Page 1

Page 2

Kodak Duplicating Microfilms

Microfilms are fine grain, high resolution microfilms with the exposure and

development latitude to duplicate/enhance varying quality originals.

Information regarding the following duplicating microfilms are included in this

document:

• Kodak Duplicating 2462 Microfilm

• Kodak Direct Duplicating 2468/3468 Microfilm

Kodak Duplicating Microfilms are

silver-halide films designed for

making high quality duplicates of

original camera and other

duplicate microfilms. Depending

on the film type used, these films

can either maintain or reverse

image polarity . These duplicating

microfilms can be used in a

variety of manufacturer’s silver

duplicators. Kodak Duplicating

• Kodak Direct Duplicating Intermediate 2470 Microfilm

Product applications Eastman Kodak Company produces Kodak Duplicating 2462 Microfilm, Kodak

Direct Duplicating 2468/3468 Microfilm and Kodak Direct Duplicating

Intermediate 2470 Microfilm. These films all require conventional processing.

Direct duplicating films maintain image polarity between generations. Kodak

Duplicating 2462 Microfilm reverses polarity.

Kodak Duplicating and

Direct Duplicating Microfilms

are primarily intended for

creating multiple distribution

copies of camera film

masters, and occasionally

as intermediate print film

masters, when creating

large quantities of duplicates

such that the original camera film is not at risk of damage. Kodak Direct

Duplicating Intermediate Microfilm is typically used as an intermediate print

master but may also be used as a distribution copy. All duplicating microfilms

use a “contact-printing” method, such that the master and duplicate are

brought into intimate contact during exposure. A description of each follows.

D-32 September 2009 1

Page 3

Kodak Duplicating Microfilm — 2462

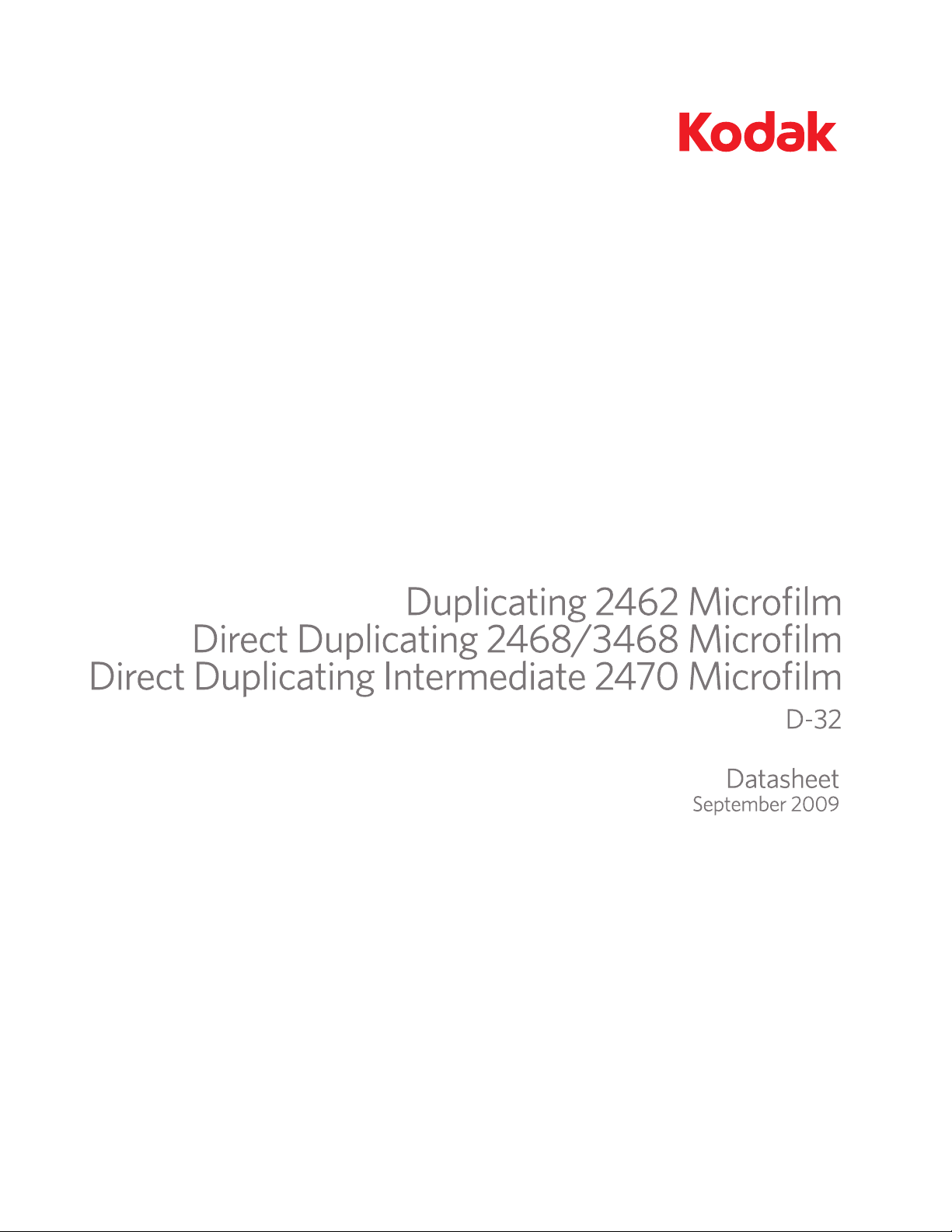

• Reverses image polarity (neg-to-pos or pos-to-neg) with conventional

processing

• Blue spectral sensitivity

• Medium contrast

• Primarily used for making positive images of publications such as

newspapers and magazines for frequent viewing

Kodak Direct Duplicating Microfilm — 2468/3468

Kodak Direct Duplicating Intermediate Microfilm — 2470 (Estar Base)

• Maintains image polarity (neg-to-neg or pos-to-pos) with conventional

processing

• Orthochromatic color sensitivity (blue-green)

• Medium contrast

• Primarily used for making distribution copies

• Maintains image polarity (neg-to-neg or pos-to-pos) with conventional

processing

• Orthochromatic color sensitivity (blue-green)

• Excellent tone reproduction

• Medium - low contrast

• Primarily used as an intermediate master to make multiple generation

copies

• Can also be used as a distribution copy

Microfilm thicknesses

Kodak silver-halide duplicating microfilms are available in the following

thicknesses:

• 2462 and 2468 Estar Base 4.0 mil — used in normal 16, 35 and 105 mm

roll film applications.

• 3468 Estar Thin Base 2.5 mil — used in 16 mm applications for reduced

loading frequency, reduced film storage requirements and maximum image

capacity per roll.

2 September 2009 D-32

Page 4

Common features The following features are common to all Kodak Duplicating Microfilms:

• Life expectancy of 500 years (LE-500) when processed and stored proper ly,

compared with 100 years (LE-100) for nonsilver duplicating films such as

diazo and vesicular.

• Ultra-high resolving power.

• Static-resistant, process-survivable backing.

• Micro-fine granularity.

• Very slow speed.

• Manufactured process is registere d to ISO 90 00 .

• Manufactured to ANSI and ISO standards specificati ons for films to be u sed

for storing records of long-term or permanent value.

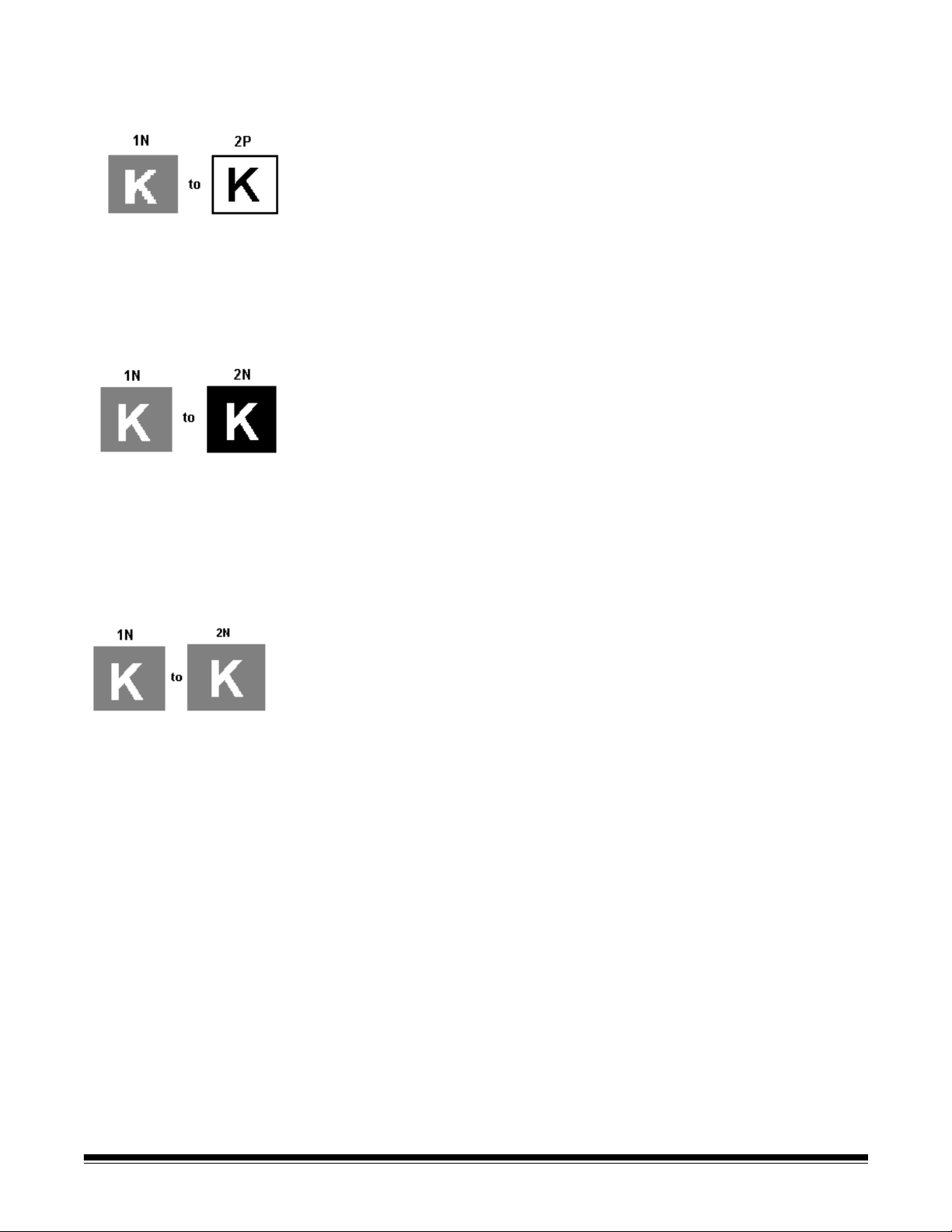

The following “duplication tree” illustrates how the various duplicating

microfilms are used to produce the desired contrast and image polarity of

distribution copies. As an example, 3N is showing 3rd generation negativeappearing distribution copies.

KEY:

CN = Camera Negative

st

generation

1 = 1

nd

2 = 2

3 = 3

generation

rd

generation

N = Negative polarity

P = Positive polarity

D-32 September 2009 3

Page 5

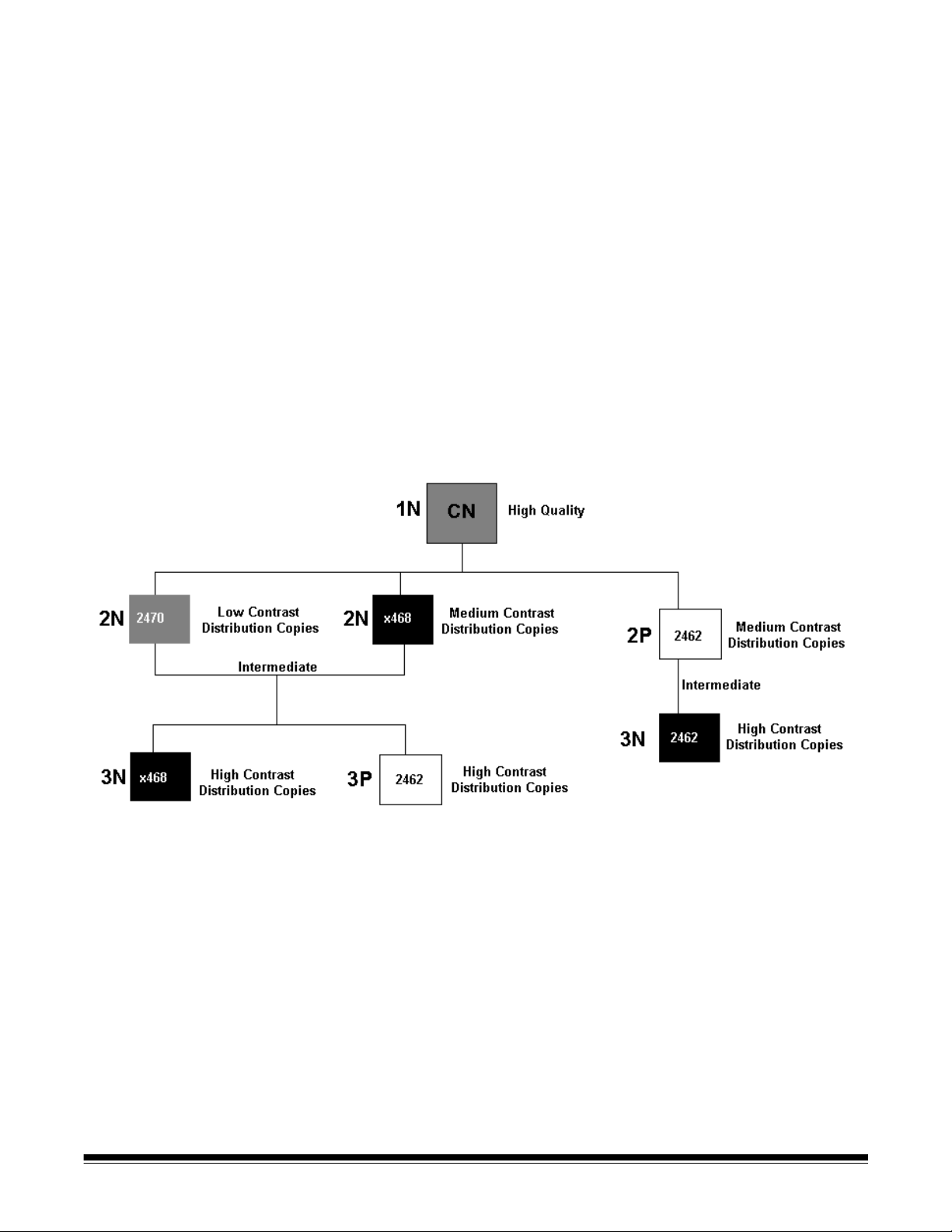

Physical properties Nominal thickness data (mils)

Microfilm Base* (mils Estar) Total†

2462, 2468, 2470 4.0 4.2

3468 2.5 2.7

* Static-resistance — process-survivable

† Unprocessed

Exposure

The following table indicates values for 1/25-secon d tu ng st en exp os ur es

calculated using the formula 45/H, where H is the exposure in lux-seconds

required for a density of .10 (1.20 for 2462 Microfilm) above minimum density

with indicated processing. This number can be used directly with incident-light

meters.

Meter Setting Value — recommended processes

2462 2.1

2468/3468 0.2

2470 0.12

Reciprocity data

For the Direct Duplicating Microfilms (2468/3468 and 2470), tungsten

exposures from 100 to 0.001 seconds, and processing in a Kodak Prostar

Processor as recommended, reciprocity failure is negligible and no correction

is normally needed. Similar results are expected with other recommended

processes.

With Duplicating Microfilm 2462 and using other than 1/50-second tungsten

exposures, correct for reciprocity failure at a density of 1.20 above D-min as

follows:

2462 Exposure Time (seconds)

100 10 1 1/10 to 1/100

Speed change (%) -75 -50 -20 none

Effective meter setting* 0.5 1.0 1.6 2.1

Correction in camera stops +2 +1 +1/3 none

*for Kodak Prostar Processor and continuous strand.

4 September 2009 D-32

Page 6

Exposure guidelines — 2468/3468 and 2470

Print density decreases with increased exposure and increases with added

development for the direct duplicating microfilms. For intermediate duplicating

masters, generally the D-min in the master should be printed to the density in

the following table. 2470 Microfilm is genera lly no t used for distrib ution copi es.

If it is used as a distribution copy, reduce D-min levels to the levels indicated

for 2468/3468 Microfilm.

Microfilm Exposure Control

Print D-min of master to a density on

the duplicate as specified below:

2462 .08 to .15

2468/3468 .10 to .15

2470 .15 to .25

Processing information

Conventional

Processor

Kodak Prostar 13.5 sec. 100°F

Deep tank 90 sec.* 8°F

Developer Fixer Wash Dry Dilution

Dwell Temp Dwell Temp Temp Temp Dev Fix

37.8°C

29.4°C

Processors and processing chemicals

Kodak Duplicating Microfilms can be processed in most typical continuousstrand type medium- and deep-tank processors using common Kodak

Processing Chemicals and parameters. They are compatible with all standard

microfilm processing equipment and high quality microfilm chemicals, although

results may vary.

IMPORTANT: For best results and to avoid aeration, always add chemical

concentrate to water, not water to concentrate.

Processor set up

Following are the specifications for all Kodak Duplicating Microfilms. These are

the starting points and mixed formats.

13.5

sec.

45-90

sec.

NOTE: The dwell times and temperatures are starting points only. Specific

systems or customer needs may demand variation from these values

based on photographic aims. Dwell time is determined by timing film

speed from entrance roller to exit roller while running in the processor.

Deep tank times given should match the photographic results of a

Prostar Processor; significantly shorter development times are

achievable with these films by using higher exposure conditions

without any detriment to image quality.

96°F

35.6°C

85°F

29.4°C

96°F

35.6°C

80°F

26.7°C

135°F

57.2°C

160°F Max

71.1°C

Ready to Use

1:7 1:3

* For 2462 Microfilm, the starting dwell time for the developer is 68 second s.

D-32 September 2009 5

Page 7

Replenishment rates Development/transport time and transport rates are set to achieve desired

photographic aims; replenishment rate settings are determined by multiplying

the transport speed by the required replenishment rates for the appropriate

film width being used.

Use the chart and formula provided to determine the developer and fixer

replenishment rates (mL/min) by multiplying transport speed (ft/min) (which is

determined by dividing the path length of the developer tank in feet by the

dwell time in seconds and multiplying by 60; see example) and the appropriate

processor replenishment specification (mL/linear ft).

Replenishment mL/linear ft

16 mm 35 mm 105 mm

DevFixDevFixDevFix

Kodak Prostar 0.75 0.75 1.5 1.5 N/A N/A

Deep Tank 1.00 1.25 2.0 2.5 6.0 7.5

NOTE: These are starting point recommendations. Actual settings may

require adjustments to maintain process activity levels. Shorter dwell

times are acceptable; however, exposure adjustments will be

necessary.

Transport

speed X

(ft/min)

A calculation of replenisher rate follows:

For Processor: Allen M-70 Processor

Type of Film: 35 mm (2468 Microfilm)

Dwell: 70 seconds

Developer Film Path: 84 feet

Replenishment (Dev): 2 (from table above)

Calculated transport speed:

x 60 sec/min = 72 ft/min

84 ft

70 sec (transport speed)

Results:

72 ft/min x 2 mL/ft = 144 mL/min

replenishment rate for developer

Replenishment/

feet of film =

(mL/Lft)

Replenishment

rate

(mL/min)

6 September 2009 D-32

Page 8

Before-process handling and storage

Handling Total safelight exposu re, whether before or after image exposure, should not

exceed 30 minutes. For darkroom handling, 2468/3468 and 2470 Microfilms

should use a Kodak 1 Safelight Filter / red or Kodak 2 Safelight Filter / dark

red, in a suitable safelight lamp with a 15-watt bulb, located at least 4 feet (1.2

meters) from the film. Use a Kodak OA Safelight Filter /greenish yellow, with

the same lamp distance conditions for 2462 Microfilm. When using gooseneck

lamps with contact printers, a Kodak 1 Safelight Filter / red is required.

Storage For optimum life of Direct Duplicating Microfilms (2468/3468 and 2470), keep

unopened packages at 55°F (13°C), at 50 percent relative humidity or below,

and protected from radiation and x-rays. Film stored at higher temperatures or

humidities for a period of six months or more may lose photographic speed or

D-max. Duplicating Microfilm (2462) can be stored at 70°F (21°C) at 50

percent relative humidity or below , and protected from radiation and x-rays. T o

avoid moisture condensation on film that has been refrigerated, allow cold film

to reach approximate room temperature before opening the package (about 3

hours if refrigerated, 5 hours if frozen).

After-process and storage information

Image stability and keeping These microfilms are manufactured to ANSI and ISO specifications for

extended term storage use. When processed as recommended, these

microfilms meet both ANSI and ISO specifications for microfilms intended for

long-term storage. These microfilms have a Life Expectancy LE-500 rating.

ISO 19801 2002, Photography — Processed Silver-Gelatin Type Black-and-

White Film — Specifications for Stability, state that the maximum permissible

concentration of thiosulfate ion is 0.014 gr am s pe r square me te r (1 .4

micrograms per square centimeter). Thiosulfate limits for Class 1 grain apply

to this microfilm.

ANSI ISO 18911 2000, Photography — Processed Safety Photographic FilmsStorage Practices, gives a ppropriate conditions for extended term (p ermanent)

and long-term storage films. Information is also available in Kodak Publication

D-31, Storage and Preservation of Microfilms. Extended term storage

conditions require a temperature of less that 70°F (21°C) and 20- to 50percent RH for polyester base microfilm.

These ANSI/ISO Standards can be obtained by contacting: Association for

Information and Image Management International (AIIM), 1100 Wayne

Avenue, Suite 1100, Silver Spring, MD 20910-5603, website: http ://

www.ansi.org or by calling 301-587-8202.

NOTE: Refer to the latest revision of each ANSI or ISO St andard specified.

D-32 September 2009 7

Page 9

Image structure Resolving power: Based on recommended process.

Film Test-Object Contrast Lines/mm

2462 1.6:1 (ISO-RPL)

1000:1 (ISO-RP)

2468/3468 1.6:1 (ISO-RPL)

1000:1 (ISO-RP)

2470 1.6:1 (ISO-RPL)

1000:1 (ISO-RP)

These values were determined according to a method similar to ANSI/ISO

6328-2000, Photography — Photographic Materials — Determining of ISO

Resolving Power, except the light source used was a high-pressure mercury

arc.

250

630

400

1000

400

1000

Characteristic curves While the data presented are typical of production coatings , they do not

represent standards which must be met by Eastman Kodak Comp any. Varying

storage, exposure, and processing conditions will affect results. The company

reserves the right to change and improve the product characteristics at any

time.

Kodak Duplicating Microfilm 2462

Kodak Microfilm Developer and Replenisher (1:7)

Kodak Prostar Processor, Diffuse Visual

Density

Log Exposure (lux seconds)

8 September 2009 D-32

Page 10

Density

Kodak Direct Duplicating Intermediate Microfilm 2470

Kodak Direct Duplicating Microfilm 2468/3468

Kodak Microfilm Developer and Replenisher (1:7)

Kodak Prostar Processor, Dif fuse Visual

Log Exposure (lux seconds)

________ Kodak Direct Duplicating Microfilm 2468/3468

- - - - - - - - Kodak Direct Duplicating Intermediate Microfilm 2470

D-32 September 2009 9

Page 11

Modulation transfer function curves

Response (%)

While the data presented are typical of production coatin g s, the y do not

represent standards which must be met by Eastman Kodak Comp any. Varying

storage, exposure, and processing conditions will affect results. The company

reserves the right to change and improve the product characteristics at any

time.

Kodak Duplicating Microfilm 2462

Tungsten: Kodak Prostar Plus Developer

Kodak Prostar Processors; Diffuse Visual

Spatial Frequency (cycles/mm))

Kodak Direct Duplicating Intermediate Microfilm 2470

Kodak Direct Duplicating Microfilm 2468

Tungsten: Kodak Prostar Plus Developer

Kodak Prostar Processors; Diffuse Visual

Response (%)

Spatial Frequency (cycles/mm))

10 September 2009 D-32

Page 12

Modulation transfer function

The MFT curve was determined using a method similar to that described in

ANSI PH2.39-1977 (R1990), Photographic Modulation Transfer Function of

Continuous-Tone Black-and-White Photographic Films, Method of Measuring.

Diffuse RMS granularity

Determined at a net diffuse density of 1.00, using the aperture indicated.

48-Micrometer

Aperture Value

2462 5 15

2468/3468 less than 5 10

2470 less than 5 10

These values represent 1,000 times the standard deviatio n of density

produced by the granular structure of the material when a uniformly exposed

and developed sample is scanned with a densitometer calibrated to read

American Standard diffuse visual density, and having a circular measuring

aperture with the indicated diameter.

Granularity is an objective measurement of the spatial variation of sample

density that generally correlates with graininess, which is the subjective effect

of the image nonuniformity upon an observation when comparisons ar e made

at the same density level.

Broadly speaking, granularity measurements with the 48-micrometer aperture

will indicate the magnitude of the graininess sensation produced by viewing

the diffusely illuminated sample with 12X monocular magnification.

NOTE: If the viewing conditions are changed from the specified conditions,

the published RMS values may no longer correctly indicate the relative

sensations of graininess produced by various samples.

48-Micrometer

Aperture Value

D-32 September 2009 11

Page 13

Spectral sensitivity curves

Log Sensitivity

(ergs/sq. cm) required

to produce specified density)

(Sensitivity = reciprocal of exposure

Kodak Duplicating Microfilm 2462

Effective Exp 1.4 sec; All recommended processes;

Diffuse Visual; D=1.0>D-min

Wavelength (nm)

Kodak Direct Duplicating Microfilm 2468/3468

Effective Exp 1.4 sec; All recommended processes;

Diffuse Visual; D=1.0>D-min

Log Sensitivity

(ergs/sq. cm) required

to produce specified density)

(Sensitivity = reciprocal of exposure

Wavelength (nm)

12 September 2009 D-32

Page 14

Log Sensitivity

(Sensitivity = reciprocal of exposure

Kodak Direct Duplicating Intermediate Microfilm 2470

All recommended processes; Diffuse Visual; D=1.0>D-min

(ergs/sq. cm) required

to produce specified density)

Wavelength (nm)

NOTE: Wh ile the data presente d are typical of production coatings, they do not represent standards which must be met by

Eastman Kodak Company. Varying storage, exposure, and processing conditions will affect results. The company

reserves the right to change and improve the product characteristics at any time.

D-32 September 2009 13

Page 15

Ordering information

Contact your Regional Sales Manager if you have any questions.

Microfilms

Code Mil Format Spec Description No/Case CAT No.

2462 4 16 mm x 1000 ft 649 Type Z plastic core 10 833 2512

16 mm x 1600 ft 649 Type Z plastic cor e 10 834 5191

35 mm x 1000 ft 778 Type K plastic core 10 802 9720

35 mm x 2000 ft 778 Type K plastic core Pallet Pk 829 2716

35 mm x 2000 ft 778 Type K plastic core 5 819 3492

105 mm x 500 ft 914 Paperboard core, no keyway 4 813 6764

105 mm x 500 ft 914 Paperboard core, no keyway 150/pallet 846 4984

2468 4 16 mm x 1000 ft 649 Type Z plastic core 10 810 5652

35 mm x 1000 ft 778 Type K plastic core 10 811 3896

35 mm x 2000 ft 778 Type K plastic core 5 801 0357

105 mm x 500 ft 914 Type Z plastic core 10 883 0705

2470 4 16 mm x 1000 ft 649 Type Z plastic core 10 817 9749

35 mm x 1000 ft 684 Type K plastic core 10 825 8345

35 mm x 2000 ft 778 Type K plastic core 5 875 1778

105 mm x 500 ft 914 Paperboard core, no keyway 4 827 4292

Ordering information

Chemicals

Chemical CAT No. Working Strength Solutions

Microfilm DEVELOPER and Replenisher — Concentrate at 1:7 yields

1 gal — 4/case 177 8869 32 gal

50 gal — 1 drum 190 1917 400 gal

Microfilm FIXER and Replenisher — Concentrate at 1:3 yields

1 gal — 4/case 817 7222 16 gal

50 gal — 1 drum 190 1164 200 gal

Kodak Prostar Processors Ready-to-use solution

Prostar Plus Developer: 1 gal — 4/case 102 2490 4 gal

Prostar Plus Fixer: 1 gal — 4/case 102 2656 4 gal

Material Safety Data Sheet s (MSDSs) on the chem icals (onl y) are available by

calling: 1-800-242-2424, ext. 43. MSDSs are also available at:

www.Kodak.com/eknec. You will need to supply the Kodak catalog number of

the chemicals for which you need MSDSs. Call the same number for MSDSs

for the actual working solutions and caution labels for the processor tanks.

Disclaimer The sensitometric curves and data in this publication represent product tested

under the conditions of exposure and processing specified. They are

representative of production coatings and, therefore, do not apply directly to a

particular box or roll of photograph ic material. They do not rep resent standards

or specifications which must be met by Eastman Kodak Company. The

company reserves the right to change and improve product characteristics at

any time.

14 September 2009 D-32

Page 16

Loading...

Loading...