Komatsu PC20R-8, PC27R-8 Maintenance Manual

Operation &

Maintenance Manual

WEAM000101

PC20R-8

PC27R-8

HYDRAULIC EXCAVATOR

SERIAL NUMBER

PC20R-8 - F30791 and up

PC27R-8 - F31103 and up

WARNING

Unsafe use of this machine may cause serious injury

or death. Operators and maintenance personnel

must read this manual before operating or

maintaining this machine. This manual should be

kept inside the cab for reference and periodically

reviewed by all personnel who will come into contact

with the machine.

FOREWORD

CAUTION

1.1 FOREWORD

• This manual has been carr ied out by Komatsu Uti lity in order to supp ly their custom ers with all the nece ssary

information on the mach ine an d the safety r egulation s related to it, together with the use a nd mainten ance instructions that ena ble the operat or to exploi t the capacity of the mac hine with optim al result s and to keep the

machine efficient over time.

• The operation manual, toget her with the sp are par ts cata log ue, is an in teg ra l part of the mac hin e and mu st ac -

company it, even when it is resold, until its final disposal.

• The manual must be h andled with th e greatest car e and always kept on boar d the machin e, so that it ca n be

consulted at any moment; it must be placed in the appropriate compartment inside the seat support, where also

the ownership documents and the logbook are usually kept.

• This manual must be given to the persons who have to use the machine and carry out the routine maintenance

operations; they must read the contents carefully more than once, in such a way as to clearly understand what

are the correct operating conditions and the dangerous conditions that must be avoided.

In case of loss or damage, request a new copy to Komatsu Utility or your Komatsu Utility Dealer.

• The illustrations contained in this manual may represent machine configurations available on request.

The machines are c onstan t ly upgraded in order to in crease their efficiency and r el ia bil it y; t his ma nua l s ums up

all the information regarding the state of technical progress at the moment in which the machine is launched on

the market.

Consult your Komatsu Utility Dealer for any updated information.

• Punctual periodic ann otations regarding the mainte nance ope rations tha t have bee n carried out are important

to have a clear prospect of the situation and to know exactly what has been done and what has to be done after

the next maintenance interval. The refore, it is advisa ble to consul t either th e hour meter a nd the maint enance

plan frequently.

• Over the years Komatsu Utility Dealers have gathered considerable experience in customer service.

If more information is need ed, do not h esitate to c ontac t your Kom atsu Uti lity Deal er: he alwa ys kn ows how to

get the best performa nce from the ma chine , he can su ggest the use of the equ ipmen t that i s most s uitab le for

specific needs and can provide the technical assistance necessary for any change that may be required to conform the machine to the safety standards and traffic rules.

Furthermore, Komatsu Utility Dealers also ensure their assistance for the supply of Komatsu Utility genuine

spare parts, which alone guarantee safety and interchangeability.

• The table included in th is ma nual m ust be fille d in with t he mac hine d ata, whi ch are th e data t hat mus t always

be indicated to the Dealer when requiring assistance and ordering spare parts.

• The incorrect use of the machine and inappropriate maintenance operations may cause serious inju-

ries and even death.

• Operators and maintenance personnel must carefully read this manual before using the machine or

performing maintenance operations.

• Any serious accident that may occur during the use of the machine or during maintenance operations

is due to failure to comply with the instructions given herein.

• The procedures and precautions described in this manual are valid for application to the machine only

when it is used correctly.

If the machine is used for any purpose or in any way othe r than those descr ibed herein, the operator

shall be responsible for his own safety and for the safety of any other person involved.

1

INFORMATION ON SAFETY

IMPORTANT

☞

1.2 INFORMATION ON SAFETY

Many accidents are caused by in sufficient knowledge of and failure to comply with the safety regulations prescribed for the maintenance operations that must be performed on the machine.

In order to avoid acciden ts, before starting work and be fore carrying out any maintenan ce operation, carefully

read and be sure to understand all the information and warnings contained in this manual and given on the plates

applied onto the machine, so that you can follow the instructions without making mistakes.

To identify the messages regarding safety that are included in this manual and written on the machine plates, the

following words have been used.

DANGER

CAUTION

Komatsu Utility cannot reasonably predict every circumstance that might involve a potential hazard during the operation or maintenance of the machi ne; for this re as on, the safet y mess ages inc lu ded in this manu al an d appl ied

onto the machine may not include all possible safety precautions.

If all the procedures and operations pr escribed for this m achine are kept t o, you can be sure t hat the operator

and the persons in the vicinity can work in total safety, with no risk of damaging the machine. In case of doubt regarding the safety measures necessary for some procedures, contact Komatsu Utility or your local Dealer.

• Th is word is us ed in the safet y warning s in the manual and on the pla tes when

the situation is dangerous and it may possibly result in serious injuries or even

death.

These messages describe the safety precautions to be taken in order to avoid

any risk. Non-compliance with these instructions may also result in serious

damage to the machine.

• This word is used in the safety warnings in the manual and on the plates to sig-

nal risks that may cause moderate damage or injuries.

The message can be used even to indica te the risk of damage to t he machine

only.

• This word is used when precautions are indicated, which must be taken to

avoid actions that may shorten the life of the machine.

DANGER

• Before starting any maintenance oper atio n, posit ion the mac hi ne on a firm and level sur face, low er t he

equipment to the ground, engage the safety locks of eithe r the equipment and t he controls and stop th e

engine.

DANGER

• T o make the information clearer, some illustrations in this manual represent the machine without safety

guards. Do not use the machine without guards and do not start the engine whe n the engine p rotection

casing is open, if this is not expressly prescribed for some specific maintenance operations.

2

INFORMATION ON SAFETY

DANGER

DANGER

DANGER

• It is strictly forbidden to modify the setting of the hyd raulic sys tem safety valv es; Komatsu Uti lity can-

not be held liable for any damage to persons, property or the machine, if this has been tampered with

by modifying the standard setting of the hydraulic system.

• Before carrying ou t any electrica l wel ding, d isconne ct th e batter y an d the a lternat or ( See “2.8 .13 PRE -

CAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR”).

• Install only authorized additional equipment (See “6.1.3 CHARACTERISTICS OF THE OPTIONAL

EQUIPMENT”).

3

INTRODUCTION

IMPORTANT

☞

1.3 INTRODUCTION

1.3.1 INTENDED USES

The KOMATSU UTILITY MACHINES described in this m anual have be en designed a nd const ructed to be u sed

mainly for EXCAVATION and EARTH-MOVING OPERATIONS.

If provided with suita ble sa fety dev i ces, t hey ca n be us ed wi th a uth or ized o p tiona l equipment having th e char ac teristics illustrated at point “6.1 AUTHORIZED OPTIONAL EQUIPMENT”.

1.3.2 IMPROPER OR UNAUTHORIZED USES

CAUTION

• This paragraph describes some of the improper or unauthorized uses of the machine; since it is impos-

sible to predict all the possible improper uses, if the machine happens to be used for p articular applications, contact your Komatsu Utility Dealer before carrying out the work.

• The instructions regarding the authorized optional equipment are given in the relevant operation and

maintenance manuals; if the equipment is supplied by Komatsu Utility, these publications are enclosed

to this manual.

• The instructions regarding the assembly of the authorized equipment, the controls requiring special ar-

rangements on the machine and the hydraulic couplings necessary for the operation of the equipment

are grouped in the final section of this manual.

KOMATSU UTILITY MACHINES are constructed exc lusively for the h andling, ex cavation and tr eatment of in ert

materials; therefore, the following uses are absolutely forbidden:

• USE OF THE MACHINE BY MINORS OR INEXPERIENCED PERSONS.

• USE OF THE MACHINE FOR LIFTING PERSONS OR OBJECTS.

• TRANSPORT OF CONTAINERS WITH FLAMMABLE OR DANGEROUS FLUIDS.

• USE OF THE BUCKET FOR DRIVING OR EXTRACTING PILES.

• USE OF THE MACHINE FOR TOWING DAMAGED VEHICLES.

4

INTRODUCTION

IMPORTANT

☞

1.3.3 MAIN CHARACTERISTICS

• Simple and easy operation

• Hydrostatic transmission obtained through two axial piston motors that operate epicyclic reduction gears.

• Upper structure rotation achieved through an orbital hydraulic motor (for PC20R only).

• Upper structure rotation ach ieved through an axial piston hyd ra ulic moto r acti ng on an epi cyc li c redu cti on ge ar

(for PC27R only)

• Main equipment serv olevers ensuring also combined mov ements that can be modulated proport ionally and

continually.

• Pedal controls for the boom swing and the optional equipment.

• Lever controls for travel and blade.

• Travel speed increase achieved through a pedal-operated push button.

• Complete series of instruments visible from the operating position.

• Lever accelerator.

• Easy maintenance with simplified intervals.

1.3.4 RUNNING-IN

Every machine is scrupulously adjusted and tested before delivery.

A new machine, however, must be used carefully for the first 100 hour s, in order to ensur e proper running- in of

the various components.

If the machine is subjected to excessive work load at the beginn ing of operatio n, its potential yield and its func tionality will be shortly and untimely reduced.

Every new machine must be used carefully, paying special attention to the following indications:

• After the start, let t he engine idle for 5 minutes, in such a way as to warm i t up gradual ly befor e actual op era-

tion.

• Avoid operating the machine with the limit loads allowed or at high speed.

• Avoid abrupt starts or accelerations, useless sudden decelerations and abrupt reversals.

• After the first 250 hou rs, carry out the following ope rations, in addition to those to be performed every 250

hours:

1 - Change the oil in the travel reduction gears.

2 - Check and adjust the engine valve clearance.

SYNTHETIC BIODEGRADABLE OIL TYPE HEES

On machines in which the syn thet ic bio degrad abl e oi l ty pe HEES is used, the fol lo win g ope ra tio ns are to be performed besides the standard maintenance operations:

• After the first 50 hours of operation, change the hydraulic circuit drain filter.

• After the first 500 hours of operation, change the hydraulic circuit oil.

• When changing the oil filters (ca rtridges) , check their inner part to make sure that the re are no depos-

its.

If considerable deposits ar e observed, find out what may have caused them before star ting the machine.

• The number of operating hours is indicated by the hour meter.

5

PRODUCT IDENTIFICATION

1.4 PRODUCT IDENTIFICATION

The KOMATSU UTILITY EXCAVATOR and its main components are identified by serial numbers stamped on the

identification plates.

The serial number and the identification numbers of the components are the only numbers that must be indicated

to the Dealer when requiring assistance and ordering spare parts.

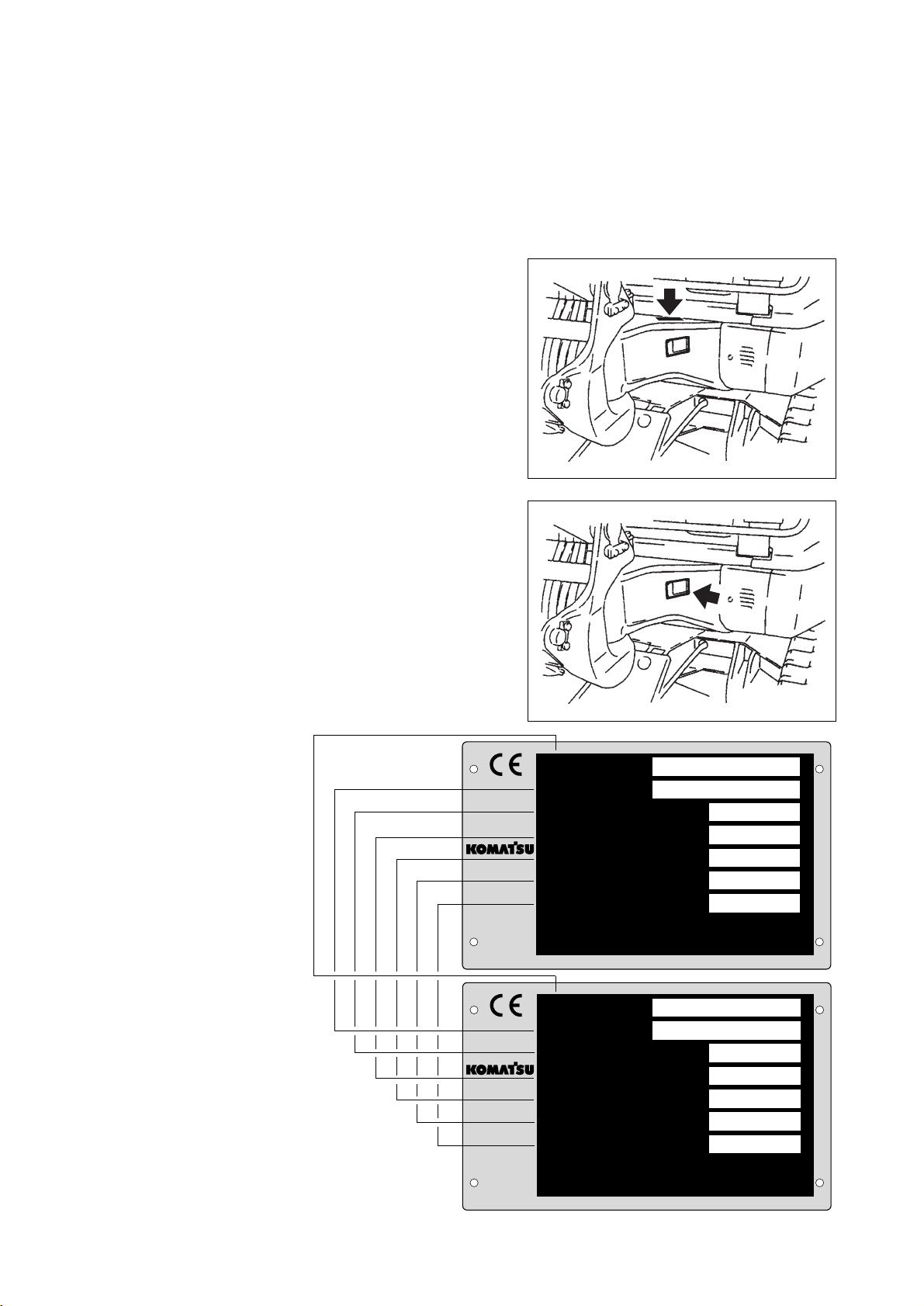

1.4.1 MACHINE SERIAL NUMBER

The machine serial number is stamped on the front upper part of

the main frame, on the left side.

RWA08630

1.4.2 MACHINE IDENTIFICATION PLATE

The KOMATSU UTILITY EXCAVATORS described in the

present manual are provide d with the CE mark, which certifies

that they are in compliance with the harmonized standards of the

European Community.

The plate provided with the mark i s appli ed on to the fron t wall of

the main frame, on the left side.

RWA08640

MODELLO - MODEL

TYP - MODELE

MATRICOLA N˚ - SERIAL N˚

FABR. NR. - SERIE NR.

ANNO - YEAR

BAUJAHR - ANNEE

MASSA TOTALE MAX - TOTAL MAX WEIGHT

ZUL. GESAMTGEWICHT - POIDS TOTAL MAX

POTENZA MOTORE - ENGINE POWER

LEISTUNG - PUISSANCE MOTEUR

MASSA MAX ASSE ANT. - MAX WEIGHT FRONT AXLE

ZUL. ACHSLAST VORN - POIDS MAX ESSIEU AV

MASSA MAX ASSE POST. - MAX WEIGHT REAR AXLE

ZUL. ACHSLAST HINTEN - POIDS MAX ESSIEU AR

MANUFACTURED BY KOMATSU UTILITY EUROPE S.p.A.

36025 NOVENTA VICENTINA (VI) ITALY UNDER LICENSE FROM KOMATSU LTD

kg

kw

kg

kg

20T-98-RB26441

RYA11760

MODEL

SERIAL N

YEAR

TOTAL MAX WEIGHT

ENGINE POWER

MAX WEIGHT FRONT AXLE

MAX WEIGHT REAR AXLE

MANUFACTURED BY KOMATSU UTILITY EUROPE S.p.A.

36025 NOVENTA VICENTINA (VI) ITALY UNDER LICENSE FROM KOMATSU LTD

kg

kw

kg

kg

6

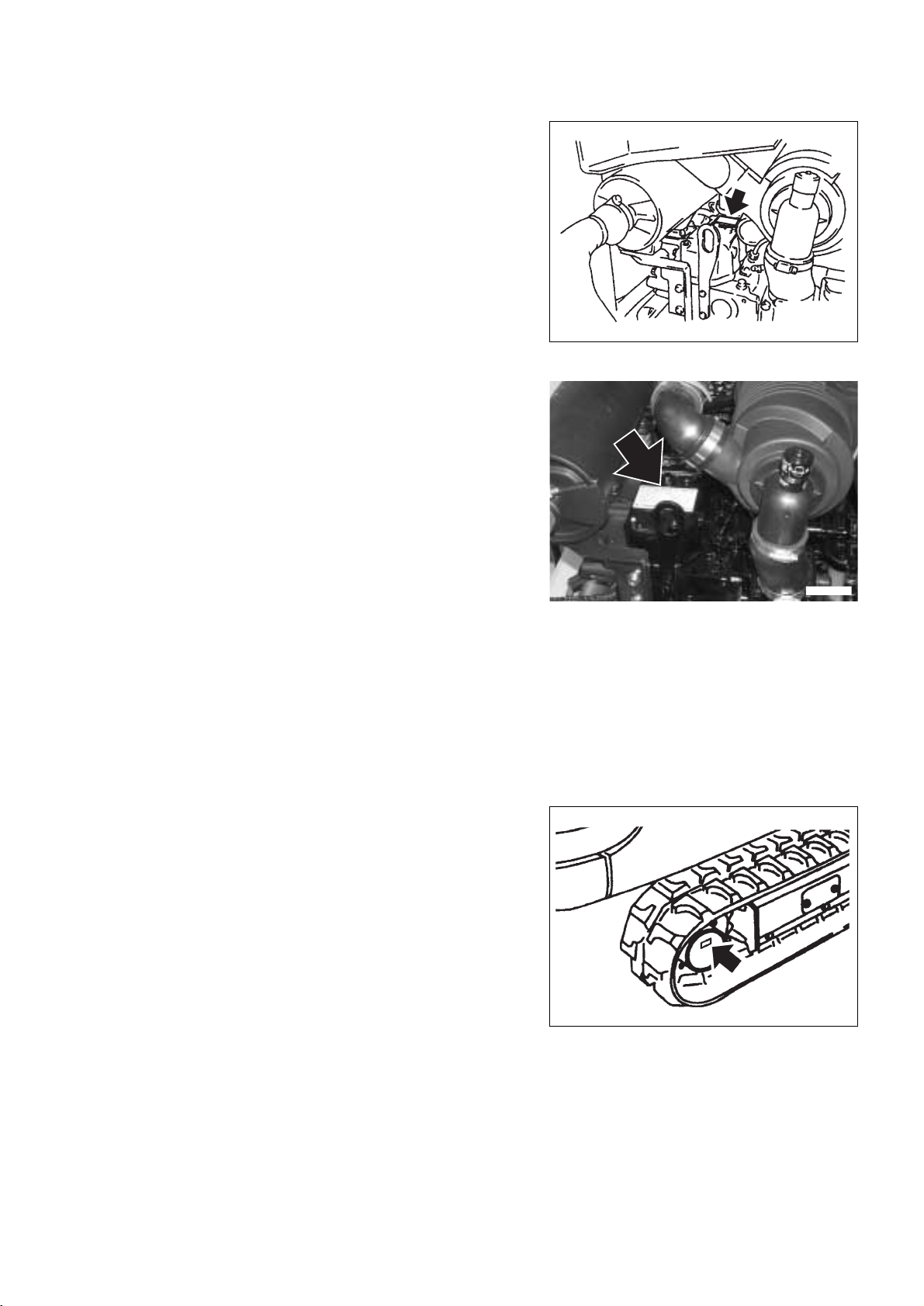

1.4.3 ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE

The engine serial numb er is stam ped on the pl ate posi tioned on

the top of the engine cylinder head cover.

The exhaust gas emi ssion plate is ap plied on the t op of the engine cylinder head cover.

PRODUCT IDENTIFICATION

RWA08650

1.4.4 TRA VEL REDUCTION GEAR SERIAL NUMBER

The serial number of the travel reduction gear is stamped on the

plate positioned on the outer side of the reduction gear cover.

RWAA10520

RWA04970

7

PRODUCT IDENTIFICATION

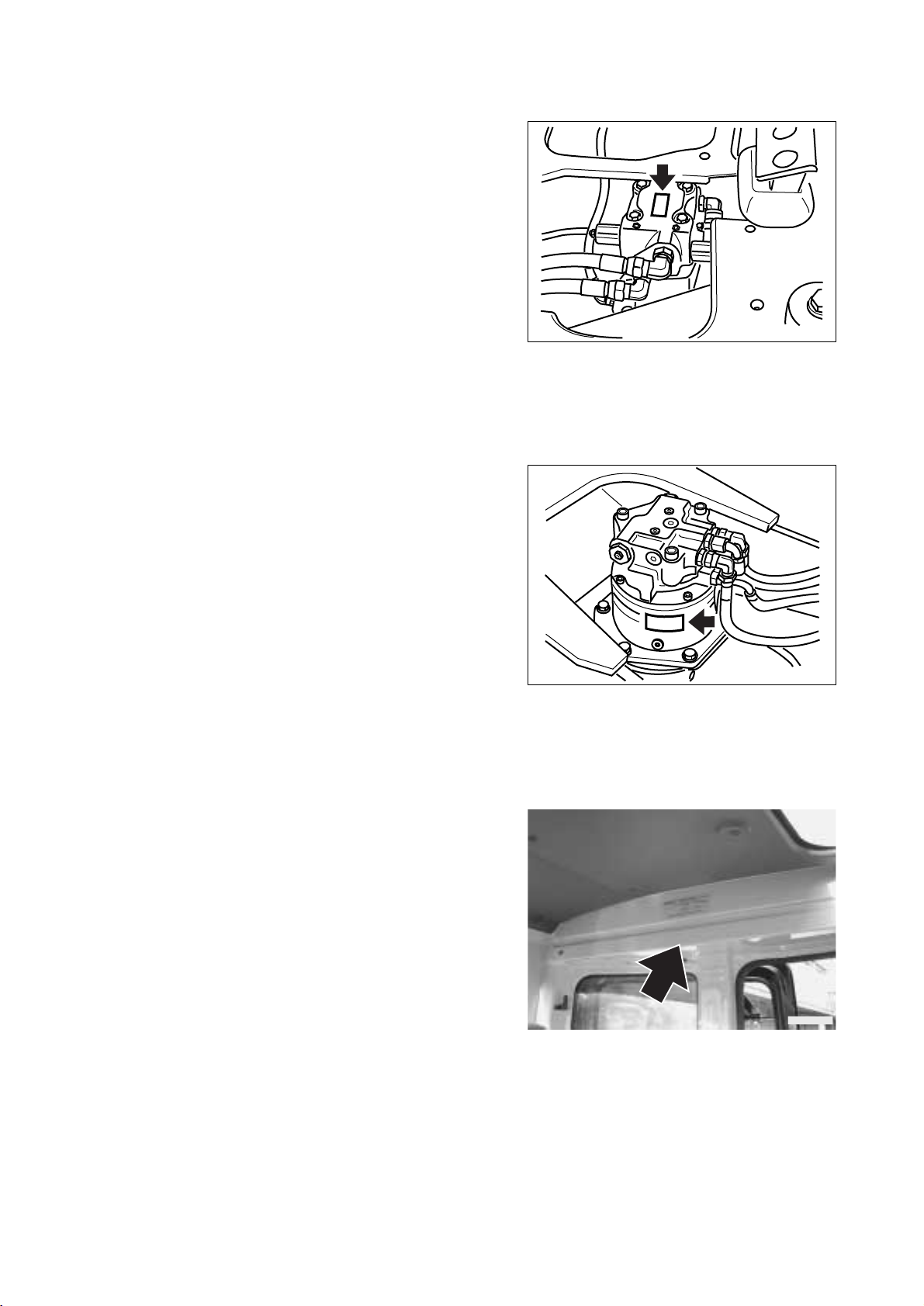

1.4.5 SWING MOTOR SERIAL NUMBER (for PC20R only)

The serial number of the swing reduction gear is stamped on the

plate positioned on the swing motor head.

1.4.6 SWING REDUCTION GEAR SERIAL NUMBER (for PC27R only)

The serial number is stamped on the plate positioned laterally on

the reduction gear body.

RWA09980

1.4.7 CAB SERIAL NUMBER

The CAB serial number is stampe d on the plate positioned on

the top left side.

RWA09990

RYAA0050

8

1.4.8 SERIAL NUMBERS AND DEALER’S ADDRESS

Machine n. Model

Engine n.

Travel reduction gear n.

Swing motor (for PC20R only) n.

Swing reduction gear (for PC27R only) n.

Cab n.

Dealer:

PRODUCT IDENTIFICATION

Address:

Person to contact:

NOTES:

Tel.

9

10

T ABLE OF CONTENTS

Page

TABLE OF CONTENTS

1.1 FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 INFORMATION ON SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.1 INTENDED USES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.2 IMPROPER OR UNAUTHORIZED USES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.3 MAIN CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3.4 RUNNING-IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 PRODUCT IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.1 MACHINE SERIAL NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.2 MACHINE IDENTIFICATION PLATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.3 ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE. . . . . . . . . . . . . . . . . . 7

1.4.4 TRAVEL REDUCTION GEAR SERIAL NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4.5 SWING MOTOR SERIAL NUMBER (for PC20R only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.6 SWING REDUCTION GEAR SERIAL NUMBER (for PC27R only) . . . . . . . . . . . . . . . . . . . . 8

1.4.7 CAB SERIAL NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.8 SERIAL NUMBERS AND DEALER’S ADDRESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SAFETY AND ACCIDENT PREVENTION

2.1 SAFETY, NOISE AND VIBRATION PLATES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.1.1 POSITION OF THE SAFETY PLATES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.1.2 PICTOGRAMS AND RELEVANT MEANINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.1.3 POSITION OF THE NOISE PLATES ON MACHINES WITH CAB . . . . . . . . . . . . . . . . . . . . 26

2.1.4 POSITION OF THE NOISE PLATES ON MACHINES WITH CANOPY . . . . . . . . . . . . . . . . 27

2.1.5 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED . . . . . . . . . . . . . . . . . . . . . . . 27

2.2 GENERAL PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.2.1 GENERAL SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.2.2 SAFETY DEVICES AND GUARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.2.4 UNAUTHORIZED MODIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.2.5 LEAVING THE OPERATOR’S SEAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.2.6 GETTING ON AND OFF THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.2.7 PREVENTING FIRES DUE TO FUEL AND OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.2.8 PREVENTING BURNS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.2.9 PREVENTING DAMAGE DUE TO ASBESTOS POWDER . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.2.10 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT . . . . . . . . . . . . . . . . . . . . 32

2.2.11 FIRE EXTINGUISHERS AND FIRST AID KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.2.12 PRECAUTIONS CONCERNING THE CAB STRUCTURE . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.2.13 PRECAUTIONS CONCERNING THE EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . 33

2.3.1 SAFETY ON THE WORK SITE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.3.2 FIRE PREVENTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.3.3 PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB . . . . . . . . . . . . . . . . . . . . . . 33

2.3.4 ROOM VENTILATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.3.5 PRECAUTIONS TO BE TAKEN FOR THE LIGHTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.3.6 CLEANING THE WINDOWS - CHECKING THE WINDSHIELD WIPER BLADES . . . . . . . . 34

11

TABLE OF CONTENTS

Page

2.4 PRECAUTIONS TO BE TAKEN WHEN WORKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.4.1 STARTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.4.2 CHECK THE DIRECTION BEFORE STARTING THE MACHINE . . . . . . . . . . . . . . . . . . . . . 35

2.4.3 CHECKS FOR TRAVELLING IN REVERSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.4.4 MOVING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.4.5 MOVING ON SLOPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.4.6 WORKING ON SLOPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.4.7 UNAUTHORIZED OPERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.4.8 PREVENTING ELECTROCUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.4.9 VISIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2.4.10 WORKING ON ICY OR SNOW-COVERED SURFACES . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2.4.11 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT . . . . . . . . . . . . . . . . . . . . 40

2.4.12 WORKING ON LOOSE GROUND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2.4.13 PARKING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.5 TRANSPORTING THE MACHINE ON MOTOR VEHICLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2.5.1 LOADING AND UNLOADING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2.5.2 TRANSPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2.6 BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2.6.1 PREVENTING RISKS THAT MAY BE DUE TO THE BATTERY . . . . . . . . . . . . . . . . . . . . . . 43

2.6.2 STARTING WITH BOOSTER CABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2.7 PRECAUTIONS FOR THE REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2.8 PRECAUTIONS FOR MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2.8.1 WARNING PLATES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2.8.2 TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2.8.3 PERSONNEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2.8.4 EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

2.8.5 WORKING UNDER THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

2.8.6 CLEANING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

2.8.7 USE OF THE ENGINE DURING MAINTENANCE OPERATIONS . . . . . . . . . . . . . . . . . . . . 47

2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY . . . . . . . . . 47

2.8.9 STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION

OR INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

2.8.10 RULES TO BE FOLLOWED DURING FUEL OR OIL TOPPING UP . . . . . . . . . . . . . . . . . . 48

2.8.11 CHECKING THE COOLANT LEVEL IN THE RADIATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

2.8.12 USING LAMPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

2.8.13 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR . . . . . . . . . . . . 49

2.8.14 PRECAUTIONS CONCERNING THE STARTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2.8.15 HANDLING HIGH-PRESSURE PIPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

2.8.16 PRECAUTIONS TO BE TAKEN WHEN HANDLING HIGH-PRESSURE OIL . . . . . . . . . . . . 50

2.8.17 PRECAUTIONS FOR MAINTENANCE OPERATIONS AT HIGH TEMPERATURES AND

HIGH PRESSURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

2.8.18 COOLING FAN AND BELT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2.8.19 WASTE MATERIALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2.8.20 PRECAUTIONS FOR THE USE OF THE synthetic biodegradable oil type HEES . . . . . . . . 51

12

T ABLE OF CONTENTS

Page

DESCRIPTION AND USE OF THE MACHINE

3.1 SAFETY LOCKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3.1.1 MACHINE LOCKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3.2 GENERAL VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

3.2.1 GENERAL VIEW OF THE MACHINE WITH CAB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

3.2.2 GENERAL VIEW OF THE MACHINE WITH CANOPY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

3.2.3 GENERAL VIEW OF THE DRIVER’S SEAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

3.3 INSTRUMENTS AND CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3.3.1 INSTRUMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3.3.2 WARNING LIGHTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3.3.3 SWITCHES AND PUSH BUTTONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

3.3.4 ELECTRICAL ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

3.3.5 MACHINE CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3.4 FUSES AND RELAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3.4.1 FUSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3.4.1.1 EQUIPMENT FUSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3.4.1.2 MAIN FUSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

3.4.2 RELAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

3.5 GUARDS AND DRIVER’S SEAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

3.5.1 ENGINE HOOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

3.5.2 RIGHT COUNTERWEIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

3.5.3 CANOPY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

3.5.4 CAB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

3.5.5 VENTILATION AND HEATING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

3.5.6 SEAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

3.5.7 SAFETY BELT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

3.5.8 EMERGENCY EXIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

3.5.9 TECHNICAL DOCUMENTATION CASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

3.5.10 FIRE EXTINGUISHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

3.5.11 FIRST AID KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

3.6 USE OF THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

3.6.1 CHECKS BEFORE STARTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

3.6.1.1 VISUAL CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

3.6.1.2 DAILY CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

3.6.1.3 OPERATIONAL CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

3.6.2 STARTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

3.6.2.1 STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES . . . . . . . . . 89

3.6.2.2 STARTING WITH COLD ENGINE OR IN COLD CLIMATES . . . . . . . . . . . . . . . . 90

3.6.3 WARMING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

3.6.4 HEATING THE HYDRAULIC OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

3.6.5 HOW TO MOVE THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

3.6.5.1 STEERING (CHANGING DIRECTION) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

3.6.5.2 MOVING ON SLOPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

3.6.5.3 MAXIMUM IMMERSION DEPTH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

13

TABLE OF CONTENTS

Page

3.7 PARKING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

3.7.1 PARKING ON LEVEL GROUND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

3.7.2 PARKING ON SLOPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

3.8 STOPPING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

3.9 TRANSPORTING THE MACHINE ON MOTOR VEHICLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

3.9.1 LOADING AND UNLOADING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

3.9.2 TRANSPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

3.10 LIFTING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

3.11 PRECAUTIONS TO BE TAKEN IN THE COLD SEASON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

3.11.1 FUEL AND LUBRICANTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

3.11.2 COOLANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

3.11.3 BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

3.11.4 OTHER PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

3.11.5 PRECAUTIONS TO BE TAKEN AT THE END OF WORK . . . . . . . . . . . . . . . . . . . . . . . . . . 103

3.12 PRECAUTIONS TO BE TAKEN IN THE WARM SEASON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

3.13 USING THE WORK EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

3.13.1 ORGANIZING THE WORK AREA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

3.13.2 POSITIONING THE MACHINE FOR DIGGING OPERATIONS . . . . . . . . . . . . . . . . . . . . . . 106

3.13.3 DIGGING METHOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

3.13.4 CHANGING THE BUCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

3.14 LONG PERIODS OF INACTIVITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

3.14.1 BEFORE THE PERIOD OF INACTIVITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

3.14.2 DURING THE PERIOD OF INACTIVITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

3.14.3 AFTER THE PERIOD OF INACTIVITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

3.15 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

3.15.1 OCCURRENCES THAT ARE NOT FAILURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

3.15.2 HOW TO REMOVE THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

3.15.3 AFTER THE FUEL HAS RUN OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

3.15.4 IF THE BATTERY IS DOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

3.15.4.1 STARTING WITH BOOSTER CABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

3.15.5 OTHER TROUBLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

3.15.5.1 ELECTRICAL CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

3.15.5.2 HYDRAULIC SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

3.15.5.3 ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

14

T ABLE OF CONTENTS

Page

MAINTENANCE

4.1 GUIDE TO MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

4.2 MAINTENANCE NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

4.2.1 NOTES REGARDING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

4.2.1.1 ENGINE OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

4.2.1.2 COOLANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

4.2.1.3 FUEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

4.2.2 NOTES REGARDING THE HYDRAULIC SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

4.2.3 NOTES REGARDING THE ELECTRICAL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

4.2.4 NOTES REGARDING LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

4.2.5 PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING . . . . . . . . . . . . . . 123

4.3 FUEL, COOLANT AND LUBRICANTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

4.3.1 HOMOLOGATED HEES SYNTHETIC BIODEGRADABLE LUBRICANTS . . . . . . . . . . . . . . 126

4.4 DRIVING TORQUES FOR SCREWS AND NUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

4.4.1 STANDARD DRIVING TORQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

4.4.2 SPECIFIC DRIVING TORQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

4.5 LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

4.5.1 LUBRICATION DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

4.6 PERIODICAL CHANGE OF THE COMPONENTS THAT ARE CONNECTED WITH SAFETY . . . . 129

4.6.1 CRITICAL PARTS FOR SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

4.7 MAINTENANCE PLAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

4.7.1 WHEN REQUIRED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

4.7.1.a WASHING THE COOLING CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

4.7.1.b DRAINING THE FUEL TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

4.7.1.c CHECKING THE ELECTRICAL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

4.7.1.d CHECKING THE STEEL TRACK TENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

4.7.1.e CHECKING THE RUBBER TRACKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

4.7.1.f CHECKING THE RUBBER TRACK TENSION . . . . . . . . . . . . . . . . . . . . . . . . . . 142

4.7.1.g CHANGING THE RUBBER TRACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

4.7.1.h CHECKING, CLEANING OR CHANGING THE AIR CLEANER CARTRIDGE . . 146

4.7.2 MAINTENANCE INTERVALS IN CASE OF USE OF THE

DEMOLITION HAMMER (BREAKER) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

4.7.2.a CHANGING THE HYDRAULIC OIL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

4.7.2.b CHANGING THE HYDRAULIC OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

4.7.3 CHECKS BEFORE STARTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

4.7.3.a VARIOUS CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

4.7.3.b CHECKING THE COOLANT LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

4.7.3.c CHECKING THE FUEL LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

4.7.3.d CHECKING THE ENGINE OIL LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

4.7.3.e CHECKING THE OIL LEVEL IN THE HYDRAULIC CIRCUIT . . . . . . . . . . . . . . . 150

4.7.3.f CHECKING THE AIR CLEANER CLOGGING INDICATOR . . . . . . . . . . . . . . . . 151

4.7.3.g CHECKING THE FUEL FILTER FOR SEDIMENT AND WATER . . . . . . . . . . . . 151

4.7.4 MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION

(Only for machines in which the synthetic biodegradable oil type HEES is used) . . . . . . . . . 152

4.7.5 MAINTENANCE EVERY 100 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

4.7.5.a LUBRICATING THE JOINTS AND THE BALL-BEARING RING . . . . . . . . . . . . . . 153

15

TABLE OF CONTENTS

4.7.6 MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . 155

4.7.7 MAINTENANCE EVERY 250 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

4.7.7.a ADJUSTING THE FAN BELT TENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

4.7.7.b CHECKING THE BATTERY ELECTROLYTE LEVEL . . . . . . . . . . . . . . . . . . . . . 156

4.7.7.c CHECKING THE OIL LEVEL IN THE TRAVEL REDUCTION GEARS . . . . . . . . 156

4.7.7.d CHANGING THE HYDRAULIC SYSTEM OIL FILTER . . . . . . . . . . . . . . . . . . . . . 157

4.7.7.e CHANGING THE ENGINE OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

4.7.8 MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION

(Only for machines in which the synthetic biodegradable oil type HEES is used) . . . . . . . . . 159

4.7.9 MAINTENANCE EVERY 500 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

4.7.9.a CHANGING THE ENGINE OIL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

4.7.9.b CHANGING THE FUEL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

4.7.9.c CHANGING THE FUEL PUMP PRECLEANER . . . . . . . . . . . . . . . . . . . . . . . . . . 161

4.7.9.d CLEANING THE OUTSIDE OF THE RADIATORS . . . . . . . . . . . . . . . . . . . . . . . 162

4.7.9.e DRAINING THE HYDRAULIC OIL TANK (Only for machines in which the

synthetic biodegradable oil type HEES is used) . . . . . . . . . . . . . . . . . . . . . . . . . . 163

4.7.10 MAINTENANCE EVERY 1000 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . 164

4.7.10.a CHANGING THE OIL IN THE TRAVEL REDUCTION GEARS . . . . . . . . . . . . . . 164

4.7.11 MAINTENANCE EVERY 2000 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . 165

4.7.11.a CHANGING THE HYDRAULIC SYSTEM OIL AND CLEANING THE SUCTION

FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

4.7.11.b CHANGING THE COOLANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

4.7.11.c CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE . . . . . . . . . 169

4.7.11.d CHECKING THE ALTERNATOR AND THE STARTER . . . . . . . . . . . . . . . . . . . . 169

Page

TECHNICAL SPECIFICATIONS

5.1 TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

5.1.1 STANDARD OVERALL DIMENSIONS (for model PC20R only) . . . . . . . . . . . . . . . . . . . . . . 172

5.1.2 TECHNICAL CHARACTERISTICS PC20R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

5.1.3 STANDARD OVERALL DIMENSIONS (for model PC27R only) . . . . . . . . . . . . . . . . . . . . . . 174

5.1.4 TECHNICAL CHARACTERISTICS PC27R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

5.1.5 LIFTING CAPACITY WITH CAB (for model PC20R only) . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

5.1.6 LIFTING CAPACITY WITH CANOPY (for model PC20R only) . . . . . . . . . . . . . . . . . . . . . . . . 177

5.1.7 LIFTING CAPACITY WITH CAB (for model PC27R only) . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

5.1.8 LIFTING CAPACITY WITH CANOPY (for model PC27R only) . . . . . . . . . . . . . . . . . . . . . . . 179

16

T ABLE OF CONTENTS

Page

AUTHORIZED OPTIONAL EQUIPMENT

6.1 AUTHORIZED OPTIONAL EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

6.1.1 PRECAUTIONS REGARDING SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

6.1.2 PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT . . . . . . . . . . . . . . . . 183

6.1.3 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

6.2 ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER (BREAKER) . . . . 185

6.2.1 DESCRIPTION AND CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

6.2.2 USE OF THE DEMOLITION HAMMER AND RULES TO BE OBSERVED . . . . . . . . . . . . . . 185

6.2.3 INSTALLING AND REMOVING THE DEMOLITION HAMMER . . . . . . . . . . . . . . . . . . . . . . . 189

6.2.3.1 INSTALLING THE HAMMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

6.2.3.2 REMOVING THE HAMMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

6.2.4 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

6.3 ARRANGEMENT FOR THE OPERATION OF OPTIONAL EQUIPMENT . . . . . . . . . . . . . . . . . . . . . 191

6.3.1 SELECTION VALVE (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

6.3.2 CONTROL PEDAL (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

6.3.3 ASSEMBLYING AND CONNECTING THE EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

6.3.4 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

17

18

SAFETY AND

ACCIDENT PREVENTION

SAFETY, NOISE AND VIBRATION PLA TES

2.1 SAFETY, NOISE AND VIBRATION PLATES

2.1.1 POSITION OF THE SAFETY PLATES

• The safety plates must always be legible and in good conditions; for this reason, if they are dirty with dust, oil or

grease, it is necessary to clean them with a solution made of water and detergent.

Do not use fuel, petrol or solvents.

• If the plates are damaged, ask for new ones to Komatsu Utility or to your Komatsu Utility Dealer.

• In case of replacement of a component provided with a safety plate, make sure that this plate is applied also on

the new piece.

• The machine can be provided with other pl ates in addition to those indicated bel ow; keep also to the instruc-

tions given in the additional plates, in any case.

MACHINE WITH CAB

RYA11880

RWA00020

RWA00030

20

RWA00010

MACHINE WITH CANOPY

RYA11890

SAFETY, NOISE AND VIBRATION PLATES

RWA00030

RWA00020

RWA00010

21

SAFETY, NOISE AND VIBRATION PLA TES

2.1.2 PICTOGRAMS AND RELEVANT MEANINGS

The warning and danger plates applied onto the machine are accompanied or represented by pictograms.

The personnel in charge with the operation and maintenance of the machine must know the symbols contained in

the pictograms perfectly; the following description illustrates what they look like and their respective meanings.

DANGER IN THE WORK AREA

• Do not approach or stand within the eq uip men t operating radi-

us when the boom and the bucket are raised.

RWA00020

DO NOT OPEN THE HOOD

• Do not open or remove the hood when the engine is running.

CONSULT THE MANUAL

• Carefully read the contents of the manual before using the ma-

chine or performing maintenance operations.

RWA00010

HYDRAULIC OIL TOPPING UP

22

RWA00030

RWA00050

FILLING THE HYDRAULIC SYSTEM WITH

OIL

(Only for machines in which the synthetic biodegradable oil

type HEES is used)

SAFETY, NOISE AND VIBRATION PLATES

REFUELLING

ENGINE LUBRICATING OIL FILTER

FUEL FILTER

BIO-OIL

D

RWA00040

RWA00080

RWA34380

ENGINE AIR SUCTION FILTER

ENGINE COOLANT

D

RWA00060

RWA00090

RWA00130

23

SAFETY, NOISE AND VIBRATION PLA TES

ENGINE COOLANT PRESSURE

HYDRAULIC OIL LEVEL

HYDRAULIC OIL FILTER

RWA00110

RWA00100

ELECTRIC OUTLET

ANCHORAGE POINT

EMERGENCY EXIT

RWA00120

RWA00070

12 V

RWA00200

24

RWA00190

LIFTING POINT

DO NOT LIFT MORE THAN 1000 kg

SAFETY, NOISE AND VIBRATION PLATES

RWA04920

> 1000 Kg

RWA00210

25

SAFETY, NOISE AND VIBRATION PLA TES

2.1.3 POSITION OF THE NOISE PLATES ON MACHINES WITH CAB

• The noise plates must always be legible and in good condi-

tions; for this reason, if they are dirty with dust, oil or grease, it

is necessary to clean them with a solu tion made of water and

detergent.

Do not use fuel, petrol or solvents.

• If the plates are damaged, ask for new ones to Komatsu Utility

or to your Komatsu Utility Dealer.

• In case of replacement of a c omponent provided wi th a noise

plate, make sure that this plate is applied also on the new

piece.

NOISE OUTSIDE THE CAB

• This value indic ates the noise level outside the machine an d

refers to the noise pe rceived by persons i n the vicinity of the

work area.

NOISE INSIDE THE CAB

• This value indicates the maximum noise level perceived by the

operator’s ears inside the cab when this is completely closed.

L

( 89/514/CE - 95/27/CE )

RYA11900

WA

RYA11910

26

L

( 89/514/CE - 95/27/CE )

p

A

RYA11920

2.1.4 POSITION OF THE NOISE PLATES ON MACHINES WITH CANOPY

• The noise plates must always be legible and in good condi-

tions; for this reason, if they are dirty with dust, oil or grease, it

is necessary to clean them with a solu tion made of water and

detergent.

Do not use fuel, petrol or solvents.

• If the plates are damaged, ask for new ones to Komatsu Utility

or to your Komatsu Utility Dealer.

SAFETY, NOISE AND VIBRATION PLATES

• In case of replacement of a c omponent provided wi th a noise

plate, make sure that this plate is applied also on the new

piece.

EXTERNAL NOISE

• This value indic ates the noise level outside the machine an d

refers to the noise pe rceived by persons i n the vicinity of the

work area.

NOISE PERCEIVED BY THE OPERATOR

• This value indicates the maximum noise level perceived by the

operator’s ears.

L

( 89/514/CE - 95/27/CE )

RYA11930

WA

RYA11940

L

p

A

( 89/514/CE - 95/27/CE )

RYA11950

2.1.5 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED

• According to the r esults of the tes ts carried out to d etermine the v ibrations transmi tted to the operat or by the

machine, the upper limbs are subjected to vibrations lower than 2.5 m/sq.sec., while the seated part of the body

is subjected to vibrations lower than 0.5 m/sq.sec.

27

GENERAL PRECAUTIONS

2.2 GENERAL PRECAUTIONS

2.2.1 GENERAL SAFETY RULES

• Only trained and authorized personnel can use the machine and perform maintenance operations.

• Follow all the safety rules, precautions and instructions when using the machine or performing maintenance op-

erations.

• When working with o ther o perators or when the work si te is o ften occ upi ed by oth er operators, make sure that

everyone knows and understands all the agreed signals and, in any case, that everyone works in such a way as

to be able to see the machine and to be visible to the operator.

2.2.2 SAFETY DEVICES AND GUARDS

• Make sure that all the guard s and covers are in the correct positio n. Have guards and cover s changed or re-

paired if damaged. Neither use the machine without guards, nor remov e the guards when the engine is running.

• Always use the proper safety devices to lock the machine when parking and fasten the safety belt.

• For the safety devices, see “3.1 SAFETY LOCKS”.

• For the safety belt, see “3.5.7 SAFETY BELT”.

• Do not remove the safety devices and always keep them in good operating conditions.

• Any improper use of the safety devices may result in serious injuries or even death.

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS

• Do not wear large or lo ose clothes, r ings and watc hes and d o

not approach the machin e with l oose l ong hair, since they can

get entagled in the moving parts of the machine and cause serious injuries or damage.

Avoid also wearing clothes dirty wi th oil or fuel, s ince they ar e

flammable.

• Wear a hard hat, goggles, safety shoes, mask, gloves and

headphones when operati ng the machine o r perfor ming maintenance operations.

• Always wear safety goggle s, a hard hat and heavy gloves if

your job involves scattering metal chips or minute materia ls;

these precautions are particularly useful when driving the

equipment connect ion pins with a h ammer and when blowing

compressed air into the air filter and the radiator to clean them.

During these operations , make a lso sure tha t no one is sta nding or working near the machine without the necessary protections.

• When working for 8 hours with a noise level exceeding 90

dBA, it is necessa ry to use headphones or ear p lugs and be

particularly careful, especially at the end of the work shift.

28

RWA00960

Loading...

Loading...