Page 1

TECHNICAL DATA /

BLACK-AND-WHITE FILM

K OD AK PR OFESSIONAL Technical

Pan Film

• Laser recording

—NOTICE—

Discontinuance of

KODAK PROFESSIONAL Technical Pan Film

KODAK PROFESSIONAL Technical Pan Film is being

discontinued due to steadily declinin g deman d over the recent

years. Changes in product component s and our manuf acturing

processes make it impractical to continue to support this

product at its current low le vels.

The last Tech Pan coating was several years ago. Since that

time, the old coating room has been shut down, the gels used

in the product formulation have become obsolete, and we no

longer manufacture the ESTAR support on which the 35 mm

product was coated. There would be consider able cost to

recreate the product, with no guarantee that it would look and

act the same as the Tech Pan Film of old.

Technical Pan Film will continue to be available until the

existing inventory has been depleted.

• Other applications such as slide making, copying, and

microfilming that require high or moderately high

contrast combined with fine grain and high resolving

power

SIZES AVAILABLE

Sizes and CAT numbers may differ from country to country.

See your dealer who supplies KODAK PROFESSIONAL

Products.

KOD AK PROFESSIONAL Technical Pan Film 2415

Size

mm x ft

35 x 150 2415

Film

Code

Base Sp No.

4-mil

(0.10 mm)

ESTAR-AH

June 2003 • P-255

Letter

Code

442 TP 129 9916

CAT No.

While there is no direct replacement for Tech Pan Film, you

may find KODAK PROFESSIONAL T-MAX 100 Film in

combination with specific B&W Developers to be a viable

alternative for some applications.

KODAK PROFESSIONAL Technical Pan Film is Kodak’s

slowest and finest-grained black-and-white film for pictorial

photography (when developed in KODAK TECHNIDOL

Liquid Developer). It is a variable-contrast panchromatic

film with extended red sensitivity; because of its extended

red sensitivity, it yields prints with a gray-tone rendering

slightly different from that produced by other panchromatic

films. (This is most noticeable in portraits, in which it

suppresses blemishes.)

Use this film for pictorial, scientific, technical, and

reversal-processing applications. It is an excellent choice for

making big enlargements or murals.

APPLICATIONS

You can vary the contrast of KODAK PROFESSIONAL

Technical Pan Film by modifying development. The wide

range of contrast levels, along with the spectral sensitization

and combination of speed and image-structure properties,

makes this film unusually versatile and suitable for many

applications:

• Pictorial photography

• Photomicrography

• Microphotography (Microfilming)

• Solar photography

• Photographing electrophoretic gels

Size

135-36 2415

KOD AK PROFESSIONAL Technical Pan 4415

Sheets

Per

Package

50 4 x 5

50 8 x 10 852 1817

KOD AK PROFESSIONAL Technical Pan Film 6415

Size

120 6415

Film

Code

Sizes

(inches)

Film

Code

Base

4-mil

(0.10 mm)

ESTAR-AH

Film

Code/Notch

Base

3.6-mil

(0.091 mm)

acetate

Letter

Code

Base CAT No.

7-mil

(0.18 mm)

ESTAR

Thick

Letter

Code

CAT No.

TP 129 7563

882 6596

CAT No.

TP 151 1054

Because 2415 Film has a thinner base than conventional

35 mm picture-taking films, 150-foot rolls finished to Sp 442

will fit in bulk-film loaders designed to accept 100-foot rolls.

Other sizes are available on a special-order basis, subject

to manufacturing limitations and current minimum-order

requirements. Minimum-order quantities for special-ord e r

sizes are generally 750 square feet (70 square metres) of

film.

©Eastman Kodak Company, 2000

Page 2

SPECTRAL SENSITIVITY

Technical Pan Film has reasonably uniform spectral

sensitivity at all visible wavelengths out to 690 nanometres

(nm). Because of this extended red sensitivity, red areas and

flesh tones may appear lighter than they would with

conventional black-and-white films. This is often an

advantage. For example, it helps conceal some skin

blemishes and often adds a pleasing luminous quality to skin

tones. (This effect is less evident in portraits made in the

shade outdoors, because there is less red light present.)

To approximate the response of conventional

panchromatic films more closely, make exposures through a

color-compensating filter such as a KODAK Color

Compensating Filter CC40C or CC50C (cyan). With this

filter, no exposure compensation is necessary; however,

there may be a slight loss in sharpness.

STORAGE AND HANDLING

High temperatures or high humidity may produce unwanted

quality changes. Store unexposed film at 75°F (24°C) or

lower in the original package. Always store film (exposed or

unexposed) in a cool, dry place. For best results, process film

as soon as possible after exposure.

Load and unload roll-film cameras in subdued light, and

rewind the film completely before unloading the camera.

Total darkness is required when you remove film from the

magazine or load and unload film holders.

Protect processed film from strong light, and store it in a

cool dry place. For more information on storing negatives,

see KODAK Publication No. E-30, Storage and Care of

Photographic Materials—Before and After Processing.

Exposure- and Contrast-Index Values for Various

Development Conditions

Contrast

Index

High 2.50 DEKTOL 3 200

2.40 to 2.70 D-19 (1:2) 4 to 7 100 to 160

2.25 to 2.55 D-19 2 to 8 100 to 200

1.20 to 2.10 HC-110 (Dil B) 4 to 12 100 to 250

1.25 to 1.75 HC-110 (Dil D) 4 to 8 80 to 125

1.10 to 2.10 D-76 6 to 12 64 to 125

1.00 to 1.50 MICRODOL-X 8 to 12 32 to 50

0.80 to 0.95 HC-110 (Dil F) 6 to 12 32 to 64

0.50 to

Low

0.70

KODAK

Developer

TECHNIDOL

Liquid

Development

Time

(minutes at

68°F [20°C])

5 to 11 16 to 25

Exposure

Index

For pictorial applications, use EI 25/15° and process the

film in KODAK TECHNIDOL Liquid Developer. (Refer to

“PROCESSING.”)

For high-contrast reversal-processing applications, use

EI 64/19° to produce slides from high-contrast subjects such

as line art. Process the film with the KODAK

PROFESSIONAL T-MAX 100 Direct Positive Film

Developing Outfit.

Filter Factors

Multiply the normal exposure by the filter factor indicated

below. If you use a through-the-lens meter, take the meter

reading without the filter over the lens, and then calculate

your exposure by using the filter factor. Where no filter

factor is listed in the table, no test was made with that filter.

EXPOSURE

The speed of this film depends on the application, the type

and degree of development, and the level of contrast

required. Therefore, no single speed value applies for all

situations. (Speed ratings may ra nge from a lo w of EI 16 for

pictorial photography to a high EI 320 for microfilming. Use

the exposure indexes in the following table with meters

marked for ISO, ASA, or DIN speeds or exposure inde xes.

They are intended for trial exposures.

You can expose this film with daylight or tungsten light.

Exposure to tungsten illumination produces a 10-percent

increase in speed and a 5-percent increase in contrast.

KODAK WRATTEN

Gelatin Filter

No.8 (yellow) 1.2 1.5

No. 11 (yellowish green) 5 —

No. 12 (deep yellow) 1.2 —

No. 15 (deep yellow) 1.2 2

No. 25 (red) 2 3

No. 47 (blue) 25 12

No. 58 (green) 12 —

* Based on a 1-second exposure and development in KODAK HC-110

Developer (Dilution D) for 8 minutes at 68°F (20°C).

† Based on a 1/25-second exposure and development in KODAK

TECHNIDOL Liquid Developer for 9 minutes at 68°F (20°C).

Tungsten

Filter Factor

Daylight

*

Filter Factor

†

2 KODAK PROFESSIONAL Technical Pan Film • P-255

Page 3

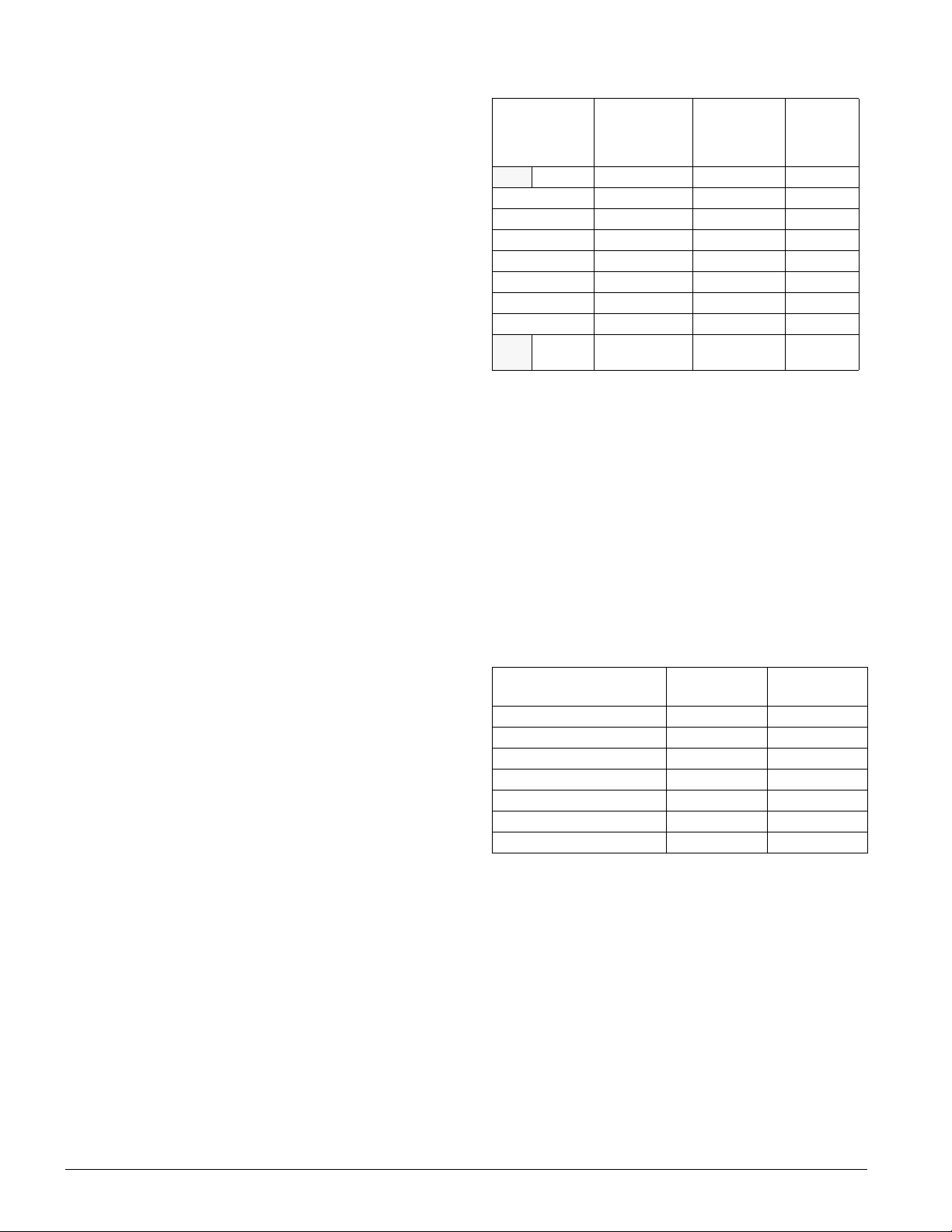

Adjustments for Long and Short Exposures

Compensate for the reciprocity characteristics of this film by

increasing exposure and adjusting the development as

shown.

If Indicated

Exposure

Time Is

(seconds)

Use This

Lens-

Aperture

Adjustment

OR

1/10,000 None None +30%

1/1,000 None None +20%

1/100 None None None

1/10 None None None

1 None None –10%

10 +

100 +1

1

⁄

stop 15 –10%

2

1

⁄

stops

2

Exposure- and Contrast-Index Values for Processing in the

KODAK VERSAMAT Film Processor, Model 11

This

Adjusted

Exposure

Time

(seconds)

Adjust

aperture

AND

Use This

Development

Adjustment

None

DARKROOM RECOMMENDATIONS

Handle unprocessed film in total darkness. After

development is half completed, you can use a KODAK

3 Safelight Filter (dark green) in a suitable safelight lamp

with a 15-watt bulb. Keep the safelight at least

4 feet (1.2 metres) from the film.

For information on safelight testing, see KODAK

Publication K-4, How Safe Is Your Safelight?

Contrast

Index

KODAK

Developer

Development

Temperature

°F (°C)

Machine

Speed

(ft/min)

Developer

Racks

2.20 VERSAMAT 885 85 (29.4) 10 1 160/23°

1.40 VERSAMAT 641 85 (29.4) 10 1 125/22°

1.40 DURAFLO RT 80 (26.5) 10 2 160/23°

* Based on a 1/25-second daylight exposure

Changes in Speed and Contrast

Due to Long- and Short-Exposure Adjustments

Camera

Stops

0

1

3

2

3

1

1

1

3

2

1

3

Exposure:

Process:

8 minutes at 68 F (20 C)

1

1

5000

500

250010000

1

1

1000

SPEED SHIFT

Tungsten or Daylight

KODAK HC-110 Developer (Dil D),

CONTRAST-INDEX SHIFT

1

1

100

1

1

50

250

Time (seconds)

1

215110125

32842101

Log

Exposure

0.10

0.00

0.10

0.20

0.30

0.40

C.I.

0.10

0.00

0.10

0.20

100

Exposure

Index

ISO/DIN

*

F002_0195AC

P-255 • P-255 3

Page 4

SPECIFIC APPLICATIONS

Pictorial Photography

These films produce high-quality pictorial negatives when

processed in KODAK TECHNIDOL Liquid Developer . (See

“PROCESSING.”) Conventional de velopers generally

produce contrast too high for normal pictorial photography.

Process the film according to the instructions for KODAK

TECHNIDOL Liquid Developer.

In pictorial applications, the fine grain permits

enlargements at magnifications of 25X or more with little

perceptible grain. The extended red sensitivity has a

haze-cutting effect in photographs of distant landscapes and

in aerial shots.

Use an exposure index of 25 for trial exposures.

Copy Applications

Y ou can use these films for copying printed material, making

reverse-text title slides, and copying continuous-tone

photographs.

Use two lamps. Place one on each side of the copy

material so that each light strikes the material at about a

45-degree angle. For originals larger than 16 x 20 inches

(40 x 50 cm), you may need four lamps (two on each side)

for uniform illumination. Determine the exposure with a

meter.

If you use a camera with a through-the-lens meter, take the

reading from a gray card in the copy position. The meter

could give you an incorrect reading from the copy itself,

depending on the amount of text.

If you do not use an exposure meter, try these starting

points: With two No. 2 photolamps in matte-surface

reflectors at about 4 feet (1.2 metres) from the copyboard,

use 1/60 second at ƒ/8. With two No. 1 photolamps, increase

the exposure by one stop.

With meters marked for ISO (ASA/DIN) speeds or exposure

indexes, use these film-speed values:

Starting-Point Exposures for Copying Printed

Materials: With meters marked for ISO (ASA/DIN) speeds

or exposure indexes, use these film-speed values:

• Tungsten 320/26°—for incident-light readings or for

reflected-light readings from a gray card (18-percent

reflectance) at the copyboard.

• Tungsten 64/19°—for reflected-light readings from a

matte white card (90-percent reflectance) at the

copyboard.

Note: These values are based on small-tank development in

KODAK Developer D-19 for 4 minutes at 68°F (20°C) with

agitation at 30-second intervals.

The exposure index is based on the formula EI = 36/H,

where H is the 1-second exposure in lux-seconds required to

produce a density of 1.20 above minimum density with the

indicated development.

Starting-Point Exposures for Making Reverse-Text

Slides: With exposure meters marked for ISO (ASA/DIN)

speeds or exposure indexes, use these film-speed values:

• Tungsten 200/24°—for incident-light readings or for

reflected-light readings from a gray card (18-percent

reflectance) at the copyboard.

• Tungsten 40/17°—for reflected-light readings from a

matte white card (90-percent reflectance) at the

copyboard.

Note: These values for reverse-text slides are based on

development in KODAK DEKTOL Developer for 3 minutes

at 68°F (20°C).

The exposure index is based on the formula EI = 10/H,

where H is the 1-second exposure in lux-seconds required to

produce a density of 0.60 above minimum density with the

indicated development.

Copying Continuous-Tone Photographs: To copy

continuous-tone photographs, use an exposure-index value

to achieve a gamma value between 0.6 and 1.0, depending on

the contrast of the original. For low-contrast originals, you

can try KODAK HC-110 Developer (Dilution B) for

6 minutes (EI 160); for higher-contrast originals, use

KODAK TECHNIDOL Liquid Developer for 9 minutes

(EI 25).

Microphotography (Microfilming)

The resolving power of Technical Pan Film allows

microfilming of most documents at reductions of up to 20X,

assuming that the copying lens is of high quality and is

carefully focused. The film plane and the plane of the

copyboard must be parallel to provide sharp focus over the

whole image area. When you photograph black-and-white

originals, use a green filter such as a KODAK WRATTEN

Gelatin Filter No. 58 or 61. This will help suppress the

chromatic aberrations found in most lenses that would be

emphasized by the extended red sensitivity of the film.

For optimum image quality, adjust the exposure to

achieve a negative density of 1.20 in the areas that

correspond to the white or light-colored areas of the original.

Process the film to a gamma of 2.0 in KODAK HC-110

Developer (Dilution D) for 8 minutes at 68° F (20°C)

(EI 125).

Photographing Electrophoretic Gels

Electrophoretic gels are often photographed to produce

prints for information storage, analysis, display, and

publication. KODAK PROFESSIONAL Technical Pan

Films yield high-quality black-and-white negatives from

which you can make high-quality prints of these gels. Adjust

exposure carefully to minimize the appearance of the gel

background tint in the prints.

Make tests to determine exposures for your lighting

conditions. Develop the film for 4 minutes in KODAK

HC-110 Developer (Dilution D) at 68°F (20°C) (EI 80).

TECHNIDOL Liquid Developer may also work with your

setup.

4 KODAK PROFESSIONAL Technical Pan Film • P-255

Page 5

Photomicrography

The low contrast of most microscopic subjects often requires

a contrast-enhancing film-and-developer combination and

(with stained specimens) a contrast-enhancing filter. For

routine photomicrography of H and E-stained tissue, try a

broad-band yellow-green filter (e.g., a KOD AK WRATTEN

Gelatin Filter No. 11) at a tungsten exposure index of 50,

developed in HC-110 Developer (Dilution B) for 8 minutes

at 68°F (20°C). Negatives should print easily and with good

contrast on normal-contrast paper. (If negatives are too

dense, use a higher exposure index; if too thin, use a lower

one. If contrast is too low , increase the de v elopment time; if

too high, decrease the time.)

For phase-contrast and differential-contrast techniques,

try a tungsten exposure index of 100, and develop in HC-110

Developer (Dilution D) for 6 minutes at 68°F (20°C). (If

necessary, adjust the exposure index or development as

described above.) This method may also be suitable for

banding techniques in chromosome photomicrography.

When you want maximum contrast, as in older karyotyping

methods, use a tungsten exposure index of about 125, and

develop in Developer D-19 for 4 minutes at 68°F (20°C).

(Because of the differing spectral sensitivities of microscope

photocells and the special characteristics of Technical Pan

Films, these exposure index recommendations cannot be

exact.)

Metallographers can easily select development conditions

from the characteristic curves shown in this pamphlet, based

on the contrast index they have used successfully with other

materials.

Electron Micrography

Use Technical Pan Film to record the output of the

fiber-optic faceplate in transmission electron microscopes

and to provide optimum contrast and resolution for

biological specimens.

Make tests to determine exposures for the accelerating

voltage and magnification. Develop for 5

Developer D-19 (1:2) at 68°F (20°C) or for 4 minutes in

Developer D-19 (full strength) at 68°F (20°C). For less

contrast, process for 8 to 12 minutes in HC-110 Developer

(Dilution B) at 68°F (20°C).

1

⁄

minutes in

2

Astronomical Photography

The extended red sensitivity of Technical Pan Films makes

them especially suited to solar photography at the H-alpha

line (656 nm), and their reasonably uniform spectral

sensitivity over the visible region of the spectrum makes them

most useful for solar filtergrams. They are also useful for

lunar and planetary photography. The extremely fine grain

and high resolving power, coupled with high-contrast

development (with Developer D-19, for example) permits

reproduction of very fine detail on objects in the solar system.

You can use these films for stellar photography, but first

hypersensitize them with forming gas or silver nitrate to

improve the film response with the long exposures required.

(For information on hypersensitization of Technical Pan

Films, see the American Astronomical Society

Photo-Bulletin, Issue No. 24, 1980, No. 2.)

Laser Photography

The extended red sensitivity of these films makes them very

useful in applications in which the exposing radiation is from

helium-neon lasers (633 nm) or red-light-emitting diodes

(typically 640 to 650 nm).

For example, Technical Pan Films are frequently

recommended for photographing holograms reconstructed

with the helium-neon lasers. Since the range of scene

brightnesses that can be recorded and reconstructed

holographically is inherently great, it is sometimes

appropriate to process the film to a low contrast (contrast

index of 0.5 to 0.6). However, in holographic interferometry,

processing the film to a contrast index of 1.5 or more will

enhance the visibility of the interferometric fringe by

increasing its modulation. Try HC-110 Developer

(Dilution B).

In image-recording or plotting applications, you can

control the film contrast during processing to convert the

modulation range of the recorder to the density range you

want on the film.

KODAK PROFESSIONAL Technical Pan Film • P-255 5

Page 6

PROCESSING

Handle unprocessed film in total darkness. After

development is half complete, you can use a suitable a

safelight lamp equipped with a KODAK 3 Safelight Filter

(dark green) and a 15-watt bulb for a few seconds. Keep the

safelight at least 4 feet (1.2 metres) from the film.

When you use these films for pictorial applications, you

must select a film-and-developer combination carefully.

With 35 mm Technical Pan Film, use TECHNIDOL Liquid

Developer. With Technical Pan Film / 4415 and 6415 (sheets

and 120 size), use only TECHNIDOL Liquid Developer.

Observe the precautionary information on the developer

packaging.

KODAK TECHNIDOL Liquid Developer

Small-Tank Processing (rolls)

You can process roll film in small 8- or 16-ounce

stainless-steel or 10- or 20-ounce plastic tanks with spiral

reels using the following instructions. With some spiral reels,

the 35 mm film may be susceptible to nonuniform processing

effects if agitation is not carefully controlled. Pouring the

developer on dry film through the light trap in the tank top

can also produce nonuniformity. To avoid processing

problems, pour the developer into the tank before you insert

the loaded reel, and follow the agitation recommendations

below.

KODAK TECHNIDOL Liquid Developer

Temperature 68°F (20°C) 77°F (25°C) 86°F (30°C)

Time 9 minutes 7

* With 35 mm film only

Development Times for

in Stainless-Steel 8- or 16- oz

or Plastic 10- or 20-oz Tanks

1

⁄

minutes 6

2

1

⁄

minutes

2

1. Fill the tank with developer adjusted to one of the

temperatures in the table.

2. In total darkness, drop the loaded reels into the tank of

solution and attach the top to the tank.

3. Firmly tap the bottom of the tank on the top of the work

surface to dislodge any air bubbles. (You can then turn

on the room lights.)

4. Provide immediate agitation by shaking the tank

vigorously up and down 10 to 12 times for 2 seconds.

Do not rotate the tank.

Liquid Developer Agitation Technique

*

Preparing a Working Solution: Mix your liquid developer

according to the instructions packaged with the developer.

Use water at 68 to 86°F (20 to 30°C).

To process one roll of 135-36 film, make 8 fl oz (237 mL)

of developer solution. Stir until the solution is completely

mixed. To process one 120-size roll or two 135-36 rolls of

film in the same process, prepare one pint (16 fl oz [473 mL])

of developer.

You can reuse the developer if you increase the

development time of the second process by 1 minute. Store

the developer in an air-tight bottle, and use it within a week.

Processing with TECHNIDOL Liquid Developer in a

Small Tank: The following procedure may vary from the

instructions provided with your tank, but you must follow it

to obtain good results.

Develop roll film for the amount of time in the table below,

according to the developer temperature you choose.

F002_0196AC

5. Let the tank sit for 30 seconds, and then start the next

2-second agitation.

6. Repeat steps 4 and 5 every 30 seconds for the remainder

of the development time.

6 KODAK PROFESSIONAL Technical Pan Film • P-255

Page 7

Final Steps in Tank Processing—

68 to 86°F (20 to 30°C)

Processing with TECHNIDOL Liquid Developer in a

Tray: Use the special agitation procedure described below

for best processing uniformity in a tray.

Step/Solution

Rinse — with agitation:

KODAK Indicator Stop Bath 0:15 to 0:30

KODAK EKTAFLO Stop Bath 0:15 to 0:30

Fix — with frequent agitation:

KODAK PROFESSIONAL Fixer 2:00 to 4:00

KODAK Rapid Fixer 1:30 to 3:00

KODAFIX Solution 2:00 to 4:00

Wash:

Running water 5:00 to 15:00

—OR—

Rinse with water

KODAK Hypo Clearing Agent

Running water

Final rinse:

KODAK PHOTO-FLO Solution 0:30

Dry — in a dust-free place

Note: Keep the rinse and fix temperatures within 3°F (1.7°C)

of the developer temperature, and the wash temperature

within 5°F (3°C) of the developer temperature.

Rinse the film in KODAK Indicator Stop Bath or KODAK

Time

(min:sec)

0:15

1:30

5:00

Presoak the film in water at 68°F (20°C) for approximately

1

2

⁄

minutes.

2

1. Locate the code notch and identify the emulsion side of

the film. Turn the first sheet so that the emulsion side

faces up and the code notch is in the lower left-hand

corner; place the sheet in the water presoak.

2. Agitate the film for 5 seconds. Place the next sheet of

film on top with the emulsion side up and the code notch

in the upper right-hand corner. (This will help you

identify the first sheet of film later.) Repeat this step for

the remaining sheets.

3. When all the sheets are in the presoak, begin timing for

1

2

⁄

2

sheet out every 5 seconds and placing it on top. Be sure

to keep the film emulsion side up and to keep the stack

immersed.

4. After 2

allow it to drain. Using the same code-notch orientation,

quickly place the sheet in the developer and agitate for

about 10 seconds. Move the remaining sheets to the

developer one at a time, agitating each for 10 seconds.

Be careful that they don’t scratch each other.

EKTAFLO Stop Bath for 15 to 30 seconds. Use running

water for 30 seconds if you don’t use a stop bath.

Fix the film with frequent agitation in KOD AK Rapid Fixer

1

for 1

⁄

to 3 minutes. Or use KODAK PROFESSIONAL

2

Fixer or KODAFIX Solution for 2 to 4 minutes.

Wash the film in clean running water for 5 to 15 minutes.

To save time and conserve water, use KODAK Hypo

Clearing Agent. Rinse the fixed film in running water for

15 seconds. Bathe the film in KODAK Hypo Clearing Agent

for 1 to 2 minutes with agitation. Then wash the film for

5 minutes in running water, providing at least one change of

water during the 5 minutes.

Develop at 68°F (20°C) for 8 minutes. Be sure the developer

is at 68°F (20°C). Agitate the film in the developer as you did

in the presoak. However, increase the rate of the initial

agitation by going through the stack of film four times in the

first minute of development. After 1 minute, take the entire

stack of film and turn it 180 degrees. Continue the agitation

at the normal rate of going through the stack twice per

minute for the rest of the development time. Continue

rotating the film as follows:

After this

many minutes

Dry the film in a dust-free place. To minimize drying marks,

treat the film with KODAK PHOTO-FLO Solution after

washing, or wipe the surface carefully with a soft viscose

sponge.

You can use heated forced air at 100°F (38°C) to reduce

drying time.

minutes. Agitate carefully by pulling the bottom

1

⁄

minutes, locate the first sheet, remove it, and

2

Rotate

the stack

2 90° left

3 180° left

4 90° right

5 180° right

6 90° left

7 180° left

To the

Tray Processing (sheets)

Mix 1 quart (32 fl oz [946]) of TECHNIDOL Liquid

Developer at one-half the working strength you’d use for roll

films. That is, use 2 packets of dev eloper concentrate and add

enough water at 68°F (20°C) to make 1 quart. Stir until the

developer is completely mixed.

You can develop the equivalent of twelve 4 x 5-inch

sheets of film in this amount of solution. Do not reuse this

solution for a second batch even if your first batch consisted

of fewer than twelve sheets.

KODAK PROFESSIONAL Technical Pan Film • P-255 7

Page 8

Final Steps in Tray Processing—

65 to 70°F (18 to 21°C)

Other KODAK Developers

To process these films in the other developers listed in the

table Exposure- and Contrast-Index Values for Various

Step/Solution

Rinse — with agitation:

KODAK Indicator Stop Bath 0:15 to 0:30

KODAK EKTAFLO Stop Bath 0:15 to 0:30

Fix — with frequent agitation:

KODAK PROFESSIONAL Fixer 2:00 to 4:00

KODAK Rapid Fixer 2:00 to 4:00

KODAFIX Solution 2:00 to 4:00

Wash:

Running water 5:00 to 15:00

—OR—

Rinse with water

KODAK Hypo Clearing Agent

Running water

Final rinse:

KODAK PHOTO-FLO Solution 0:30

Dry — in a dust-free place

Time

(min:sec)

0:15

1:30

5:00

Development Conditions or the Quick Reference Guide to

Developers, follow the instructions for your tank.

Before using any developer, make sure that the solution is

free of small air bubbles. If bubbles adhere to the emulsion,

they may cause small undeveloped clear spots on the film

(dark spots on the print). Bubbles may form more easily if

you mix cold and hot water. If bubbles do form, let the

developer stand until they dissipate. Attaching an aerator to

the water supply will help eliminate small bubbles.

Develop to the contrast index for your application; see

“Exposure” and the characteristic curves. The contrast index

depends primarily on the developer, temperature, dilution,

and processing technique. It is affected less by exposure time

and normal product variability.

KODAK VERSAMAT 641 Developer Replenisher

KODAK VERSAMAT 641 Developer Starter

KODAK VERSAMAT 641 Fixer and Replenisher

Processing Sequence

Rinse the film at 65 to 70°F (18 to 21°C) in KODAK

Indicator Stop Bath or KODAK EKTAFLO Stop Bath for

15 to 30 seconds. Use running water for 30 seconds if no stop

bath is available.

Put the first sheet into the stop bath and agitate vigorously.

Put the remaining sheets into the stop bath one at a time, and

agitate each vigorously for about 5 seconds. Go through the

stack at the normal pace.

Fix the film at 65 to 70°F (18 to 21°C) in KODAK

PROFESSIONAL Fixer, KODAK Rapid Fixer, or

KODAFIX Solution for 2 to 4 minutes. Move the sheets to

the fixer one at a time. Continue the agitation.

Wash the film in running water at 65 to 70°F (18 to 21°C)

for 5 to 15 minutes. T o sav e time and conserve water , you can

use KODAK Hypo Clearing Agent. First rinse the film in

running water for 15 seconds. Tr ansfer the stack of film to

the hypo clearing agent solution and agitate for 1

1

⁄

minutes.

2

Then wash the film for 5 minutes in running water, providing

at least one change of water during this time. Treat the film

with KODAK PHOTO-FLO Solution and hang it up to dry;

do not squeegee.

Step

Develop 1 4 ft (1.2 m)

Fix 3 12 ft (3.8 m)

Wash 2 8 ft (2.4 m)

Dry — 8 ft (2.4 m)

To produce a contrast i ndex of about 1.4, start with a machine

speed of 10 feet per minute (3.05 m/min).

No. of

Racks

Path

Length

Temperature

85 ±0.5°F

(29.4 ±0.3°C)

85°F (29°C)

nominal

75 to 80°F

(24 to 27°C)

135 to 140°F

(57 to 60°C)

KODAK VERSAMAT 885 Developer Replenisher

KODAK VERSAMAT 885 Developer Starter

KODAK VERSAMAT 885 Fixer and Replenisher

Processing Sequence

Step

Develop 1 4 ft (1.2 m)

Fix 3 12 ft (3.8 m)

Wash 2 8 ft (2.4 m)

Dry — 8 ft (2.4 m)

To produce a contrast index of about 2.2, start with a machine

speed of 10 feet per minute (3.05 m/min). You will obtain

adequate washing at speeds up to 15 feet per minute

(4.5 m/min).

No. of

Racks

Path

Length

Temperature

85 ±0.5°F

(29.4 ±0.3°C)

85°F (29°C)

nominal

75 to 80°F

(24 to 27°C)

135 to 140°F

(57 to 60°C)

8 KODAK PROFESSIONAL Technical Pan Film • P-255

Page 9

KODAK DURAFLO RT Developer Replenisher

KODAK DURAFLO RT Developer Starter

KODAK Rapid Fixer

Processing Sequence

Step

No. of

Racks

Develop 1 8 ft (2.4 m)

Fix 3 12 ft (3.8 m)

Wash 2 8 ft (2.4 m)

Dry — 8 ft (2.4 m)

To produce a contrast index of about 1.4, start with a machine

speed of 8 feet per minute (2.4 m/min). Washing at this speed will

not provide archival quality, but it should be adequate for many

scientific recording applications.

* Use a lower dryer temperature (95 to 110°F or 35 to 44°C) with 2415

Film if spots form due to rapid drying. Lower temperatures may also be

adequate if you are drying only roll film.

Path

Length

Temperature

80 ±0.5°F

(27 ±0.3°C)

80°F (27°C)

nominal

70 to 75°F

(21 to 24°C)

135 to 140°F

(57 to 60°C)

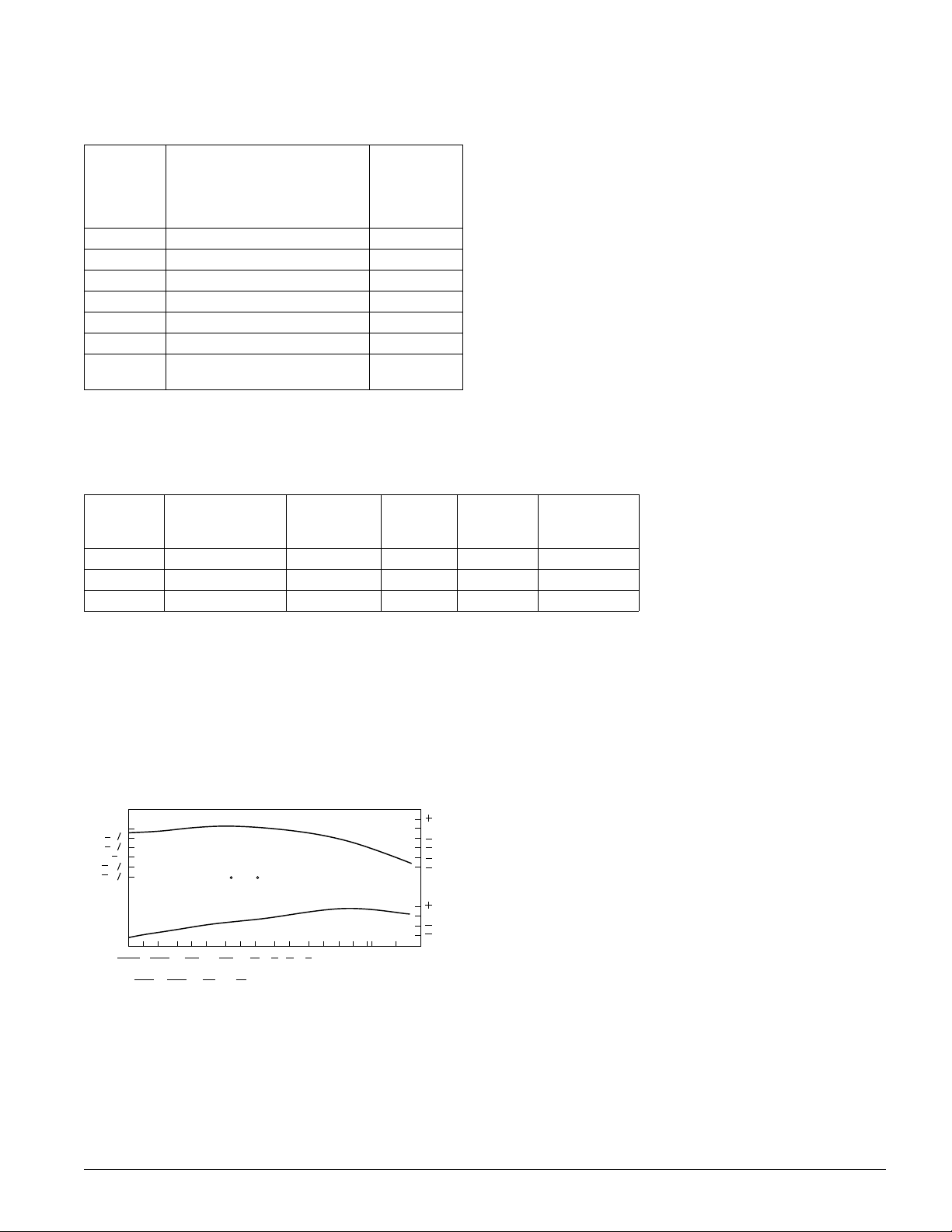

Spectral-Sensitivity Curves

3.0

Effective Exposure:1.4 sec visible, 0.2 sec ultraviolet

Process:

2.0

*

1.0

LOG SENSITIVITY

0.0

*

1.0

F002_0194AC

KODAK HC-110 Developer (Dil D),

8 minutes at 68 F (20 C)

Diffuse Density=

0.3 above D-min

Diffuse Density=

1.0 above D-min

WAVELENGTH (nm)

*Sensitivity = reciprocal of exposure (erg/cm ) required

to produce specified density

2

700 750650600550500450400350300250

Modulation-Transfer Curves

200

PRINTING

The 0.1 neutral density built into the ESTAR-AH Base is

one-half to one-third that found in conventional 35 mm

picture-taking films. Correctly exposed and processed

pictorial negatives may appear to be “thinner” than normal.

It is important to take this into account when you judge the

printability of negatives.

The micro-fine grain of Technical Pan Film makes

possible printing at higher magnifications than are usually

acceptable with conventional picture-taking films.

Enlargements made at magnifications greater than 25X with

highly specular (point-source) enlargers may show a random

distribution of poorly defined white specks in otherwise

dense areas. The specks are caused by tiny matte particles

coated on the back surface of the film. You can mask the

specks, with little loss in the overall sharpness of the image,

by using an enlarger with a diffuse or semi-diffuse light

source.

IMAGE-STRUCTURE CHARACTERISTICS

The data in this section are based on development at

68°F (20°C) in KODAK HC-110 De veloper (Dilution D) for

8 minutes or KODAK TECHNIDOL Liquid Developer for

9 minutes.

100

70

50

30

20

Process: Small tank,

10

7

5

RESPONSE (%)

3

2

TungstenExposure:

KODAK HC-110 Developer (Dil D),

8 minutes at 68 F (20 C);

KODAK TECHNIDOL Liquid Developer,

8 minutes at 68 F (20 C);

1

1001 2 3 4 5 10 20 50 200 600

SPATIAL FREQUENCY (cycles/mm)

F002_0180AC

NOTICE: The sensitometric curves and data in this

publication represent product tested under the conditions of

exposure and processing specified. They are representative

of production coatings, and therefore do not apply directly to

a particular box or roll of photographic material. They do not

represent standards or specifications that must be met by

Eastman Kodak Company. The company reserves the right

to change and improve product characteristics at any time.

KODAK Developer

HC-110 (Dilution D) TECHNIDOL Liquid

Diffuse rms

Granularity

* Read at a net diffuse density of 1.0 using a 48-micrometre aperture

and 12X magnification.

8 Extremely fine 5 Micro fine

*

KODAK PROFESSIONAL Technical Pan Film • P-255 9

Page 10

Characteristic Curves

4.0

3.0

2.0

DENSITY

1.0

0.0

3.0

F002_0188AC

4.0

3.0

2.0

DENSITY

1.0

Exposure:

Process:

Tungsten, 1/25 second

Small tank, KODAK DEKTOL

Developer, 3 minutes at 68 F (20 C),

agitation at 30-second intervals

200Exposure Index:

2.50Contrast Index:

=3.60

2.0

1.0

LOG EXPOSURE (lux-seconds)

Exposure:

Process:

CONTRAST

3.00

2.50

2.00

Tungsten, 1 second

Small tank, KODAK Developer D-19;

2, 4, and 8 minutes at 68 F (20 C),

agitation at 30-second intervals

EXPOSURE

INDEX

DEVELOPMENT TIME

(minutes)

INDEX

200

150

100

8642

0.0 1.0

8 min =3.50

4 min =2.90

2 min =2.80

4.0

3.0

2.0

DENSITY

1.0

0.0

3.0

4.0

3.0

2.0

DENSITY

1.0

Exposure:

Process:

CONTRAST

2.00

1.80

1.60

1.40

1.20

Daylight, 1/25 second

Small tank, KODAK HC-110 Developer (Dil B),

4, 6, 8, and 12 minutes at 68 F (20 C),

agitation at 30-second intervals

EXPOSURE

86

(minutes)

INDEX

250

200

150

100

1210

INDEX

4

DEVELOPMENT TIME

2.0

LOG EXPOSURE (lux-seconds)

Exposure:

Process:

Tungsten, 1/25 second

Small tank, KODAK HC-110 Developer (Dil D),

4, 6, and 8 minutes at 68 F (20 C),

agitation at 30-second intervals

(minutes)

EXPOSURE

INDEX

745

86

150

100

50

CONTRAST

INDEX

1.80

1.60

1.40

1.20

DEVELOPMENT TIME

12 min =2.70

8 min =2.05

6 min =1.60

4 min =1.40

8 min =2.00

6 min =1.65

4 min =1.35

1.00.01.0

F002_0185AC

0.0

3.0

4.0

3.0

2.0

DENSITY

1.0

2.0

LOG EXPOSURE (lux-seconds)

Exposure:

Process:

CONTRAST

Tungsten, 1 second

Small tank, KODAK Developer

D-19 (1:2), 4, 5 , and 7 minutes at

68 F (20 C), agitation at

30-second intervals

INDEX

3.00

2.80

2.60

2.40

2.20

DEVELOPMENT TIME

1

2

EXPOSURE

4567

(minutes)

INDEX

200

150

100

F002_0182AC

7 min =3.60

1

2

5 min =3.50

4 min =3.20

1.00.01.0

0.0

3.0

4.0

3.0

2.0

DENSITY

1.0

2.0

LOG EXPOSURE (lux-seconds)

Exposure:

Process:

CONTRAST

Tungsten, 1 second

Small tank, KODAK HC-110 Developer (Dil F),

6, 8, and 10 minutes at 68 F (20 C),

agitation at 30-second intervals

8

(minutes)

EXPOSURE

INDEX

60

50

40

30

INDEX

0.95

0.90

0.85

0.80

610

DEVELOPMENT TIME

F002_0183AC

10 min =1.30

8 min =1.20

1.00.01.0

6 min =1.05

0.0

3.0

2.0

1.0

LOG EXPOSURE (lux-seconds)

0.0 1.0

F002_0189AC

0.0

3.5

2.5

1.5

LOG EXPOSURE (lux-seconds)

0.5

F002_0184AC

10 KODAK PROFESSIONAL Technical Pan Film • P-255

Page 11

4.0

3.0

2.0

DENSITY

1.0

Exposure:

Process:

CONTRAST

Daylight, 1/25 second

Small tank, KODAK TECHNIDOL Liquid

Developer 5, 7, 9, and 11 minutes at

68 F (20 C), agitation at 30-second intervals

Developing

Time (min)

5

9 min =0.65

1159

7

9

11

11 min =0.70

INDEX

0.70

0.60

0.50

0.40

DEVELOPMENT TIME

(minutes)

7

Exposure

Index

16

20

25

25

7 min =0.60

5 min =0.50

Contrast

Index

0.48

0.58

0.64

0.70

Exposure:

4.0

Process:

Chemicals at 85 F (29.4 C); KODAK

VERSAMAT Film Processor,

Model 11; 1 developer rack

Daylight, 1/25 second

KODAK VERSAMAT 885

3.0

CONTRAST

INDEX

2.60

2.20

2.0

1.80

DENSITY

1.40

1.00

510

15 20

MACHINE SPEED

1.0

(fpm)

EXPOSURE

INDEX

250

200

150

100

25

5 fpm =3.60

10 fpm =2.80

15 fpm =2.20

20 fpm =1.60

25 fpm =1.35

0.0

3.0

4.0

3.0

2.0

DENSITY

1.0

0.0

3.0

F002_0186AC

4.0

3.0

2.0

DENSITY

1.0

0.0

3.0

2.0

1.0

LOG EXPOSURE (lux-seconds)

Exposure:

Process:

Tungsten, 1/25 second

Small tank, KODAK Developer D-76;

6, 8, 10, and 12 minutes at 68 F (20 C),

agitation at 30-second intervals

86

(minutes)

EXPOSURE

INDEX

125

100

75

50

1210

CONTRAST

INDEX

2.00

1.75

1.50

GAMMA

1.25

1.00

DEVELOPMENT TIME

8 min =1.50

6 min =1.20

2.0

LOG EXPOSURE (lux-seconds)

Exposure:

Process:

5, 10, 15, 20, and 25 ft/min at 85 F (29.4 C);

KODAK VERSAMAT Film Processor,

Model 11; 1 developer rack

Daylight, 1/25 second

KODAK VERSAMAT 641 Chemicals at

CONTRAST

INDEX

2.20

1.80

1.40

1.00

0.60

MACHINE SPEED

510

15 20

(fpm)

EXPOSURE

INDEX

200

150

100

50

25

20 fpm =1.05

25 fpm =0.85

2.0

1.0

LOG EXPOSURE (lux-seconds)

0.0 1.0

F002_0193AC

12 min =2.50

10 min =2.00

5 fpm =2.90

10 fpm =1.55

15 fpm =1.30

0.0 1.0

F002_0191AC

1.00.01.0

DENSITY

0.0

3.0

2.0

LOG EXPOSURE (lux-seconds)

Exposure:

4.0

Process:

KODAK VERSAMAT Film Processor,

Daylight, 1/25 second

KODAK DURAFLO RT Developer at

5, 10, 15, and 20 ft/min at 85 F (29.4 C);

Model 11; 2 developer racks

3.0

CONTRAST

INDEX

2.20

1.80

2.0

1.0

1.40

1.00

0.60

510

MACHINE SPEED

(fpm)

DENSITY

0.0

3.0

2.0

LOG EXPOSURE (lux-seconds)

EXPOSURE

INDEX

15 20

200

150

100

50

1.0

1.0

0.0 1.0

F002_0190AC

5 fpm =2.40

10 fpm =1.60

15 fpm =1.00

20 fpm =0.80

0.0 1.0

F002_0192AC

KODAK PROFESSIONAL Technical Pan Film • P-255 11

Page 12

QUICK REFERENCE GUIDE TO DEVELOPERS

KODAK

PROFESSIONAL

Technical Pan Film

(sizes)

2415

(135 and long rolls)

4415

(4 x 5- and

8 x 10-inch)

6415

(120)

Pictorial

TECHNIDOL

Liquid

TECHNIDOL

Liquid

Reverse-

Text

Slides

DEKTOL

Copying

Printed

Material

D-19

HC-110

(Dil B) or

TECHNIDOL

Liquid

KODAK Developer to Use for–

Copying

ContinuousTone Photos

HC-110

(Dil B),

TECHNIDOL

Liquid

Microphoto-

graphy

HC-110

(Dil D)

HC-110

(Dil D) or

TECHNIDOL

Liquid

Electro-

phoretic

Gels

HC-110

(Dil B),

TECHNIDOL

Liquid

Photo-

microg-

raphy

HC-110

(Dil B),

D-19, or

HC-110

(Dil D)

Electron

Microg-

(1:2), or

HC-110

MORE INFORMATION

Kodak has many publications to assist you with information on Kodak products, equipment, and materials.

Additional information is available on the Kodak website and through the U.S.A./Canada faxback system.

The following publications are available from dealers who

sell Kodak products, or you can contact Kodak in your

country for more information.

E-30 Storage and Care of KODAK Photographic

Materials—Before and After Processing

F-2 Pathways to Black and White

E103BF KODAK PROFESSIONAL Black-and-White Films

E103CF Chemicals for KODAK PROFESSIONAL

Black-and-White Films

For the latest version of technical support publications for

KODAK PROFESSIONAL Products, visit Kodak on-line at:

http://www.kodak.com/go/professional

If you have questions about KODAK PROFESSIONAL

Products,

call Kodak.

In the U.S.A.:

1-800-242-2424, Ext. 19, Monday–Friday

9 a.m.–7 p.m. (Eastern time)

In Canada:

1-800-465-6325, Monday–Friday

8 a.m.–5 p.m. (Eastern time)

Note: The Kodak materials described in this publication for use

with KODAK PROFESSIONAL Technical Pan Film are

available from dealers who supply KODAK PROFESSIONAL

Products. You can use other materials, but you may not obtain

similar results.

raphy

D-19,

D-19

(Dil B)

Astro-

nomical

D-19

Laser

HC-110

(Dil B)

KODAK PROFESSIONAL Technical

Pan Film

KODAK Publication No. P-255

CAT 817 2785

Kodak, D-19, D-76, Dektol, Duraflo, Ektaflo, Estar,

HC-110, Kodafix, Microdol-X, Photo-Flo, Technidol,

T-Max, Versamat, and Wratten are trademark

Minor Revision 6-03

Printed in U.S.A.

Loading...

Loading...