Knight Equipment OP Installation Manual

MF & OP SIGNAL FILTER

(MANUAL ADDENDUM)

OVERVIEW

The purpose of this addendum is to inform you of a low voltage signal filtering feature on the Multi-Flow and OnPremise dispensing systems that is not covered in the instruction manual you have. All other functions of these

systems will remain the same.

The signal filtering capability can help prevent unwanted injections caused by stray signals or “bleed“ voltages.

Typically you will have only one signal common, however, if using “split commons”, each common can be

independently set to filter signals.

OPERATION

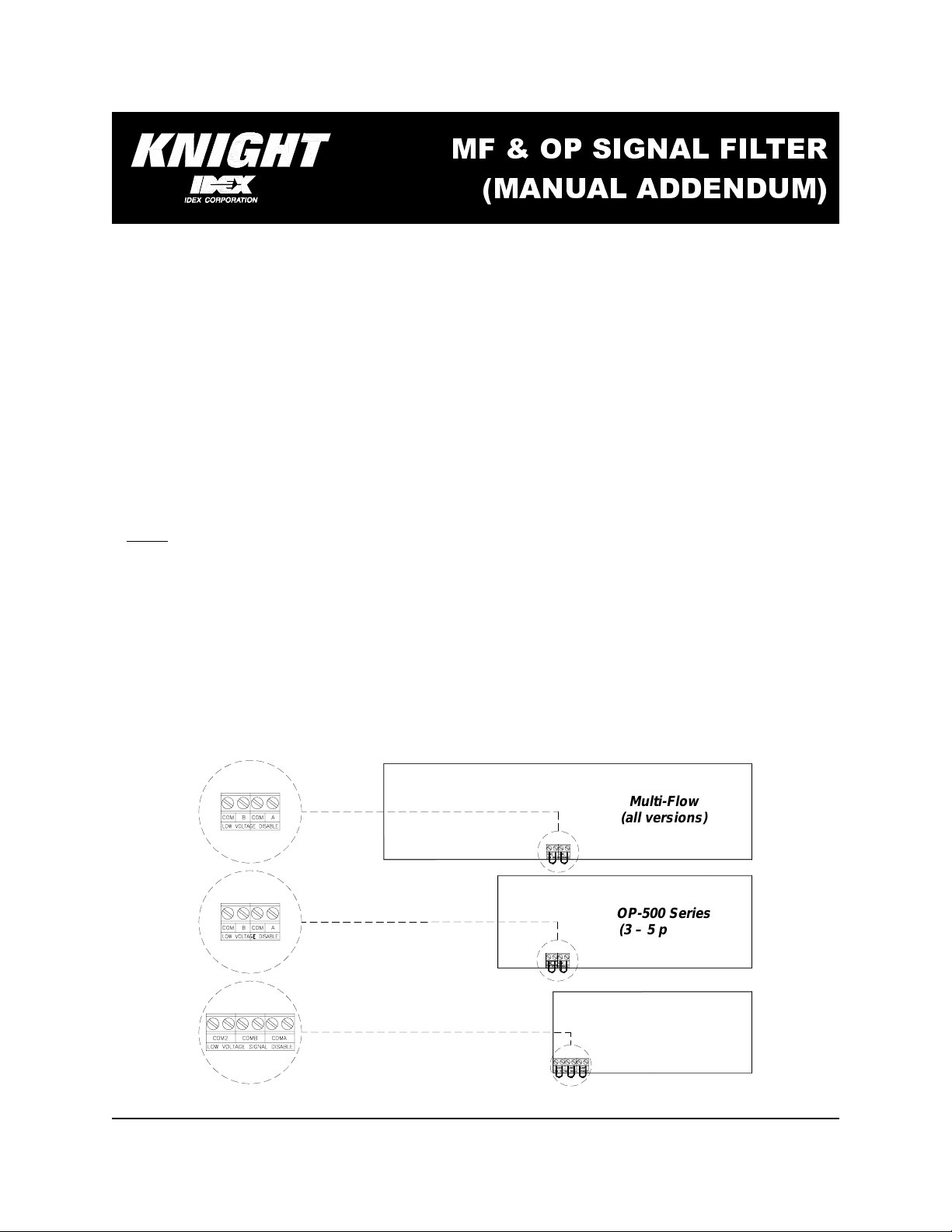

The signal filter is activated by removing a jumper wire on the pump circuit board. There is one jumper wire for

common A and one for common B (if required). See the diagram below for location of the jumper wires.

• When the jumper wire is removed, the signal input range is 70 – 240 volts.

• With the jumper wire in place (normal) the signal input range is 24 – 240 volts.

• Do not connect any signal wires or common wires to the terminals where the jumper wires go.

The following steps apply to both the Multi-Flow and On-Premise Series

(1) Locate the signal filtering jumper wires using the diagram below for reference.

(2) To filter signals that use common A, remove the jumper wire from the terminals marked “COM A LOW

VOLTAGE DISABLE“.

(3) To filter signals that use common B (if required), remove the jumper wire from the terminals marked “COM B

LOW VOLTAGE DISABLE“.

(4) For OP-502 custom applications only: To filter signals that use common 2 (if required), remove the jumper wire

from the terminals marked “COM 2 LOW VOLTAGE DISABLE“.

Multi-Flow

(all versions)

OP-500 Series

(3 – 5 pumps)

OP-500 Series

(2 pump only)

0900883 Rev: REL (02/03)

DISCLAIMER

Knight Inc. does not accept responsibility for the mishandling, misuse, or non-performance of the described items

when used for purposes other than those specified in the instructions. For hazardous materials information consult

label, MSDS, or Knight Inc. Knight products are not for use in potentially explosive environments. Any use of our

equipment in such an environment is at the risk of the user, Knight does not accept any liability in such

circumstances.

WARRANTY

All Knight controls and pump systems are warranted against defects in material and workmanship for a period of

ONE year. All electronic control boards have a TWO year warranty. Warranty applies only to the replacement or

repair of such parts when returned to factory with a Knight Return Authorization (KRA) number, freight prepaid, and

found to be defective upon factory authorized inspection. Bearings and pump s eals or rubber and synthetic rubber

parts such as “O” rings, diaphragms, squeeze tubing, and gaskets are considered expendable and are not covered

under warranty. Warranty does not cover liability resulting from performance of this equipment nor the labor to

replace this equipment. Product abuse or misuse voids warranty.

KNIGHT INC.

World Headquarters: 20531 Crescent BayDrive, Lake Forest, CA 92630-8825 (USA) TEL: 949-595-4800, FAX:949-595-4801, www.knightequip.com

Atlanta Branch:

415 GeesMill Business

Court NE, Suite 200

Conyers, GA 30013 USA

TEL: 770-760-8777

FAX: 770-761-0199

Toronto Branch:

2880 Argentia Road, Unit 6

Mississauga, Ontario

L5N 7X8 Canada

TEL: 905-542-2333

FAX: 905-542-1536

London Branch:

#15 Brunel Centre

Newton Road, Crawley

West Sussex UK RH109TU

TEL: 44-1293-615570

FAX: 44-1293-615585

A Unit of IDEX Corporation

Sydney Branch:

Unit 28, 317-321

Woodpark Rd., Smithfield

NSW Australia 2164

TEL: 61-29-725-2588

FAX: 61-29-725-2025

AmsterdamBranch:

Marssteden 68

7547 TD Enschede

The Netherlands

TEL: 31-53-428-58-00

FAX: 31-53-428-58-09

0900883 Rev: REL (02/03)

Spain Branch:

Port Ginesta, Local 210

08860 Sitges

Barcelona Spain

TEL: 34-936-342-130

FAX: 34-936-643-477

Loading...

Loading...