Page 1

Versamark DP5000 Series Printers

DP5120, DP5122 and DP5240

Installation Guide

Page 2

Page 3

Versamark DP5000 Series Printers

DP5120, DP5240, and DP5122

Installation Guide

Page 4

FCC Compliance Statement

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference, in which case the user will be required to correct the interference at his own expense.

Note: Good quality, shielded (braided shielded) cables must be used for the RS-232-C and Centronics interfaces.

Canadian EMI Compliance Statement

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils numériques de la classe A

prescrites dans le Règlement sur le brouillage radioélectrique édicté par le ministère des Communications du Canada.

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set out in the Radio Interference Regulations of the Canadian Department of Communications.

EMI-CISPR 22/EN 55 022/CE Marking

Warning: This is a Class A product. In a domestic environment, this product may cause radio interference in which case the user may be

required to take adequate measures.

Versamark DP5000 Series Printers Printing Systems Installation Guide

Part Number Media Revision Date Description ECN

0114348-603 PDF 001 05/2008 Revision for DH5122 Printhead and the K4KB K8287

© Kodak, 2008. All rights reserved.

This document contains proprietary information of Eastman Kodak Company or its licensors and is their exclusive property. It may not be

reproduced without a written agreement from Eastman Kodak Company. No patent or other license is granted to this information.

The software described in this document is furnished under a license agreement. The software may not be used or copied except as provided in

the license agreement.

Eastman Kodak Company makes no warranty of any kind with regard to the contents of this document, including, but not limited to, the implied

warranties of merchantability and fitness for a particular purpose. Eastman Kodak Company shall not be liable for any errors or for

compensatory, incidental or consequential damages in connection with the furnishing, performance, or use of this document or the examples

contained herein. Information concerning products not manufactured by Eastman Kodak Company. is provided without warranty or

representation of any kind, and Eastman Kodak Company will not be liable for any damages resulting from the use of such information.

Kodak and Versamark are trademarks of Eastman Kodak Company.

0114348-603 05/2008

Page 5

Scope

This guide describes installation procedures for the following products:

•K

ODAK VERSAMARK DP5120 Printer (5120)

•K

ODAK VERSAMARK DP5240 printer (5240)

These printers have 1" printheads

•K

ODAK VERSAMARK DP5122 printer (5122)

This printer has a 2" printhead

•K

ODAK VERSAMARK CS150 System Controller.

The controller and up to three DP5000 series printers comprise a

printing system.

In this guide, Printing System refers specifically to a Kodak Versamark

CS150 system Controller (CS150), one or more DP5000 series printers,

and the standard enclosure (cabinet) supplied by Kodak.

This guide does not describe the Kodak Versamark 5000 Printer, Kodak

Versamark 5100 Printing System, Kodak Versamark 5242 Printing

System, or Kodak Versamark 5300 Printing System. Jetscape software

and Mailscape Version 3.96 (including the Read & Image option) are

described only as shipped in the dual controller configuration. See below.

Important: Availability of the Jetscape products described in this guide is limited.

Contact technical support before ordering or planning to purchase any

Jetscape product.

The procedures in this guide should be performed only by a Kodak Versamark field engineer, or a service technician trained by Kodak Versamark,

Inc.

Installation Guide 3

Page 6

Scope

!

WARNING

!

DANGER

Text Notations

Safety Notations

Note: Information that needs to be brought to the reader’s attention.

Caution: A situation where a mistake could result in the destruction of data or

This manual uses the following typographical conventions.

This style Refers to

Ready

go

ENTER

[NEXT] Buttons and lights on the printer operator panel.

Save Software command buttons and sections of dialog boxes,

File → Open

ALT+F1

ALT, TAB

xx,yy Variable in error messages and text.

jobfile.dat File names.

Text displayed by the software.

Anything you type, exactly as it appears, whether referenced

in text or at a prompt.

Special keys on the keyboard, such as enter, alt, and

spacebar.

such as group boxes, text boxes, and text fields.

A menu and a specific menu command.

Pressing more than one key at the same time.

Pressing more than one key in sequence.

The following definitions indicate safety precautions to the operator.

system-type damage.

A potential hazard that could result in serious injury or death.

An imminent hazard that will result in serious injury or death.

4 DP5000 Series Printers

Page 7

Scope

Service and Support

Technical equipment support is available 24 hours a day, 7 days a week.

Software and applications support is available 8:00 a.m. to 5:00 p.m.

EST/EDT, Monday through Friday.

Call for telephone or on-site technical support; to order parts or supplies;

to request documentation or product information.

Phone Fax

U.S.A., Canada, and

worldwide

Europe +41-21-806-0404 +41-21-806-1920

Asia/Pacific Rim +65-6744-6400 +65-6744-6700

Japan +81-03-5621-2220 +81-03-5621-6195

Updated service

information

Customer support customer@kodakversamark.com

http://www.kodakversamark.com

+1-800-472-4839

+1-937-259-3739

+1-937-259-3808

Installation Guide 5

Page 8

Page 9

Contents

Chapter 1. Preparation

Safety Precautions............................................................................................ 1-1

Lifting Technique........................................................................................ 1-1

Electrical Safety ......................................................................................... 1- 1

Fluidic Safety.............................................................................................. 1-2

Required Tools ................................................................................................. 1- 2

Chapter 2. Unpacking

Printer ............................................................................................................... 2-1

Removing Packaging ................................................................................. 2- 2

Printer Inventory......................................................................................... 2- 3

Moving the Printer ...................................................................................... 2-4

Printing System................................................................................................. 2- 5

Removing System Packaging .................................................................... 2-5

System Inventory ....................................................................................... 2- 8

System Unpacking ................................................................................... 2- 10

Accessories .............................................................................................. 2- 11

Printheads....................................................................................................... 2-12

DH5120 Printhead.................................................................................... 2-13

DH5240 Printhead.................................................................................... 2-14

DH5122 Printhead.................................................................................... 2-15

Chapter 3. Printer Installation

Printer Positioning............................................................................................. 3-1

Printer Stand Installation ............................................................................ 3- 1

Customer-Supplied Support....................................................................... 3- 3

Fluid Container Installation ............................................................................... 3-4

Internal ....................................................................................................... 3-4

Ink Bottle.............................................................................................. 3-5

Replenisher Bottle ............................................................................... 3-6

External ...................................................................................................... 3- 7

Voltage Selection.............................................................................................. 3-8

Printer Connections .......................................................................................... 3- 9

Printer Power ........................................................................................... 3- 11

Ethernet.................................................................................................... 3- 12

RS 232 (Serial)......................................................................................... 3- 13

Centronics (Parallel)................................................................................. 3- 14

Control I/O ................................................................................................ 3- 15

Tach and Cue........................................................................................... 3- 16

K4K .......................................................................................................... 3-17

Sort / Stop ................................................................................................ 3-18

Chapter 4. System Installation

Enclosure Positioning ....................................................................................... 4- 1

Controller Positioning........................................................................................ 4-2

System Connections......................................................................................... 4-4

Cabinet Connections .................................................................................. 4- 4

System Power...................................................................................... 4- 4

Installation Guide 1

Page 10

Contents

External Tach and Cue ........................................................................ 4-5

Controller Connections ............................................................................... 4- 5

Data Cable ........................................................................................... 4 - 6

Keyboard and Mouse ........................................................................... 4 - 7

Monitor Interface .................................................................................. 4- 7

Power Cables ....................................................................................... 4- 8

Installing Software............................................................................................. 4-8

Chapter 5. Printhead Installation

DH5120 Printhead............................................................................................. 5- 2

DH5240 Printhead............................................................................................. 5- 3

DH5122 Printhead............................................................................................. 5- 4

Chapter 6. Testing

Electronics Tests............................................................................................... 6-1

Fluidics Tests .................................................................................................... 6 - 2

System Tests .................................................................................................... 6 - 3

Printhead Adjustment........................................................................................ 6 -5

Phase Adjustment....................................................................................... 6-5

Adjusting Voltage........................................................................................ 6 - 6

Appendix A. Installation Checklists

Printer Checklist ............................................................................................... A- 1

Printhead Checklist .......................................................................................... A-1

Printing System Checklist ................................................................................ A-2

Appendix B. Tach and Cue Wiring

Appendix C. Site Requirements

Electrical Requirements ................................................................................... C- 1

Environmental Requirements........................................................................... C- 2

Space Requirements........................................................................................ C -2

2 DP5000 Series Printers

Page 11

Figures

Figure 2.1 Printer on shipping pallet ......................................................... 2 - 2

Figure 2.2 Printing system pallet, shrink wrap removed ........................... 2 - 5

Figure 2.3 Printing system box, ready for unpacking ................................ 2 - 6

Figure 2.4 Printing system box, side walls removed ................................. 2 - 6

Figure 2.5 DH5120 printhead, capsule inside inner box ......................... 2 - 13

Figure 2.6 DH5240 printhead, capsule inside inner box ......................... 2 - 14

Figure 2.7 DH5122 printhead.................................................................. 2 - 15

Figure 3.1 Printer on stand ....................................................................... 3 - 2

Figure 3.2 Screw locations, printer stand.................................................. 3 - 2

Figure 3.3 Printer positioning limits, height and distance.......................... 3 - 3

Figure 3.4 Ink bottle compartment, DP5122 printer .................................. 3 - 5

Figure 3.5 External 20-liter cubitainer fluid supply .................................... 3 - 7

Figure 3.6 External 55-gallon supply containers ....................................... 3 - 8

Figure 3.7 Voltage selector switch cover .................................................. 3 - 8

Figure 3.8 Fuse removal, circuit breaker switch ....................................... 3 - 9

Figure 3.9 Voltage selector switch, DP5120 and DP5240 ........................ 3 - 9

Figure 3.10 Connectors, printer back panel.............................................. 3 - 10

Figure 3.11 Power cord connector, printer back panel ............................. 3 - 11

Figure 3.12 Ethernet connection, printer back panel ................................ 3 - 12

Figure 3.13 RS 232 (serial) connection, printer back panel...................... 3 - 13

Figure 3.14 Parallel data connection, printer ............................................ 3 - 14

Figure 3.15 Control I/O connection, printer back panel ............................ 3 - 15

Figure 3.16 Tach and cue connection....................................................... 3 - 16

Figure 3.17 K4K connection, DP5240....................................................... 3 - 17

Figure 3.18 Connector wiring, relay contact cable.................................... 3 - 19

Figure 3.19 Sort relay cable connection, printer back panel..................... 3 - 19

Figure 4.1 Cabinet, ready for positioning .................................................. 4 - 1

Figure 4.2 Enclosure ready for positioning ............................................... 4 - 2

Figure 4.3 Controller components on system enclosure........................... 4 - 3

Figure 4.4 Hardware and cable kit cables................................................. 4 - 3

Figure 4.5 Power cord connection, printing system .................................. 4 - 5

Figure 4.6 Controller PC connectors, back panel ..................................... 4 - 6

Figure 4.7 Controller data, keyboard and mouse cables .......................... 4 - 7

Figure 4.8 Video connection, controller PC .............................................. 4 - 7

Figure 4.9 PC and monitor power cables.................................................. 4 - 8

Figure 5.1 DH5120 printhead, in shipping container................................. 5 - 2

Figure 5.2 DH5240 printhead, in shipping container................................. 5 - 3

Figure 5.3 DH5122 printhead in shipping container.................................. 5 - 4

Figure 6.1 Missing spots or bands of print ................................................ 6 - 5

Figure 6.2 Dark defect, defines low end of print window .......................... 6 - 7

Figure B.1 Tach and cue wiring, DP5000 series printers .......................... B - 1

Figure C.1 DH5122 printhead dimensions ............................................... C - 3

Installation Guide 3

Page 12

Contents

Figures

4 DP5000 Series Printers

Page 13

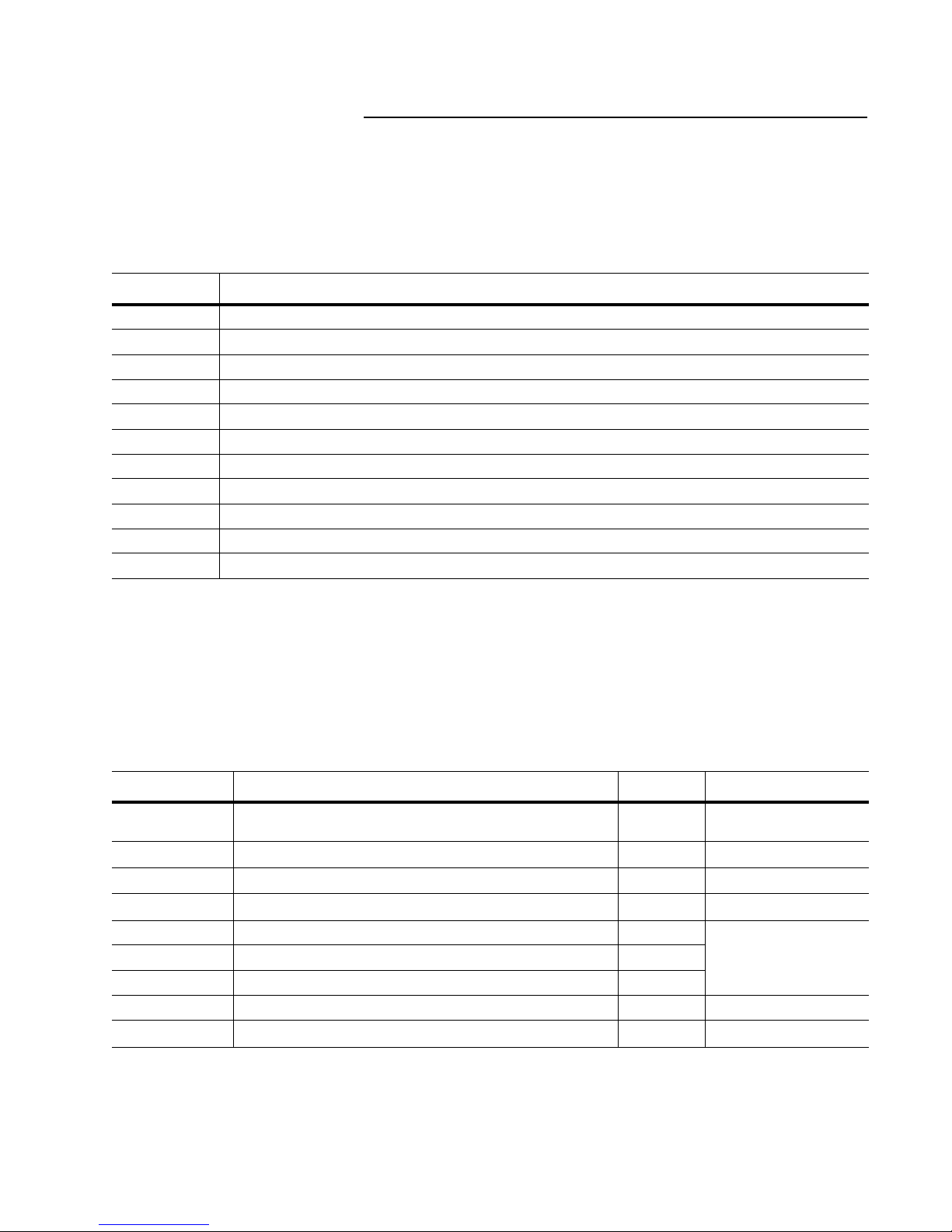

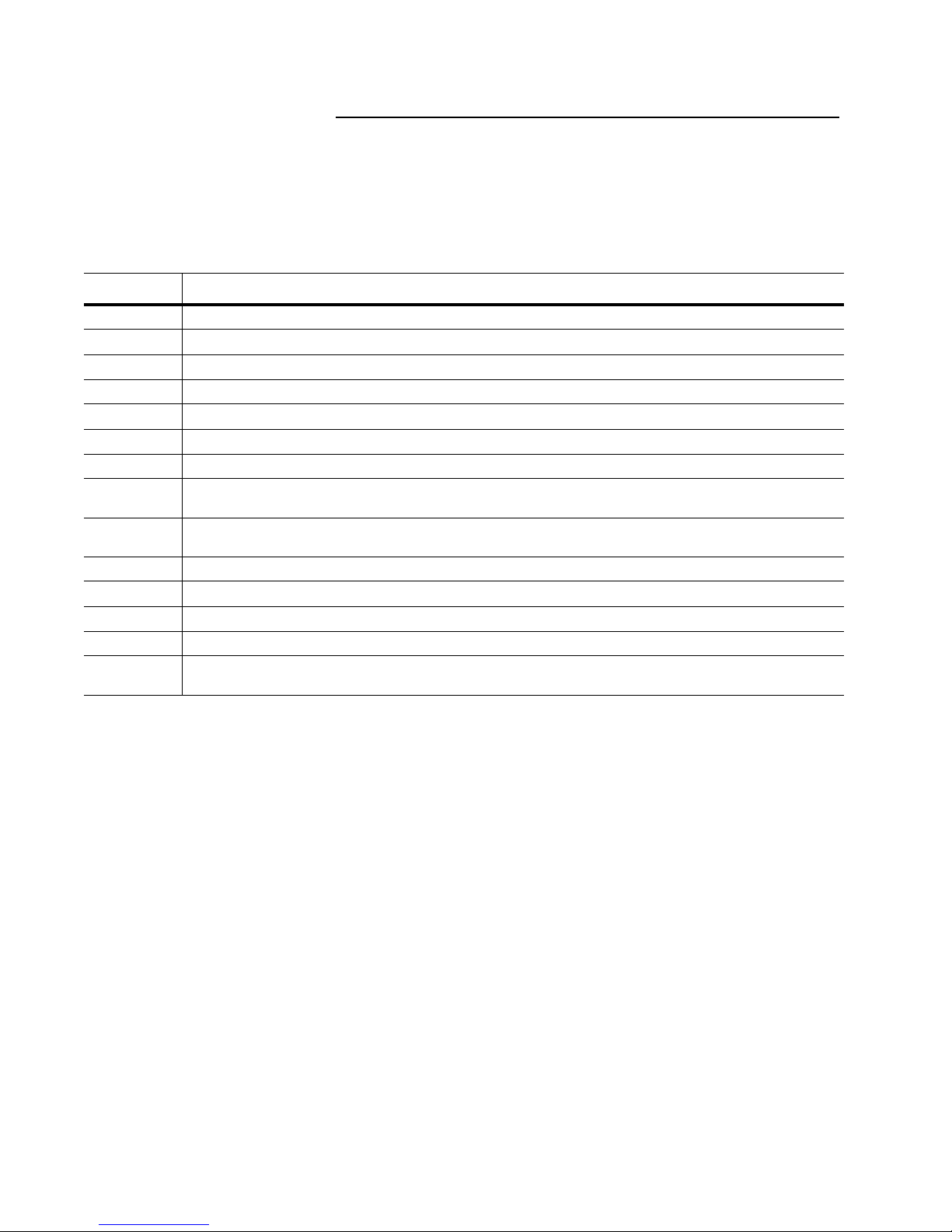

Tables

Table 2.1 Printer model shipping numbers............................................. 2-3

Table 2.2 Components, typical printer shipment .................................... 2- 3

Table 2.3 Printing system models and shipping numbers ...................... 2- 8

Table 2.4 Components, typical printing system shipment ...................... 2 -9

Table 2.5 System shipment contents.................................................... 2- 11

Table 2.6 Printhead models and shipping numbers ............................. 2 -12

Table 3.1 Fluid part numbers, DP5000 series printers ........................... 3-4

Table 3.2 Relay contact cable wiring .................................................... 3-18

Table 5.1 Printhead container contents, DH5120 printhead................... 5-2

Table 5.2 Printhead container contents, DH5240 printhead................... 5-3

Table 5.3 Printhead box contents, DH5122............................................ 5-4

Table C.1 Electrical requirements .......................................................... C - 1

Table C.2 Environmental requirements .................................................. C-2

Table C.3 Space requirements............................................................... C - 2

Installation Guide 3

Page 14

Contents

Tables

4 DP5000 Series Printers

Page 15

Safety Precautions

Chapter 1. Preparation

This chapter describes the requirements for an installation, and the

following procedures and guidelines:

• Safety precautions

• Required tools.

Read all procedures thoroughly prior to installation. Follow any warnings

and special instructions that appear in the manuals and on labels affixed

to the printer and system components to avoid physical harm to you or the

components.

Observe the following safety precautions during all installation

procedures.

Lifting Technique

Apply the following guidelines to moving components.

• Use two persons to lift the printer box, the printing system enclosure,

or any large component, or any box that exceeds 50 lbs (27 kg).

• Lift carefully using the legs and not the back (see OSHA standards).

Electrical Safety

Apply the following guidelines when working with any internal component

of the printer, or around any power source.

• Observe all precautions regarding high voltage.

• Use proper procedures for handling electrical equipment (see OSHA

standards).

• Observe all precautions in warning and caution notations (see

”Scope”).

• Observe proper electro-static discharge (ESD) precautions.

• Use proper voltage levels, and observe proper grounding techniques.

• Observe all precautions for working around electrical devices that

remain charged after input power is cut off.

Installation Guide 1-1

Page 16

Chapter 1. Preparation

Required Tools

Required Tools

Fluidic Safety

Apply the following guidelines when handling ink, replenisher, or purge

fluid.

• Read the Material Safety Data Sheet (MSDS) for a fluid before

handling it, and follow all instructions in the documentation shipped

with the fluid.

• Clean up any spill immediately.

• Wear approved protective equipment (see OSHA standards).

• Dispose of hazardous material properly (see OSHA standards and all

local, state, and Federal regulations that apply).

Before starting the installation, check that you have the following required

tools and equipment.

• Standard FE took kit (0177490).

• ESD protection kit (0110094).

The following kits are recommended, but not required.

• DTR test kit (0178399)

• DP5120/DP5240 flush kit (0177491).

1-2 DP5000 Series Printers

Page 17

Printer

Chapter 2. Unpacking

This chapter describes how to unpack the following components:

• Printer

• Printing system

• Printheads.

To ensure that you complete all steps of these procedures use the

checklists in “Appendix A”.

The printer components are shrink-wrapped to a shipping pallet (see

Figure 2.1). Depending on the contents of the product order, other boxes

may be shipped on the same pallet.

Installation Guide 2-1

Page 18

Chapter 2. Unpacking

Printer

Removing Packaging

Use the following procedure to remove the pallet packaging.

1. Use a forklift or hand truck to move the pallet as close as possible to

the final location intended for the printer.

2. Position the pallet where there is 3 ft. (1 m) of clear working space on

all four sides.

3. Cut the shrink-wrap and remove it from the pallet.

Caution: Do not cut into the boxes. Use a box knife or other short-bladed tool and

cut where pallet contents do not touch the shrink wrap.

4. Remove the smaller boxes from the pallet and set them aside for later

unpacking.

Note: A typical printer shipment includes three extra boxes (see “Printer

Inventory”). Figure 2.1 shows the pallet with the shrink wrap and smaller

boxes removed.

Figure 2.1 Printer on shipping pallet

Note: Set the accessories box aside for later unpacking.

Note: Leave the packaging on the printhead housing at the end of the umbilical.

2-2 DP5000 Series Printers

5. Cut the bands on the printer box.

6. Remove the box lid.

7. Remove the printer accessories box from inside the printer box.

8. Cut open the end (short side) of the box at the back of the printer.

a. Access the back of the printer where the handle is located.

9. Fold down or tear off the cut side of the box.

10. Remove all the packaging from the pallet and the area around the

printer.

11. Continue with the shipment inventory.

Page 19

Chapter 2. Unpacking

Printer Inventory

Before starting to unpack the shipment, use the following procedure to

inventory its contents.

1. Check the type of printer identified by the number on the printer box

(see Table 2.1).

Table 2.1 Printer model shipping numbers

Part Number Printer Model and Options

0170151 KODAK VERSAMARK DP5120 DK GREY PRINTER, 12' UMBILICAL

0170154 KODAK VERSAMARK DP5240 DK GREY PRINTER, 12' UMBILICAL

0170155 KODAK VERSAMARK DP5240 DK GREY PRINTER, 24' UMBILICAL

0170156 KODAK VERSAMARK DP5240 DK GREY PRINTER, 24' UMBILICAL, K4K

0170159 KODAK VERSAMARK DP5120 DK GREY PRINTER, 24' UMBILICAL

0170161 KODAK VERSAMARK DP5120 DK GREY PRINTER, 24' UMBILICAL, K4K

0170162 KODAK VERSAMARK DP5122 DK GREY PRINTER, 12' UMBILICAL

0170163 KODAK VERSAMARK DP5122 DK GREY PRINTER, 24' UMBILICAL

0170168 KODAK VERSAMARK DP5120 DK GREY PRINTER, 12' UMBILICAL,W/TRANSFORMER

0170175 KODAK VERSAMARK DP5120 DK GRAY PRINTER, 12' UMBILICAL, K4K MINUS BOARD

0170176 KODAK VERSAMARK DP5240 DK GREY PRINTER, 12' UMBILICAL, HI MEMORY

Printer

2. Check the pallet contents against the packing slip (or copy of the

order acknowledgement form). Note any short or over shipments.

Table 2.2 lists the contents of a typical printer shipment. The printer,

printheads, base cabinet, and printhead mount are individually boxed.

All other items are shipped together in one accessories box. A

shipment can include additional components, most commonly ink and

extra printheads.

Table 2.2 Components, typical printer shipment

Part Number Description Quantity Location

0170162 KODAK VERSAMARK DP5122 DK GREY PRINTER, 12'

UMBILICAL

0100238-026 CORD-PWR 16AWG 13A 125V 7.5FT 1

0187976 PRINTER HARDWARE KIT 1 Inside printer box

0188200 PRINTHEAD 2

0177489 INSTALLATION KIT 1

0188398 MANUALS KIT-DP5122 PRINTER 1

0187412 CATCH PAN-SERVICE (1"/2") 1

0187887 BASE CABINET ASSEMBLY DK GREY 1 Separate box

0187733 PRINTHEAD MOUNT - STAND ASSY 1

1 Printer box

Inside printer box

Separate box

Accessories box

Separate box

1

2

3

4

1. A domestic (US), European or Japanese power cord is shipped depending on the shipment destination.

2. Two printheads are shipped with a DP5240 or DP5122 printer; only one printhead is shipped with a DP5120 printer.

3. Labeled with the printer model part number or the printer serial number.

4. Shipped on a separate pallet if necessary. An alternate is the LABEL BASE 2" PRINTHEAD MOUNT (0187734).

Installation Guide 2-3

Page 20

Chapter 2. Unpacking

Printer

Moving the Printer

Use the following procedure to move the printer off of the shipping pallet:

1. Cut the straps securing the printing system box to the pallet.

2. Remove the box lid.

3. Remove any loose packing material from inside the printer box.

Note: Manuals, cables, software and other small items are packed inside the

installation kit box. If only a printer and printheads were shipped, these

items will be shipped inside a separate box.

4. Cut open the end of the box next to the umbilical connection.

5. Fold down the cut box wall.

6. Uncoil the umbilical and lay it on top of the printer, or to one side.

7. Make sure the umbilical does not obstruct moving the printer.

Caution: The following steps require two persons.

8. If two persons are available, work together to lift the printer out of its

packing base and set it on a level surface.

9. If only one person is available, pull the printer slowly out of the box

and off the pallet.

Caution: Do not let the printer drop or tip over.

10. Coil the umbilical around the umbilical hanger on the printer rear

panel and nest the printhead housing in the coils.

11. Continue with “System Unpacking”.

2-4 DP5000 Series Printers

Page 21

Printing System

Ramps

Controller,

installation kit,

and printhead boxes

Chapter 2. Unpacking

Printing System

A printing system is shipped strapped to a shipping pallet (see Figure

2.2). Unpacking a system consists of the following procedures:

• Removing system packaging

• System inventory

• System unpacking

• Accessories.

Removing System Packaging

The components of a standard printing system components are shipped

in four or more boxes packed on one pallet. The number of pallets and

their contents can vary depending on the type of system ordered. Use the

following procedure to unpack the system.

1. Move the shipping pallet as close as possible to the final location

intended for the printing system.

Note: Use a forklift or hand truck to move the pallet.

2. Position the pallet where there is 3 ft. (1 m) of clear, working space on

all four sides.

3. Cut the shrink-wrap and remove it from the pallet (see Figure 2.2).

Caution: Do not cut into the boxes. Use a box knife or other short-bladed tool and

cut where pallet contents do not touch the shrink wrap.

Figure 2.2 Printing system pallet, shrink wrap removed

4. Remove the two wooden ramps from the shipping pallet and set them

aside for later use.

5. Remove all boxes except the printing system box from the pallet. Set

these boxes aside for later unpacking.

6. Cut the bands securing the printing system box lid (see Figure 2.3).

Installation Guide 2-5

Page 22

Chapter 2. Unpacking

Ramp diagram

Box lid

Bands

Cutouts

for ramps

Plastic cover

Printing System

Figure 2.3 Printing system box, ready for unpacking

7. Remove the box lid.

8. Remove and discard the cut bands.

9. Remove the side walls of the box (see Figure 2.4).

Figure 2.4 Printing system box, side walls removed

2-6 DP5000 Series Printers

10. Remove the plastic cover from the printing system.

11. Remove the packing material from around the base of the printing

system enclosure on the short side of the box next to the two cutouts

in the pallet rim for the ramps.

12. Remove the screws taped to the ramps.

13. Secure the ramps to the pallet with the screws supplied. Use the predrilled holes on the pallet frame at each cutout.

Page 23

Chapter 2. Unpacking

Printing System

14. Unlock the printing system enclosure (cabinet) caster locks.

Caution: The following steps should be done by two persons. If you are alone,

exercise additional caution.

15. If two persons are available, tilt the cabinet slightly toward either of its

long sides, and then pull any packing material under it out. If you are

alone, cut away any packing material underneath the cabinet that

blocks the casters

16. Roll the cabinet down the ramp and onto the floor.

17. Stop the cabinet when it is level with all four casters on the floor and

lock the casters.

Hint: It is easier and safer to pull the cabinet down the ramp rather than to push

it down. The printer weighs approximately 100 lbs (45 kg), and pulling the

cabinet down allows you to guide and slow it as it moves down the ramps.

Caution: Do not let the cabinet roll free or tip more than 20 degrees as it moves

down the ramps.

18. Remove any packaging material from inside the cabinet.

19. Remove the umbilical and printhead housing from inside the cabinet

and coil the umbilical on top of the cabinet and nest the printhead

housing within the coils.

Note: Leave the protective packaging on the printhead housing. This packaging

should not be removed until you perform the printhead installation (see

“Printheads”).

20. Roll the cabinet to where the printing system is to be installed.

21. Continue with the printing system installation procedure (see “System

Inventory”).

Installation Guide 2-7

Page 24

Chapter 2. Unpacking

Printing System

System Inventory

Before starting to unpack the printing system enclosure, use the following

procedure to inventory its contents.

1. Check the type of printing system identified by the number on the

printer box (see Table 2.3).

Table 2.3 Printing system models and shipping numbers

Part Number Printer Model and Options

0170152 KODAK VERSAMARK DP5120 DK GREY SYSTEM, NO MTU, 12' UMBILICAL, JETSCAPE

0170153 KODAK VERSAMARK DP5120 DK GREY SYSTEM, NO MTU, 12' UMBILICAL, CS150

0170157 KODAK VERSAMARK DP5240 DK GREY SYSTEM, NO MTU, 12' UMBILICAL, JETSCAPE

0170158 KODAK VERSAMARK DP5240 DK GREY SYSTEM, NO MTU, 12' UMBILICAL, CS150

0170160 KODAK VERSAMARK DP5120 DK GREY SYSTEM, NO MTU, 24' UMBILICAL, JETSCAPE

0170164 KODAK VERSAMARK DP5122 DK GREY SYSTEM, NO MTU, DUAL CONTROLLER, 12' UMBILICAL

0170165 KODAK VERSAMARK DP5122 DK GREY SYSTEM, NO MTU, DUAL CONTROLLER, 24' UMBILICAL

0170166 KODAK VERSAMARK DP5122 DK GREY SYSTEM, NO MTU, DUAL CONTROLLER, 12' UMBILICAL,

0170167 KODAK VERSAMARK DP5122 DK GREY SYSTEM, NO MTU, DUAL CONTROLLER, 24' UMBILICAL,

0170169 KODAK VERSAMARK DP5240 DK GRAY SYSTEM, NO MTU, 12' UMBILICAL, DUAL CONTROLLER

0170170 KODAK VERSAMARK DP5120 DK GRAY SYSTEM, NO MTU, 24' UMBILICAL, CS150, K4K

0170171 KODAK VERSAMARK DP5120 DK. GREY SYSTEM, MTU,12' UMBILICAL, JETSCAPE

0170172 KODAK VERSAMARK DP5120 DK. GREY SYSTEM, NO MTU,12' UMBILICAL, DUAL CONTROLLER

0170173 KODAK VERSAMARK DP5122 DK GRAY SYSTEM, NO MTU, DUAL CONTROLLER, 12' UMBILICAL, w/

MPI

MPI

TRANSFORMER

2-8 DP5000 Series Printers

Page 25

2. Check the pallet contents against the packing slip (or copy of the

order acknowledgement form). Note any short or over shipments.

Table 2.4 lists the contents of a typical system shipment. The system

cabinet, printheads, printhead mount, and are individually boxed. All

other items are shipped together in one accessories box labeled with

the shipment part number or the printer serial number. A shipment

can include additional components, most commonly ink and extra

printheads.

Table 2.4 Components, typical printing system shipment

Chapter 2. Unpacking

Printing System

Part

Number

Description

0170165 KODAK VERSAMARK DP5122 DK GREY SYSTEM, NO MTU, DUAL

CONTROLLER, 24' UMBILICAL

0100238-

CORD-PWR 16AWG 13A 125V 7.5FT 1

026

0185072

DUAL CONTROLLER PC KIT

2

Quantity

1

Location

1

On pallet

Accessories box

1 Separate box

- MONITOR 1 Separate box

0188200

PH-2"/120 DPI PKD

3

2 Separate box

0177489 INSTALLATION KIT 1

0188399 MANUALS KIT-DP5122 PRINTING SYSTEM 1

0187412 CATCH PAN-SERVICE (1"/2") 1

Accessories box

0177184 TACH KIT-BELT DRIVEN TRANSPORT 1

0175780 CUE ASSY (6 FT) W/PKG 1

0187887 BASE CABINET ASSEMBLY DK GREY 1 Separate box

0187734 LABEL BASE 2" PRINTHEAD MOUNT 1

-

1. Quantity if shipped on the printer pallet, or location if shipped separately.

2. This kit is the Pioneer PC (chassis and documentation).

3. Two printheads are shipped with a DP5240 or DP5122 printer, one with a DP5120 printer.

4. Shipped on a separate pallet. An alternate is the PRINTHEAD MOUNT - STAND ASSY (0187733).

5. The two wooden ramps are taped together with the screws taped to them.

RAMPS (W/ SCREWS)

5

1 On top of boxes

Separate box

4

Installation Guide 2-9

Page 26

Chapter 2. Unpacking

Printing System

System Unpacking

Use the following procedure to unpack the system controller (host) and

other components of a printing system.

1. Move all the boxes to the location where the system is to be installed.

2. Place the monitor and computer (system controller PC) boxes by the

cabinet. They are unpacked when installed (see Chapter 4, “System

Installation”).

3. Unpack the PC peripherals box; it contains the following items:

• Keyboard

•Mouse

• PC manuals

• PC cables.

4. Set the PC peripherals aside until ready to begin the system

installation.

5. Unpack the system accessories box. The following contains the

system components:

• Manuals set (up to six books)

•Cables

• Power cord kit

• Installation kit.

6. If options or accessories were included in the shipment, unpack those

items (see “Accessories”). Otherwise, continue with the installation

procedure (see “Printing System”).

2-10 DP5000 Series Printers

Page 27

Accessories

Use the following general procedure as a guideline for unpacking any

accessories included in the shipment.

1. Use the shipping numbers on the boxes to identify which options are

Table 2.5 System shipment contents

Chapter 2. Unpacking

Printing System

part of the shipment (see Table 2.5).

Part Number Description Notes / Function

0175834 BASE CABINET ASSY Rollaround stand - DP5120/

0187887 BASE CABINET ASSEMBLY DK GRAY Printer stand - DP5122

0176498 PRINTHEAD MOUNT STAND Rollaround stand - DP5120/

0187733 PRINTHEAD MOUNT 2" STAND ASSY Rollaround stand for DP5122

0177499 CATCH PAN ASSY For DP5120 and DP5240

0187412 1"/2" SERVICE CATCHPAN ASSEMBLY For DP5122

0176499 LABEL BASE PRINTHEAD MOUNT For DP5120 and DP5240

0187734 LABEL BASE 2" PRINTHEAD MOUNT For DP5122

0182591 RESTRAINT - UMBILICAL Imaging tower option

0178202 PRINTHEAD MOUNT ASSY Transport option

0104009-211 POWER CONDITIONER 120VAC IN/OUT

0104009-212 POWER CONDITIONER 230VAC IN 120VAC

OUT

0180088 REMOTE OPERATOR PANEL 0113455

0187611 CS150 MULTI-PRINTER KIT H/W Hardware and software

0187612 MULTI-PRINTER INTERFACE JETSCAPE Hardware and software

0179993 PRECISION MT 1 INCH PH ASSY Adapter for 4" printhead

0180117 NON-STITCH MT 1 INCH PH ASSY Adapter for 4" printhead

DP5240

DP5240

System option

mount

mount

Reference

Document

Vendor document

0113754

Vendor document

0113754

Vendor document

01140540186038 CS150 MULTI-PRINTER KIT S/W Software

0113757

0113758

2. Unpack each accessory box and locate the documentation.

3. Refer to installation instructions listed in Table 2.5 for detailed

information on each component.

4. For software and memory options, see the DP5000 Series software

Installation Guide (0114083).

5. Continue with the printhead unpacking procedure.

Installation Guide 2 - 11

Page 28

Chapter 2. Unpacking

Printheads

Printheads

Each DP5000 series printhead has a different part number and is shipped

in a separate box (see Table 2.6). The following sections identify the

printheads and provide general installation guidelines. Refer to the

documents listed in Table 2.6 for detailed instructions.

Table 2.6 Printhead models and shipping numbers

Part Number Printer Model and Options Installation Documents

0139750 KODAK VERSAMARK DH5120 PRINTHEAD

0181000 KODAK VERSAMARK DH5240 PRINTHEAD

0188200 KODAK VERSAMARK DH5122 PRINTHEAD

DP5000 series printheads

Replacement Instructions (0114252-602) and

Packing Instructions (0114253-602)

2-12 DP5000 Series Printers

Page 29

Chapter 2. Unpacking

Printheads

DH5120 Printhead

Use the following procedure to unpack the 1", 120-dpi printhead:

1. Take the printhead box to the location where the printer is to be

installed.

2. Open the outer (printhead shipping) box.

3. Remove the following contents of the box (see Figure 2.5):

• Inner printhead box

• Printhead return form (0113477) and shipping label (0193675)

• Ink card (0113590)

• Test pattern print sample.

Note: The printhead Replacement Instructions (0114252-602) and Packing

Instructions (0114253-602) are in the printer or system installation kit.

4. Note the serial number on the inner box label. This number should

match the printhead serial number on the outer box label. Record this

number for the installation report.

5. Open the inner box.

Caution: Cut the tape carefully using a box knife or other short-bladed tool to avoid

cutting the printhead capsule inside.

6. Remove the printhead capsule carefully to avoid damaging the

protruding components (catcher flex cable assembly).

7. Open the capsule and remove the printhead assembly.

Note: Four Phillips screws secure the capsule.

8. Store the printhead assembly in a safe location near the printer until

you are ready for printhead installation.

9. Retain the printhead packaging (outer box, inner box, and capsule).

Note: This packaging must be used if the printhead is returned.

10. Continue with the printer or printing system installation procedure.

Figure 2.5 DH5120 printhead, capsule inside inner box

Installation Guide 2 - 13

Page 30

Chapter 2. Unpacking

Printheads

DH5240 Printhead

Use the following procedure to unpack the 1", 240-dpi printhead:

1. Take the printhead box to the location where the printer is to be

installed (and the second, spare printhead box, if one was included in

the shipment).

2. Open the outer (printhead shipping) box.

3. Remove the following contents of the box (see Figure 2.6):

• Inner printhead box

• Printhead return form (0113477) and shipping label (0193675)

• Ink card (0113590)

• Test pattern print sample.

Note: The printhead Replacement Instructions (0114252-602) and Packing

Instructions (0114253-602) are in the printer or system installation kit.

4. Note the serial number on the inner box label. This number should

match the printhead serial number on the outer box label. Record this

number for the installation report.

5. Open the inner box.

Caution: Cut the tape carefully using a box knife or other short-bladed tool to avoid

cutting the printhead capsule inside.

6. Remove the printhead capsule carefully to avoid damaging the

protruding components (catcher flex cable assembly).

7. Open the capsule and remove the printhead assembly.

Note: Four Phillips screws secure the capsule.

8. Store the printhead assembly in a safe location near the printer until

you are ready for printhead installation.

9. Retain the printhead packaging (outer box, inner box, and capsule).

Note: This packaging must be used if the printhead is returned.

10. Continue with the printer or printing system installation procedure.

Figure 2.6 DH5240 printhead, capsule inside inner box

2-14 DP5000 Series Printers

Page 31

Chapter 2. Unpacking

Printheads

DH5122 Printhead

Use the following procedure to unpack the 2", 120-dpi printhead:

1. Take the printhead box to the location where the printer is to be

installed (and the second, spare printhead box, if one was included in

the shipment).

2. Open the outer (printhead shipping) box.

3. Remove the following contents of the box (see Figure 2.7):

• Inner printhead box

• Description Kit - Packaging (0189959)

• Swabs (0103007).

Note: The printhead Replacement Instructions (0114252-602) and Packing

Instructions (0114253-602) are in the printer or system installation kit.

4. Note the serial number on the inner box label. This number should

match the printhead serial number on the outer box label. Record this

number for the installation report.

5. Open the inner box.

6. Remove the top cushion section and remove the printhead capsule.

7. Open the printhead capsule and remove the printhead assembly.

Note: Four Phillips screws secure the capsule.

8. Store the printhead assembly in a safe location near the printer until

you are ready for printhead installation.

9. Retain the printhead packaging (outer box, inner box, and capsule).

Note: This packaging must be used if the printhead is returned.

10. Continue with the printer or printing system installation procedure.

Figure 2.7 DH5122 printhead

Installation Guide 2 - 15

Page 32

Chapter 2. Unpacking

Printheads

2-16 DP5000 Series Printers

Page 33

Printer Positioning

!

WARNING

Chapter 3. Printer Installation

Printer installation consists of the following procedures:

• Printer positioning

• Fluid container installation

• Voltage selection (not required for DP5122)

• Printer connections.

To ensure that you complete all steps of the procedures, complete the

“Printer Checklist” in Appendix A.

The unpacked printer is ready to be positioned for operation. The

following sections describe positioning the printer on one of the following

operating locations:

• Printer stand

• Customer-supplied support.

Two persons are required to lift and move the printer. Do not attempt to

move or carry the printer alone.

Printer Stand Installation

Use the following procedure to install the printer on the rollaround printer

stand:

1. Position the assembled stand next to the printer shipping pallet.

2. Remove the packing material from the pallet to clear the base of the

printer (all four bottom edges of the printer enclosure).

3. Locate the four holes in the top of the stand that correspond to the

printer feet. Orient the stand with its sliding doors at the front of the

printer (the operator panel end).

Note: The stand is rectangular and the printer fits only in one orientation.

4. Holding the printer baseplate, lift the printer off the pallet and set it on

the stand (see Figure 3.1). Set the rubber printer feet on the holes in

the stand top.

Caution: Do not lift the printer by holding only the umbilical hanger. The hanger will

bend or break if it bears the full weight of the printer. Support some of the

weight of the printer with one hand under the baseplate, and then you can

grip the hanger to lift with your other hand.

Installation Guide 3-1

Page 34

Chapter 3. Printer Installation

Rubber foot position on stand

Screw access to foot

Printer Positioning

Figure 3.1 Printer on stand

5. Adjust the printer so that all four feet line up with the holes in the

stand top.

6. Secure the printer to the stand with the four screws provided with the

stand (see Figure 3.2).

Note: The screws go up through the stand top into the four feet.

Figure 3.2 Screw locations, printer stand

3-2 DP5000 Series Printers

Page 35

Chapter 3. Printer Installation

Printer baseplate

Umbilical limit = 8 ft (2.44m)

Lower limit = 2 ft (61 cm)

Upper limit = 6 ft (1.83 m)

Maximum gap =

0.5 inch (12.7 mm)

Printer

Stand

Printer Positioning

Customer-Supplied Support

Apply the following guidelines to mount the printer on a customersupplied support.

• Place the printer on a level surface capable of bearing at least 120 lbs

(55 kg).

• If possible, secure the printer to the support by installing screws

through the surface and into the four printer feet.

• Do not mount the printhead higher than 6 ft (1.83 m) above the printer

baseplate (fluid cabinet base).

• Do not route the umbilical higher than 8 ft (2.44 m) above the printer

baseplate.

• Do not mount the printhead, or route the umbilical lower than 2 ft (61

cm) below the printer baseplate,

• Do not mount the printhead more than 0.5 inch (12.7 mm) above the

substrate (printing surface).

• Figure 3.3 diagrams all positioning specifications.

• Do not stretch the umbilical. Mount the printer close enough to the

printhead that the umbilical reaches without being visibly strained.

• Leave at least 3 in (8 cm) of ventilation clearance on both sides and

at the rear of the printer.

Note: The front panel must remain unobstructed to allow access to the ink

compartment.

Figure 3.3 Printer positioning limits, height and distance

Installation Guide 3-3

Page 36

Chapter 3. Printer Installation

Fluid Container Installation

Fluid Container Installation

Use the following procedures to install or connect one the following types

of fluid containers:

• Internal

• External.

Internal

Two standard, 51-oz fluid containers (1.5 L ASSY-BLADDER IN

CARTON) are installed in the fluid compartment; they hold the following

fluids:

•Ink

• Replenisher fluid.

Ink and replenisher container numbers identify the type of ink or

replenisher fluid. For all types of ink and replenisher fluid shipped in the

standard container, packaging and installation are the same.

Table 3.1 lists the most common fluids used in DP5000 series printers.

Table 3.1 Fluid part numbers, DP5000 series printers

Fluid Part Number Standard Container Notes

1000 Black Ink 6001000-05

1006 Black Ink 6001006-05

1007 Black Ink 6001007-05

1025 Blue Ink 6001025-05

1026 Red Ink 6001026-05

1040 IR Black Ink 6001040-05

1080 Gold 872 Ink 6001080-05

5000 Black Ink 0174292

5000 Blue Ink 0139425 Also in 20L cubitainer

1014 Replenisher 6001014-05

5000 Purge Fluid 0174290

1. Shipped by case or ½ case; a case is four 1.5L fluid containers.

1.5L bladder in carton

Standard / Case

1

For DP51205000 Red Ink 0173481

3-4 DP5000 Series Printers

Page 37

Chapter 3. Printer Installation

Ink bottle connection

Replenisher bottle connection

Fluid Container Installation

Ink Bottle

Use the following procedure to install the ink bottle:

1. Open the fluid compartment door and locate the fluid bottle

connections (see Figure 3.4).

Note: See the diagram of this procedure on the label inside the fluid

compartment door and refer to the instructions shipped with the ink.

Figure 3.4 Ink bottle compartment, DP5122 printer

2. Carefully open the cardboard container and remove the cap from the

bottle.

Note: Retain the cap to put back on the empty bottle when it is removed.

3. Install the ink container in the right position between the metal

supports with the cutouts in the container facing out (toward the door).

Hint: Pull up on the bottle neck while sliding it into position.

4. Make sure that the flower-shaped collar of the bottle is above the

metal support arm.

Caution: If the bottle collar is left under the support arm, the bottle (bladder) will

collapse inside the container and block the bottom of the ink supply tube.

This problem produces a spurious ink bottle empty error.

5. When you position the container, listen for the click of the quick-

disconnect. The click confirms that the ink supply connection has

sealed properly.

6. Press down on the locking plate until it punctures the bottle seal and

locks the container into place.

7. Continue with the “Replenisher Bottle” procedure.

Installation Guide 3-5

Page 38

Chapter 3. Printer Installation

Fluid Container Installation

Replenisher Bottle

Use the following procedure to install the replenisher bottle:

1. Locate the fluid bottle connections inside the ink compartment (see

Figure 3.4).

2. Carefully open the cardboard container and remove the cap from the

bottle.

Note: Retain the cap to put back on the empty bottle when it is removed.

3. Install the replenisher container in left position between the metal

supports with the cutouts in the container facing out (toward the door).

Hint: Pull up on the bottle neck while sliding it into position.

4. Make sure that the flower-shaped collar of the bottle is above the

metal support arm.

Caution: If the bottle collar is left under the support arm, the bottle (bladder) will

collapse inside the container and block the bottom of the replenisher

supply tube. Over time, this problem produces high ink concentration.

5. When you position the container, listen for the click of the quickdisconnect. The click confirms that the ink supply connection has

sealed properly.

6. Press down on the locking plate until it punctures the bottle seal and

locks the container into place.

7. Continue with the “Voltage Selection” or “Printer Connections”

procedure.

3-6 DP5000 Series Printers

Page 39

Chapter 3. Printer Installation

Fluid Container Installation

External

Use the following procedure to connect an external ink supply to the

DP5122 printer:

Note: Replenisher must be supplied from the standard, 1.5 liter internal

container (only ink is typically used in sufficient volume to justify an

external supply).

1. Locate the fluid bottle connection inside the ink compartment (see

Figure 3.4).

2. Connect the supply line quick-disconnect to the fluid bottle connector.

For more information on external ink supply options, contact technical

support (see “Scope”).

Note: The standard external supply line (0183648) is 20-ft (6 m) and 1/4-inch (6

mm) diameter. Lines up to 30-ft (9 m) and 3/8-inch (10 mm) diameter can

be used.

3. Attach the nozzle to the external supply container.

a. Use a standard nozzle for the 20.0 l (5.3 gal) cubitainer (see

Figure 3.5). The standard nozzles are 1/4-inch (0118739) and 3/

8-inch (0118740).

Figure 3.5 External 20-liter cubitainer fluid supply

b. For a 55-gal (208 l) drum, or other non-standard container, an

adapter is required (see Figure 3.6).

4. Connect the ink supply line to the nozzle.

5. Route the line into the fluid compartment and position it so that the

line runs out through the notch in the door.

6. Close the door and check the lines for pinching and kinking.

Installation Guide 3-7

Page 40

Chapter 3. Printer Installation

Nozzle adapter

Voltage Selection

Voltage Selection

Figure 3.6 External 55-gallon supply containers

Use the following procedure to set the input voltage for a DP5120 or

DP5122 printer.

Caution: Do not power up the printer until the correct voltage switch is selected.

Applying power at the incorrect voltage will damage the printer.

1. Locate the circuit breaker switch and confirm that it is in the offline (O)

position (see Figure 3.7).

2. Locate the voltage selector switch above the circuit breaker switch.

3. Loosen the two screws securing the safety cover to the switch (see

Figure 3.7).

Figure 3.7 Voltage selector switch cover

3-8 DP5000 Series Printers

4. Remove the fuse (0178607) (see Figure 3.8).

Page 41

Chapter 3. Printer Installation

Selector switch

120V

1

00

V

2

4

0

V

230V

2

2

0

V

2

00

V

(cover on)

Printer Connections

Figure 3.8 Fuse removal, circuit breaker switch

5. Rotate the safety cover counter-clockwise to clear the rotary switch.

a. Use a large, flat-blade screwdriver to turn the switch.

6. Select the correct voltage for the input power source at the installation

site. Six settings are provided (see Figure 3.9); the factory default

setting is 120V. The setting is indicated by the triangle on the rotary

switch.

Printer Connections

7. Replace the fuse.

8. Replace and secure the safety cover.

Figure 3.9 Voltage selector switch, DP5120 and DP5240

Use the procedures in the following sections to install the necessary

printer connections. The type of data connection used depends on the

printing system and printing application. The printer requires the following

connections:

• Printer power

• Tach and cue

• One of three types of data connection:

• Ethernet

• Centronics (parallel) and RS 232 (serial)

•K4K.

Installation Guide 3-9

Page 42

Chapter 3. Printer Installation

K4K

Power

Sort / Stop

Centronics

Printer Connections

The printer may use either of the following printing system hardware

interfaces:

• Control I/O

• Sort / Stop.

The cables required for the printer connections are provided in one of the

following kits shipped with the printer:

• HARDWARE AND CABLE KIT (0175833)

• SHIPPING KIT - PRINTER (0178223)

• HARDWARE & CABLE KIT - DARK GRAY (0187976).

Figure 3.10 shows the printer connectors.

Figure 3.10 Connectors, printer back panel

3-10 DP5000 Series Printers

Page 43

Chapter 3. Printer Installation

Power cord connector

Circuit breaker switch

Printer Connections

Printer Power

Use the following procedure to connect the printer power cord.

1. Confirm the circuit breaker switch is in the offline position (O).

Note: This switch is on the printer rear panel (see Figure 3.11).

2. For a DP5120 or DP5240, check that the voltage selector switch is

set correctly (see “Voltage Selection”).

Note: The DP5122 does not have the voltage selector switch.

3. Plug the female end of the power cord to the circuit breaker

receptacle on the printer back panel.

Note: The standard printer power cord is CORD-JUMPER ACC UL/CSA

<HAR> M/F 10A/250V 8'- 2" (2.5m), part number 0100238-102.

4. Plug the male end of the cord into a compatible power source

receptacle.

In a printing system, this cord is factory installed; it is plugged into a

receptacle in the cabinet power distribution panel.

For specifications on printer power requirements see “Appendix C. Site

Requirements”.

Figure 3.11 Power cord connector, printer back panel

Installation Guide 3 - 11

Page 44

Chapter 3. Printer Installation

Ethernet

Printer Connections

Ethernet

If the installation requires the Ethernet data input option, connect the

external, coaxial data cable to the transceiver BNCM connector on the

printer back panel (see Figure 3.12).

The standard Ethernet cables are:

• CBL-COAX THINET BNCM/BNCM 6FT (0100378-203)

• CBL-COAX THINET BNCM/BNCM 30FT (0100378-207).

Ethernet operation requires special printer software and internal

hardware. Besides the transceiver that provides the BNCM connector

(0178559), an internal cables connect the transceiver to the DS Main

board (0178981 and 0178530). All the necessary components are

available in the 5000 SERIES ENET KIT (0181331).

For specifications of the Thinet connector used by the DP5000 series

printers, see the Service Guide.

Figure 3.12 Ethernet connection, printer back panel

3-12 DP5000 Series Printers

Page 45

Chapter 3. Printer Installation

RS 232 (serial)

Printer Connections

RS 232 (Serial)

If the installation requires the Centronics cable data interface, connect the

external serial cable to connector RS 232 on the printer back panel (see

Figure 3.13). This cable goes to a COM port on the system controller

(host) PC (see “Controller Connections” in Chapter 4, “System

Installation”).

Note: CABLE-SERIAL PC: 5120/5240 (0139601) is the standard serial cable.

For detailed specifications of the RS 232 cable signals used by the

DP5000 series printers, see the Service Guide.

Figure 3.13 RS 232 (serial) connection, printer back panel

Installation Guide 3 - 13

Page 46

Chapter 3. Printer Installation

Parallel (Centronics)

Printer Connections

Centronics (Parallel)

If the installation requires the Centronics (parallel) data interface, connect

the external parallel cable to the CENTRONICS connector on the printer

back panel (see Figure 3.14). This cable goes to the parallel printer port

on the system controller (host) PC (see “Controller Connections” in

Chapter 4, “System Installation”).

Note: CABLE-PARALLEL, 6 FOOT (0139268) is the standard parallel cable.

For detailed specifications of the CENTRONICS cable signals used by

the DP5000 series printers, see the Service Guide.

Figure 3.14 Parallel data connection, printer

3-14 DP5000 Series Printers

Page 47

Chapter 3. Printer Installation

Control I/O

Printer Connections

Control I/O

If the installation requires connecting the printer to a 200 or 220 system

controller, an I/O box, or to an external device activated by sort codes, the

control I/O connection can be used with one of the following cables:

• CABLE ASSY-SIGS SORT CODE ADPT (0139375).

This cable adapts the control I/O connector to the J1 connector on the

system controller I/O board, or to an I/O box using the same 40-pin

connector.

• CABLE ASSY-SIGS SORT CODE ADAPT (24") 0178602.

This cable adapts the control I/O connector to the cable used for the

SORT / STOP (relay contact closure) cable. This cable typically goes

to a stacker, sorter, or other inline device activated by sort codes

embedded in the image data being printed.

Either cable is connected to the CONTROL I/O connector on the printer

back panel (see Figure 3.15).

For detailed information on the signals used by the Control I/O cable, see

the Service Guide.

Figure 3.15 Control I/O connection, printer back panel

Installation Guide 3 - 15

Page 48

Chapter 3. Printer Installation

Tach and Cue

Printer Connections

Tach and Cue

The printer requires one of the following types of tach and cue to print:

• External

• Internal

•Custom.

Internal tach and cue are used for testing and for special applications.

This section describes the external tach and cue connection. Internal tach

and cue is produced by software and has no hardware requirements. For

information on configuring a system for custom tach and cue operation,

such as a differential encoder, contact technical support.

Use the following procedure to connect the standard tach and cue

connections shipped with the printer:

1. Connect one end of the 9-pin CABLE ASSY-TACH/CUE EXT

(0139366) to the TACH / CUE connector on the printer back panel

(see Figure 3.16).

2. Connection to a 200 or 220 system controller requires CABLE,

6240:5120/5240 TACH/CUE. This cable connects the printer to the

tach and cue board in the controller.

3. Connect the other end of the cable to extension CABLE, 5120/5240

TACH/CUE EXT. 20FT.PKGD (0183205). The extension goes to the

tach encoder and cue sensor.

Note: In a system installation, this cable goes to a T/C port on the system

controller PC.

4. Check that the tach encoder is installed on the document transport

with its friction wheel in contact with a belt or chain that is moving at

the same speed as the substrate (paper).

5. Check that the cue sensor eye is mounted over reflective tape or in

line with the pre-printed cue marks on the web, and located close to

and upstream of the printhead.

Note: See also the vendor documentation shipped with the tach encoder and

cue sensor. Tach and cue wiring is described in “Appendix B, Tach and

Cue Wiring.”

Figure 3.16 Tach and cue connection

3-16 DP5000 Series Printers

Page 49

Chapter 3. Printer Installation

K4K (optional)

Printer Connections

K4K

If the printing system configuration requires use of the K4K connector,

connect the CABLE - K4K (0186773) to the optional K4K connector on

the printer back panel (see Figure 3.17). The K4K connector can be used

for either of the following data connections:

• K4K data (Admark mode)

• High-Speed parallel (pass-through mode)

If the printer has the K4K option installed, the external cable is provided in

the printer accessories kit. Field upgrade kits for K4K are available

(contact technical support).

K4K operation requires the optional K4K board in the printer data system

and internal cables. For hardware installation procedures and detailed

specifications of the K4K cable signals used by the DP5000 series

printers, see the Service Guide.

Figure 3.17 K4K connection, DP5240

Installation Guide 3 - 17

Page 50

Chapter 3. Printer Installation

Printer Connections

Sort / Stop

If the printing system requires sort codes sent over the sort relay

connector, a sort relay cable must be connected between the external

device or an I/O box and the SORT / STOP connector on the printer back

panel. Either of the following types of cable can be used:

• Cable, relay contacts:

The standard CABLE, RELAY CONTACTS (0178910) is 30.0 ft (9.14

m). This cable is part of FRU 0178938 which includes this procedure

as instruction 0178939.

•Custom:

A customer-supplied cable can be used for specialized applications.

A custom cable can have wires only for the connector pins being

used.

The following procedure describes how to connect the standard cable.

For custom cable specifications, or additional information regarding the

use of sort codes, contact technical support.

Use the following procedure to connect the relay contacts cable to the

SORT / STOP connector:

1. Select which side (half) of the split cable to use depending on type of

contacts on the external device (see Table 3.2).

Table 3.2 Relay contact cable wiring

Wire # Wire Color Contact / Type Function

1 Brown 1 (hot) / Normally CLOSED

2 Blue 2 (neutral) / Normally CLOSED

3 Green / Yellow - (Ground)

4

No pins Not used5

6

7 Green / Yellow - (Ground) Shield

8 Brown 1 (hot) / Normally OPEN

9 Blue 2 (neutral) / Normally OPEN

1. The green/yellow wires (not shown) are not connected to a contact. They provide partial shock protection when high voltage is

present.

BASE STOP

1

Shield

SORT A

3-18 DP5000 Series Printers

Page 51

Chapter 3. Printer Installation

!

WARNING

Printer Connections

2. Route the cable with the connector at the printer and the cut ends at

the device to be activated (see Figure 3.18).

Figure 3.18 Connector wiring, relay contact cable

3. Plug the cable into the SORT / STOP connector on the printer back

panel (see Figure 3.19).

Do not touch the terminals in the cable connector when connecting or

disconnecting the cable. The cable terminals are a high-voltage hazard

when the cable runs from a label base.

Figure 3.19 Sort relay cable connection, printer back panel

4. Power off the device or I/O box being connected.

5. Strip and separate the wires in the cut end of the cable.

6. Connect the brown wire to the terminal for contact 1 (hot).

7. Connect the blue wire to the terminal for contact 2 (neutral).

8. Cap the unused end of the cable.

Installation Guide 3 - 19

Page 52

Chapter 3. Printer Installation

Printer Connections

3-20 DP5000 Series Printers

Page 53

Enclosure Positioning

Umbilical

not coiled

Casters

Chapter 4. System Installation

This chapter describes the following printing system installation

procedures:

• Enclosure positioning

• Controller positioning

• System connections

• Installing software.

To ensure that you complete all steps of these procedures, complete the

in “Printing System Checklist” in Appendix A.

Use the following procedure to position the system enclosure:

1. Check that the umbilical is safely coiled inside the cabinet and that all

packing material is clear of the casters. If the umbilical was uncoiled,

coil it safely inside the cabinet (see Figure 4.1).

Figure 4.1 Cabinet, ready for positioning

2. Unlock the enclosure casters.

The casters should have been locked after removing the enclosure

from its shipping pallet (see “Chapter 2. Removing System

Packaging”).

Installation Guide 4-1

Page 54

Chapter 4. System Installation

Casters, unlocked

Enclosure front

Controller Positioning

3. Roll the cabinet by pushing the front (see Figure 4.2). The enclosure

is easier to control if pushed and steered from the front because the

front casters swivel, and the rear casters are fixed.

Figure 4.2 Enclosure ready for positioning

Note: Less clearance makes cabling the system difficult.

Controller Positioning

4. If possible, position the system enclosure where you have at least 3

feet (1m) of clearance in front and in back.

5. Lock the casters.

6. Route the umbilical.

Use the following procedure to position the controller components on top

of the system enclosure:

1. When the cabinet is properly positioned, check that the casters are

locked to ensure that the cabinet does not roll while components are

being placed on top of it.

2. Check that all boxes were brought from the location where the

shipping pallet was unpacked.

3. Unpack the controller PC and place the processor chassis on top of

the enclosure.

4. Unpack the monitor and place it on top of the controller PC (see

Figure 4.3).

Caution: Take all precautions recommended by the monitor manufacturer to

4-2 DP5000 Series Printers

protect the monitor from dust.

5. Unpack the keyboard and place it on top of the enclosure. The

keyboard skin can be installed, if desired.

6. Unpack the mouse and mouse pad and place them on top of the

enclosure.

Page 55

Chapter 4. System Installation

Controller PC (chassis)

Monitor

Keyboard

Mouse and pad

0139601

0139268

Controller Positioning

Figure 4.3 Controller components on system enclosure

7. Unpack the system accessories box.

8. Disconnect the retaining cable attaching the printer rear panel to the

enclosure. The retaining cable secures the printer during shipping,

but prevents it from being pulled out for service access.

9. Set all the cables aside for later use (see Figure 4.4).

Figure 4.4 Hardware and cable kit cables

Installation Guide 4-3

Page 56

Chapter 4. System Installation

System Connections

System Connections

System connections are the external cables that connect the system

enclosure (cabinet) and the system controller PC to other components of

the printing system. System connections are divided into the following

groups:

• Cabinet connections

• Controller connections.

Printer cable connections are described in Chapter 3, “Printer

Installation”.

If the multi-printer interface option is part of the installation, follow the

connection procedure in the Multi-Printer Interface Option Installation

Instructions (0114054).

Note: This guide shows a dual-controller PC installation.

Cabinet Connections

The following cables connect the system enclosure to other components

of the printing system:

• System (cabinet) power

• Tach and cue (external).

Connections to the printer are described in Chapter 3, “Printer

Installation” (see Figure 3.10). Tach and cue wiring is detailed in Appendix

B.

Apply the following general guidelines to making system connections:

• For detailed information on the interfaces and connectors, see the

Service Guide.

• Cable tie and bundle all cables that pass through the opening in the

top of the cabinet.

• Route the umbilical, cabinet power cord, tach and cue, and other

external cables through the left side of the printer cabinet rear panel.

System Power

Systems are shipped with one of the following power cord options,

depending on which is compatible with the installation location.

• Domestic power cord, 13A, 125V (0100238-026)

• European power cord, 10A, 200-230V (0181015)

• Japanese power cord, 12A, 100V (0100238-017).

Apply the following guidelines when installing a power cord:

• If installing a printing system in an environment that uses 50 Hz, 220

volts (or higher), use the European power cord.

• On a DP5120 or DP5122 printer, check that the voltage selector

switch is properly set.

• On a Jetscape controller PC, set the voltage switch to 115V if the

printer voltage is set to 100 or 120 volts. Set the PC to 240V if the

printer voltage is set to 200, 220, 230, or 240 volts.

4-4 DP5000 Series Printers

Page 57

Chapter 4. System Installation

Strain relief cable tie

System power cord

System Connections

Check that the power cord option received is correct, and then connect it

using the following procedure:

1. Put the power strip line switch in the offline (O) position.

2. Plug the female end of the cord into the main receptacle on the

enclosure power strip (see Figure 4.5).

3. Install the cable-tie strain relief as shown in Figure 4.5.

4. Plug the male end of the power cord into the input power source

receptacle.

Figure 4.5 Power cord connection, printing system

External Tach and Cue

Connect the external tach and cue CABLE ASSY-TACH/CUE EXT

(0139366) between the Tach encoder/Cue sensor cabling and the TACH/

CUE connector on the rear panel of the printer.

The standard external tach and cue cable is included in the installation kit.

This cable can be used to connect a printer directly to its tach and cue

source. Other cables of different lengths are available, including CABLE

ASSY-SHLD 9DM/ 9DF 10FT (0100378-003).

For connection to a system controller 100 or 200/220, use CABLE-S100/

S200:5120/5240 TACH/CUE, 10 FT. (0178740). This cable is included in

the Ethernet kit.

Controller Connections

The following cables connect the system controller PC components to

each other and to components in the cabinet:

• Data cable

• Keyboard and mouse

Installation Guide 4-5

Page 58

Chapter 4. System Installation

PC power

LPT3

LPT1

COM3

COM4

COM2

LPT2

Video

Serial mouse

Network port

(COM1)

PS2 mouse

PS2 keyboard

System Connections

• Monitor interface (SVGA)

• Power cables (PC and Monitor).

Figure 4.6 shows all the system controller PC connectors. Not all

connectors are used.

Note: The tach and cue connection to the PC is described in “Cabinet

Connections” because it connects the system enclosure to another

printing system component.

Figure 4.6 Controller PC connectors, back panel

4-6 DP5000 Series Printers

Data Cable

The data cable is connected between the controller PC and the printer.

The data cable can be any of the following types:

• CENTRONICS (parallel) and RS 232 (serial)

•K4K

Connect the RS 232 (serial) cable (0178552 or 0139601) to a COM port

on the PC. COM2 is the standard configuration, but another port can be

used. The correct COM port must be configured in Jetscape or CS150.

Connect the CENTRONICS (parallel) cable (0178550) to an LPT port on

the PC. The other end goes to the CENTRONICS connector on the

printer connector panel. LPT1 is the standard configuration, but another

port can be used. The correct LPT port must be configured in Jetscape or

CS150. The CS150 dongle is already connected to LPT1 on a CS150 or

dual controller (see the controller software Installation Guide).

Connect the K4K cable to an LPT port on the PC. The correct LPT port

must be configured in Jetscape or CS150.

For a multi-printer system, see the Multi-Printer Interface Installation

Instructions for a connection diagram.

Page 59

Chapter 4. System Installation

PS/2 mouse

Keyboard (with PS/2 adapter)

Monitor SVGA interface cable

System Connections

Keyboard and Mouse

The keyboard and mouse have integral cables. Connect the keyboard

adapter (serial to PS/2) packaged with it to the keyboard cable, and then