Knight Equipment MX HOSPITALITY Installation Manual

MX HOSPITALITY

INSTRUCTION MANUAL

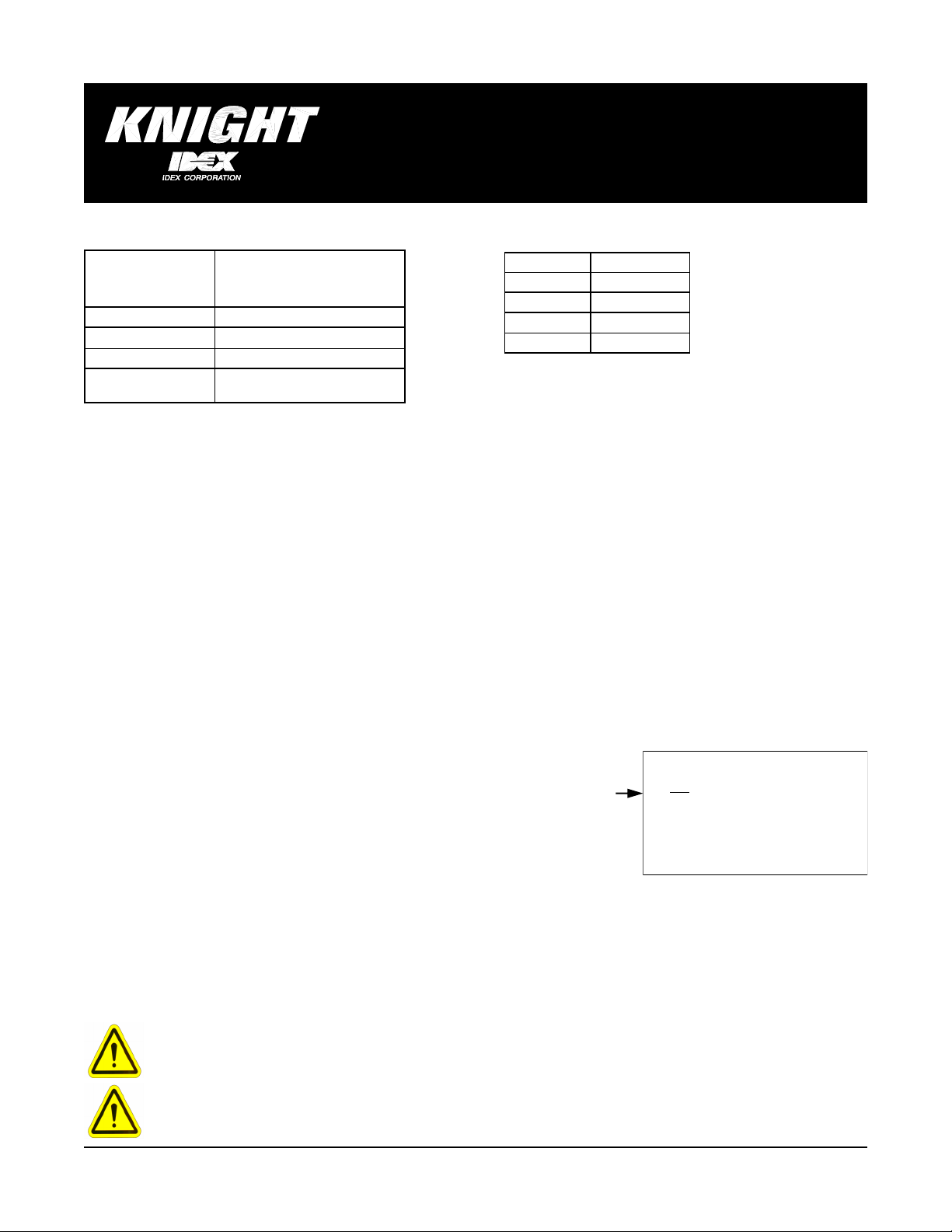

SPECIFICATION MATERIAL SPECIFICATION

Flow rates 1 GPM (3.8 LPM) bottle fill

4 GPM (15.2 LPM) bucket fill

1 GPM (3.8 LPM) bucket fill

Back flow preventer Flex-gap

Temperature

Ideal operating pressure

Minimum Pressure

Maximum Pressure

Max: 140° F (60° C)

40-50 PSI (2.8 - 3.5 bar)

20 PSI (1.4 bar)

100 PSI (6.9 bar)

Cover ABS

Flex-gap Polypropylene

O-ring EPDM

Water Valve Acetal

Water Inlet Brass

INSTALLATION

Mounting the unit

(1) Choose a convenient location close to water supply and not more than 5’ off floor.

(2) Hold proportioner against wall and mark keyholes — use a level for marking holes.

(3) Drill holes and install either toggle bolts or masonry screws (not supplied).

(4) Hang the unit and tighten screws. Always refer to hardware manufacturer’s

specifications for weight capacity and usage.

Attaching the drip tray (optional)

(1) Locate tray 12“ to 15“ below spouts. Mount in the same manner as proportioner.

(2) Attach a length of 1/4" tubing to drip tray for draining liquids.

(3) Divert drain tube to sink, drain, or five gallon holding jug.

Connecting the water supply

This proportioner operates best with a flowing water pressure of 40 - 50 PSI.

Fluctuating pressure can affect dilution ratios — use a water source that is not feeding

other equipment whenever possible. Water temperature should be between 40ºF and

140ºF.

(1) Attach male connector on high pressure supply hose to inlet side of proportioner

using garden hose washer.

(2) Attach female connector on high pressure hose to water source.

(3) Turn on water and check for possible leaks.

IMPORTANT NOTE:

If proportioner is connected to a janitor’s

sink with an atmospheric vacuum breaker, a

special connection kit is required by

A.S.S.E. specification 1055. Failure to use

this kit, or equivalent connection means, will

invalidate the A.S.S.E. and I.A.P.M.O.

(UPC) certification. Specify P/N 7600187

when ordering the kit.

SAFETY AND SERVICING TIPS

Avoid direct contact with chemicals — handle containers with caution. To avoid spillage, be careful not to tip containers.

Insert chemical suction line into container so that footvalve and ceramic weight sink to the bottom.

If valve fails to draw chemical, check the metering tip and footvalve for blockage — soak in warm water to clear.

CAUTION: Wear protective clothing and eyewear when dispensing chemicals or other

materials. Observe safety handling instructions (MSDS) of chemical mfrs.

CAUTION: When installing any equipment, ensure that all national and local safety and

plumbing codes are met.

0901135 Rev A (12/13)

Page 1 of 4

CHOOSING THE FLOW RATE

The flow rate is controlled by a venturi tube located within the venturi body. Venturi tubes have their GPM rating molded on the

side, or can be identified by color; WHITE = 1 GPM/ BLACK = 4 GPM.

To change the venturi tube:

(1) Remove the cover by gently snapping it away from the unit.

(2) Disconnect tubing from venturi body.

(3) Twist the venturi body counter-clockwise to remove it from the water valve.

(4) Push out existing venturi tube by inserting a pen up through the bottom of the venturi body (note the order of the parts as

they are removed from the flex-gap/venturi body).

(5) Insert the new venturi tube (for the desired flow rate) into the venturi body, ensuring that it seats firmly. Replace the flex-

gap parts in the order removed from the previous step.

(6) Twist the venturi body clockwise to reattach it to the water valve.

CHOOSING DILUTION RATES

IMPORTANT: Be sure to use the correct dilution chart for metering tip selection.

Metering tip selection

For each valve in the system, install appropriate metering tip from the charts at the bottom of the page. Be sure the metering

tip is threaded in hand-tight only.

Calibrating actual product ratios

To easily calculate the ounces per gallon for a specific product:

(1) Fill a graduated cylinder or spray bottle (that has ounce markings) with product.

(2) Install metering tip closest to desired ounces per gallon — see dilution charts.

(3) Drop chemical pick-up tube into the container holding the product.

(4) Activate valve until chemical line is primed up to the metering tip.

(5) Note how many ounces (of product) are in the container.

(6) Activate valve again, and fill a one gallon container with water/product mix.

(7) Note how many ounces (of product) were used.

(8) You now have determined actual ounces per gallon for this product.

METERING TIP CHART

1 GPM 4 GPM

TIP COLOR OZ/GAL RATIO OZ/GAL RATIO

NO INSERT 28 3.6:1 25 4.3:1

WHITE 22 4.8:1 20 5.4:1

YELLOW 18 6.1:1 18 6.1:1

PINK 16 7.0:1 16 7.0:1

GREEN 15 7.8:1 12 12:1

BLACK 14 8.5:1 10 15:1

BROWN 12 10:1 7 20:1

GRAY 8 15:1 5 31:1

BLUE 6 20:1 4 42:1

RED 3 42:1 3 63:1

PEACH 2.5 50:1 2 72:1

LT BLUE 2.0 63:1 1.5 101:1

PURPLE 1.75 74:1 1 127:1

LT GREEN 1.5 84:1 0.75 170:1

ORANGE 1 127:1 0.50 255:1

LT BROWN 0.5 255:1 0.25 511:1

Page 2 of 4

This chart is based upon the chemical

viscosity of water (CPS = 1.0) and should

only be used as a guide. Actual ratios and

flow rates may vary due to product

viscosity, flow pressure, and tubing

distance.

0901135 Rev A (12/13)

Loading...

Loading...