Knight Equipment On-Premise Pro Installation Manual

On-Premise Pro

Instruction Manual

0901133 Rev: A (11/13) Page 1 of 20

TABLE OF CONTENTS

Introduction ........................................................................................................... 4

Features ............................................................................................................... 4

Pre-installation ...................................................................................................... 5

Installation ............................................................................................................ 5

Operating Modes .................................................................................................. 6

Programming ........................................................................................................ 7

Load Counts ....................................................................................................... 10

Drain Mode ......................................................................................................... 11

Other Features ................................................................................................... 12

Troubleshooting .................................................................................................. 15

System Wiring Diagram ...................................................................................... 16

System Parts Diagram ........................................................................................ 17

Conformity Documentation ................................................................................. 19

Warranty Information .......................................................................................... 20

Knight Locations ................................................................................................. 20

Equipment Ratings

This includes equipment supply, description of I/O connections, duty cycle and operating environmental conditions.

1. Pollution degree 2;

2. Installation category 2;

3. Altitude 2000 m;

4. Humidity 50% to 80%

5. Power supply 100 - 240 VAC, 2.0 A, 50/60 Hz

6. Indoor use only;

7. Temperature 5°C to 40°C;

8. Mains supply voltage fluctuations are not to exceed 10 percent of the nominal supply voltage;

Electrical Ratings

Chemical dispensing pumps, Models OP-PRO, permanently connected, rated 100 - 240 VAC, 2.0 A, 50/60 Hz

Replacement on I/O Board: 2Amp, 250V, 6.3x32mm, Fast-Acting

Replacement on PCB inside SIB Module: 0.5Amp, 250V, 6.3x32mm, Fast-Acting

Approvals mark:

CAUTION: Wear protective clothing and eyewear when dispensing chemicals or

other materials. Observe safety handling instructions (MSDS) of chemical mfrs.

CAUTION: To avoid severe or fatal shock, always disconnect main power when

servicing the unit.

CAUTION: When installing any equipment, ensure that all national and local

safety, electrical, and plumbing codes are met.

Page 2 of 20 0901133 Rev: A (11/13)

8

1

3

5

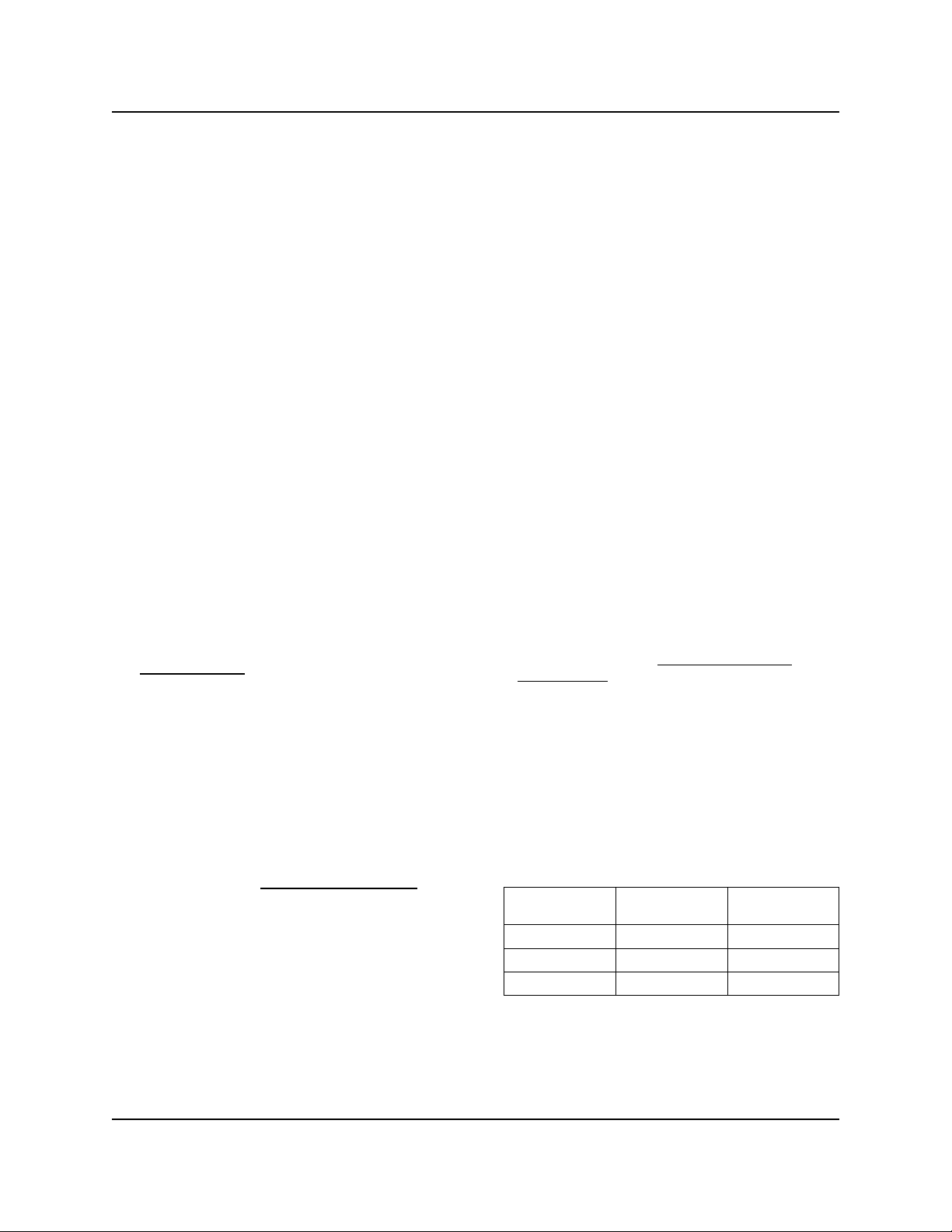

QUICK-START PROGRAMMING

6

10

4

9 2 7

The steps below will give you just the basics to quickly setup a new system — more details and complete

programming information are included in the following pages of this manual.

(1) Press once (for default 000 access code).

(2) Press ENTER...―ACC‖ will flash briefly on the display. You now have access.

(3) Note that the pump time LED will be flashing.

(4) Press pump SELECT until desired pump number is displayed.

NOTE: If using a flush manifold, program pump ―F‖ on all formulas to set flush time.

(5) Press formula SELECT until desired formula number appears.

(6) Use / to input the pump time or flush time (or delay time) in seconds.

(7) Press ENTER…the display will flash indicating that your entry has been saved.

(8) To program a pump delay time, press MODE until delay time LED is flashing. Repeat steps 4 – 7.

(9) To set the load count pump, press ENTER twice (note that pump time & delay time LEDs turn off). Use pump

SELECT to choose the pump number that will be used to count loads for each formula. After a few seconds, the

pump time LED will return, indicating that your entry has been saved.

(10) Press RESET when finished programming and ready to run.

0901133 Rev: A (11/13) Page 3 of 20

INTRODUCTION

FEATURES

The On-Premise Pro was designed to meet today’s

laundry chemical injection needs with economy and

flexibility in mind. Advanced microprocessor technology

makes the OP-Pro one of Knight’s least expensive

laundry injectors, yet has all the features to meet every

type of on-premise laundry condition.

The On-Premise Pro is a three component system, with

each component performing a specific function. See

diagram below for illustration of the following:

(1) The Signal Interface Module (SIB) receives supply

signals from the washmachine.

(2) Signals are routed to the Remote Control which

controls all timing and programming functions.

Pump run times and delay times are activated for

the selected formula number.

(3) The output circuit board located inside the pump

cabinet then runs the pumps for the correct amount

of time.

3

8 formula capability for various soil conditions

Independent pump run times to provide specific

volume injections

Individual delay times for all wash formulas gives

greater flexibility with ―fixed‖ timer washwheels

Programmed data is stored in non-volatile memory

and not affected by voltage spikes or power outages

Optional Drain Mode and Relay Mode

Optional Auto Formula Select

Formula and level enable/disable capability

Flush mode can be used with all modes of operation

Optional flush manifold with solenoid provides single

line diluted chemical injection

LED display on the remote control lets the user know

which pump is running, and which formula is active

The signal input circuitry will accept and verify a

signal that is in the range of 24 to 240 volts

2

1

QUICK-REFERENCE

Listed below is a guide for quickly setting features that are explained in detail throughout this manual. As a reminder,

you must have access (enter access code) to change any of the settings.

Setting Formula # Pump # Range/Choice

Access code A 1 0 – 255

Signal lockout time A 2 0 – 75 minutes

Delay units A 3 1 = seconds 60 = minutes

Pump 7 & 8 enable A 4 0 = disabled 1 = enabled

Drain mode A 5 0 = disabled 1 = enabled

Invert drain signal A 6 0 = normal 1 = inverted

Levels disable A 7 0 = levels 1 = no levels

System reset timer A 8 0 – 75 minutes

Auto formula select time A A 0 = disabled 1 — 5 to select time

Auto formula select mode A F 0 = micro 1 = chart

* Formula disable Various F 0 = enable 1 = disable

NOTE: The pump time LED must be flashing when setting all features above, except formula disable.

* Delay time LED must be flashing when setting the formula disable feature (only).

Page 4 of 20 0901133 Rev: A (11/13)

PRE-INSTALLATION

Before the equipment is installed, you should survey the

installation site thoroughly. At the very least, your survey

should include the following:

Check to make sure that all functions of the

washmachine are operating properly. Including; card

reader or timer, water solenoids, flush down valves,

water level switch, machine motor, and drain valve.

Check the proposed location for a 100 to 240 VAC

power source.

Check voltage of all supply signals that will be used

from the washmachine. Measure voltage between

supply signal and signal common with a voltmeter.

DO NOT check signal voltage between supply signal

and case (earth) ground.

Measure the distance from chemical supply

containers to pump housing, and from pump housing

to injection point inside washmachine.

INSTALLATION

(1) Disconnect all power to washer.

(2) Mount pump cabinet in a convenient location no

higher than 8’ above, and within 10’ horizontally, of

supply containers. This is usually near the washer,

however dispenser can be mounted as a remote

pumping system.

(3) Using the provided mounting bracket, mount the

Remote Control to the front of the washer where

operators can easily access it. Secure the bracket

to washer using provided mounting screws or DualLock fastening strips (be sure to first clean the

mounting surface as the adhesive will not stick to a

dirty surface). Connect the low voltage cable from

the remote to the pump cabinet.

(4) Connect 100 to 240 VAC power source to main

power connection in pump cabinet. Use suitable

conduit for electrical wiring (per applicable wiring

codes). NOTE: Low voltage cables do not require

conduit.

(5) Install and wire the Signal Interface Module (SIB)

per notes to the right.

(6) For each pump, cut the suction tube to length and

insert one end into the appropriate supply container

using PVC pipe as a support. Insert other end of

suction tube into the left (input) side of the pump’s

squeeze tube.

(7) For each pump, cut the discharge tube to length

and insert one end into the right (output) side of the

pump’s squeeze tube. Form an anti-siphon loop

(pointing ―down―) with the other end of discharge

tube and insert into the supply pocket of the

machine.

(8) The system is now ready to be powered up and

programmed.

The Signal Interface Module (SIB):

The SIB receives supply signals from the washer, then

communicates with the dispenser to run the pumps. The

low voltage cable allows a quick, clean connection from

the module to the pump system without requiring

conduit.

(1) Mount the module using the provided Dual Lock

adhesive strip. The module can be mounted inside

the washer’s controls, along side the washer’s

controls, or to the bottom of the pump cabinet.

(2) Connect the low voltage cable from the module to

the OP-Pro pump system.

(3) Connect the supply signals to the SIB per wire

colors on the SIB label. If using Drain Mode, only

one signal is required (pump #1).

(4) If you have one signal common (typical) connect

the common to ―COM A‖ on the SIB. If you have

two signal commons, you will need to remove a

resistor inside the SIB before connecting the

common wires! See the following details.

Splitting signal commons:

(1) Remove the four screws from the bottom of the SIB

to open the module.

(2) Locate the three resistors marked R1, R2, and R4,

on the left side of the module (each resistor has a

single black band).

(3) Cut and remove the resistor that will ―split‖ the

commons between the desired pumps. Be sure to

remove only one resistor.

CUT RESISTOR

R2 1, 2 3, 4, 5, 6

R1 1, 2, 3 4, 5, 6

R4 1, 2, 3, 4, 5 6

TO USE COM A

FOR PUMPS

AND COM B

FOR PUMPS

(4) Close the module and replace the four screws

when finished.

0901133 Rev: A (11/13) Page 5 of 20

OPERATING MODES

Normal operation:

The system is capable of 8 user selectable formulas

with each formula having unique run times and delay

times for each pump. Signals from the washer trigger

the pumps, then the On-Premise Pro’s microprocessor

takes control to count down delay and/or run times.

Wash formulas can be selected by either of the two

following options:

The machine operator can select the formula using

the formula SELECT button to choose the appropriate

wash formula before the washcycle begins.

Auto formula select can be used to allow the washer

to control the formula choice with a signal.

The first time pumps 1 - 6 are signaled, they will run

―level‖ 1. The next time these pumps are signaled in the

same formula, they will run ―level‖ 2 providing that any

signal lockout time (if used) has expired. Pumps 1 - 6

will not run again until the Load Count Pump is signaled,

formula number changed, or the RESET button is

pressed.

No more than 3 pumps (if applicable) should be

programmed to run simultaneously.

Pumps 1 - 6 are the only pumps with ―two level‖

capability. Level 1 can be ―skipped over‖ if desired, by

not programming any pump run time for that level.

When the first signal is applied, no pump action will

occur — the second signal will then activate the

second level as usual.

Relay mode:

The intended use of relay mode is for machines that are

microprocessor controlled. The pumps run for as long

as their respective signals are present. The system ―bypasses‖ its run time and delay time capabilities during

relay mode operation.

Formula numbers are not selectable in relay mode (as

they are not needed) — an ―r‖ will be displayed in the

formula number window indicating the system is in relay

mode. Flush mode can be used in relay mode if

chemicals are to be flushed with water to the washer.

To set relay mode, enter the access code, then use

FORMULA SELECT to choose formula ―r―. Set the load

count pump as explained in the Load Count section.

(Note: There is a one second qualifying time in relay

mode. For the pump to run for 10 seconds the signal

must be set for 11 seconds.)

Drain mode:

Drain Mode maximizes the versatility of the OP-Pro by

providing a simple and reliable signal interface to

washers that do not have typical supply signal

connections, or where the washer’s supply signals are

not operating correctly.

Installation time is quicker, as there is only one signal

source required from the washer for Drain Mode to

operate. See page 11 for complete details.

Flush mode:

The Flush Pump turns on with any pump running, then

activates its own programmed run time when the pump

shuts off. The system ―looks‖ for contact at the flow

switch terminals (see wiring diagram) to verify proper

flush. If a flow switch is not used, jumper JP1 should be

in place. A ―flush error‖ happens when no contact is

detected (switch or jumper) at the FLUSH ERR

terminals while only the Flush Pump runs. Flush errors

are indicated by the Remote Control flashing and ―F‖ in

the pump window. Also, the buzzer (optional) will sound.

Programming pump ―F‖ is only required for systems that

will inject with a flush manifold.

Page 6 of 20 0901133 Rev: A (11/13)

Loading...

Loading...