Page 1

KODAK VERSAMARK DP5000 Series

Remote Control Panel

Operator’s Manual

DP5120, DP5240, and DP5122 Printers

Kodak Versamark, Inc.

Page 2

Page 3

K

ODAK VERSAMARK

DP5000 Series Remote Control Panel

Operator’s Guide

DP5120, DP5240, and DP5122 Printers

Page 4

FCC Compliance Statement

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference, in which case the user will be required to correct the interference at his own expense.

Note: Good quality, shielded (braided shielded) cables must be used for the RS-232-C and Centronics interfaces.

Canadian EMI Compliance Statement

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils numériques de la classe A

prescrites dans le Règlement sur le brouillage radioélectrique édicté par le ministère des Communications du Canada.

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set out in the Radio Interference Regulations of the Canadian Department of Communications.

EMI-CISPR 22/EN 55 022/CE Marking

Warning: This is a Class A product. In a domestic environment, this product may cause radio interference in which case the user may be

required to take adequate measures.

KODAK VERSAMARK DP5000 Series Remote Control Panel

Operator’s Guide

Part Number Media Revision Date Description ECN

0113455-602

0113455-603

Print

PDF

001 05/2005 Revision for new features and Kodak format K5282

Previous Releases

Part Number Revision Date Description ECN

0113455 Print 002 04/2001 Final revision for DP5122 printer PKG960

0113455 Print 001 03/2001 Preliminary revision for DP5122 printer PKG938

0113767 Print 00 04/1997 Initial release 08821

© Eastman Kodak Company, 2005. All rights reserved.

This document contains proprietary information of Kodak Versamark, Inc. or its licensors and is their exclusive property. It may not be

reproduced without a written agreement from Kodak Versamark, Inc. No patent or other license is granted to this information.

The software described in this document is furnished under a license agreement. The software may not be used or copied except as provided in

the license agreement.

Kodak Versamark, Inc. makes no warranty of any kind with regard to the contents of this document, including, but not limited to, the implied

warranties of merchantability and fitness for a particular purpose. Kodak Versamark shall not be liable for any errors or for compensatory,

incidental or consequential damages in connection with the furnishing, performance, or use of this document or the examples contained herein.

Information concerning products not manufactured by Kodak Versamark, Inc. is provided without warranty or representation of any kind, and

Kodak Versamark, Inc. will not be liable for any damages resulting from the use of such information.

Kodak and Versamark are trademarks of Eastman Kodak Company.

0113455-602

0113455-603 5/2005 Printed in U.S.A.

Page 5

Scope

This guide describes how to operate a KODAK VERSAMARK DP5000 series printer

using the Remote Control Panel. The Remote Control Panel (RCP) is a hand-held

device that allows an operator to configure the printing behavior of the printer and

enables basic printer servicing without connecting a PC to the printer. The RCP is

available as an option for the DP5120, DP5240, and DP5122 printers. The RCP

can be used to perform the following operating procedures:

• Adjusting printhead phase and voltage

• Changing fluid system states in the clean, normal or purge tables

• Configuring printing behavior

• Configuring tach and cue settings

• Viewing the printer error log.

The RCP does not initiate printer operation and when it is connected, printer

operating procedures are unchanged. The RCP allows the operator to do certain

procedures while too far from the printer to reach the buttons on its fixed operator

panel.

Some legacy OEM printer controllers require the operator to configure printing

behavior at the printer. These controllers were designed for the obsolete 5000

printer (not the current DP5000 series printers). For configuration, the 5000 printer

had an 4-button operator panel with LCD display. The RCP gives this configuration capability to the current DP5000 series printers that have a 13-button operator panel without display (see Figure 2 on page 3).

Refer to the following Kodak Versamark, Inc. manuals for additional information:

• DP5000 series

This printed manual is shipped with every printer.

• DP5000 series

This CD-ROM contains the following PDFs:

•Service Guide

Operator’s Guide iii

Operator’s Guide

Service Manual

(0113941-603)

(011848-602)

(0113940-011)

Page 6

Scope

Text Notations

• Illustrated Parts List

• Service Diagrams

• Installation Guide

(0113943-603)

(0113943-603)

(0113944-603).

To order this CD-ROM, contact technical support.

The procedures in this guide should be performed only by a printer operator

trained by Kodak Versamark, Inc.

This manual uses the following typographical conventions.

This style Refers to

Ready

go

ENTER

[NEXT] Buttons and lights on the printer operator panel.

Save Software command buttons and sections of dialog boxes,

File → Open

ALT+F1

ALT, TAB

xx,yy

jobfile.dat File names.

Text displayed by the software.

Anything you type, exactly as it appears, whether referenced

in text or at a prompt.

Special keys on the keyboard, such as enter, alt, and

spacebar.

such as group boxes, text boxes, and text fields.

A menu and a specific menu command.

Pressing more than one key at the same time.

Pressing more than one key in sequence.

Variable in error messages and text.

iv DP5000 Series Remote Control Panel

Page 7

Scope

Safety Notations

Note: Information that needs to be brought to the reader’s attention.

Caution: A situation where a mistake could result in the destruction of data or system-type

Service and Support

The following definitions indicate safety precautions to the operator.

damage.

!

WARNING

A potential hazard that could result in serious injury or death.

!

DANGER

An imminent hazard that will result in serious injury or death.

Technical equipment support is available 24 hours a day, 7 days a week.

Software and applications support is available 8:00 a.m. to 5:00 p.m. EST/EDT,

Monday through Friday.

Call for telephone or on-site technical support; to order parts or supplies;

to request documentation or product information.

Phone Fax

U.S.A., Canada, and

worldwide

+1-800-472-4839

+1-937-259-3739

+1-937-259-3808

Europe +41-22-354-1400 +41-22-354-1480

Asia/Pacific Rim +65-6744-6400 +65-6744-6700

Japan +81-3-5621-2220 +81-3-5621-2221

Updated service

information

Customer support customer@kodakversamark.com

Operator’s Guide v

http://www.kodakversamark.com

Page 8

Page 9

Remote Control Panel Procedures

The procedures in this guide are divided into the following sections:

•Installation

• Display

• Selection screen

• Numeric input screen

•Installation

• Operation

• IJPDS Ethernet kit.

The first four section form an introduction that describes the Remote

Control Panel (RCP) hardware. The last section describes the IJPDS

Ethernet Kit option.

Operator’s Guide 1

Page 10

Remote Control Panel Procedures

Installation

Installation

The RCP is connected to the RS232 port on the back of the printer (see

Figure 1) and is powered by that port. The printer provides power only

when it is powered on. The RCP can remain attached during power-up

and shutdown cycles, and can be connected or disconnected when the

printer is powered on (hot plugged).

To install the cable to the remote control panel, carefully push the female

plug snugly into position. Be very careful not to bend the pins. To connect

the remote control panel to the printer, connect the serial port connector

to the RS-232 port at the back of the printer.

Note: Once the cable is connected to the remote control, leave it connected.

When connecting and disconnecting, do so from the printer end only.

Figure 1 Remote control panel attached to DP5120 printer

2 DP5000 Series Remote Control Panel

Page 11

Display

Remote Control Panel Procedures

Display

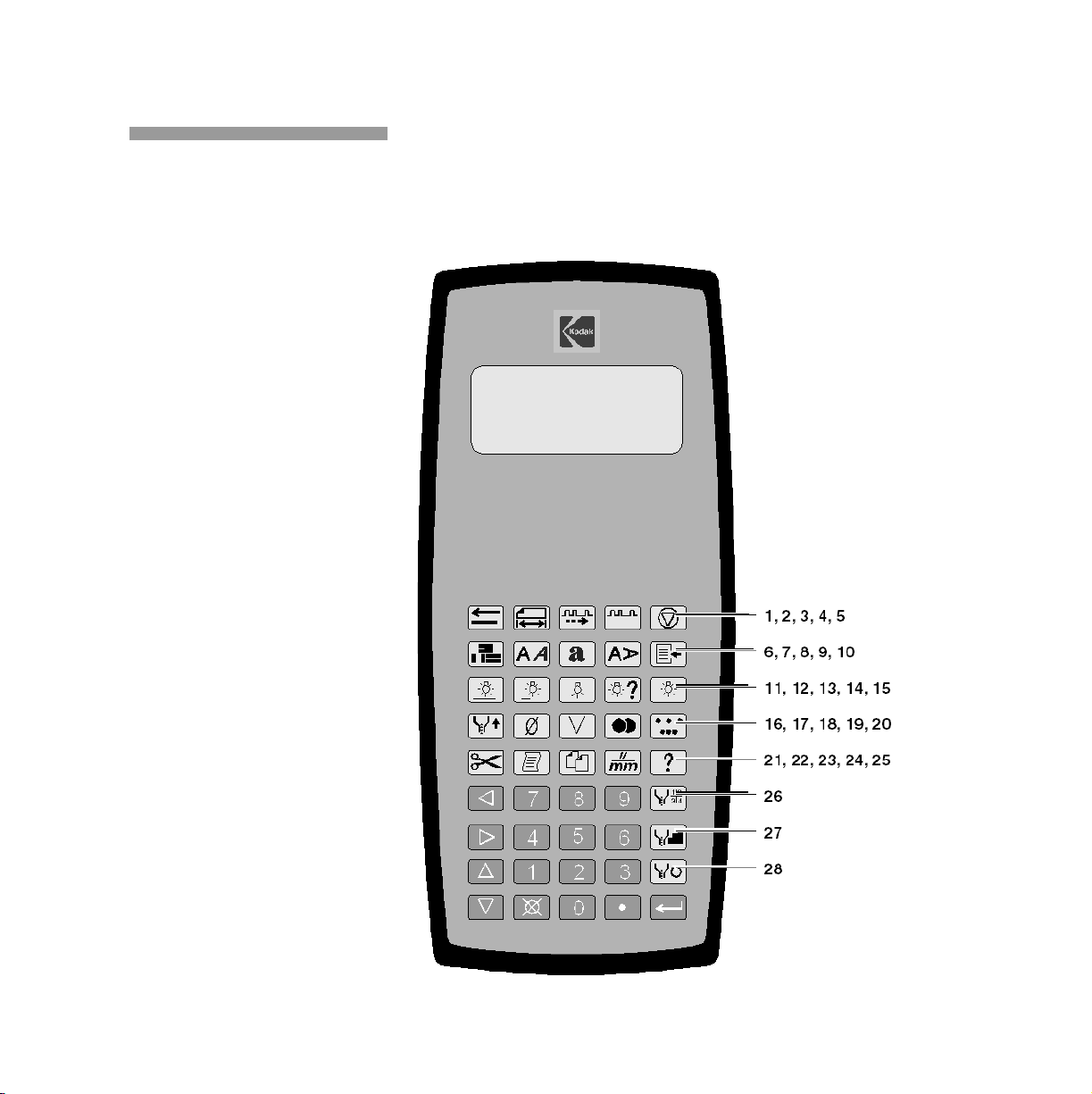

The Remote Control Panel is a hand held device that allows the operator

to configure the printing behavior of the printer and enable basic printer

servicing. The RCP has the following functional components (see Figure

2):

• LCD display

•Keypad.

Figure 2 Remote Control Panel functional components

LCD display

Keypad

Printer operator panel

The panel case protects its internal circuitry. To properly maintain the

remote control, apply the following guidelines to its care and use:

• Do not drop the remote control panel or immerse it in water.

• Clean the remote control panel with a damp cloth, do not use solvents

or cleaners. Wipe the remote control panel with a dry cloth after it has

been exposed to moisture.

• Do not take the remote control panel apart. There are no user

serviceable parts inside.

Operator’s Guide 3

Page 12

Remote Control Panel Procedures

Display

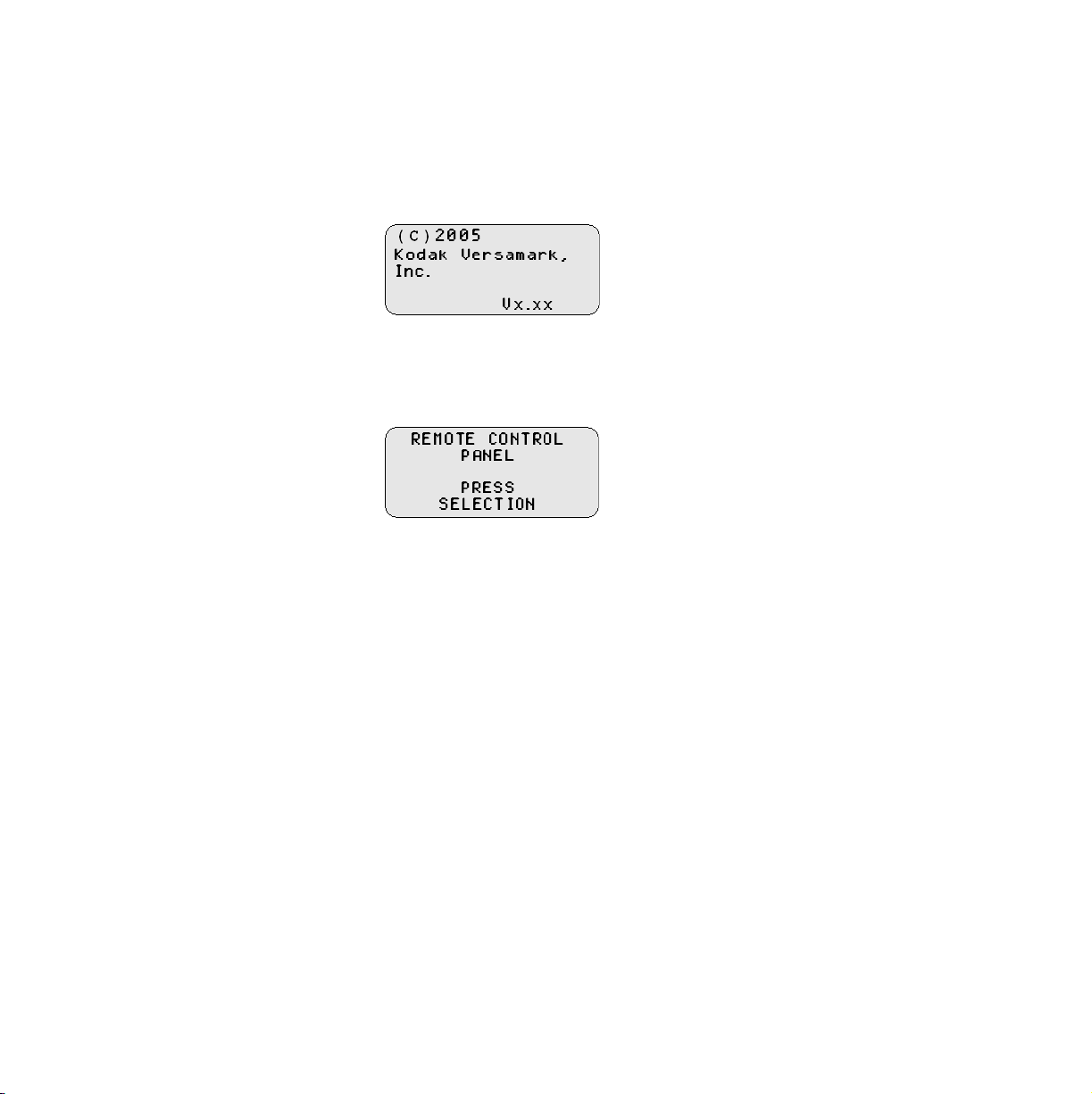

When the RCP is connected, the copyright screen (shown below)

appears and remain displayed connection is established with the printer.

If copyright screen does not clear in 2-3 minutes, check that the cable is

securely connected to the printer port.

The initial selection screen appears 5 seconds after the remote control

panel establishes printer connection. Press any key to skip the 5 second

delay.

4 DP5000 Series Remote Control Panel

Page 13

Selection Screen

Important: When the selection screen is displayed, press the up or down arrow keys

Remote Control Panel Procedures

Selection Screen

A selection screen displays the current printer setting in reverse video.

The user uses the arrow keys (shown below) to move between available

selections.

to change the contrast setting of the LCD display.

To activate the selection chosen press the enter key (shown below).

To keep the existing setting press the escape key (shown below).

Note: In Ready, some printer settings cannot be changed and the arrow keys

are disabled. Put the printer in Standby to enable the arrow keys, then

change the settings.

Operator’s Guide 5

Page 14

Remote Control Panel Procedures

Numeric Input Screen

Numeric Input Screen

In a numeric input screen the current printer setting is displayed above

the reverse video input field. The maximum allowable value is displayed

in the lower right hand corner of the screen. The minimum allowable value

is displayed above the maximum allowable value.

• Use the left and right arrows to move within the input field.

• Use the down arrow key to delete the current character.

• Use the numeric keys to enter a new value.

• Press

• Press

ENTER (↵) to send the value setting to the printer.

ESCAPE (!) to return to the previous screen without updating

the value setting to the printer.

Note: If an invalid setting is sent to the printer, the selection will flash and the

previous screen will not appear.

6 DP5000 Series Remote Control Panel

Page 15

Operation

Remote Control Panel Procedures

Operation

The figure below shows the numbers used in the section headings of this

guide to identify the function keys on the remote control panel. Use the

numbers to look up the description of a function or key icon.

Operator’s Guide 7

Page 16

Remote Control Panel Procedures

Keypad

Keypad

1) TRANSPORT DIRECTION

Transport Direction specifies the direction the substrate is moving under

the printhead. See the DP5000 Series

transport direction. This parameter has the following options:

N = Normal

The substrate moves under the printhead starting from the print array

edge of the printhead.

R = Reverse

The substrate moves under the printhead starting from opposite the

print array edge of the printhead.

Operator’s Guide

for details on

Use the arrow keys to position the cursor and then press

selection.

Note: This parameter cannot be changed while the printer is in the Ready State.

8 DP5000 Series Remote Control Panel

↵ to make the

Page 17

Remote Control Panel Procedures

Keypad

2) SUBSTRATE LENGTH

Substrate Length enters a value for the length of the print area. If 0 (zero)

is selected, the print area length is determined by the cue sensor input.

The range for this parameter varies depending on the printer resolution as

follows:

• 120 dpi resolution = 0.0 to 136.0 inches (0.0 to 345.44 cm).

• 240 dpi resolution = 0.0 to 68.0 inches (0.0 to 172.72 cm).

• 480 dpi resolution = 0.0 to 34.0 inches (0.0 to 86.36 cm).

Use the arrow keys to position the cursor, then use the numeral keys to

enter a value and press

Note: This parameter cannot be changed while the printer is in the Ready State.

↵ to confirm the entry.

Operator’s Guide 9

Page 18

Remote Control Panel Procedures

Keypad

3) TACH RATE

Tach Rate specifies the rate of the tachometer installed on the document

transport. This value is measured in pulses per inch (ppi) and the

following options are available:

120

Selects 120 pulses per inch (ppi)

240

Selects 240 ppi

480

Selects 480 ppi

960

Selects 960 ppi

Use the arrow keys to position the cursor and then press

selection.

Printer Resolution (dpi) Supported Tach Rate (ppi)

5120/5122

5240

Note: This parameter cannot be changed while the printer is in the Ready State.

10 DP5000 Series Remote Control Panel

↵ to make the

120x120 120, 240, 480

120x240 120, 240, 480, 960

240x240 120, 240, 480, 960

240x480 240, 480, 960

Page 19

Remote Control Panel Procedures

Keypad

4) TACH SOURCE

Tach Source specifies the source of the tachometer signal. The following

options are displayed:

N = Normal

Tach is entered at the tach/cue connector on the printer connector

panel.

K = K4K

If the K4K interface option is installed, the tach may be entered at the

K4K connector on the printer connector panel.

I = Internal

Used for testing purposes only, this option generates an internal tach

signal.

Use the arrow keys to position the cursor. Press

Note: This parameter cannot be changed while the printer is in the Ready State.

Operator’s Guide 11

↵ to make the selection.

Page 20

Remote Control Panel Procedures

Keypad

5) BASE STOP MODE

Base Stop Mode selects the type of base stop signal to be used. This

signal can be used by the printer to stop the document transport. The

following options are available:

M = Momentary

The signal is activated for 3 seconds when the printer goes offline.

C = Continuous

The signal is activated when the printer goes offline and is

deactivated when the printer goes online. This option allows the

controller to test the printer for online/offline status at any time and

prevents the document transport from being started when the printer

is offline.

Use the arrow keys to position the cursor, then press

selection.

Note: This parameter cannot be changed while the printer is in the Ready State.

12 DP5000 Series Remote Control Panel

↵ to make the

Page 21

Remote Control Panel Procedures

6) CHARACTER SET LANGUAGE

Character Set Language selects from the following list of options:

1 = USA ASCII 13 = SPANISH-1

2 =IRV-2 14 =SPANISH-2

3 = UNITED KINGDOM 15 =SPANISH-3

4 = SWEDEN ISO-11 16 =SPANISH-4

5 = FINLAND/SWEDEN 17 = LATIN AMERICAN

6 =CANADA 18 =GERMAN

7 = JAPAN 19 = FRENCH-1

8 =ITALIAN-1 20 = FRENCH-2

9 =ITALIAN-1 21 = CHINA

10 = ITALIAN-1 22 = DANISH

11 = PORTUGUESE-1 23 = DANISH/NORWAY

12 = PORTUGUESE-2 24 =NORWAY

25 = HUNGARY

26 = SERBIA/CROATIA/SLOVENIA

Keypad

Use the numeral keys to enter the number for a character set from the list

and then press

Use the numeral keys to select a display language value. Press

make the selection.

Note: This parameter cannot be changed while the printer is in the Ready State.

Operator’s Guide 13

↵ to confirm the selection.

↵ to

Page 22

Remote Control Panel Procedures

Keypad

7) CHARACTER SET MODE

Character Set Mode selects the character set language from a list of

extended character sets (character positions 128-255). The following

options are available:

1 = USA ASCII-7

2 = IBM PC-8

3 = Danish/Norwegian-8

4 = Roman-8

5 =ECMA-94

6 =ISO

Use the numeral keys to select a value and press

selection.

Note: This parameter cannot be changed while the printer is in the Ready State.

↵ to make the

14 DP5000 Series Remote Control Panel

Page 23

Remote Control Panel Procedures

Keypad

8) DEFAULT FONT

Use the up and down arrows to scroll the list. Press ↵ to make the

selection.

Select the default font for the printer from the list of available fonts. The

default font is selected by ID number. The font list is sorted by number in

ascending order.

While the font list is being read from the printer, the busy indicator, a small

bar (

⎯) will rotate in the lower left corner of the display.

The plus sign (+) appears by the top entry or bottom entry when more

entries are available above or below those shown on the display.

Note: This parameter cannot be changed while the printer is in the Ready State.

Operator’s Guide 15

Page 24

Remote Control Panel Procedures

Keypad

9) TEXT ORIENTATION and K4K INPUT FORMAT

Use the arrows to select a parameter, then press ↵ to display that screen.

Text Orientation

Use the arrows to select and then press ↵ confirm one of these options:

0°

The printed image is readable as printed when the substrate is

moving left to right.

90°

The image is printed perpendicular to substrate movement with

the left edge of the text against the top of the piece.

180°

270°

K4K Input Format

Use the arrows then

N = Native Input Command (NIC) input

A = Admark format.

16 DP5000 Series Remote Control Panel

The image is printed upside-down when the substrate is moving

left to right.

The image is printed perpendicular to substrate movement with

the left edge of the text against the bottom of the piece.

↵ to select and confirm one of these options:

Page 25

Remote Control Panel Procedures

Keypad

10) DEFAULT LINE SPACING

Use the up and down arrows keys to scroll the list. Press ↵ to make the

selection.

The plus sign (+) appears by the top entry or bottom entry when more

entries are available above or below those shown on the display.

F = FONT SET

F appears at the top of the scroll when the line spacing is taken from

the active font.

U = USER DEFINED

U appears at the bottom of the scroll.

When U is selected, the following input screen appears.

Use the arrow keys to position the cursor. Use the numeral keys to enter a

value. Press

values and to return to the selection screen above.

If English is the selected unit of measure, the following options are

available:

Font Set, 2 lpi, 3 lpi, 4 lpi, 5 lpi, 6 lpi, 7 lpi, 8 lpi, 9 lpi, 10 lpi, 11 lpi, 12

lpi, and User-Defined.

If Metric is the selected unit of measure, the following options are

available:

Font Set, 0.8 l/cm, 1.2 l/cm, 1.6 l/cm, 2.0 l/cm, 2.4 l/cm, 2.8 l/cm, 3.2 l/

cm, 3.6 l/cm, 4.0 l/cm, 4.4 l/cm, 4.8 l/cm, and User-Defined.

Note: This parameter cannot be changed while the printer is in the Ready State.

Operator’s Guide 17

↵ to send the value to the printer. Press ! to enter no

Page 26

Remote Control Panel Procedures

Keypad

11) CUE DELAY

Cue Delay is the distance from the leading edge of the substrate to the

start of the image target area. This value determines image position,

which is the first line of the printed image as it appears on the substrate.

Cue Delay has the same maximum length limits that Substrate Length

has (based on resolution setting).

Use the arrow keys to position the cursor. Use the numeral keys to enter a

value and then press

Note: This parameter cannot be changed while the printer is in the Ready State.

↵ to confirm the entry.

18 DP5000 Series Remote Control Panel

Page 27

Remote Control Panel Procedures

Keypad

12) CUE DISTANCE

Cue Distance is measured from the cue sensor to the print array. The

minimum cue distance 1.0 in. (2.54 cm). (See the DP5000 Series

Operator’s Guide

Cue Distance has the same maximum dimension limits that Substrate

Length has (based on resolution setting).

Use the arrow keys to position the cursor, then use the numeral keys to

enter a value and press

Note: This parameter cannot be changed while the printer is in the Ready State.

for details on cue distance.)

↵ to confirm the entry.

Operator’s Guide 19

Page 28

Remote Control Panel Procedures

Keypad

13) CUE SOURCE

Use the arrow keys to select on of the following options, then press ↵ to

confirm the selection.

N = Normal

Cue is entered at the tach/cue connector on the printer connector

panel.

K = K4K

If the K4K interface option is installed, cue may be entered at the K4K

connector on the printer connector panel.

I = Internal

Used for testing purposes only, this option generates an internal cue

signal.

O = I/O

Cue is entered at the I/O connector on the printer connector panel.

NI = Normal Inverted

Inverts the current cue signal coming from the tach/cue connector.

KI = K4K Inverted

Inverts the cue signal co5ming from the K4K connector.

II = Internal Inverted

Inverts the cue signal being generated internally.

OI = I/O Inverted

Inverts the cue signal coming from the I/O connector.

Note: This parameter cannot be changed while the printer is in the Ready State.

20 DP5000 Series Remote Control Panel

Page 29

Remote Control Panel Procedures

Keypad

14) CUE ERROR

Use the arrow keys to select one of the following options, then press ↵ to

confirm the selection.

I = Ignore

Continue printing when a cue or piece overrun error is detected.

C = Cue

Stop printing when a cue overrun error is detected and report error

MC-05. This error occurs when the substrate feed rate is too high,

data is missing, or too much data exists for each image.

P = Piece

Stop printing when a piece overrun error is detected and report error

MC-08. This error results from an image length that exceeds the print

area. See Parameter 2. “Substrate Length”.

C/P = Cue/Piece

Stop printing when a cue or piece overrun error is detected. Either an

MC-05 or MC-08 error message is generated.

Note: This parameter cannot be changed while the printer is in the Ready State.

Operator’s Guide 21

Page 30

Remote Control Panel Procedures

Keypad

15) CUE MODE

Cue mode specifies the printer’s internal response to the cue signal.

Use the arrow keys to select one of the following options, then press

confirm the selection:

N = Normal

The printer handles cue distance, cue delay, and time of flight

compensation information when the cue signal is received.

P = Pass Through

Printing is enabled immediately after the cue signal is received, with

no delay for internal processing.

W = Web

Printing begins when the cue signal is received and continues as long

as data is available to print.

Note: This parameter cannot be changed while the printer is in the Ready State.

↵ to

22 DP5000 Series Remote Control Panel

Page 31

Remote Control Panel Procedures

Keypad

16) PRINTHEAD HEIGHT

Printhead Height specifies the distance between the print array (bottom of

the printhead) and the substrate.

Use the arrow keys to select one of the displayed values, then press

confirm the selection.

Apply the following guidelines to setting this parameter:\

• Printhead height affects print quality. To ensure the highest print

quality, the lowest possible print height should always be used.

• Optimum print quality for both the 5120, 5240, and 5122 printers is

obtained at a printhead height of 0.125 inch. (3.2 mm). At this height,

high resolution print is at Near Letter Quality (NLQ).

• When using a printhead height that exceeds 0.125 in. (3.2 mm),

select Odd Skip/Even Skip as the Print Density.

• Using Odd Skip/Even Skip print density reduces the maximum print

job speed. Test samples should always be printed to verify that print

quality is appropriate for the current job.

Note: This parameter cannot be changed while the printer is in the Ready State.

↵ to

Operator’s Guide 23

Page 32

Remote Control Panel Procedures

Keypad

17) PRINTHEAD PHASE

Use the arrow keys to position the cursor, then press ↵ to confirm the

selection.

Enter the value for the printhead charging phase, which appears on the

printhead label. This value is factory-set for the 5240 and 5122 printheads

(but not the 5120 printhead). Phase can be adjusted if problems with print

quality arise. The range is 1 to 55 counts. Check print quality after

adjusting this value. (See the DP5000 Series

on verifying print quality.)

Note: This parameter cannot be changed while the printer is in the Ready State.

Operator’s Guide

for details

24 DP5000 Series Remote Control Panel

Page 33

Remote Control Panel Procedures

Keypad

18) PRINTHEAD VOLTS

Use the arrow keys to position the cursor, then press ↵ to confirm the

selection.

Enter the value for the charge lead voltage being applied to the printhead,

which appears on the printhead label. This value is factory-set for the

5240 and 5122 printheads (but not the 5120 printhead), and that setting is

on printhead label. Voltage can be adjusted if problems with print quality

arise. The range is 100 to 180 volts. Check print quality after adjusting this

value. (See the DP5000 Series

print quality.)

Operator’s Guide

for details on verifying

Operator’s Guide 25

Page 34

Remote Control Panel Procedures

Keypad

19) PRINT DENSITY

Print Density is the number of drops of ink used to produce a dot of ink on

the substrate. Print quality can be improved by changing print density,

making the image lighter or darker; however, changing print density can

also affect print resolution, making the resolution of smaller fonts more

difficult to read.

Use the arrow keys to select one of the following options, then press

confirm the selection:

1 = 1 Drop per Dot

One drop of ink is released to print one dot of ink on the substrate.

2= 2 Drops per Dot

Two drops of ink are released to print one dot of ink on the substrate.

O/E = Odd/Even

One drop of ink is released to print a dot of ink on the substrate;

however, every other drop of ink is skipped. This option can improve

print quality by eliminating a condition known as crosstalk. Crosstalk

occurs when the charge applied to one drop of ink disturbs the flight

of an adjacent drop, causing that drop to be deflected. This parameter

is not valid for the 5240 printer.

OS/ES = Odd-Skip/Even-Skip

Printing occurs every second cycle, alternating with a non-printing

cycle. This option should be used when printing at printhead heights

exceeding the recommended height of 0.125 in. (0.32 cm). Print

quality is improved by reducing crosstalk.

Note: This parameter cannot be changed while the printer is in the Ready State.

↵ to

26 DP5000 Series Remote Control Panel

Page 35

Remote Control Panel Procedures

Keypad

20) RESOLUTION

Select the print resolution, which is the degree of sharpness of an image,

measured in dots per inch (dpi). Vertical print resolution is perpendicular

to document movement, while horizontal resolution is parallel to

document movement. Control Panel only displays the parameter options

available for the printer you are operating.

When the print resolution is changed, the printer reloads its embedded

fonts. This operation may take several minutes.

When printing at high resolution, use a high resolution font and set the

printhead height at 0.12 in. (0.30 cm) or less from the substrate.

Use the arrow keys to select one of the following displayed options, then

↵ to confirm the selection:

press

120x120

Standard resolution for the 5120 and 5122

120x240

High resolution for the 5120 and 5122

240x240

Standard resolution for the 5240

240x480

High resolution for the 5240.

Note: This parameter cannot be changed while the printer is in the Ready State.

Operator’s Guide 27

Page 36

Remote Control Panel Procedures

Keypad

21) PIECE TERMINATION and SORT CONTROLS

Use the arrows to select a parameter, then press ↵ to display that screen.

Piece Termination

Piece Termination specifies the method used by the printer to identify

when the last piece of data for a piece is received.

Use the arrow keys to select one of the following options, then press

confirm the selection:

M = Margin

The end of the piece is reached when the bottom margin is exceeded

or the printer receives a form feed character.

F = Form Feed

The end of the piece is reached when the printer receives a form feed

character.

28 DP5000 Series Remote Control Panel

↵ to

Page 37

Remote Control Panel Procedures

Keypad

Sort Controls

Sort controls define how sort commands are processed when present.

Use the arrow keys to select any of the following four parameters

displayed, then press

SORT MODE

ACTIVATION EDGE

SORT PULSE WIDTH

SORT A-E

Sort Mode

↵ to display the screen for that parameter:

Use the arrow keys to select one of the following options, then press

↵ to confirm the selection:

S = Select

Use when only one sort gate is activated per document.

B = Binary

Use when two or more sort gates are activated per document.

The combination is based upon the binary value of the character

in the sort commands. When binary is used, the sort command in

the input data determines the sort gate to be activated; however,

each sort gate uses the delay and duration values assigned to

sort code A.

Operator’s Guide 29

Page 38

Remote Control Panel Procedures

Keypad

Sort Activation Edge

Sort Activation Edge specifies the edge of the piece at which the sort

gate activation or deactivation occurs. Use the arrow keys to select

one of the following options, then press

L = Leading

Activation and deactivation of the sort gate occurs at the start of

the first row of the printed image.

T = Trailing

Activation and deactivation of the sort gate occurs at the end of

the last row of the printed image.

Sort Pulse Width

↵ to confirm the selection:

Sort Pulse Width determines the length of time in seconds that the

sort gate remains active. The range is 0.00 to 9.99 sec. The sort gate

is activated in 0.01 sec. increments. If a pulse width of 0.00 is

selected, the sort pulse is activated for a cue period. A cue period is

the time elapsing between signals. Use the arrow keys to position the

cursor, then use the numeral keys to enter a value and press

confirm the entry.

Note: Because 0.01 seconds is too short to activate the relay, the minimum

delay should be 0.02 seconds.

30 DP5000 Series Remote Control Panel

↵ to

Page 39

Remote Control Panel Procedures

Keypad

Sort A-E

Sort A-E specifies the handling of five sort gate outputs for the printer.

Use the arrow keys to select on the displayed sort codes, then press

↵ to display the screen for that code.

On the Sort Code display, use the arrow keys to select each of the

following parameters, then press

parameter:

DELAY

DURATION

↵ to display the screen for that

Sort Code Delay is the number of pieces printed between detection of

a sort code and activation of the specified sort gate. When a value of

0 is entered, the sort gate is activated at the document containing the

code. When the sort mode is Binary, only values for sort code A are

applicable. The range is 0 to 99 pieces. Use the arrow keys to

position the cursor and then use the numeral keys to enter a value.

Press

↵ to confirm the entry.

Operator’s Guide 31

Page 40

Remote Control Panel Procedures

Keypad

Sort Code Duration is the number of pieces printed before the sort

gate is deactivated. When the sort mode is Binary, only values for sort

code A are applicable. The range is 0-99 pieces. When 0 is selected,

the sort gate is not activated.

If a sort gate is already activated and that sort gate is detected again,

the sort gate remains active for the specified duration for the second

time. The delay and duration values have the same meaning for the

other gates.

Use the arrow keys to position the cursor and then use the numeral

keys to enter a value. Press

↵ to confirm the value.

32 DP5000 Series Remote Control Panel

Page 41

Remote Control Panel Procedures

Keypad

22) PRINTING COMPLETE

Printing Complete specifies when you wish the host controller to be

notified that a piece has been printed by specifying the edge of the

document at which the printing completed signal is activated. Use the

cursor to select one of the following options, then press

selection:

T 10µs

Selects TRAILING edge and 10 microseconds

L 10µs

Selects LEADING and 10 microseconds

T 20ms

Selects TRAILING and 20 milliseconds

L 20ms

Selects LEADING and 20 milliseconds

↵ to confirm the

The following guidelines apply to these parameters:

Trailing

The signal is activated when at the end of the last row of the

printed image.

Leading

The signal is activated at the start of the first row of the printed

image.

Note: This parameter cannot be changed while the printer is in the Ready State.

Operator’s Guide 33

Page 42

Remote Control Panel Procedures

Keypad

23) DUPLICATION COUNT

Duplication Count specifies the number of times (1 to 999999) the printer

is to print the document. For example, if 5 is entered, 5 copies of the

document are printed.

Use the arrow keys to position the cursor, then use the numeral keys to

enter a value and press

Note: This parameter cannot be changed while the printer is in the Ready State.

↵ to confirm the entry.

34 DP5000 Series Remote Control Panel

Page 43

Remote Control Panel Procedures

Keypad

24) UNITS

Units selects the units of measure for position and length values. Use the

cursor to select one of the following options, then press

selection:

I

INCH selects English units of measure

M

METRIC selects standard International units of measure.

↵ to confirm the

Operator’s Guide 35

Page 44

Remote Control Panel Procedures

Keypad

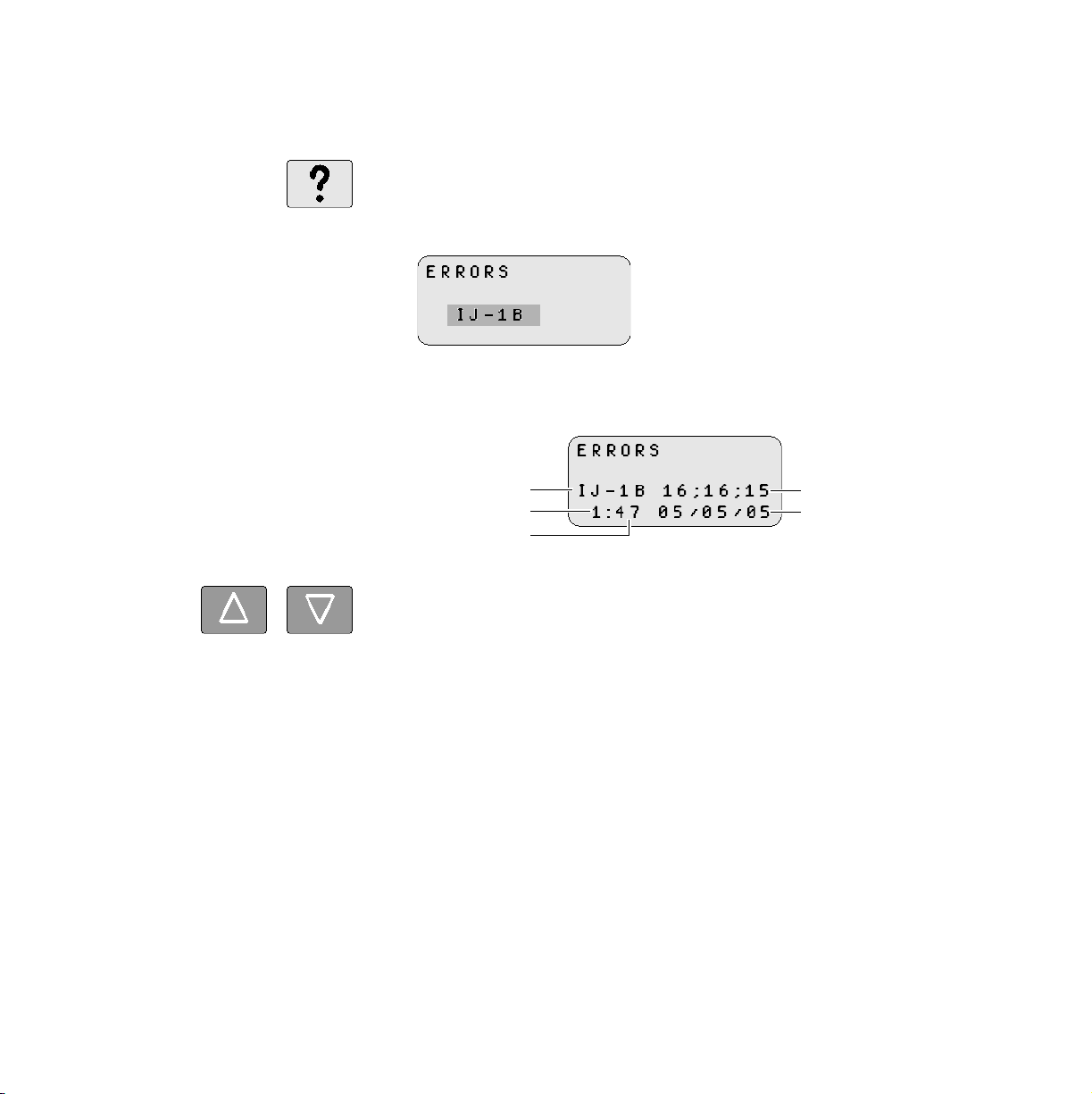

25) ERRORS

When the errors key (?) is pressed, one of the following displays appears:

•ERRORS

Any pending error is displayed (example shown below).

• ERROR LOG

If no error is pending, the error log is displayed (as shown below).

Error code

Entry displayed

Total entries read

Time of displayed entry

Date of displayed entry

Use the up and down arrow keys to scroll through the log (if it contains

multiple entries). The last entry logged by the printer is entry 1. To view

previously logged errors, press the down error.

Press

↵ to clear display and return to previous display.

36 DP5000 Series Remote Control Panel

Page 45

Remote Control Panel Procedures

Keypad

26) PRINTHEAD STATE TABLE

Printhead state table select a fluid system state for the printer. Use the

cursor to select one of the following options, then press

selection:

C = Circulate

Defines the states used to bring up the printhead for diagnostic

operation.

N = Normal

Defines the states used to bring the printhead up or down during

normal operation.

P = Purge

Defines the states used during a fluid system purge.

Transitions between states take varying amounts of time.

↵ to confirm the

Note: This parameter can only be changed while the printer is in the Down

State.

Operator’s Guide 37

Page 46

Remote Control Panel Procedures

Keypad

27) PRINTHEAD STATE NUMBER

Current state

Previous state

Current table

Printhead State Number specifies the state within the active table

selected by the Printhead State Table key. The current state is displayed

over the previous state. A rotating bar (

⎯) displayed in place of the

previous state indicates the printer is in transition to prior requested state.

Use the arrow keys on this display to select a fluid system state. Position

the cursor of the state number and use the numeral keys to enter a value,

then press enter (

↵) to put the printer in that state.

The current state is identified by the following codes on this display:

N

Selects the Normal Up table

C

Selects the Circulate table

P

Selects the Purge table.

Transitions between states take varying amounts of time.

38 DP5000 Series Remote Control Panel

Page 47

Remote Control Panel Procedures

28) PRINTHEAD COMMAND

Printhead commands generate the printer operations listed below:

S

Selects Standby to turn the fluid system on with the eyelid closed.

This state allows you to leave the fluid system on but protects the

orifice plate from contamination. Use this action when leaving the

printer idle for more than 1 hour (but less than 7 hours) or when

troubleshooting.

R

Selects Ready to turn the fluid system on with the eyelid open. The

printer must be placed in the ready before attempting to print.

D

Selects Down to turn the fluid system off and close the eyelid.

C

Initiates a printhead clean.

Keypad

Use the arrow keys to position the cursor over a code, then press

enter that command.

Operator’s Guide 39

↵ to

Page 48

Remote Control Panel Procedures

IJPDS Ethernet Kit

IJPDS Ethernet Kit

If the remote control panel is to be used with a 5000 series printer with the

IJPDS Ethernet Kit option, only the following functions will be accessible

on the Remote Control Panel.

• Tach rate

• Tach source

• Cue source

•Cue mode

• Printhead phase

• Printhead volts

• Resolution

• Errors

• Printhead state table

• Printhead state number

• Printhead commands

If the remote control panel is used with a 5000 series printer operating

with IJPDS Ethernet, the following screen will be displayed when a

function is selected that is not available.

Press

40 DP5000 Series Remote Control Panel

↵ or ! to return to previous display.

Page 49

Page 50

0113455-602

0113455-603

© Kodak Versamark, Inc.

Loading...

Loading...