Page 1

DDS-1000

INSTRUCTION MANUAL

THEORY OF OPERATION

The DDS-1000 Dry Dispensing System is designed to dispense solid, or “screen-feed” chemicals into a washer. Each

dispenser includes a 24 volt water solenoid, Power Bowl Ultra dry detergent feeder (with vacuum breaker), step-down

transformer, fully assembled and ready to install.

The DDS-1000 is designed as a “stand alone” dispenser that can be used on any top-load or front-load laundry

machine. The DDS-1000 feed time is controlled by the laundry machine programmer.

GETTING STARTED

Be sure to inspect the installation site prior to beginning your installation. It’s important that you locate the source for

dispenser power (signal) as well as hot water. To complete the installation, you may need the following parts:

• Hose “Y” with 3/4" female garden hose thread

• High pressure hose, 3/4" MGHT x 3/4" FGHT

• #10 x 1" sheet-metal screws and wall anchors

• Optional top-mount bracket kit #7600668 is av ailable for top mounting the dispenser on the laundry machi ne

INSTALLATION

(1) Mount the DDS-1000 on the wall in a convenient location for operators to load and unload product containers.

The dispenser should be installed above the vertical height of the injection point on the washer.

(2) Connect the 5/8" ID vinyl injection tubing supplied with the unit to the outlet fitting on the bottom of unit. Cut the

discharge tubing to desired length and secure to washer supply inlet point. A 70° elbow barb fitting is supplied for

connection to washer.

(3) If an injection point is not available or desired, the injection tube can be manually placed in the machine each

load.

(4) Locate the chemical supply signal outputs on the washer for each dispenser you wish to signal. The signal must

be maintained for the duration of dispensing time.

(5) Route the supply signal wiring (usually 115/208/230 VAC) from the washer to the dispenser power input barrier

located on the vertical stainless steel panel. A 24 VAC signal can also be wired directly to the solenoid coil (see

wiring diagram on page 4).

(6) Connect common leg to the terminal marked “common” and the hot leg to the terminal marked with the same

voltage as that coming from the washer. Use approved electrical conduit to route signals to dispenser.

NOTE: Disconnect power before wiring to the dispenser. Always check power with a voltmeter prior to

connecting to dispenser.

0900969 Rev: C (05/07) Page 1 of 8

Page 2

(7) Connect the water source to the dispenser using a 3/4" male garden hose fitting, or 1/2" FNPT x 1/2" barb brass

fitting to nylobraid tubing, or to hard-plumb use 1/2" FNPT x 1/2" sweat (copper) fitting. A 3/4" hose “Y” can be

used to plumb the dispenser between the water source and the washer (see diagram on page 5).

Important:

with chemical manufacturer for recommended water temperature and optimum pressure.

(8) To maintain consistent injections, water pressure should be regulated at 25-50 PSI. Water temperature and

pressure will determine required dispenser run time.

(9) Connect the vacuum breaker to the unit using the supplied copper tubes. Tighten compression fittings on the

inlet and outlet fittings and check for leaks.

(10) See page 3 for connecting multiple units.

Check all local plumbing codes for backflow prevention and water line connection standards. Check

CONTROLLING FEED TIME

The chemical dosage, or feed time, of the DDS-1000 is controlled directly by the washer’s supply signal. Supply

signals should be programmed (at the washer) for the length of time required to dispense the required amount of

chemical for each operation. Consult the washer manual for programming of the washer’s supply signal outputs.

Page 2 of 8 0900969 Rev: C (05/07)

Page 3

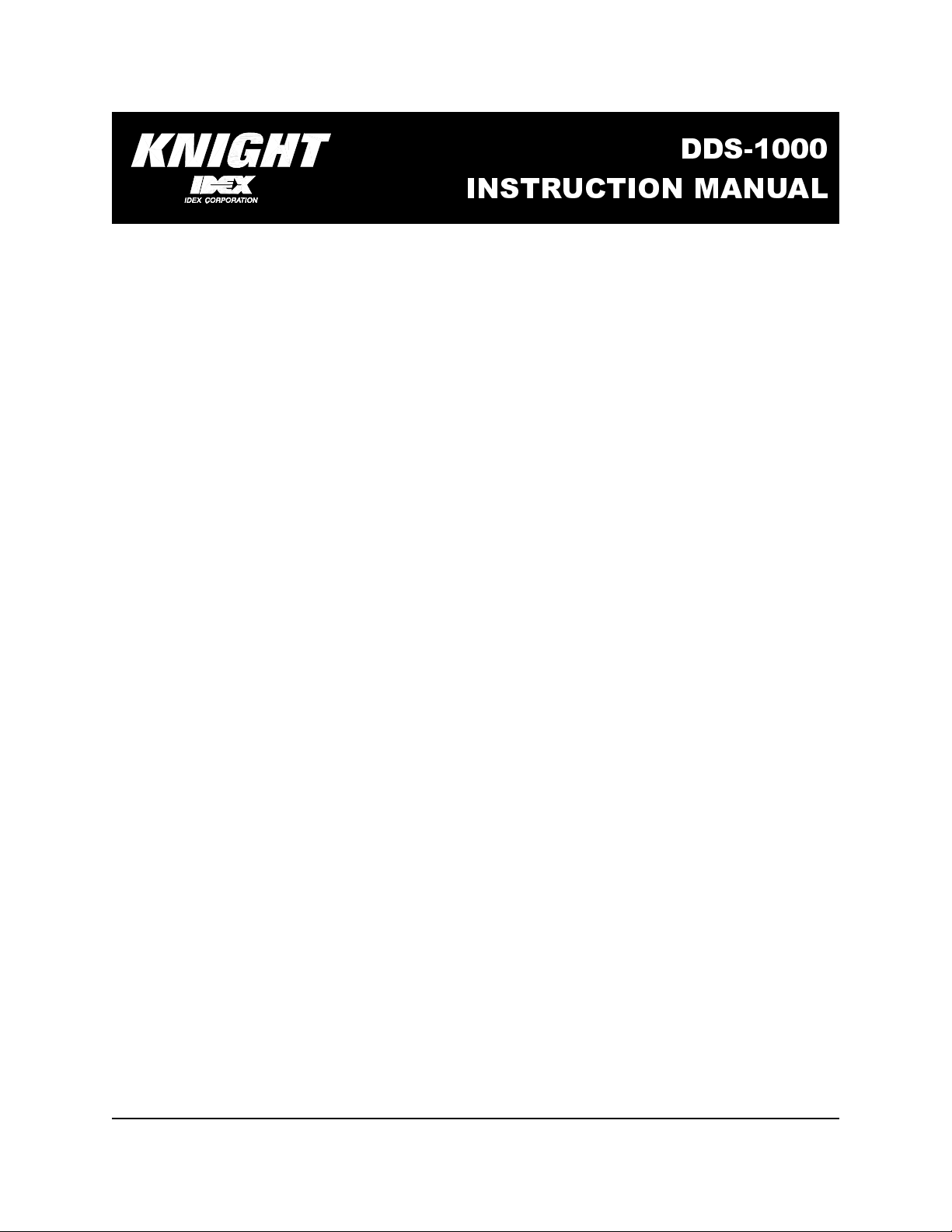

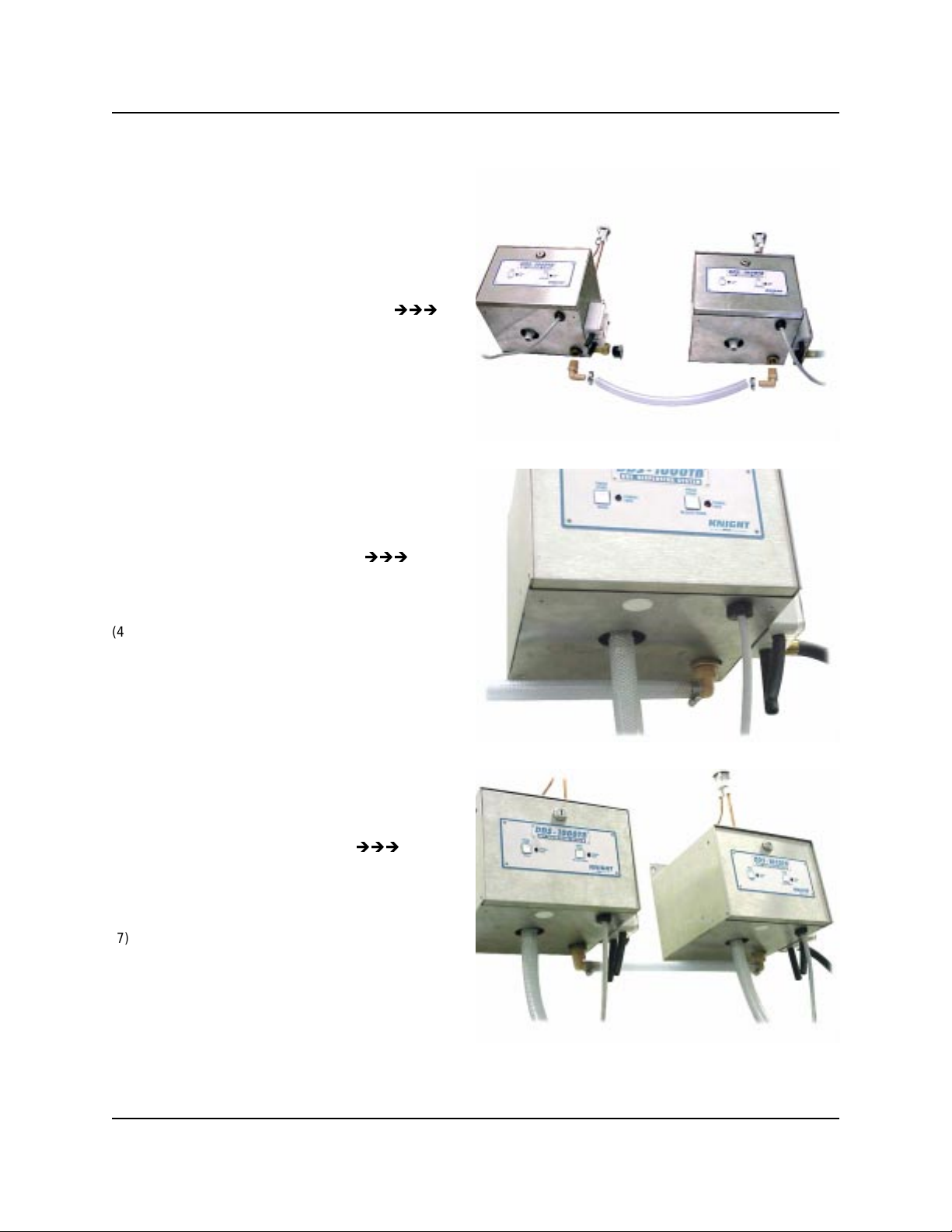

MULTIPLE UNIT CONNECTION

Connecting multiple DDS-1000 dispensers is quick

and easy with the DDS-1000 Connector Kit (Part

Number 7600672).

(1) Align units on the mounting surface side by side

and as close together as possible. Kit includes a

15 inch length of ½” ID Nylobraid tubing.

(2) Remove ½” plastic plug from brass “T” on bottom

of unit.

(3) Replace plug with ½” NPT x ½” Barb Elbow

fitting. Be sure to use plumbing tape or pipe

sealing compound to prevent leaks.

(4) Repeat above procedure for each unit connected.

(5) Insert plastic plug into ¾” hose adapter on each

unit except the unit closest to the water source.

(6) Connect ½” Nylobraid tubing to Barb Fittings

using stainless steel hose clamps.

(7) Connect “Source” water supply hose to unit

closest to water supply.

(8) Turn on water supply, press detergent / bleach /

softener start buttons and check for leaks.

0900969 Rev: C (05/07) Page 3 of 8

Page 4

DDS-1000 WIRING DIAGRAM

Page 4 of 8 0900969 Rev: C (05/07)

Page 5

DDS-1000 ASSEMBLY DIAGRAM

0900969 Rev: C (05/07) Page 5 of 8

Page 6

OPTIONAL WATER TEMPERING VALVE AND PRESSURE REGULATOR

We recommend the use of a water tempering valve and pressure regulator for optimal dry-feed performance.

Connect the tempering valve and pressure regulator before the water inlet of the DDS-1000 (see illustration below).

The tempering valve will allow the water temperature to be increased or decreased by turning the adjustment dial.

The adjustment range is 120° to 160° F. The pressure regulator will regulate the water pressure from 0 to 60 PSI.

Most manufacturers recommend pressure of 18-25 PSI (1.2 – 1.7 BAR) at a temperature of 120º-135° F (48°-57° C).

Connect to DDS-1000

Water Inlet

Cold Water

Pressure gauge assembly can be purchased at your local hardware store (see parts list below)

1 - 1/2” MNPT x 1/4” Brass Reducer

1 - 1/4” Pressure Gauge

2 - 1/4” Brass Close Nipple

7407118 Pressure

Regulator

Hot Water

7407119 Water Tempering

Valve

1 - 1/4” MNPT x 3/8” Barb

1 - 1/4” FPT Brass Tee

OPERATION

Insert a chemical capsule into the bowl of the DDS-1000. Run a few test cycles and inspect the operation of both the

washer and DDS-1000 to ensure proper chemical feed is achieved. Check all plumbing for leaks.

CALIBRATION OF SOLID DETERGENTS

As general rule of thumb program 10 seconds of run time for one ounce (28.3 grams) of detergent. For 2 ounces

(56.7 grams) set the run time for 20 seconds. First weigh the capsule (electronic scale may be needed) then start or

signal the dispenser. Weigh the capsule again after the run time is completed to calculate amount dispensed. Run the

capsule 2 or 3 times to see if the amount is consistent.

Page 6 of 8 0900969 Rev: C (05/07)

Page 7

TROUBLESHOOTING

Water leaking from inlet fittings

• Check for proper connection at fittings.

• Check for holes or splits on plumbing lines.

Chemical is not feeding

• Check washer signal for proper operation.

• Check to see if solenoid is opening properly.

• Check to see if water supply is on.

• Check inside of vacuum breaker for any debris or blockage.

• Check for proper water pressure.

• Check operation of Power Bowl Ultra water valve.

• Check operation of Power Bowl Ultra spray-jet.

Concentration too high or too low

• Check water temperature. Consult with solid chemical manufacturer for recommended temperature.

• Check water supply for fluctuations in pressure.

• Check feed time of control and adjust as needed.

Power Bowl Ultra is over-flowing

• Output hose is blocked, or plugged up.

• The end of the output hose is above the mounting height of the DDS-1000.

0900969 Rev: C (05/07) Page 7 of 8

Page 8

DISCLAIMER

Knight LLC does not accept responsibility for the mishandling, misuse, or non-performance of the described items

when used for purposes other than those specified in the instructions. For hazardous materials information consult

label, MSDS, or Knight LLC. Knight products are not for use in potentially explosive environments. Any use of our

equipment in such an environment is at the risk of the user, Knight does not accept any liability in such

circumstances.

WARRANTY

All Knight controls and pump systems are warranted against defects in material and workmanship for a period of

ONE year. All electronic control boards have a TWO year warranty. Warranty applies only to the replacement or

repair of such parts when returned to factory with a Knight Return Authorization (KRA) number, freight prepaid, and

found to be defective upon factory authorized inspection. Bearings and pump seals or rubber and synthetic rubber

parts such as “O” rings, diaphragms, squeeze tubing, and gaskets are considered expendable and are not covered

under warranty. Warranty does not cover liability resulting from performance of this equipment nor the labor to

replace this equipment. Product abuse or misuse voids warranty.

FOOTNOTE

The information and specifications included in this publication were in effect at the time of approval for printing.

Knight, LLC reserves the right, however, to discontinue or change specifications or design at any time without notice

and without incurring any obligation whatsoever.

Knight Headquarters

Tel: 949.595.4800

Fax: 949.595.4801

USA Toll Free

Tel: 800.854.3764

Fax: 800.752.9518

KNIGHT LLC,

Tel: 905.542.2333

Fax: 905.542.1536

A Unit of IDEX Corporation (www.knightequip.com)

Knight Canada

Knight Europe

Tel: 44.1293.615.570

Fax: 44.1293.615.585

Knight Australia

Tel: 61.2.9725.2588

Fax: 61.2.9725.2025

Knight N. Asia

Tel: 82.2.3481.6683

Fax: 82.2.3482.5742

Knight S. Asia

Tel: 65.6763.6633

Fax: 65.6764.4020

Page 8 of 8 0900969 Rev: C (05/07)

Loading...

Loading...