE

(A) Front

(B) Rear

1-8

(C) Left

(D) Right

FOREWORD INTRODUCTION

(E) Operator's seat (F) Sprocket

In this manual, the terms front, rear, left, and right refer to the travel direction as seen from the operator's seat

when the operator's seat is facing the front and the sprocket is at the rear of the machine.

VISIBILITY FROM OPERATOR'S SEAT

This machine complies with the visibility standard (ISO 5006).

This machine maintains a proximity visibility of a height of 1.5m at a point 1m away from the outside surface of

the machine and a visibility for a radius of 12m.

Protective structures

This machine is equipped with a structure to protect the operator (ROPS) conforming to ISO12117-2.

1-9

ENGINE TECHNOLOGY TO CONFORM EXHAUST GAS EMISSION FOREWORD

ENGINE TECHNOLOGY TO CONFORM EXHAUST GAS EMISSION

About Engine Technology

This engine technology combines a Komatsu Diesel Particulate Filter (KDPF) and Komatsu’s Urea Selective

Catalytic Reduction (SCR) to conform EU Stage IV emission regulation in the European Union.

• Komatsu Diesel Particulate Filter (KDPF): A device which captures diesel particular matter or soot in the

exhaust gas to purify exhaust gas. If soot is accumulated to a certain level in the filter, a purification process

to burn the soot is performed automatically to keep the filtering performance of KDPF high.

• Komatsu’s Urea SCR system: A device which decomposes the toxic nitrogen oxides (NOx) mixed in the

exhaust gas into harmless nitrogen and water. Spraying the reagent (Diesel Exhaust Fluid) into the exhaust

gas produces a reaction between the nitrogen oxides and ammonia generated from the urea solution and

decomposes the nitrogen oxides into nitrogen and water.

About Diesel Exhaust Fluid (DEF)

Diesel Exhaust Fluid is the reagent for the SCR system.

DEF is the abbreviation for Diesel Exhaust Fluid, and is represented as DEF throughout this manual.

DEF is a colorless transparent and aqueous urea solution made with 32.5 % urea (AUS32) and 67.5 % deion-

ized water. Urea as main constituent is a material which is used for cosmetics, medical and pharmaceutical

products, and fertilizer, etc.

Commercial DEF, commonly referred to as AdBlue® in the European Union, that quality standards are maintained in accordance with DIN70070 and ISO 22241-1, to be used.

AdBlue® is a registered trade-mark of VDA (Verband der Automobilindustrie e.V.: Automobile Association of

Germany).

1-10

FOREWORD PRODUCT INFORMATION

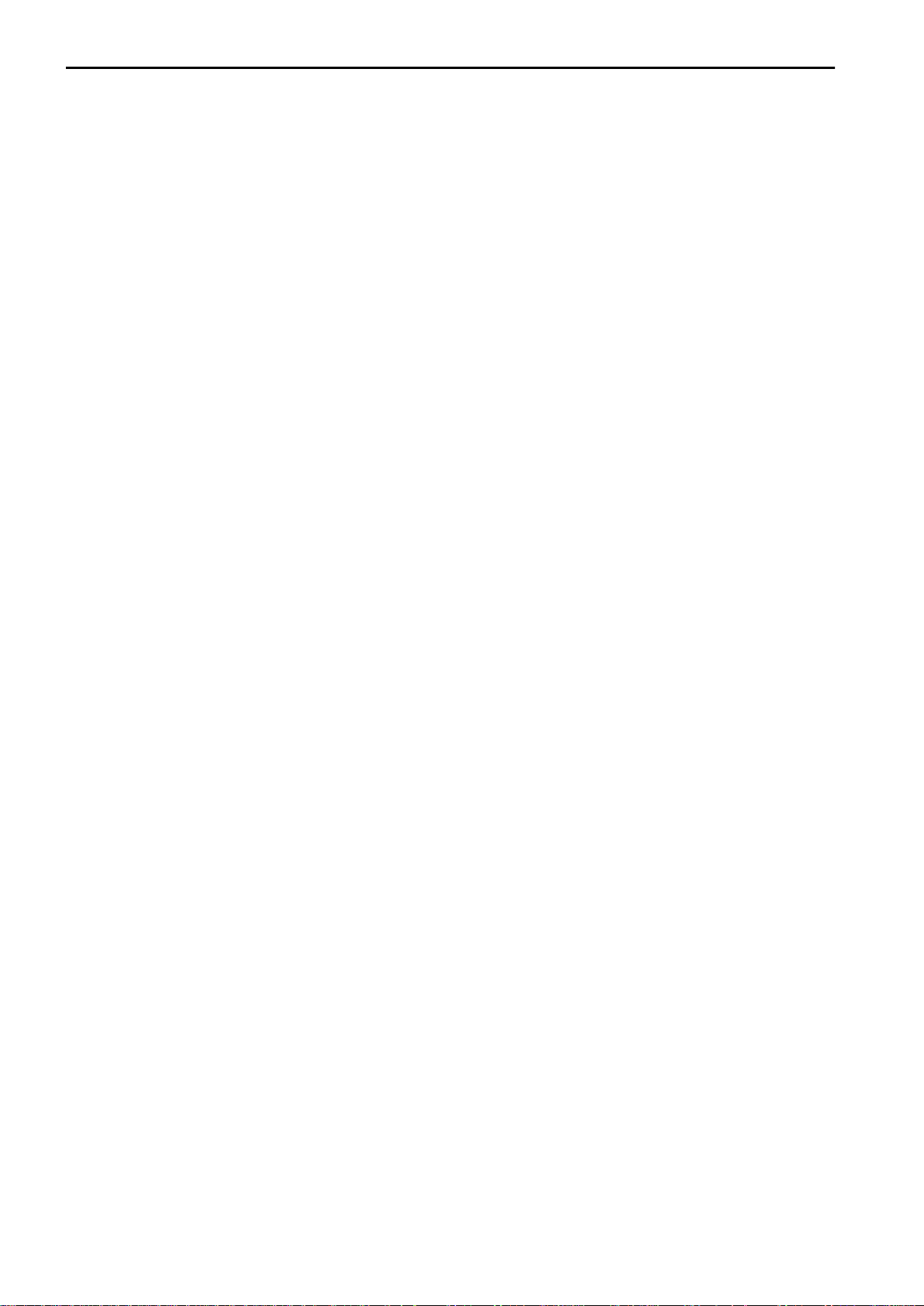

PRODUCT INFORMATION

When requesting service or ordering replacement parts, inform your Komatsu distributor of the following items.

LOCATION OF PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE

It is located on the right bottom of the operator's cab.

The design of the nameplate differs according to the district.

LOCATION OF ENGINE NUMBER PLATE

It is located on top of the engine cylinder head cover.

1-11

PRODUCT INFORMATION FOREWORD

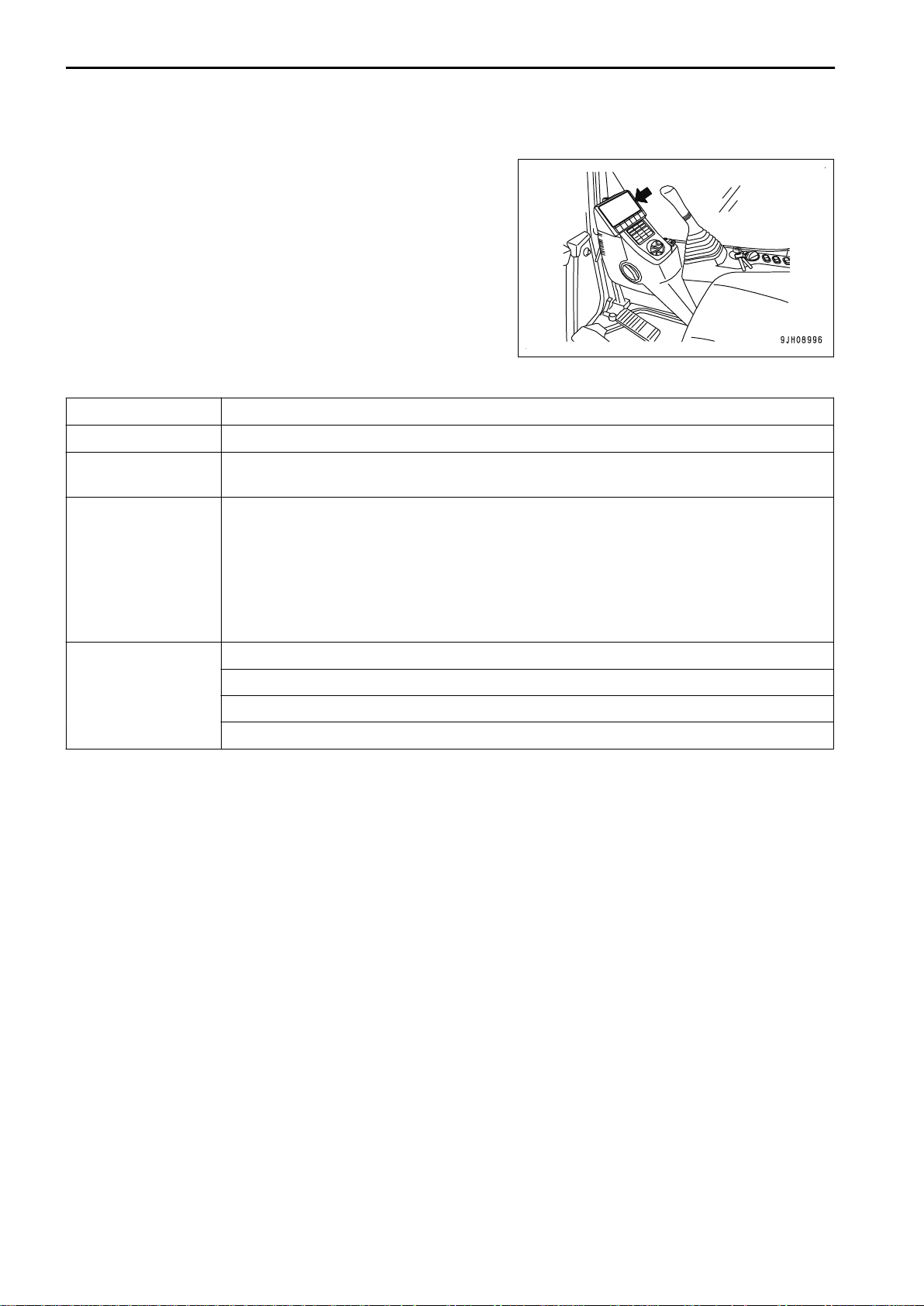

SERVICE METER LOCATION

This is displayed on the machine monitor.

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR

Machine serial No.

Engine serial No.

Product identification

number (PIN)

Manufacturers name:

Address:

Distributor name

Address

Service Personnel

Phone/Fax

KOMATSU UK Ltd

Durham Road

Birtley

Chester-le-Street

County Durham DH3 2QX

United Kingdom

1-12

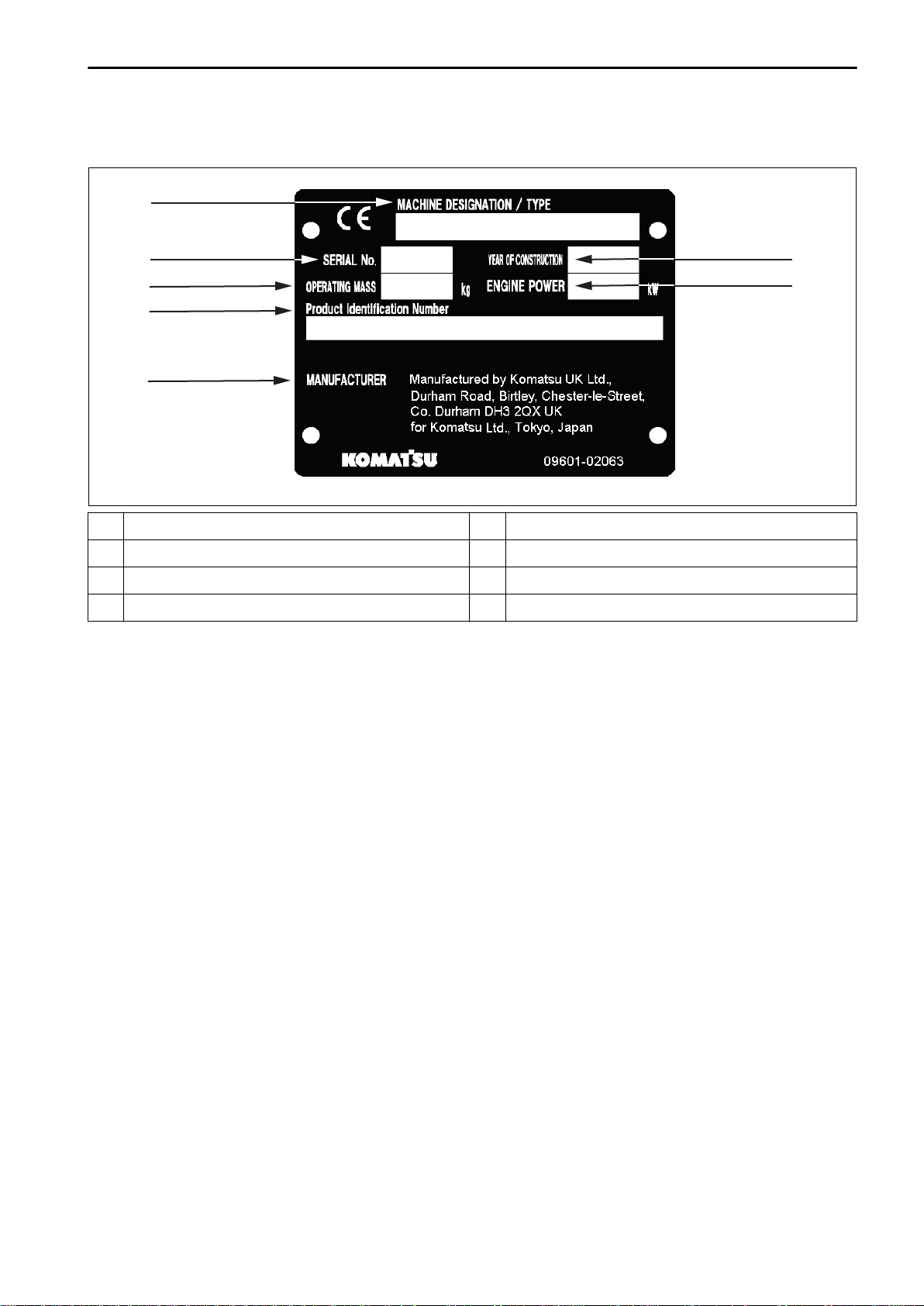

KS000853

A

B

D

F

G

C

E

FOREWORD SERIAL PLATE

SERIAL PLATE

A MACHINE DESIGNATION/TYPE E ENGINE POWER

B SERIAL NUMBER F PRODUCT IDENTIFICATION NUMBER

C YEAR OF CONSTRUCTION G MANUFACTURER

D WEIGHT

1-13

DECLARATION OF CONFORMITY FOREWORD

DECLARATION OF CONFORMITY

The manufacturer:

KOMATSU UK Ltd

Durham Road

Birtley

Chester-le-Street

County Durham DH3 2QX

Declares that this machine:

PC490-11

PC490LC-11

Fulfils all the relevant provisions of following EC Directives:

Machine Directive

Electro Magnetic Compatibility Directive 2004/108/EC until 19 April 2016

Outdoor Noise Directive 2000/14/EC amended by 2005/88/EC

Radio Equipment and Telecommunications

Terminal Equipment Directive

Radio Equipment Directive 2014/53/EU after 13 June 2016

2006/42/EC

2014/30/EU after 20 April 2016

1999/5/EC until 12 June 2016

1-14

FOREWORD TABLE OF CONTENTS

TABLE OF CONTENTS

FOREWORD.................................................................................................................................................... 1-1

READ THIS MANUAL............................................................................................................................... 1-2

SAFETY INFORMATION .......................................................................................................................... 1-3

SAFETY LABELS ..................................................................................................................................... 1-4

NOISE....................................................................................................................................................... 1-5

VIBRATION LEVELS ................................................................................................................................ 1-6

VIBRATION - OPERATING CONDITION ........................................................................................... 1-6

GUIDE TO REDUCE VIBRATION LEVELS ON MACHINE ................................................................ 1-6

INTRODUCTION ...................................................................................................................................... 1-8

MAIN USE OF MACHINE .................................................................................................................. 1-8

DEMOLITION WORK......................................................................................................................... 1-8

DIRECTIONS OF MACHINE.............................................................................................................. 1-8

VISIBILITY FROM OPERATOR'S SEAT ............................................................................................ 1-9

ENGINE TECHNOLOGY TO CONFORM EXHAUST GAS EMISSION................................................... 1-10

PRODUCT INFORMATION......................................................................................................................1-11

LOCATION OF PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE .......1-11

LOCATION OF ENGINE NUMBER PLATE .......................................................................................1-11

SERVICE METER LOCATION ......................................................................................................... 1-12

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR............................................................ 1-12

SERIAL PLATE ....................................................................................................................................... 1-13

DECLARATION OF CONFORMITY ........................................................................................................ 1-14

SAFETY........................................................................................................................................................... 2-1

SAFETY.................................................................................................................................................... 2-2

SAFETY LABELS ..................................................................................................................................... 2-4

LOCATION OF SAFETY LABELS...................................................................................................... 2-5

CONTENTS OF SAFETY LABELS .................................................................................................... 2-7

GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE .................................... 2-18

PRECAUTIONS BEFORE STARTING OPERATION........................................................................ 2-18

PREPARATIONS FOR SAFE OPERATION ..................................................................................... 2-18

PRECAUTIONS TO PREVENT FIRE............................................................................................... 2-19

PRECAUTIONS WHEN GETTING ON OR OFF MACHINE............................................................. 2-21

DO NOT GET CAUGHT IN WORK EQUIPMENT ............................................................................ 2-23

PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES........................................................ 2-23

PROTECTION AGAINST FALLING, FLYING OR INTRUDING OBJECTS....................................... 2-24

ACTIONS IN THE EVENT OF DAMAGE TO SAFETY STRUCTURES............................................ 2-24

UNAUTHORIZED MODIFICATION .................................................................................................. 2-24

PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS.................................................... 2-24

PRECAUTIONS RELATED TO CAB GLASS ................................................................................... 2-25

PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING..................................................... 2-25

PRECAUTIONS FOR OPERATION ........................................................................................................ 2-26

PRECAUTIONS FOR JOBSITE....................................................................................................... 2-26

START ENGINE............................................................................................................................... 2-30

PRECAUTIONS FOR OPERATION ................................................................................................. 2-32

PRECAUTIONS FOR TRANSPORTATION...................................................................................... 2-38

TOWING AND BEING TOWED........................................................................................................ 2-39

LIFTING OPERATIONS ................................................................................................................... 2-39

PRECAUTIONS FOR MAINTENANCE................................................................................................... 2-41

PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE ................................... 2-41

PRECAUTIONS FOR CHECK AND MAINTENANCE ...................................................................... 2-44

PRECAUTIONS FOR DEF...................................................................................................................... 2-51

GENERAL CHARACTER AND PRECAUTIONS FOR HANDLING .................................................. 2-51

PRECAUTIONS FOR ADDING........................................................................................................ 2-51

SAFETY RULES FOR STORAGE ................................................................................................... 2-51

PRECAUTIONS FOR FIRE HAZARD AND LEAKAGE .................................................................... 2-51

OTHER PRECAUTIONS.................................................................................................................. 2-51

OPERATION.................................................................................................................................................... 3-1

1-15

TABLE OF CONTENTS FOREWORD

GENERAL VIEW....................................................................................................................................... 3-2

MACHINE EQUIPMENT NAME ......................................................................................................... 3-2

CAB EQUIPMENT NAMES................................................................................................................ 3-4

CONTROLS AND GAUGES NAMES................................................................................................. 3-5

EXPLANATION OF COMPONENTS......................................................................................................... 3-9

EXPLANATION OF MACHINE MONITOR EQUIPMENT ................................................................... 3-9

SWITCHES...................................................................................................................................... 3-90

CONTROL LEVERS AND PEDALS................................................................................................. 3-98

OTHER EQUIPMENT .................................................................................................................... 3-101

MACHINE OPERATIONS AND CONTROLS ........................................................................................ 3-144

CHECKS AND ADJUSTMENT BEFORE STARTING ENGINE ...................................................... 3-144

METHOD FOR STARTING ENGINE.............................................................................................. 3-173

METHOD FOR OPERATIONS AND CHECKS AFTER STARTING ENGINE ................................. 3-176

METHOD FOR STOPPING ENGINE ............................................................................................. 3-186

METHOD FOR STARTING MACHINE (TRAVEL FORWARD AND REVERSE) AND STOPPING MA-

CHINE........................................................................................................................................ 3-189

METHOD FOR STEERING MACHINE........................................................................................... 3-192

METHOD FOR SWINGING MACHINE .......................................................................................... 3-193

METHOD FOR OPERATING WORK EQUIPMENT ....................................................................... 3-194

HANDLE WORKING MODE .......................................................................................................... 3-195

PROHIBITED OPERATIONS ......................................................................................................... 3-197

PRECAUTIONS FOR OPERATION ............................................................................................... 3-201

PRECAUTIONS FOR WORKING ON SLOPE ............................................................................... 3-203

METHOD FOR ESCAPING FROM MUD ....................................................................................... 3-204

RECOMMENDED APPLICATIONS................................................................................................ 3-205

EFFECTIVE USE OF HYDRAULIC EXCAVATOR.......................................................................... 3-206

METHOD FOR REPLACING AND INVERTING BUCKET.............................................................. 3-207

METHOD FOR PARKING MACHINE............................................................................................. 3-210

METHOD FOR CHECKING AFTER FINISHING WORK................................................................ 3-212

LOCK............................................................................................................................................. 3-212

HANDLE AIR CONDITIONER............................................................................................................... 3-218

EXPLANATION OF AIR CONDITIONER EQUIPMENT.................................................................. 3-219

METHOD FOR OPERATING AIR CONDITIONER......................................................................... 3-223

HANDLING RADIO ............................................................................................................................... 3-231

EXPLANATION OF RADIO EQUIPMENT ...................................................................................... 3-231

METHOD FOR CONTROLLING RADIO ........................................................................................ 3-233

STOW ANTENNA .......................................................................................................................... 3-236

SPACE FOR RADIO CASSETTE................................................................................................... 3-236

TRANSPORTATION.............................................................................................................................. 3-237

PRECAUTIONS FOR TRANSPORTING MACHINE ...................................................................... 3-237

SELECT TRANSPORTATION METHOD........................................................................................ 3-237

LOADING AND UNLOADING WITH TRAILER .............................................................................. 3-238

METHOD FOR LIFTING MACHINE............................................................................................... 3-248

SPREAD AND NARROW TRACK FRAME GAUGE....................................................................... 3-249

COLD WEATHER OPERATION............................................................................................................ 3-252

COLD WEATHER OPERATION INFORMATION ........................................................................... 3-252

PRECAUTIONS AFTER DAILY WORK COMPLETION ................................................................. 3-253

AFTER COLD WEATHER SEASON .............................................................................................. 3-254

PRECAUTIONS FOR LONG-TERM STORAGE ................................................................................... 3-255

PREPARATION FOR LONG-TERM STORAGE............................................................................. 3-255

MAINTENANCE DURING LONG-TERM STORAGE...................................................................... 3-255

STARTING MACHINE AFTER LONG-TERM STORAGE............................................................... 3-255

TROUBLES AND ACTIONS ................................................................................................................. 3-257

ACTIONS WHEN RUNNING OUT OF FUEL ................................................................................. 3-257

PHENOMENA THAT ARE NOT FAILURES................................................................................... 3-258

PRECAUTIONS FOR TOWING MACHINE.................................................................................... 3-258

PRECAUTIONS FOR SEVERE JOB CONDITION......................................................................... 3-259

PRECAUTIONS FOR DISCHARGED BATTERY ........................................................................... 3-260

1-16

FOREWORD TABLE OF CONTENTS

OTHER TROUBLE......................................................................................................................... 3-263

MAINTENANCE............................................................................................................................................... 4-1

PRECAUTIONS FOR MAINTENANCE..................................................................................................... 4-2

CHECK SERVICE METER READING ............................................................................................... 4-2

KOMATSU GENUINE REPLACEMENT PARTS ................................................................................ 4-2

KOMATSU GENUINE LUBRICANTS................................................................................................. 4-2

ALWAYS USE CLEAN WASHER FLUID............................................................................................ 4-2

FRESH AND CLEAN LUBRICANTS .................................................................................................. 4-2

CHECK DRAINED OIL AND USED FILTER....................................................................................... 4-2

PRECAUTIONS FOR REFILLING OIL OR FUEL .............................................................................. 4-2

PRECAUTIONS FOR ADDING DEF ................................................................................................. 4-2

WELDING INSTRUCTIONS............................................................................................................... 4-2

DO NOT DROP THINGS INSIDE MACHINE ..................................................................................... 4-2

PRECAUTIONS FOR KDPF .............................................................................................................. 4-2

PRECAUTIONS FOR SCR ASSEMBLY ............................................................................................ 4-3

DUSTY JOBSITES............................................................................................................................. 4-3

AVOID MIXING OIL............................................................................................................................ 4-3

LOCK INSPECTION COVERS .......................................................................................................... 4-3

BLEED AIR FROM HYDRAULIC CIRCUIT ........................................................................................ 4-3

PRECAUTIONS WHEN INSTALLING HYDRAULIC HOSES ............................................................. 4-3

CHECKS AFTER INSPECTION AND MAINTENANCE...................................................................... 4-3

FUEL AND LUBRICANTS TO MATCH THE AMBIENT TEMPERATURE........................................... 4-3

CLOSE ENGINE HOOD SECURELY................................................................................................. 4-4

OUTLINE OF MAINTENANCE.................................................................................................................. 4-5

HANDLE OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC .................................................. 4-5

HANDLE ELECTRICAL COMPONENTS ........................................................................................... 4-9

STANDARD TIGHTENING TORQUE FOR BOLTS AND NUTS .............................................................. 4-10

MAINTENANCE SCHEDULE.................................................................................................................. 4-12

MAINTENANCE SCHEDULE TABLE............................................................................................... 4-12

MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER ............................................................. 4-13

MAINTENANCE PROCEDURE .............................................................................................................. 4-15

WHEN REQUIRED .......................................................................................................................... 4-15

CHECK AUTOMATIC GREASE SYSTEM........................................................................................ 4-41

CHECKS BEFORE STARTING........................................................................................................ 4-43

EVERY 50 HOURS MAINTENANCE ............................................................................................... 4-44

EVERY 250 HOURS MAINTENANCE ............................................................................................. 4-45

EVERY 500 HOURS MAINTENANCE ............................................................................................. 4-48

EVERY 1000 HOURS MAINTENANCE ........................................................................................... 4-58

EVERY 2000 HOURS MAINTENANCE ........................................................................................... 4-65

EVERY 4000 HOURS MAINTENANCE ........................................................................................... 4-75

EVERY 4500 HOURS MAINTENANCE ........................................................................................... 4-78

EVERY 5000 HOURS MAINTENANCE ........................................................................................... 4-78

EVERY 8000 HOURS MAINTENANCE ........................................................................................... 4-80

EVERY 9000 HOURS MAINTENANCE ........................................................................................... 4-80

SPECIFICATIONS ........................................................................................................................................... 5-1

SPECIFICATIONS .................................................................................................................................... 5-2

EXPLANATION OF LIFT CAPACITY CHART (6.7M BOOM).............................................................. 5-4

EXPLANATION OF LIFT CAPACITY CHART (7.1M BOOM).............................................................. 5-7

ATTACHMENTS AND OPTIONS ..................................................................................................................... 6-1

PRECAUTIONS FOR USING ATTACHMENT AND OPTIONS.................................................................. 6-2

PRECAUTIONS WHEN SELECTING ................................................................................................ 6-2

READ THE OPERATION AND MAINTENANCE MANUAL THOROUGHLY....................................... 6-2

PRECAUTIONS WHEN REMOVING AND INSTALLING ................................................................... 6-2

PRECAUTIONS WHEN USING ......................................................................................................... 6-2

QUICK COUPLER SYSTEM..................................................................................................................... 6-4

HANDLING QUICK COUPLER .......................................................................................................... 6-4

AUTOMATIC GREASE SYSTEM .............................................................................................................. 6-7

HANDLING AUTOMATIC GREASE SYSTEM.................................................................................... 6-7

1-17

TABLE OF CONTENTS FOREWORD

DIAGRAM OF AUTOMATIC GREASING POINTS ............................................................................. 6-8

SYSTEM OPERATION ...................................................................................................................... 6-8

CHANGING THE GREASE INTERVAL WITH THE IN-CAB DISPLAY ............................................... 6-8

INDICATION ON THE IN-CAB DISPLAY............................................................................................ 6-9

CHECK AUTOMATIC GREASE SYSTEM........................................................................................ 6-10

HANDLE BUCKET WITH HOOK............................................................................................................. 6-13

PRECAUTIONS FOR OPERATION ................................................................................................. 6-13

HANDLE MACHINE READY FOR INSTALLATION OF ATTACHMENT .................................................. 6-14

EXPLANATION OF COMPONENTS ON MACHINE EQUIPPED WITH ATTACHMENT................... 6-14

METHOD FOR CHANGE-OVER AND CONNECT HYDRAULIC CIRCUIT FOR MACHINE READY

FOR INSTALLATION OF ATTACHMENT...................................................................................... 6-18

METHOD FOR REMOVING AND INSTALLING ATTACHMENT ...................................................... 6-21

METHOD FOR OPERATING ATTACHMENT................................................................................... 6-24

LONG-TERM STORAGE ................................................................................................................. 6-28

MAINTENANCE OF ADDITIONAL FILTER FOR BREAKER............................................................ 6-29

SPECIFICATIONS ........................................................................................................................... 6-32

ARM/PIN INFORMATION ....................................................................................................................... 6-33

ATTACHMENTS AND OPTIONS ............................................................................................................ 6-34

INSTALL ATTACHMENT.................................................................................................................. 6-34

ROCK BUCKET SELECTION .......................................................................................................... 6-35

TOOL CONTROL SYSTEM ............................................................................................................. 6-36

TRACK SHOES SELECTION .......................................................................................................... 6-37

RECOMMENDED ATTACHMENT OPERATIONS................................................................................... 6-39

HYDRAULIC BREAKER .................................................................................................................. 6-39

REPLACEMENT PARTS.................................................................................................................................. 7-1

PERIODIC REPLACEMENT OF DEFINED LIFE PARTS.......................................................................... 7-2

DEFINED LIFE PARTS LIST.............................................................................................................. 7-2

CONSUMABLE PARTS ............................................................................................................................ 7-3

CONSUMABLE PARTS ..................................................................................................................... 7-3

RECOMMENDED FUEL, COOLANT, AND LUBRICANT .......................................................................... 7-5

LUBRICATION CHART...................................................................................................................... 7-5

USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE ........ 7-6

RECOMMENDED BRANDS AND QUALITIES OTHER THAN KOMATSU GENUINE OILS .............. 7-8

INDEX.............................................................................................................................................................. 8-1

1-18

SAFETY

Please read and make sure that you fully understand the precautions described in this manual and the safety labels on the machine. When operating or

servicing the machine, always follow these precautions strictly.

2-1

SAFETY SAFETY

SAFETY

SAFETY LABELS ............................................................................................................................................ 2-4

LOCATION OF SAFETY LABELS............................................................................................................. 2-5

CONTENTS OF SAFETY LABELS ........................................................................................................... 2-7

GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE ........................................... 2-18

PRECAUTIONS BEFORE STARTING OPERATION............................................................................... 2-18

ENSURE SAFE OPERATION .......................................................................................................... 2-18

UNDERSTAND THE MACHINE....................................................................................................... 2-18

PREPARATIONS FOR SAFE OPERATION ............................................................................................ 2-18

PRECAUTIONS FOR SAFETY-RELATED EQUIPMENT ................................................................. 2-18

INSPECT MACHINE........................................................................................................................ 2-18

WEAR WELL-FITTING CLOTHES AND PROTECTIVE EQUIPMENT............................................. 2-18

KEEP MACHINE CLEAN ................................................................................................................. 2-18

PRECAUTIONS FOR INSIDE OPERATOR'S COMPARTMENT ...................................................... 2-19

PROVIDE FIRE EXTINGUISHER AND FIRST AID KIT ................................................................... 2-19

IF ANY PROBLEM IS FOUND ......................................................................................................... 2-19

PRECAUTIONS TO PREVENT FIRE...................................................................................................... 2-19

ACTIONS IF FIRE OCCURS ........................................................................................................... 2-19

PREVENT FIRE............................................................................................................................... 2-20

PRECAUTIONS WHEN GETTING ON OR OFF MACHINE.................................................................... 2-21

USE HANDRAILS AND STEPS WHEN GETTING ON OR OFF MACHINE..................................... 2-21

NO JUMPING ON OR OFF MACHINE............................................................................................. 2-21

LIFTING OF PERSONNEL PROHIBITED........................................................................................ 2-22

NO PEOPLE ON ATTACHMENTS................................................................................................... 2-22

PRECAUTIONS WHEN STANDING UP FROM OPERATOR'S SEAT.............................................. 2-22

PRECAUTIONS WHEN LEAVING MACHINE.................................................................................. 2-22

EMERGENCY EXIT FROM OPERATOR'S CAB.............................................................................. 2-22

ELECTROMAGNETIC INTERFERENCE......................................................................................... 2-23

DO NOT GET CAUGHT IN WORK EQUIPMENT ................................................................................... 2-23

PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES............................................................... 2-23

PROTECTION AGAINST FALLING, FLYING OR INTRUDING OBJECTS.............................................. 2-24

ACTIONS IN THE EVENT OF DAMAGE TO SAFETY STRUCTURES................................................... 2-24

UNAUTHORIZED MODIFICATION ......................................................................................................... 2-24

PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS........................................................... 2-24

PRECAUTIONS RELATED TO CAB GLASS .......................................................................................... 2-25

PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING............................................................ 2-25

PRECAUTIONS FOR OPERATION ............................................................................................................... 2-26

PRECAUTIONS FOR JOBSITE.............................................................................................................. 2-26

INVESTIGATE AND CONFIRM JOBSITE CONDITIONS................................................................. 2-26

PRECAUTIONS WHEN WORKING ON LOOSE GROUND............................................................. 2-26

DO NOT GO CLOSE TO HIGH-VOLTAGE CABLES........................................................................ 2-26

ENSURE GOOD VISIBILITY............................................................................................................ 2-27

CHECK SIGNS AND SIGNALMAN'S SIGNALS............................................................................... 2-29

BEWARE OF ASBESTOS DUST..................................................................................................... 2-30

START ENGINE...................................................................................................................................... 2-30

USE WARNING TAGS ..................................................................................................................... 2-30

CHECKS AND ADJUSTMENT BEFORE STARTING ENGINE ........................................................ 2-30

PRECAUTIONS WHEN STARTING ENGINE .................................................................................. 2-31

IN COLD WEATHER........................................................................................................................ 2-31

START ENGINE WITH JUMPER CABLES ...................................................................................... 2-31

PRECAUTIONS FOR OPERATION ........................................................................................................ 2-32

CHECKS BEFORE OPERATION..................................................................................................... 2-32

WHEN TRAVELLING IN FORWARD OR REVERSE AND SWINGING............................................ 2-33

PRECAUTIONS WHEN TRAVELLING............................................................................................. 2-33

PRECAUTIONS WHEN TRAVELLING ON SLOPES ....................................................................... 2-34

PRECAUTIONS WHEN OPERATING ON SLOPES ........................................................................ 2-35

PROHIBITED OPERATIONS ........................................................................................................... 2-35

2-2

SAFETY SAFETY

PRECAUTIONS WHEN OPERATING ON SNOW OR FROZEN SURFACES.................................. 2-37

PRECAUTIONS WHEN PARKING MACHINE ................................................................................. 2-37

PRECAUTIONS FOR TRANSPORTATION............................................................................................. 2-38

PRECAUTIONS WHEN LOADING AND UNLOADING.................................................................... 2-38

TOWING AND BEING TOWED............................................................................................................... 2-39

PRECAUTIONS FOR TOWING AND BEING TOWED..................................................................... 2-39

LIFTING OPERATIONS .......................................................................................................................... 2-39

GENERAL PRECAUTIONS FOR LIFTING OPERATIONS .............................................................. 2-39

PRECAUTIONS FOR MAINTENANCE.......................................................................................................... 2-41

PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE .......................................... 2-41

DISPLAY WARNING TAG DURING INSPECTION AND MAINTENANCE ....................................... 2-41

KEEP WORK PLACE CLEAN AND TIDY ........................................................................................ 2-41

SELECT SUITABLE PLACE FOR INSPECTION AND MAINTENANCE .......................................... 2-41

ONLY AUTHORIZED PERSONNEL................................................................................................. 2-41

APPOINT LEADER WHEN WORKING WITH OTHERS .................................................................. 2-41

STABILITY ....................................................................................................................................... 2-41

GUARDS ......................................................................................................................................... 2-42

END OF SERVICE LIFE .................................................................................................................. 2-42

STOP ENGINE BEFORE CARRYING OUT INSPECTION AND MAINTENANCE ........................... 2-42

TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING.......................................... 2-42

PRECAUTIONS WHEN INSTALLING, REMOVING, OR STORING ATTACHMENTS...................... 2-43

PRECAUTIONS FOR WORKING AT HIGH PLACES ...................................................................... 2-43

PRECAUTIONS WHEN WORKING ON MACHINE.......................................................................... 2-43

PRECAUTIONS WHEN WORKING UNDER MACHINE OR WORK EQUIPMENT .......................... 2-44

USE PROPER TOOLS .................................................................................................................... 2-44

PRECAUTIONS FOR CHECK AND MAINTENANCE ............................................................................. 2-44

TURN BATTERY DISCONNECT SWITCH TO OFF POSITION....................................................... 2-44

PRECAUTIONS FOR WELDING ..................................................................................................... 2-44

HANDLE BATTERY ......................................................................................................................... 2-45

PRECAUTIONS WHEN USING HAMMER ...................................................................................... 2-45

PRECAUTIONS FOR HIGH-TEMPERATURE COOLANT ............................................................... 2-46

PRECAUTIONS FOR HIGH-TEMPERATURE OIL........................................................................... 2-46

PRECAUTIONS FOR HIGH-TEMPERATURE PARTS..................................................................... 2-46

PRECAUTIONS FOR HIGH-PRESSURE OIL.................................................................................. 2-46

PRECAUTIONS FOR HIGH-PRESSURE FUEL .............................................................................. 2-47

HANDLE HIGH-PRESSURE HOSES AND PIPING ......................................................................... 2-47

PRECAUTIONS FOR HIGH VOLTAGE............................................................................................ 2-47

PRECAUTIONS FOR NOISE........................................................................................................... 2-47

PRECAUTIONS FOR HIGH-PRESSURE GREASE WHEN ADJUSTING TRACK TENSION .......... 2-48

DO NOT DISASSEMBLE RECOIL SPRING .................................................................................... 2-48

HANDLE ACCUMULATOR AND GAS SPRING............................................................................... 2-48

PRECAUTIONS FOR COMPRESSED AIR...................................................................................... 2-49

MAINTENANCE OF AIR CONDITIONER ........................................................................................ 2-49

CHEMICAL HAZARD....................................................................................................................... 2-49

PRECAUTIONS FOR DISPOSING OF WASTE MATERIALS .......................................................... 2-49

METHOD FOR SELECTING WINDOW WASHER FLUID................................................................ 2-49

PERIODIC REPLACEMENT OF DEFINED LIFE PARTS................................................................. 2-49

PRECAUTIONS FOR DEF............................................................................................................................. 2-51

GENERAL CHARACTER AND PRECAUTIONS FOR HANDLING ......................................................... 2-51

PRECAUTIONS FOR ADDING............................................................................................................... 2-51

SAFETY RULES FOR STORAGE .......................................................................................................... 2-51

PRECAUTIONS FOR FIRE HAZARD AND LEAKAGE ........................................................................... 2-51

OTHER PRECAUTIONS......................................................................................................................... 2-51

2-3

kk

SAFETY LABELS SAFETY

SAFETY LABELS

WARNING

Be sure that you fully understand the correct position, content and how to avoid a danger shown in the

safety labels.

Handle the warning signs and safety labels used on this machine as follows.

• Always keep the safety labels clean so that you can read it properly. When cleaning the safety labels, do

not use organic solvents or gasoline. These may cause the labels to peel off.

• If the safety labels are damaged, lost, or cannot be read properly, replace them with new ones. For details

of the part numbers for the safety labels, see this manual or the actual label, and place an order to your

Komatsu distributor.

• There are also other labels in addition to the warning signs and safety labels. Handle those labels in the

same way.

2-4

a

b

c

d

e

f

g

h

KS000848

T

T

SAFETY SAFETY LABELS

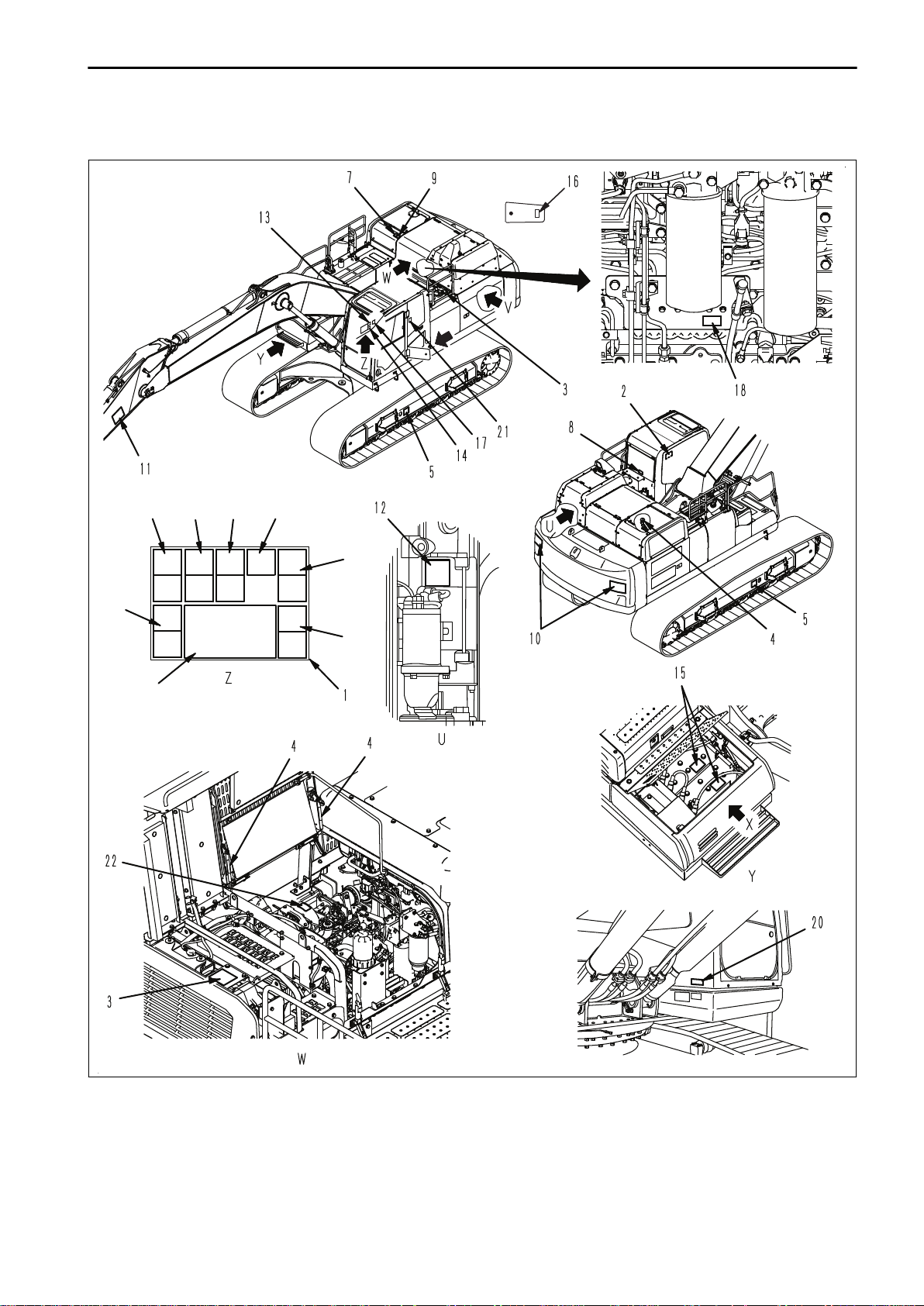

LOCATION OF SAFETY LABELS

2-5

KS000850

SAFETY LABELS SAFETY

1. Combined safety information label

(a) Warning for operation, inspection and maintenance

(b) Warning when leaving the operator's seat

(c) Warning no passengers

(d) Warning danger of falling objects

(e) Warning against high-voltage cables

(f) Control levers operational function diagram

(g) Caution when standing in the operator cab

(h) Warning when reversing

2. Caution when stowing front window

3. Caution for high temperature coolant and oil

4. Caution for handling accumulator and gas spring

5. Caution for adjusting track tension

6. Caution for handling cable

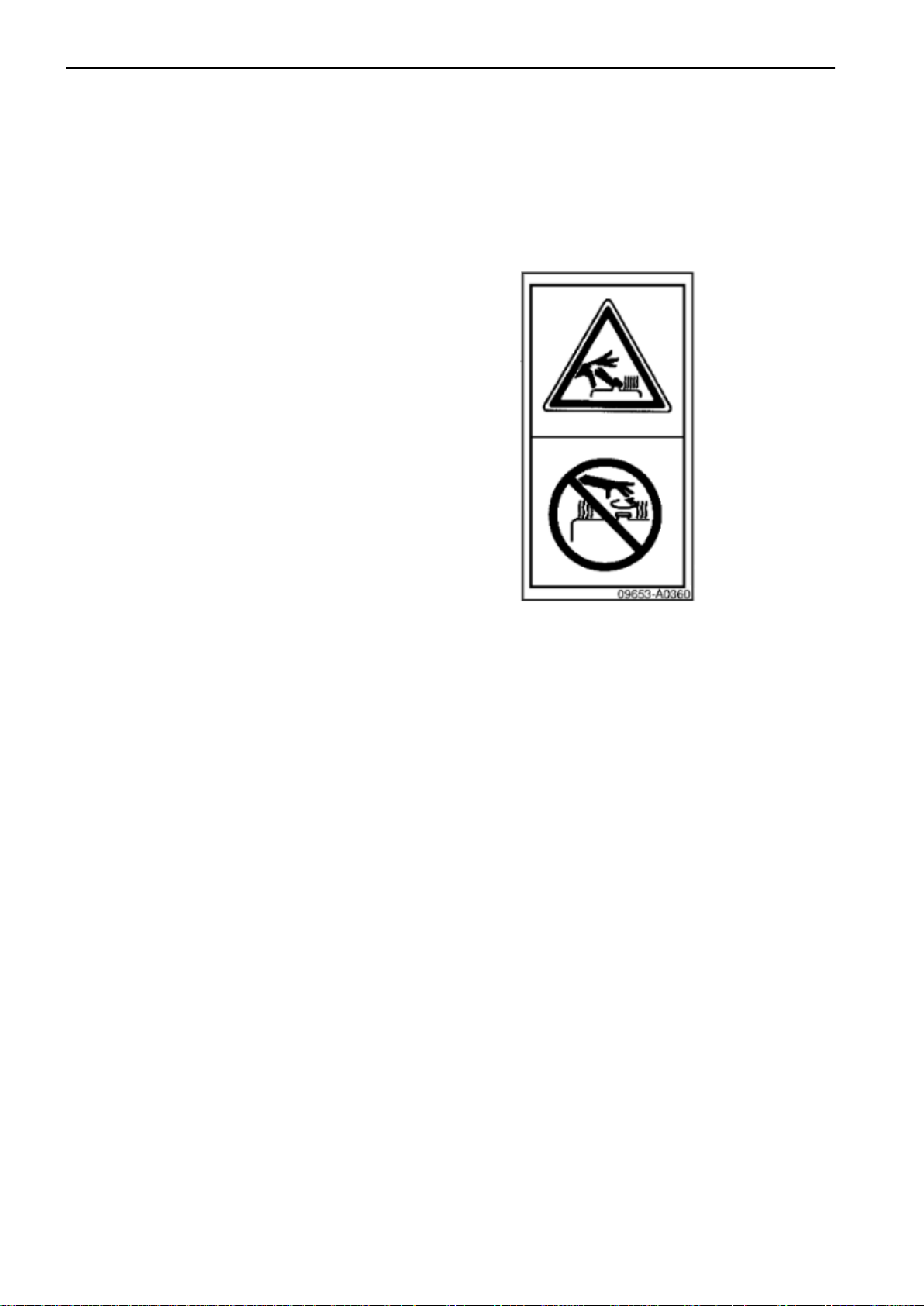

7. Caution stop rotation during inspection and maintenance

8. Emergency escape

2-6

9. Caution against falling

10. Danger do not enter within swing range

11. Caution against work equipment

12. Caution do not start by short-circuiting

13. Warning for use of hydraulic quick coupler piping

system

14. Warning when swinging and travelling in reverse

15. Caution for handling batteries

16. Caution when replacing fresh air filter

17. Caution for blast jobsite

18. Caution against high-pressure fuel

19. Caution against high temperature

20. Warning for handling ROPS

21. Caution for overloading machine

22. Caution against high temperature

23. Caution for handling DEF

24. Caution for handling DEF

SAFETY SAFETY LABELS

25. Warning for operation, inspection and maintenance

26. Caution for high-temperature resistance

CONTENTS OF SAFETY LABELS

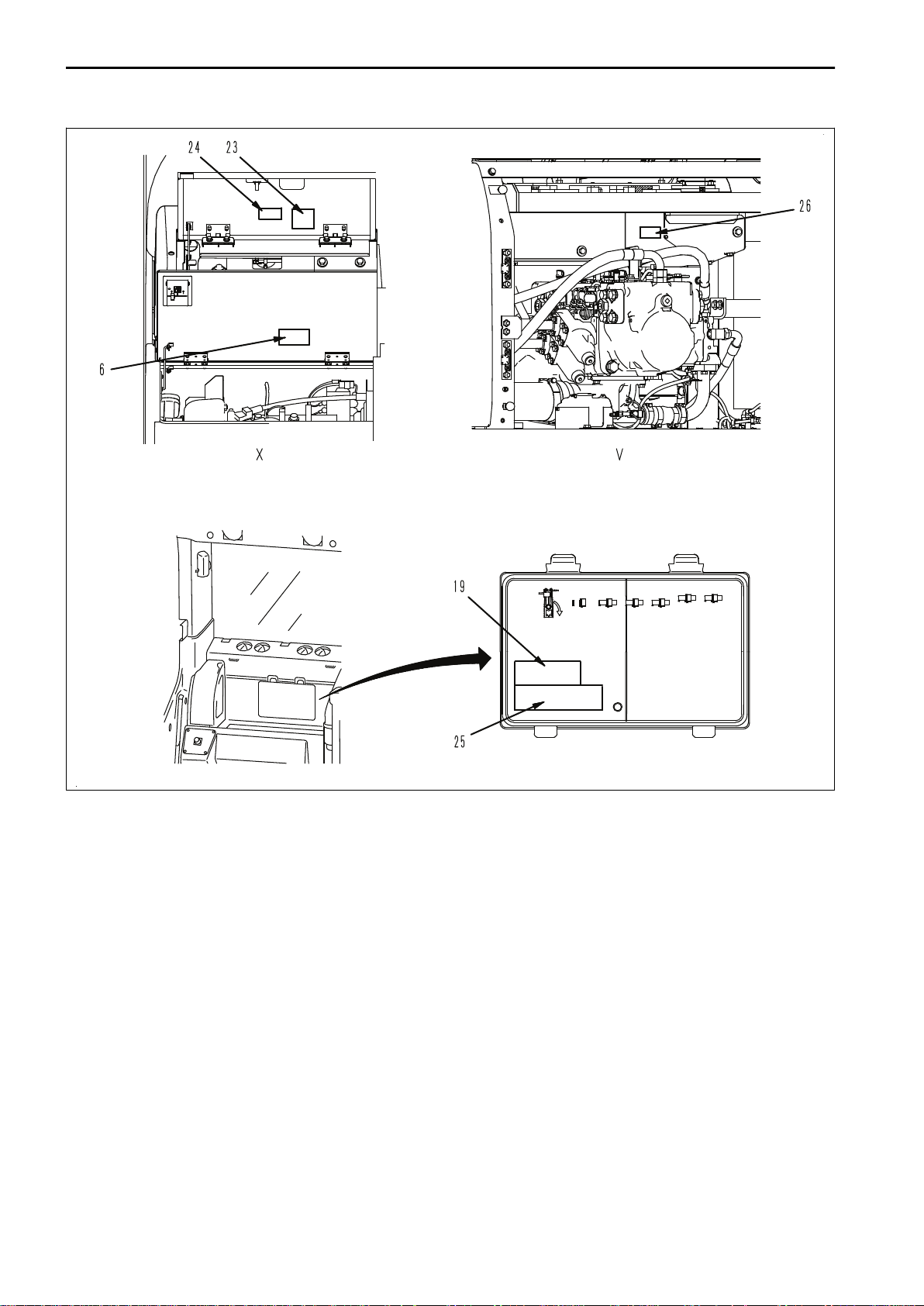

Combined safety information label

(1) (2A5-00-21180)

• Warnings for operation, inspection and maintenance.

• Improper operation and maintenance can cause serious injury or death.

• Read the manual and labels before operation and maintenance.

Follow instructions and warnings in manual and in labels on

machine.

Detailed explanations of the content of each label are as follows:

Warning for operation, inspection and maintenance

• Warning

• a. Read the manual before operating, inspection, maintenance, disassembly, assembly and transportation.

Warning when leaving the operator's seat

• b. Before standing up from operator's seat.

• Lower the work equipment to the ground and move safety

lock lever (located near seat) to lock position to avoid hitting unlocked operation levers.

• Sudden and unwanted machine movement can cause serious injury or death.

2-7

SAFETY LABELS SAFETY

Warning no passengers

• c. No passengers allowed to ride on the machine while it is

moving.

Warning danger of falling objects

• d. Do not operate where a danger of falling objects exists.

Consult your dealer for fitting of FOPS (FALLING OBJECT

PROTECTIVE STRUCTURE) protection.

Warning going too close to electric cables.

• e. An electrocution hazard if the machine is brought too

near to electric power lines.

• Keep a safe distance from electric power lines.

2-8

SAFETY SAFETY LABELS

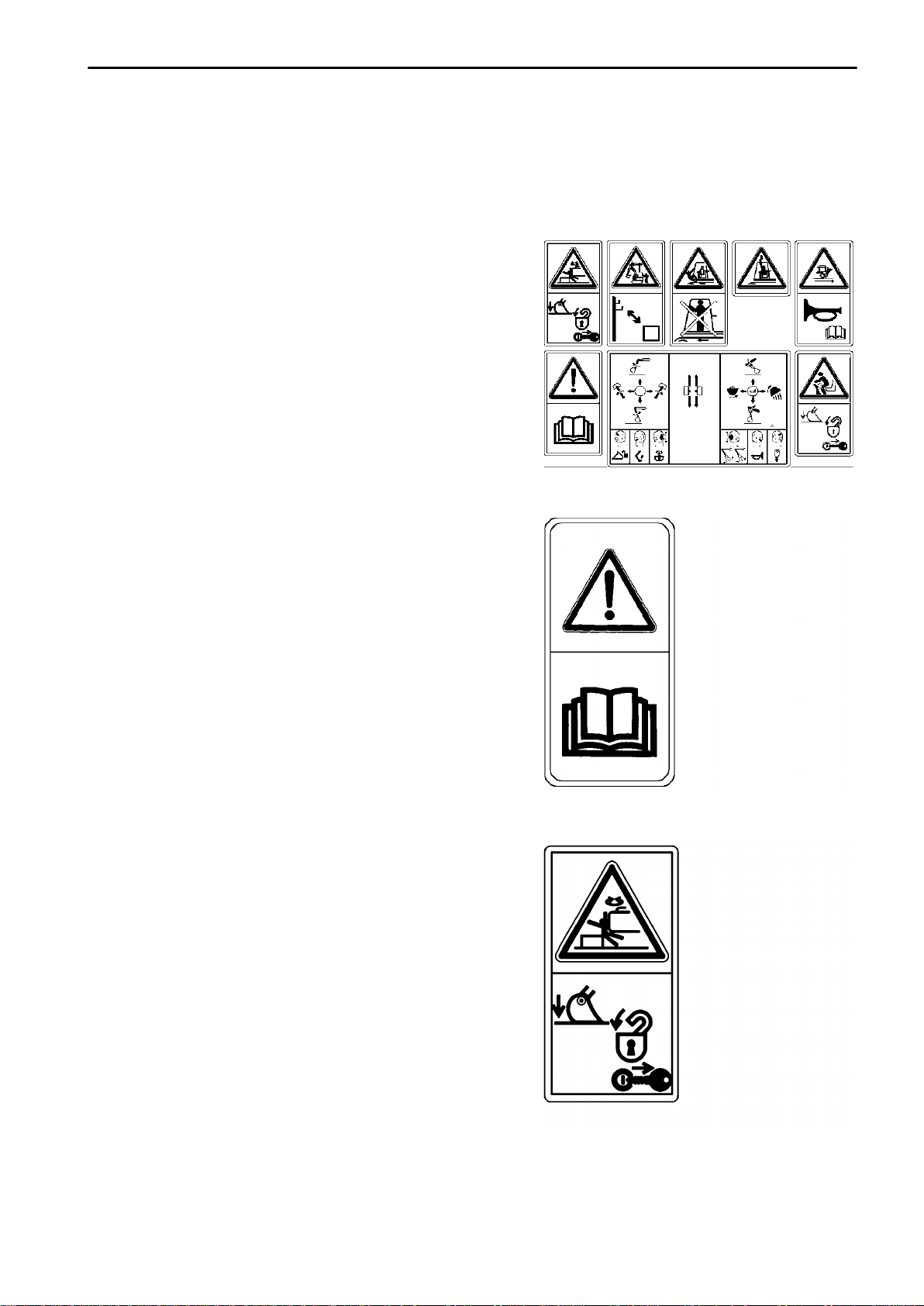

Control levers operational function diagram

f. Control levers operating pattern.

In order to prevent an accident resulting in injury or death

caused by error-operation, confirm the machine motion and indicated operating pattern, when operating machines. Pay attention to the circumference and operate slowly when confirming

the machine motion.

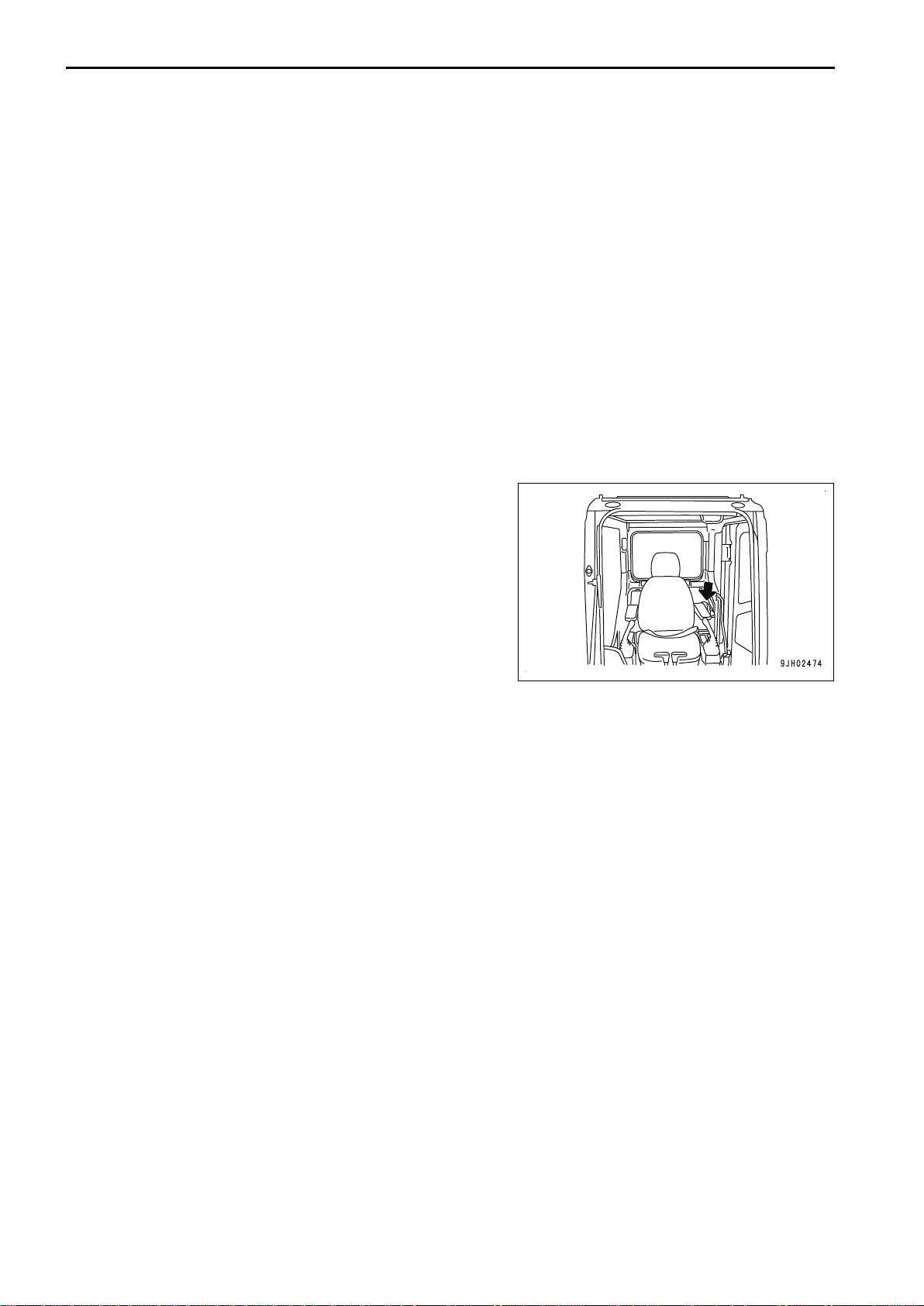

Caution when standing in operator cab

• g. Take care when standing in the operator cab.

• Before standing up from the operator's seat (such as when

opening or closing the front window, or when removing or

installing the bottom window, or when adjusting the operator's seat), always lower the work equipment completely to

the ground, set lock lever (1) securely to the LOCK position

(L), then stop the engine. If you accidentally touch the control levers (pedals) when they are not locked, there is a

hazard that the machine may suddenly move and cause

serious injury or property damage.

2-9

kk

SAFETY LABELS SAFETY

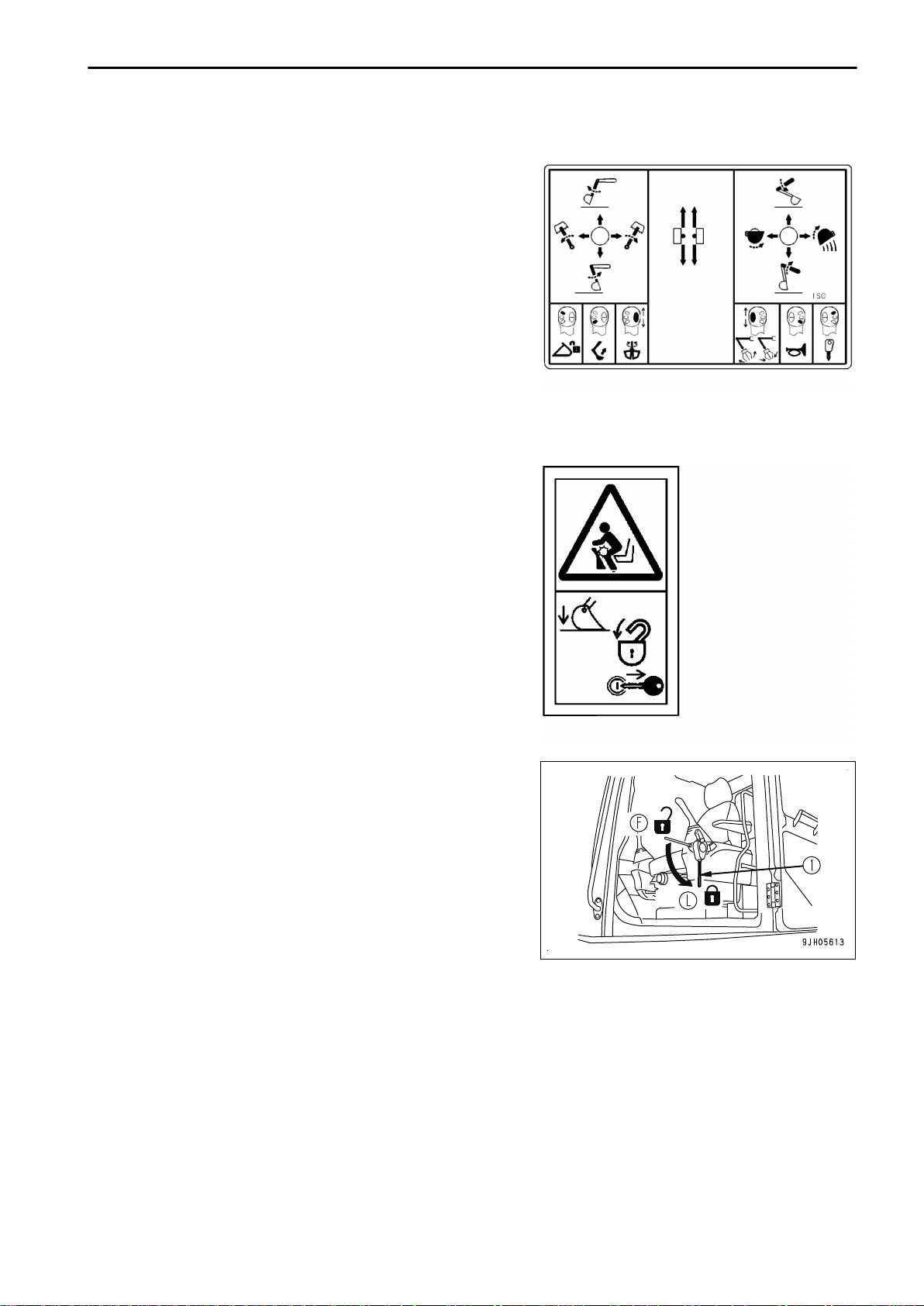

Warning when reversing

• h. Take care when reversing.

To prevent SEVERE INJURY or DEATH, do the following before moving machine or its attachments:

• Sound horn to alert people nearby.

Be sure no one is on or near machine or in swing area.

Rotate cab for full view of travel path if it can be done safely.

Use spotter if view is obstructed.

Follow the above even if machine is equipped with travel

alarm, mirrors and rear view camera.

WARNING

To open or close the front or ceiling window, never

stand up from the operator's seat before throwing the

safety lock lever to the lock position.

Inadvertently touching any of the working equipment

control levers might cause the machine to start moving all of a sudden, probably resulting in a serious injury.

Caution when stowing front window

(2) Caution when stowing front window (09803-A0481)

• Sign indicates a hazard from falling window.

• After raising window, be sure to lock it in place with lock

pins.

Caution for high temperature coolant and hydraulic oil

(3) Caution for high temperature coolant and hydraulic oil

(09653-A0481).

• Never remove the cap when the engine is at operating

(high) temperature. Steam or high temperature oil blowing

up from the radiator or hydraulic tank will cause personal

injury and/or burns.

• Never remove the radiator cap or hydraulic tank oil filler

cap when cooling water or hydraulic oil is at high temperature.

2-10

Loading...

Loading...