Komatsu PC210, PC210LC-6K, PC240LC, PC240NLC-6K Service Manual

EEAM006011

Operation &

Maintenance Manual

PC210, PC210LC

PC240LC,PC240NLC-

HYDRAULIC EXCAVATOR

SERIAL NUMBER

PC210-6K - K34552

PC210LC-6K - K34552

PC240LC-6K - K34227

PC240NLC-6K - K34227

and up

and up

and up

and up

-

6K

6K

WARNING

Unsafe use of this machine may cause serious injury or

death. Operators and maintenance personnel must read

this manual before operating or maintaining this

machine. This manual should be kept inside the cab for

reference and periodically reviewed by all personel who

will come into contact with the machine.

FOREWORD

FOREWORD

This manual provides rules and guidelines which will help you use this machine safely and effectively. Keep this

manual handy and have all personnel read it periodically. If this manual has been lost or has become dirty and can

not be read, request a replacement manual from Komatsu or your Komatsu distributor.

If you sell the machine, be sure to give this manual to the new owners.

Continuing improvements in the design of this machine can lead to changes in detail which may not be reflected in

this manual. Consul t Komatsu or your Komatsu distr ibutor for th e latest avai lable inf ormatio n for your machi ne or

for questions regarding information in this manual.

WARNING

● This operation & maintenance manual may contain

attachments and optional equipment that are not available in your area. Please consult you r loca l Komatsu distributor for those items you require.

● This machine complies with EC directive (89/392/EEC).

Machines complying with this directive display the CE

mark

● Improper operation and maintenance of this machine can

be hazardous and could result in serious injury or death.

● Operators and maintenance personnel should read this

manual thoroughly before beginning operation or maintenance.

● Some actions involved in operation and maintenance of

the machine can cause a seri ous accid e nt, if the y are not

done in a manner described in this manual.

● The procedures and precautions given in this manual

apply only to intended uses of the machine. If you use

your machine for any unintended uses that are n ot specifically prohibited, you must be sure that it is safe for

you and others. In no event should you or others engage

in prohibited uses or actions as described in this manual.

● Komatsu delivers machines that comply with all applica-

ble regulations and standards of the country to which it

has been shipped. If this machine has been purchased in

another country or purchased from someone in another

country, it may lack certain safety devices and specifications that are necessary for use in your country. If there

is any question about whe ther your product compli es

with the applicable standards and regulations of your

country, consult Komatsu or your Komatsu distributor

before operating the machine.

● The description of safety is given in see “SAFETY

INFORMATION” on page 2. and in "SAFETY" from

page 17.

1

SAFETY INFORMATION

SAFETY INFORMATION

SAFETY MESSAGES

Most accidents are caused by the failure to follow fundamental

safety rules for the operation and maintenance of machines.

To avoid accidents, read, understand and follow all precautions

and warnings in this manual an d on the machin e before perf orming operation and maintenance.

To ide ntify h azar ds on the m achin e picto rial dec als ar e used (see

“POSITION FOR ATTACHING SAFETY LABELS” on page 49).

RED WARNING TRIANGLE - This is used on safety labels

where there is a high prob ability o f serious injury or deat h if the

hazard is not avoided. These safety messages or l abels usually

describe precautions that must be taken to avoid the hazard. Failure to avoid this h azard m ay al so r esult in s erious damage to the

machine.

ORANGE WARNING TRIANGLE - This is used on safety

labels where there is a po tentially dangerous s ituation which

could result in se ri ou s i nj ury o r deat h i f the haz ar d is not av oid ed.

These safety messages or labels usually desc ribe precautions

that must be taken to avoid the haza rd. Fail ure to av oid this h azard may also result in serious damage of the machine

YELLOW SAFETY TRIANGLE - This is used on safety

labels for hazards which could result in minor or moderate injury if

the hazard is not avoided. This word might also be used for a hazard where the only result could be damage to the machine.

NOTICE

This word is used for precau tions that must be taken to

avoid actions which could shorten the life of the machine.

Safety precautions are described in "SAFETY" from page 17.

Komatsu cannot predict every circumstance that might involve a

potential hazard in operation and maintenance. Therefore the

safety message in this manual and on the machine may not

include all possible safety precautions. If any procedures or

actions not speci fically rec ommended or allowed in this manual

are used, you m us t be s ur e tha t y ou a nd ot her s can do such pro cedures and actions sa fely a nd without dam aging the mac hine. If

you are unsure about the safety of some procedures, contact

Komatsu or your Komatsu distributor.

2

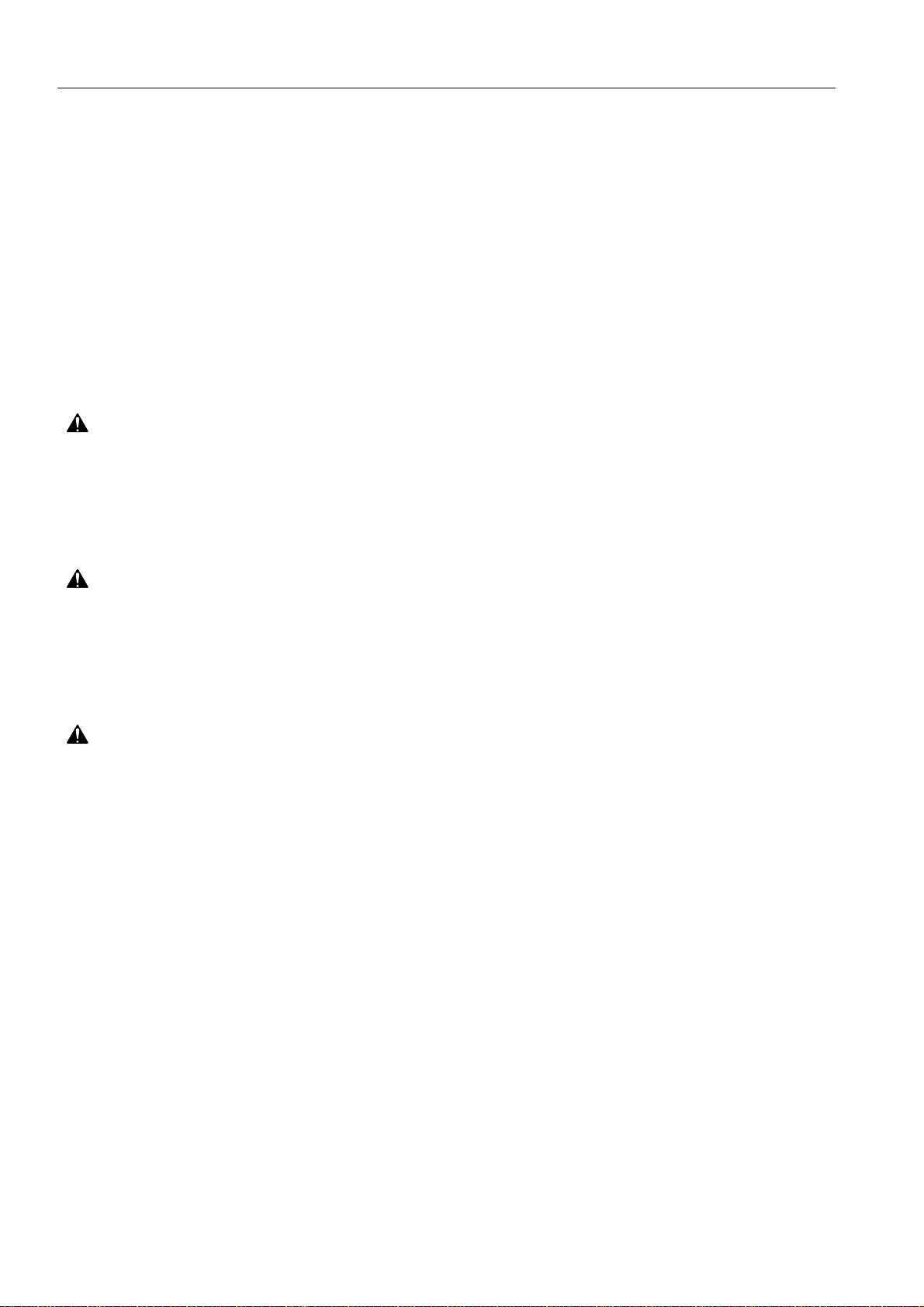

NOISE PC210, PC210LC-6K

Valid until 31 December 2001

● Operator ears noise value (Sound pressure level)

SAFETY INFORMATION

LpA

77

95/27/EC

● Ambient noise value (Sound power level)

Noise level indicated is the guaranteed value as specified in the

directive 86/662/EEC as amended by 95/27/EC

LWA

105

95/27/EC

3

SAFETY INFORMATION

Valid as of 1 January 2002

● Sound pressure level at the operator's station, measured

according to ISO6396 (Dynamic test method, simulated working cycle)

● Sound power leve l emitted. Th is is the guaran teed value as

specified in European directive 2000/14/EC.

4

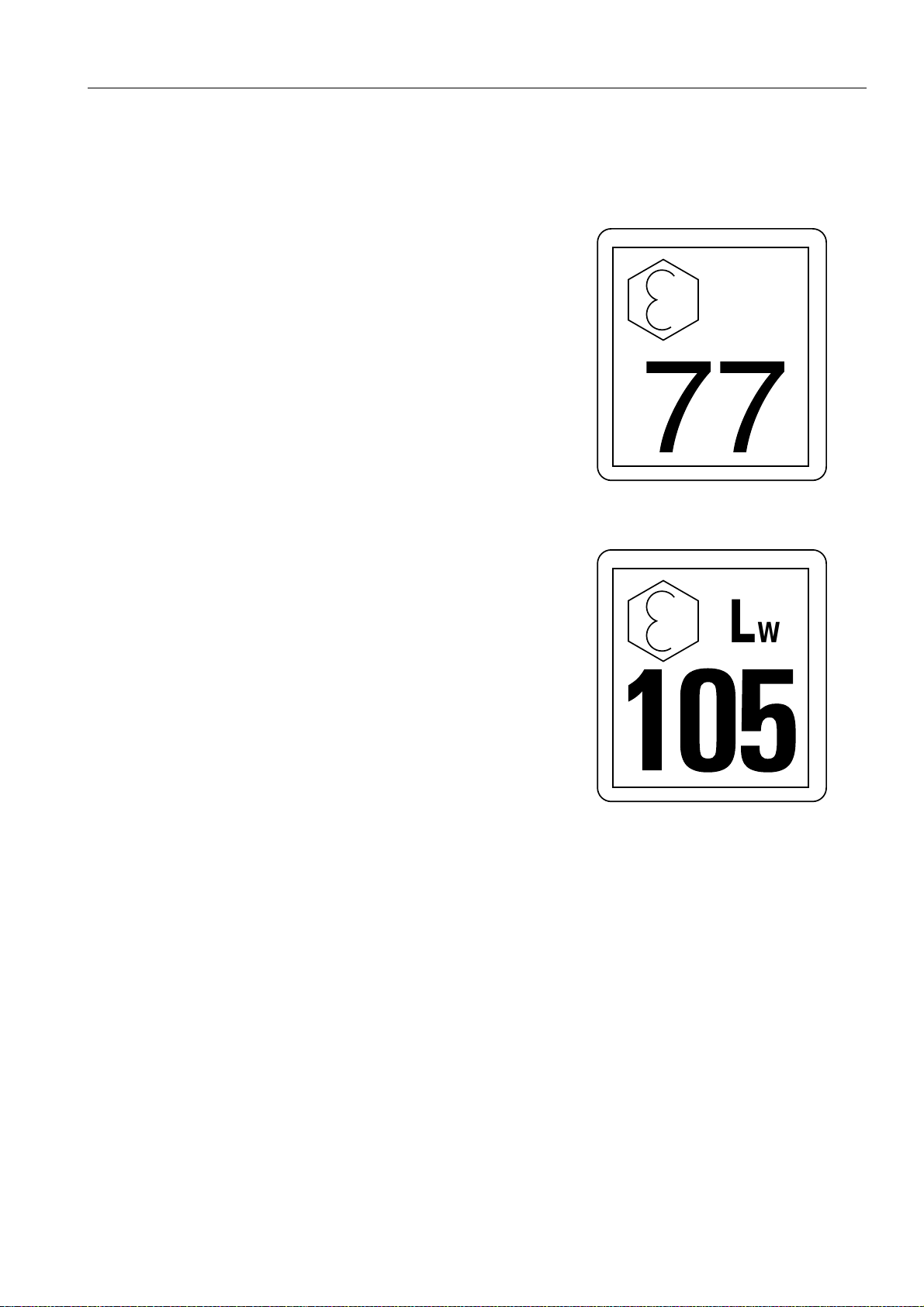

NOISE PC240LC, PC240NLC-6K

Valid until 31 December 2001

● Operator ears noise value (Sound pressure level)

SAFETY INFORMATION

LpA

77

95/27/EC

● Ambient noise value (Sound power level)

Noise level indicated is the guaranteed value as specified in the

directive 86/662/EEC as amended by 95/27/EC

LWA

105

95/27/EC

5

SAFETY INFORMATION

Valid as of 1 January 2002

● Sound pressure level at the operator's station, measured

according to ISO6396 (Dynamic test method, simulated working cycle)

● Sound power leve l emitted. Th is is the guaran teed value as

specified in European directive 2000/14/EC.

VIBRATION

The weighted root mean square acceleration valu e to which the

operator’s arms are subjected does not exceed 2.5 m/s²

The weighted root mean square acceleration valu e to which the

operator’s body is subjected does not exceed 0.5 m/s²

These results were obtained by accelerometers during trench digging.

6

INTRODUCTION

INTENDED USE

This Komatsu HYDR AUL IC EXCAVATOR is designed t o be used

mainly for the following work:

● Digging

● Smoothing work

● Ditching work

● Loading work

See the section “WORK POSSIBLE USING HYDRAULIC

EXCAVATOR” on page 129 for further details

FEATURES

INTRODUCTION

● This Komatsu HYDRAULIC EXCAVATOR is equipped with

various controls based on an advanced electronics system.

● The monitor panel greatly facilitates daily maintenance and

self-diagnosis.

● Working mode, travel speed and swing priority are selectable.

● Digging and lifting forc e can b e increas ed by ligh t-touch co n-

trol. (For details, see operation section.)

● Adjustable wrist contro l levers make operations sm ooth and

easy.

● Fresh filtered air conditioner assures comfortable operation.

● Low noise level and smart urban style design and colouring.

● Superb operation pe rformance provided by powerful engine

and high-performance hydraulic pumps.

● Low fuel consumption con troll ed by a n electro nic cont rol sys-

tem provides an environment-friendly machine.

7

INTRODUCTION

BREAKING IN YOUR NEW MACHINE

Your Komatsu machi ne ha s b een t horo ughl y ad just ed a nd te sted

before shipment.

However, operating the machine under severe condi tions at the

beginning can adversely affect the performance and shorten the

machine life.

Be sure to break in the machine for the initial 100 hours (as indicated by the hour meter.)

During breaking in:

● Idle the engine for 5 minutes after starting it up.

● Avoid operation with heavy loads or at high speeds.

● Sudden starting or acceleration, unnecessarily abrupt braking

and sharp turning should be avoided except in cases of emergency.

Additionally for the first 20 hours

● Avoid operating engine for prolonged periods at constant

speed (including idle.)

● Avoid high speed travelling for period s of more than 5 min-

utes.

Pay particular attention to oil pressure and temperature indicators

& check coolant and oil levels frequently during breaking in.

The precautions given i n this manu al for operatin g, m aintenanc e,

and safety procedures are only those that apply when this product

is used for the specified purpose. If the machine is used for a purpose that is not list ed in this ma nual, Koma tsu cannot bear an y

responsibility for safety. All consideration of safety in such operations is the responsibility of the user.

Operations that are prohibited in this manual must never be carried out under any circumstances.

8

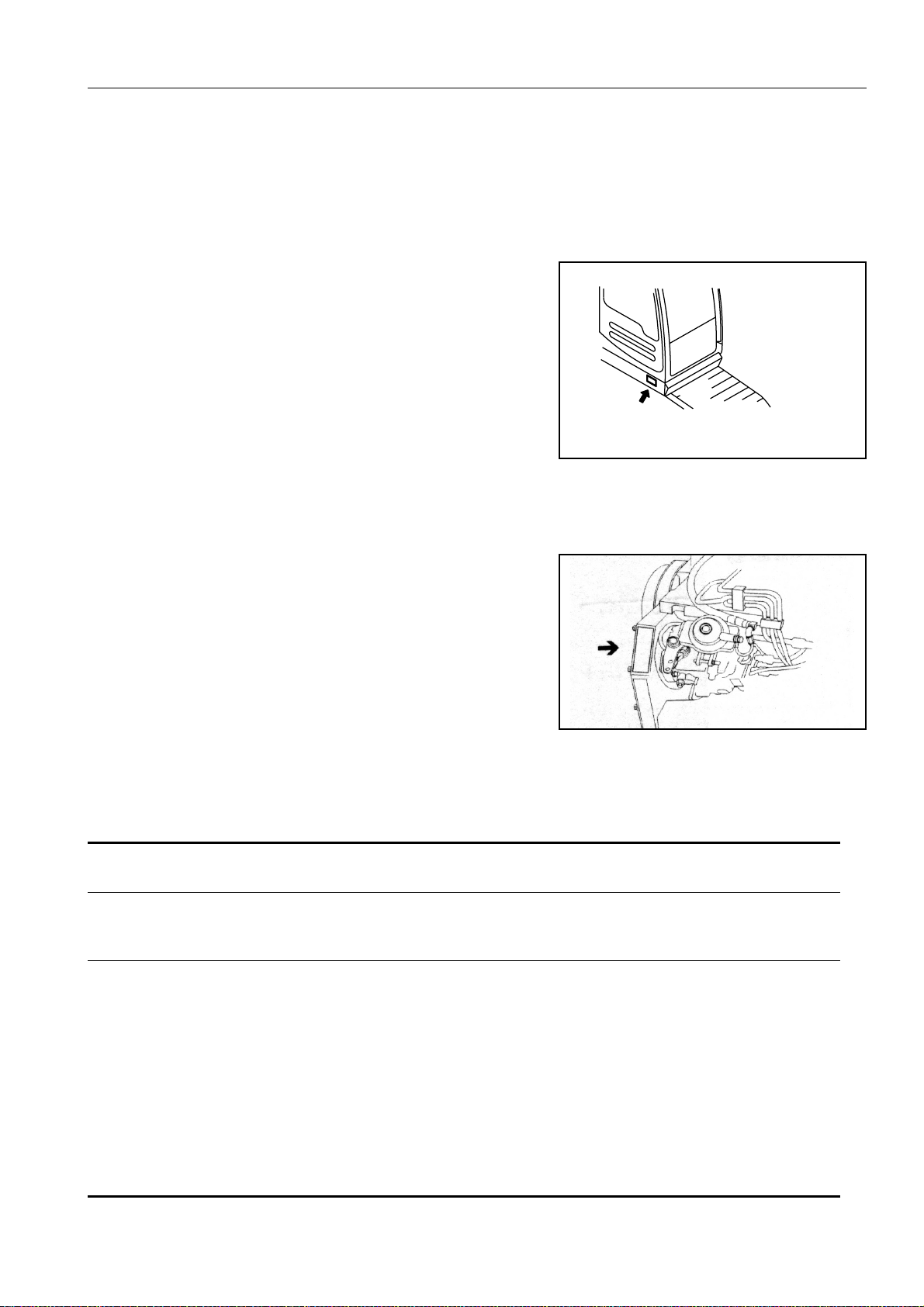

LOCATION OF PLATES, TABLES TO ENTER SERIAL NO. AND DISTRIBUTOR

LOCATION OF PLATES, TABLES TO ENTER SERIAL NO.

AND DISTRIBUTOR

MACHINE SERIAL NO. PLATE POSITION

On the front bottom right of the operator’s cab

ENGINE SERIAL NO. PLATE POSITION

AM088910

On the upper side of the engine cylinder head cover.

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

Machine serial No.

Engine serial No.

Manufacturers name: KOMATSU UK Ltd.

Address: Durham Road

Birtley

Chester-Le street

County Durham DH32QX

United Kingdom

Distributor

Address

Phone

9

LOCATION OF PLATES, TABLES TO ENTER SERIAL NO. AND DISTRIBUTOR

MACHINE SERIAL PLATE.

MASS

Komatsu UK Ltd, Birtley, Co. Durham, United Kingdom

205-00-K1290

10

CONTENTS

FOREWORD .................... ................................. ................................ ................................ ...................................... 1

SAFETY INFORMATION ........................................................................................................................................ 2

SAFETY MESSAGES ............................ ...... ....... ...... ....... ...... ....................................... ...... ......................... 2

NOISE PC210, PC210LC-6K ........................................................................................................................ 3

NOISE PC240LC, PC240NLC-6K ................................................................................................................ 5

VIBRATION ................................................................................................................................................... 6

INTRODUCTION ..................................................................................................................................................... 7

INTENDED USE ........................................................................................................................................... 7

FEATURES ......................... .......................... .................... ......................... ................................................... 7

BREAKING IN YOUR NEW MACHINE ........................................................................................................ 8

LOCATION OF PLATES, TABLES TO ENTER SERIAL NO.

AND DISTRIBUTOR ............................................................................................................................................... 9

MACHINE SERIAL NO. PLATE POSITION .................................................................................................. 9

ENGINE SERIAL NO. PLATE POSITION .................................................................................................... 9

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR ................................................................................ 9

MACHINE SERIAL PLATE. ....................................... ....... ...... ...... ....... ...... ....... ...... .................................... 10

SAFETY.............................................................................................................. 17

GENERAL PRECAUTIONS ... ...... ....... ...... ....... ...... ....... ...... ....... ...... ...... ....................................... ....................... 18

PRECAUTIONS DURING OPERATION .................................... ...... ...... ....... ...... ....... ...... ....... ...... ....... ................ 26

BEFORE STARTING ENGINE ................................................................................................................... 26

OPERATING MACHINE ............................................................................................................................. 28

TRANSPORTATION .................. ................................ ................................ ................................................. 35

BATTERY ................................................................................................................................................... 36

TOWING ..................................................................................................................................................... 37

BUCKET WITH HOOK ................................................................................................................................ 38

PRECAUTIONS FOR MAINTENANCE .................. ....... ...... ....... ...... ...... ....... ...... ....... ...... ....... ...... ....................... 41

BEFORE CARRYING OUT MAINTENANCE ............................................................................................. 41

DURING MAINTENANCE ........................................................................................................................... 44

POSITION FOR ATTACHING SAFETY LABELS ................................................................................................ 49

POSITION FOR ATTACHING SAFETY LABELS ......................... ....... ...... ....... ...... ....... ...... ....... ...... ....... ... 49

OPERATION.......................................................................................................55

GENERAL VIEW .............................................. ...... ....... ...... ....... ...... ...... ....... ...... ....... ...... .................................... 56

GENERAL VIEW OF MACHINE ................................................................ ....... ...... ....... ...... ....... ................ 56

GENERAL VIEW OF CONTROLS AND GAUGES ..................................................................................... 57

11

EXPLANATION OF COMPONENTS .................................................................................................................... 59

MACHINE MONITOR ................................................................................................................................. 59

METERS ..................................................................................................................................................... 65

SWITCHES ................................................................. ................................................................................ 70

CONTROL LEVERS, PEDALS ................................................................................................................... 76

AIR CONDITIONER .................................................................................................................................... 87

CAB RADIO ................................................................................................................................................ 90

FUSE .......................................................................................................................................................... 91

FUSIBLE LINK ............................................................................................................................................ 92

CONTROLLERS ......................................................................................................................................... 92

TOOL BOX .................................................................................................................................................. 92

REFUELLING PUMP .................................................................................................................................. 93

HANDLING THE ACCUMULATOR ..................... ....................................... ...... ....... ...... ....... ...... ....... ......... 94

OPERATION ........................... .................................................... .......................................................................... 95

CHECK BEFORE STARTING ENGINE ...................................................................................................... 95

STARTING ENGINE ................................................................................................................................. 106

OPERATIONS AND CHECKS AFTER STARTING ENGINE ................................................................... 108

MOVING MACHINE OFF .......................................................................................................................... 114

STEERING MACHINE .............................................................................................................................. 117

STOPPING MACHINE .............................................................................................................................. 119

SWINGING ............................................................................................................................................... 120

OPERATION OF WORK EQUIPMENT ....................................................................................................121

HANDLING ACTIVE MODE . ...... ....... ...... ....... ...................................... ....... ...... ....... ...... ....... ...... .............. 122

WORKING MODE SELECTION ............................................................................................................... 123

PROHIBITIONS FOR OPERATION ......................................................................................................... 125

PRECAUTIONS FOR OPERATION ......................................................................................................... 127

PRECAUTIONS WHEN TRAVELLING UP OR DOWN HILLS ................................................................. 128

HOW TO ESCAPE FROM MUD ............................................................................................................... 129

WORK POSSIBLE USING HYDRAULIC EXCAVATOR ........................................................................... 129

REPLACEMENT AND INVERSION OF BUCKET .................................................................................... 131

PARKING THE MACHINE ........................................................................................................................ 133

CHECK AFTER FINISHING WORK ......................................................................................................... 134

STOPPING ENGINE ................................................................................................................................. 134

CHECK AFTER STOPPING ENGINE ...................................................................................................... 135

TRANSPORTATION ...................... .......................... .......................... ......................... ........................................ 137

LOADING, UNLOADING WORK .............................................................................................................. 137

COLD WEATHER OPERATION ........................................................................................................................ 142

PRECAUTIONS FOR LOW TEMPERATURE .......................................................................................... 142

PRECAUTIONS AFTER COMPLETION OF WORK ................................................................................ 143

LONG-TERM STORAGE .................................................................................................................................... 145

BEFORE STORAGE ................................................................................................................................. 145

DURING STORAGE ................................................................................................................................. 145

AFTER STORAGE .................................................................................................................................... 146

STARTING MACHINE AFTER LONG-TERM STORAGE ........................................................................ 146

12

TROUBLESHOOTING .................. ....... ...... ....... ...... ....... ...... ....... ...... ...... ....... ...... ....... ...... ....... ........................... 147

PHENOMENA THAT ARE NOT FAILURES ............................................................................................. 147

METHOD OF TOWING MACHINE ........................................................................................................... 147

USING METHOD FOR LIGHT-WEIGHT TOWING HOLE ........................................................................ 148

PRECAUTIONS ON PARTICULAR JOBSITES ....................................................................................... 148

IF BATTERY IS DISCHARGED ................................................................................................................ 149

OTHER TROUBLE ................................................................................................................................... 152

OPERATION INSTRUCTIONS FOR HIGH REACH WORK EQUIPMENT FOR PC240-6 ................................ 157

PRECAUTIONS WHEN OPERATING ...................................................................................................... 157

CHECK BEFORE STARTING .................................................................................................................. 163

OPERATION ................. ................................ ................................ ................................. ........................... 164

RAISING WORK EQUIPMENT ................................................................................................................. 165

WORKING RANGE AND USING RANGE OF BOOM .............................................................................. 165

WORKING RANGE AND RANGE OF USE OF BOOM ............................................................................ 166

TRANSPORTATION (HIGH REACH DEMOLITION) ............................................................................... 167

MAINTENANCE ...............................................................................................169

GUIDES TO MAINTENANCE ............................................................................................................................. 170

OUTLINES OF SERVICE ................................................................................................................................... 173

OUTLINE OF OIL, FUEL, COOLANT ....................................................................................................... 173

EXPLANATION OF LUBRICATION CHART DECAL ............................................................................... 176

OUTLINE OF ELECTRICAL SYSTEM ..................................................................................................... 178

OUTLINE OF HYDRAULIC SYSTEM ....................................................................................................... 178

WEAR PARTS LIST ........................................................................................................................................... 180

USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE .................... 181

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS ..................................................................... 185

LIST OF NECESSARY TOOLS ................................................................................................................ 185

TORQUE LIST .......................................................................................................................................... 186

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS .......................................................................... 187

MAINTENANCE SCHEDULE CHART ............................................................................................................... 190

MAINTENANCE SCHEDULE CHART

190

MAINTENANCE WHEN USING HYDRAULIC BREAKER ....................................................................... 193

SERVICE PROCEDURE .................................................................................................................................... 194

INITIAL 250 HOURS SERVICE ................................................................................................................ 194

WHEN REQUIRED ................................................................................................................................... 194

CHECK BEFORE STARTING .................................................................................................................. 206

EVERY 100 HOURS SERVICE ............................................................................................................... 211

EVERY 250 HOURS SERVICE ................................................................................................................ 214

EVERY 500 HOURS SERVICE ................................................................................................................ 218

13

EVERY 1000 HOURS SERVICE .............................................................................................................. 224

EVERY 2000 HOURS SERVICE .............................................................................................................. 227

EVERY 4000 HOURS SERVICE .............................................................................................................. 229

EVERY 5000 HOURS SERVICE .............................................................................................................. 229

SPECIFICATIONS............................................................................................233

SPECIFICATIONS .............................................................................................................................................. 234

PC210-6K, PC210LC-6K ........... ....... ....................................... ...... ...... ....... ...... ....... ...... ....... .................... 234

SPECIFICATIONS .............................................................................................................................................. 238

PC240LC-6K, PC240NLC-6K ................................................................................................................... 238

explanation of LIFTING CAPACITY CHART ............................................................................................ 241

OPTIONS, ATTAC HM E NTS ............. ... .. ............... .. .. ............... .. ... .. .............. ...251

PRECAUTIONS RELATED TO SAFETY ........................................................................................................... 252

PRECAUTIONS WHEN INSTALLING ATTACHMENTS .......................................................................... 253

HANDLING BUCKET WITH HOOK ........................ ...... ....... ...... ....... ...... ...... ....... ...... ....... ...... ....... .................... 254

CHECKING FOR DAMAGE TO BUCKET WITH HOOK .......................................................................... 254

PROHIBITED OPERATIONS ................................................................................................................... 254

PRECAUTIONS DURING OPERATIONS ................................................................................................ 254

MACHINES READY FOR ATTACHMENTS ...................................................................................................... 255

EXPLANATION OF COMPONENTS ........................................................................................................ 255

ATTACHMENT MOUNTING/DISMOUNTING PROCEDURE .................................................................. 259

INTRODUCTION OF ATTACHMENTS ................... ...... ....... ...... ....... ...... ...... ....... ...... ....... ...... ........................... 264

SPECIFICATION, USE ............................................................................................................................. 264

ATTACHMENT INSTALLATION COMBINATION TABLE ........................................................................ 266

SELECTION OF TRACK SHOES ............................................................................................................. 268

SELECTION OF BUCKET TEETH ........................................................................................................... 270

HANDLING TRAPEZOIDAL BUCKET ...................................................................................................... 270

USING THE EXTENSION ARM ................................................................................................................ 272

HANDLING THE CLAMSHELL BUCKET ................................................................................................. 272

EXTENDING MACHINE SERVICE LIFE ............................................................................................................ 273

HYDRAULIC BREAKER ........................................................................................................................... 273

POWER RIPPER ...................................................................................................................................... 277

MAIN FIELDS OF APPLICATIONS .......................................................................................................... 277

FORK GRAB ................. ....... ...... ....... ...... ....... ...... ....................................... ...... ....... ...... ........................... 278

GRAPPLE BUCKET ................................................................................................................................. 280

SCRAP GRAPPLE .................................................................................................................................... 281

CRUSHER & SMASHER .......................................................................................................................... 283

HYDRAULIC PILE DRIVER ...................................................................................................................... 284

HYDRAULIC EXCAVATOR WITH MULTIPURPOSE CRANE ................................................................. 286

14

2-PC BOOM .............................................................................................................................................. 288

6.4 M STRAIGHT BOOM .......................................................................................................................... 293

FRONT DOZER BLADE ........................................................................................................................... 298

15

16

SAFETY

WARNING

Read and follow all safety precautions. Fail ure to do so may

result in serious injury or death.

This safety section also co ntains precautions for optiona l equipment and attachments.

17

GENERAL PRECAUTIONS SAFETY

WARNING: For reasons of safety, always follow these safety precautions.

GENERAL PRECAUTIONS

SAFETY RULES

● ONLY trained and authorised personnel can operate and

maintain the machine.

● Follow all safety rules, precautions and instructions when

operating or performing maintenance on the machine.

● When working with another op erator or a person on worksite

traffic duty, be sure all personnel understand all han d signals

that are to be used.

● A seat belt must be w or n at a ll tim es whe n op er ati ng m ac hin -

ery.

SAFETY LA BEL S

● Please read and understand the safety labels stuck to the

machine.

● Always keep the safety labels clean.

● If the safety label c omes off or is los t or damaged , stick it on

again or contact your Komatsu distributor and replace it with a

new part.

SAFETY FEATURES

● Be sure all guards and covers are in their proper position.

Have guards and covers repaired if damaged.

● Use safety features such as safety lock lever properly.

● NEVER remove any safety features. ALWAYS keep them in

good operating condition.

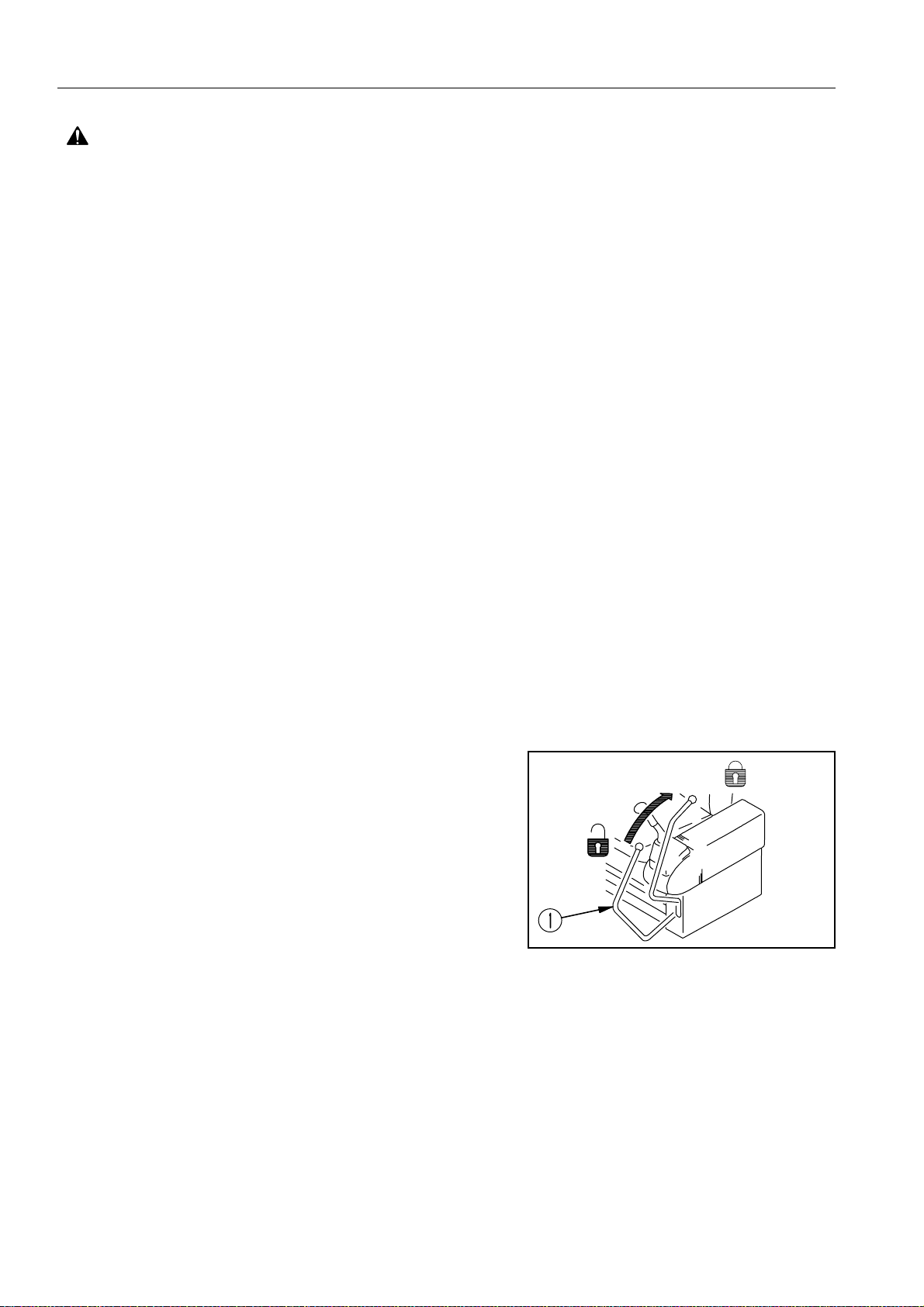

Safety lever, see “PARKING THE MACHINE” on page 133.

Seat belt → see “USING THE SEAT BELT” on page 103.

● Improper use of safety features could result in serious bodily

injury or death.

AB30576C

18

SAFETY GENERAL PRECAUTIONS

WARNING: Failure to follow these safety precautions may lead to a serious accident.

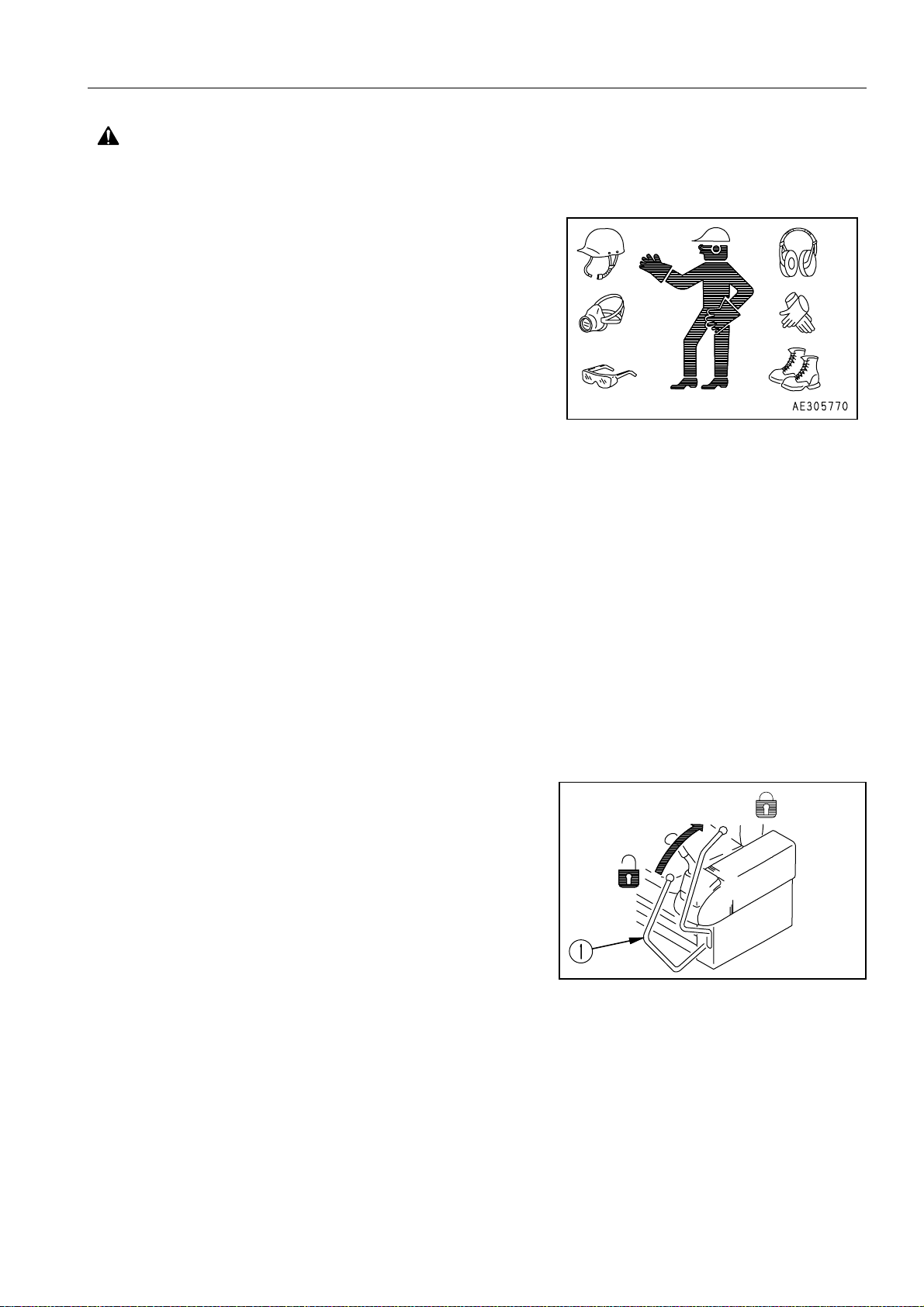

CLOTHING AND PERSONAL PROTECTIVE ITEMS

● Avoid loose clothing, jewellery, and loose long hair. They can

catch on contr ols or in movi ng parts and cau se ser ious injur y

or death. Also, do not wear oily clo ths beca us e they are fla mmable.

● Wear a hard hat, safety glasses, safety shoes, mask or

gloves when operating or maintaining the machine. Always

wear safety goggles, hard hat and heavy gloves if your job

involves scattering metal chips or minute materials <—> this

is so particularly when driving pins with a hammer and when

cleaning the air cleaner element with compressed air.

● Check also that there is no one near the machine.

Driving in pins, see “ REPLACEMENT AND INVERSION

OF BUCKET” on page 131.

Cleaning of air cleaner elem ent, see “WH EN REQUIRED”

on page 194.

UNAUTHORISED MODIFICATION

Any modificati on made withou t authorisat ion from Kom atsu can

create hazards.

Before making a modi fication, cons ult your Koma tsu distributor.

Komatsu will not be respon sible for any in jury or dama ge caused

by any unauthorised modification.

ALWAYS APPLY LOCK WHEN LEAVING OPERATOR’S SEAT

● When standing up from the operator’s seat, always plac e the

safety lock lever securely in the LOCK position. If you accidentally touch the travel or swing lever when they are not

locked, the work equipme nt may sudden ly move and cau se

serious injury or damage.

● When leaving the machine, lower the work e quipment com-

pletely to the ground, set the safety lock lever to the LOCK

position, then stop the engine and use the key to lock all the

equipment. Always take the key with you.

Work equipment posture see “PARKING THE MACHINE”

on page 133.

AB30576C

19

GENERAL PRECAUTIONS SAFETY

WARNING: For reasons of safety, always follow these safety precautions.

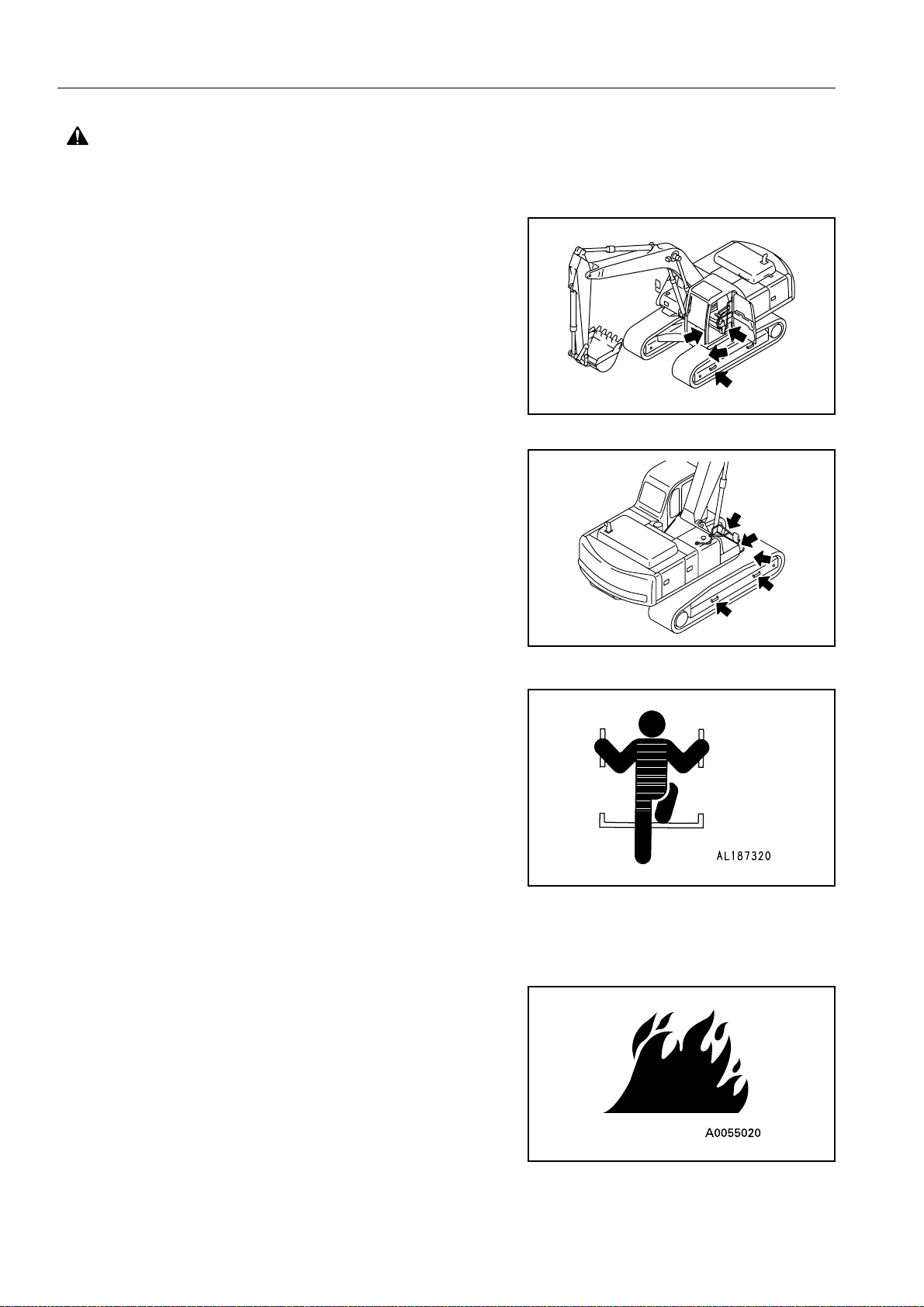

MOUNTING AND DISMOUNTING

● NEVER jump on or off the mac hine. NEVER get on or off a

moving machine.

● When mounting or dismounting, always face the machine and

use the handrails, machine or track frame steps, and track

shoes.

● Do not hold any control levers when getting on or off the

machine.

AM088940

● Ensure safety by al ways ma intaining at leas t three- point con -

tact of hands and feet with the handrails, steps or track shoes.

● Always remove an y oil or mud f rom the han drails, steps and

track shoes. If they are damaged, repair them and tighten any

loose bolts.

● If grasping the door handrail when mounting or dismounting

or moving on the track, open and lock the door securely in the

open position. Otherwise, the door may move suddenly, causing you to lose balance and fall.

FIRE PREVENTION FOR FUEL AND OIL

Fuel, oil, and antifreeze can be ignite d by a fla me. Fuel is particularly FLAMMABLE and can be HAZARDOUS.

● Keep flames away from flammable fluids.

● Stop the engine and do not smoke when refuelling.

AM088950

20

SAFETY GENERAL PRECAUTIONS

WARNING: Failure to follow these safety precautions may lead to a serious accident.

● Tighten all fuel and oil caps securely.

● Refuelling and o iling should be carried ou t in well ventilated

areas.

● Keep oil and fuel in a secure place and do not allow unauthor-

ised persons to enter.

PRECAUTIONS WHEN HANDLING AT HIGH TEMPERATURES

● Immediately after operations are stopped, the engine coolant,

engine oil, and hydraulic oil are at high temperatures, and are

still under pressure. Attempting to remove the cap, drain the

oil or water, or replace the filters may lead to s erious burns.

Always wait for the temperature to go down, and follow the

specified procedures when carrying out these operations.

● To prevent hot water from spurting out:

❍ Turn engine off.

❍ Allow water to cool.

❍ Slowly loosen cap to relieve pressure before removing.

● To prevent hot oil from spurting out:

❍ Turn engine off.

❍ Allow oil to cool.

❍ Slowly loosen cap to relieve pressure before removing.

21

GENERAL PRECAUTIONS SAFETY

WARNING: For reasons of safety, always follow these safety precautions.

ASBESTOS DUST HAZARD PREVENTION

Asbestos dust can be HAZARDOUS to your health if it is inhaled.

Your Komatsu machin e and genu ine Kom atsu spare parts do not

contain any asbestos. Use only genuine Komatsu spare parts. If

spare parts containing asbestos ar e used, th e followin g precautions must be observed:

● NEVER use compressed air for cleaning.

● Use water for cleaning to keep down the dust.

● Operate the machine with the wind to your back, wh enever

possible.

● Use an approved respirator if necessary.

CRUSHING OR CUTTING PREVENTION

Do not enter, or put your hand or arm or any other part of your

body between movable parts such as between the work equipment and cylinders, or between the machine and work equipment.

If the work equipment is operated, the clearance will change and

this may lead to serious damage or personal injury.

FIRE EXTINGUISHER AND FIRST AID KIT

Know how to use fire extinguisher (if installed).

Provide a first aid kit at the storage point.

Know what to do in the event of a fire.

Be sure you know the phone numbers of persons you should con-

tact in case of an emergency.

22

SAFETY GENERAL PRECAUTIONS

WARNING: Failure to follow these safety precautions may lead to a serious accident.

PROTECTION AGAINST FALLING OR FLYING OBJECTS

If there is any danger of falli ng or fly ing ob jects hit ting the o perator, install protective guards in place to protect the operator as

required for each pa rticular situation.

● For work with breakers, install a front guard on the wind-

shield. Also, place a laminate coating sheet over the windshield.

● For demolition or shear work, install a front guard on the

windshield and a top guard on the cab. Also, place a laminate

coating sheet over the windshield.

● For work in mines, quarries, demolition, tunnels or other

places where there is danger of falling rocks, put FOPS (falling object protective structure) in place. Also, place a laminate coating sheet over the windshield.

The above comments ar e made with regards to typical wor king conditions. By all means you should put on other guards if

required by conditions at your particular site.

For details of safety guards, please contact your Komatsu distributor.

Also, even for other types of work, if there is any danger of

being hit by falling or flying objects or of objects entering the

operator’s cab, select and i nstall a guard that matches the

working conditions.

Be sure to close the front window before commencing work.

Level 1 acceptance is intended for protection from small fall-

ing rocks, flying objects and other debris encountered in operations such as highway mainten ance, landscaping and light

construction site services

Level 1 Guards:

❍ Fitted directly onto the roof and front of the cab.

(B)

(C)

AB30052C

(B): Top guard (C): Front guard (I)

23

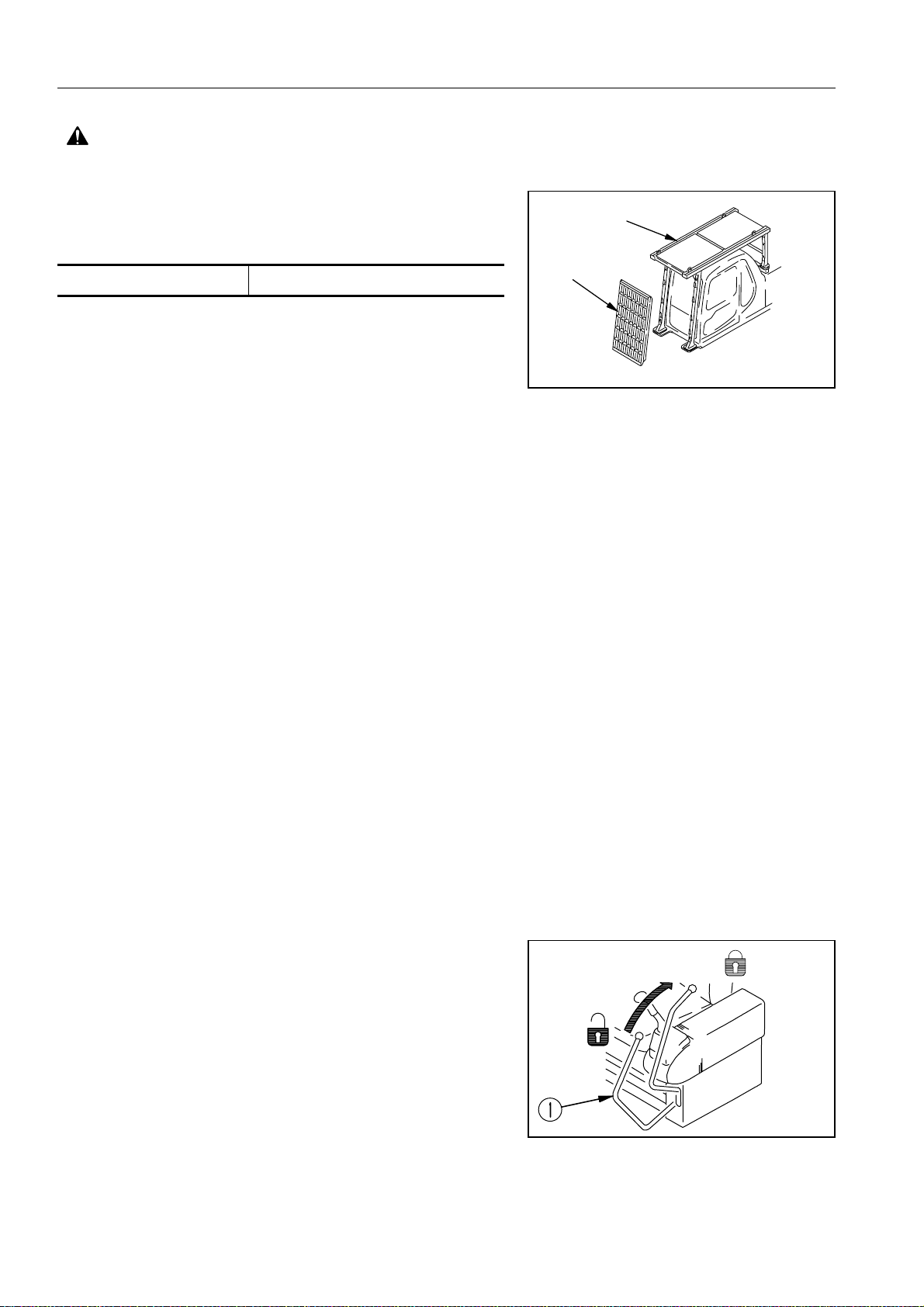

GENERAL PRECAUTIONS SAFETY

WARNING: For reasons of safety, always follow these safety precautions.

When carrying out the above operations, make sure to keep

all persons other than the operator outside the range of falling

or flying objects. Be particular ly sure to ma inta in a prop er dis-

(A)

tance when carrying out shear operations.

(A): FOPS (B) Front guard

Level 2 acceptance is intended for protection from large falling rocks, flying objects and other debris encountered in operations such as demolition work, building constr uctions and

general heavy site work.

Level 2 Guards

❍ Fops fitted directly to the revolving frame

❍ Front guard fitted directly to front of the fops

NOTE: The above guards are the minimum required for typical

working conditions as described above and are in

accordance with the lates t requirements of ISO/DIS

10262 (draft standard).

PRECAUTIONS FOR ATTACHMENTS

● When installing and using an optional attachment, read the

instruction manual for the attachment and the information

related to attachments in this manual.

(B)

AB30053C

● Do not use attachments that are not authorised by Komatsu

or your Komatsu distributor. Use of unauthorised attachments

could create a safety problem and adversely affect the proper

operation and useful life of the machine.

● Any injuries, accidents, product failures resulting from the use

of unauthorised attachmen ts will not be the resp onsibilit y of

Komatsu.

MACHINES WITH ACCUMULATOR

On machines equipped with an accumulator, for a short time after

the engine is stopped , the work e quipment will lo wer under its

own weight when the work equipment control lever is shifted to

LOWER. After the engine is stopped, set the safety lock lever to

the lock position (and also lock the attachment pedal with the lock

pin).

When releasing the pressure inside the work equipment circuit on

machines equipped with an accumulator, follow the procedure

given in the inspection and maintenance section.

Method of releasing pressure see “HANDLING THE

ACCUMULATOR” on page 94.

AB30576C

The accumulator is filled with high-pressure nitrogen gas, and it is

extremely dang erous if it is hand led in th e wrong w ay. Always

observe the following precautions.

24

SAFETY GENERAL PRECAUTIONS

WARNING: Failure to follow these safety precautions may lead to a serious accident.

● Never make any hole in the accumulator or expose it to flame

or fire.

● Do not weld anything to the accumulator.

● When carrying ou t disassembly or maint enance of the accu-

mulator, or when disposing of the accumulator, it is necessary

to release the gas from the accumulator. A special air bleed

valve is necessary for this operation, so please contact your

Komatsu distributor.

Gas in accumulator see “HANDLING THE ACCUMULATOR” on page 94.

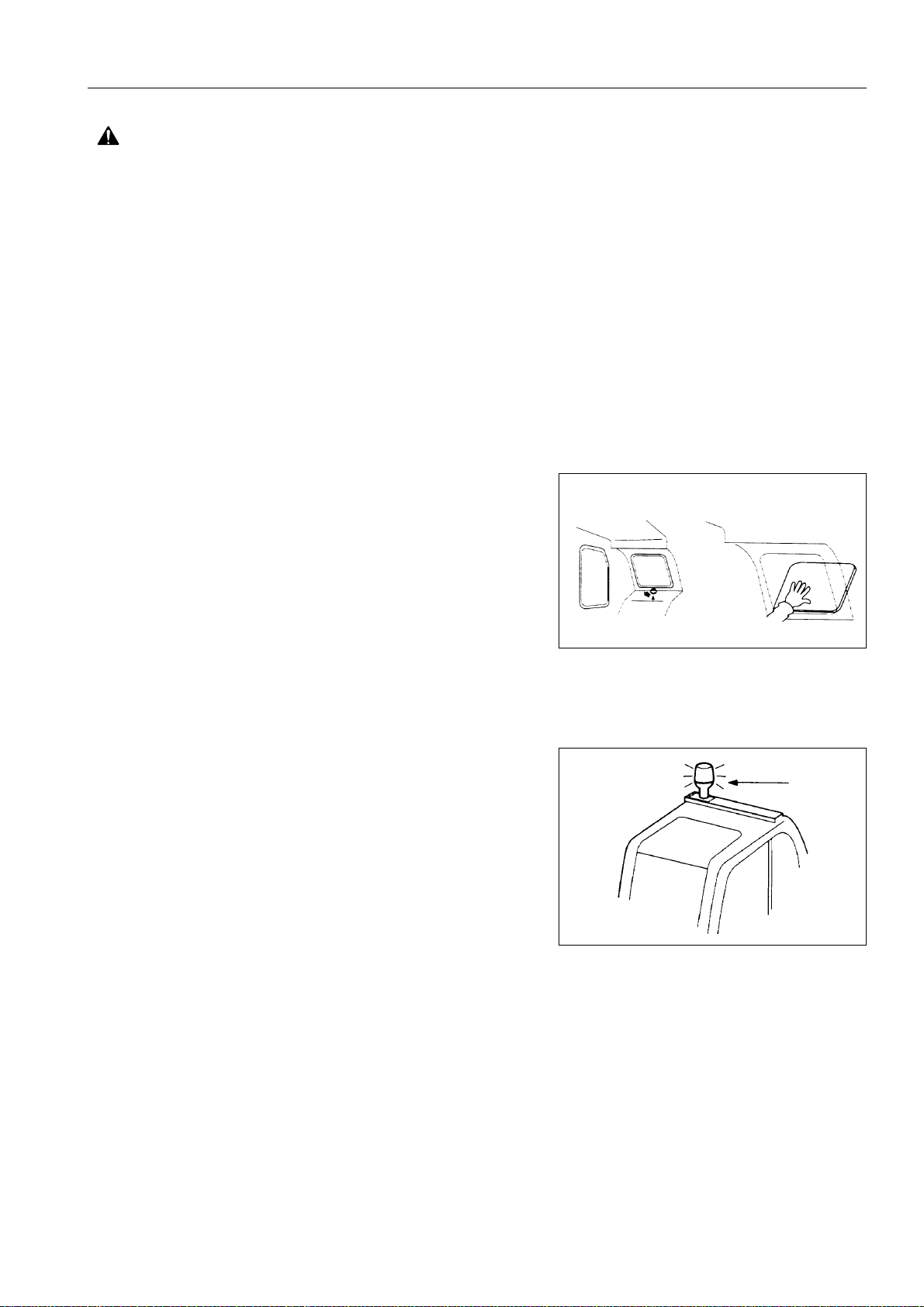

EMERGENCY EXIT

● When exit by normal means is prevented in an eme rgency

you can get out through the emergency exit (rear window).

● Pull the ring at the b ottom of the window and remove strip.

This will allow you to push out glass.

ROTATING BEACON (Option)

When the machine is operated on or beside a road, a rotating

beacon is required to avoid a traffic accident.

Contact your Komatsu distributor to install beacon lamp.

ELECTROMAGNETIC INTERFERENCE

When this machine is o perat ing cl ose to a s ource of high el ectromagnetic interference, such as a radar station, some abnormal

phenomena may be observed.

● The display on the monitor panel may behave erratically.

● The warning buzzer may sound.

These effects do not signify a malfunction and the machine will

return to normal as soon as the source of interference is removed.

25

PRECAUTIONS DURING OPERATION SAFETY

WARNING: For reasons of safety, always follow these safety precautions.

PRECAUTIONS DURING OPERATION

BEFORE STARTING ENGINE

SAFETY AT WORKSITE

● Before starting the engine , thoroughly check the area fo r any

unusual conditions that could be dangerous.

● Before starting the engine, examine the terrain and soil condi-

tions of the worksite. Determine the best and safest method

of operation.

● Make the slope as horizontal as possible before co ntinuing

operations.

● If you need to operate on a street, protect pedestrians and

cars by designating a person for worksite traffic duty or by

instal ling fences around the worksite.

● If water lines, gas lines, an d high- voltage electric al lines may

be buried u nder the wor ksi te, contac t ea ch u tili ty and iden tify

their locations. Be careful not to sever or cut any of these

lines.

● Check the depth and flow of water before o perating in water

or crossing a river. NEVER be in water which is in excess of

the permissible water depth.

Permissible water depth see “PRECAUTIONS FOR

OPERATION” on page 127.

FIRE PREVENTION

● Thoroughly remove wood chips, leaves, paper and other

flammable things accumulate d on the engin e compartment.

They could cause a fire.

● Check fuel, lu br ic at i on, an d hy draulic system s f or le aks. H ave

any leaks repaired. Wipe up any excess oil, fuel or other flammable fluids.

Check point see “WALK-AROUND CHECK” on page 95.

● Be sure a fire extinguisher is present and working.

AE341030A

IN OPERATOR’S CAB

● Do not leave tools or spare parts lying around i n the opera-

tor’s compartment. They may damage or break the control

levers or switch es. Always put them in the tool box on the left

or right side of the machine.

26

SAFETY PRECAUTIONS DURING OPERATION

WARNING: Failure to follow these safety precautions may lead to a serious accident.

● Keep the cab f loor, controls, st eps and handrails free of oil ,

grease, snow, and excess dirt.

Handling sea t belt →see “USING THE SEAT BELT” on

page 103.

VENTILATION FOR ENCLOSED AREAS

● If it is necessary to s tart the engine within an enc losed area,

provide adequate ven tilat ion. Exha ust fu mes from th e eng ine

can KILL.

PRECAUTIONS FOR MIRRORS, WINDOWS AND LIGHTS

● Remove all dirt from the surfac e of the wi ndows and lights to

ensure that you can see well.

● Adjust the rear view mirror so that you can see clearly from

the operator’s seat, and always keep the surface of the mirror

clean. If any glass is broken, replace it with a new part.

● Check that the head lamps and working lamps are installed to

match the oper ating condit ions. Check a lso tha t they li ght up

properly.

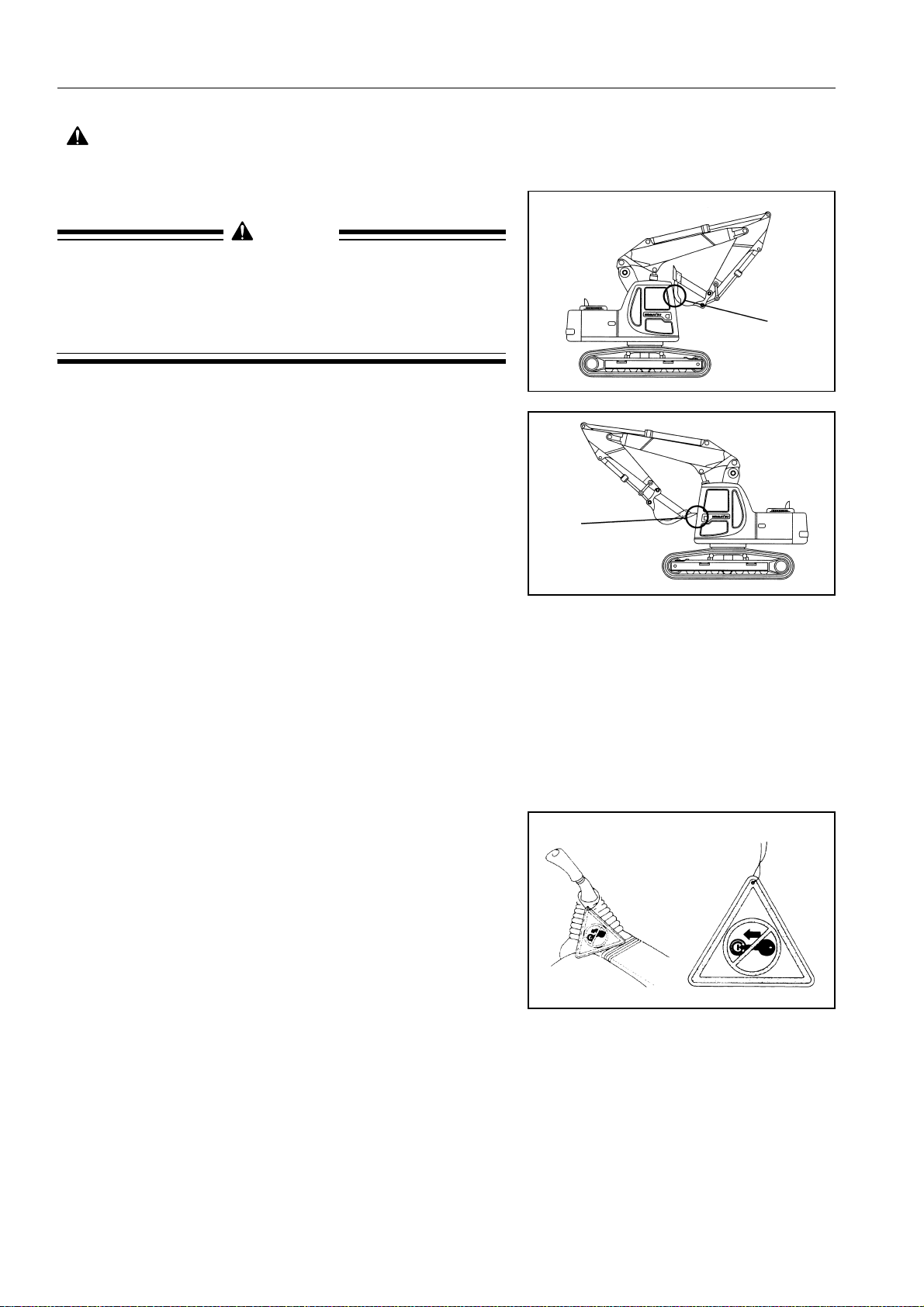

PRECAUTIONS WHEN HANDLING (TWO PIECE BOOM)

When operating the boom arm 2-piece type, select a specialist

operator and do not allow any other person to operate the

machine.

● Check that the ground insi de the operating range is flat and

firm.

● Always operate the work equipment slowly.

WARNING

Especially when lowering the work equipment, move it as

slowly as possible to prevent any shock to the machine

(operate the w ork e quip ment i n th e sam e wa y as when o perating a crane).

● Pay attention to warning decal in the cab.

27

PRECAUTIONS DURING OPERATION SAFETY

WARNING: For reasons of safety, always follow these safety precautions.

WARNING

If the bucket is operated in a certain way, it comes in contact

with the machine body (operator ’s cab, upper boom, cy linders and undercarriage). When operating the work equipment, take sufficient care not to bring it in contact with the

machine body.

Interference

OPERATING MACHINE

WHEN STARTING THE ENGINE

● Walk around your machine again just before mounting it, to

check for people and objects that might be in the way.

● NEVER start the engine if a warning tag has been attached to

the wrist control.

● When starting the engine, sound the horn as an alert.

● Start and operate the machine only while seated.

● Fasten your seat belt securely at all times during operation.

● Do not allow anyone other than the operator to ride in the cab

or on the machine body.

Interference

● For machines equipped with a travel alarm buzzer, check that

the warning device operates correctly.

28

Loading...

Loading...