KOHLER K-304, K-305 User Manual

Installation Guide

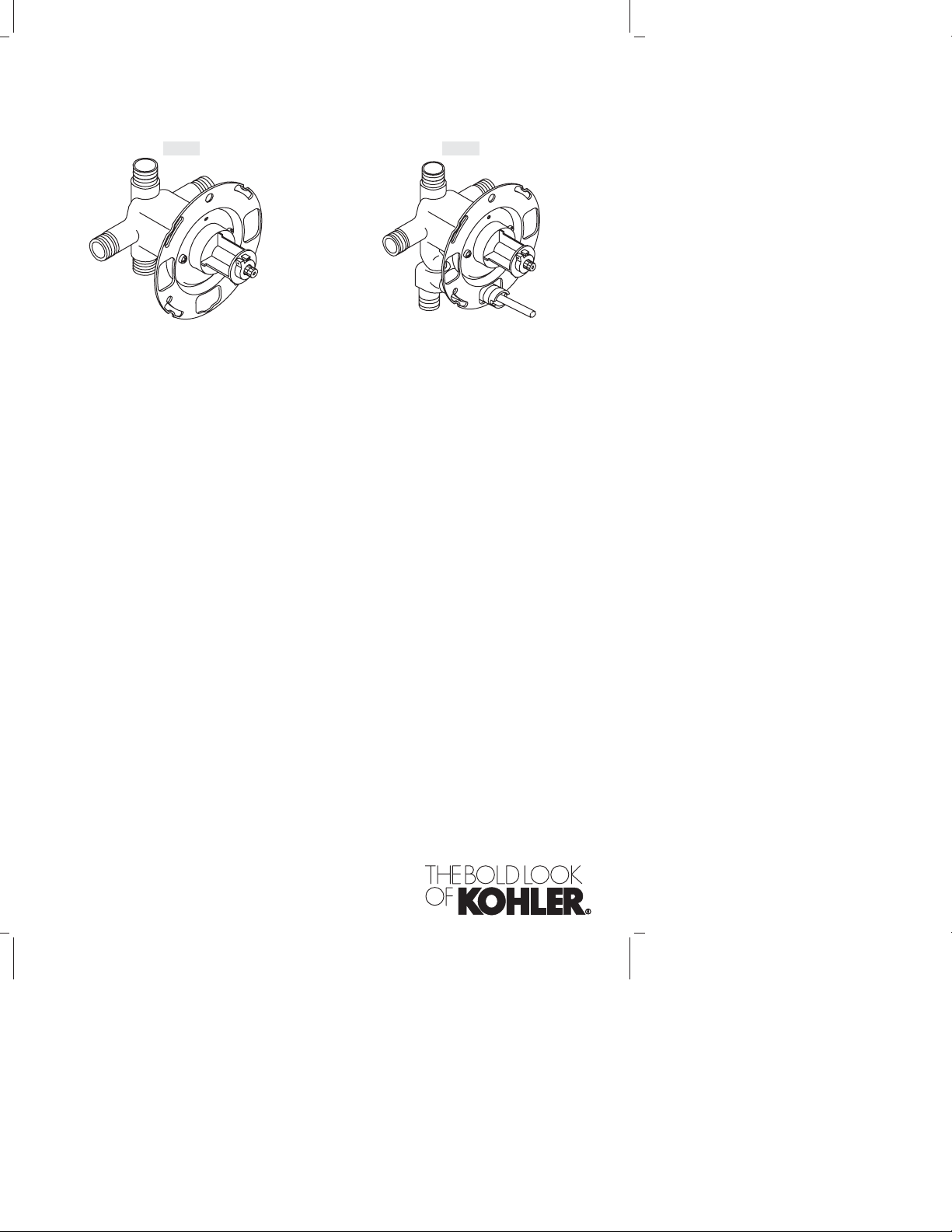

Pressure Balancing Valve

K-304 K-305

M product numbers are for Mexico (i.e. K-12345M)

Los números de productos seguidos de

M corresponden a México (Ej.

K-12345M)

Français, page “Français-1”

Español, página “Español-1”

114811-2-CG

IMPORTANT INSTRUCTIONS

WARNING: Risk of scalding or other severe injury.

•

Before completing installation, the installer must set the

maximum water temperature setting of this valve to minimize the

risks associated with scalding hazards according to ASTM F 444.

•

Do not install a shut-off device on either outlet of this valve. The

installation of any such device may create a cross-flow condition

at the valve and affect the water temperature.

•

Factors that change the temperature of the water supplied to the

valve, such as seasonal water temperature changes, and water

heater replacement or servicing, will change the maximum water

temperature supplied by the valve and may create a scalding

hazard. The pressure-balanced valve will not compensate for

changes in the water supply temperature; adjust the maximum

water temperature setting of this pressure-balanced valve when

such changes occur.

•

Pressure-balanced valves may not provide protection against

scalding if there is a failure of other temperature-limiting devices

elsewhere in the plumbing system.

WARNING: Risk of product damage. Only silicone based

lubricants should be used with these valves. Use of petroleum

based lubricants on the valve is harmful to the O-rings, seals,

and plastic components. Use of petroleum based lubricants will

void the warranty.

The installer is responsible for installing the valve and adjusting the

maximum water temperature of this pressure-balanced valve

according to instructions.

This valve meets or exceeds ANSI A112.18.1 and ASSE 1016.

If you do not understand any of the installation or temperature

adjustment instructions in this document, in the United States please

contact our Customer Service Department at 1-800-4-KOHLER.

Outside the U.S., please contact your distributor.

The PEX connections are designed for use with any ASTM F 1807

compliant copper crimp rings and ASTM F 887 compliant PEX tubing.

These fittings are not compatible with ASTM F 1960 cold expansion

fittings with PEX reinforcing ring assemblies.

The PEX potable fittings on this valve have been third party certified by CSA using the following: Sioux Chief 1/2”

copper crimp ring and CSA certified VANGARD VANEX

Chief 1/2” crimp tool in accordance with the Sioux Chief instructions.

IMPORTANT NOTICE TO INSTALLERS! Please fill in the blanks in

the information box in the Homeowners Guide and on the valve label.

Retain the Homeowners Guide for future reference.

1/2” PEX potable tubing. Crimps were made using a Sioux

®

114811-2-CG 2 Kohler Co.

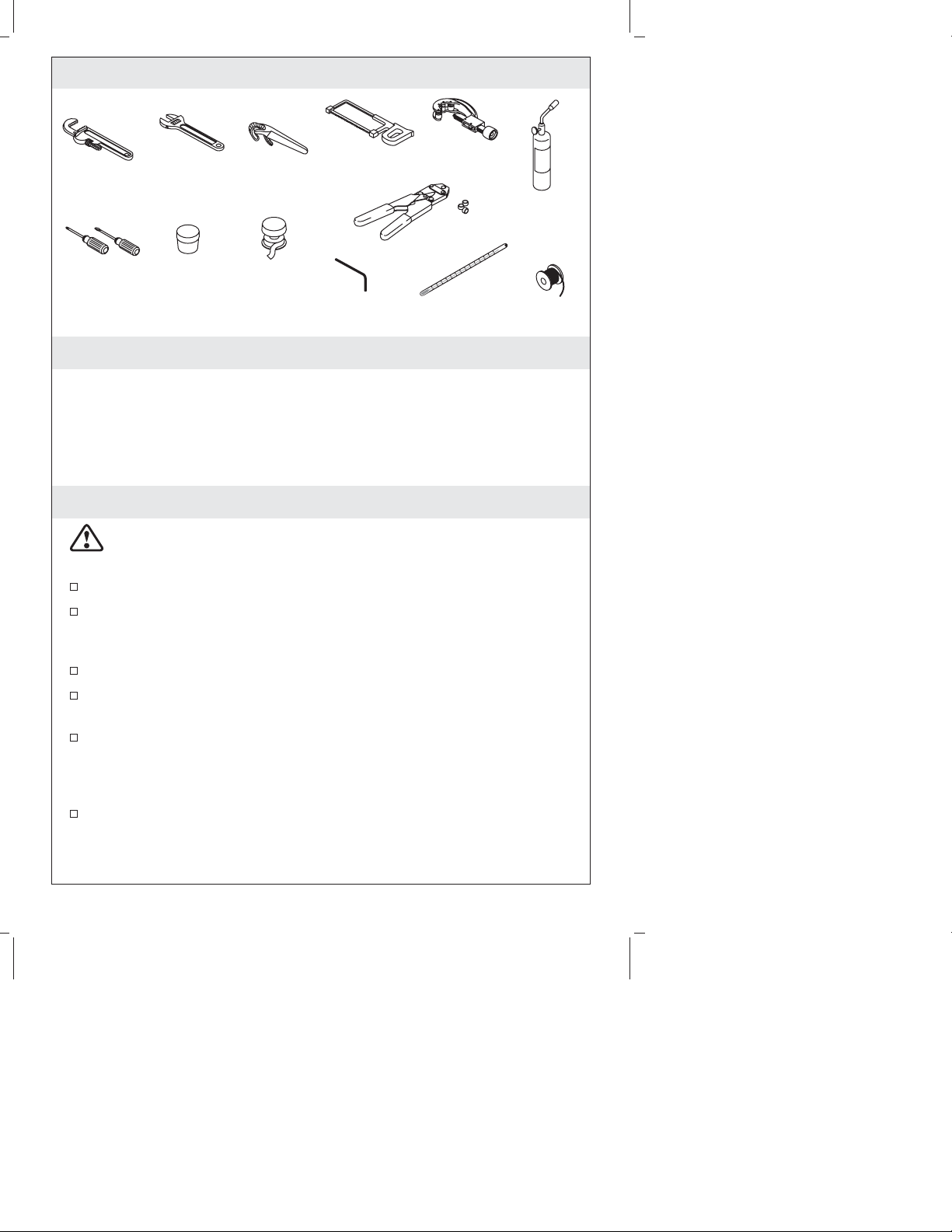

Tools and Materials

Pipe

Wrench

Assorted

Screwdrivers

Adjustable

Wrench

Plumbers

Putty

Strap

Wrench

Thread

Sealant

Hacksaw or Tubing Cutter

PEX Crimp Tool

Hex

Wrench

Thermometer

Thank You For Choosing Kohler Company

We appreciate your commitment to Kohler quality. Please take a few

minutes to review this manual before you start installation. If you

encounter any installation or performance problems, please don’t

hesitate to contact us. Our phone numbers and website are listed on

the back cover. Thanks again for choosing Kohler Company.

Before You Begin

CAUTION: Risk of product damage. The valve contains plastic

components. Do not apply excessive heat if you solder the valve

connections.

Observe all local plumbing and building codes.

The valve shuts off by water pressure. Do not force the handle in

any direction. To turn the valve off, gently turn it to the ″Off″

position.

Flush all piping thoroughly before installing this valve.

Do not use plastic pipe between the valve and the spout. Use

1/2″ nominal copper tube or 1/2″ iron pipe.

Only connect a non-restricted flow spout to an uncapped spout

outlet. Do not connect restricted flow devices (such as

deck-mount spouts, bodysprays, or diverters) unless the shower

outlet on the valve is capped.

Install a pipe or tube in a straight drop of 7″ (17.8 cm) to 18″ (45.7

cm) with only one elbow between the valve and the

wall-mounted spout. Other types of installation may cause

unsatisfactory shower performance.

Propane

Torch

Solder

Kohler Co. 3 114811-2-CG

Before You Begin (cont.)

Kohler Co. reserves the right to make revisions in the design of

products without notice, as specified in the Price Book.

114811-2-CG 4 Kohler Co.

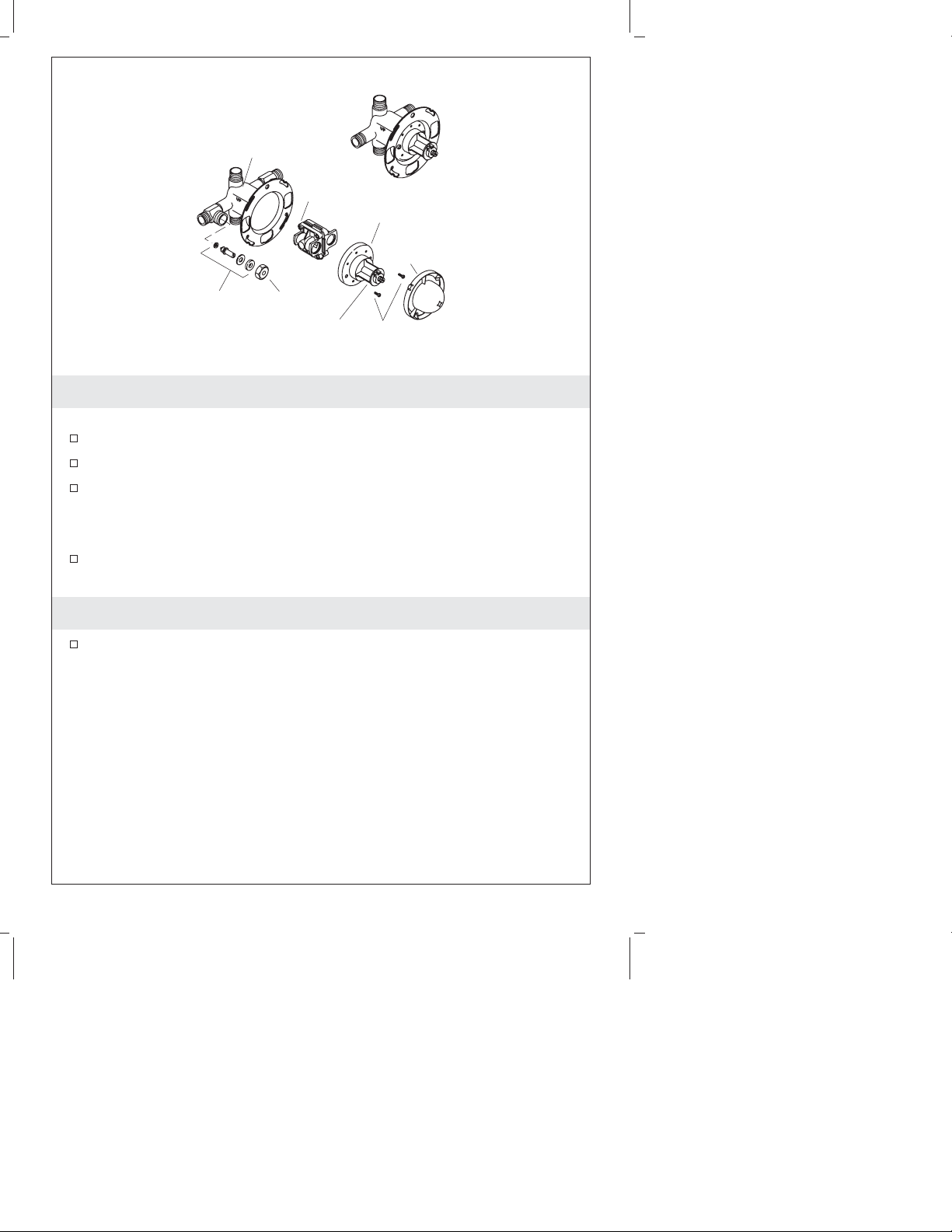

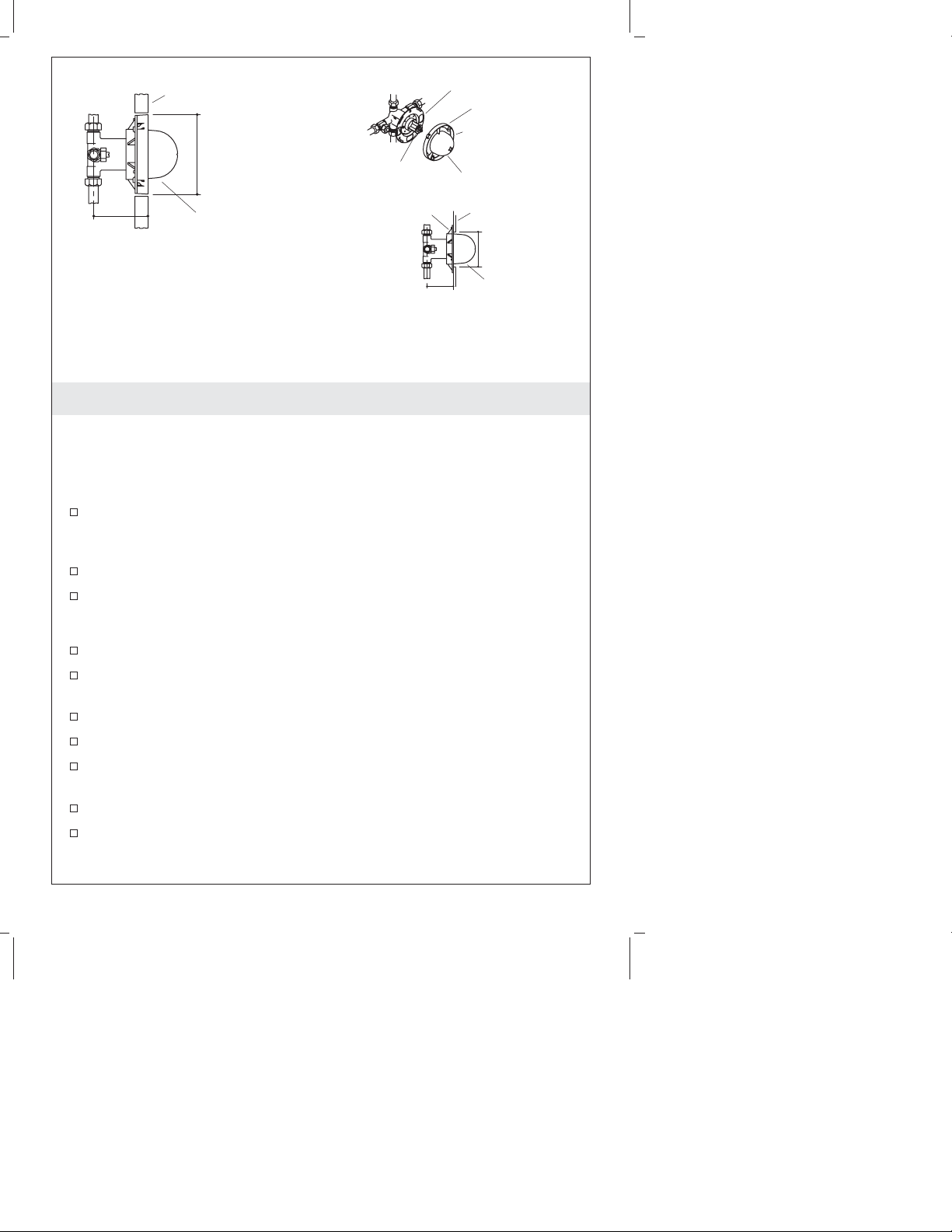

Valve

Body

Less StopsWith Stops

Pressure

Balancing Unit

Collar

Plaster

Guard

Stem

Assembly

Stop Nut

Valve

Cap

Screws

1. Prepare the Site

Rough Plumbing

Shut off the main water supply.

Install or relocate the supplies as necessary.

If the bathing fixture has been installed, cover the fixture to

prevent surface damage.

Support Framing

Determine the location of the valve, and install the support

framing.

2. Prepare the Valve

Carefully remove the stop nut and stem assembly, valve cap,

collar, and pressure balancing unit before you apply soldering

heat to the valve body.

Kohler Co. 5 114811-2-CG

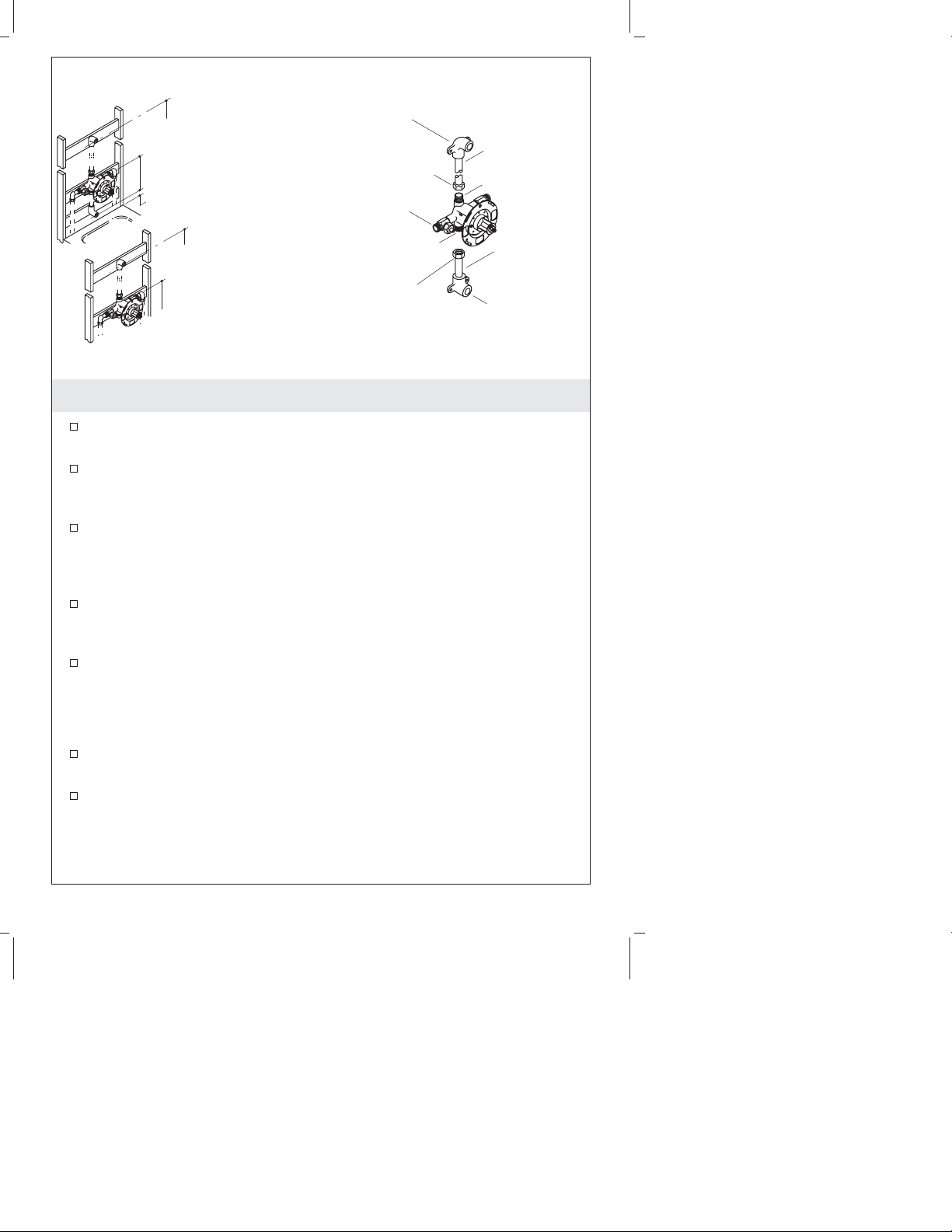

72" (182.9 cm) –

78" (198.1 cm) to

Floor (Typical)

Bath/Shower

10"

(25.4 cm)

4" (10.2 cm)

Shower Installation

Installation

72" (182.9 cm) –

78" (198.1 cm)

to Floor (Typical)

48" (122 cm)

to Floor

Shower Ell

1/2" Adapter or

Solder Direct

Hot Side

Bath Outlet

1/2" Adapter or

Solder Direct

1/2" Copper

or Pipe

Shower Outlet

1/2" Copper

or Pipe

Bath Ell

3. Install the Valve

Install the valve on the support framing so the ″UP″ mark on the

valve is facing upward.

Install elbows and adapters (if needed) to 1/2″ copper tubing or

1/2″ pipe of proper length. Apply thread sealant, and connect the

piping to the bath and shower outlets of the valve.

For copper or iron supplies: Connect the water supplies to the

valve body using elbows, 1/2″ copper tubing or pipe, and

adapters (if needed). Use thread sealant on all threaded

connections.

For CPVC supplies: Connect the water supplies to the valve

body using CPVC elbows, 1/2″ CPVC tubing, and CPVC

adapters. Use thread sealant on all threaded connections.

For PEX supplies: Install a 1/2″ water supply using a PEX copper

crimp ring. Refer to the instructions provided by the PEX crimp

tool manufacturer to properly install the PEX copper crimp ring.

IMPORTANT! Secure the piping to the framing.

Temporarily install 1/2″ nipples to the bath and shower elbows

so they will extend at least 2″ (5.1 cm) beyond the finished wall.

If you removed the inner valve components for soldering,

carefully reinstall them now.

114811-2-CG 6 Kohler Co.

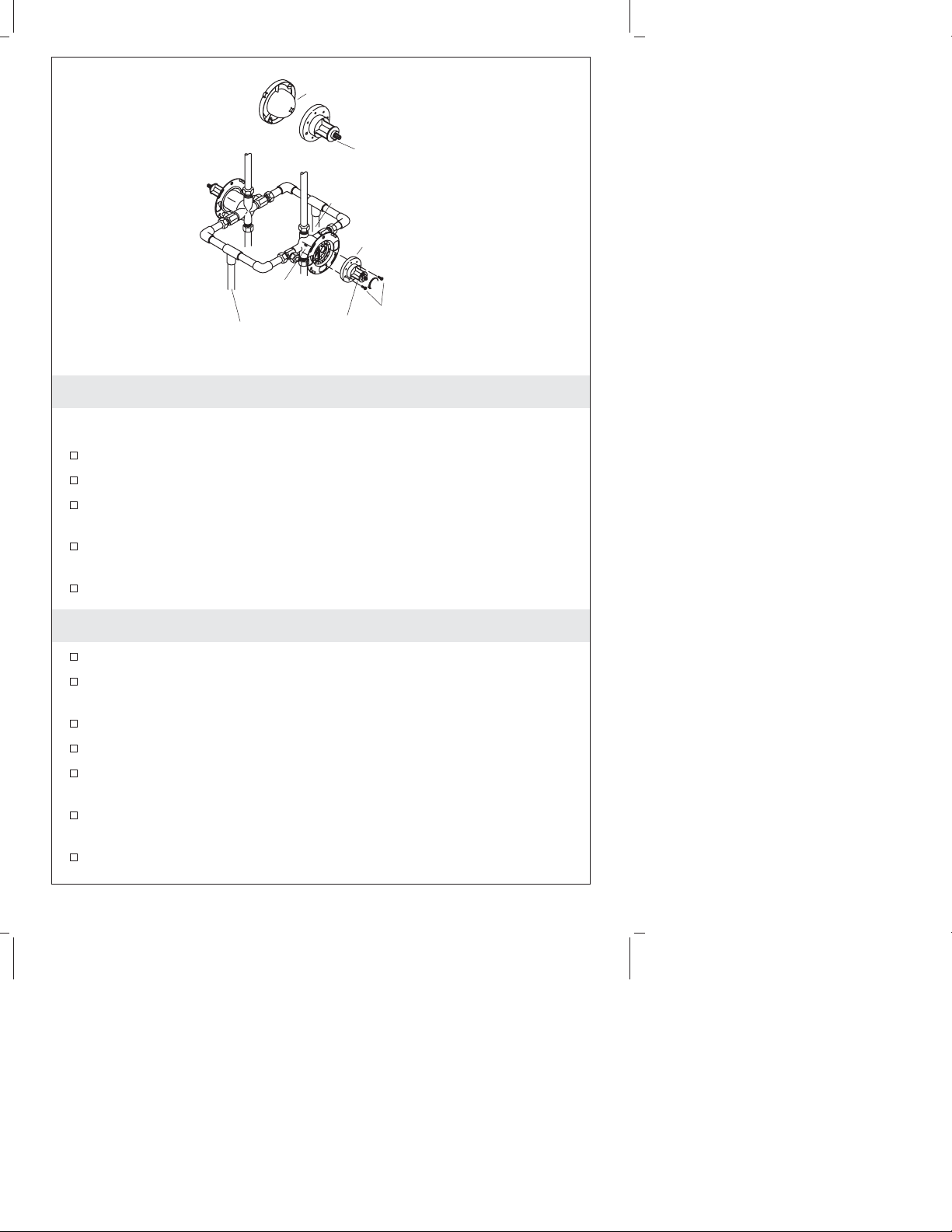

Plaster Guard

Tab

Hot

Supply

Collar

Valve

Body

Cold Supply

Cap

Assembly

180˚

Screws

4. Back-to-Back Valve Installation

NOTE: Never install the valve body upside down.

Install both valves following the valve installation instructions.

The supplies to one of the valves will be reversed.

Remove the plaster guard, cap, cap assembly, and collar from the

valve with the reversed supply connections.

Rotate the cap assembly and collar 180° (tab on the bottom).

Reassemble and securely tighten the screws.

Reinstall the plaster guard.

5. Installation Checkout

Install caps to the temporary bath and shower nipples.

Turn on the hot and cold water supplies, and check the new

installation for leaks.

Remove the caps from the temporary nipples.

Remove the plaster guard.

Turn the valve stem to the ″On″ position, and cycle the control

through its operating range. Check for leaks.

For bath and shower installations, check the diverter system from

spout to showerhead.

Turn the valve off.

Kohler Co. 7 114811-2-CG

Installation Checkout (cont.)

If the valve has stops, rotate both stop adjustments fully

clockwise.

Turn the valve on and verify that water does not run.

Turn the valve off and rotate both stop adjustments fully

counterclockwise.

Reinstall the plaster guard.

Install the trim according to the instructions packed with the trim.

114811-2-CG 8 Kohler Co.

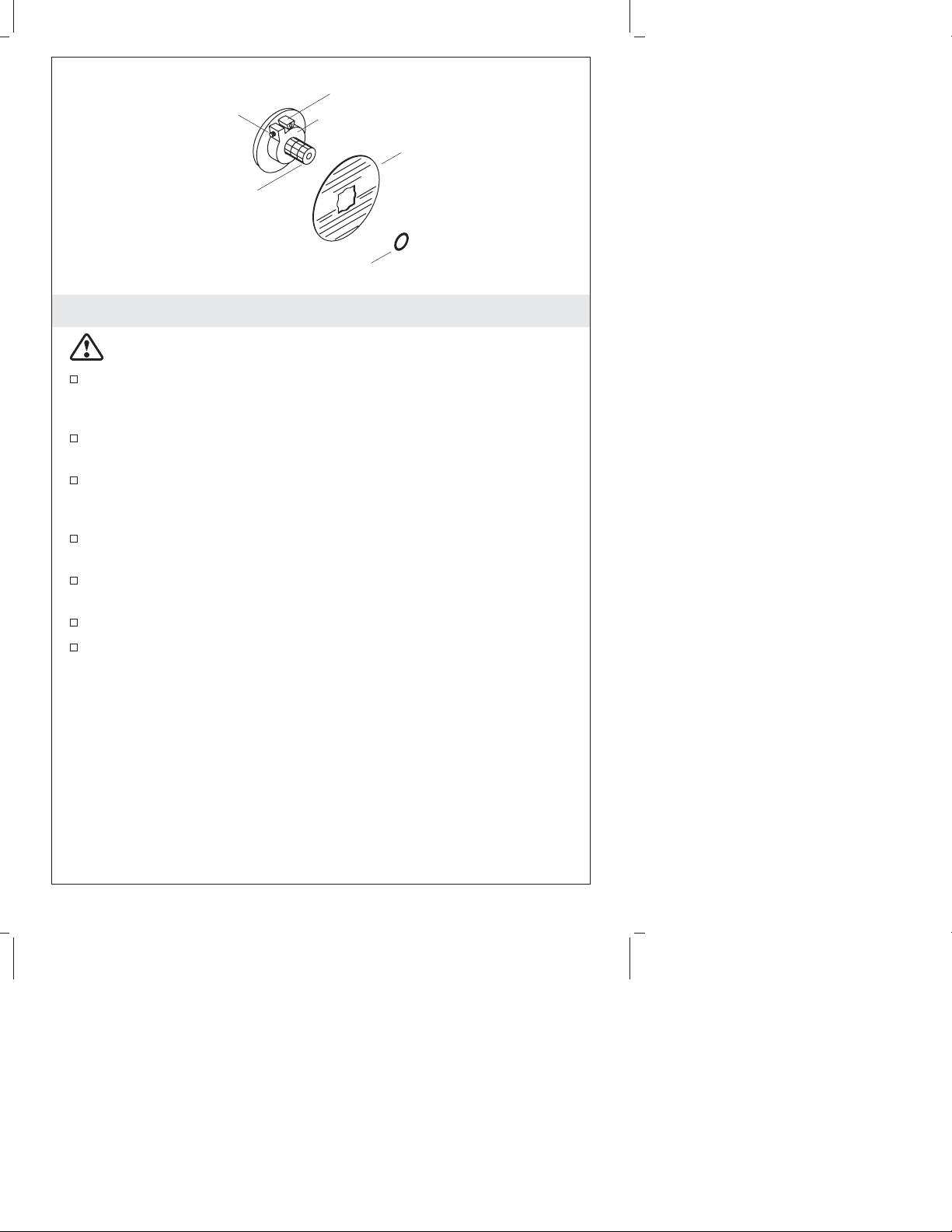

2-3/4" (7 cm) –

3-1/2" (8.9 cm)

Rough-In Depth

Finished Wall

5-9/16"

(14.1 cm) D.

Plaster Guard

Valve Stem

Backing Plate

2-3/4" (7 cm)

Rough-In Depth

Backing Plate

Outer Ring

Plaster Guard

Dome

Wall Material

4" (10.2 cm) D.

Plaster Guard

Thick Wall

Thin Wall

6. Complete the Finished Wall

NOTE: Thick wall installations are typically tile, plaster, marble, or

similar materials. Thin wall installations are typically fiberglass and

acrylic.

Thick Wall Installation

Provide a 5-9/16″ (14.1 cm) diameter hole in the wall material.

The flat front surface of the plaster guard must be flush with the

finished wall.

Complete the finished wall.

Do not remove the plaster guard until instructed.

Thin Wall Installation

Remove the plaster guard from the backing plate.

Twist the plaster guard dome to separate it from the outer ring.

Discard the outer ring.

Slide the dome over the valve stem.

Provide a 4″ (10.2 cm) diameter hole in the wall material.

Make openings for the stops (if included) by using the holes in

the backing plate as a guide.

Secure the backing plate to the back of the wall material.

Do not remove the dome until instructed to do so.

Kohler Co. 9 114811-2-CG

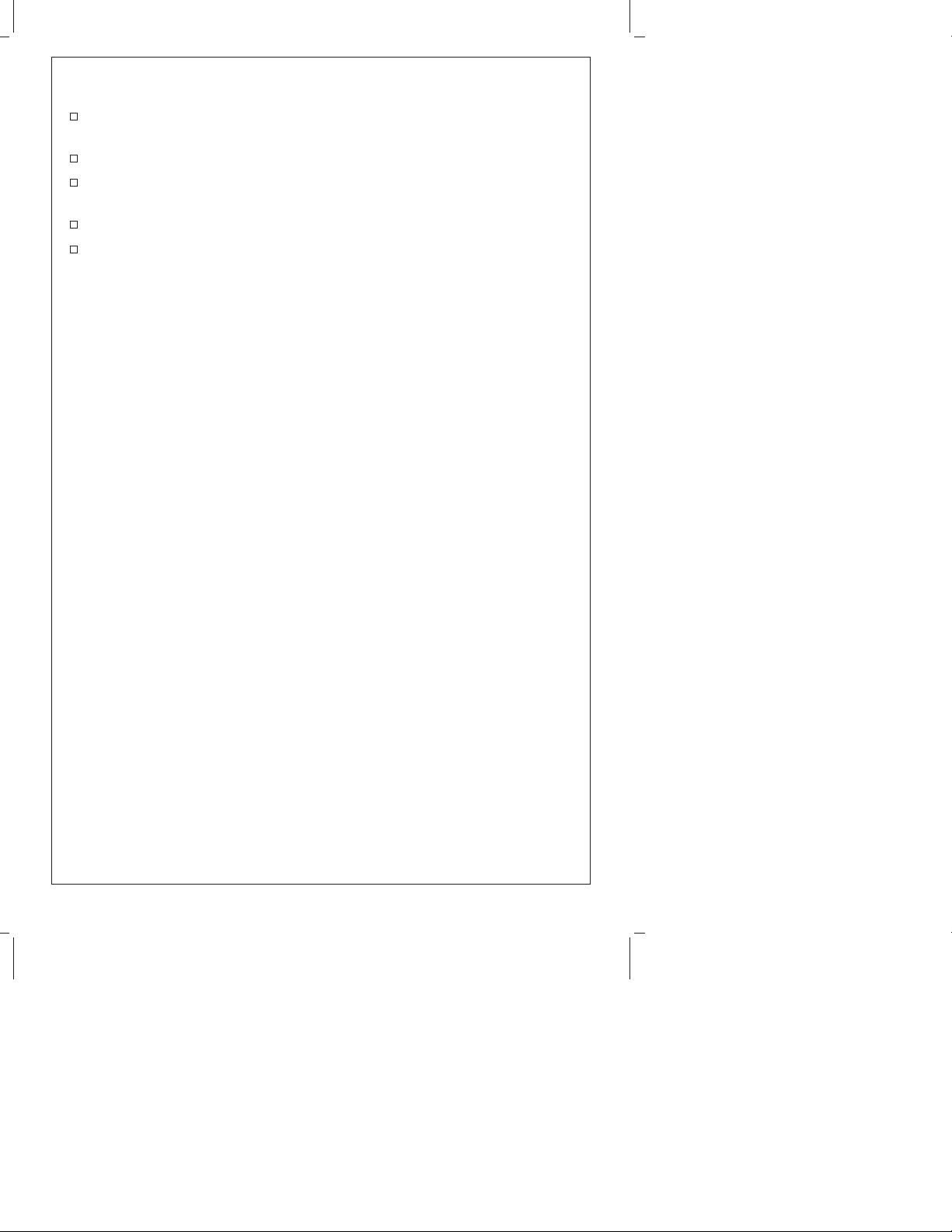

Ta b

Setscrew

Valve

Stem

Collar

Valve

Label

O-Ring

7. Optional Temperature Limiting Adjustment

CAUTION: Risk of personal injury. The water temperature

should never be set above 120° F (49° C).

Turn the valve clockwise to the full open position and let the hot

water run for several minutes. Position a thermometer in the

water stream and check the temperature.

For minor water temperature changes, adjust the setscrew, and

recheck the water temperature.

For major water temperature changes, remove the O-ring and

collar from the valve stem. Slowly rotate the valve stem until the

desired maximum water temperature is reached.

Reinstall the collar on the valve stem with the setscrew against

the side of the tab.

Reinstall the O-ring, rotate the valve stem counterclockwise to

shut the water off.

Recheck the water temperature.

Complete the information on the valve label (if supplied).

114811-2-CG 10 Kohler Co.

Loading...

Loading...