Komatsu PC210-7K, PC210LC, PC210NLC-7K, PC230NHD-7K, PC240LC Service Manual

...

UEAM001704

Operation &

Maintenance Manual

PC210-7K

PC210LC, PC210NLC-7K

PC230NHD-7K

PC240LC, PC240NLC-7K

HYDRAULIC EXCAVATOR

u

p

d

n

a

1

0

0

0

K

4

K

K

K

u

p

d

n

a

1

0

0

0

K

4

p

d

u

n

a

1

0

0

0

4

-

K

p

u

d

n

a

1

0

0

0

4

K

-

p

u

d

n

a

1

0

0

0

K

4

-

p

d

u

n

a

1

0

0

0

4

-

K

S

E

R

E

R

P

P

P

P

P

P

C

C

C

C

C

K-

7

C

-

L

0

1

2

7

-

C

L

N

0

1

2

7

-

D

H

N

0

3

2

K

7

C

-

L

0

4

2

7

-

C

N

L

0

4

2

B

M

N

U

L

I

A

K

7

-

0

1

C

2

WARNING

Unsafe use of this machine may cause serious injury or

death. Operators and maintenance personnel must read

this manual before operating or maintaining this

machine. This manual should be kept inside the cab for

reference and periodically reviewed by all personel who

will come into contact with the machine.

FOREWORD

11

1

FOREWORD FOREWORD

FOREWORD

This manual provides rules and guidelines which will help you use this machine safely and effectively. The precautions in this manual must be followed at all times while operating or performing maintenance . Most accidents are

caused by the failure to follow fundamental safety rules for the operation and maintenance of machines. Accidents

can be prevented by knowing beforehand conditions that may cause a hazard when performing operation and

maintenance.

WARNING

Operators and maintenance personnel must always do as follows before beginning operation or maintenance.

• Always be sure to read and understand this manual thoroughly before performing operation and

maintenance.

• Read the safety messages given in this manual and the safety labels affixed to the machine thoroughly and be sure that you understand them fully.

Keep this manual in the storage location for the Operation and Maintenance Manual given below, and

have all personnel read it periodically.

If this manual has been lost or has become dirty and cannot be read, request a replacement manual

immediately from Komatsu or your Komatsu distributor.

If you sell the machine, be sure to give this manual to the new owners together with the machine.

Komatsu delivers machines that comply with all applicable regulations and standards of the country to

which it has been shipped. If this machine has been purchased in another country or purchased from

someone in another country, it may lack certain safety devices and specifications that are necessary for

use in your country. If there is any question about whether your product complies with the applicable

standards and regulations of your country, consult Komatsu or your Komatsu distributor before operating the machine.

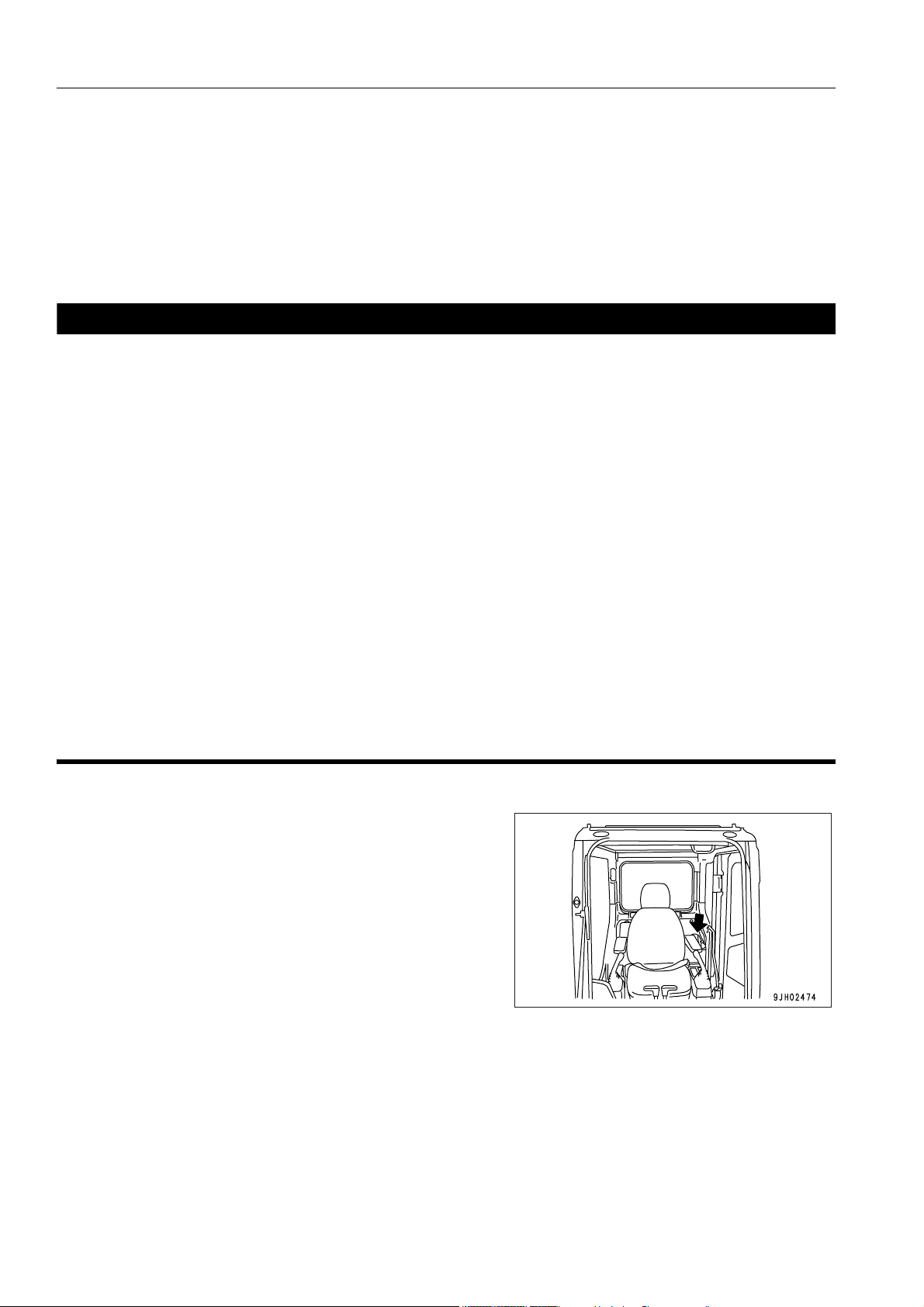

Storage location for the Operation and Maintenance Manual:

Storage box on the left side of the operator's seat.

2

FOREWORD SAFETY INFORMATION

SAFETY INFORMATION

To enable you to use this machine safely, safety precautions and labels are given in this manual and affixed to the

machine to give explanations of situations involving potential hazards and of the methods of avoiding such situations.

Signal words

The following signal words are used to inform you that there is a potentially hazardous situation that may lead to

personal injury or damage.

In this manual and on machine labels, the following signal words are used to express the potential level of hazard.

.

DANGER

WARNING

CAUTION

Example of safety message using signal word

Indicates an imminently hazardous situation which, if not avoided, will result in death

or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor

or moderate injury. This word is used also to alert against unsafe practices that may

cause property damage.

WARNING

To avoid hitting unlocked operation levers, lower equipment to ground and move SAFETY LOCK LEVER

(located near seat) to LOCK position before getting up from the operator's seat.

Sudden and unwanted machine movement can cause serious injury or death.

Other signal words

In addition to the above, the following signal words are used to indicate precautions that should be followed to protect the machine or to give information that is useful to know.

.

NOTICE

REMARKS

This word is used for precautions that must be taken to avoid actions which could shorten the

life of the machine.

This word is used for information that is useful to know.

3

SAFETY INFORMATION FOREWORD

Safety labels

Safety labels are affixed to the machine to inform the operator or maintenance worker on the spot when carrying

out operation or maintenance of the machine that may involve hazard.

This machine uses "Safety labels using words" and "Safety labels using pictograms" to indicate safety procedures.

Safety labels using pictogram

Safety pictograms use a picture to express a level of hazardous condition equivalent to the signal word. These safety pictograms use pictures in order to let the operator or maintenance

worker understand the level and type of hazardous condition at

all times. Safety pictograms show the type of hazardous condition at the top or left side, and the method of avoiding the hazardous condition at the bottom or right side. In addition, the

type of hazardous condition is displayed inside a triangle and

the method of avoiding the hazardous condition is shown

inside a circle.

Part No.

Komatsu cannot predict every circumstance that might involve a potential hazard in operation and maintenance.

Therefore, the safety messages in this manual and on the machine may not include all possible safety precautions. If any procedures or actions not specifically recommended or allowed in this manual are used, it is your

responsibility to take the necessary steps to ensure safety.

In no event should you engage in prohibited uses or actions described in this manual.

The explanations, values, and illustrations in this manual were prepared based on the latest information available

at that time. Continuing improvements in the design of this machine can lead to changes in detail which may not

be reflected in this manual. Consult Komatsu or your Komatsu distributor for the latest available information of your

machine or for questions regarding information in this manual.

The numbers in circles in the illustrations correspond to the numbers in ( ) in the text. (For example: → (1))

4

FOREWORD SAFETY INFORMATION

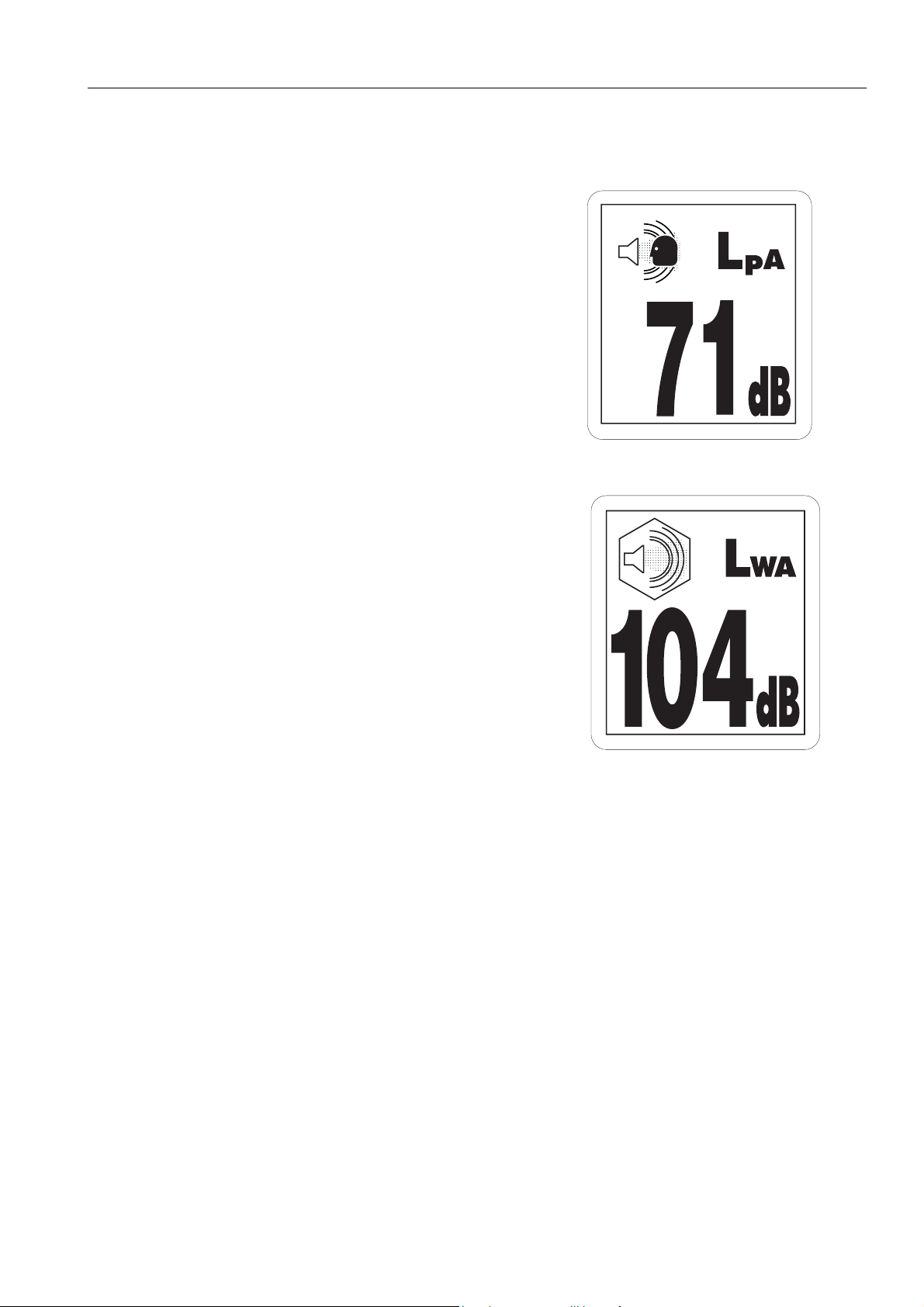

NOISE (PC210,210LC,210NLC, PC230NHD)

• Sound pressure level at the operator’s station, measured

according to ISO6396 (Dynamic test method,simulated

working cycle).

• Sound power level emmited. This is the guaranteed value

as specified in the European directive 2000/14/EC

VIBRATION

The weighted root mean square acceleration value to which

the operator’s arms are subjected does not exceed 2.5 m/s²

The weighted root mean square acceleration value to which

the operator’s body is subjected does not exceed 0.5 m/s²

These results were obtained by accelerometers during trench digging.

5

SAFETY INFORMATION FOREWORD

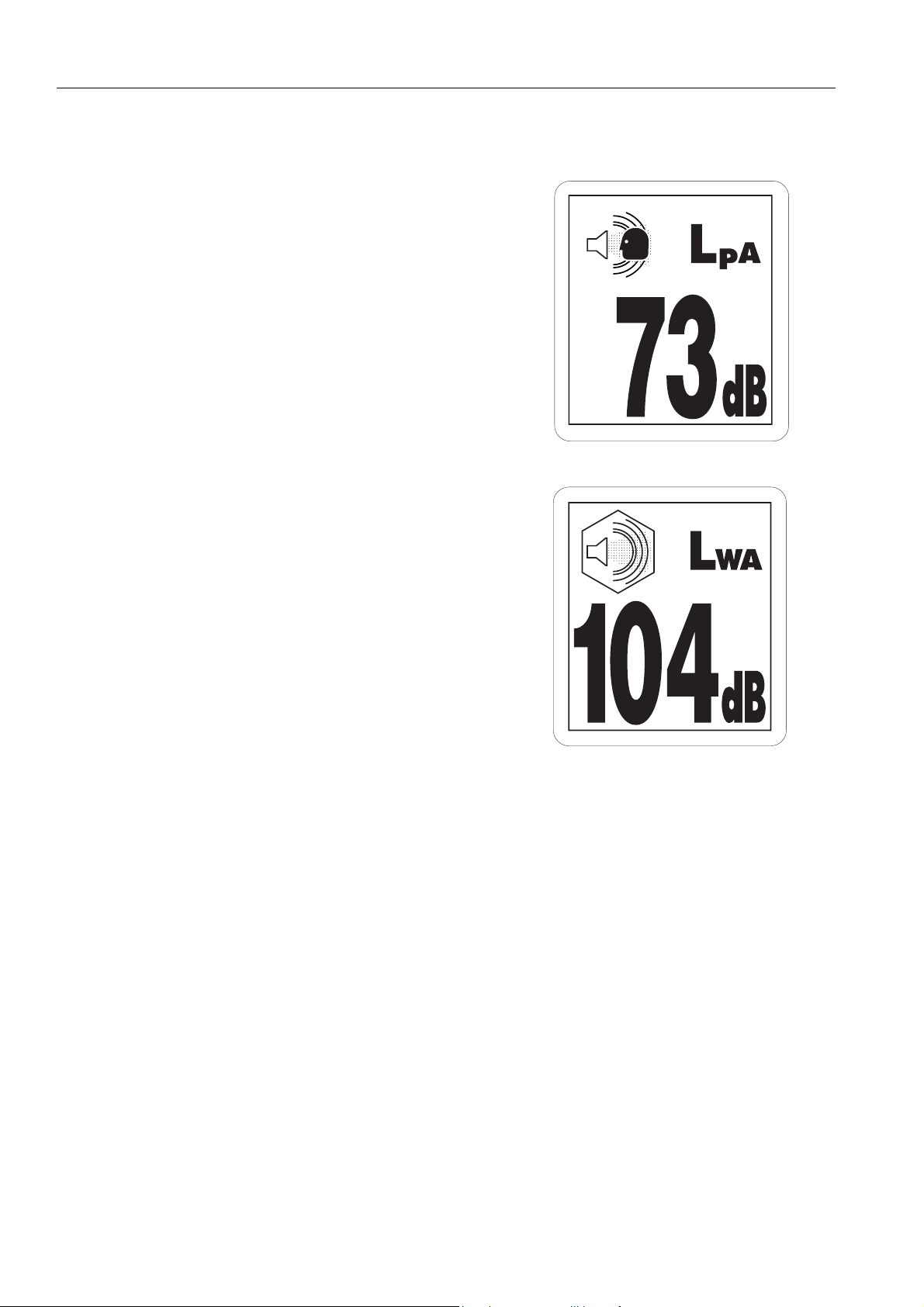

NOISE (PC240LC,240NLC)

• Sound pressure level at the operator’s station, measured

according to ISO6396 (Dynamic test method,simulated

working cycle).

• Sound power level emmited. This is the guaranteed value

as specified in the European directive 2000/14/EC

VIBRATION

The weighted root mean square acceleration value to which

the operator’s arms are subjected does not exceed 2.5 m/s²

The weighted root mean square acceleration value to which

the operator’s body is subjected does not exceed 0.5 m/s²

These results were obtained by accelerometers during trench digging.

6

FOREWORD INTRODUCTION

INTRODUCTION

This Komatsu HYDRAU L I C E XCAVATO R is designed to be u s e d mainly for the fo l l o w i ng works:

● Digging work

● Leveling work

● Ditching work

● Loading work

● Demolition work

See the section "RECOMMENDED APPLICATIONS (PAGE 166)" for further details.

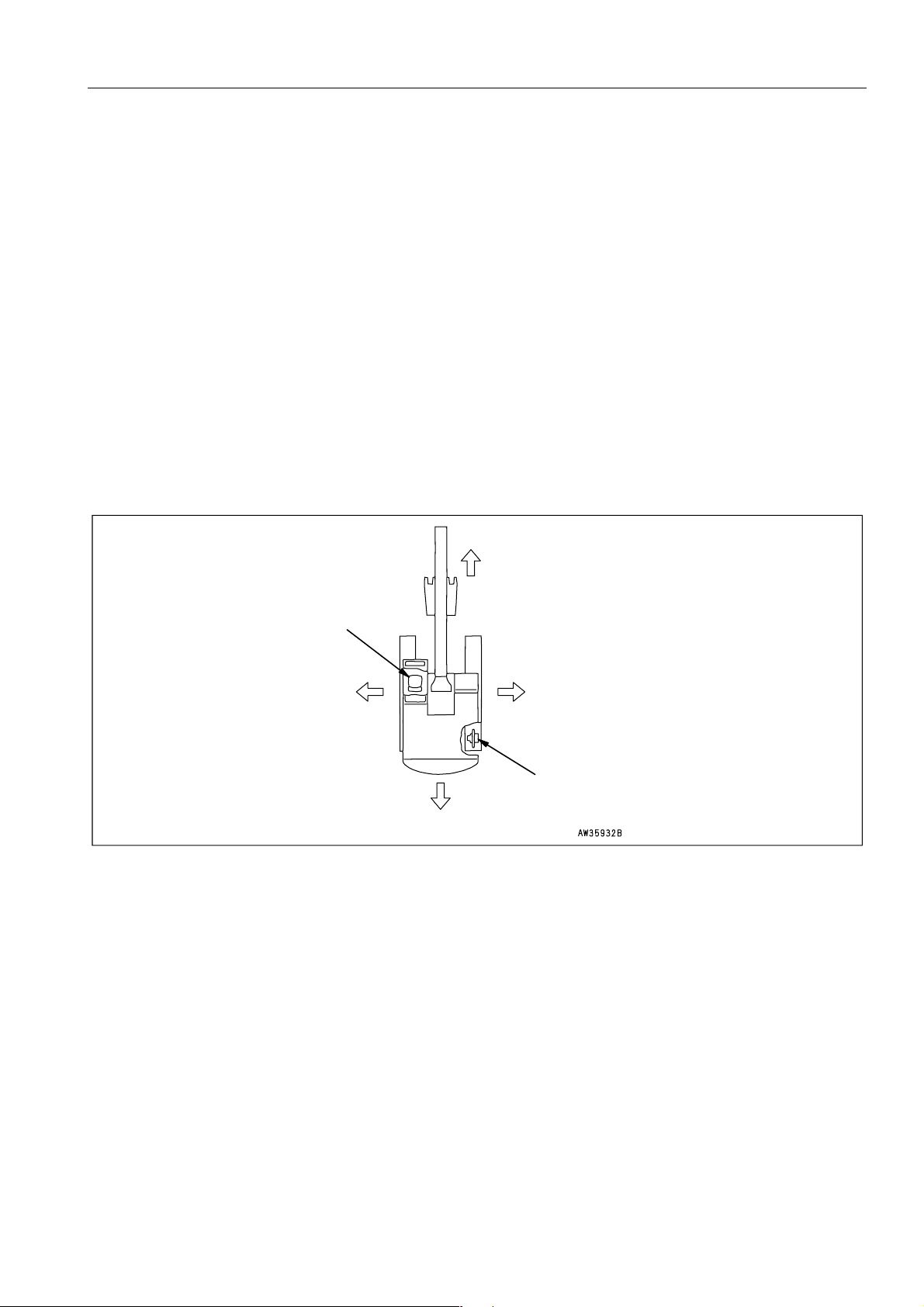

DIRECTIONS OF MACHINE

FRONT

Operator’s seat

LEFT

RIGHT

Sprocket

REAR

In this manual, the terms front, rear, left, and right refer to the travel direction as seen from the operator's cab when

the operator's cab is facing the front and the sprocket is at the rear of the machine.

7

PRODUCT INFORMATION FOREWORD

PRODUCT INFORMATION

When requesting service or ordering replacement parts, please inform your Komatsu distributor of the following

items.

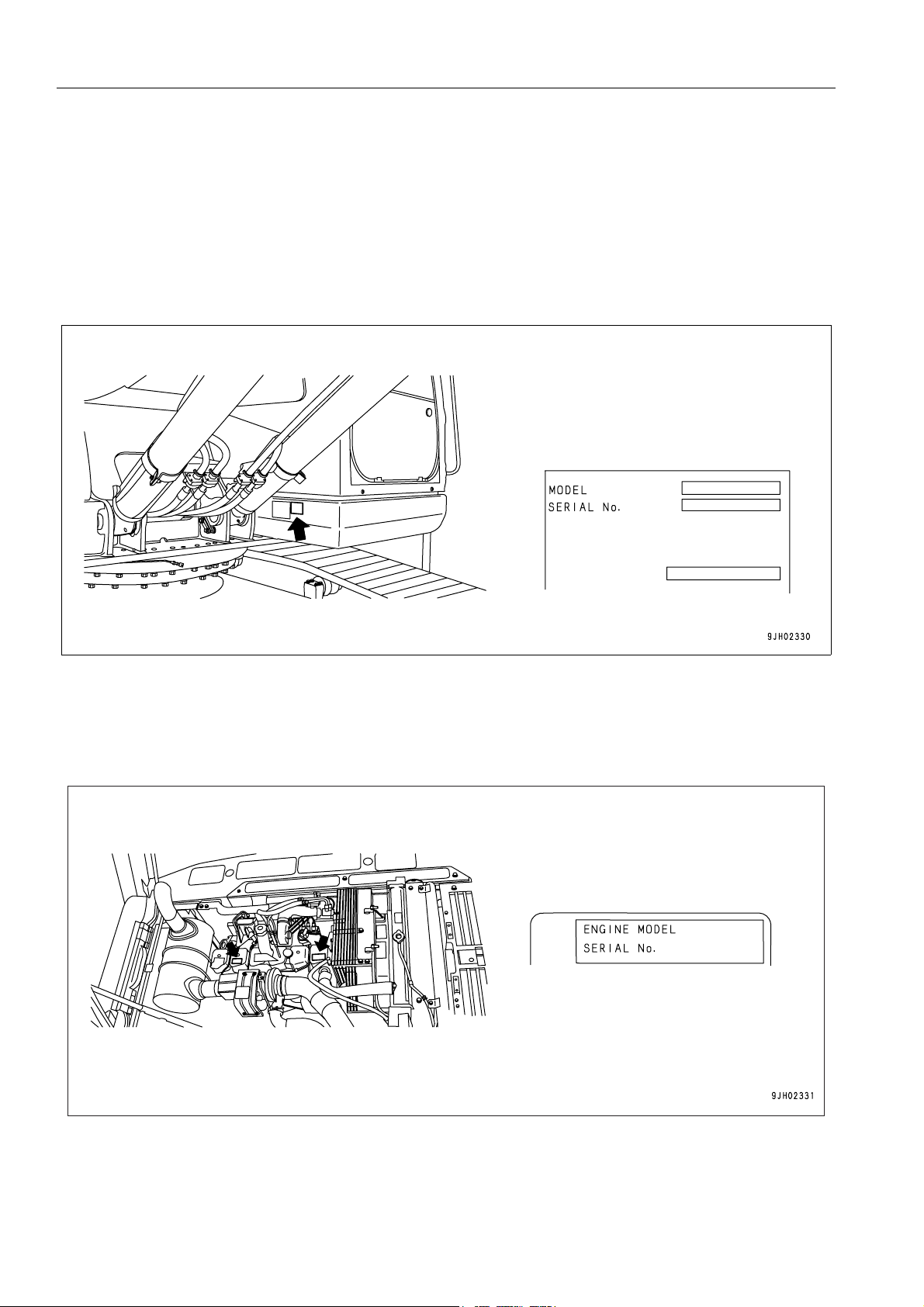

MACHINE SERIAL NUMBER PLATE AND ITS LOCATION

On the bottom right of the operator's cab

PRODUCT IDENTIFICATION NUMBER

A

ENGINE SERIAL NUMBER PLATE AND ITS LOCATION

On the top of the No.1 cylinder head cover (The EPA auxiliary nameplate is on the top of the No. 5 cylinder head

cover.)

EPA: Environmental Protection Agency, U.S.A.

8

FOREWORD PRODUCT INFORMATION

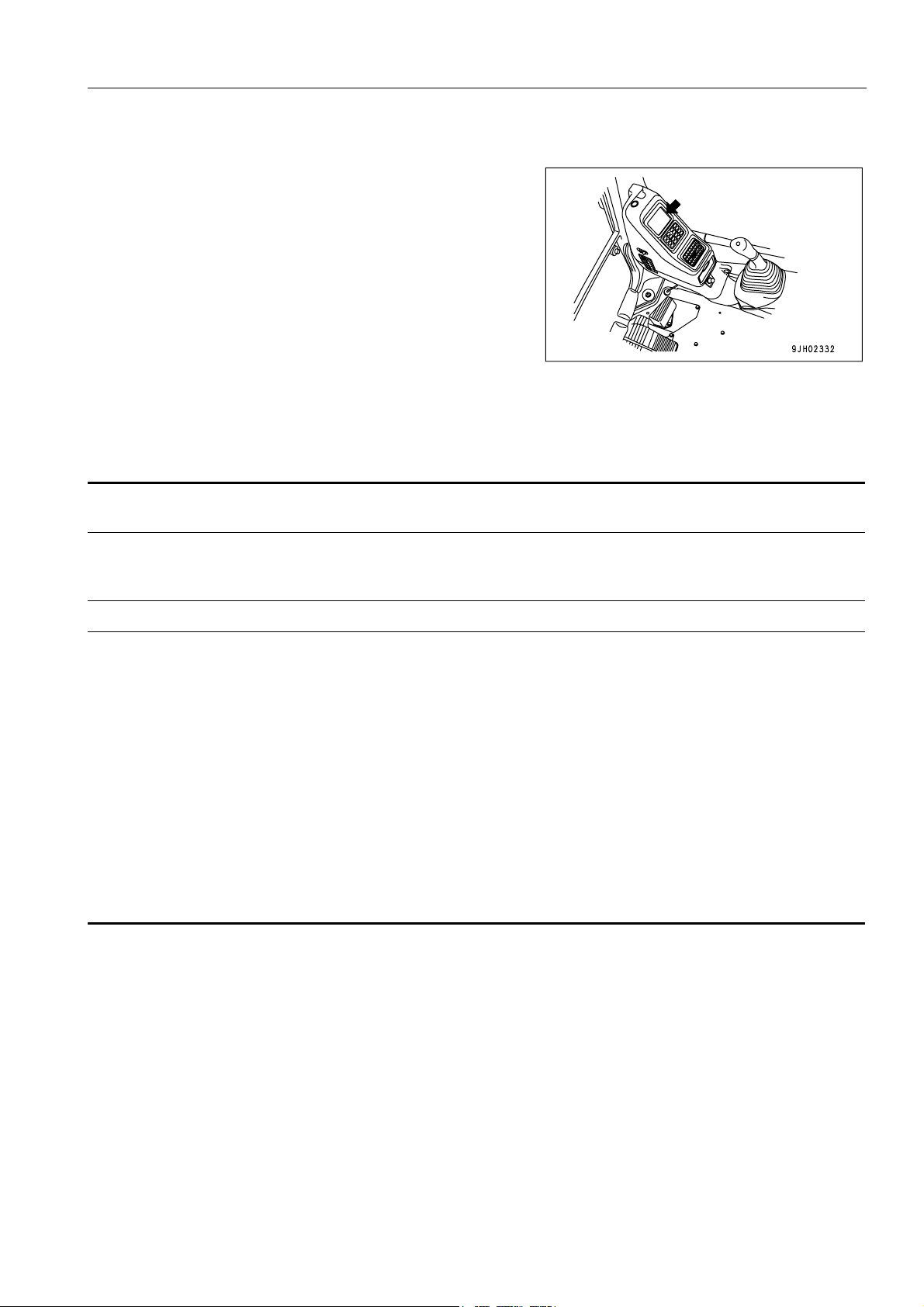

SERVICE METER LOCATION

On top of the machine monitor

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

Machine serial No.

Engine serial No.

Product Identification Number

Manufacturers name:

Address:

Distributor

Address

Phone

KOMATSU UK Ltd.

Durham Road

Birtley

Chester-Le street

County Durham DH32QX

United Kingdom

9

PRODUCT INFORMATION FOREWORD

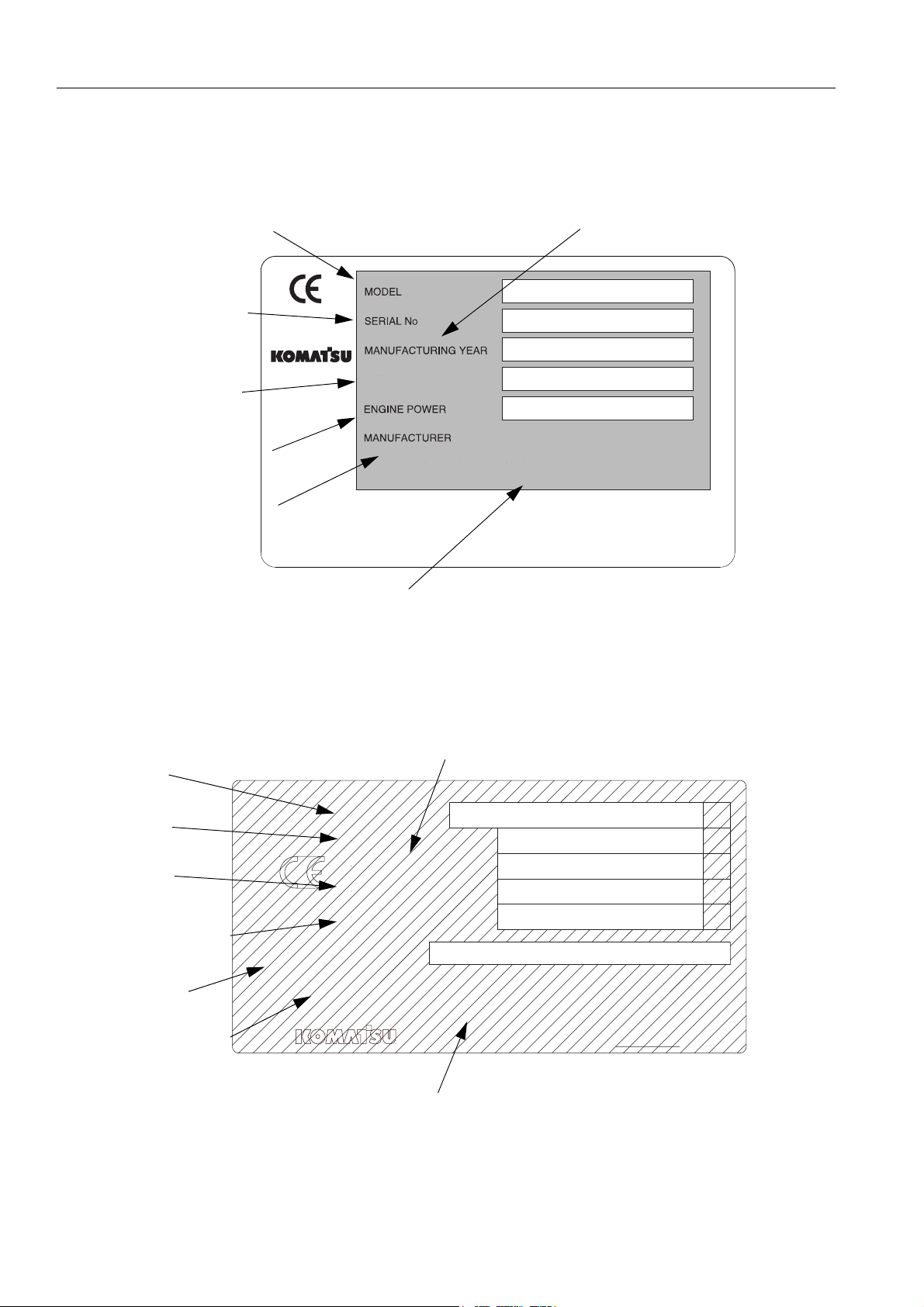

MACHINE SERIAL PLATE

Valid until 31 December 2003

MODEL

SERIAL

WEIGHT

ENGINE POWER

MANUFACTURER

MANUFACTURING YEAR

MASS

Komatsu UK Ltd, Birtley, Co. Durham, United Kingdom

205-00-K1290

Komatsu UK Ltd, Birtley, Co Durham, United Kingdom

Valid as of 1 January 2004

MODEL

SERIAL

WEIGHT

ENGINE POWER

PRODUCT ID

NUMBER

MANUFACTURER

MANUFACTURING YEAR

MODEL

SERIAL No.

MANUFACT. YEAR

MASS

ENGINE POWER

Product Identification Number

MANUFACTURER

Manufactured by Komatsu UK Ltd.

for Komatsu Ltd.,Tokyo,Japan

Komatsu UK Ltd, Birtley, Co Durham, United Kingdom

kg

kW

205-00-K1291

10

FOREWORD PRODUCT INFORMATION

11

CONTENTS FOREWORD

CONTENTS

FOREWORD

FOREWORD............................................................................................................................................................ 2

SAFETY INFORMATION......................................................................................................................................... 3

NOISE (PC210,210LC,210NLC, PC230NHD) ............................................................................................... 5

VIBRATION.................................................................................................................................................... 5

NOISE (PC240LC,240NLC)........................................................................................................................... 6

VIBRATION.................................................................................................................................................... 6

INTRODUCTION...................................................................................................................................................... 7

DIRECTIONS OF MACHINE ......................................................................................................................... 7

PRODUCT INFORMATION ..................................................................................................................................... 8

MACHINE SERIAL NUMBER PLATE AND ITS LOCATION ......................................................................... 8

ENGINE SERIAL NUMBER PLATE AND ITS LOCATION ............................................................................ 8

SERVICE METER LOCATION ...................................................................................................................... 9

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR ................................................................................. 9

MACHINE SERIAL PLATE .......................................................................................................................... 10

SAFETY

SAFETY INFORMATION....................................................................................................................................... 18

POSITION FOR ATTACHING SAFETY LABELS................................................................................................. 20

POSITION FOR ATTACHING SAFETY LABELS ........................................................................................ 20

SAFETY LABELS ........................................................................................................................................ 21

SAFETY INFORMATION....................................................................................................................................... 28

SAFETY MACHINE OPERATION......................................................................................................................... 38

STARTING ENGINE .................................................................................................................................... 38

OPERATION ................................................................................................................................................ 40

TRANSPORTATION .................................................................................................................................... 46

BATTERY .................................................................................................................................................... 47

TOWING ...................................................................................................................................................... 49

LIFTING OBJECTS WITH BUCKET ............................................................................................................ 50

SAFETY MAINTENANCE INFORMATION ........................................................................................................... 51

OPERATION

GENERAL VIEW ................................................................................................................................................... 60

GENERAL VIEW OF MACHINE .................................................................................................................. 60

12

FOREWORD CONTENTS

GENERAL VIEW CONTROLS AND GAUGES............................................................................................ 61

EXPLANATION OF COMPONENTS..................................................................................................................... 62

MACHINE MONITOR .................................................................................................................................. 62

BASIC CHECK ITEMS................................................................................................................................. 65

SWITCHES .................................................................................................................................................. 87

CONTROL LEVERS, PEDALS .................................................................................................................... 93

CEILING WINDOW...................................................................................................................................... 96

FRONT WINDOW........................................................................................................................................ 97

EMERGENCY EXIT FROM OPERATOR'S CAB ...................................................................................... 102

DOOR LOCK ............................................................................................................................................. 102

CAP, COVER WITH LOCK........................................................................................................................ 103

HOT AND COOL BOX ............................................................................................................................... 104

CAB RADIO ............................................................................................................................................... 104

MAGAZINE BOX........................................................................................................................................ 104

ASHTRAY .................................................................................................................................................. 105

HANDLING AIR CONDITIONER ............................................................................................................... 106

CAR RADIO ............................................................................................................................................... 119

FUSE ......................................................................................................................................................... 120

FUSIBLE LINK ........................................................................................................................................... 121

CONTROLLER (COMPUTER) .................................................................................................................. 122

TOOLBOX.................................................................................................................................................. 122

GREASE GUN HOLDER ........................................................................................................................... 122

REFUELLING PUMP ................................................................................................................................. 123

HANDLING THE ACCUMULATOR ........................................................................................................... 123

MACHINE OPERATIONS AND CONTROLS...................................................................................................... 125

BEFORE STARTING ENGINE .................................................................................................................. 125

STARTING ENGINE .................................................................................................................................. 138

AFTER STARTING ENGINE ..................................................................................................................... 142

IN COLD AREAS (AUTOMATIC WARMING-UP OPERATION) ............................................................... 146

STOPPING THE ENGINE ......................................................................................................................... 150

CHECK AFTER SHUTTING OFF ENGINE ............................................................................................... 150

MACHINE OPERATION ............................................................................................................................ 151

STEERING THE MACHINE....................................................................................................................... 155

SWINGING ................................................................................................................................................ 157

WORK EQUIPMENT CONTROLS AND OPERATIONS ........................................................................... 158

OPERATING WORKING MODE ............................................................................................................... 159

PROHIBITED OPERATIONS .................................................................................................................... 160

GENERAL OPERATION INFORMATION ................................................................................................. 162

TRAVELING ON SLOPES......................................................................................................................... 163

ESCAPE FROM MUD................................................................................................................................ 165

RECOMMENDED APPLICATIONS........................................................................................................... 166

REPLACEMENT AND INVERSION OF BUCKET ..................................................................................... 168

PARKING MACHINE ................................................................................................................................. 171

CHECK AFTER FINISHING WORK .......................................................................................................... 172

LOCKING................................................................................................................................................... 173

TRANSPORTATION............................................................................................................................................ 174

13

FOREWORD CONTENTS

TRANSPORTATION PROCEDURE.......................................................................................................... 174

SPECIAL TRANSPORTATION INSTRUCTIONS FOR PC210NLC-7 AND PC230NHD-7 ....................... 174

LOADING AND UNLOADING WITH TRAILER ......................................................................................... 175

LIFTING MACHINE.................................................................................................................................... 182

COLD WEATHER OPERATION ......................................................................................................................... 184

COLD WEATHER OPERATION INFORMATION...................................................................................... 184

AFTER DAILY WORK COMPLETION....................................................................................................... 186

AFTER COLD WEATHER SEASON ......................................................................................................... 187

LONG TERM STORAGE..................................................................................................................................... 188

BEFORE STORAGE.................................................................................................................................. 188

DURING STORAGE .................................................................................................................................. 188

AFTER STORAGE..................................................................................................................................... 189

TROUBLESHOOTING......................................................................................................................................... 190

AFTER RUNNING OUT OF FUEL............................................................................................................. 190

PHENOMENA THAT ARE NOT FAILURES.............................................................................................. 190

TOWING THE MACHINE .......................................................................................................................... 191

LIGHTWEIGHT TOWING HOOK............................................................................................................... 191

PRECAUTIONS ON PARTICULAR JOBSITES ........................................................................................ 192

DISCHARGED BATTERY ......................................................................................................................... 193

OTHER TROUBLE .................................................................................................................................... 197

MAINTENANCE

MAINTENANCE INFORMATION ........................................................................................................................ 204

LUBRICANTS, COOLANT AND FILTERS ......................................................................................................... 207

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC .................................................... 207

EXPLANATION OF LUBRICATION CHART DECAL ................................................................................ 211

ELECTRIC SYSTEM MAINTENANCE ...................................................................................................... 213

HANDLING HYDRAULIC SYSTEM........................................................................................................... 213

WEAR PARTS LIST ............................................................................................................................................ 214

USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE ..................... 215

PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS .......................................................... 215

TIGHTENING TORQUE SPECIFICATIONS ....................................................................................................... 218

TIGHTENING TORQUE LIST.................................................................................................................... 218

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS ........................................................................... 219

SAFETY CRITICAL PARTS....................................................................................................................... 219

MAINTENANCE SCHEDULE.............................................................................................................................. 220

MAINTENANCE SCHEDULE CHART....................................................................................................... 220

MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER...................................................................... 222

MAINTENANCE PROCEDURE........................................................................................................................... 223

14

FOREWORD CONTENTS

INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS) .................................... 223

WHEN REQUIRED .................................................................................................................................... 224

CHECK BEFORE STARTING ................................................................................................................... 248

EVERY 100 HOURS MAINTENANCE....................................................................................................... 248

EVERY 250 HOURS MAINTENANCE....................................................................................................... 250

EVERY 500 HOURS MAINTENANCE....................................................................................................... 257

EVERY 1000 HOURS MAINTENANCE..................................................................................................... 265

EVERY 2000 HOURS MAINTENANCE..................................................................................................... 268

EVERY 4000 HOURS MAINTENENCE..................................................................................................... 270

EVERY 5000 HOURS MAINTENANCE..................................................................................................... 271

SPECIFICATIONS

SPECIFICATIONS............................................................................................................................................... 274

EXPLANATION OF LIFTING CAPACITY CHART (PC210, PC210LC, PC210NLC-7K) ........................... 277

EXPLANATION OF LIFTING CAPACITY CHART (PC210, PC210LC, PC230NHD - 2 PIECE BOOM)... 281

EXPLANATION OF LIFTING CAPACITY CHART (PC230NHD-7K) ......................................................... 284

EXPLANATION OF LIFTING CAPACITY CHART (PC240LC, PC240NLC-7K) ........................................ 286

EXPLANATION OF LIFTING CAPACITY CHART (PC240LC,NLC-7K 2 PIECE BOOM) ......................... 289

ATTACHMENTS AND OPTIONS

GENERAL PRECAUTIONS ................................................................................................................................ 294

PRECAUTIONS RELATED TO SAFETY .................................................................................................. 294

PRECAUTIONS WHEN INSTALLING ATTACHMENTS ........................................................................... 296

HANDLING BUCKET WITH HOOK .................................................................................................................... 297

CHECKING FOR DAMAGE TO BUCKET WITH HOOK ........................................................................... 297

PROHIBITED OPERATIONS .................................................................................................................... 297

MACHINES READY FOR ATTACHMENTS ....................................................................................................... 298

EXPLANATION OF COMPONENTS ......................................................................................................... 298

HYDRAULIC CIRCUIT............................................................................................................................... 301

ATTACHMENT MOUNTING/DISMOUNTING PROCEDURE ................................................................... 304

OPERATION.............................................................................................................................................. 306

LONG-TERM STORAGE........................................................................................................................... 308

SPECIFICATIONS ..................................................................................................................................... 308

ATTACHMENT GUIDE........................................................................................................................................ 309

COMBINATIONS OF WORK EQUIPMENT............................................................................................... 309

SELECTION OF TRACK SHOES.............................................................................................................. 312

SELECTION OF BUCKET TEETH ............................................................................................................ 313

STANDARDS FOR SELECTING VERTICAL PIN TYPE AND HORIZONTAL PIN TYPE TEETH............ 313

HANDLING OF RUBBER PAD SHOE AND ROAD LINER ....................................................................... 314

HANDLING TRAPEZOIDAL BUCKET....................................................................................................... 316

HANDLING EXTENSION ARM.................................................................................................................. 317

15

FOREWORD CONTENTS

HANDLING CLAMSHELL BUCKET .......................................................................................................... 318

RECOMMENDED ATTACHMENT OPERATIONS ............................................................................................. 319

HYDRAULIC BREAKER ............................................................................................................................ 319

2-PC BOOM......................................................................................................................................................... 324

FEATURES OF 2-PIECE BOOM & ARM .................................................................................................. 324

OPERATION.............................................................................................................................................. 325

TRANSPORTATION.................................................................................................................................. 328

STRAIGHT BOOM PC210/240-7K...................................................................................................................... 331

OPERATION.............................................................................................................................................. 331

WORKING RANGE (PC 210 STRAIGHT BOOM) ..................................................................................... 335

TRANSPORTATION (PC 210 Straight Boom equipment)......................................................................... 336

WORKING RANGE (PC 240 STRAIGHT BOOM) ..................................................................................... 337

TRANSPORTATION (PC 240 Straight Boom equipment)......................................................................... 338

SUPER LONG FRONT BOOM AND ARM PC210/240-7

OPERATION INSTRUCTION FOR SUPER LONG FRONT BOOM AND ARM ................................................. 340

CONTROL LEVERS, PEDALS .................................................................................................................. 345

TRANSPORT & STORAGE OF SUPER LONG FRONT MACHINE ......................................................... 348

WORKING RANGE OF SUPER LONG FRONT........................................................................................ 350

LIFTING CAPACITY PC210 LC 15 m SUPER LONG FRONT.................................................................. 351

LIFTING CAPACITY PC210 NLC 15 m SUPER LONG FRONT ............................................................... 352

LIFTING CAPACITY PC240 LC 18 m SUPER LONG FRONT.................................................................. 353

LIFTING CAPACITY PC240 NLC 18 m SUPER LONG FRONT ............................................................... 354

MAINTENANCE................................................................................................................................................... 355

SPECIAL SERVICE REQUIREMENTS FOR SUPER LONG FRONT WORK EQUIPMENT .................... 355

EVERY 50 HOURS SERVICE ................................................................................................................... 356

EVERY 100 HOURS SERVICE ................................................................................................................ 357

16

SAFETY

11

WARNING

Please read and make sure that you fully understand precautions described in this manual and the safety labels on

the machine. When operating or servicing the machine,

always follow these precautions strictly.

17

SAFETY INFORMATION SAFETY

SAFETY INFORMATION

SAFETY INFORMATION ....................................................................................................................................... 18

POSITION FOR ATTACHING SAFETY LABELS .................................................................................................. 20

POSITION FOR ATTACHING SAFETY LABELS ............................................................................................. 20

SAFETY LABELS.............................................................................................................................................. 21

SAFETY INFORMATION ....................................................................................................................................... 28

SAFETY RULES .......................................................................................................................................... 28

IF ABNORMALITIES ARE FOUND ............................................................................................................. 28

WORKING WEAR AND PERSONAL PROTECTIVE ITEMS ...................................................................... 28

FIRE EXTINGUISHER AND FIRST AID KIT ............................................................................................... 28

SAFETY EQUIPMENT................................................................................................................................. 29

KEEP MACHINE CLEAN ............................................................................................................................. 29

KEEP OPERATOR'S COMPARTMENT CLEAN ......................................................................................... 29

LEAVING OPERATOR'S SEAT WITH LOCK.............................................................................................. 29

HANDRAILS AND STEPS ........................................................................................................................... 30

MOUNTING AND DISMOUNTING .............................................................................................................. 31

NO PERSONS ON ATTACHMENTS........................................................................................................... 31

BURN PREVENTION .................................................................................................................................. 31

FIRE PREVENTION AND EXPLOSION PREVENTION.............................................................................. 32

ACTION IF FIRE OCCURS ......................................................................................................................... 33

WINDSHIELD WASHER FLUID .................................................................................................................. 33

FALLING OBJECTS, FLYING OBJECTS AND INTRUDING OBJECTS

PREVENTION.............................................................................................................................................. 33

ATTACHMENT INSTALLATION .................................................................................................................. 33

ATTACHMENT COMBINATIONS................................................................................................................ 34

CAB WIDOW GLASSES.............................................................................................................................. 34

UNAUTHORIZED MODIFICATIONS ........................................................................................................... 34

SAFETY AT JOBSITE ................................................................................................................................. 34

WORKING ON LOOSE GROUND............................................................................................................... 34

DISTANCE TO HIGH VOLTAGE CABLES.................................................................................................. 35

ENSURE GOOD VISIBILITY ....................................................................................................................... 35

VENTILATION FOR ENCLOSED AREA ..................................................................................................... 36

SIGNALMAN'S SIGNAL AND SIGNS .......................................................................................................... 36

EMERGENCY EXIT FROM OPERATOR'S CAB......................................................................................... 36

ELECTROMAGNETIC INTERFERENCE ....................................................................................................36

ASBESTOS DUST HAZARD PREVENTION............................................................................................... 37

SAFETY MACHINE OPERATION ......................................................................................................................... 38

STARTING ENGINE ......................................................................................................................................... 38

CHECKS BEFORE STARTING ENGINE .................................................................................................... 38

SAFETY RULES FOR STARTING ENGINE ............................................................................................... 39

STARTING ENGINE IN COLD WEATHER .................................................................................................39

OPERATION ..................................................................................................................................................... 40

CHECKS AFTER STARTING ENGINE ....................................................................................................... 40

SAFETY RULES FOR CHANGING MACHINE DIRECTIONS .................................................................... 40

SAFETY RULES FOR TRAVELLING .......................................................................................................... 41

TRAVELLING ON SLOPES ......................................................................................................................... 42

OPERATIONS ON SLOPES........................................................................................................................ 43

PROHIBITED OPERATIONS ...................................................................................................................... 43

OPERATIONS ON SNOW ........................................................................................................................... 45

PARKING MACHINE ................................................................................................................................... 45

TRANSPORTATION ......................................................................................................................................... 46

18

SAFETY SAFETY INFORMATION

SHIPPING THE MACHINE .......................................................................................................................... 46

BATTERY ......................................................................................................................................................... 47

BATTERY HAZARD PREVENTION ............................................................................................................ 47

STARTING ENGINE WITH BOOSTER CABLES ........................................................................................ 48

TOWING ........................................................................................................................................................... 49

SAFETY RULES FOR TOWING.................................................................................................................. 49

LIFTING OBJECTS WITH BUCKET ................................................................................................................. 50

SAFETY RULES FOR LIFTING OBJECTS ................................................................................................. 50

SAFETY MAINTENANCE INFORMATION............................................................................................................ 51

WARNING TAG ........................................................................................................................................... 51

KEEP WORK PLACE CLEAN AND TIDY.................................................................................................... 51

APPOINT LEADER WHEN WORKING WITH OTHERS ............................................................................. 51

STOP ENGINE BEFORE CARRYING OUT MAINTENANCE ..................................................................... 52

TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING .................................................... 53

PROPER TOOLS......................................................................................................................................... 53

ACCUMULATOR ......................................................................................................................................... 54

PERSONNEL............................................................................................................................................... 54

ATTACHMENTS .......................................................................................................................................... 54

WORK UNDER THE MACHINE .................................................................................................................. 54

NOISE.......................................................................................................................................................... 55

WHEN USING HAMMER............................................................................................................................. 55

WELDING WORKS...................................................................................................................................... 55

REMOVING BATTERY TERMINALS .......................................................................................................... 55

SAFETY FIRST WHEN USING HIGH-PRESSURE GREASE TO ADJUST TRACK TENSION ................. 56

DO NOT DISASSEMBLE RECOIL SPRINGS ............................................................................................. 56

SAFETY RULES FOR HIGH-PRESSURE OIL............................................................................................ 56

SAFETY HANDLING HIGH-PRESSURE HOSES....................................................................................... 57

WASTE MATERIALS................................................................................................................................... 57

AIR CONDITIONER MAINTENANCE.......................................................................................................... 57

COMPRESSED AIR .................................................................................................................................... 57

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS .................................................................... 58

19

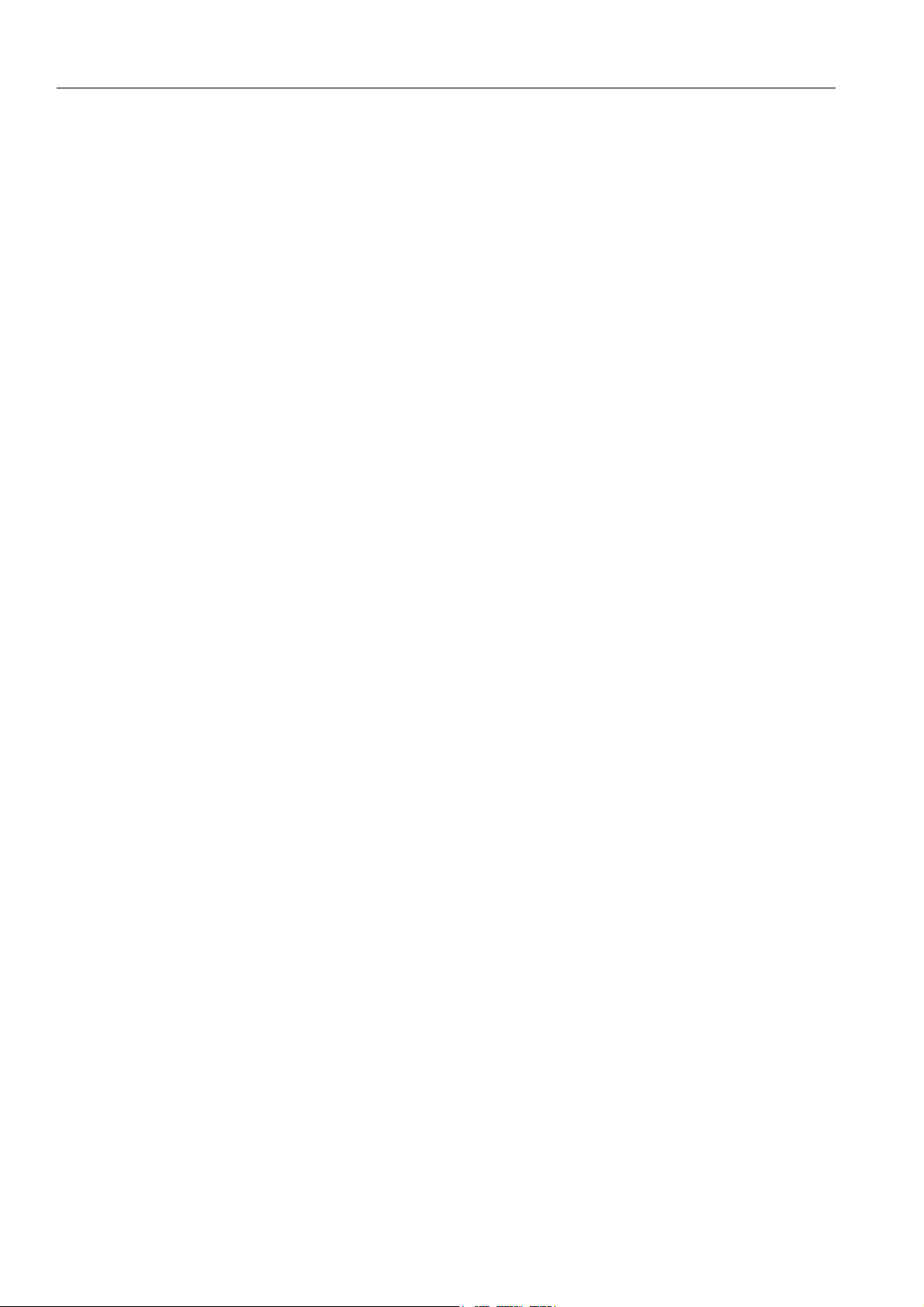

POSITION FOR ATTACHING SAFETY LABELS SAFETY

POSITION FOR ATTACHING SAFETY LABELS

The following warning signs and safety labels are used on this machine.

• Be sure that you fully understand the correct position and content of labels.

• To ensure that the content of labels can be read properly. Be sure that they are in the correct place and always

keep them clean. When cleaning them, do not use organic solvents or gasoline, there may cause the labels to

peel off.

• There are also other labels in addition to the warning signs and safety labels. Handle those labels in the same

way.

• If the labels are damaged, lost, or cannot be read properly, replace them with new ones. For details of the part

numbers for the labels, see this manual or the actual label, and place an order with Komatsu distributor.

POSITION FOR ATTACHING SAFETY LABELS

611

X

Z

10

e

c

b

d

9

X

2

2

3

4

20

12

a

f

7

13

5

8

9

10

SAFETY POSITION FOR ATTACHING SAFETY LABELS

SAFETY LABELS

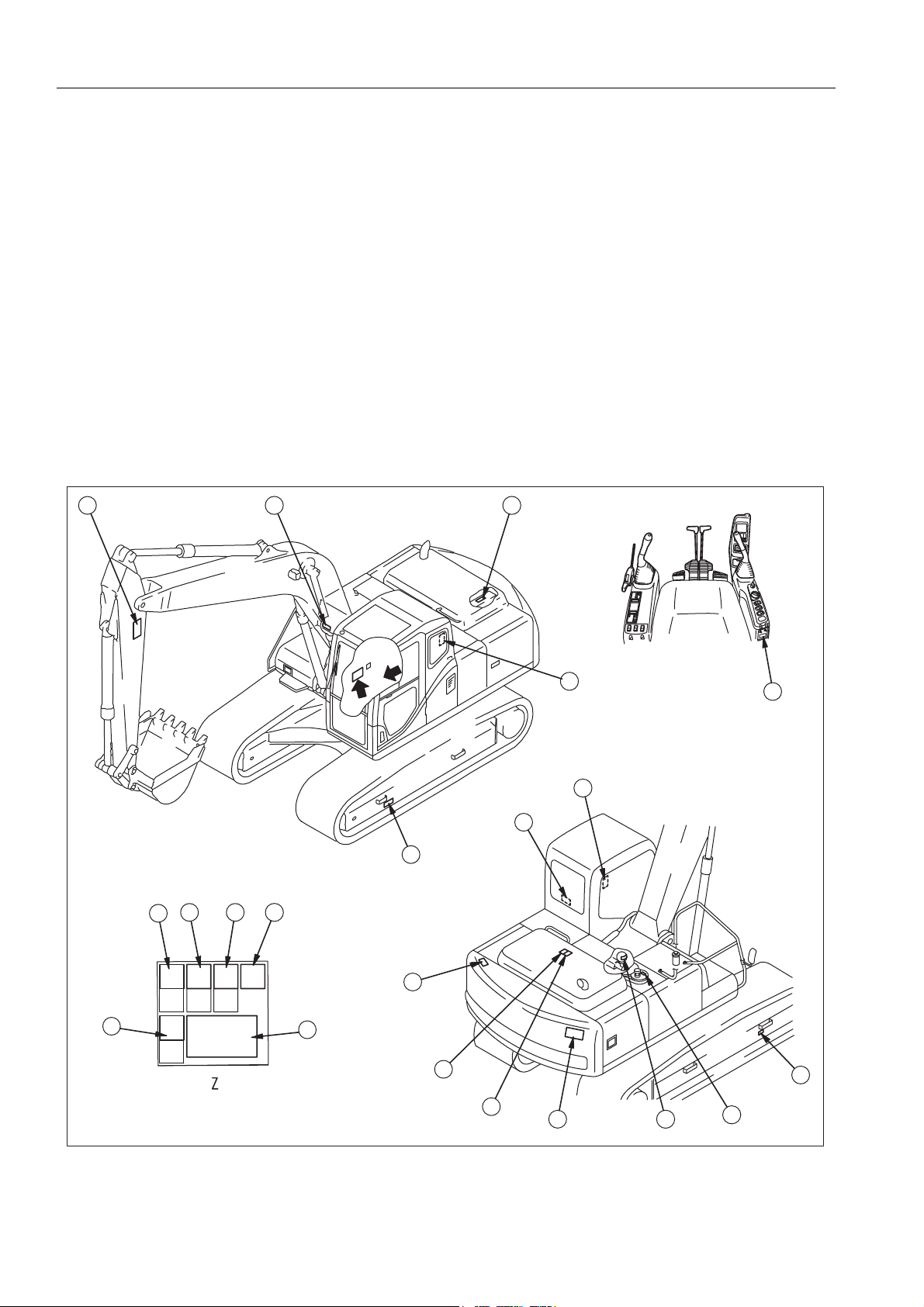

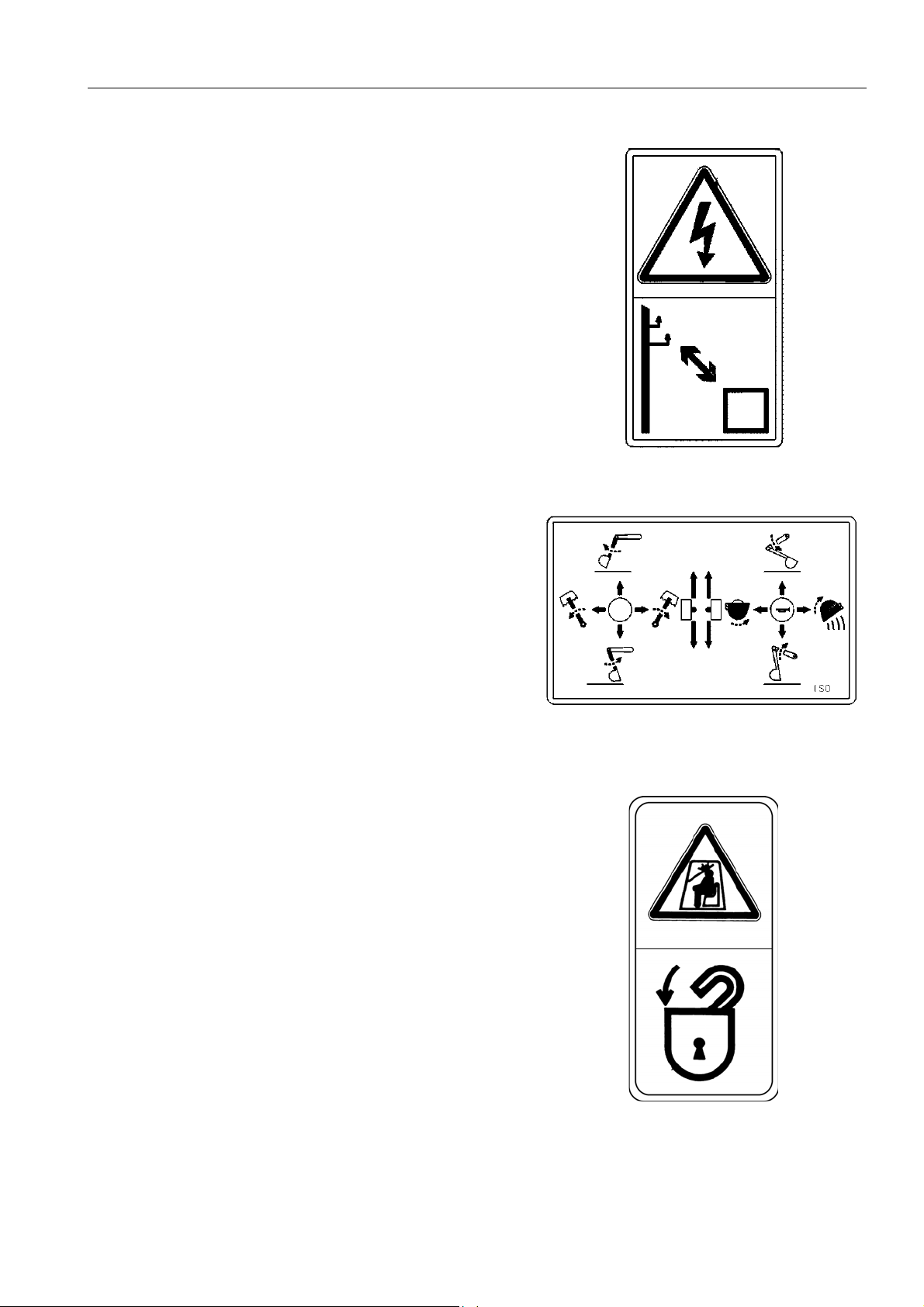

1. (207-00-K1950)

• Warnings for operation, inspection and maintenance

• Improper operation and maintenance can cause serious

injury or death.

• Read the manual and labels before operation and maintenance.

Follow instructions and warnings in manual and in labels

on machine.

• a. Keep the manual in machine cab near operator.

If this manual is lost, please contact your Komatsu distribu-

tor for a replacement.

21

POSITION FOR ATTACHING SAFETY LABELS SAFETY

• b. Always apply lock when leaving operator’s seat.

• c. WARNING - No passengers

No passengers allowed to ride on machine while it is moving

• d. WARNING - DANGER OF FALLING OBJECTS

Do not operate where a danger of falling objects exists.

Consult your dealer for fitting of FOPS protection

.

22

SAFETY POSITION FOR ATTACHING SAFETY LABELS

•e. HAZARDOUS - Voltage hazard

Serious injury or death can occur if machine or attachments are not kept safe distance away from electric lines

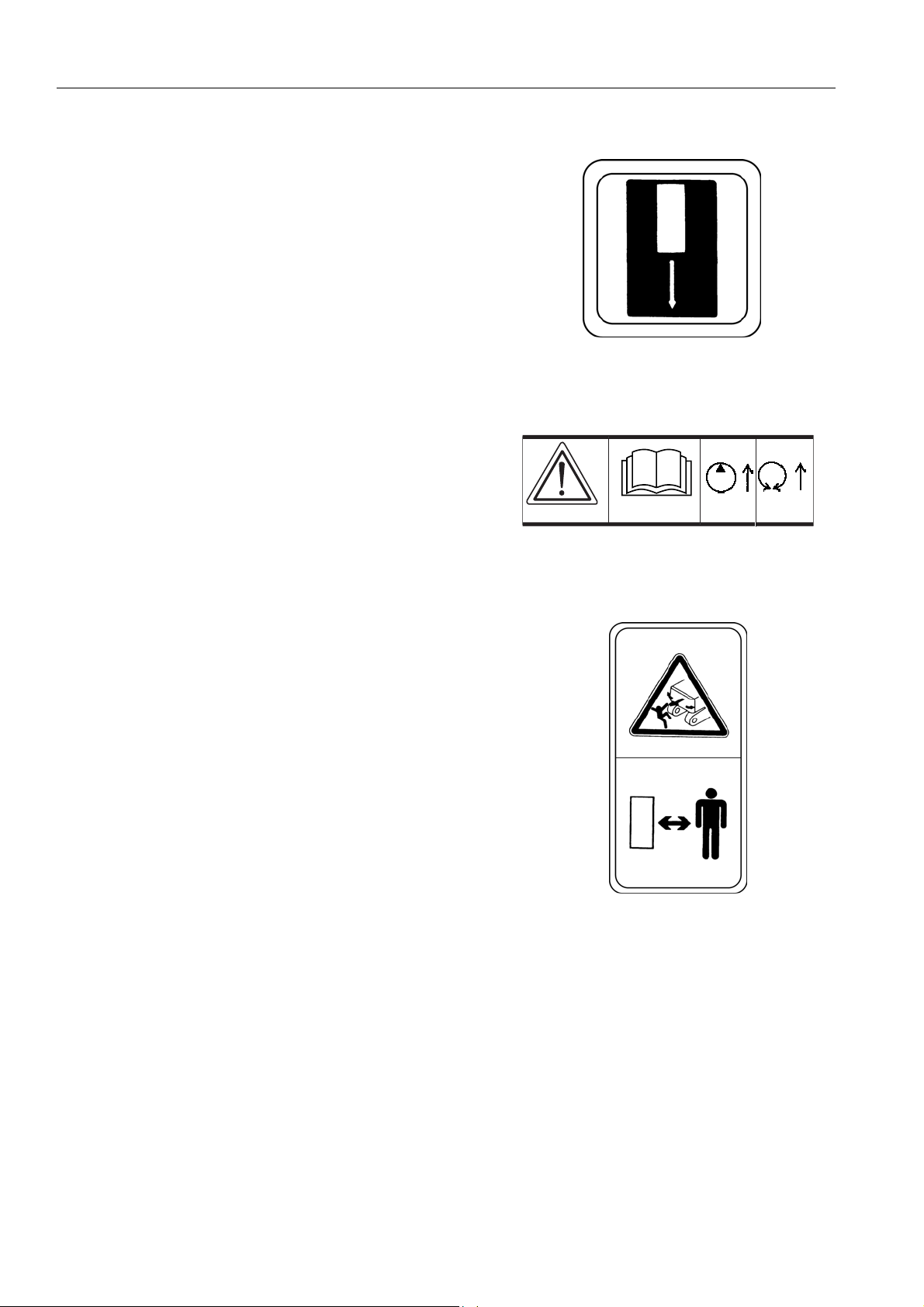

•f. Control levers operational function diagram.

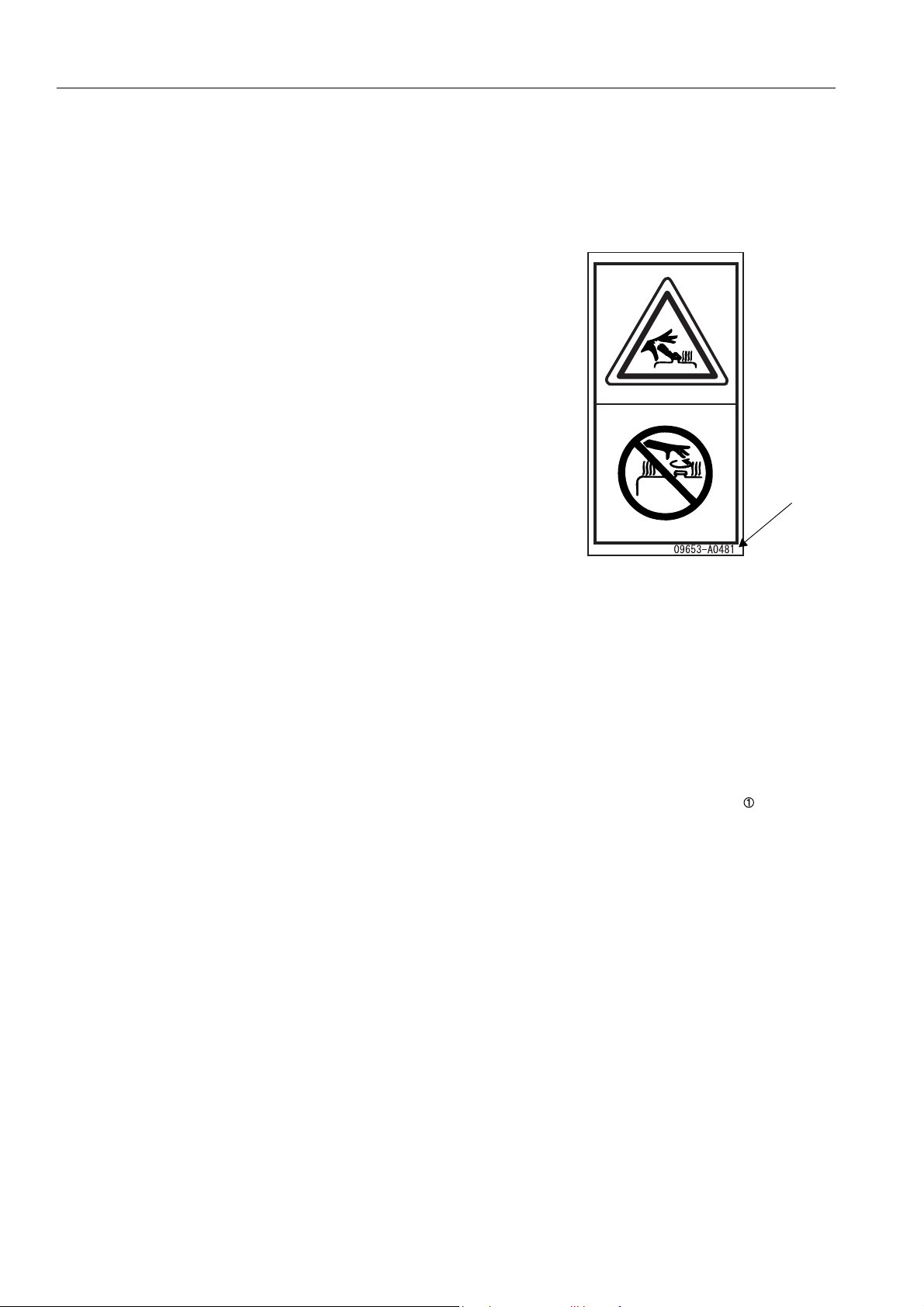

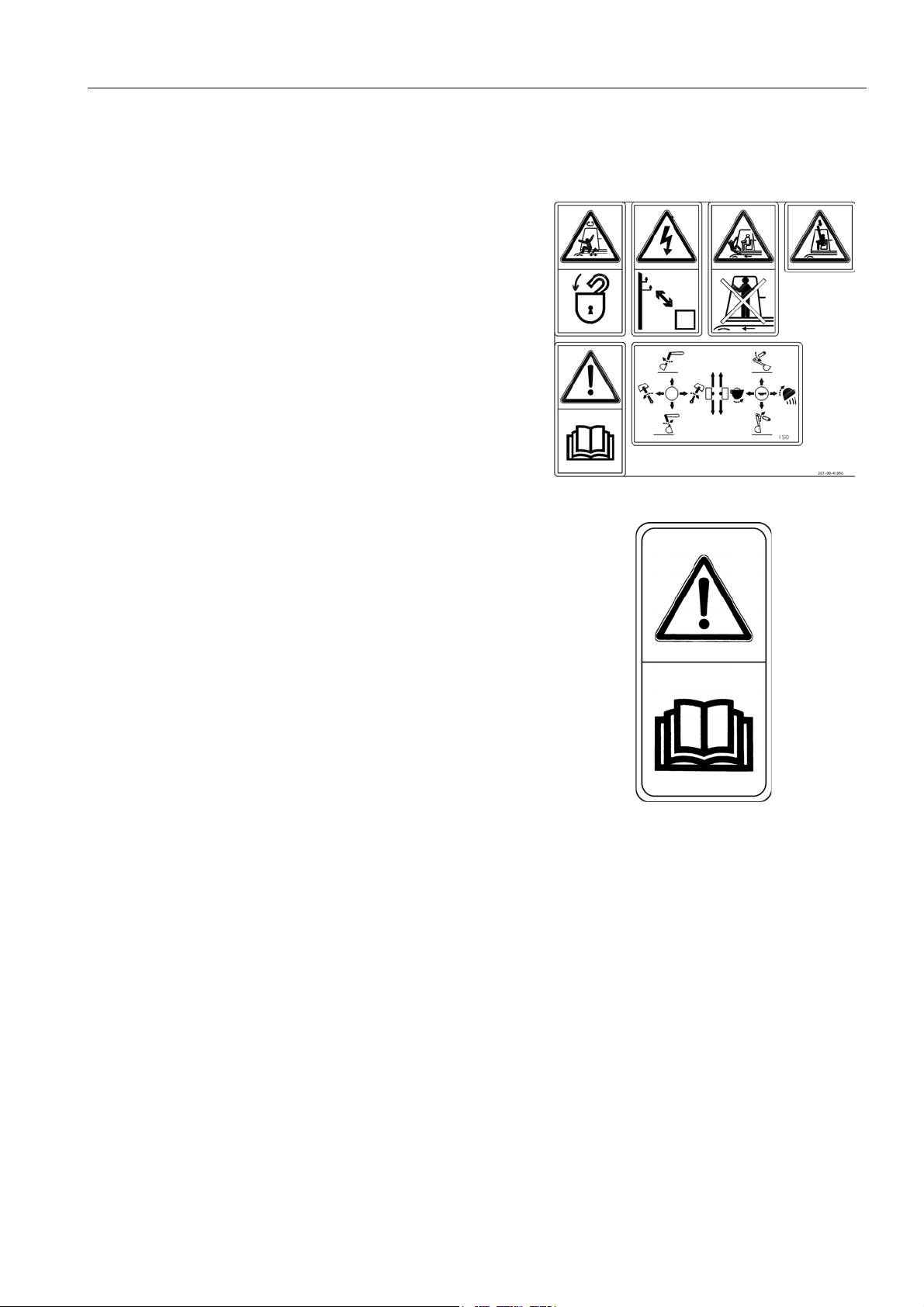

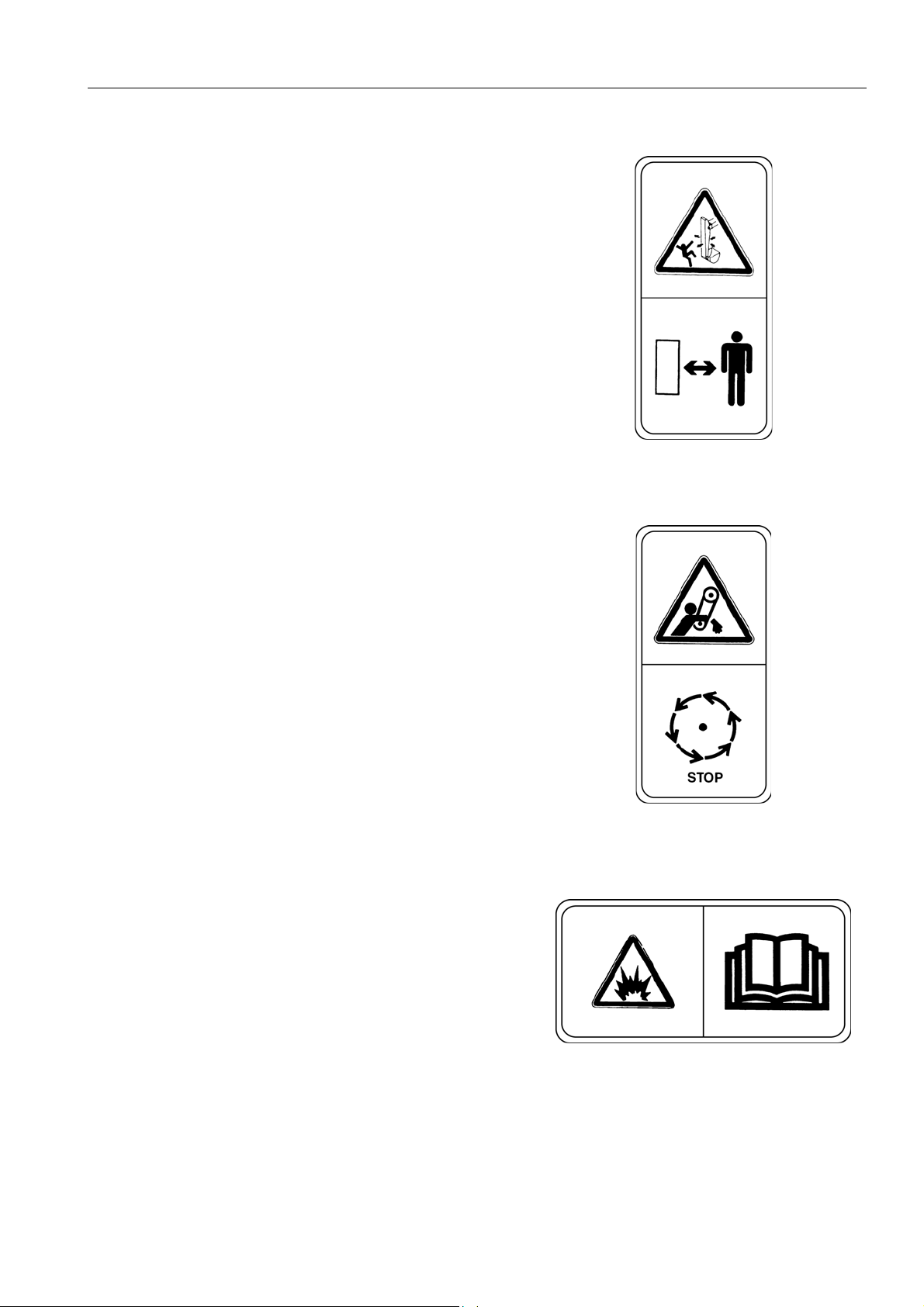

2. (09083-A0481)

• Warning when opening front window

• When raising window, lock it in place with lock catchers on

both sides.

• Falling window can cause injury.

23

POSITION FOR ATTACHING SAFETY LABELS SAFETY

3. (20Y-00-K2220)

• Emergency exit

• Read operation manual before operation

4. (207-00-71370)

• Pump Control override switch and swing lock override

switch

• Read the operation manual before operation

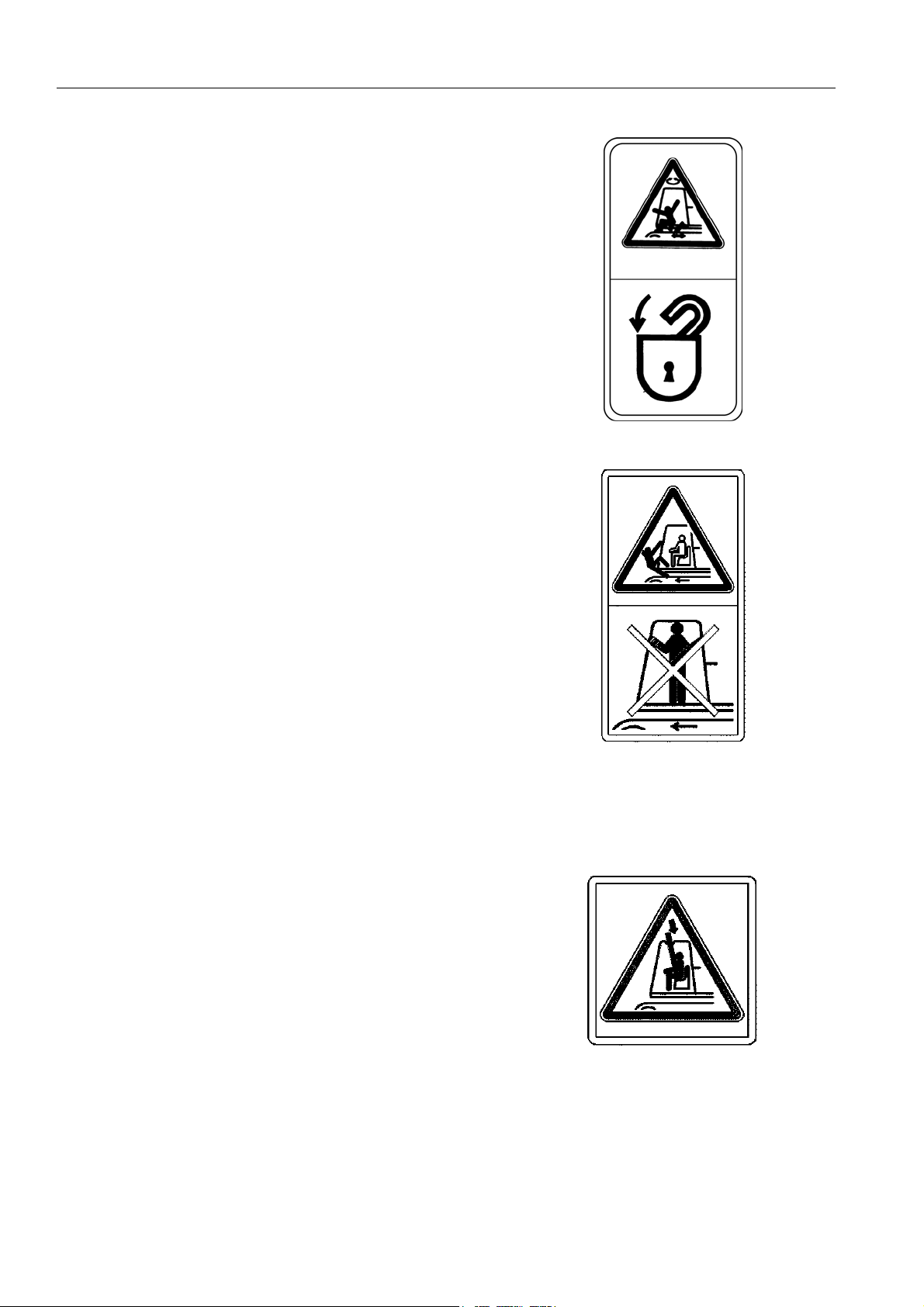

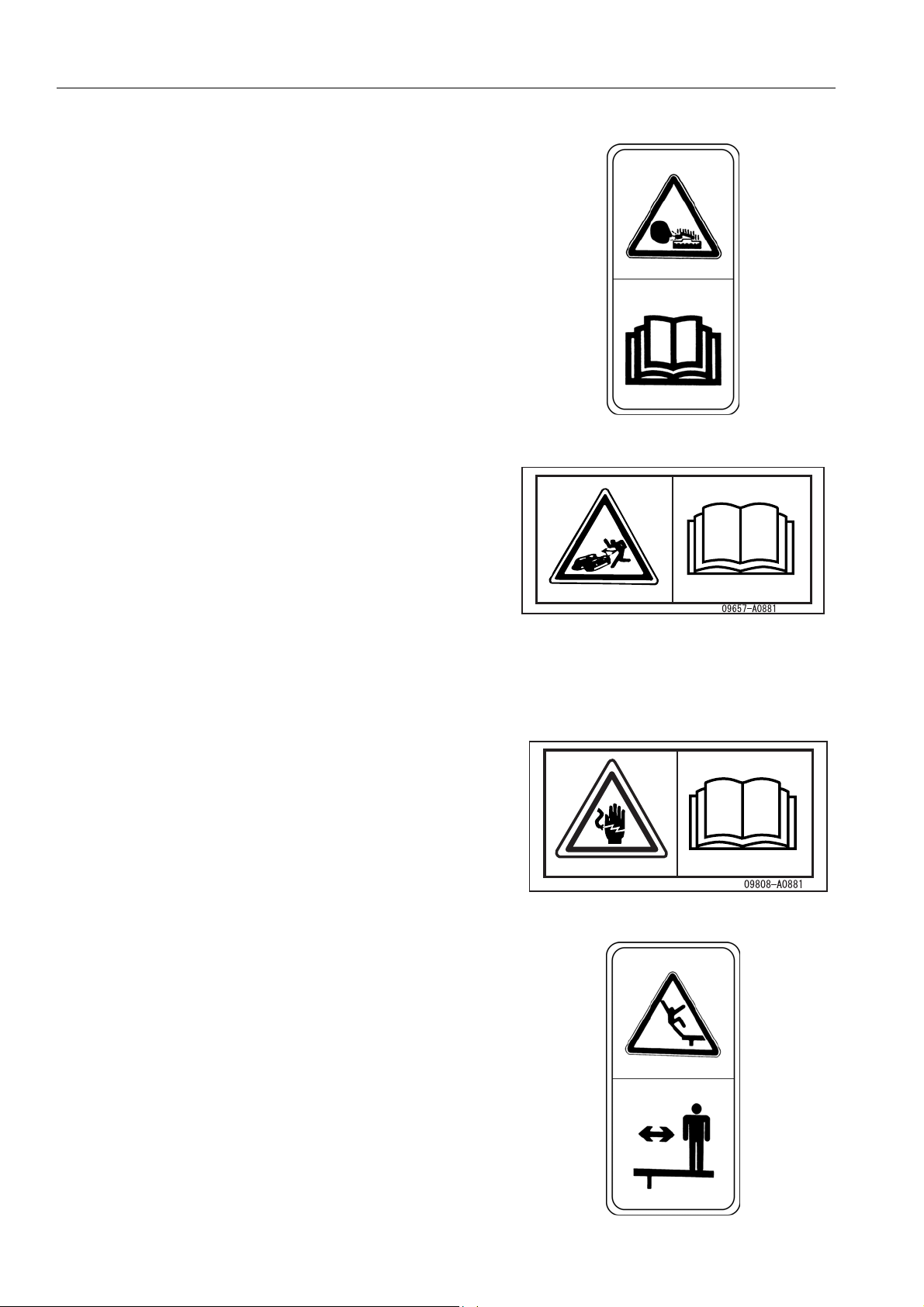

5. (09133-A3281)

Keeping out of moving area

To prevent SEVERE INJURY or DEATH do the following before

moving machine or its attachments:

• Sound horn to alert people nearby.

• Be sure no one is on or near machine or in the swing area.

• Rotate cab for full view of travel path if it can be done

safely.

• Use spotter if view is obstructed.

Always follow the above

24

SAFETY POSITION FOR ATTACHING SAFETY LABELS

6. (09805-A0881)

Keeping out of working range area.

• Make sure no one is in the work equipment swing area.

7. (09667-A0481)

• Do not open cover while engine is running.

8. (09659A057B) Warnings for handling the accumulator

Explosion hazard

• Keep away from flame.

• Do not weld or drill.

• Read operation manual before operation.

25

POSITION FOR ATTACHING SAFETY LABELS SAFETY

9. (09653-A0581)

Warning for high temperature coolant and oil.

• Hot water and oil hazard

• To prevent hot water and oil from spurting out:

• Turn engine off.

• Allow water to cool.

• Slowly loosen cap to relieve pressure before removing.

Read operation manual before operation.

10. (09657-A0881)

• Precautions when adjusting track tension

11. (09808-A0881)

• Precautions when handling cable

12. (09805-A0881)

• Warning for falling from upper-structure.

• Keep away from sides of machine.

• Keep of counterweight.

• Do not ride on machine when it is moving

26

SAFETY POSITION FOR ATTACHING SAFETY LABELS

13. (09805-C0881)

• Roll-over precautions

• Sign indicates a hazard of falling.

• Do not stand on this place here.

27

SAFETY INFORMATION SAFETY

SAFETY INFORMATION

SAFETY RULES

• Only trained and authorized personnel can operate and maintain the machine.

• Follow all safety rules, precautions and instructions when operating or performing maintenance on the

machine.

• If you are under the influence of alcohol or medication, your ability to safely operate or repair your machine

may be severely impaired putting yourself and everyone else on your jobsite in danger.

• When working with another operator or with a person on worksite traffic duty, be sure that all personnel understand all hand signals that are to be used.

IF ABNORMALITIES ARE FOUND

If you find any abnormality in the machine during operation or maintenance (noise, vibration, smell, incorrect

gauges, smoke, oil leakage, etc., or any abnormal display on the warning devices or monitor), report to the person

in charge and have the necessary action taken. Do not operate the machine until the abnormality has been corrected.

WORKING WEAR AND PERSONAL PROTECTIVE ITEMS

• Do not wear loose clothing or accessories. There is a danger that they may catch on control levers or other protruding parts.

• If you have long hair and it hangs out from your hard hat,

there is a danger that it may get caught up in the machine.

Tie your hair up and be careful not to let it get caught.

• Always wear a hard hat and safety shoes. If the nature of

the work requires it, wear safety glasses, mask, gloves, ear

plugs, and safety belt when operating or maintaining the

machine.

• Check that all protective equipment functions properly

before using it.

FIRE EXTINGUISHER AND FIRST AID KIT

Always follow the precautions below to prepare for action if any injury or fire should occur.

• Make sure that fire extinguishers have been provided and

read the labels to ensure that you know how to use them in

emergencies.

• Carry out periodic inspection and maintenance to ensure

that the fire extinguisher is up to date and usable.

• Store a first aid kit on board. Carry out periodic checks and

add to the contents if necessary.

28

Loading...

Loading...