Page 1

FLYWHEEL HORSEPOWER

125 kW 168 HP @ 2000 rpm

OPERATING WEIGHT

PC220-7: 22840 – 23360 kg

50,350 – 51,500 lb

PC220LC-7: 23990 – 24550 kg

52,890 – 54,120 lb

Photo may include optional equipment.

PC220-7

PC220LC-7

PC

220

HYDRAULIC EXCAVATOR

Page 2

3

FLYWHEEL HORSEPOWER

125 kW 168 HP @ 2000 rpm

OPERATING WEIGHT

PC220-7: 22840–23360 kg

50,350 –51,500 lb

PC220LC-7: 23990 –24550 kg

52,890 –54,120 lb

BUCKET CAPACITY

0.72–1.26 m

3

0.94–1.65 yd

3

Photo may include optional equipment.

2

● Bucket Digging Power Is Increased 21%

Bucket Digging Power = Bucket digging force

x bucket speed. Bucket digging force is increased

9% and bucket digging speed is increased 12%, so

bucket digging power is increased 21%. (Compared

with PC220-6)

Easy Maintenance

● Replacement interval is extended for engine

oil, engine oil filter and hydraulic filter

● Remote mounted engine oil filter and

fuel drain valve for easy access

● Water separator is standard equipment

● Easier radiator cleaning

● Fuel tank capacity is increased

● BMRC bushings on work equipment

extend lubricating interval from

100 hours to 500 hours (optional)

See page 8 and 9.

Excellent Reliability and Durability

● High rigidity work equipment

● Sturdy frame structure

● Reliable Komatsu manufactured major components

● Highly reliable electronic devices

See page 5.

Harmony with Environment

● Low emission engine

A powerful turbocharged and air to air aftercooled Komatsu SAA6D102E-2

provides 125 kW 168 HP.

● Economic mode saves fuel consumption

● Low operation noise

● Easily recycled design

See page 5.

● High Production and

Low Fuel Consumption

Production is increased with

larger output during Active

mode while fuel efficiency

is further improved.

● Maximum Drawbar Pull

Increased 16% offering

superb steering and slope

climbing performance.

● Maximum Digging

Height is 10 m 32'10",

a benefit in jobs requiring

a longer reach.

See page 4.

Productivity Features

● Higher Lifting Capacity

PC220-7’s lateral stability is

improved, lifting capacity also

increased.

Large Comfortable Cab

New PC220-7’s cab volume is increased by 14%, offering an

exceptionally roomy operating environment

● Highly pressurized cab with optional air conditioner

● Low noise design

● Low vibration with cab damper mounting

● FOG capable with optional bolt-on top guard

FOG has been renamed to OPG (Operator Protective Guards) top guard level 2 by ISO 10262

See page 6.

WALK-AROUND

H YDRAULIC E XCAVATOR

HYDRAULIC EXCAVATOR

PC220-7 0

PC220-7

Page 3

● Low Noise

Noise is reduced not only from the engine but also

during swing and hydraulic relief. Dynamic noise level

is 104 dB.

● Environment Oriented Mode (Economy Mode)

Economy mode meets the needs of the 21st century.

Economy mode offers the user fuel savings, quiet

operation and less CO

2

emission.

● Fuel consumption is reduced 16% (compared with

Active mode).

● Production is the same as the PC220-6

Heavy-duty mode.

● Easily Recycled

PC220-7 is designed with consideration of recycling and

uses natural resources effectively.

● Sound suppressing material is made from PET

(polyethylene terephthalate) resin that is easy to recycle.

● All exterior parts are made from steel.

● Engine and hydraulic system oil and filter replacement

interval are extended to save earth resources.

● All resin-made parts are indicated by material code

symbol.

5

The increased output and fuel savings of the Komatsu

SAA6D102E-2 engine result in increased production and

improved production per unit of fuel.

Engine

The PC220-7 gets its exceptional power and work capacity

from a Komatsu SAA6D102E-2 engine. Output is 125 kW

168 HP, providing increased hydraulic power and improved

fuel efficiency.

Hydraulics

Unique two-pump system ensures smooth compound

movement of the work equipment. HydrauMind controls

both pumps for efficient engine power use. This system

also reduces hydraulic loss during operation.

Large Digging Height

PC220-7’s maximum digging height is 10 m 32'10",

facilitating jobs that require a longer reach, such as

demolition and slope finishing.

Larger Lifting Capacity

PC220-7’s lateral stability is improved, as a result, the

PC220-7 lifting capacity is

increased. Example: lifting

capacity over side (reach 6.1

m 20', height 4.6 m 15')

is increased from 4.45 ton

4.9 U.S. ton to 4.8 ton

5.3 U.S. ton.

Larger Digging Power Provides

Increased Production

Bucket Digging Power is obtained by bucket digging force x

bucket digging speed. New PC220-7 bucket digging force is

increased by 9% and bucket digging speed is increased by

12%, resulting total bucket digging power is increased 21%

(bucket digging force compared with PC220-6). The digging

force and speed generated result in the largest digging

power and the largest production in the 22 ton

24 U.S. ton class.

High Production and Low Fuel Consumption

4

Bucket Digging Force Bucket Digging Speed

x

Bucket Digging Power

=

increase

21%12%

increaseincrease

9%

Larger Maximum Drawbar Pull

PC220-7’s maximum drawbar pull is increased by 16%,

provides superb steering and slope climbing performance.

Maximum drawbar pull: 202 kN 20570 kg 45,350 lb

Drawbar pull/operating weight: 0.91

Three Working Modes

Working Mode Selection

The PC220-7 excavator is equipped with three working

modes (A, E and B mode). Each mode is designed to match

engine speed, pump speed, and system pressure with the

current application. This provides the flexibility to match

equipment performance to the job at hand.

Economy Mode

Economy mode is environmentally friendly. Fuel consumption

is reduced 16% (compared with PC220-7 Active mode)

and production is equal to the PC220-6 Heavy-duty mode.

Power Max Function

This function temporarily increases digging force by 7% for

added power in tough situations.

Working Mode Application Advantage

Active mode

● Maximum production/power

A

● Fast cycle times

E Economy mode ● Excellent fuel economy

B

Breaker

● Optimum engine rpm,

operation hydraulic flow

Excellent Reliability and Durability

Harmony with Environment

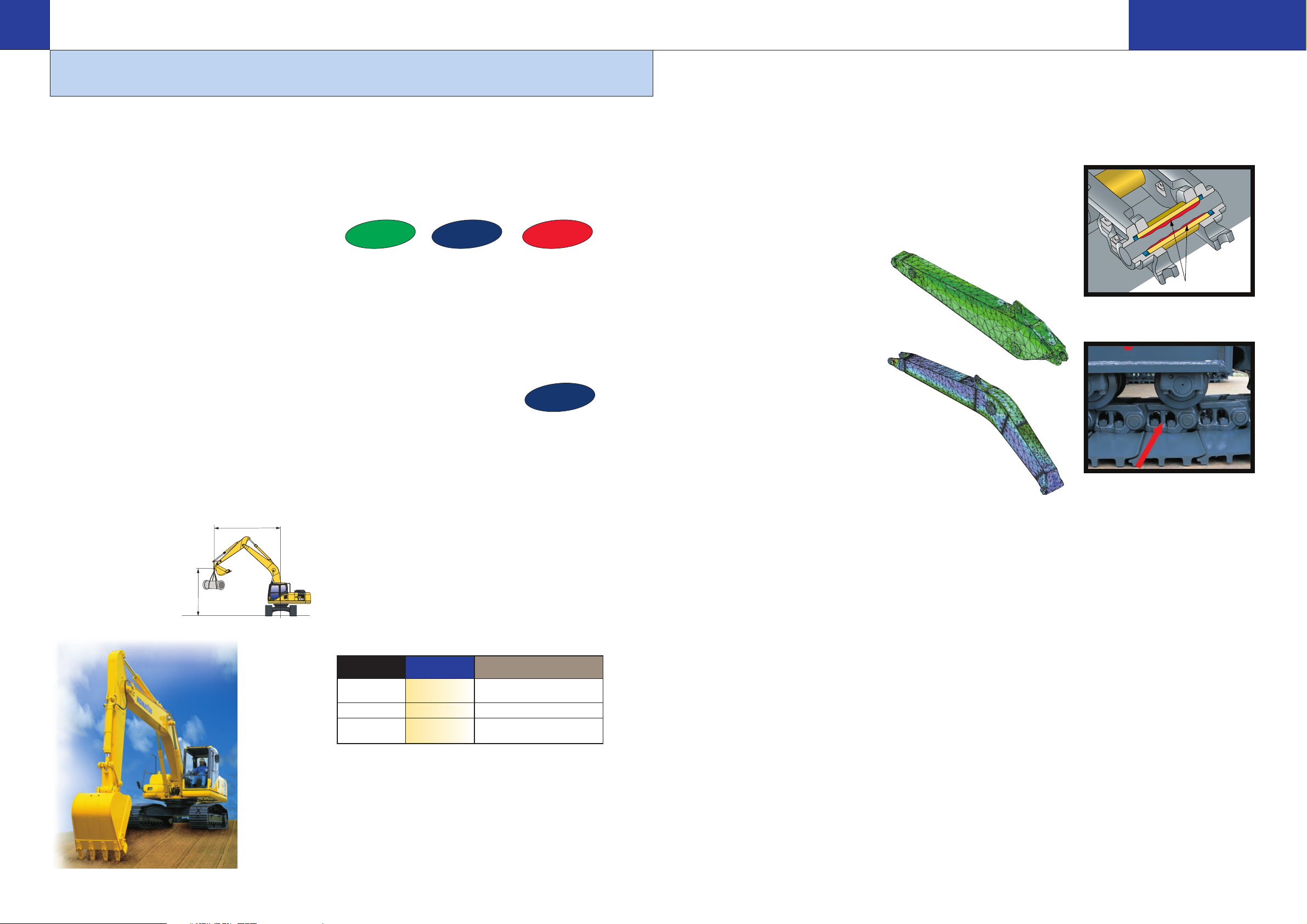

Grease Sealed Track provides excellent

undercarriage durability

Track Link with Strut

PC220-7 uses track links with

strut providing superb durability

● High Rigidity Work Equipment

The arm and boom are strengthened to correspond to increasing bucket and arm

digging forces. The arm and boom cross sectional strength are also increased

25% and 8% respectively. The boom and arm have large cross-sectional

dimensions as well as continuous groove welding, improving digging and side-

contact strength.

● Sturdy Frame Structure

The revolving frame, center frame and

undercarriage are designed by using the

most advanced three-dimensional

CAD and FEM analysis technology.

● Reliable Components

All of the major machine components,

such as engine, hydraulic pumps,

hydraulic motors and control valves, etc.,

are exclusively designed and manufactured by Komatsu.

● Highly Reliable Electronic Devices

Exclusively designed electronic devices

have passed severe testing.

● Controller ● Sensors

● Connectors ● Heat resistant wiring

● Metal guard rings protect all the hydraulic cylinders

and improve reliability.

16%

increase

PRODUCTIVITY FEATURES

H YDRAULIC E XCAVATOR

HYDRAULIC EXCAVATOR

PC220-7

PC220-7 0

4.6 m 15'

6.1 m 20'

4.8 ton

5.3 U.S. ton

Grease

Page 4

7

PC220-7 cab interior is spacious and provides a comfortable working

environment…

Large Comfortable Cab

6

Comfortable Cab

New PC220-7’s cab volume is increased by 14%, offering an

exceptionally comfortable operating environment. The large

cab enables full flat reclining of the seat back with headrest.

Pressurized Cab

With optional air conditioner, air filter and a higher internal air

pressure (6.0 mm Aq 0.2" Aq) prevent external dust from

entering the cab.

Low Noise Design

Noise level is remarkably reduced, not only engine noise but

also noise when swinging and hydraulic relief.

Low Vibration with Cab Damper Mounting

PC220-7 uses new, improved multi-layer viscous mount

system that incorporates longer stroke and the addition

of a spring. The new cab damper mounting combined

with strengthened left and right side decks aids vibration

reduction at operator seat.

Vibration at floor is reduced from 120 dB (VL) to 115 dB (VL).

dB (VL) is index for expressing size of vib ration.

Rubber

Silicon Oil

Spring

Cab Damper

Mounting

Multi-Layer

Viscous Mount

Floor Vibration

Comparison of Riding Comfort

Conditions:

● Traveling over obstacle

one side track

● Traveling speed forward high

Pitch vertical direction on graph shows size of vibration.

Washable Cab Floormat

The PC220-7’s cab floormat

is easy to keep clean. The

gently inclined surface has a

flanged floormat and drainage

holes to facilitate runoff.

Photo may include optional equipment.

Photo may include optional equipment.

Skylight

Sliding

Window

Multi-Position Controls

The multi-position, pressure proportional control

levers allow the operator to work in comfort

while maintaining precise control. A double-slide

mechanism allows the seat and controllers to move

together or independently, allowing the operator

to position the controllers for maximum

productivity and comfort.

Safety Features

Cab

FOG capable with optional bolt-

on top guard.

Wide Visibility

The right side window pillar has

been removed and the rear

pillar reshaped to provide better

visibility. Blind spots have been

decreased by 34%.

Pump/engine room partition

prevents oil from spraying on

the engine if a hydraulic hose

should burst.

Thermal and fan guards are

placed around high-temperature

parts of the engine and fan

drive.

Steps with non-skid sheet

and large handrail.

Steps with

non-skid sheet provide anti-slip

footing for maintenance.

Seat Sliding Amount: 340 mm 13.4",

increased 120 mm 4.7"

Large Handrail

Seat with headrest

reclined full flat

Thermal Guard and Non-skid Sheet

Defroster (optional)

WORKING ENVIRONMENT

H YDRAULIC E XCAVATOR

HYDRAULIC EXCAVATOR

PC220-7

PC220-7 0

Automatic Air Conditioner (optional)

A 6,900 kcal air conditioner

is utilized. The bi-level

control function keeps the

operator's head and feet

cool and warm respectively.

This improved air flow

function keeps the inside of

the cab comfortable

throughout the year.

Cab Frame Mounted Wiper Bottle Holder and

Magazine Rack

Page 5

PC220-7 PC220-6

500 100

● Easy Access to Engine Oil

Filter and Fuel Drain Valve

Engine oil filter and fuel drain

valve are remotely mounted to

improve accessibility.

Reducing Maintenance Costs

● Hydraulic Oil and Filter/Engine Oil and Filter

Replacement Interval Extended

The new high performance filters are used in hydraulic circuit

and engine. Hydraulic oil filter, engine oil, and engine oil

filter element replacement intervals are significantly extended

to reduce maintenance costs.

Comparison of Replacement Intervals unit: hours

Self-Diagnostic Monitor

The PC220-7 features the most advanced diagnostics

system in the industry. The Komatsu exclusive system

identifies maintenance items, reduces diagnostic times,

indicates oil and filter replacement hours and displays error

codes.

Continuous Machine Monitoring System

When turning starting switch ON, Check-before-starting

item and caution items appear on the liquid crystal panel.

If abnormalities are found, a warning lamp blinks and

a warning buzzer sounds. The continuous machine condition

checks help prevent the development of serious problems

and allows the operator to concentrate on the controls.

Abnormalities on Electronic System Display

with Code

When an error occurs during operation, a user code

is displayed. When an important user code is displayed,

a caution lamp blinks and a warning buzzer sounds

to prevent the development of serious problems.

Oil Maintenance Function

When machine exceeds oil or filter replacement time,

oil maintenance monitor lights to inform operator.

A

B

D

C

E

F

G

H

I

J

K

L

M

N

O

P

A Engine Water Temperature

B Battery Charge

C Engine Oil Pressure

D Air Cleaner Clogging Monitor

E Auto-Decel Switch

F Travel Speed Select Switch

G Working Mode Select Switch

H Fuel Level Monitor

I User or Trouble Code Display

J Service Meter Display

K Engine Oil Level

L Engine Preheat

M Swing Lock Display

N Oil Maintenance

O Windshield Wiper Switch

P Windshield Washer Switch

Easy Maintenance

Komatsu designed the PC220-7 to have easy service access.

We know by doing this, routine maintenance and servicing are

less likely to be skipped, which can mean a reduction in costly

downtime later on. Here are some of the many service

features found on the PC220-7.

● Easy Radiator Cleaning

Clearance between radiator

and oil cooler is increased

to facilitate radiator core

cleaning with an air nozzle.

● Water Separator is

standard equipment,

removing water mixed in

fuel and preventing fuel

system damage.

● Self-diagnostic Monitor

allows display of vital selfdiagnosis, as well as displaying up to 39 different faults.

Easy Radiator Cleaning

Remote

Mounted

Engine Oil Filter

Water

Separator

● Fuel Tank Capacity Increased

Fuel tank capacity is increased from 340 ltr 89.8 U.S. gal

to 400 ltr 105.7 U.S. gal to extend operating hours before

refueling. Fuel tank is treated for rust prevention and

improved corrosion resistance.

PC220-7 PC220-6

Engine oil 500 250

Engine oil filter 500 250

Hydraulic oil 5,000 5,000

Hydraulic oil filter 1,000 500

All Work Equipment Lubrication Intervals Are

500 Hours with optional BMRC Bushings

(except bucket pin bushings)

Newly developed BMRC bushings are used on the work

equipment. All bushing lubrication intervals of work equipment

are extended from 100 hours to 500 hours (except bucket

pin bushings), reducing maintenance costs.

BMRC (Beta Matrix Reinforced Copper Alloy)

A bushing made by combining a

sintered copper layer

impregnated with oil for better

fitting and a backing metal. It is

used for severe application parts

which receive low rocking

stresses and high loads to

prevent creaking and scuffing

because of its excellent sliding

characteristics.

8

Working Mode Application Advantage

Active mode

● Maximum production/power

A

● Fast cycle times

E Economy mode ● Excellent fuel economy

L Lifting mode

● Hydraulic pressure is

increased by 7%

B

Breaker

● Optimum engine rpm,

operation hydraulic flow

A newly developed Multi-Function Color Monitor has multiple

functions, such as Working mode selection, hydraulic pump

oil flow adjustment for matching to attachment, and

maintenance interval notice, etc.

Working Mode Selection

The Multi-Function Color Monitor has Lifting mode in

addition to the standard three-mode selection

(A, E, and B modes).

Hydraulic Pump Oil Flow Adjustment System

When installing attachments (breaker, crusher, etc.) and

B, A, or E mode is selected, it is possible to adjust engine and

hydraulic pump discharge flow to match attachment

characteristics. Selection is possible throughout the LCD

(Liquid Crystal Display). This system also allows throttling

of the attachment side discharge flow to provide smooth

work equipment movement and compound operation

with work equipment and attachment.

High Mid Low

Travel Speed

5.5 km/h 4.2 km/h 3.1 km/h

3.4 mph 2.6 mph 1.9 mph

Automatic Three-Travel Speed

Travel speed is automatically shifted from high to low

speed according to the pressure of the travel. This optional

system is available as part of the Multi-Function Color

Monitor.

Lifting Mode

When the Lifting mode is selected,

lifting capacity is increased by

7% by raising hydraulic pressure.

EMMS (Equipment

Management

Monitoring System)

Monitor Function

Controller monitors engine oil level,

coolant temperature, battery charge

and air clogging, etc. If controller

finds any abnormality, it is displayed on the LCD.

Maintenance Function

Monitor informs replacement time of oil and filters on LCD

when the replacement interval is reached.

Trouble Data Memory Function

Monitor stores abnormalities for effective troubleshooting.

Work Equipment Lubrication Interval unit:hours

(except bucket pin bushings)

9

OPTIONS TO UPDATE THE VALUE

Multi-Function Color Monitor

MAINTENANCE FEATURES

H YDRAULIC E XCAVATOR

HYDRAULIC EXCAVATOR

PC220-7

PC220-7 0

Sintered Al bronze layer impregnated

with high-performance lubricating oil

Backing metal (steel)

Page 6

10

ENGINE

Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Komatsu SAA6D102E-2

Type . . . . . . . . . . . . . . . . . . . . Water-cooled, 4-cycle, direct injection

Aspiration. . . . . . . . . . . . . . . . . . . . . . . . . Turbocharged, aftercooled

Number of cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102 mm 4.02"

Stroke. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120 mm 4.72"

Piston displacement. . . . . . . . . . . . . . . . . . . . . . . . . . 5.88 ltr 359 in

3

Flywheel horsepower:

SAE J1349 . . . . . . . . . . . . . . . . . . . 125 kW 168 HP @ 2000 rpm

DIN6270 . . . . . . . . . . . . . . . . . . . . . 125 kW 170 PS @ 2000 rpm

Governor . . . . . . . . . . . . . . . . . . . . . . . All-speed control, mechanical

HYDRAULICS

Type . . HydrauMind (Hydraulic Mechanical Intelligence New Design)

system, closed-center system with load sensing valves and

pressure compensated valves

Number of selectable working modes . . . . . . . . . . . . . . . . . . . . . . . 3

Main pump:

Type . . . . . . . . . . . . . . . . . . . . . Variable displacement piston type

Pumps for . . . . . . . . Boom, arm, bucket, swing, and travel circuits

Maximum flow. . . . . . . . . . . . . . . . . . 439 ltr/min 116 U.S. gal/min

Supply for control circuit . . . . . . . . . . . . . . . . . Self-reducing valve

Hydraulic motors:

Travel. . . . . . . . . . . . . . . 2 x axial piston motor with parking brake

Swing . . . . . . . . . . 1 x axial piston motor with swing holding brake

Relief valve setting:

Implement circuits . . . . . . . . . . . 37.3 MPa 380 kgf/cm25,400 psi

Travel circuit. . . . . . . . . . . . . . . . 37.3 MPa 380 kgf/cm25,400 psi

Swing circuit. . . . . . . . . . . . . . . . 28.4 MPa 290 kgf/cm24,120 psi

Pilot circuit . . . . . . . . . . . . . . . . . . . . 3.2 MPa 33 kgf/cm2470 psi

Hydraulic cylinders:

(Number of cylinders – bore x stroke x rod diameter)

Boom . . . . . . 2 – 130 mm x 1335 mm x 90 mm 5.1" x 52.6" x 3.5"

Arm . . . . . . 1 – 140 mm x 1635 mm x 100 mm 5.5" x 64.4" x 3.9"

Bucket: . . . . . . . . . . . . . . . . . for 2.5 m 8'2" and 3.05 m 10'0" Arm

1 – 130 mm x 1020 mm x 90 mm 5.1" x 40.2" x 3.5"

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . for 2.0 m 6'7" Arm

1 – 140 mm x 1009 mm x 100 mm 5.5" x 39.7" x 3.9"

DRIVES AND BRAKES

Steering control . . . . . . . . . . . . . . . . . . . . . . . Two levers with pedals

Drive method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydrostatic

Maximum drawbar pull . . . . . . . . . . . . . . 202 kN 20570 kg 45,350 lb

Gradeability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70%, 35°

Maximum travel speed: High . . . . . . . . . . . . . . . . . 5.5 km/h 3.4 mph

(Auto-Shift) Low . . . . . . . . . . . . . . . . . 3.1 km/h 1.9 mph

Service brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydraulic lock

Parking brake. . . . . . . . . . . . . . . . . . . . . . . . . Mechanical disc brake

SWING SYSTEM

Drive method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydrostatic

Swing reduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Planetary gear

Swing circle lubrication . . . . . . . . . . . . . . . . . . . . . . . Grease-bathed

Service brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydraulic lock

Holding brake/Swing lock . . . . . . . . . . . . . . . . Mechanical disc brake

Swing speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.7 rpm

UNDERCARRIAGE

Center frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X-frame

Track frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Box-section

Seal of track . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Sealed track

Track adjuster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydraulic

Number of shoes (each side):

PC220-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

PC220LC-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Number of carrier rollers . . . . . . . . . . . . . . . . . . . . . . . . . 2 each side

Number of track rollers (each side):

PC220-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

PC220LC-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

COOLANT AND LUBRICANT

CAPACITY (REFILLING)

Fuel tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400 ltr 105.7 U.S. gal

Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30.9 ltr 8.2 U.S. gal

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24.0 ltr 6.3 U.S. gal

Final drive, each side . . . . . . . . . . . . . . . . . . . . . . 4.5 ltr 1.2 U.S. gal

Swing drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.6 ltr 1.7 U.S. gal

Hydraulic tank . . . . . . . . . . . . . . . . . . . . . . . . . . 143 ltr 37.8 U.S. gal

OPERATING WEIGHT (APPROXIMATE)

Operating weight including 5850 mm 19'2" one-piece boom,

3045 mm 10'0" arm, SAE heaped 1.0 m31.31 yd3backhoe bucket,

rated capacity of lubricants, coolant, full fuel tank, operator, and

standard equipment.

PC220-7 PC220LC-7

Operating Ground Operating Ground

Shoes Weight Pressure Weight Pressure

600 mm 22840 kg

50.0 kPa

23990 kg

48.1 kPa

0.51 kgf/cm

2

0.49 kgf/cm

2

23.6" 50,350 lb

7.25 psi

52,890 lb

6.97 psi

700 mm 23100 kg

43.1 kPa

24270 kg

41.2 kPa

0.44 kgf/cm

2

0.42 kgf/cm

2

27.6" 50,930 lb

6.26 psi

53,510 lb

5.97 psi

800 mm 23360 kg

38.2 kPa

24550 kg

36.3 kPa

0.39 kgf/cm

2

0.37 kgf/cm

2

31.5" 51,500 lb

5.55 psi

54,120 lb

5.26 psi

11

K

G

D, L

M

I

J

N

H, Q

A

P

C

E

O

F

B

G.L.

0

-1

-2

-3

-4

-5

-6

-7

0123456789

10

5

6

7

8

9

10

11

12

11

(m)

1

2

3

4

H

A

B

C

DE

F

G

(m)

2440 8'

WORKING RANGE

DIMENSIONS

BACKHOE BUCKET, ARM, AND BOOM COMBINATION

Arm Length 2000 mm 6'7" 2500 mm 8'2" 3045 mm 10'0"

A Overall length 9865 mm 32'4" 9960 mm 32'8" 9885 mm 32'5"

B Length on ground (transport): PC220-7 6470 mm 21'3" 5920 mm 19'5" 5190 mm 17'0"

PC220LC-7 6660 mm 21'10" 6115 mm 20'1" 5390 mm 17'8"

C Overall height (to top of boom) 3220 mm 10'7" 3295 mm 10'10" 3160 mm 10'4"

PC220-7 PC220LC-7

D Overall width 2980 mm 9'9" 3280 mm 10'9"

E Overall height (to top of cab) 3015 mm 9'11" 3015 mm 9'11"

F Ground clearance, counterweight 1100 mm 3'7" 1100 mm 3'7"

G Ground clearance (minimum) 440 mm 1'5" 440 mm 1'5"

H Tail swing radius 2940 mm 9'8" 2940 mm 9'8"

I Track length on ground 3460 mm 11'4" 3845 mm 12'7"

J Track length 4265 mm 14'0" 4640 mm 15'3"

K Track gauge 2380 mm 7'10" 2580 mm 8'6"

L Width of crawler 2980 mm 9'9" 3280 mm 10'9"

M Shoe width 600 mm 23.6" 700 mm 27.6"

N Grouser height 26 mm 1.0" 26 mm 1.0"

O Machine cab height 2110 mm 6'11" 2110 mm 6'11"

P Machine cab width 2710 mm 8'11" 2710 mm 8'11"

Q Distance, swing center to rear end 2905 mm 9'6" 2905 mm 9'6"

Arm 2000 mm 6'7" 2500 mm 8'2" 3045 mm 10'0"

A Max. digging height 9665 mm 31'9" 9790 mm 32'1" 10000 mm 32'10"

B Max. dumping height 6715 mm 22'0" 6860 mm 22'6" 7035 mm 23'1"

C Max. digging depth 5825 mm 19'1" 6320 mm 20'9" 6920 mm 22'8"

D Max. vertical wall

digging depth

4750 mm 15’7" 5130 mm 16'10" 6010 mm 19'9"

E Max. digging depth

of cut for 8' level

5585 mm 18'4" 6100 mm 20'0" 6700 mm 22'0"

F Max. digging reach 9270 mm 30'5" 9670 mm 31'9" 10180 mm 33'5"

G Max. digging reach

at ground level

9070 mm 29'9" 9480 mm 31'1" 10020 mm 32'10"

H Min. swing radius 3300 mm 10'10" 3320 mm 10'11" 3450 mm 11'4"

Bucket digging force 176 kN 152 kN 152 kN

at power max. 17900 kgf/39,460 lb 15500 kgf/34,170 lb 15500 kgf/ 34,170 lb

Arm crowd force 155 kN 142 kN 119 kN

at power max. 15800 kgf/34,830 lb 14500 kgf/31,970 lb 12100 kgf/ 26,680 lb

Bucket digging force 197 kN 172 kN 172 kN

at power max. 20100 kgf/44,310 lb 17500 kgf/38,580 lb 17500 kgf/ 38,580lb

Arm crowd force 161 kN 148 kN 129 kN

at power max. 16400 kgf/36,160 lb 15100 kgf/33,290 lb 13200 kgf/29,100 lb

ISO rating SAE rating

Bucket Capacity

Number

(heaped) Width Weight Arm Length

SAE, PCSA CECE Without Side Cutters With Side Cutters With Side Cutters

of Teeth

2.00 m 6'7" 2.50 m 8'2" 3.05 m10'0"

0.72 m3 0.94 yd30.65 m30.85 yd

3

900 mm 35.4" 1005 mm 39.6" 658 kg 1,450 lb 3

1.00 m31.31 yd30.90 m31.18 yd31155 mm 45.5" 1260 mm 49.6” 734 kg 1,620 lb 4

1.14 m31.49 yd31.00 m31.31 yd31300 mm 51.2" 1405 mm 55.3" 793 kg 1,750 lb 5 □□

1.26 m

3

1.65 yd31.10 m31.44 yd31400 mm 55.1" 1505 mm 59.3" 845 kg 1,860 lb 5 □

General purpose use, density up to 1.8 ton/m31.52 U.S. ton/yd

3

Light duty work, density up to 1.2 ton/m

3

1.01 U.S. ton/yd

3

□ General purpose use, density up to 1.5 ton/m31.26 U.S. ton/yd3X Not usable

SPECIFICATIONS

H YDRAULIC E XCAVATOR

HYDRAULIC EXCAVATOR

PC220-7

PC220-7 0

Page 7

LIFTING CAPACITY

A

B

C

12

LIFTING CAPACITY

A

B

C

13

A: Reach from swing center

B: Bucket hook height

C: Lifting capacity

Cf: Rating over front

Cs: Rating over side

: Rating at maximum reach

Conditions:

● 5850 mm 19'2" one-piece boom

* Load is limited by hydraulic capacity rather than tipping. Ratings are based on SAE Standard No. J1097. Rated loads do not exceed 87% of hydraulic lift capacity

or 75% of tipping load.

PC220-7 Arm: 2500 mm 8'2" Bucket: 1.0 m31.31 yd

3

Shoe: 600 mm 23.6" triple grouser

A MAX 7.6 m 25' 6.1 m 20' 4.6 m 15' 3.0 m 10' 1.5 m 5'

B Cf Cs Cf Cs Cf Cs Cf Cs Cf Cs Cf Cs

7.6 m *4600 kg *4600 kg *4650 kg *4650 kg

25' *10,100 lb *10,100 lb *10,200 lb *10,200 lb

6.1 m *4400 kg 3750 kg *4650 kg *4650 kg

20' *9,700 lb 8,300 lb *10,300 lb *10,300 lb

4.6 m *4450 kg 3100 kg 4950 kg 3350 kg *5350 kg 5050 kg *6100 kg *6100 kg

15' *9,800 lb 6,800 lb 10,900 lb 7,400 lb *11,700 lb 11,100 lb *13,500 lb *13,500 lb

3.0 m 4100 kg 2750 kg 4800 kg 3250 kg *6350 kg 4750 kg 8250 kg 7500 kg

10' 9,100 lb 6,100 lb 10,600 lb 7,200 lb *14,000 lb 10,500 lb 18,200 lb 16,600 lb

1.5 m 3950 kg 2600 kg 4650 kg 3100 kg 6700 kg 4450 kg *10300 kg 6900 kg

5' 8,700 lb 5,800 lb 10,300 lb 6,900 lb 14,800 lb 9,900 lb *22,700 lb 15,200 lb

O m 4050 kg 2700 kg 4550 kg 3000 kg 6450 kg 4250 kg 10300 kg 6550 kg *7250 kg *7250 kg

0' 9,000 lb 5,900 lb 10,000 lb 6600 lb 14,300 lb 9,400 lb 22,800 lb 14,500 lb *16,000 lb *16,000 lb

–1.5 m 4500 kg 2950 kg 4500 kg 3000 kg 6400 kg 4200 kg 10200 kg 6450 kg *12450 kg *12450 kg *8000 kg *8000 kg

–5' 9,900 lb 6,500 lb 10,000 lb 6,600 lb 14,100 lb 9,200 lb 22,500 lb 14,300 lb *27,400 lb *27,400 lb *17,700 lb *17,700 lb

–3.0 m 5500 kg 3650 kg 6450 kg 4250 kg 10350 kg 6550 kg *16450 kg 13100 kg *13150 kg *13150 kg

–10' 12,100 lb 8,000 lb 14,200 lb 9,300 lb 22,800 lb 14,500 lb *36,300 lb 28,900 lb 29,000 lb *29,000 lb

–4.6 m *8000 kg 5500 kg *9350 kg 6650 kg *13700 kg 13650 kg

–15' *17,600 lb 12,100 lb *20,600 lb 14,700 lb *30,200 lb 30,100 lb

PC220-7 Arm: 2000 mm 6'7" Bucket: 1.0 m31.31 yd

3

Shoe: 600 mm 23.6" triple grouser

A MAX 7.6 m 25' 6.1 m 20' 4.6 m 15' 3.0 m 10' 1.5 m 5'

B Cf Cs Cf Cs Cf Cs Cf Cs Cf Cs Cf Cs

7.6 m *4750 kg *4750 kg

25' *10,500 lb *10,500 lb

6.1 m *4500 kg 4100 kg *5200 kg 5100 kg

20' *9,900 lb 9,100 lb *11,400 lb 11,300 lb

4.6 m *4550 kg 3300 kg *5800 kg 4950 kg *6850 kg *6850 kg *9750 kg *9750 kg

15' *10,000 lb 7,300 lb *12,800 lb 10,900 lb *15,100 lb *15,100 lb *21,500 lb *21,500 lb

3.0 m 4400 kg 2950 kg 4750 kg 3200 kg *6750 kg 4650 kg *8850 kg 7100 kg

10' 9,700 lb 6,500 lb 10,400 lb 7,000 lb *14,900 lb 10,300 lb 19,500 lb 15,700 lb

1.5 m 4250 kg 2800 kg 4600 kg 3050 kg 6600 kg 4400 kg 10500 kg 6700 kg

5' 9,400 lb 6,200 lb 10,200 lb 6,800 lb 14,600 lb 9,700 lb 23,100 lb 14,800 lb

O m 4400 kg 2900 kg 4550 kg 3000 kg 6400 kg 4200 kg 10200 kg 6450 kg

0' 9,700 lb 6,400 lb 10,000 lb 6,600 lb 14,200 lb 9,300 lb 22,500 lb 14,200 lb

–1.5 m 4900 kg 3250 kg 6350 kg 4150 kg 10200 kg 6450 kg *13000 kg 12900 kg

–5' 10,800 lb 7,100 lb 14,100 lb 9,200 lb 22,500 lb 14,200 lb *28,600 lb 28,400 lb

–3.0 m 6200 kg 4100 kg 6500 kg 4300 kg 10400 kg 6600 kg *15350 kg 13250 kg

–10' 13,700 lb 9,100 lb 14,300 lb 9,400 lb 22,900 lb 14,600 lb *33,900 lb 29,200 lb

–4.6 m *8150 kg 6800 kg *8350 kg 7700 kg

–15' *17,900 lb 15,000 lb *18,400 lb 15,500 lb

PC220-7 Arm: 3045 mm 10'0" Bucket: 1.0 m31.31 yd

3

Shoe: 600 mm 23.6" triple grouser

A

MAX

7.6 m 25' 6.1 m 20' 4.6 m 15' 3.0 m 10' 1.5 m 5'

B Cf Cs Cf Cs Cf Cs Cf Cs Cf Cs Cf Cs

7.6 m *2900 kg *2900 kg *3900 kg *3900 kg

25' *6,400 lb *6,400 lb *8,700 lb *8,700 lb

6.1 m *2750 kg *2750 kg *3700 kg 3500 kg *4100 kg *4100 kg

20' *6,100 lb *6,100 lb *8,200 lb 7,800 lb *9,000 lb 9,000 lb

4.6 m *2800 kg 2750 kg *4600 kg 3450 kg *4800 kg *4800 kg

15' *6,200 lb 6,000 lb *10,100 lb 7,600 lb *10,600 lb *10,600 lb

3.0 m *2950 kg 2450 kg 4900 kg 3350 kg *5900 kg 4900 kg *7450 kg *7450 kg *11800 kg *11800 kg

10' *6,500 lb 5,500 lb 10,800 lb 7,400 lb 13,000 lb 10,800 lb *17,900 lb *17,900 lb *26,000 lb *26,000 lb

1.5 m *3250 kg 2350 kg 4750 kg 3200 kg 6850 kg 4600 kg *9700 kg 7150 kg *6850 kg *6850 kg

5' *7,200 lb 5,200 lb 10,400 lb 7,000 lb 15,100 lb 10,100 lb *21,400 lb 15,700 lb *15,100 lb *15,100 lb

O m 3650 kg 2400 kg 4,600 kg 3050 kg 6550 kg 4350 kg 10500 kg 6700 kg *7800 kg *7800 kg

0' 8,100 lb 5,300 lb 10,100 lb 6,700 lb 14,500 lb 9,600 lb 23,200 lb 14,800 lb *17,100 lb *17,100 lb

–1.5 m 4000 kg 2600 kg 4550 kg 3000 kg 6450 kg 4200 kg 10300 kg 6550 kg *11150 kg 11150 kg *6900 kg *6900 kg

–5' 8,800 lb 5,800 lb 10,000 lb 6,600 lb 14,200 lb 9,300 lb 22,700 lb 14,400 lb *24,600 lb 24,600 lb *15,200 lb *15,200 lb

–3.0 m 4700 kg 3100 kg 6400 kg 4200 kg 10350 kg 6550 kg *16050 kg 13100 kg *10750 kg *10750 kg

–10' 10,400 lb 6,900 lb 14,200 lb 9,300 lb 22,800 lb 14,500 lb *35,400 lb 28,900 lb *23,700 lb *23,700 lb

–4.6 m 6500 kg 4300 kg 6600 kg 4350 kg *10400 kg 6750 kg *15200 kg 13500 kg

–15' 14,300 lb 9,500 lb 14,500 lb 9,600 lb 23,000 lb 14,900 lb *33,500 lb 29,800 lb

A: Reach from swing center

B: Bucket hook height

C: Lifting capacity

Cf: Rating over front

Cs: Rating over side

: Rating at maximum reach

Conditions:

● 5850 mm 19'2" one-piece boom

* Load is limited by hydraulic capacity rather than tipping. Ratings are based on SAE Standard No. J1097. Rated loads do not exceed 87% of hydraulic lift capacity

or 75% of tipping load.

PC220LC-7 Arm: 2000 mm 6'7" Bucket: 1.0 m31.31 yd

3

Shoe: 700 mm 27.6" triple grouser

A MAX 7.6 m 25' 6.1 m 20' 4.6 m 15' 3.0 m 10' 1.5 m 5'

B Cf Cs Cf Cs Cf Cs Cf Cs Cf Cs Cf Cs

7.6 m *4750 kg *4750 kg

25' *10,500 lb *10,500 lb

6.1 m *4500 kg *4500 kg *5200 kg *5200 kg

20' *9,900 lb *9,900 lb *11,400 lb *11,400 lb

4.6 m *4550 kg 3850 kg *5800 kg 5700 kg *6850 kg *6850 kg *9750 kg *9750 kg

15' *10,000 lb 8,500 lb *12,800 lb 12,500 lb *15,100 lb *15,100 lb *21,500 lb *21,500 lb

3.0 m *4800 kg 3450 kg *5800 kg 3700 kg *6750 kg 5400 kg *8850 kg 8300 kg

10' *10,600 lb 7,600 lb *12,800 lb 8,200 lb *14,900 lb 11,900 lb *19,500 lb 18,300 lb

1.5 m 5200 kg 3300 kg 5650 kg 3600 kg *7700 kg 5100 kg *10800 kg 7850 kg

5' 11,500 lb 7,300 lb 12,500 lb 7,900 lb *17,000 lb 11,300 lb *23,800 lb 17,300 lb

O m 5400 kg 3400 kg 5600 kg 3500 kg 7950 kg 4950 kg *11650 kg 7600 kg

0' 11,900 lb 7,500 lb 12,300 lb 7,700 lb 17,500 lb 10,900 lb *25,700 lb 16,800 lb

–1.5 m 6050 kg 3800 kg 7900 kg 4900 kg *11650 kg 7600 kg *13000 kg *13000 kg

–5' 13,300 lb 8,400 lb 17,400 lb 10,800 lb *25,700 lb 16800 lb *28,600 lb *28,600 lb

–3.0 m *7550 kg 4800 kg 7850 kg 5000 kg *10850 kg 7750 kg *15350 kg *15350 kg

–10' 16,600 lb 10,600 lb 17,300 lb 11,100 lb *23,900 lb 17,100 lb *33,900 lb *33,900 lb

–4.6 m *8150 kg 7950 kg *8350 kg 8200 kg

–15' *17,900 lb 17,500 lb *18,400 lb 18,000 lb

PC220LC-7 Arm: 2500 mm 8'2" Bucket: 1.0 m31.31 yd

3

Shoe: 700 mm 27.6" triple grouser

A MAX 7.6 m 25' 6.1 m 20' 4.6 m 15' 3.0 m 10' 1.5 m 5'

B Cf Cs Cf Cs Cf Cs Cf Cs Cf Cs Cf Cs

7.6 m *4600 kg *4600 kg *4650 kg *4650 kg

25' *10,100 lb *10,100 lb *10,200 lb *10,200 lb

6.1 m *4400 kg 4350 kg *4650 kg *4650 kg

20' *9,700 lb 9,600 lb *10,300 lb *10,300 lb

4.6 m *4450 kg 3600 kg *5000 kg 3900 kg *5350 kg *5350 kg *6100 kg *6100 kg

15' *9,800 lb 7,900 lb *11,100 lb 8,600 lb *11,700 lb *11,700 lb *13,500 lb *13,500 lb

3.0 m *4750 kg 3250 kg *5500 kg 3800 kg *6350 kg 5500 kg *8250 kg *8250 kg

10' *10,500 lb 7,100 lb *12,100 lb 8,400 lb *14,000 lb 12,100 lb *18,200 lb *18,200 lb

1.5 m 4850 kg 3100 kg 5700 kg 3650 kg *7400 kg 5200 kg *10300 kg 8050 kg

5' 10,800 lb 5,800 lb 12,600 lb 8,000 lb *16,300 lb 11,500 lb *22,700 lb 17,800 lb

O m 5000 kg 3150 kg 5600 kg 3550 kg 8000 kg 5000 kg *11450 kg 7700 kg *7250 kg *7250 kg

0' 11,100 lb 7,000 lb 12,400 lb 7,800 lb 17,600 lb 11,000 lb *25,300 lb 17,000 lb *16,000 lb *16,000 lb

–1.5 m 5550 kg 3500 kg 5550 kg 3500 kg 7900 kg 4900 kg *11800 kg 7650 kg *12450 kg *12450 kg *8000 kg *8000 kg

–5' 12,200 lb 7,700 lb 12,300 lb 7,700 lb 17,400 lb 10,800 lb *26,000 lb 16,800 lb *27,400 lb *27,400 lb *17,700 lb *17,700 lb

–3.0 m 6800 kg 4250 kg 7950 kg 4950 kg *11250 kg 7700 kg *16450 kg 15700 kg *13150 kg *13150 kg

–10' 14,900 lb 9,400 lb 17,600 lb 10,900 lb *24,900 lb 17,000 lb *36,300 lb 34,700 lb 29,000 lb *29,000 lb

–4.6 m *8000 kg 6400 kg *9350 kg 7800 kg *13700 kg *13700 kg

–15' *17,600 lb 14,100 lb *20,600 lb 17,200 lb *30,200 lb *30,200 lb

PC220LC-7 Arm: 3045 mm 10'0" Bucket: 1.0 m31.31 yd

3

Shoe: 700 mm 27.6" triple grouser

A

MAX

7.6 m 25' 6.1 m 20' 4.6 m 15' 3.0 m 10' 1.5 m 5'

B Cf Cs Cf Cs Cf Cs Cf Cs Cf Cs Cf Cs

7.6 m *2900 kg *2900 kg *3900 kg *3900 kg

25' *6,400 lb *6,400 lb *8,700 lb *8,700 lb

6.1 m *2750 kg *2750 kg *3700 kg *3700 kg *4100 kg *4100 kg

20' *6,100 lb *6,100 lb *8,200 lb *8,200 lb *9,000 lb 9,000 lb

4.6 m *2800 kg *2800 kg *4600 kg 4000 kg *4800 kg *4800 kg

15' *6,200 lb *6,200 lb *10,100 lb 8,800 lb *10,600 lb *10,600 lb

3.0 m *2950 kg 2900 kg *5150 kg 3850 kg *5900 kg 5650 kg *7450 kg *7450 kg *11800 kg *11800 kg

10' *6,500 lb 6,400 lb *11,400 lb 8,500 lb 13,000 lb 12,400 lb *16,500 lb *16,500 lb *26,000 lb *26,000 lb

1.5 m *3250 kg 2800 kg *5800 kg 3700 kg *7050 kg 5350 kg *9700 kg 8300 kg *6850 kg *6850 kg

5' *7,200 lb 6,200 lb *12,800 lb 8,200 lb *15,500 lb 11,700 lb *21,400 lb 18,300 lb *15,100 lb *15,100 lb

O m *3750 kg 2850 kg 5650 kg 3600 kg *8000 kg 5100 kg *11200 kg 7900 kg *7800 kg *7800 kg

0' *8,300 lb 6,300 lb 12,500 lb 7,900 lb *17,600 lb 11,200 lb *24,700 lb 17,400 lb *17,100 lb *17,100 lb

–1.5 m *4600 kg 3100 kg 5600 kg 3500 kg 7950 kg 4950 kg *11800 kg 7700 kg *11150 kg 11150 kg *6900 kg *6900 kg

–5' *10,100 lb 6,800 lb 12,300 lb 7,800 lb 17,500 lb 10,900 lb *26,100 lb 17,000 lb *24,600 lb 24,600 lb *15,200 lb *15,200 lb

–3.0 m 5800 kg 3650 kg 7950 kg 4950 kg *11650 kg 7750 kg *16050 kg 15700 kg *10750 kg *10750 kg

–10' 12,800 lb 8,100 lb 17,500 lb 10,900 lb *25,700 lb 17,000 lb *35,400 lb 34,600 lb *23,700 lb *23,700 lb

–4.6 m *7250 kg 5050 kg *7400 kg 5100 kg *10400 kg 7950 kg *15200 kg *15200 kg

–15' *16,000 lb 11,100 lb *16,300 lb 11,300 lb *23,000 lb 17,500 lb *33,500 lb *33,500 lb

Page 8

LIFTING CAPACITY WITH LIFTING MODE ON MULTI-FUNCTION COLOR MONITOR

A

B

C

15

LIFTING CAPACITY WITH LIFTING MODE ON MULTI-FUNCTION COLOR MONITOR

A

B

C

14

A: Reach from swing center

B: Bucket hook height

C: Lifting capacity

Cf: Rating over front

Cs: Rating over side

: Rating at maximum reach

Conditions:

● 5850 mm 19'2" one-piece boom

PC220-7 Arm: 2000 mm 6'7" Bucket: 1.0 m31.31 yd

3

Shoe: 600 mm 23.6" triple grouser

A MAX 7.6 m 25' 6.1 m 20' 4.6 m 15' 3.0 m 10' 1.5 m 5'

B Cf Cs Cf Cs Cf Cs Cf Cs Cf Cs Cf Cs

7.6 m *5150 kg *5150 kg

25' *11,400 lb *11,400 lb

6.1 m *4850 kg 4100 kg *5700 kg 5100 kg

20' *10,700 lb 9,100 lb *12,500 lb 11,300 lb

4.6 m 4900 kg 3300 kg *6350 kg 4950 kg *7450 kg *7450 kg *10600 kg *10600 kg

15' 10,800 lb 7,300 lb *14,000 lb 10,900 lb *16,500 lb *16,500 lb *23,400 lb *23,400 lb

3.0 m 4400 kg 2950 kg 4750 kg 3200 kg 6900 kg 4650 kg *9650 kg 7100 kg

10' 9,700 lb 6,500 lb 10,400 lb 7,000 lb 15,200 lb 10,300 lb *21,300 lb 15,700 lb

1.5 m 4250 kg 2800 kg 4600 kg 3050 kg 6600 kg 4400 kg 10500 kg 6700 kg

5' 9,400 lb 6,200 lb 10,200 lb 6,800 lb 14,600 lb 9,700 lb 23,100 lb 14,800 lb

O m 4400 kg 2900 kg 4550 kg 3000 kg 6400 kg 4200 kg 10200 kg 6450 kg

0' 9,700 lb 6,400 lb 10,000 lb 6,600 lb 14,200 lb 9,300 lb 22,500 lb 14,200 lb

–1.5 m 4900 kg 3250 kg 6350 kg 4150 kg 10200 kg 6450 kg *13950 kg 12900 kg

–5' 10,800 lb 7,100 lb 14,100 lb 9,200 lb 22,500 lb 14,200 lb *30,800 lb 28,400 lb

–3.0 m 6200 kg 4100 kg 6500 kg 4300 kg 10400 kg 6600 kg *16750 kg 13250 kg

–10' 13,700 lb 9,100 lb 14,300 lb 9,400 lb 22,900 lb 14,600 lb *36,900 lb 29,200 lb

–4.6 m *8900 kg 6800 kg *9100 kg 7000 kg

–15' *19,500 lb 15,000 lb *20,100 lb 15,500 lb

PC220-7 Arm: 2500 mm 8'2" Bucket: 1.0 m31.31 yd

3

Shoe: 600 mm 23.6" triple grouser

A MAX 7.6 m 25' 6.1 m 20' 4.6 m 15' 3.0 m 10' 1.5 m 5'

B Cf Cs Cf Cs Cf Cs Cf Cs Cf Cs Cf Cs

7.6 m *4950 kg *4950 kg *5000 kg *5000 kg

25' *11,000 lb *11,000 lb *11,100 lb *11,100 lb

6.1 m *4750 kg 3750 kg *5100 kg *5100 kg

20' *10,500 lb 8,300 lb *11,300 lb *11,300 lb

4.6 m 4550 kg 3100 kg 4950 kg 3350 kg *5850 kg 5050 kg *6650 kg *6650 kg

15' 10,000 lb 6,800 lb 10,900 lb 7,400 lb *12,900 lb 11,100 lb *14,700 lb *14,700 lb

3.0 m 4100 kg 2750 kg 4800 kg 3250 kg *6950 kg 4750 kg *9000 kg 7500 kg

10' 9,100 lb 6,100 lb 10,600 lb 7,200 lb *15,300 lb 10,500 lb *19,900 lb 16,600 lb

1.5 m 3950 kg 2600 kg 4650 kg 3100 kg 6700 kg 4450 kg 10700 kg 6900 kg

5' 8,700 lb 5,800 lb 10,300 lb 6,900 lb 14,800 lb 9,900 lb 23,600 lb 15,200 lb

O m 4050 kg 2700 kg 4550 kg 3000 kg 6450 kg 4250 kg 10300 kg 6550 kg *7850 kg *7850 kg

0' 9,000 lb 5,900 lb 10,000 lb 6600 lb 14,300 lb 9,400 lb 22,800 lb 14,500 lb *17,300 lb *17,300 lb

–1.5 m 4500 kg 2950 kg 4500 kg 3000 kg 6400 kg 4200 kg 10200 kg 6450 kg *13400 kg 12850 kg *8650 kg *8650 kg

–5' 9,900 lb 6,500 lb 10,000 lb 6,600 lb 14,100 lb 9,200 lb 22,500 lb 14,300 lb *29,500 lb 28,300 lb *19,000 lb *19,000 lb

–3.0 m 5500 kg 3650 kg 6450 kg 4250 kg 10350 kg 6550 kg *17900 kg 13100 kg *14150 kg *14150 kg

–10' 12,100 lb 8,000 lb 14,200 lb 9,300 lb 22,800 lb 14,500 lb *39,500 lb 28,900 lb *31,200 lb *31,200 lb

–4.6 m 8350 kg 5500 kg *10250 kg 6650 kg *14950 kg 13650 kg

–15' 18,400 lb 12,100 lb *22,600 lb 14,700 lb *32,900 lb 30,100 lb

* Load is limited by hydraulic capacity rather than tipping. Ratings are based on SAE Standard No. J1097. Rated loads do not exceed 87% of hydraulic lift capacity

or 75% of tipping load.

PC220-7 Arm: 3045 mm 10'0" Bucket: 1.0 m31.31 yd

3

Shoe: 600 mm 23.6" triple grouser

A MAX 7.6 m 25' 6.1 m 20' 4.6 m 15' 3.0 m 10' 1.5 m 5'

B Cf Cs Cf Cs Cf Cs Cf Cs Cf Cs Cf Cs

7.6 m *3150 kg *3150 kg *4300 kg *4300 kg

25' *7,000 lb *7,000 lb *9,500 lb *9,500 lb

6.1 m *3050 kg *3050 kg *4050 kg 3500 kg *4500 kg *4500 kg

20' *6,700 lb *6,700 lb *8,900 lb 7,800 lb *9,900 lb *9,900 lb

4.6 m *3050 kg 2750 kg 5050 kg 3450 kg *5250 kg 5200 kg

15' *6,700 lb 6,000 lb 11,100 lb 7,600 lb *11,600 lb 11,400 lb

3.0 m *3250 kg 2450 kg 4900 kg 3350 kg *6450 kg 4900 kg *8150 kg 7800 kg *12850 kg *12850 kg

10' *7,100 lb 5,400 lb 10,800 lb 7,400 lb *14,200 lb 10,800 lb *17,900 lb 17,200 lb *28,300 lb *28,300 lb

1.5 m *3550 kg 2350 kg 4750 kg 3200 kg 6850 kg 4600 kg *10550 kg 7150 kg *7400 kg *7400 kg

5' *7,800 lb 5,200 lb 10,400 lb 7,000 lb 15,100 lb 10,100 lb *23,300 lb 15,700 lb *16,300 lb *16,300 lb

O m 3650 kg 2400 kg 4600 kg 3050 kg 6550 kg 4350 kg 10500 kg 6700 kg *8400 kg *8400 kg

0' 8,100 lb 5,300 lb 10,100 lb 6,700 lb 14,500 lb 9,600 lb 23,200 lb 14,800 lb *18,500 lb *18,500 lb

–1.5 m 4000 kg 2600 kg 4550 kg 3000 kg 6450 kg 4200 kg 10300 kg 6550 kg *12000 kg *12000 kg *7450 kg *7450 kg

–5' 8,800 lb 5,800 lb 10,000 lb 6,600 lb 14,200 lb 9,300 lb 22,700 lb 14,400 lb *26,400 lb *26,400 lb *16,400 lb *16,400 lb

–3.0 m 4700 kg 3100 kg 6400 kg 4200 kg 10350 kg 6550 kg *17300 kg 13100 kg *11150 kg *11150 kg

–10' 10,400 lb 6,900 lb 14,200 lb 9,300 lb 22,800 lb 14,400 lb *38,100 lb 28,900 lb *25500 lb *25,500 lb

–4.6 m 6500 kg 4300 kg 6600 kg 4350 kg 10550 kg 6750 kg *16550 kg 13500 kg

–15' 14,300 lb 9,500 lb 14,500 lb 9,600 lb 23,300 lb 14,900 lb *36,500 lb 29,800 lb

A: Reach from swing center

B: Bucket hook height

C: Lifting capacity

Cf: Rating over front

Cs: Rating over side

: Rating at maximum reach

Conditions:

● 5850 mm 19'2" one-piece boom

* Load is limited by hydraulic capacity rather than tipping. Ratings are based on SAE Standard No. J1097. Rated loads do not exceed 87% of hydraulic lift capacity

or 75% of tipping load.

PC220LC-7 Arm: 3045 mm 10'0" Bucket: 1.0 m31.31 yd

3

Shoe: 700 mm 27.6" triple grouser

A MAX 7.6 m 25' 6.1 m 20' 4.6 m 15' 3.0 m 10' 1.5 m 5'

B Cf Cs Cf Cs Cf Cs Cf Cs Cf Cs Cf Cs

7.6 m *3150 kg *3150 kg *4300 kg *4300 kg

25' *7,000 lb *7,000 lb *9,500 lb *9,500 lb

6.1 m *3050 kg *3050 kg *4050 kg *4050 kg *4500 kg *4500 kg

20' *6,700 lb *6,700 lb *8,900 lb *8,900 lb *9,900 lb 9,900 lb

4.6 m *3050 kg *3050 kg *5050 kg 4000 kg *5250 kg *5250 kg

15' *6,700 lb *6,700 lb *11,100 lb 8,800 lb *11,600 lb *11,600 lb

3.0 m *3250 kg 2900 kg *5650 kg 3850 kg *6450 kg 5650 kg *8150 kg *8150 kg *12850 kg *12850 kg

10' *7,100 lb 6,400 lb *12,500 lb 8,500 lb 14,200 lb 12,400 lb *17,900 lb *17,900 lb *28,300 lb *28,300 lb

1.5 m *3550 kg 2800 kg 5800 kg 3700 kg *7700 kg 5350 kg *10550 kg 8300 kg *7400 kg *7400 kg

5' *7,800 lb 6,200 lb 12,800 lb 8,200 lb *17,000 lb 11,700 lb *23,300 lb 18,300 lb *16,300 lb *16,300 lb

O m *4050 kg 2850 kg 5650 kg 3600 kg 8100 kg 5100 kg *12200 kg 7900 kg *8400 kg *8400 kg

0' *9,000 lb 6,300 lb 12,500 lb 7,900 lb 17,900 lb 11,200 lb *26,900 lb 17,400 lb *18,500 lb *18,500 lb

–1.5 m 4900 kg 3100 kg 5600 kg 3500 kg 7950 kg 4950 kg *12900 kg 7700 kg *12000 kg 12000 kg *7450 kg *7450 kg

–5' 10,800 lb 6,800 lb 12,300 lb 7,800 lb 17,500 lb 10,900 lb *28,400 lb 17,000 lb *26,400 lb 26,400 lb *16,400 lb *16,400 lb

–3.0 m 5800 kg 3650 kg 7950 kg 4950 kg *12700 kg 7750 kg *17300 kg 15700 kg *11500 kg *11500 kg

–10' 12,800 lb 8,100 lb 17,500 lb 10,900 lb *28,000 lb 17,000 lb *38,100 lb 34,600 lb *25,500 lb *25,500 lb

–4.6 m *7950 kg 5050 kg *8100 kg 5100 kg *11350 kg 7950 kg *16550 kg 16150 kg

–15' *17,600 lb 11,100 lb *17,800 lb 11,300 lb *25,100 lb 17,500 lb *36,500 lb 35,600 lb

PC220LC-7 Arm: 2000 mm 6'7" Bucket: 1.0 m31.31 yd

3

Shoe: 700 mm 27.6" triple grouser

A MAX 7.6 m 25' 6.1 m 20' 4.6 m 15' 3.0 m 10' 1.5 m 5'

B Cf Cs Cf Cs Cf Cs Cf Cs Cf Cs Cf Cs

7.6 m *5150 kg *5150 kg

25' *11,400 lb *11,400 lb

6.1 m *4850 kg 4750 kg *5700 kg *5700 kg

20' *10,700 lb 10,500 lb *12,500 lb *12,500 lb

4.6 m *4900 kg 3850 kg *6350 kg 5700 kg *7450 kg *7450 kg *10600 kg *10600 kg

15' *10,800 lb 8,500 lb *14,000 lb 12,500 lb *16,500 lb *16,500 lb *23,400 lb *23,400 lb

3.0 m *5200 kg 3450 kg *5800 kg 3700 kg *7350 kg 5400 kg *9650 kg 8300 kg

10' *11,500 lb 7,600 lb *12,800 lb 8,200 lb *16,300 lb 11,900 lb *21,300 lb 18,300 lb

1.5 m 5200 kg 3300 kg 5650 kg 3600 kg 8150 kg 5100 kg *11750 kg 7850 kg

5' 11,500 lb 7,300 lb 12,500 lb 7,900 lb 18,000 lb 11,300 lb *25,900 lb 17,300 lb

O m 5400 kg 3400 kg 5600 kg 3500 kg 7950 kg 4950 kg *12700 kg 7600 kg

0' 11,900 lb 7,500 lb 12,300 lb 7,700 lb 17,500 lb 10,900 lb *28,000 lb 16,800 lb

–1.5 m 6050 kg 3800 kg 7900 kg 4900 kg *12700 kg 7600 kg *13950 kg *13950 kg

–5' 13,300 lb 8,400 lb 17,400 lb 10,800 lb *28,000 lb 16800 lb *30,800 lb *30,800 lb

–3.0 m 7650 kg 4800 kg 8050 kg 5000 kg *11800 kg 7750 kg *16750 kg 15850 kg

–10' 16,600 lb 10,600 lb 17,700 lb 11,100 lb *26,100 lb 17,100 lb *36,900 lb 34,900 lb

–4.6 m *8900 kg 7950 kg *9100 kg 8200 kg

–15' *19,600 lb 17,500 lb *20,100 lb 18,000 lb

PC220LC-7 Arm: 2500 mm 8'2" Bucket: 1.0 m31.31 yd

3

Shoe: 700 mm 27.6" triple grouser

A MAX 7.6 m 25' 6.1 m 20' 4.6 m 15' 3.0 m 10' 1.5 m 5'

B Cf Cs Cf Cs Cf Cs Cf Cs Cf Cs Cf Cs

7.6 m *4950 kg *4950 kg *5000 kg *5000 kg

25' *11,000 lb *11,000 lb *11,100 lb *11,100 lb

6.1 m *4750 kg 4350 kg *5100 kg *5100 kg

20' *10,500 lb 9,600 lb *11,300 lb *11,300 lb

4.6 m *4850 kg 3600 kg *5500 kg 3900 kg *5850 kg 5800 kg *6650 kg *6650 kg

15' *10,700 lb 7,900 lb *12,200 lb 8,600 lb *12,900 lb 12,800 lb *14,700 lb *14,700 lb

3.0 m 5050 kg 3250 kg 5900 kg 3800 kg *6950 kg 5500 kg *9000 kg 8700 kg

10' 11,100 lb 7,100 lb 13,000 lb 8,400 lb *15,300 lb 12,100 lb *19,900 lb 19,200 lb

1.5 m 4850 kg 3100 kg 5700 kg 3650 kg *8100 kg 5200 kg *11200 kg 8050 kg

5' 10,800 lb 5,800 lb 12,600 lb 8,000 lb *17,900 lb 11,500 lb *24,800 lb 17,800 lb

O m 5000 kg 3150 kg 5600 kg 3550 kg 8000 kg 5000 kg *12500 kg 7700 kg *7850 kg *7850 kg

0' 11,100 lb 7,000 lb 12,400 lb 7,800 lb 17,600 lb 11,000 lb *27,600 lb 17,000 lb *17,300 lb *17,300 lb

–1.5 m 5550 kg 3500 kg 5550 kg 3500 kg 7900 kg 4900 kg *12850 kg 7650 kg *13400 kg *13400 kg *8650 kg *8650 kg

–5' 12,200 lb 7,700 lb 12,300 lb 7,700 lb 17,400 lb 10,800 lb *28,300 lb 16,800 lb *29,500 lb *29,500 lb *19,000 lb *19,000 lb

–3.0 m 6800 kg 4250 kg 7950 kg 4950 kg *12300 kg 7700 kg *17900 kg 15700 kg *14150 kg *14150 kg

–10' 14,900 lb 9,400 lb 17,600 lb 10,900 lb *27,100 lb 17,000 lb *39,500 lb 34,700 lb 31,200 lb *31,200 lb

–4.6 m *8750 kg 6400 kg *10250 kg 7800 kg *14950 kg *14950 kg

–15' *19,300 lb 14,100 lb *22,600 lb 17,200 lb *32,900 lb *32,900 lb

Page 9

OPTIONAL EQUIPMENT

STANDARD EQUIPMENT

• Alternator, 35 Ampere, 24V

• Auto-Decel

• Automatic engine warm-up system

• Automatic de-aeration system for fuel line

• Batteries, 110 Ah/2 x 12V

• Boom holding valve

• Cab, capable FOG with optional bolt-on

top guard

• Counterweight

• Dry type air cleaner, double element

• Electric horn

• Engine, Komatsu SAA6D102E

• Engine overheat prevention system

• Fan guard structure

• Hydraulic track adjusters (each side)

• Monitor panel, 7-segment

• Power maximizing system

• PPC hydraulic control system

• Radiator & oil cooler dust proof net

• Rear view mirror, R.H.

• Starting motor, 4.5 kW/24 v x 1

• Suction fan

• Track guiding guard, center section

• Track roller

—PC220-7, 8 each side

—PC220LC-7, 10 each side

• Track shoe

—PC220-7, 600 mm 24" triple grouser

—PC220LC-7, 700 mm 28" triple grouser

• Working light, 2 (boom and RH)

• Working mode selection system

• Air conditioner with defroster

• Alternator, 60 ampere, 24 v

•Arms

—3045 mm 10'0" arm assembly

—2500 mm 8'2" arm assembly

—2000 mm 6'7" arm assembly

• Batteries, large capacity

• Bolt-on top guard OPG level 2 (FOG)

• Boom, 5850 mm 19'2"

• Cab accessories

—Rain visor

—Sun visor

• Cab front guard

—Full height guard

—Half height guard

• Heater with defroster

• Long lubricating intervals for implement

bushing (500 hours)

• Multi-Function Color Monitor

• Rearview mirror (LH)

• Seat belt, retractable

• Seat, suspension

• Service valve

• Shoes, triple grouser shoes

—PC220-7

700 mm 27.6",

800 mm 31.5"

—PC220LC-7

600 mm 23.6", 800 mm 31.5"

• Starting motor, 5.5 kW/24 v x 1

• Track roller guards (full length)

• Track frame undercover

• Travel alarm

• Working lights (2 on cab)

• Ditch cleaning bucket

—Capacity

SAE heaped 0.80 m

3

1.05 yd

3

CECE heaped 0.70 m30.92 yd

3

Width 1800 mm 70.9"

• Slope finishing bucket for scraping

slopes of banks

—Capacity

SAE heaped 0.4 m30.52 yd

3

CECE heaped 0.35 m30.46 yd

3

—Width 2000 mm 78.7"

• Trapezoidal bucket is ideal for digging

ditches and for drainage works

—Capacity

SAE heaped 0.7 m30.92 yd

3

CECE heaped 0.5 m30.65 yd

3

• Ripper bucket for hard and rocky ground

—Capacity

SAE heaped 0.62 m30.81 yd

3

CECE heaped 0.56 m30.73 yd

3

Width 990 mm 39.0"

• Single-shank ripper and three-shank

ripper are recommended for rock-digging

and crushing, hard soil digging,

pavement-removal works, etc.

SPECIAL PURPOSE BUCKET

www.Komatsu.com

CEN00045-03 Materials and specifications are subject to change without notice.

is a trademark of Komatsu Ltd. Japan.

Printed in Japan 200808 IP.As(10)

Loading...

Loading...