KOHLER K-2972, K-2975, K-2973, K-2976 Installation Manual

Installation and Care Guide

Thermostatic Mixing Valve

K-2972, K-2975 K-2973, K-2976

M product numbers are for Mexico (i.e. K-12345M)

Los números de productos seguidos de

M corresponden a México (Ej.

K-12345M)

Français, page “Français-1”

Español, página “Español-1”

1205551-2-C

IMPORTANT INSTRUCTIONS

READ AND SAVE FOR THE

CONSUMER

WARNING: Risk of scalding or other severe injury.

CAUTION: Risk of scalding hazard. This device has been

calibrated at the factory to ensure a safe maximum water

temperature. Any variance in settings or water inlet

conditions from those used during factory calibration may

raise the discharge temperature above the safe limit, and may

present a scalding hazard.

•

Before completing installation, the installer must set the

maximum water temperature setting of this valve to minimize the

risks associated with scalding hazards according to ASTM F 444.

The installer is responsible for adjusting the maximum water

temperature of this valve according to instructions.

This valve meets or exceeds ASME A112.18.1/CSA B125.1 and ASSE

1016/ASME A112.18.1016/CSA B125.16.

If you do not understand any of the temperature adjustment

instructions in this document, in the United States please contact our

Customer Care Center at 1-800-4KOHLER. Outside the U.S., please

contact your distributor.

IMPORTANT NOTICE: Please fill in the blanks on the valve label and

below, in the NOTICE TO HOMEOWNERS box. Retain this guide for

future reference.

•

The valve is calibrated to 104°F (40°C) at the first stop position,

and the maximum temperature limit stop is positioned so the

outlet water temperature does not exceed 120°F (49°C).

•

Factory calibrated inlet conditions are:

Hot and cold water pressure = 43.5 psi (300 kPa)

Hot water supply temperature = 149°F (65°C)

Cold water supply temperature = 59°F (15°C)

•

If inlet conditions differ from those used during factory

calibration, it may be necessary to re-calibrate the valve after

installation. The installer must check the mixed flow

temperature after installation, and adjust the valve as needed

according to the instructions.

1205551-2-C 2 Kohler Co.

IMPORTANT INSTRUCTIONS (cont.)

NOTICE TO HOMEOWNERS! This device has been preset by

_______________________ of _______________________________ to

ensure a safe maximum temperature. Any change in the setting may

raise the discharge temperature above the limit considered safe, and

lead to scalds.

Date: ______________

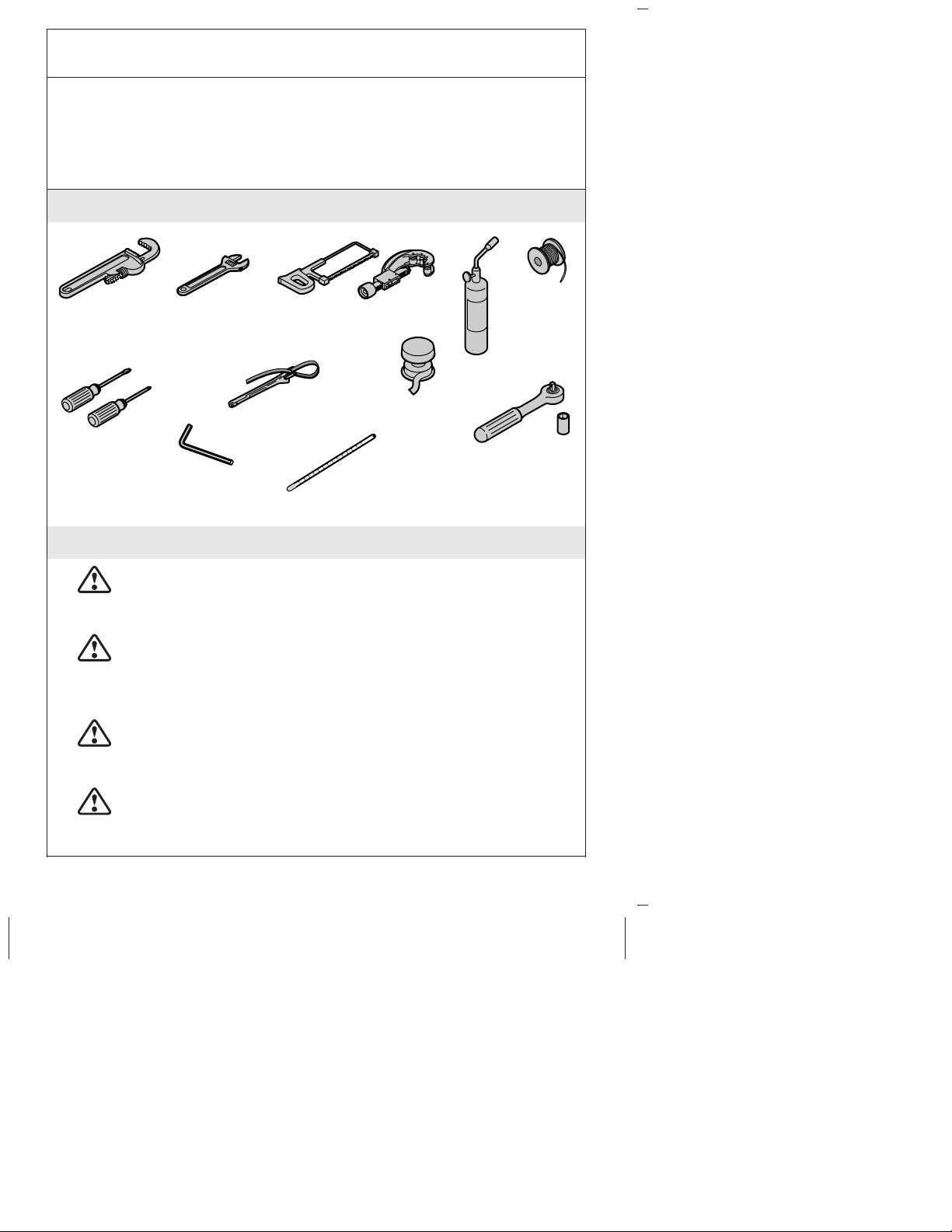

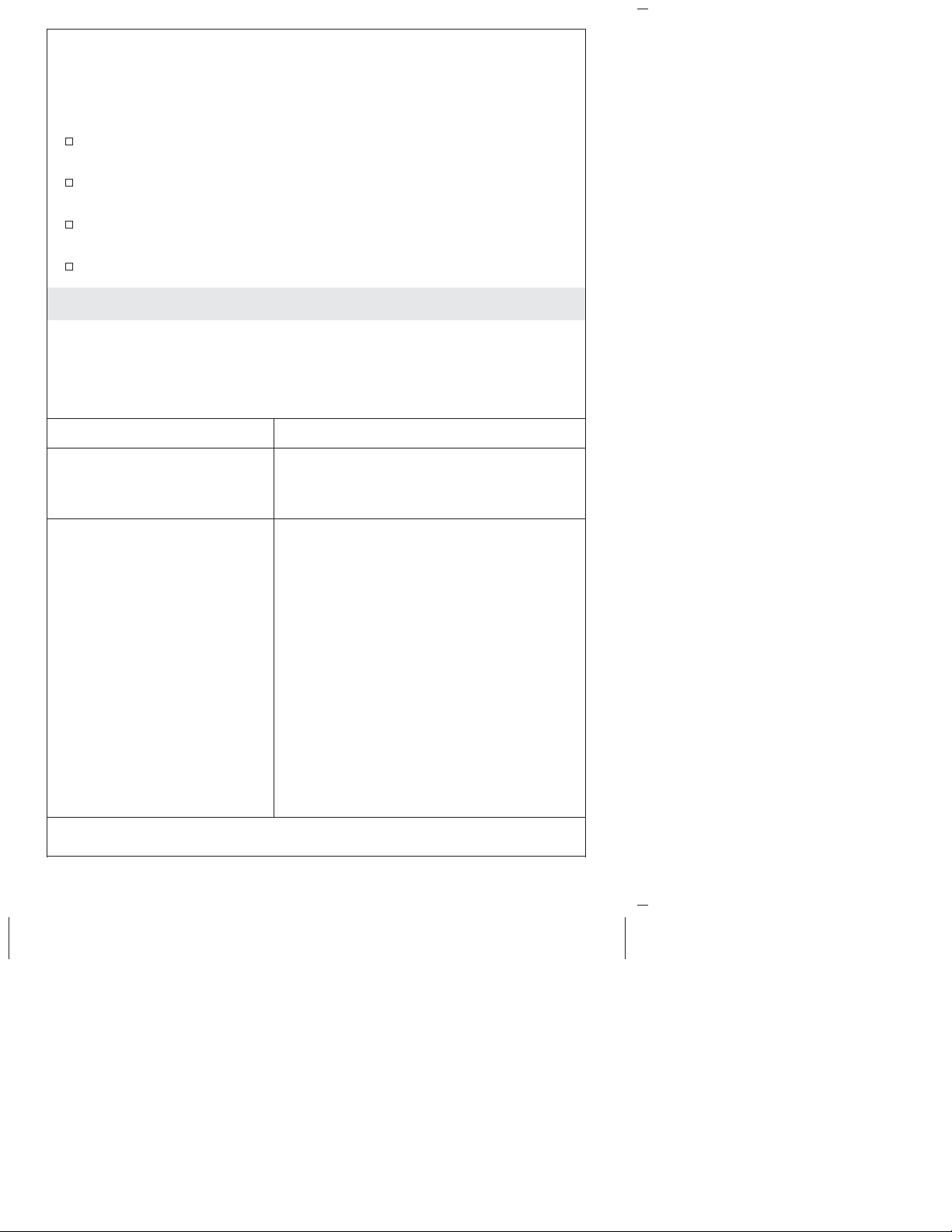

Tools and Materials

Solder

Pipe

Wrench

Assorted

Screwdrivers

Adjustable

Wrench

Strap Wrench

10 mm

Hex Wrench

Hacksaw or

Tubing Cutter

Thermometer

Propane

Torch

Thread

Sealant

Wrench and

1/2" (13 mm)

Hex Socket

Before You Begin

WARNING: Risk of scalding. High water temperature can

cause severe burns. Set the water temperature at or below

120°F (49°C) following the adjustment procedure.

WARNING: Risk of scalding or other severe injury. Before

completing installation, the installer must set the maximum

water temperature setting of this valve to minimize the risks

associated with scalding hazards according to ASTM F 444.

CAUTION: Risk of personal injury. If the water

temperature is set too high, scalding will occur. The water

temperature should never be set above 120°F (49°C).

CAUTION: Risk of scalding. This device has been calibrated

at the factory to ensure a safe maximum water temperature.

Any variance in settings or water inlet conditions from those

used during factory calibration may raise the discharge

Kohler Co. 3 1205551-2-C

Before You Begin (cont.)

temperature above the safe limit, and may present a scalding

hazard. Responsibility for installation and adjustment of this

device in accordance with these instructions lies with the

installer.

NOTICE: Risk of product damage. This valve contains plastic and

rubber components. Do not sweat or braze directly to the valve

body. Do not apply excessive heat to the valve body when you

make solder connections. Do not apply flux or acids directly to the

valve, as damage to the seals, plastic components, and trim finish

may result.

NOTICE: Risk of product damage. Do not apply petroleum-based

lubricants to the valve components, as damage may result.

NOTICE: Risk of product damage. Inlet and outlet threaded joint

connections should be made with plumbers PTFE tape or liquid

sealant. Oil-based, non-setting compounds should not be used.

NOTICE: Do not force the handle in any direction. Forcing the

handle will damage the valve.

Observe all local plumbing and building codes.

Shut off the water supply.

Inspect the supply piping for damage. Replace as necessary.

The bottom port of the thermostatic mixing valve is intended for

use as a bath filler only. If a bath spout is not used with this

product, cap the bottom port.

The K-2972 and K-2975 thermostatic mixing valves do not contain

an integral volume control/shut-off valve. You must install a

separate volume control/shut-off valve (K-2974 or K-2977)

downstream of any used valve outlet.

The K-2973 and K-2976 thermostatic mixing valves contain a

single volume control/shut-off valve for controlling the water

flow through the shower outlet. When plumbing to the valve’s

bath outlet, you must install a separate volume control shut-off

valve (K-2974 or K-2977) downstream from the bath outlet.

1205551-2-C 4 Kohler Co.

Before You Begin (cont.)

The thermostatic mixing valves do not have an integral aspirator.

For installations that use a bath diverter spout, you must install a

twin ell (K-9663) with integral aspirator between the valve and

the bath spout. If these thermostatic mixing valves are installed

without an aspirator, it will cause water to flow from the shower

and bath spout at the same time.

Determine the correct drain size and capacity for your

installation. If two thermostatic mixing valves are used together,

water volumes between 18 and 30 gal/min (60 and 114 l/min) or

more are possible, depending upon the water supply pressure.

Determine the correct water heater size and capacity for your

installation. A typical shower installation uses an approximate

mix of 75% hot water and 25% cold. A custom shower application

using three 2.5 gal/min (9.5 l/min) showerheads can use about 45

gallons (170 liters) of hot water in 8 minutes. Choose a water

heater large enough for your installation.

The valve is calibrated to 104°F (40°C) at the first stop position.

The maximum temperature limit stop is positioned so the outlet

water temperature does not exceed 120°F (49°C).

The factory calibrated pressure for hot and cold water inlets is

43.5 psi (300 kPa). The factory calibrated hot water supply

temperature is 149°F (65°C) and the cold water supply

temperature is 59°F (15°C).

If the inlet conditions differ from those used during factory

calibration, it may be necessary to re-calibrate the valve after

installation. The installer must check the mixed flow

temperature after installation and adjust the valve as needed

according to the instructions.

If possible, flush all piping thoroughly before installing the valves

to prevent early clogging of filter screens.

Kohler Co. 5 1205551-2-C

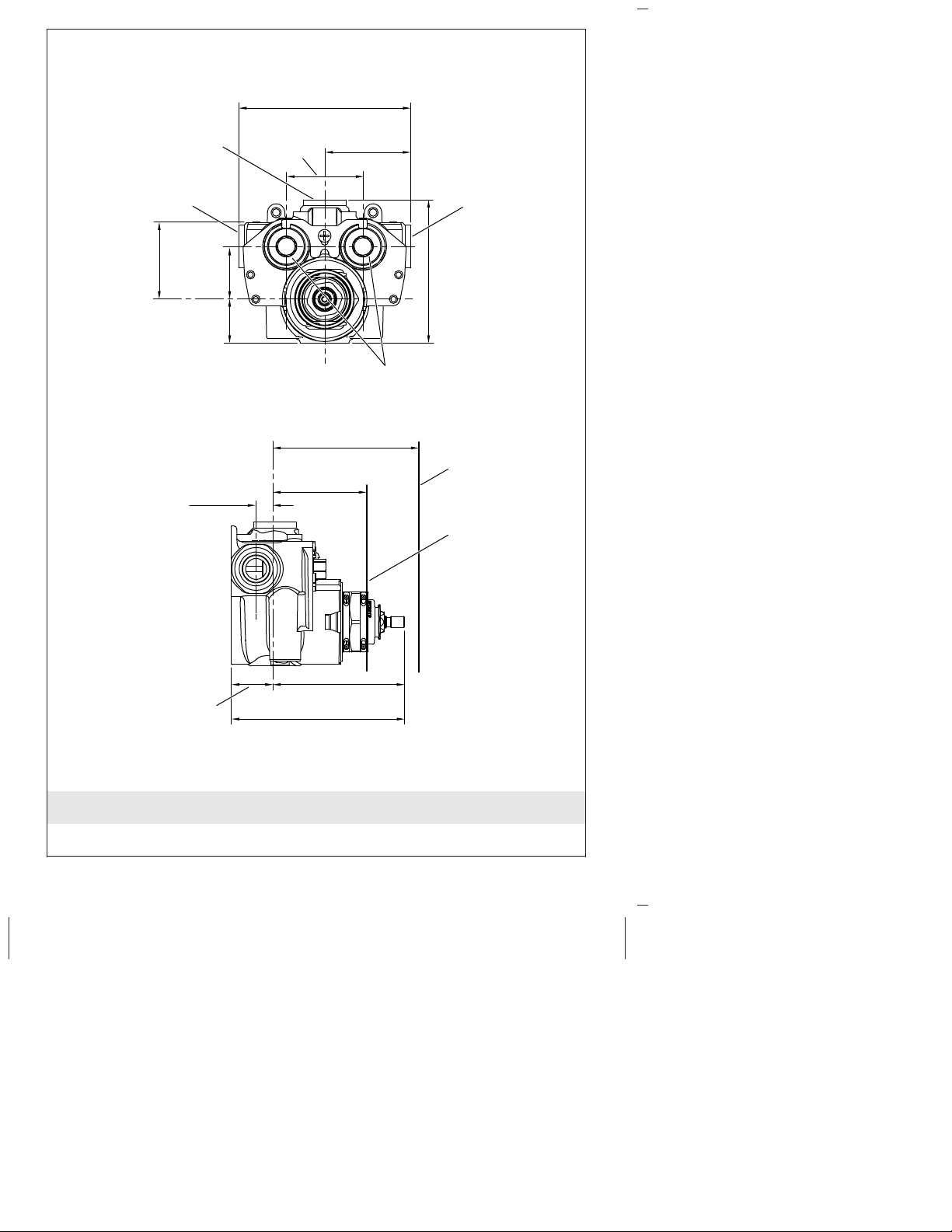

4-5/8" (117 mm)

1/2" NPT

Shower Outlet

1/2" NPT

Hot Inlet

2-1/16"

(52 mm)

1-7/16"

(37 mm)

1-1/8"

(29 mm)

1/2"

(13 mm)

2-1/16"

(52 mm)

2-7/16"

(62 mm)

2-5/16"

(59 mm)

Stop

3-3/4" (95 mm)

1/2" NPT

Cold Inlet

3-7/8"

(98 mm)

Max

Finished Wall

Min

Finished Wall

3-1/2" (89 mm)

1-3/16" (30 mm)

4-5/8" (117 mm)

K-2972 - 1/2″ Valve Roughing-In

1205551-2-C 6 Kohler Co.

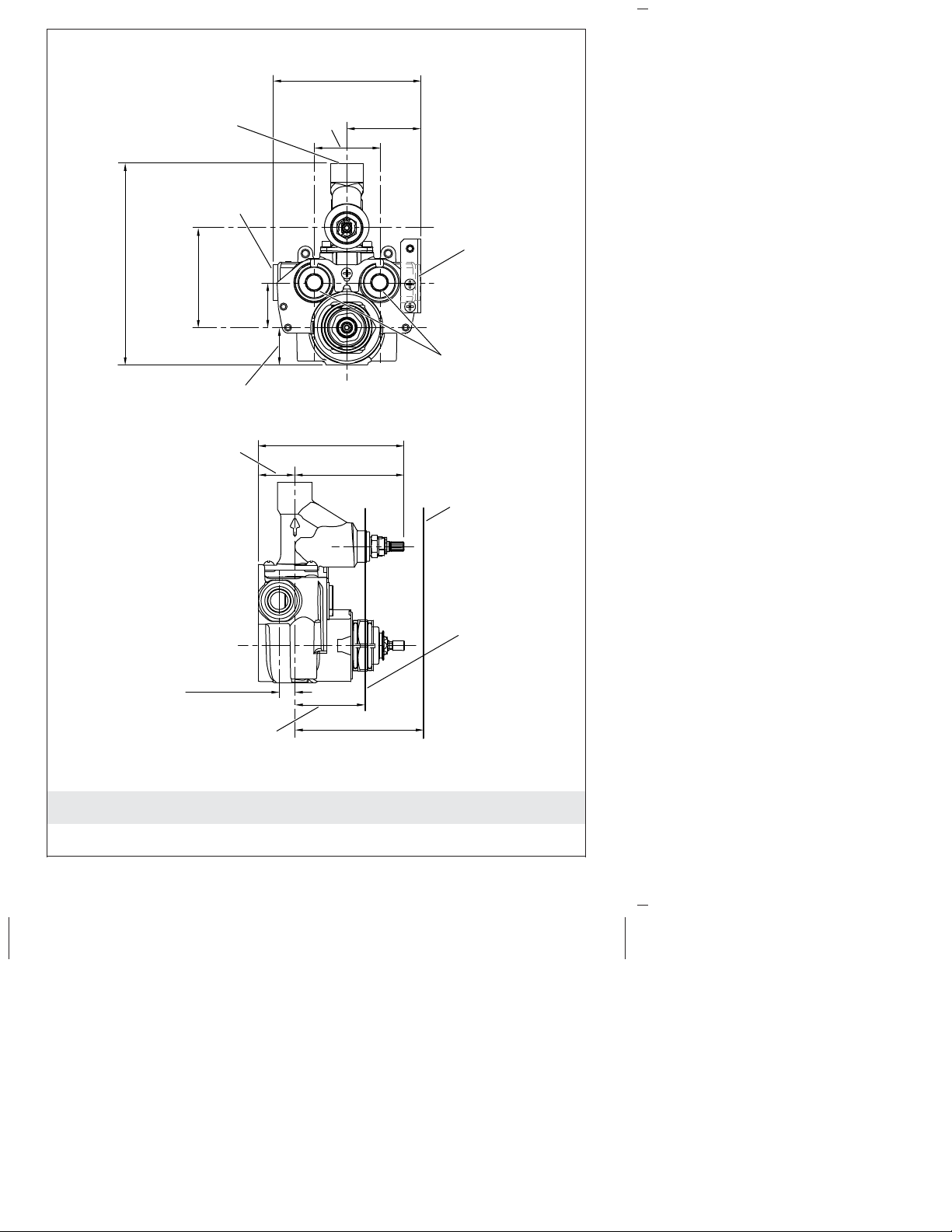

4-5/8" (117 mm)

6-3/8"

(162 mm)

1/2" NPT

Shower Outlet

1/2" NPT

Hot Inlet

3-1/8"

(79 mm)

1-3/16" (30 mm)

1-3/16" (30 mm)

1-7/16"

(37 mm)

2-1/16"

(52 mm)

4-5/8" (117 mm)

3-1/2" (89 mm)

2-5/16"

(59 mm)

1/2" NPT

Cold Inlet

Stop

Max

Finished Wall

Min

Finished Wall

1/2"

(13 mm)

2-7/16"

(62 mm)

3-3/4" (95 mm)

K-2973 - 1/2″ Valve Roughing-In

Kohler Co. 7 1205551-2-C

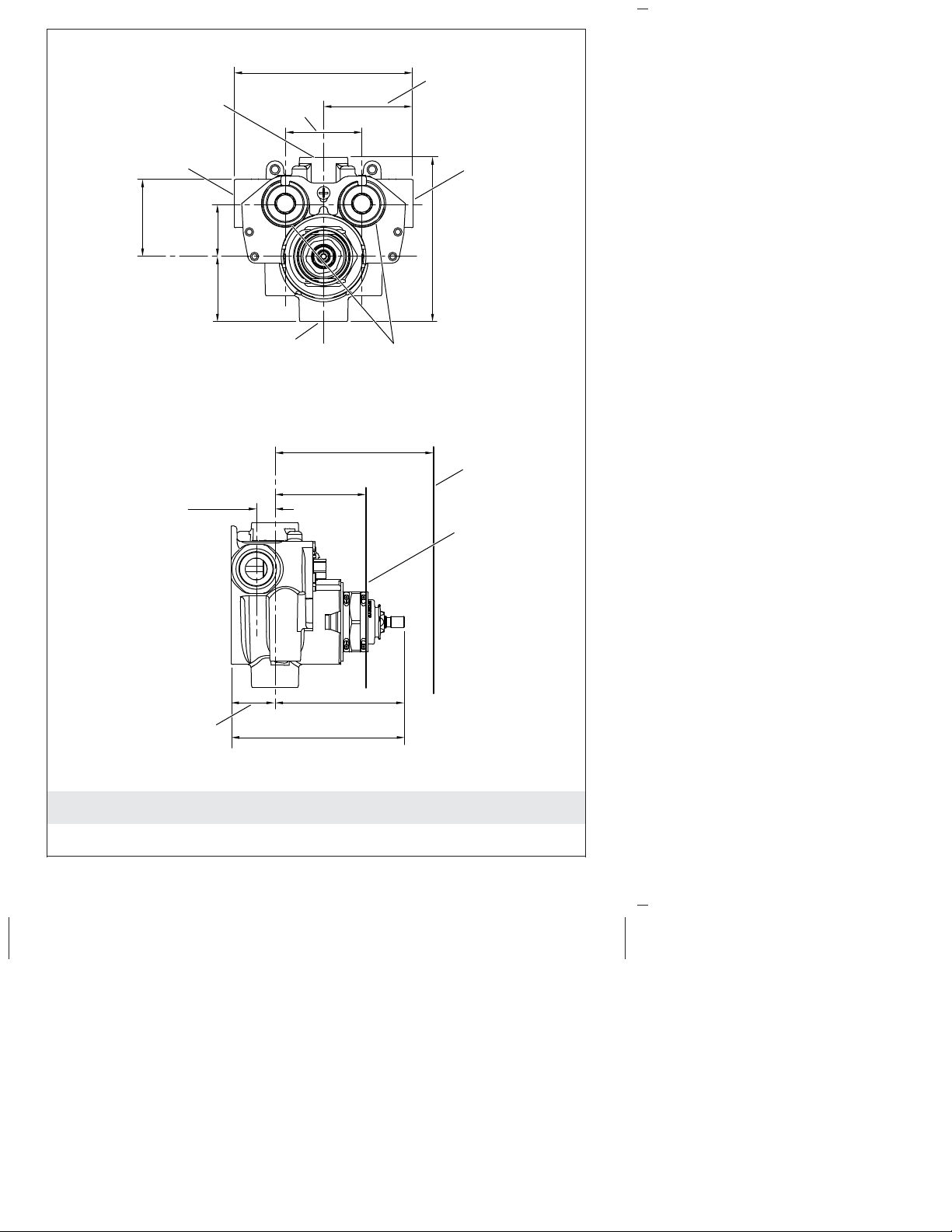

3/4" NPT

Shower Outlet

4-13/16" (122 mm)

2-1/16"

(52 mm)

2-3/8" (60 mm)

3/4" NPT

Hot Inlet

2-1/16"

(52 mm)

1-7/16"

(37 mm)

1-1/8"

(29 mm)

1/2"

(13 mm)

3/4" NPT

Bath Outlet

2-7/16"

(62 mm)

Stop

3-3/4" (95 mm)

3/4" NPT

Cold Inlet

4-7/16"

(113 mm)

Max

Finished Wall

Min

Finished Wall

3-1/2" (89 mm)

1-3/16" (30 mm)

4-5/8" (117 mm)

K-2975 - 3/4″ Valve Roughing-In

1205551-2-C 8 Kohler Co.

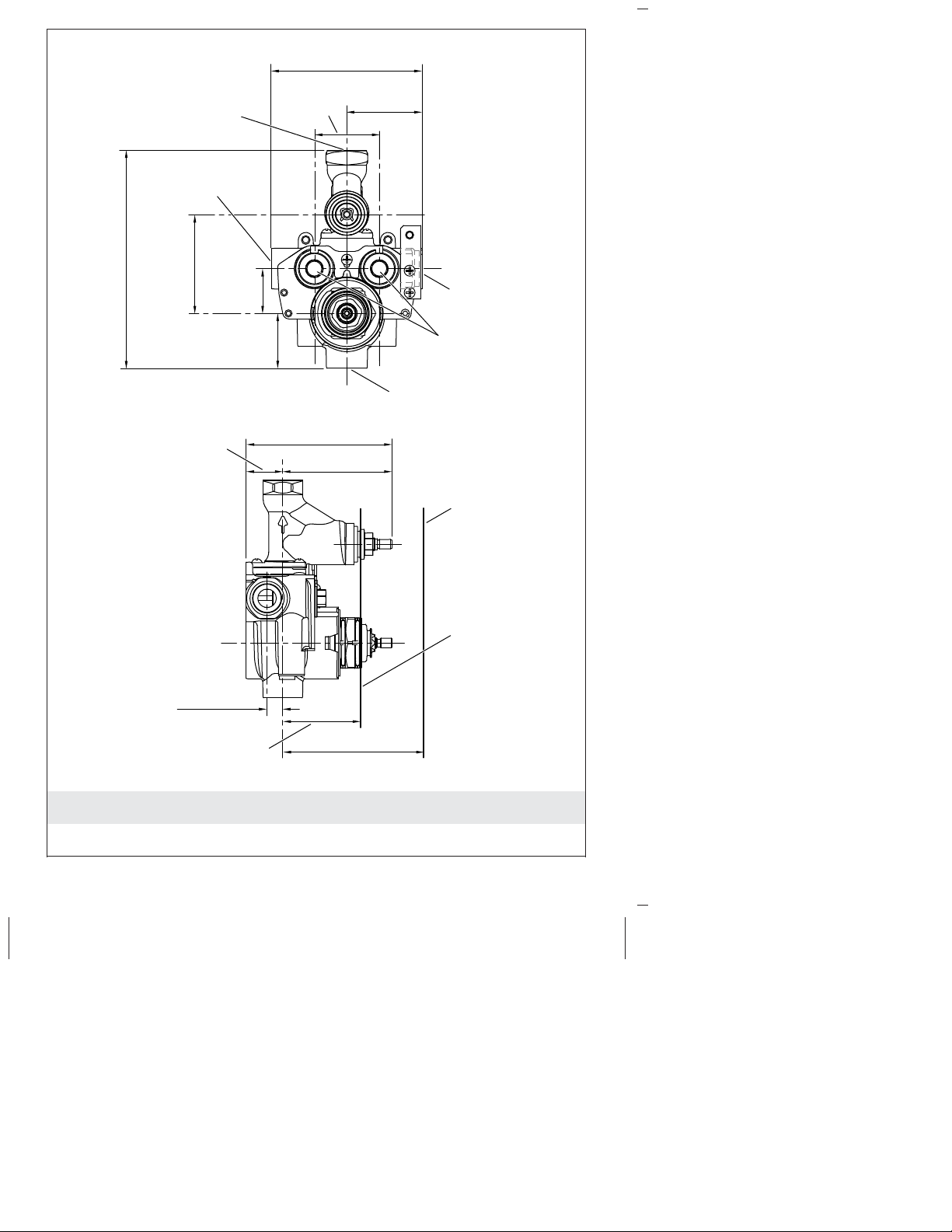

6-15/16"

(176 mm)

3/4" NPT

Shower Outlet

3/4" NPT

Hot Inlet

3-3/16"

(81 mm)

1-3/16" (30 mm)

1-7/16"

(37 mm)

1-3/4"

(44 mm)

4-13/16" (122 mm)

2-1/16"

(52 mm)

4-5/8" (117 mm)

3-1/2" (89 mm)

2-3/8"

(60 mm)

3/4" NPT

Cold Inlet

Stop

3/4" NPT

Bath Outlet

Max

Finished Wall

Min

Finished Wall

1/2"

(13 mm)

2-7/16" (62 mm)

3-3/4" (95 mm)

K-2976 - 3/4″ Valve Roughing-In

Kohler Co. 9 1205551-2-C

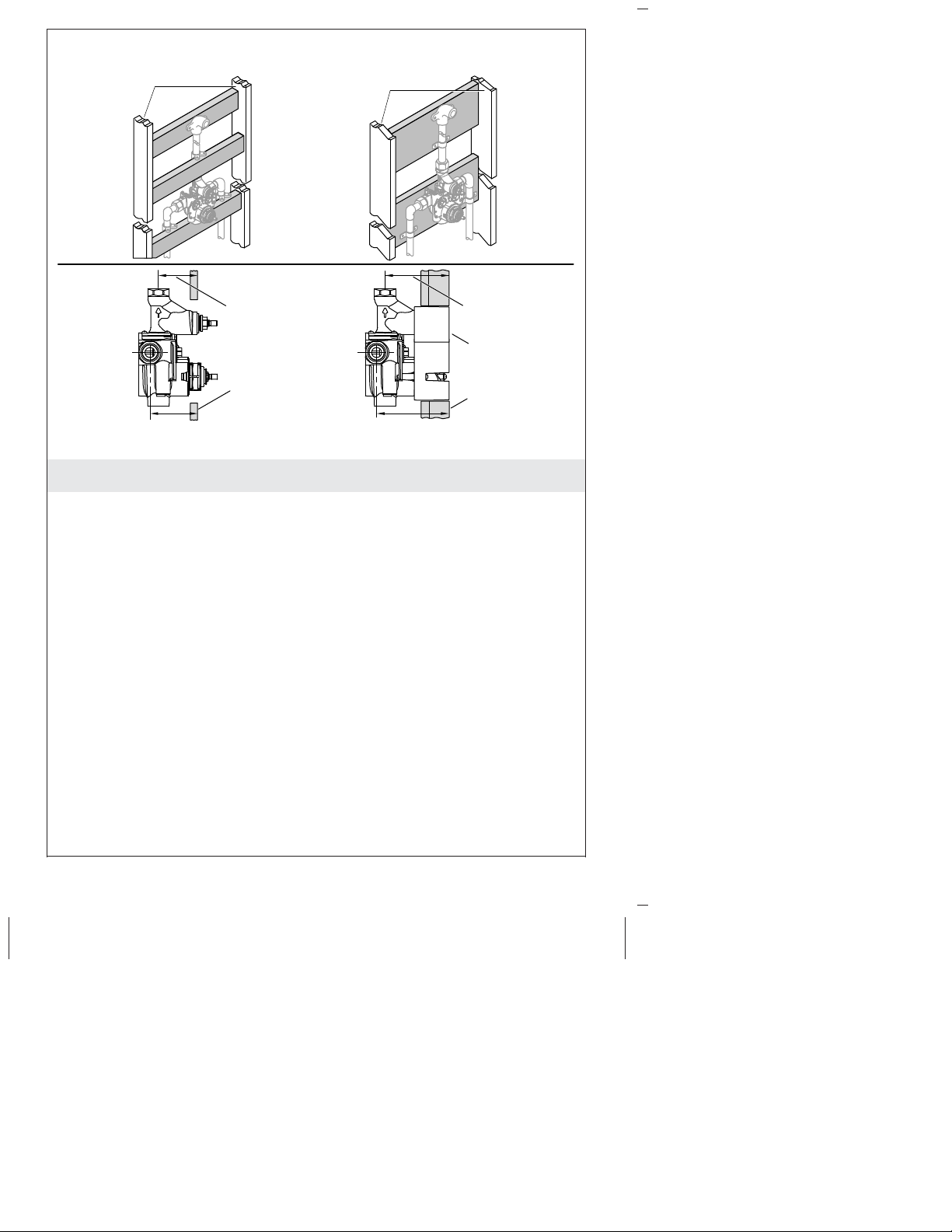

2x4

Thick WallThin Wall

2x6

2-7/16"

(62 mm)

Finished

Wall

4-1/4" (108 mm) Max2-15/16" (75 mm) Min

3-3/4" (95 mm)

Plaster Guard

Finished Wall

1. Install the Support Framing

IMPORTANT! Make sure the valve is mounted at the correct depth

so it will be properly positioned when the finished wall is installed.

NOTE: Shower only configuration is shown. Adjust the support as

needed for other configurations.

NOTE: Install a backer board behind the valve for installations on

2x6 studding only.

NOTE: A backer board may not fit behind the valve for installations

on 2x4 studding. Support the pipes directly above and/or below the

valve. This will also provide support for the valve.

NOTE: When installing the K-2972 or K-2973 valve, use 1/2″

nominal copper tubing and fittings throughout this installation.

Smaller diameter piping upstream or downstream of the valve will

reduce performance of the valve.

1205551-2-C 10 Kohler Co.

Install the Support Framing (cont.)

NOTE: When installing the K-2975 or K-2976 valve, use 3/4″

nominal copper tubing and fittings throughout this installation.

Smaller diameter piping upstream or downstream of the valve will

reduce performance of the valve.

Determine the desired location for the valve according to the

roughing-in information, and construct suitable stud and support

framing for your configuration and valve.

If the finished wall is drywall, 1/2″ (13 mm) drywall or thicker

should be used or the finished wall will not be strong enough.

Determine the finished wall thickness. The finished wall should

not extend beyond the outside edge of the plaster guard. The

valve can be mounted with the plaster guard flush with the

finished wall for maximum wall thickness. If the plaster guard is

recessed, the finished wall is too thick. Refer to the diagram

above.

Install water hammer arrestors in the hot and cold water supply

lines.

Determine the desired location for the valve according to the

roughing-in information, and construct suitable stud and support

framing.

Kohler Co. 11 1205551-2-C

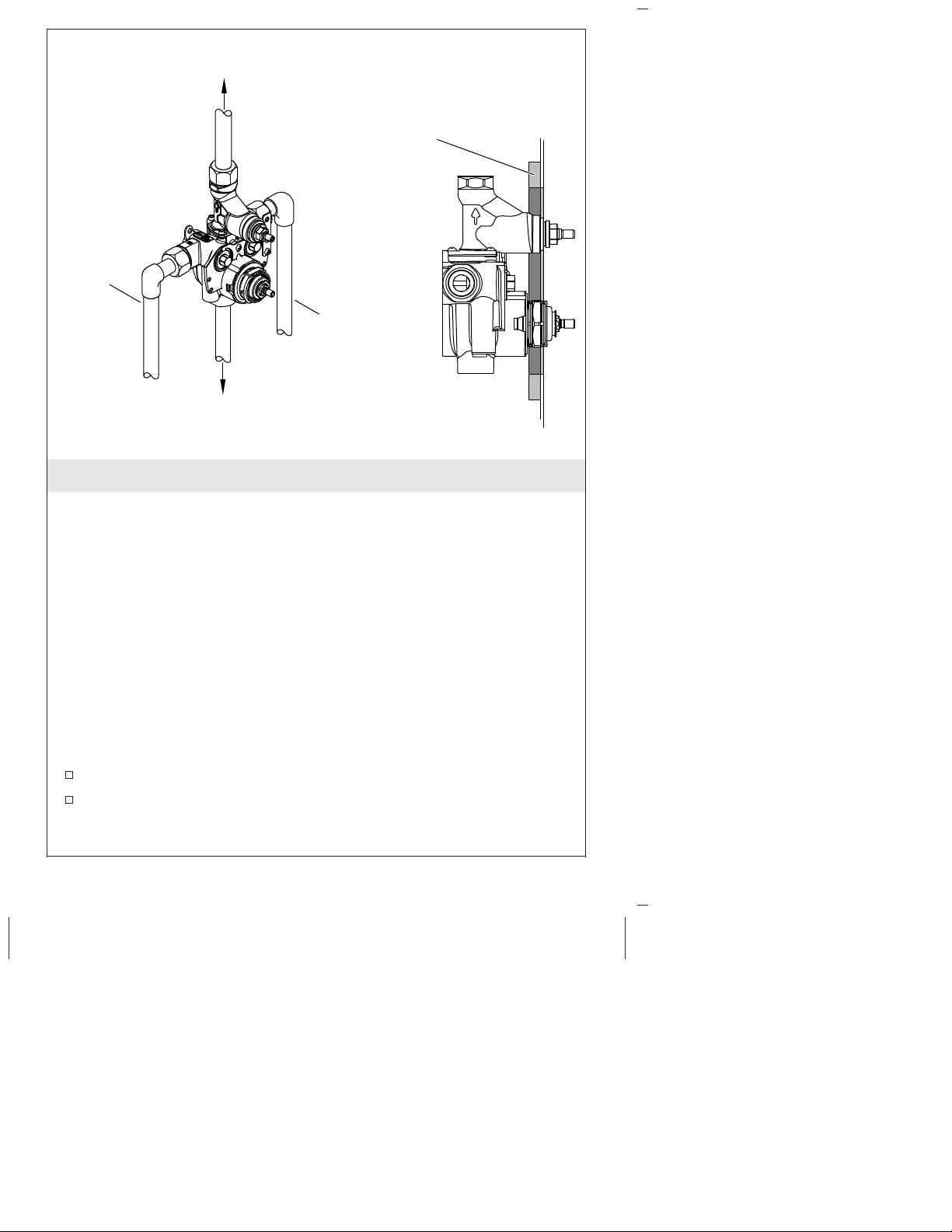

To Showerhead

For finished wall thicknesses

less than 3/16" (5 mm), install

1/2" (13 mm) plywood backing

behind cutout.

K-2976-KS

Shown

Hot

Supply

Cold

Supply

To Bath Spout Volume Control

Cap outlet if not used.

2. Install the Valve

NOTICE: Risk of product damage. This valve contains plastic and

rubber components. Do not sweat or braze directly to the valve

body. Do not apply excessive heat to the valve body when you

make solder connections. Do not apply flux or acids directly to the

valve, as damage to the seals, plastic components, and trim finish

may result.

NOTICE: Risk of product damage. Do not apply petroleum-based

lubricants to the valve components, as damage may result.

NOTICE: Risk of product damage. Inlet and outlet threaded joint

connections should be made with plumbers PTFE tape or liquid

sealant. Oil-based, non-setting compounds should not be used.

NOTE: A plaster guard is attached to the face of the mixing valve.

Do not remove it until instructed.

Flush the hot and cold water supply lines to remove any debris.

Use thread sealant and connect the hot and cold water supply

lines to the valve inlet ports. Ensure that the corresponding water

supply lines are connected to the correct inlet ports.

1205551-2-C 12 Kohler Co.

Install the Valve (cont.)

NOTE: If the existing hot and cold plumbing makes this

configuration inconvenient or if it is advantageous to reverse the hot

and cold ports (such as back-to-back installations), see the ″Reverse

the Inlet Supplies″ section.

For K-2973 and K-2976 valves, make certain that the integral

volume control/shut-off valve portion of the assembly is on top

when installed.

Connect the water outlet lines to the valve ports. Plug any

unused outlet port.

IMPORTANT! Secure the piping to the framing.

NOTE: When using the plaster guard to trace the cut-out, the tick

marks located outside of the guard will assist you in identifying the

spline centers.

Use the plaster guard to determine the depth of the valve in the

wall, and to trace the cut-out line in the wall material.

NOTE: The finished wall must be within the MIN-MAX depth

shown on trim adapters 1, 2, and 3 of the plaster guard.

Turn on the water supply lines to the valves.

Run water through the mixing valve, all showers, and the spout.

Remove the plaster guard to access and inspect the valve.

Kohler Co. 13 1205551-2-C

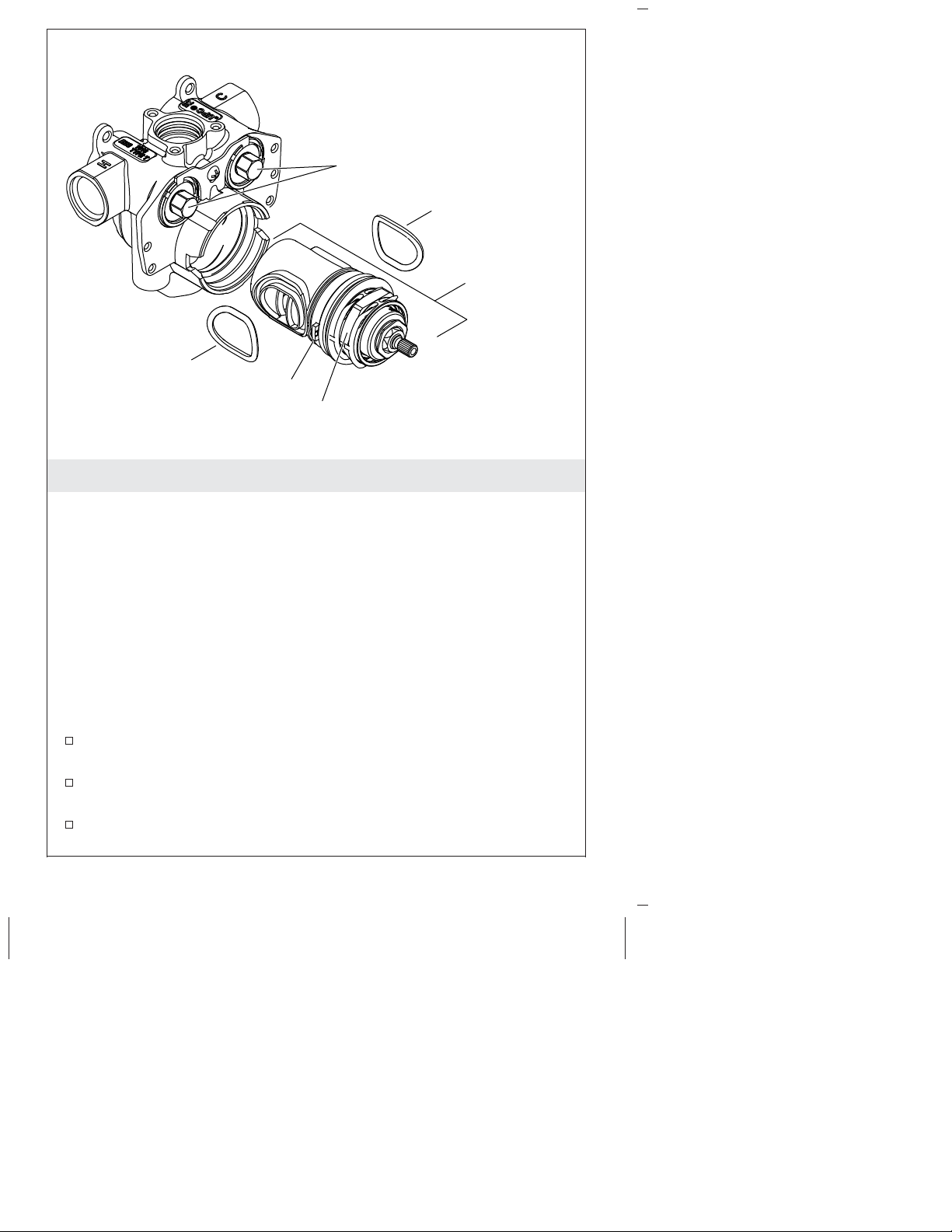

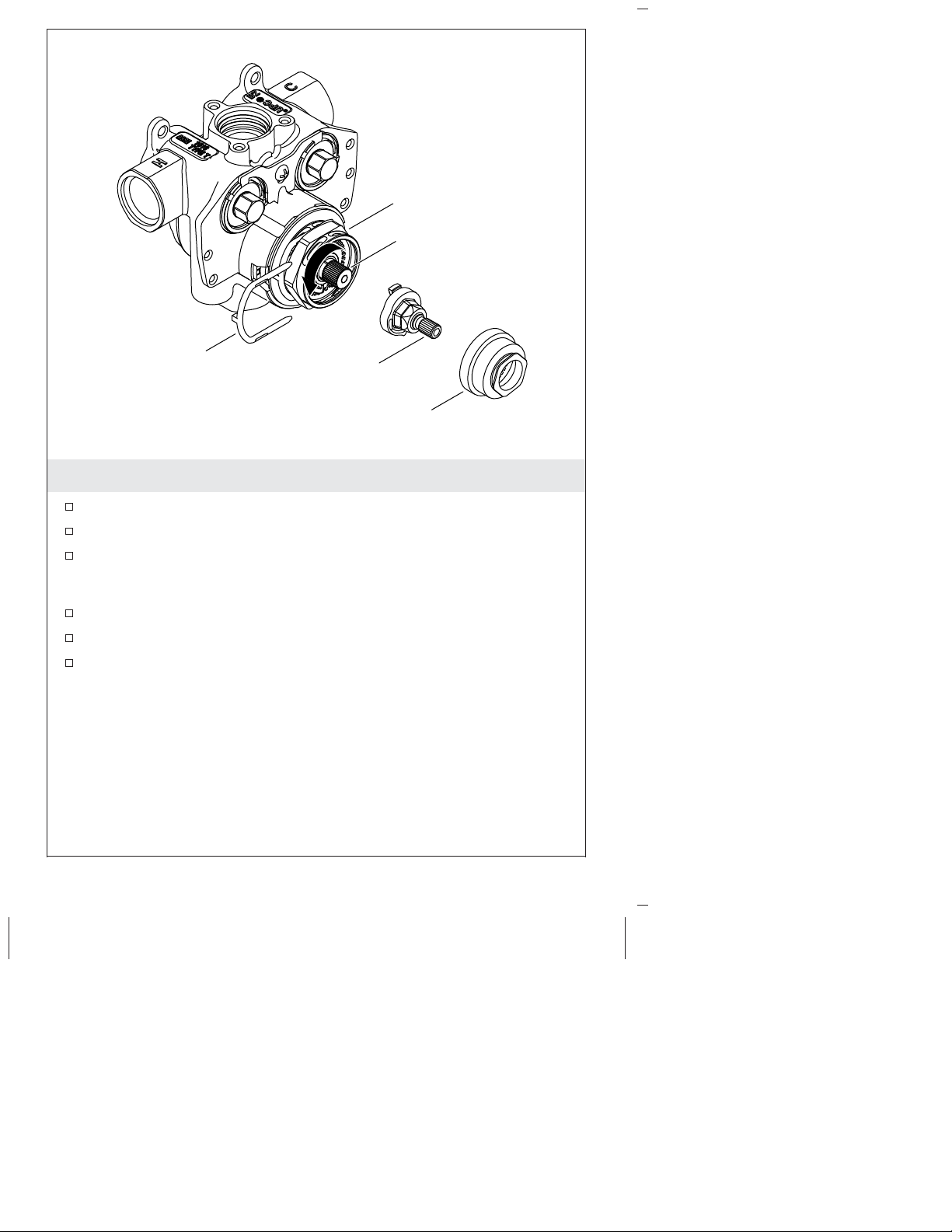

Remove the cartridge and rotate 180˚.

Supply Stops

Seal

Cartridge

Seal

Tab

Head Nut

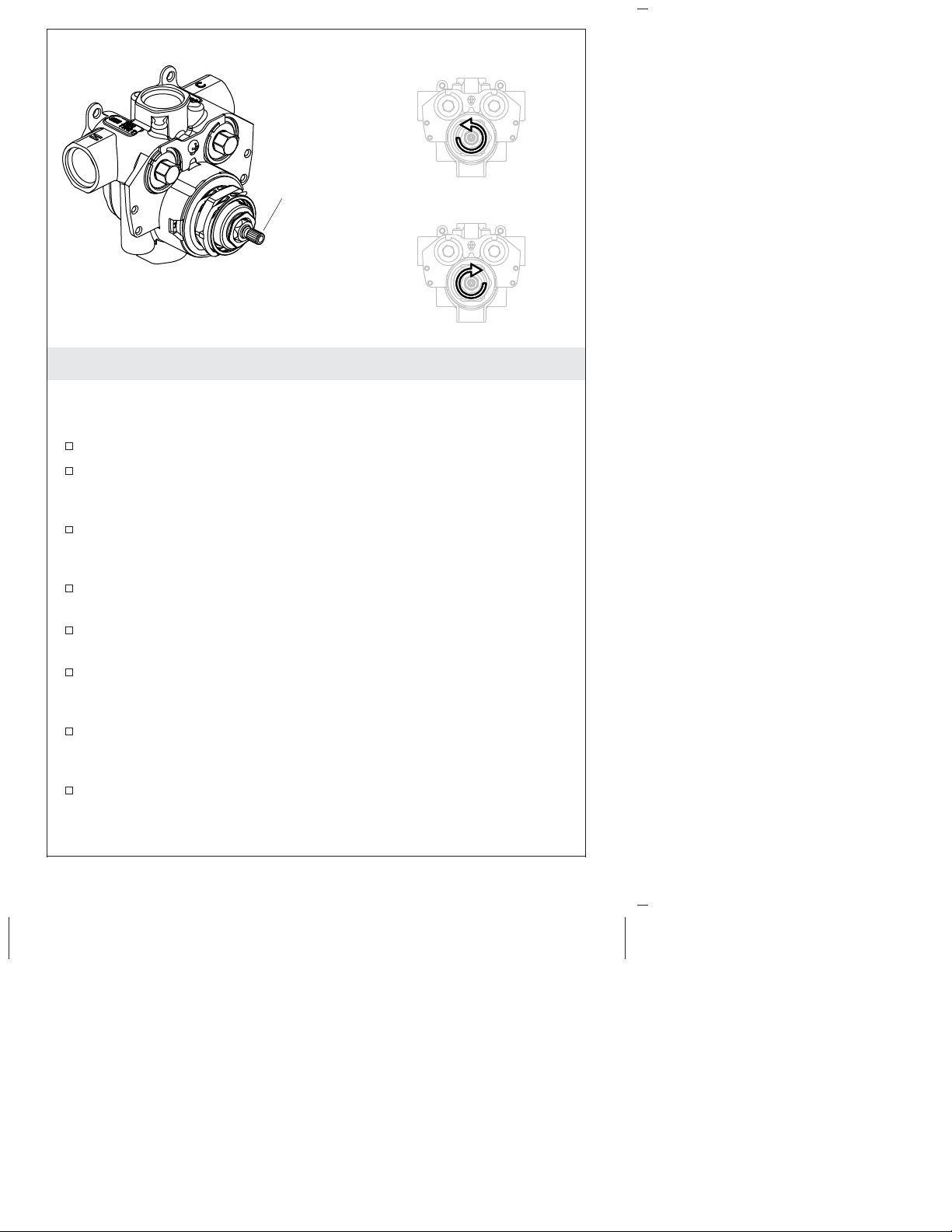

3. Reverse the Inlet Supplies

IMPORTANT! The steps in this section are optional. Only perform

these steps when the hot and cold inlet supplies are reversed.

The inlet connections are indicated on the inlet ports of the

thermostatic valve assembly. Left is HOT and right is COLD. If this

configuration is not suitable for your installation, the cartridge may

be rotated 180° to reverse the hot and cold inlet ports.

NOTE: DO NOT pull the removal clip from the cartridge assembly

at any time during this procedure. The retaining clip helps hold the

temperature limit stop and detent components in place and reduces

or eliminates the need for temperature adjustments.

With the valve already installed and pressurized:

Turn both integral supply stops 90° counterclockwise until they

contact the stop bracket.

Turn the volume control valve stem (not shown) fully clockwise

to release the pressure.

Slowly loosen the head nut, turning it counterclockwise. This will

begin to draw the cartridge out of the valve body.

1205551-2-C 14 Kohler Co.

Reverse the Inlet Supplies (cont.)

NOTE: Some water may be released. Use a bucket and towels to

contain the water.

Pull the head nut with the cartridge out of the valve body.

NOTE: Two seals may fall out when the cartridge is removed. Set

the seals aside.

Rotate the cartridge 180°.

Verify the cold cartridge inlet is on the left when the valve stem

adapter is facing you.

NOTE: The hot and cold cartridge inlets are identified on the top

and sides of the cartridge tabs. The tabs are labeled ″H″ and ″C″ to

identify hot and cold.

TIP: Rotating the cartridge back and forth or installing with a

push-pull motion will reduce the possibility of pinching the side

seals.

Reinstall the seals onto each side of the cartridge.

Carefully push the cartridge back into the valve body. Make sure

both cartridge tabs are properly seated inside the cartridge slots

of the valve body.

Handtighten the head nut onto the valve body. Do not

overtighten.

Return the integral supply stops back to their original position.

Make note of reversed inlet supplies on the valve for future

servicing.

Kohler Co. 15 1205551-2-C

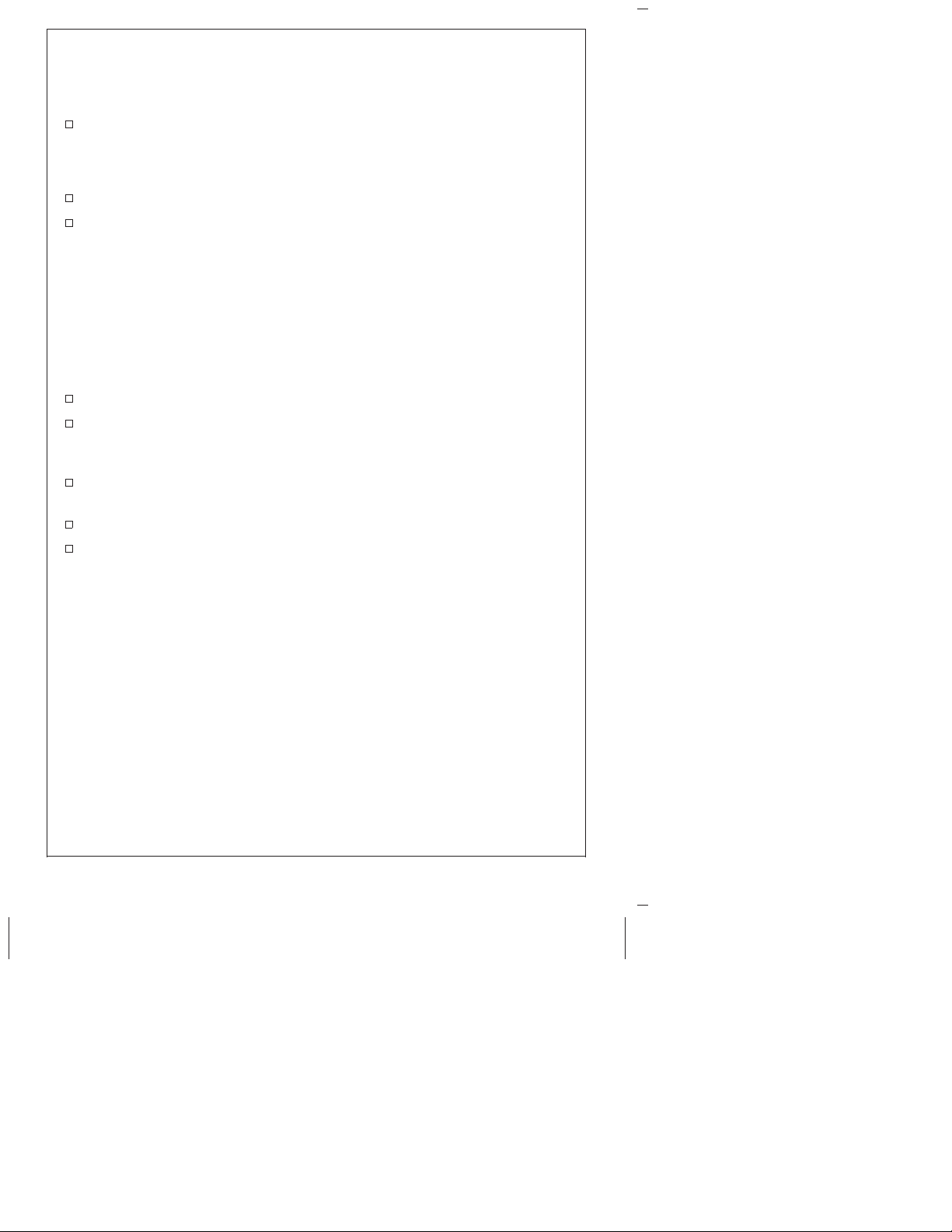

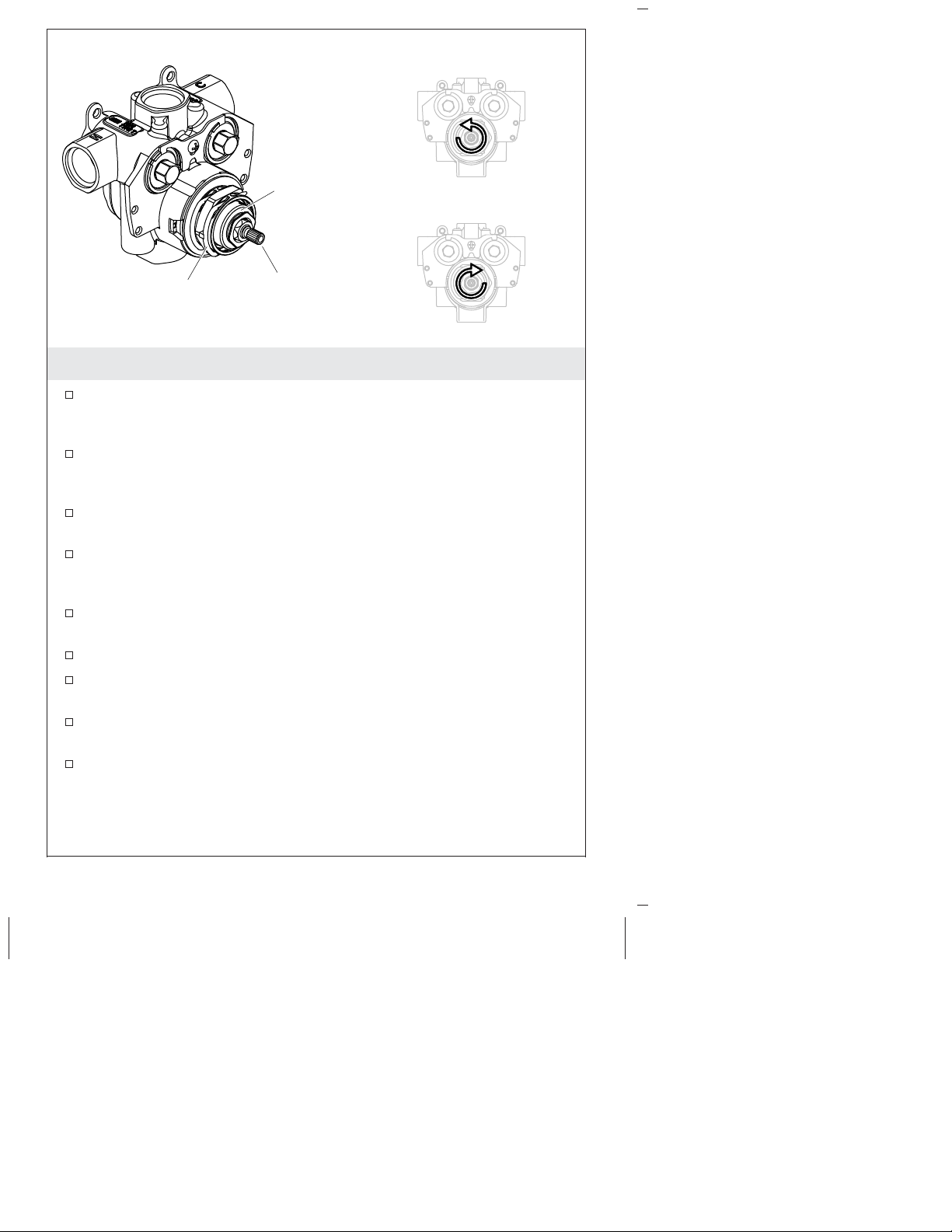

Turn integral supply stops 90˚

Supplies Closed

for OPEN/CLOSE.

Locking Bar

Supplies Open

Integral

Supply Stops

Integral Supply Stop Operation

NOTE: Use a socket wrench with 1/2″ (13 mm) socket to adjust the

stops.

Turn Off the Stops

Use a socket wrench to turn the integral stops 90°

counterclockwise to close both the hot and cold water inlet

supplies.

NOTE: If the inner body turns, but the outer ring does not turn,

firmly tighten (clockwise) the integral stop. Then rotate

counterclockwise. The outer ring should then turn with the integral

stop.

NOTE: If the outer ring still does not turn, slide the locking bar up

by loosening the screw. Free the integral stops by turning them

clockwise and then turn them back to their original position. Slide

the locking bar back in place and secure with the screw.

Confirm the stops are closed using the diagram above.

Turn the volume control counterclockwise to release excess water

(not shown).

1205551-2-C 16 Kohler Co.

Integral Supply Stop Operation (cont.)

The cartridge or check valves may now be removed for servicing

or replacement.

NOTE: Keep a rag handy to catch excess water that will gradually

drain when the valve cartridge is removed.

Kohler Co. 17 1205551-2-C

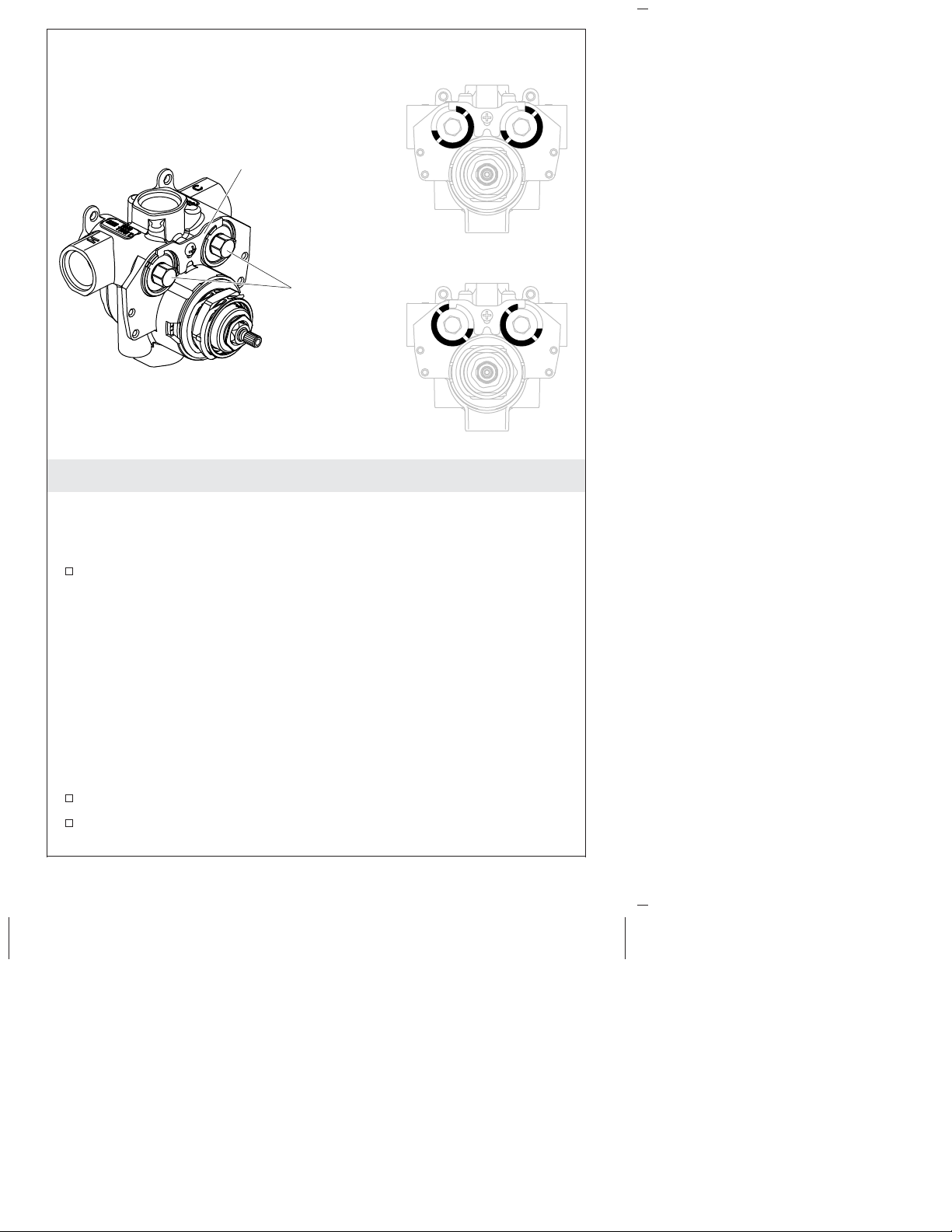

Twist.

Remove screen.

Servicing the Filters

Remove the trim.

Close both stops following the instructions in the previous

section.

Use a socket wrench with 1/2″ (13 mm) socket to remove the stop

assembly (hot is left side, cold is right side).

Remove the screen assembly by turning and pulling from the

check valve body.

Clean or replace the screen assembly as needed.

Clean or replace the check valve body as needed.

Reinstall the screen assembly to the check valve body by pushing

in and turning 90°.

Reinstall the check valve body by turning clockwise until it drives

the stop body open.

Open the supply stops and check for leaks.

Reinstall the trim.

1205551-2-C 18 Kohler Co.

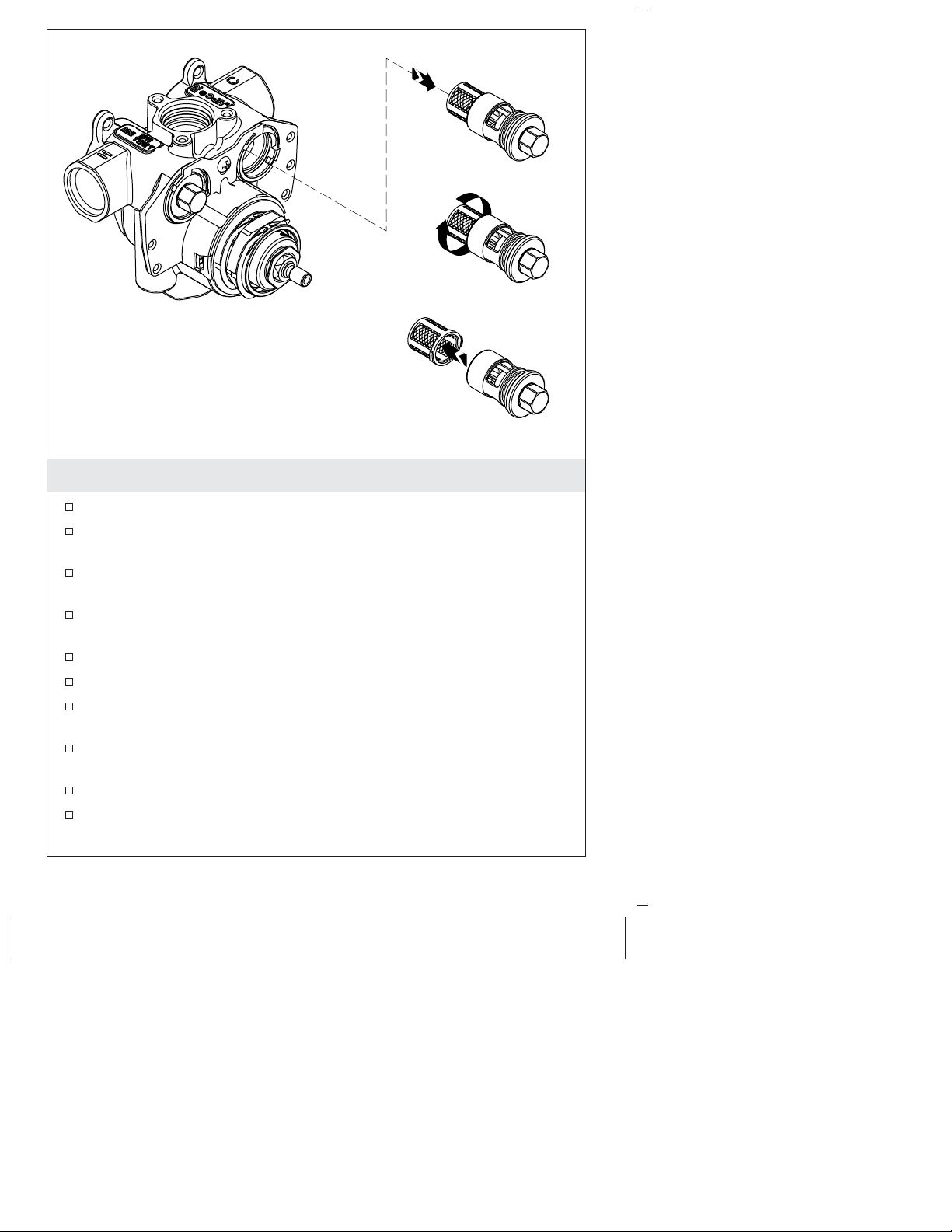

Increase Temperature

Spline

Adapter

Decrease Temperature

Check the Temperature Setting

NOTE: The thermostatic valve cartridge is calibrated at the factory

for a shower temperature of approximately 104°F (40°C) to 105°F

(41°C) and a maximum hot temperature of 120°F (49°C).

Turn the water on.

Attach a trim handle or plaster guard (found in volume control

valve K-2974 or K-2977 or transfer valve K-728) onto the valve

spline adapter.

Turn the spline adapter fully counterclockwise so the trim handle

or plaster guard can no longer move. The spline adapter is now

in the full hot position.

Allow the water to run for several minutes to stabilize the water

supply temperatures.

Position a thermometer in the water stream to check the

temperature of the hot water.

If the water temperature exceeds 120°F (49°C) or is less than

desired, proceed to the ″Adjust the Hot Temperature Limit″

section.

Turn the trim handle or plaster guard clockwise until you hear a

click. Do not turn any further. This is the shower temperature

position.

Remove the trim handle or plaster guard from the valve spline

adapter.

Kohler Co. 19 1205551-2-C

Check the Temperature Setting (cont.)

Position a thermometer in the water stream to check the shower

temperature.

If the water temperature is less than 104°F (40°C) to 105°F (41°C)

or is more than desired, proceed to the ″Adjust the Shower

Temperature″ section.

If both settings are correct, fill out the ″NOTICE TO

HOMEOWNERS″ section in the beginning of this document.

1205551-2-C 20 Kohler Co.

Head Nut

Valve Stem

Outer Clip

Spline Adapter

Detent Collar

Adjust the Hot Temperature Limit

Remove the outer clip from the head nut.

Remove the detent collar.

Remove the spline adapter.

NOTE: Keep the detent collar off while making adjustments.

Turn the valve stem fully counterclockwise.

Using the volume control valve (not shown), turn on the water.

Allow the water to flow for several minutes until the water

temperature stabilizes.

Kohler Co. 21 1205551-2-C

Adapter Tab

Hot Temperature

Limit Stop

Valve Stem

Spline Adapter

Hot Temperature

Limit Stop

Adapter Tab

Adjust the Hot Temperature Limit (cont.)

Using a thermometer, check the temperature of the water.

Turn the valve stem clockwise until the water temperature

reaches 120°F (49°C).

Reinstall the spline adapter with the adapter tab positioned flush

with the hot temperature limit stop on the cartridge.

Using the volume control valve (not shown), turn off the water.

1205551-2-C 22 Kohler Co.

Detent

Collar

Increase Temperature

Decrease Temperature

Outer Clip

Spline

Adapter

Adjust the Shower Temperature

If the detent collar is installed: Remove the outer clip and

disengage the detent collar from the teeth of the cartridge. Do not

remove the collar; allow it to hang from the cartridge.

If the detent collar is not installed: Loosely position the detent

collar over the cartridge, ensuring the collar does not engage the

cartridge teeth.

Place the trim handle (not shown) or plaster guard (not shown)

onto the valve spline adapter.

Turn the spline adapter fully counterclockwise so the trim handle

or plaster guard can no longer move. The spline adapter is now

in the full hot position.

Remove the trim handle or plaster guard from the valve spline

adapter.

Using the volume control valve (not shown), turn on the water.

Allow the water to flow for several minutes until the water

temperature stabilizes.

Hold a thermometer in the water stream to check the water

temperature.

Once the water temperature reaches the set hot temperature limit

(section ″Adjust the Hot Temperature Limit″) begin slowly

rotating the detent collar and spline adapter clockwise.

Kohler Co. 23 1205551-2-C

Adjust the Shower Temperature (cont.)

NOTE: While rotating the detent collar, small in-and-out

adjustments will be required to ensure the collar does not engage

the cartridge teeth. Use the detent collar to rotate the spline adapter.

While rotating the collar and spline adapter, monitor the water

outlet temperature.

When the temperature reaches 104-105°F (40-40.5°C), push the

detent collar in until it engages the teeth of the cartridge.

With the clip tab positioned toward the valve, reinstall the clip to

the head nut.

Using the volume control valve (not shown), turn off the water.

Troubleshooting

NOTICE: This section is for general aid only. For warranty

service, call 1-800-4KOHLER from within the USA and Canada, or

001-800-456-4537 from within Mexico.

For service parts information, visit your product page at

www.kohler.com/serviceparts.

Symptoms Probable Cause/Recommended Action

1. Only hot or cold water

from the water outlet.

2. Fluctuating or reduced

flow rate.

A. Inlet supplies are reversed. See

″Reverse the Inlet Supplies″ section.

B. Check filter screens for blockage.

Clear if necessary.

A. External condition variation such as

reduced pressure.

B. Check filter screens for blockage.

Clear if necessary.

C. Make sure that the minimum flow

rate is sufficient for supply conditions.

D. Make sure that dynamic inlet

pressures are nominally balanced and

sufficient.

E. Make sure that inlet temperature

differentials are sufficient.

F. Service stops are not fully opened.

Rotate both service stops clockwise until

fully open.

G. Check thermostatic performance;

replace the thermostatic cartridge, if

necessary.

1205551-2-C 24 Kohler Co.

Troubleshooting (cont.)

Symptoms Probable Cause/Recommended Action

3. No flow from shower

control water outlet.

4. Blend temperature drift. A. Indicates operating conditions have

5. Hot water in cold supply

or cold water in hot

supply.

6. Maximum blend

temperature setting too

hot or too cold.

7. Water leaking from the

valve body.

8. Flow knob or

temperature knob is stiff

to operate.

A. Filter screens are blocked. Clear filter

screens.

B. Hot or cold supply failure. Replace

the supply valve.

C. Flow control cartridge not working.

Check and replace if necessary.

D. Service stops are shut off. Rotate both

service stops clockwise until fully open.

changed. No action is needed.

B. Refer to symptom 2.

C. Hot supply temperature fluctuation.

D. Supply pressure fluctuation.

A. Indicates crossflow. Replace check

valve.

A. Indicates incorrect maximum

temperature setting; refer to the ″Adjust

the Hot Temperature Limit″ section.

B. Refer to symptom 4.

C. Refer to symptom 5.

A. Seal(s) worn or damaged. Obtain

service kit and replace seal(s).

B. If leaking from around the

temperature spindle, replace the

thermostatic cartridge.

A. Impaired free movement of internal

components. Replace the appropriate

cartridge.

B. Supply pressures are too high. Fit

pressure reducing valve.

Warranty

KOHLER®Faucet Lifetime Limited Warranty

Kohler Co. warrants its Faucets* manufactured after January 1, 1997, to

be leak and drip free during normal residential use for as long as the

original consumer purchaser owns his or her home. If the Faucet

should leak or drip during normal use, Kohler Co. will, free of charge,

mail to the purchaser the cartridge necessary to put the Faucet in good

working condition. This warranty applies only to Kohler Faucets

Kohler Co. 25 1205551-2-C

Warranty (cont.)

installed in the United States of America, Canada or Mexico (″North

America″).

Kohler Co. also warrants all other aspects of the faucet or accessories

(″Faucet″)*, (except gold, non-Vibrant

, non-chrome finishes) to be free

®

of defects in material and workmanship during normal residential use

for as long as the original consumer purchaser owns his or her home.

This warranty applies only to Kohler Faucets installed in North

America. If a defect is found in normal residential use, Kohler Co. will,

at its election, repair, provide a replacement part or product, or make

appropriate adjustment. Damage to a product caused by accident,

misuse, or abuse is not covered by this warranty. Improper care and

cleaning will void the warranty**. Proof of purchase (original sales

receipt) must be provided to Kohler Co. with all warranty claims.

Kohler Co. is not responsible for labor charges, installation, or other

incidental or consequential costs. In no event shall the liability of

Kohler Co. exceed the purchase price of the Faucet.

If the Faucet is used commercially or is installed outside of North

America, or if the finish is gold, non-Vibrant or a painted or powder

coated color finish, Kohler Co. warrants the Faucet to be free from

defects in material and workmanship for one (1) year from the date the

product is installed, under Kohler Co.’s standard one-year limited

warranty.

If you believe that you have a warranty claim, contact Kohler Co.,

either through your Dealer, Plumbing Contractor, Home Center or

E-tailer, or by writing Kohler Co., Attn.: Customer Care Center, 444

Highland Drive, Kohler, WI 53044, USA. Please be sure to provide all

pertinent information regarding your claim, including a complete

description of the problem, the product, model number, color, finish,

the date the product was purchased and from whom the product was

purchased. Also include your original invoice. For other information,

or to obtain the name and address of the service and repair facility

nearest you, call 1-800-4-KOHLER (1-800-456-4537) from within the

USA and Canada, and 001-800-456-4537 from within Mexico, or visit

www.kohler.com within the USA, www.ca.kohler.com from within

Canada, or www.mx.kohler.com in Mexico.

KOHLER CO. AND/OR SELLER ARE PROVIDING THESE

WARRANTIES IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO

THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. KOHLER CO. AND/OR

SELLER DISCLAIM ALL LIABILITY FOR SPECIAL, INCIDENTAL

OR CONSEQUENTIAL DAMAGES. Some states/provinces do not

allow limitations of how long an implied warranty lasts or the

1205551-2-C 26 Kohler Co.

Warranty (cont.)

exclusion or limitation of such damages, so these limitations and

exclusions may not apply to you. This warranty gives the consumer

specific legal rights. You may also have other rights that vary from

state/province to state/province.

This is Kohler Co.’s exclusive written warranty.

*Trend

components; WaterHaven

faucets, MasterShower®tower, BodySpa systems and

®

tower, systems and components; Tripoint

®

®

faucets, Polished Gold, non-Vibrant and painted or powder coated

finishes, fittings; all items within the ″Fixture Related″ section of the

Kohler Faucets Price Book, drains, Duostrainer

sink strainers,

®

soap/lotion dispensers, Moxie®Wireless Speaker; and faucets used in

commercial settings, and outside North America, are covered by

Kohler Co.’s one-year limited warranty.

**Never use cleaners containing abrasive cleansers, ammonia, bleach,

acids, waxes, alcohol, solvents or other products not recommended for

chrome. This will void the warranty.

Kohler Co. 27 1205551-2-C

Loading...

Loading...