Knight Equipment APC-200 Installation Manual

APC-200 INSTRUCTION MANUAL

INTRODUCTION

The Liquidtrol Air Pump Control is designed to interface an ILCS-6900

Dispensing System to one or two optional Air Operated Double Diaphragm

Pumps. Air pumps are generally used as an alternative to peristaltic pumps

where feed rates in excess of three gallons per minute are required.

The APC-200 unit is installed in close proximity to the ILCS-6900 and

connects to the air pumps using 3/8” air line. Air pumps should be mounted

near the chemical source and push chemical to the point of use.

THEORY OF OPERATION

The APC-200 Liquidtrol Air Pump Control includes one or two air solenoid

valves for operating one or two Air Operated Double Diaphragm Pumps.

Built-in pressure regulators provide control of the air pump feed rate and

allow accurate calibration of the chemical volumes. An air filter prevents

“dirty” or “wet” air from contaminating the air solenoid valve. Adjustments for

the pressure regulator are located in the APC-200 cabinet to discourage

tampering by unauthorized users.

INSTALLATION

See diagrams on the following page for illustration of the steps below.

(1) Mount unit on a wall in a location that is near the ILCS-6900 System.

(2) Connect incoming air source to the inlet fitting using 3/8“ poly tubing.

Max recommended pressure is 150 PSI.

(3) Connect the outlet fitting(s) from the air solenoid valves to the air pump

inlet port using 3/8” poly tubing.

(4) Connect the solenoid(s) to the desired output circuits on the ILCS pump

output board using conduit and wiring that complies with all applicable

electrical codes. The solenoids are connected to a wiring barrier inside

the APC control box for quick and easy connection.

(5) Use of an air-operated 2-way valve is recommended for installations

where siphoning can occur. See part numbers to the lower right.

OPERATION / START-UP

Consult Air Pump operation manual for mfr’s operating specifications.

(1) Manually activate pump(s) using the prime button(s) on the ILCS pump

board. Priming a “dry” pump m ay require you flood the pump suction

with water. Suction line should be no longer than 10 feet (3 meters).

(2) The air pump will typically be easier to prime when running at a slower

speed. The speed and volume delivery of the pump can be controlled

by turning the regulator clockwise to increase pressure and counterclockwise to decrease pressure.

(3) Once the pump is primed, adjust the air pressure as needed and

calibrate the ILCS-6900 per the directions in the ILCS programming

manual (Dispenser Programming Routines menu).

Knight Air-Operated 2-Way

Valves can be ordered using the

following part numbers:

P/N 1600954 — for 1” ID line

P/N 1600955 — for 1/2” ID line

0900957 Rev: B (08/02) Page1of4

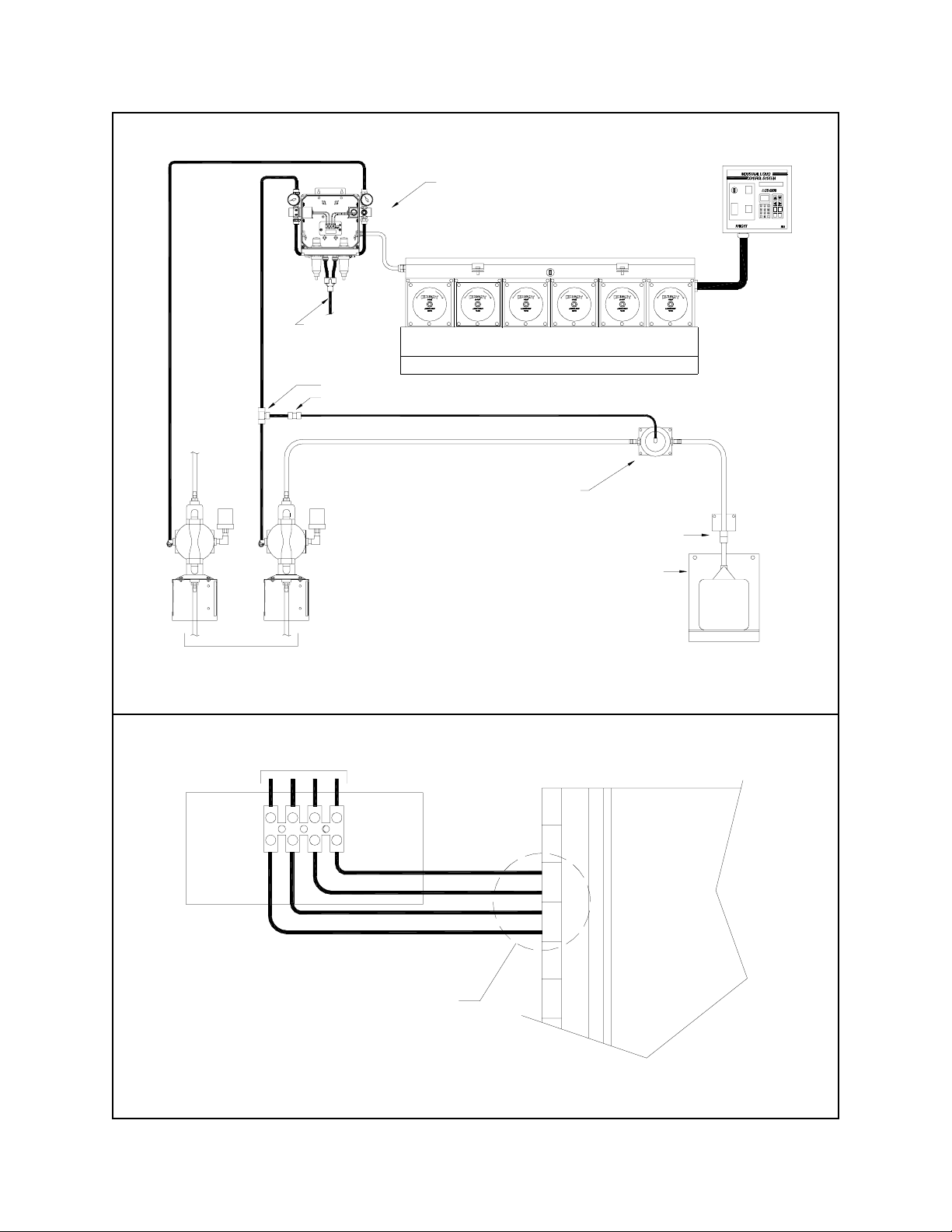

INSTALLATION AND WIRING DIAGRAMS

TO CHEMICAL TANKS

APC-200 AIR PUMP CONTROL

O

INCOMING

AIR SOURCE

W

L

F

W

O

L

F

QUICK-CONNECT 3/8" TEE FITTING (P/N 0600605)

QUICK-CONNECT 3/8" - 1/4" REDUCER (P/N 0600609)

EXAMPLE OF USING AIR OPERATED

2-WAY VALVE FOR APPLICATIONS

WHERE SIPHONING CAN OCCUR

NOTE: AIR PUMPS CAN BE LOCATED

REMOTELY AND "PUSH" CHEMICAL TO

THE POINT OF DISPENSE, HOWEVER A

SLIGHT AIR PRESSURE DROP CAN OCCUR

THE FARTHER THE PUMPS ARE FROM

THE APC-200. THIS MAY REQUIRE AN

ADJUSTMENT TO THE AIR PRESSURE TO

GET THE DESIRED OUTPUT FLOW RATE.

I.L.C.S.

DATAMANAG EMENTSYSTEM

CYCLE

ON/OFF

START

MAIN

POWER

FORMULA

WATER

GHIDEFABC

2

3

1

MNO

JKL

PQR

YES

5

6

4

VWX

STU

YZ

8

7

9

ENTERNORESET

P

R

I

M

E

SPACE

H

B

A

T

C

0

C

O

U

N

T

C

A

L

.

O

W

O

W

O

L

F

L

F

W

L

F

W

O

L

F

SPOUT

CONTAINER

SHELF

TO AIR SOLENOIDS

PUMP OUTPUTS #7 AND #8 ARE

SHOWNINTHISEXAMPLE.THIS

IS A TYPICAL APPLICATION,

HOWEVERTHE APC-200CAN BE

WIRED TO ANY AVAILABLE PUMP

OUTPUTS ON THE CONTROL BOARD.

CUTAWAY VIEW OF ILCS

PUMP OUTPUT BOARD (POB)

P

#

U

10

M

P

P

#

U

9

M

P

P

#

U

8

M

P

P

#

U

7

M

P

P

#

U

6

M

P

P

#

U

5

M

P

ILCS-APC-INSTALL/0 82102

Page2of4 0900957 Rev: B (08/02)

Loading...

Loading...