Knight Equipment DAIRY-CHEM Installation Manual

INSTRUCTION MANUAL

INTRODUCTION

Dairy Chem Systems are designed to dispense non-foaming dairy cow teat dip products from a chemical storage

vessel to a teat dip spray head or fill valve. VS versions use an external vacuum switch on the pipeline to control

dispensing only when milking lines are in use. Systems with dual-pump configuration can be setup to operate in the

following ways:

• Run both pumps simultaneously to inject two different chemicals.

• Run one pump at a time, but alternate between pumps at various intervals (using the selector valve on units so

equipped) to extend the life of both pumps.

• Run one pump at a time, but only switch pumps when needed (using the selector valve on units so equipped) to

keep one as a spare.

SPECIFICATIONS

Chemical Compatibility Santoprene: acids, alkalines, soaps, alcohols, ketones.

Air Operated Pump Materials Polypropylene Body w/ Santoprene Seals and

Air Requirements / Consumption Minimum 40 PSI / Maximum 80 PSI clean dry air

Diaphragm.

5-10 SCFM during operation.

SAFETY PRECAUTIONS

• Read and understand the MSDS sheets for the chemicals that will be used — consult your chemical supplier if you

have any questions.

• Always wear safety goggles and protective gloves while handling chemicals.

• Avoid contact of chemicals with skin and eyes. If contact occurs, rinse affected area with water for 15 minutes, and

seek medical attention, if needed.

MAINTENANCE

• Periodically drain the bowl on the air regulator/filter by pushing up the stem on the bottom of the bowl till the water

runs out.

• The bowl can be removed (by turning counter-clockwise) to clean the filter element. When replacing the bowl, be

sure that the O-ring is properly positioned on top of the bowl.

0901159 Rev: A (06/03) Page 1 of 8

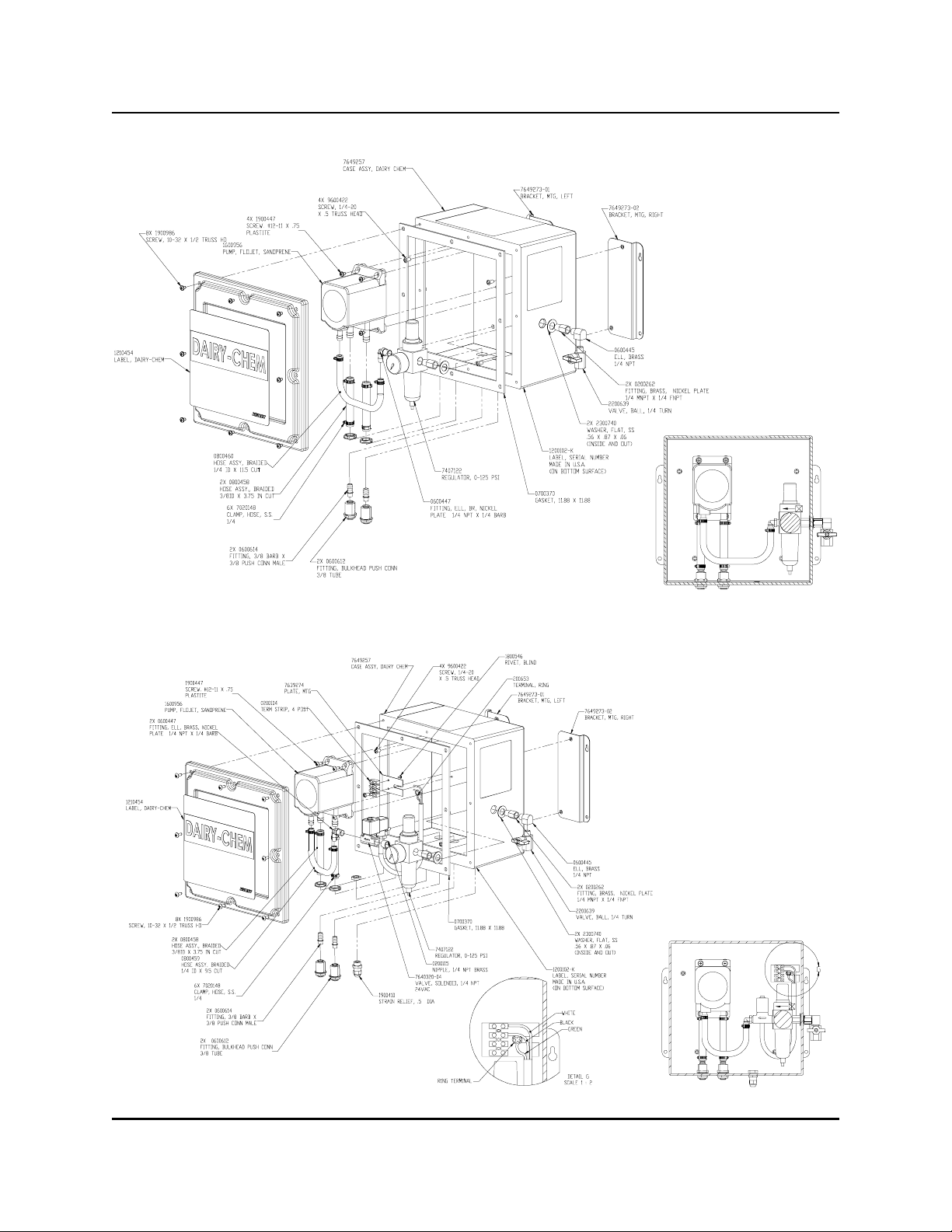

INSTALLATION — SINGLE PUMP

(1) Select the desired location to mount the control box — should not be more than 6 ft (2 meters) from the floor.

(2) Mount the control box using the hardware provided or other mounting hardware as needed.

(3) There are two 1/4” and two 3/8” quick-connect barbed fittings provided with the unit. Attach the pickup line to the

barbed end of the appropriate size fitting — insert the fitting into the left side port on the bottom of the unit. Route

the other end of the pickup line to the chemical supply.

(4) Attach the discharge line to the barbed end of the appropriate size fitting — insert the fitting into the right side

port on the bottom of unit. Route the other end of the discharge line to the injection point.

(5) Connect the air supply to the 1/4” NPT inlet valve on the right side of the unit. Be sure to use clean dry air only!

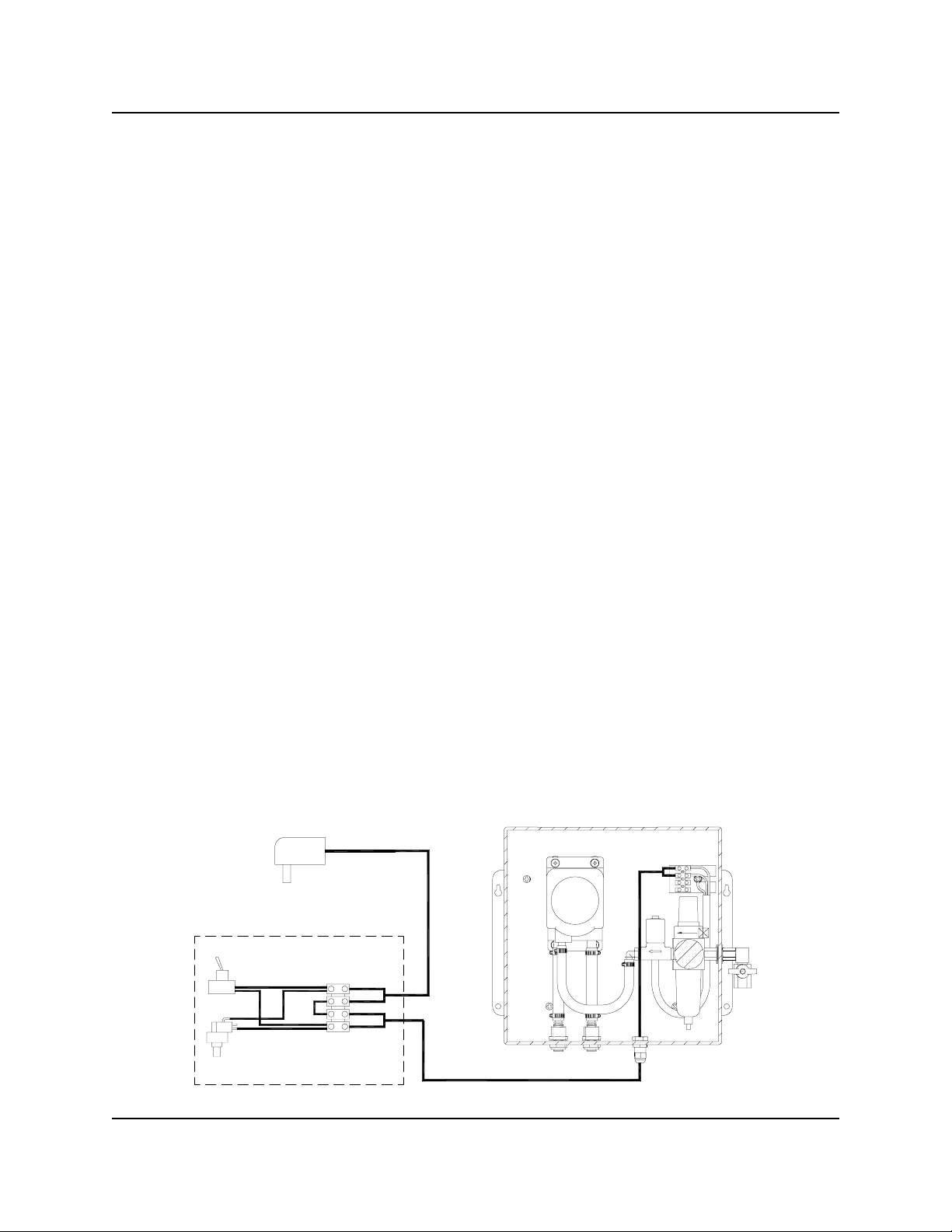

The remaining steps are for vacuum switch equipped units only

(6) Mount the vacuum switch enclosure in a convenient location and nearby to a 115 VAC outlet.

(7) Connect tubing from the vacuum source (pipeline) to the barb fitting on the vacuum switch enclosure. Route the

tubing carefully to avoid pinching the tube at any point.

(8) Wire the vacuum switch enclosure to the pump unit as shown in the wiring diagram below. Be sure to route the

wire through the provided strain relief fittings on both the switch enclosure and pump unit.

(9) Plug the transformer into the outlet.

OPERATION — SINGLE PUMP

(1) Turn the air inlet valve on (counter-clockwise till handle is vertical) to operate the pump.

(2) This step is for vacuum switch equipped units only: The pump will run whenever there is vacuum present, or

when the over-ride switch (toggle switch) is turned on. The tee-handle valve on the vacuum switch enclosure

should be in the vertical position for normal operation, but can be used to by-pass the vacuum switch by turning

to the horizontal position. This allows the unit to be controlled by the over-ride switch only.

(3) The air pump will typically be easier to prime when running at a slower speed. The speed and volume delivery of

the pump can be controlled by turning the regulator clockwise to increase pressure and counter-clockwise to

decrease pressure.

(4) Once the pump is primed, adjust the air pressure as needed to achieve the desired feed rate.

(5) To stop the pump, turn the air inlet valve off (clockwise till handle is horizontal).

TRANSFORMER

TOGGLE

SWITCH

VACUUM

SWITCH

VACUUM SWITCH ENCLOSURE

PUMP UNIT

Page 2 of 8 0901159 Rev: A (06/03)

SINGLE PUMP

SINGLE PUMP (VS)

0901159 Rev: A (06/03) Page 3 of 8

Loading...

Loading...