Komatsu PC210-11, PC240-11, PC290-11, PC360-11, PC390-11 Service Manual

...

Mobile Lubrication Library

WARNING

Komatsu PC210-11/PC240-11/PC290-11

and PC360-11/ PC390-11/PC490-11

Excavator Installation Instructions

Instructions for installing a Graco automatic lubrication system on a

333514B

Komatsu PC210-11/PC240-11/PC290-11 and

PC360-11/PC390-11/PC490-11 Excavator.

Part No. 17J900

Maximum System Working Pressure: 2750 psi (18.96 MPa, 189.6 bar)

Important Safety Information

Read all warnings and instructions in all

Graco related component manuals and all

Komatsu equipment manuals. Save all

instructions.

Related Graco Component Manuals*

Manual No. Manual Title

332291 G3 Pump

3A2960 GLC2200 Controller

312497 MSP Divider Valves

*Refer to these instruction manuals for additional information related to the installation and operation of system

components.

The information contained in this document is only a recommendation for an automatic lubrication system and is not intended to

replace the installation and maintenance instructions provided by the original equipment manufacturer.

FLUID INJECTION HAZARD

Fluid leaks from incorrectly installed or ruptured

components, and/or failure to verify the components are properly installed and tested, can

result in serious injury such as fluid spraying in

the eyes or on skin and fluid injection, or equipment damage. Installation must be done by a

qualified professional or Komatsu certified technician and tested prior to use.

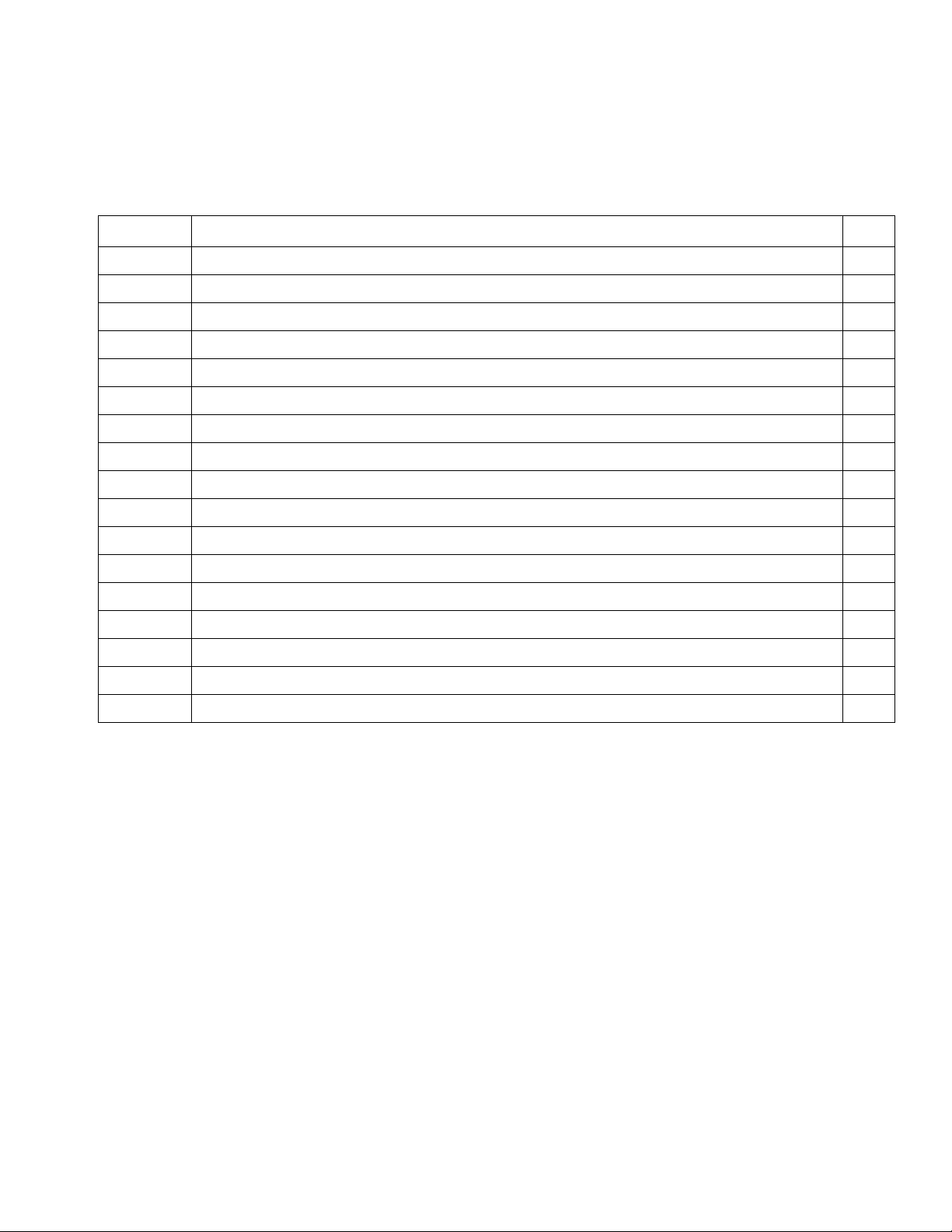

Table of Contents

Table of Contents

Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . 3

Recommended Tools and Supplies . . . . . . . . . . . . 4

Installation Notes . . . . . . . . . . . . . . . . . . . . . . . . 4

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . 6

Bearing Point Fittings . . . . . . . . . . . . . . . . . . . . . . . 7

MSP Divider Valves . . . . . . . . . . . . . . . . . . . . . . . . 14

MSP Valve Component Identification . . . . . . . . 14

MSP Divider Valve Assembly . . . . . . . . . . . . . . 14

MSP Divider Valve Assembly . . . . . . . . . . . . . . 16

Weld Stud Guidelines . . . . . . . . . . . . . . . . . . . . . . 17

G3 Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

G3 Mounting Bracket Installation . . . . . . . . . . . 23

Remote Fill Installation . . . . . . . . . . . . . . . . . . . . . 24

GLC2200 Controller . . . . . . . . . . . . . . . . . . . . . . . . 28

GLC2200 Controller Wiring . . . . . . . . . . . . . . . . . . 30

Hose Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Hose Assembly Instructions . . . . . . . . . . . . . . . 33

Hose Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Hose Installation . . . . . . . . . . . . . . . . . . . . . . . . 34

Arm and Bucket Valve . . . . . . . . . . . . . . . . . . . . 37

Boom and Swing Circle Valve . . . . . . . . . . . . . . 40

GLC2200 Controller Programming . . . . . . . . . . . . 43

Filling and Purging . . . . . . . . . . . . . . . . . . . . . . . . 46

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Routine Service and Equipment Maintenance . . 47

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 52

2

NOTE: Photographs may include optional equipment.

Installation Checklist

Installation Checklist

The following checklist is provided as a tool to ensure all installation proce dures are completed.

Completed Description Page

Walk around the equipm ent; use a grease gun to verify that all lube points receive grease. 6

Grease all zerks, before removal 6

Remove zerks and Komatsu extensions. 6

Install bearing point fittings 7

Assemble MSP Divider Valves 14

Install P-clamp, anchor and MSP valve weld studs 19

Assemble the G3 pump and fittings 21

Install G3 pump 22

Install remote fill 24

Install and route G3 power cable 25

Install GLC2200 controller 28

Wire GLC2200 controller and pump 30

Route and wrap hoses between divider valves, bearing points an d pump 34

Install P-clamps, zip ties, and other anchors 34

Program GLC2200 controller 43

Fill the G3 pump reservoir with grease; purge the main feed lines 46

Run test program; verify all connections are tight; verify all points are receiving lubricant 47

NOTE: Photographs may include optional equipment.

3

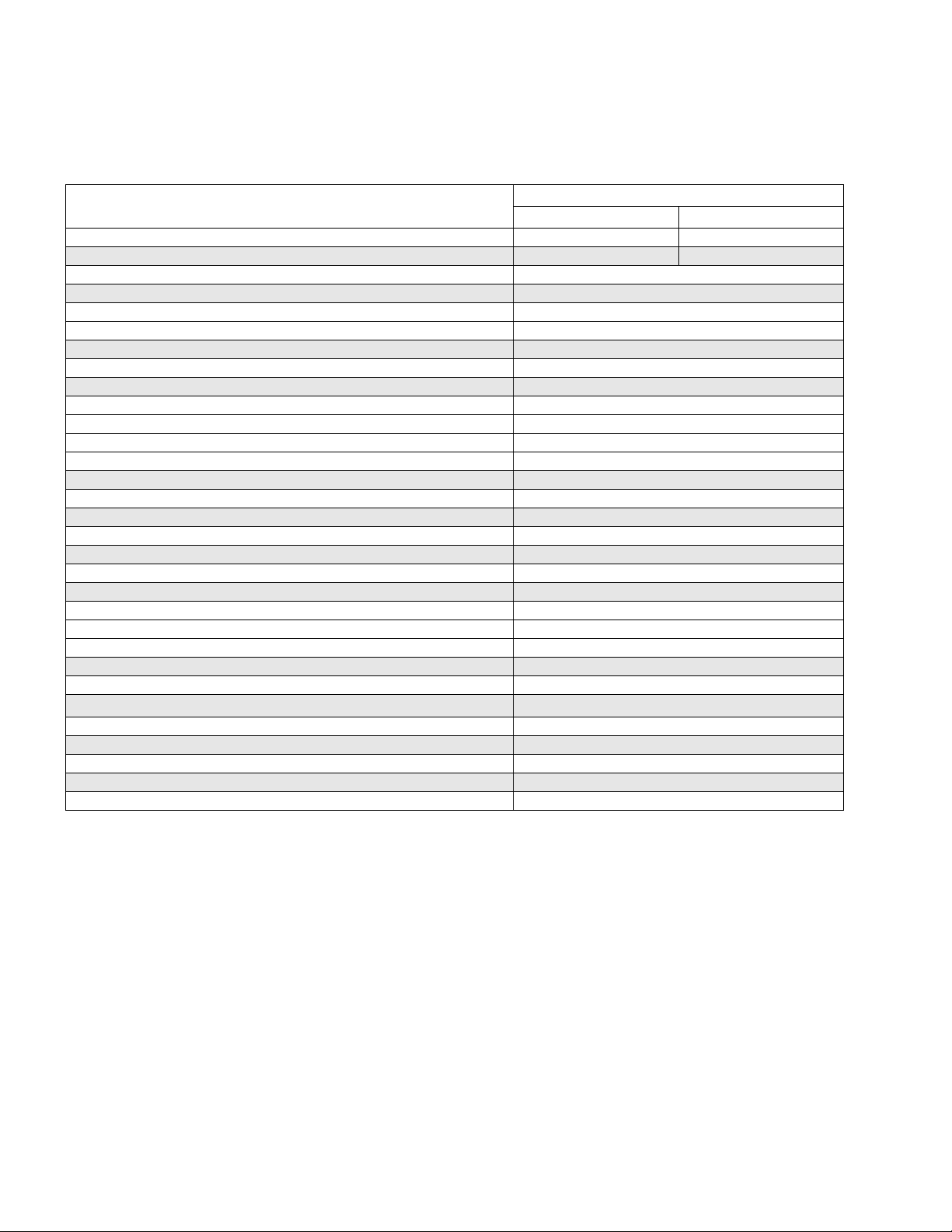

Recommended Tools and Supplies

Recommended Tools and Supplies

Size/Description

Tool

Combination wrench* 1/4 in. - 3/4 in. 6 mm - 20 mm

Socket set, standard and deep well with ratchet* 3/8 in. - 3/4 in. 9.5 mm - 20 mm

Screwdrivers: standard and Phillips 1 short; 1 long

Adjustable wrench 1 small; 1 medium

High speed drill (corded or cordless)

Drill bit - steel, high quality 5/16 in., 11/16 in.

Center punch fine point

Pipe taper tap 1/8 in. NPT

Hammer

Angle grinder

Grinding disc Heavy grade grinding disc

Flap disc 60 - 80 grit

Cutoff disc High quality disc

Cutting blade / knife Razor blade cutting tool

Standard pliers Rubber handle

Needle nose pliers Rubber handle

Side cut pliers (diagonal cutters) Rubber handle

Slip joint pliers Rubber handle

Locking pliers Small or medium

Electrician’s wire striper / crimper General duty wire striper / crimper

Soldering iron 30 watt minimum

Electrical solder

Soldering flux

Shrink tubing Various sizes

Electrical tape Black, small roll

Thread sealant

Multi-tester / voltmeter Must test DC/AC/Ohms

Electrical connectors Ring connectors (14 gauge)

Tape measure Standard / metric

Komatsu primer and paint Color should match the Komatsu equipment

Documentation / writing implements Small note pad, pen, pencil, marker

Liquid thread sealant such as Loctite® 656

US Metric

*Both US and Metric sizes of these tools are recommended.

®

Loctite

All other Trademarks used herein are the property of their respective owners.

is a registered trademark of the Henkel Corporation.

Installation Notes

• Do not use PTFE tape on fitting threads . Liquid pip e

sealant is recommended for use in lubrication systems to eliminate the potential for contamination. If

you must use PTFE tape, always skip the first two

threads on the fitting.

• Refer to the Installation Checklist provided on page

3 to ensure all installation procedures have been

completed.

4

NOTE: Photographs may include optional equipment.

• Prime and paint all bare metal surfaces prior to

installation with matching K omatsu primer an d paint.

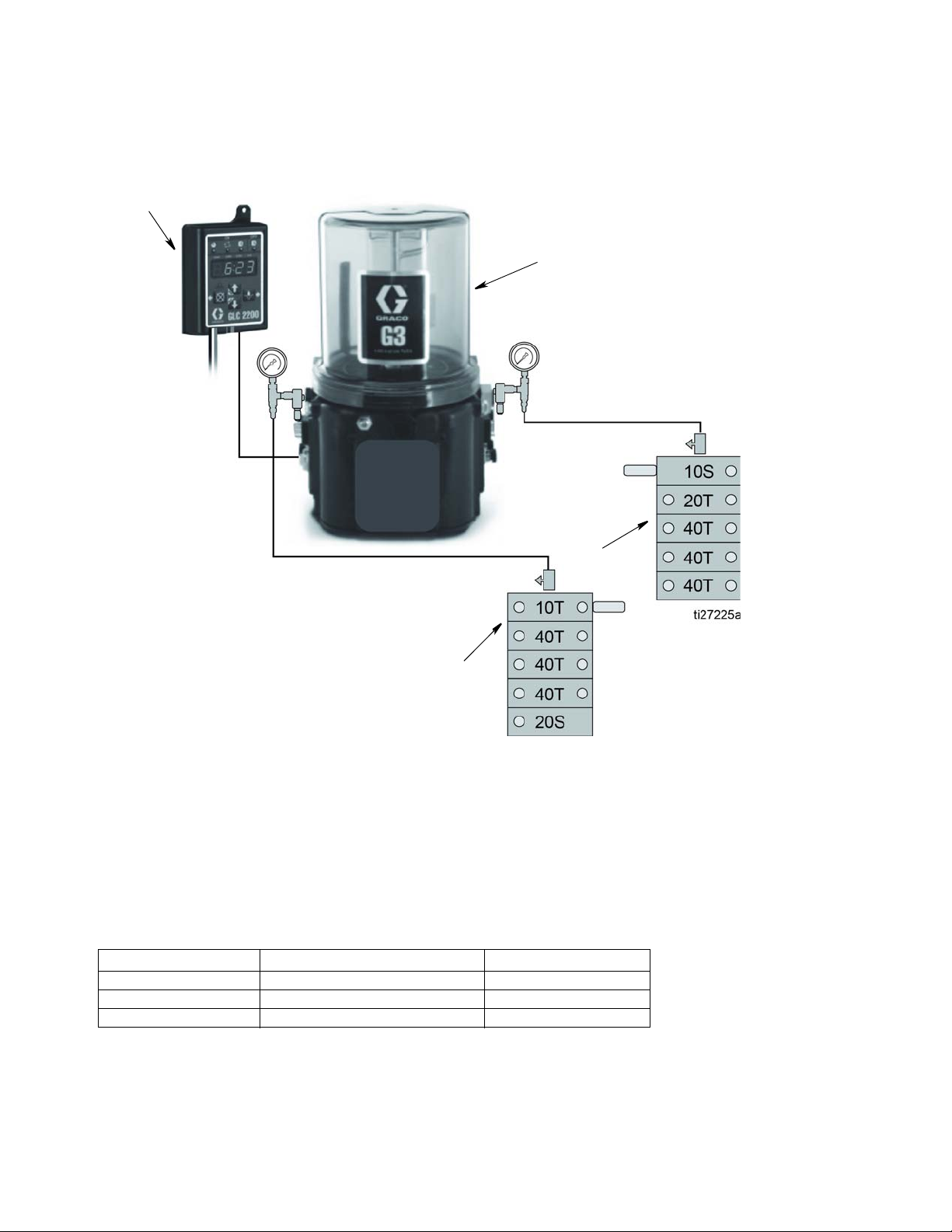

Typical Installation

A

B

C

D

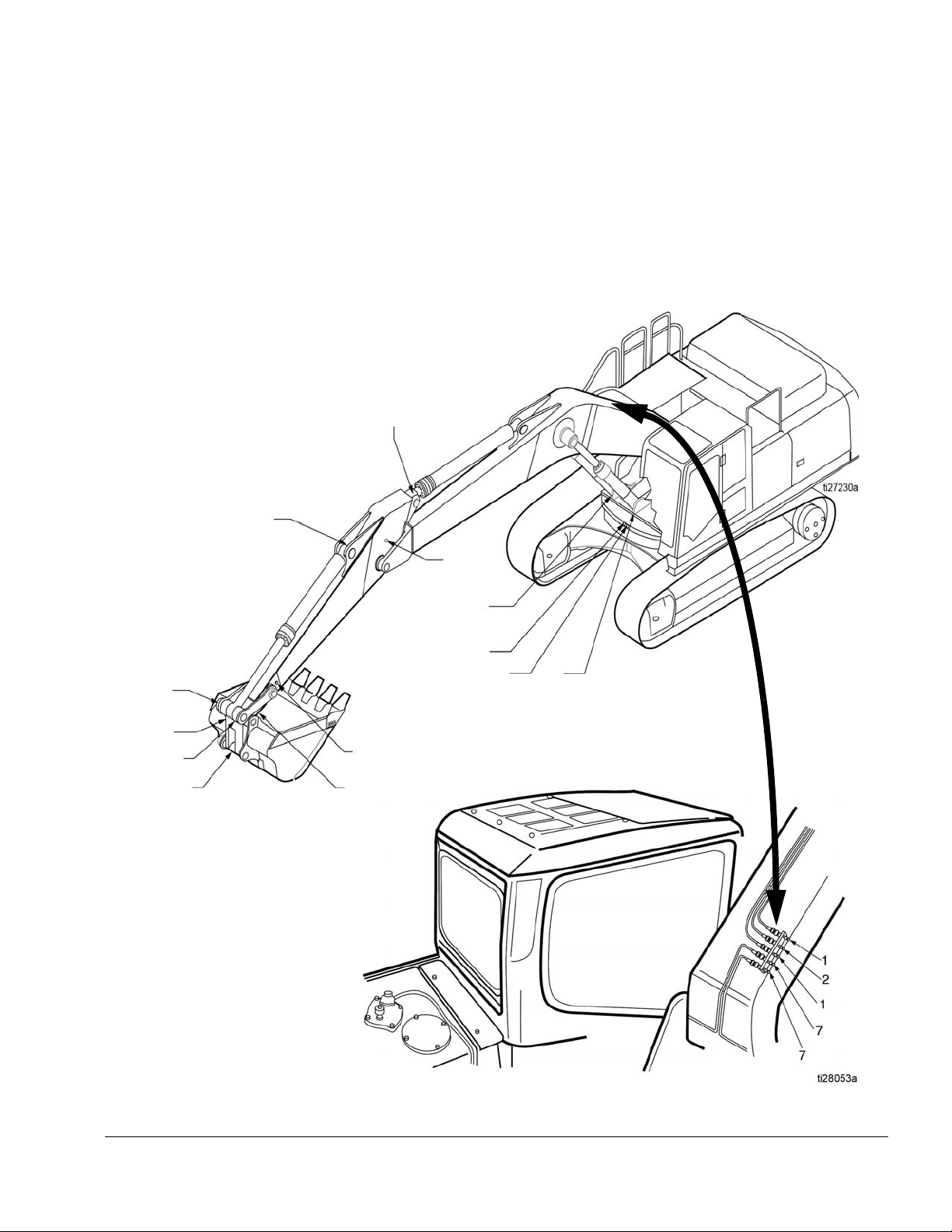

Typical Installation

Key

A GLC2200 Controller

B G3 Automatic Lubrication Pump

C MSP Divider Valve - Boom and Swing Circle Valve

D MSP Divider Valve - Arm and Bucket Valve

Run Time

MODEL Pump ON Time Pump OFF Time

PC210-11/PC240-11 1 minutes and 45 seconds 1 hour

PC290-11/PC360-11 2 minutes 1 hour

PC390-11/PC490-11 2 minutes and 10 seconds 1 hour

NOTE: Photographs may include optional equipment.

5

Installation

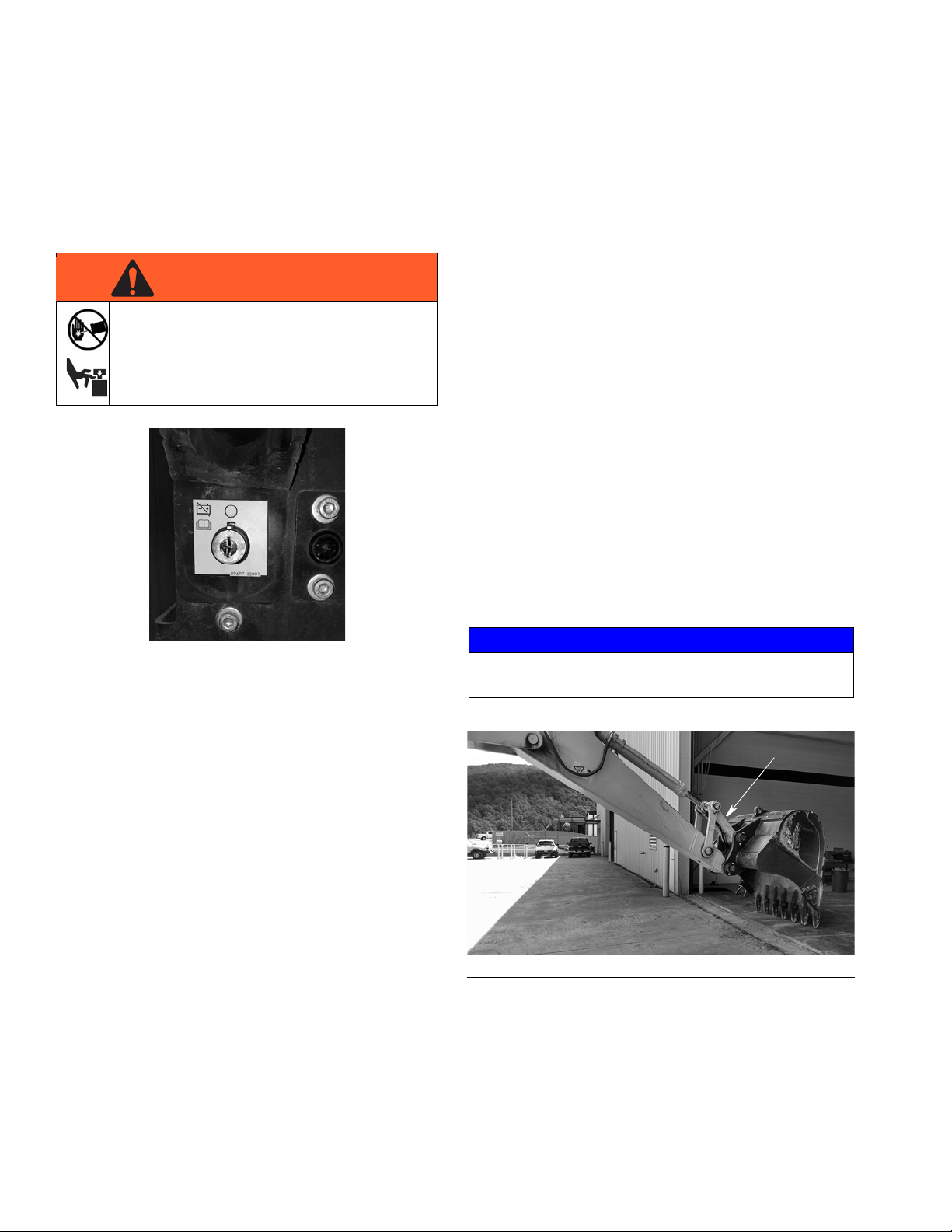

WARNING

H-Link

Installation

Before You Start

Disconnect battery before installing the

lubrication equipment. Installing lubrication

equipment on powered machinery could result

in serious injury from skin injection or parts

moving unexpectedly.

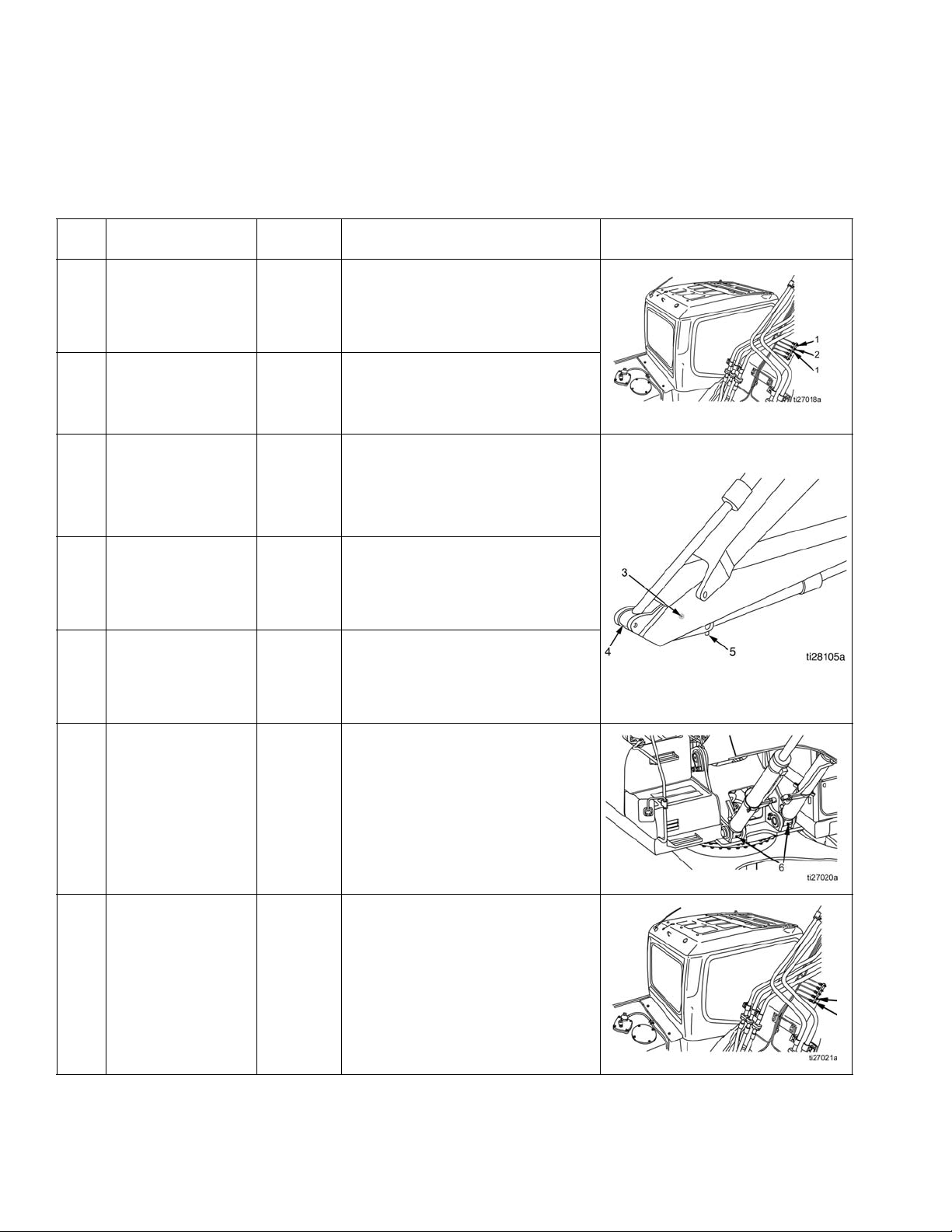

FIG. 1: Battery Disconnect

1. Walk around the machine with a grease gun and

verify that every bearing point is accepting grease.

(Refer to F

points). This will ensure that the valves can dispense grease to the bearing points by identifying

potentially blocked passages from the grease zerk

to the bearing point.

IG. 3, page 7 to identify lubrication

Zerk Fittings

a. Use a clean cloth or rag to remove excessive

grease, contaminants and dirt from the work

area.

b. Remove all g rease zerks and Komatsu exten-

sions from their installation locations.

c. Use a clean cloth or rag to remove any remain-

ing grease, contaminants or dirt from the area

around the passage way to the bearing points.

d. If required use 1/8 in. NPT pipe tap to chase t he

passage threads.

2. Flip over the H-link on th e e xcavator bucket (F

(The zerk fittings must face the inside of the arm.)

3. After the H-link is reversed, manually grease the

lube points again to verify grease is being accepted.

NOTICE

It may be necessary to rotate the pins while greasing

to get the grease to purge .

IG. 2).

6

FIG. 2

NOTE: Photographs may include optional equipment.

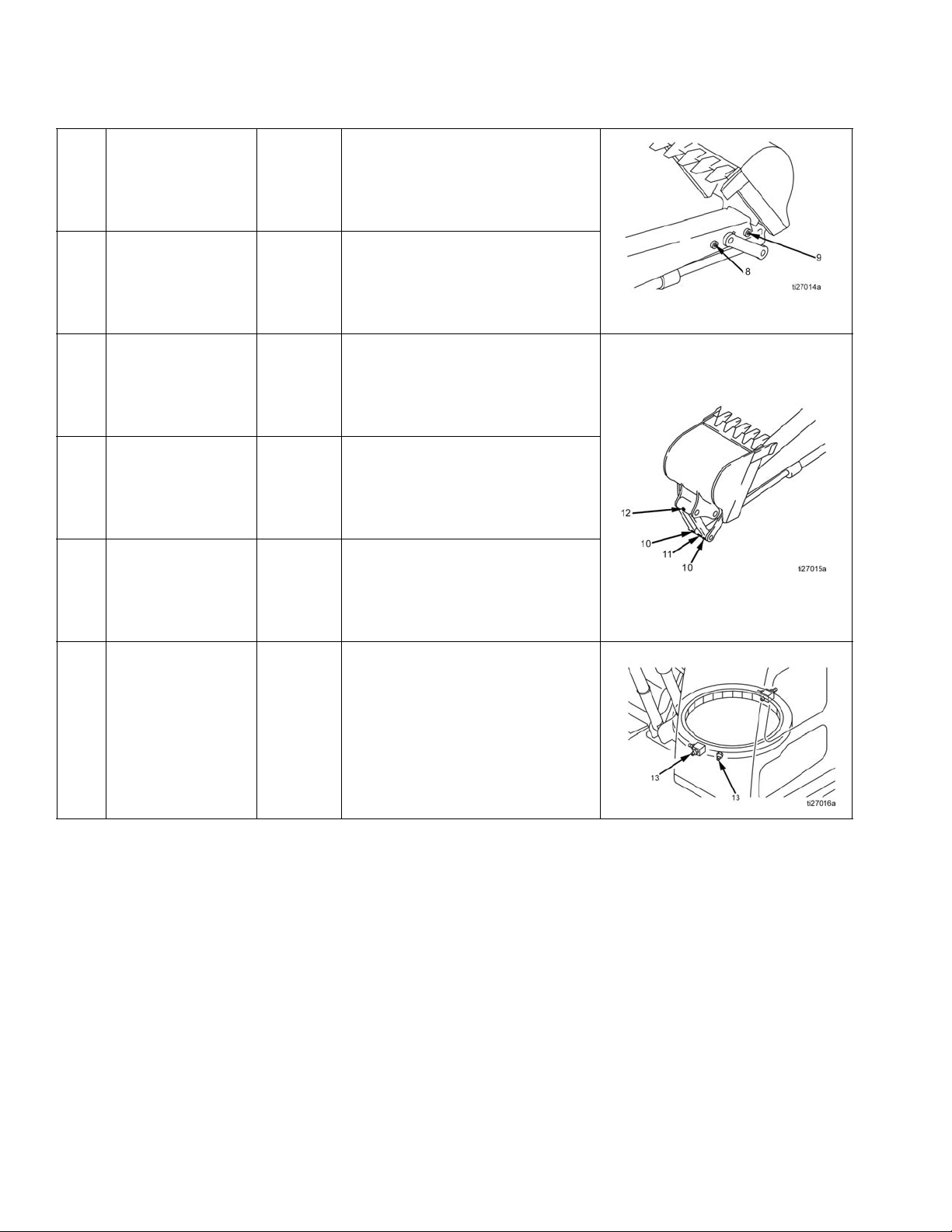

Bearing Point Fittings

6

13

4

3

5

9

8

12

10

11

10

13

6

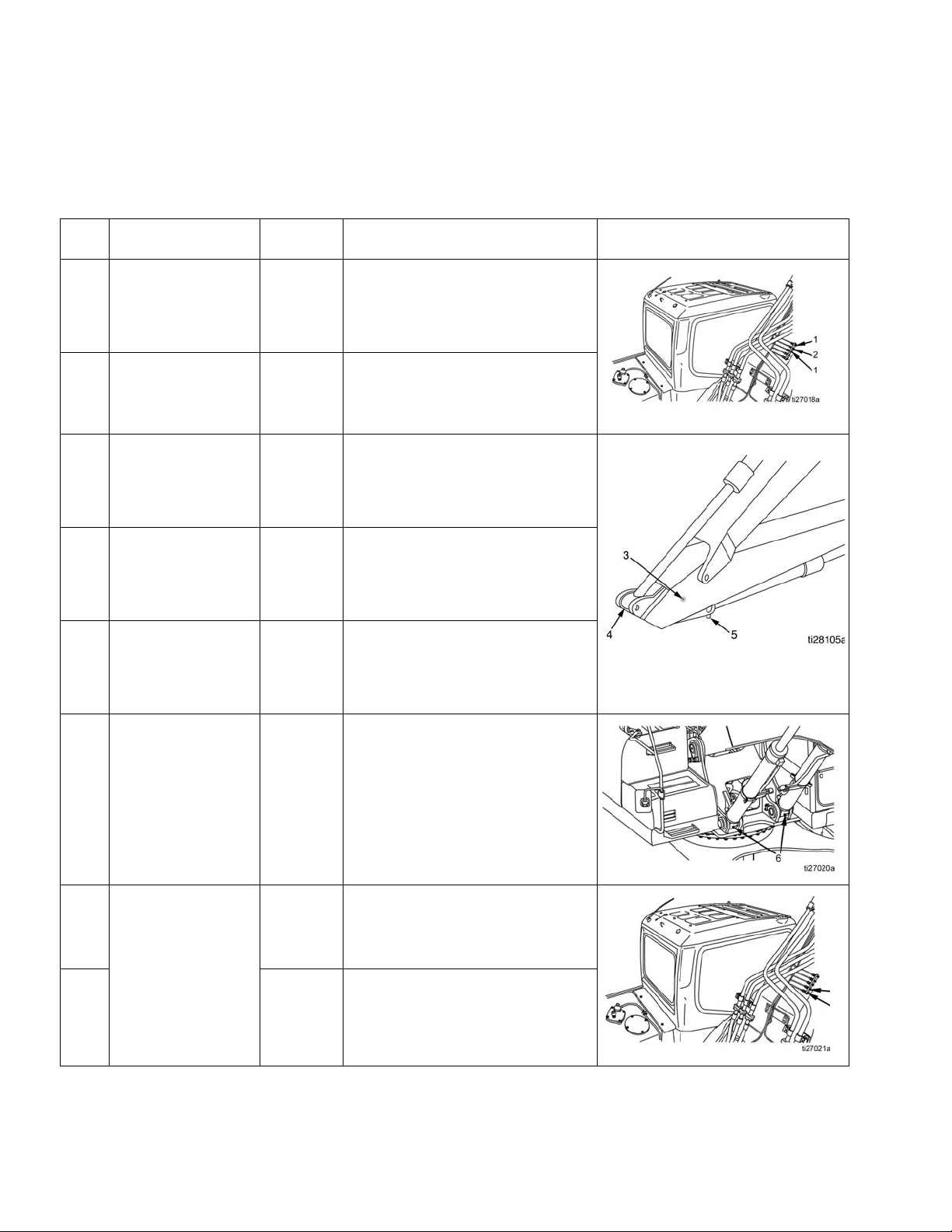

Bearing Point Fittings

1. Apply thread sealant to supplied bearing point fittings.

2. Install fittings in bearing points. Refer to F

the Bearing Point Fitting Table, page 8 for installation locations and parts.

IG. 3 and

3. Refer to Bearing Point Fitting Table, beginning on

page 8, to determine the location of the bearing

points on your model.

FIG. 3

NOTE: Photographs may include optional equipment.

7

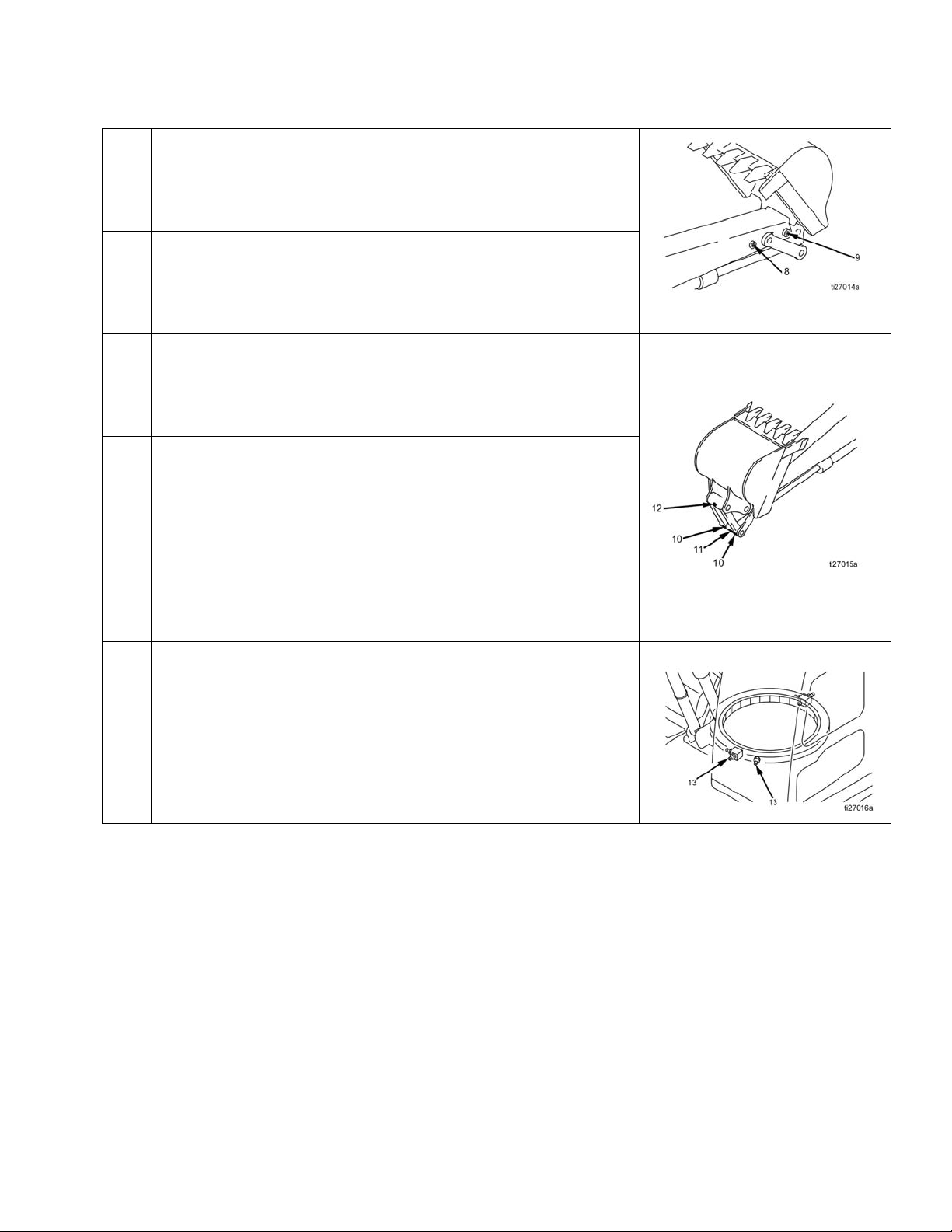

Bearing Point Fittings

7

7

Bearing Point Fittings Table: PC210-11/PC240-11 Models

NOTE: Bef ore starting a lube cycle, set the machine to the grea sing postur e. I f y ou are unsure of this procedur e, see

the Komatsu Excavator instruction manual.

Ref

No. Location Part No. Description

Boom cylinder rod

1

pins (2 places)

Arm cylinder foot pin

2

(1 place)

Boom and arm con-

3

nection pin (1 place)

Arm cylinder rod

4†

end (1 place)

Bucket cylinder foot

5

pin (1 place)

17K062

556763

17K062

556763

17G422

556763

Adapter, long, BSPT x NPT

Elbow, JIC 90° 1/8 inch x 4

Adapter, long, BSPT x NPT

Elbow, JIC 90° 1/8 inch x 4

Adapter, short, BSPT x NPT

Elbow, JIC 90° 1/8 inch x 4

556763 Elbow, JIC 90° 1/8 inch x 4

17G422

556763

Adapter, short, BSPT x NPT

Elbow, JIC 90° 1/8 inch x 4

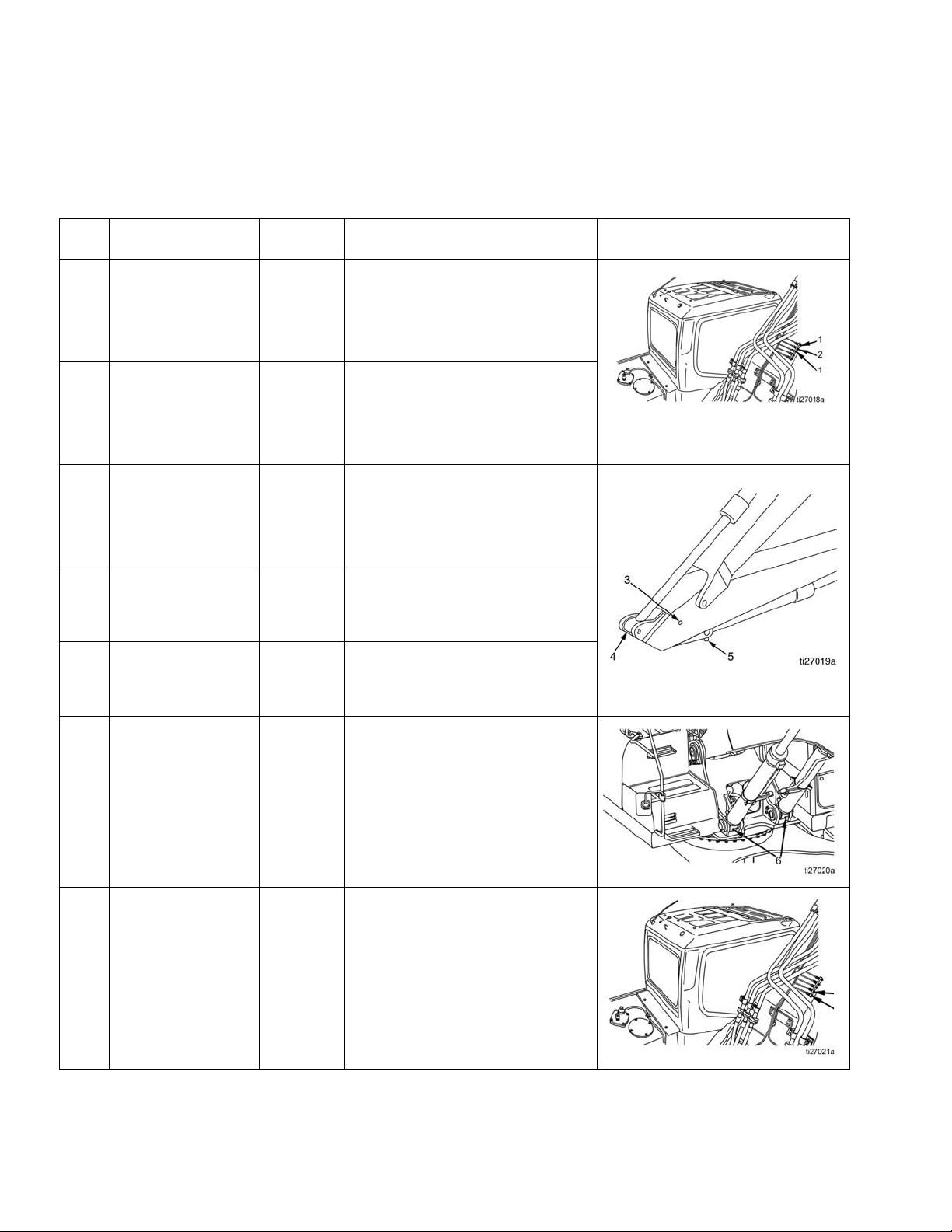

Boom cylinder foot

6

pins (2 places)

17G422

556763

17K062

Adapter, short, BSPT x NPT

Elbow, JIC 90° 1/8 inch x 4

Adapter, long, BSPT x NPT

7

556763

Elbow, JIC 90° 1/8 inch x 4

Boom foot pins (2

places)

7*

8

17K062

17K061

555749

NOTE: Photographs may include optional equipment.

Adapter, long, BSPT x NPT

Adapter, street elbow, BSPT x NPT

Connector, #4, JIC, 1/8 PM

Bearing Point Fittings

Arm and link con-

8

nection pin (1 place)

Arm and bucket con-

9

nection pin (1 place)

H-Link connecting

10

pins (2 places)

Bucket cylinder rod

11

pin (1 place)

Bucket and link con-

12

nection pin (1 place)

17K061

555749

17K061

555749

17G422

556763

17K061

555749

17G422

556763

Adapter, street elbow, BSPT x NPT

Connector, #4, JIC, 1/8 PM

Adapter, street elbow, BSPT x NPT

Connector, #4, JIC, 1/8 PM

Adapter, short, BSPT x NPT

Elbow, JIC 90° 1/8 inch x 4

Adapter, street elbow, BSPT x NPT

Connector, #4, JIC, 1/8 PM

Adapter, short, BSPT x NPT

Elbow, JIC 90° 1/8 inch x 4

Swing circle (2

13

places)

† Tap rod end with 1/8 NPT tap. Rod end may need to be flipped over to allow clearance for fittings during articulation

17K062

556763

Adapter, long, BSPT x NPT

Elbow, JIC 90° 1/8 inch x 4

Grind slot in cap around zerk wide enough to tighten fittings approximately 1-1/4 inch wide.

NOTE: Photographs may include optional equipment.

9

Bearing Point Fittings

7

7

Bearing Point Fittings Table: PC290-11/PC360-11 Models

NOTE: Bef ore starting a lube cycle, set the machine to the grea sing postur e. I f y ou are unsure of this procedur e, see

the Komatsu Excavator instruction manual.

Ref

No. Location Part No. Description

Boom cylinder rod

1

pins (2 places)

Arm cylinder foot pin

2

(1 place)

Boom and arm con-

3

nection pin (1 place)

Arm cylinder rod

4†

end (1 place)

Bucket cylinder foot

5

pin (1 place)

17K062

556763

17K062

556763

17K061

555749

Adapter, long, BSPT x NPT

Elbow, JIC 90° 1/8 inch x 4

Adapter, long, BSPT x NPT

Elbow, JIC 90° 1/8 inch x 4

Adapter, street elbow, BSPT x NPT

Connector, #4, JIC, 1/8 PM

556763 Elbow, JIC 90° 1/8 inch x 4

17G422

556763

Adapter, short, BSPT x NPT

Elbow, JIC 90° 1/8 inch x 4

10

Boom cylinder foot

6

pins (2 places)

Boom foot pins (2

places)

7

17G422

556763

17K062

556763

NOTE: Photographs may include optional equipment.

Adapter, short, BSPT x NPT

Elbow, JIC 90° 1/8 inch x 4

Adapter, long, BSPT x NPT

Elbow, JIC 90° 1/8 inch x 4

Bearing Point Fittings

Arm and link con-

8

nection pin (1 place)

Arm and bucket con-

9

nection pin (1 place)

H-Link connecting

10

pins (2 places)

Bucket cylinder rod

11

pin (1 place)

Bucket and link con-

12

nection pin (1 place)

17K061

555749

17K061

555749

17G422

556763

17K061

555749

17K062

556763

Adapter, street elbow, BSPT x NPT

Connector, #4, JIC, 1/8 PM

Adapter, street elbow, BSPT x NPT

Connector, #4, JIC, 1/8 PM

Adapter, short, BSPT x NPT

Elbow, JIC 90° 1/8 inch x 4

Adapter, street elbow, BSPT x NPT

Connector, #4, JIC, 1/8 PM

Adapter, long, BSPT x NPT

Elbow, JIC 90° 1/8 inch x 4

Swing circle (2

13

places)

† Tap rod end with 1/8 NPT tap. Rod end may need to be flipped over to allow clearance for fittings during articulation.

Remove plug from cylinder end and install plug on opposite side of cylinder where zerk was located.

17K062

556763

Adapter, long, BSPT x NPT

Elbow, JIC 90° 1/8 inch x 4

Grind slot in cap around zerk wide enough to tighten fittings approximately 1-1/4 inch wide.

NOTE: Photographs may include optional equipment.

11

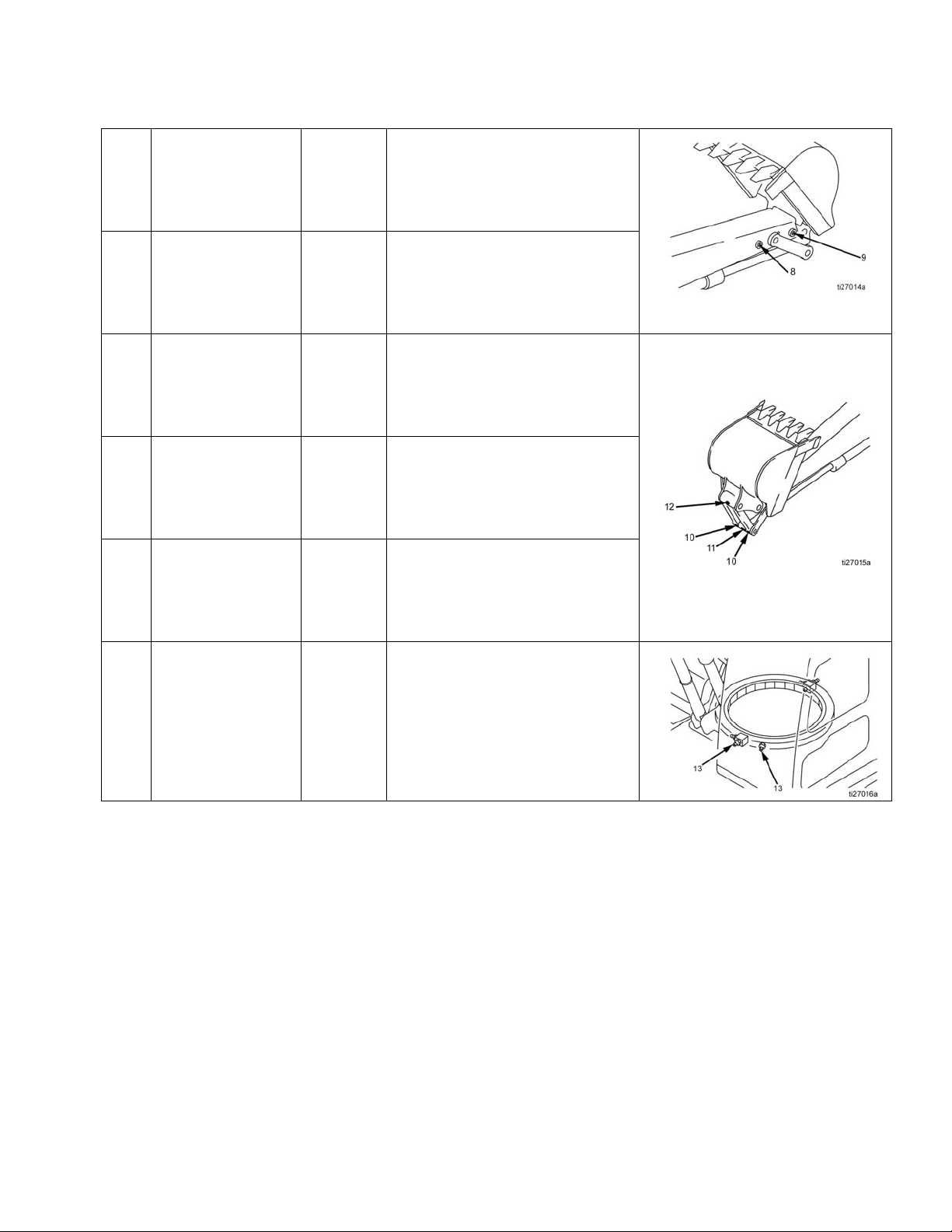

Bearing Point Fittings

7

7

Bearing Point Fittings Table: PC390-11/PC490-11 Models

NOTE: Bef ore starting a lube cycle, set the machine to the grea sing postur e. I f y ou are unsure of this procedur e, see

the Komatsu Excavator instruction manual.

Ref

No. Location Part No. Description

Boom cylinder rod

1

pins (2 places)

Arm cylinder foot pin

2

(1 place)

Boom and arm con-

3

nection pin (1 place)

Arm cylinder rod

4

end (1 place)

Bucket cylinder foot

5

pin (1 place)

17K062

556763

17K062

556763

17K061

555749

17K062

15K783

555749

17G422

556763

Adapter, long, BSPT x NPT

Elbow, JIC 90° 1/8 inch x 4

Adapter, long, BSPT x NPT

Elbow, JIC 90° 1/8 inch x 4

Adapter, street elbow, BSPT x NPT

Connector, #4, JIC, 1/8 PM

Adapter, long, BSPT x NPT

Elbow, street

Connector, #4, JIC, 1/8 PM

Adapter, short, BSPT x NPT

1/8 inch x 4 JIC 90° elbow

12

Boom cylinder foot

6

pins (2 places)

Boom foot pins (2

7

places)

17G422

556763

17K062

556763

NOTE: Photographs may include optional equipment.

Adapter, short, BSPT x NPT

Elbow, JIC 90° 1/8 inch x 4

Adapter, long, BSPT x NPT

Elbow, JIC 90° 1/8 inch x 4

Bearing Point Fittings

Arm and link con-

8

nection pin (1 place)

Arm and bucket con-

9

nection pin (1 place)

H-Link connecting

10

pins (2 places)

Bucket cylinder rod

11

pin (1 place)

Bucket and link con-

12

nection pin (1 place)

17K062

556763

17K061

555749

17K062

556763

17K061

555749

17K062

556763

Adapter, long, BSPT x NPT

Elbow, JIC 90° 1/8 inch x 4

Adapter, street elbow, BSPT x NPT

Connector, #4, JIC, 1/8 PM

Adapter, long, BSPT x NPT

Elbow, JIC 90° 1/8 inch x 4

Adapter, street elbow, BSPT x NPT

Connector, #4, JIC, 1/8 PM

Adapter, long, BSPT x NPT

Elbow, JIC 90° 1/8 inch x 4

Swing circle (2

13

places)

Remove plug from cylinder end and install plug on opposite side of cylinder where zerk was located.

17K062

556763

Adapter, long, BSPT x NPT

Elbow, JIC 90° 1/8 inch x 4

Grind slot in cap around zerk wide enough to tighten fittings approximately 1-1/4 inch wide.

NOTE: Photographs may include optional equipment.

13

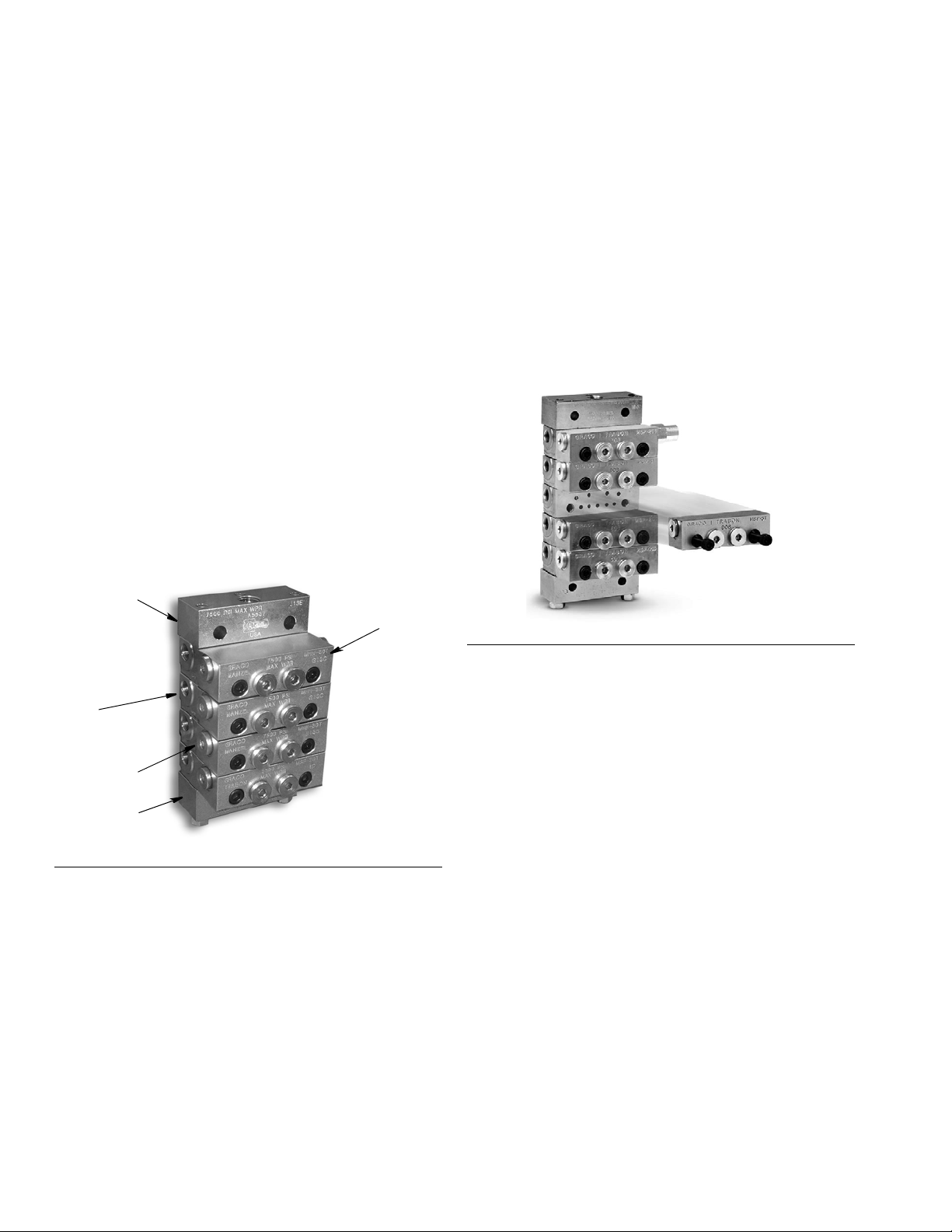

MSP Divider Valves

A

B

C

D

E

MSP Divider Valves

The Divider Valve Assembly includes the following components:

• MSP divider valve base

• MSP divider valve assembly

• 1/8 in. x 4 JIC straight outlet fittings

• Inlet fittings

• Cycle indicators

• Performance indicators

Prepare a clean, flat area to assemble the valves.

MSP Valve Component Identification

NOTE: The MSP Divider Valves shown in FIG. 4 - FIG.

10 are provided for reference only. The MSP Divider

Valves used in your installation may include fewer or

more blocks and appear slightly different than those

shown in the reference figures.

MSP Divider Valve Assembly

1. The MSP Divider Valves require assembly (FIG. 5).

NOTE: Refer to the MSP Divider Valve Assembly

Table and MSP Divider Valve and Lube Points

Assembly reference illustrations, F

(page 16), to verify assemb ly orientation.

a. Remove components from packaging.

b. Assemble metering valves to base plates as

shown in F

IG. 5.

IG. 12 - FIG. 13

FIG. 4

Key:

A Valve Section

B Inlet Section

C Indicator / Port Plug

D End Plug

E End Section

FIG. 5

14

NOTE: Photographs may include optional equipment.

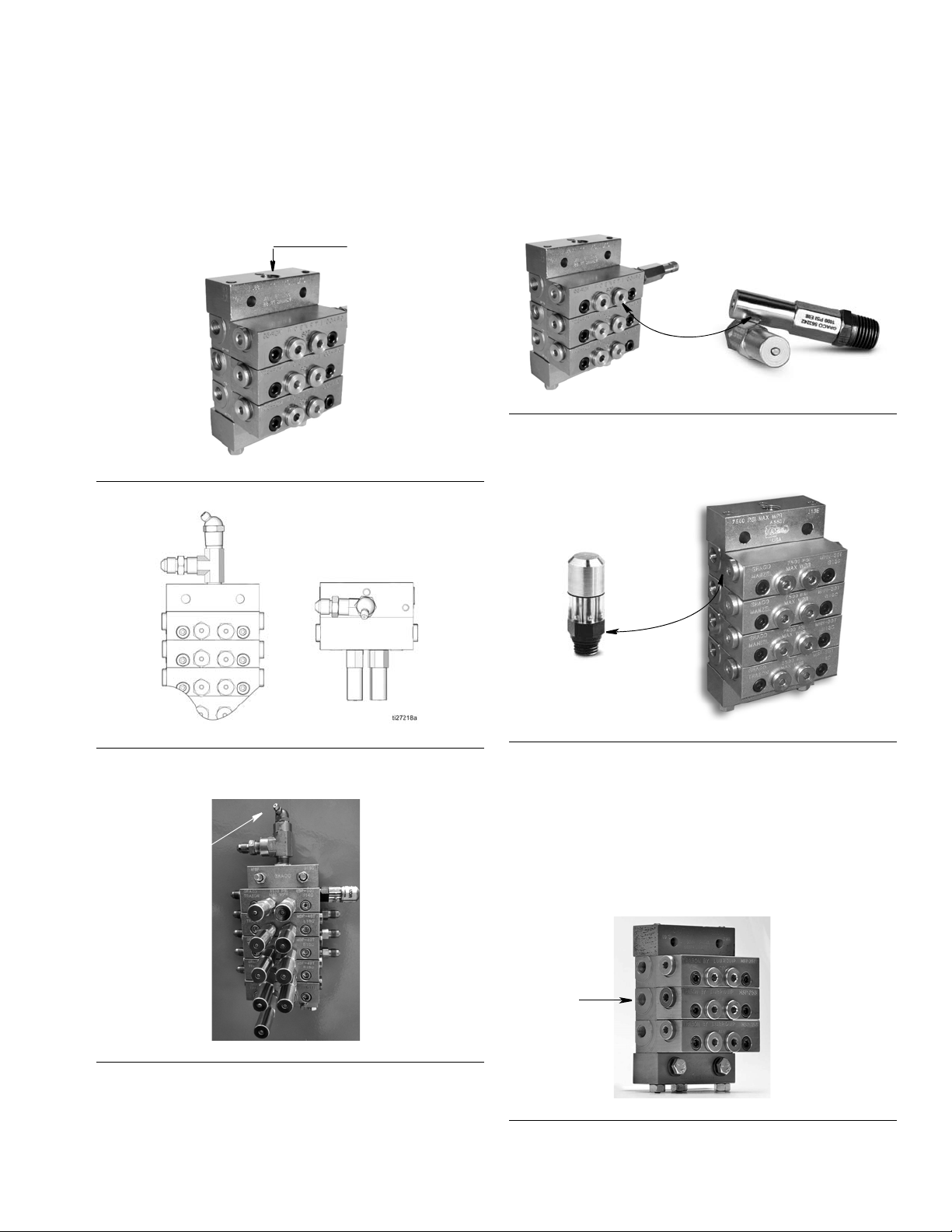

MSP Divider Valves

zerk

Performance

Indicator

Cycle Indicator

Outlet

Port

2. Install inlet fitting assembly in ports (FIG. 6).

• Inlet fitting assembly includes: a 1/4 inch tee, a

1/4 x 4 JIC and a zerk fitting

• Orient zerk fitting so it is always easily accessible (see F

IG. 6 and FIG. 7).

FIG. 6

5. Install 1500 psi (10.34 bar , 103.4 MP a) p erformance

indicators in ports (F

IG. 9):

NOTE: Refer to the MSP Divider Valve Assembly

(page 16) to verify assembly orientation.

FIG. 9

6. Install cycle indicators in valves (F

IG. 10).

• Magnetic Cycle indicators (quantity 2)

FIG. 7

3. Install grease zerk fittings and zerk cover (F

FIG. 8

4. Remove end plugs and indicator port plugs before

IG. 8).

installing performance and cycle indicators in the

MSP Divider Valve assembly.

NOTE: Photographs may include optional equipment.

FIG. 10

7. Install outlet plugs in all open ports as shown in the

MSP Divider Valve Assembly reference illustrations

IG. 12 and FIG. 13, page 16.

(F

8. Install outlet fittings in all ports (F

IG. 11).

• All outlets use 1/8 in. x 4 JIC straight fittings

(included in kit).

FIG. 11

15

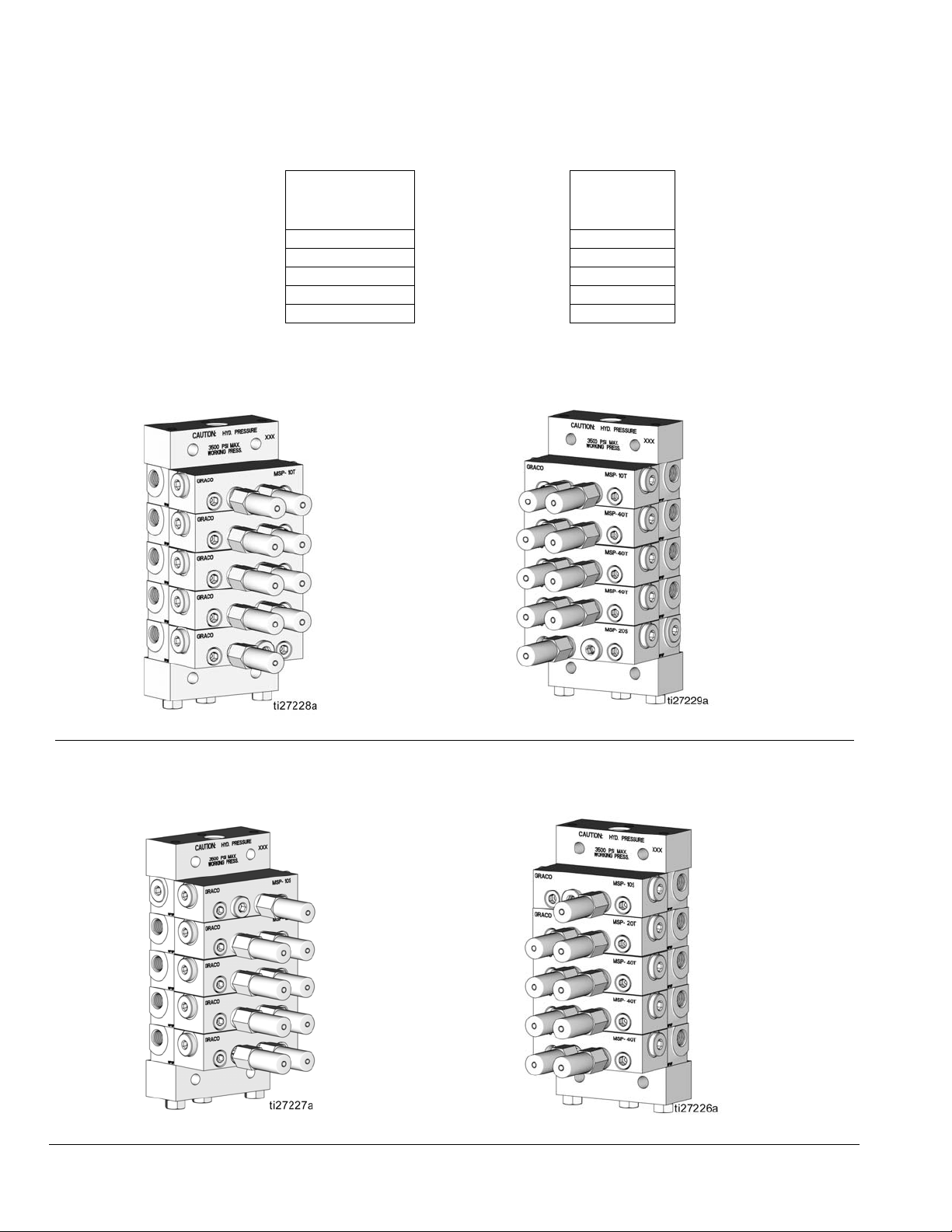

MSP Divider Valves

MSP Divider Valve Assembly

Boom and Swing

Circle Valve

IG. 12)

(F

10T Plug 10S

40T 20T

40T 40T

40T 40T

20S Plug 40T

MSP Divider Valve and Lube Points Assembly

Boom and Swing Circle Valve (FIG. 12)

Arm and

Bucket Valve

(FIG. 13)

FIG. 12

Arm and Bucket Valve (F

FIG. 13

16

IG. 13)

NOTE: Photographs may include optional equipment.

Loading...

Loading...