Page 1

Looking for more information?

Visituson the

•

Price

web

Quotations •

at http://www.artisan-scientific.com for more information:

Drivers·

Technical

Specifications.

Manuals and Documentation

Artisan

Scientific

•

TensofThousandsofIn-Stock

•

HundredsofManufacturers

is

You~

Source

Items

Supported

for:

Quality

Service Center Repairs

Experienced Engineers and Techniciansonstaffinour

State-of-the-art Full-Service In-House Service Center Facility

We

bUy

used

equipment!

Sell

your

excess.

Talk to a liveperson: 88EM38-S0URCE fB88-887-68721 I Contact

underutilized. and idle used equipment. Contact oneofour

We

New

•

Fast

•

Leasing

and

Certified-Used/Pre:-awned ECJuiflment

Shipping and

/ Monthly

DelIve1y

Rentals

• Equipment Demos

•

Consignment

InstraView Remote Inspection

Remotely inspect equipment before purchasing with

Innovative InstraView-website at http://www.instraview.com

also

offer

credit

usbyemail: sales@artisan-scientific.com I Visit ourwebsite: http://www.artisan-scientific.com

for

Buy-Backs

and

Customer

Trade-Ins

Service

Representatives todayl

our

Page 2

User’s Manual

Laser Bar Code Reader

BL-500 Series

Page 3

No part of this document is to be reproduced or utilized in any form or by any

means without the written consent of KEYENCE Corporation.

The contents of this document are subject to revision without notice.

If you have any problems or questions regarding this document, please contact

one of the KEYENCE offices listed on the last page of this document.

KEYENCE is not responsible for any results of the application of the product.

If the document contains incomplete printing, it can be exchanged for a complete

one.

• MS-DOS is a registered trademark of Microsoft U. S. A.

• MS-Windows is a trademark of Microsoft U. S. A.

• Other company names and product names are registered trademarks or trademarks of the respective companies.

Page 4

Contents

Safety Precautions ...........................................................................................................xi

Symbols ...........................................................................................................................................................xi

General precautions .........................................................................................................................................xi

Laser Safety Precautions ................................................................................................xii

Classification ...................................................................................................................................................xii

Warning labels ................................................................................................................................................xii

Label location ..................................................................................................................................................xii

Safety consideration .......................................................................................................................................xiii

Safety features ...............................................................................................................................................xiv

Unpacking .......................................................................................................................xiv

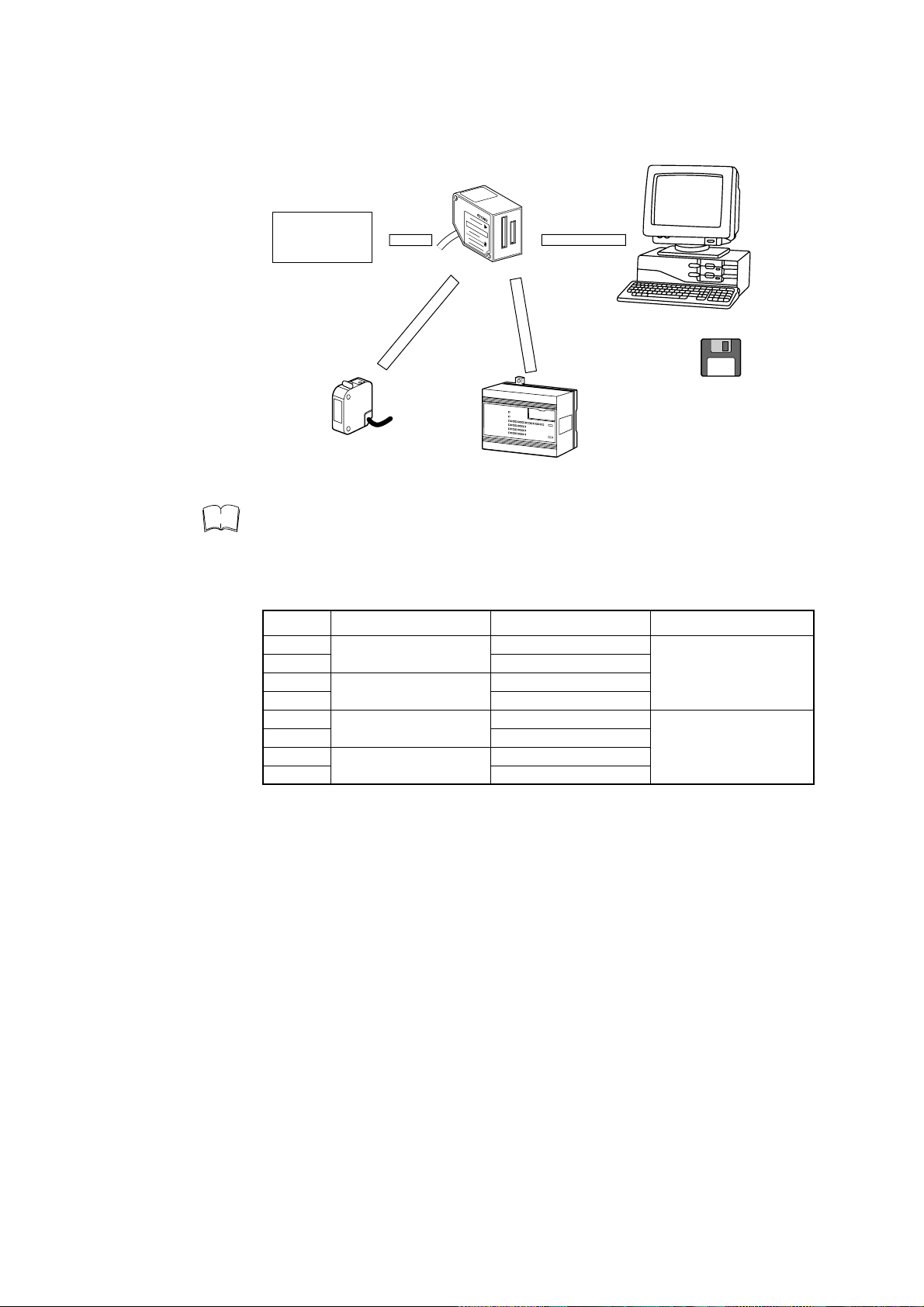

System Configuration .....................................................................................................xv

Laser Bar-Code Reader Model Types: ...........................................................................................................xv

Other Options ..................................................................................................................................................xv

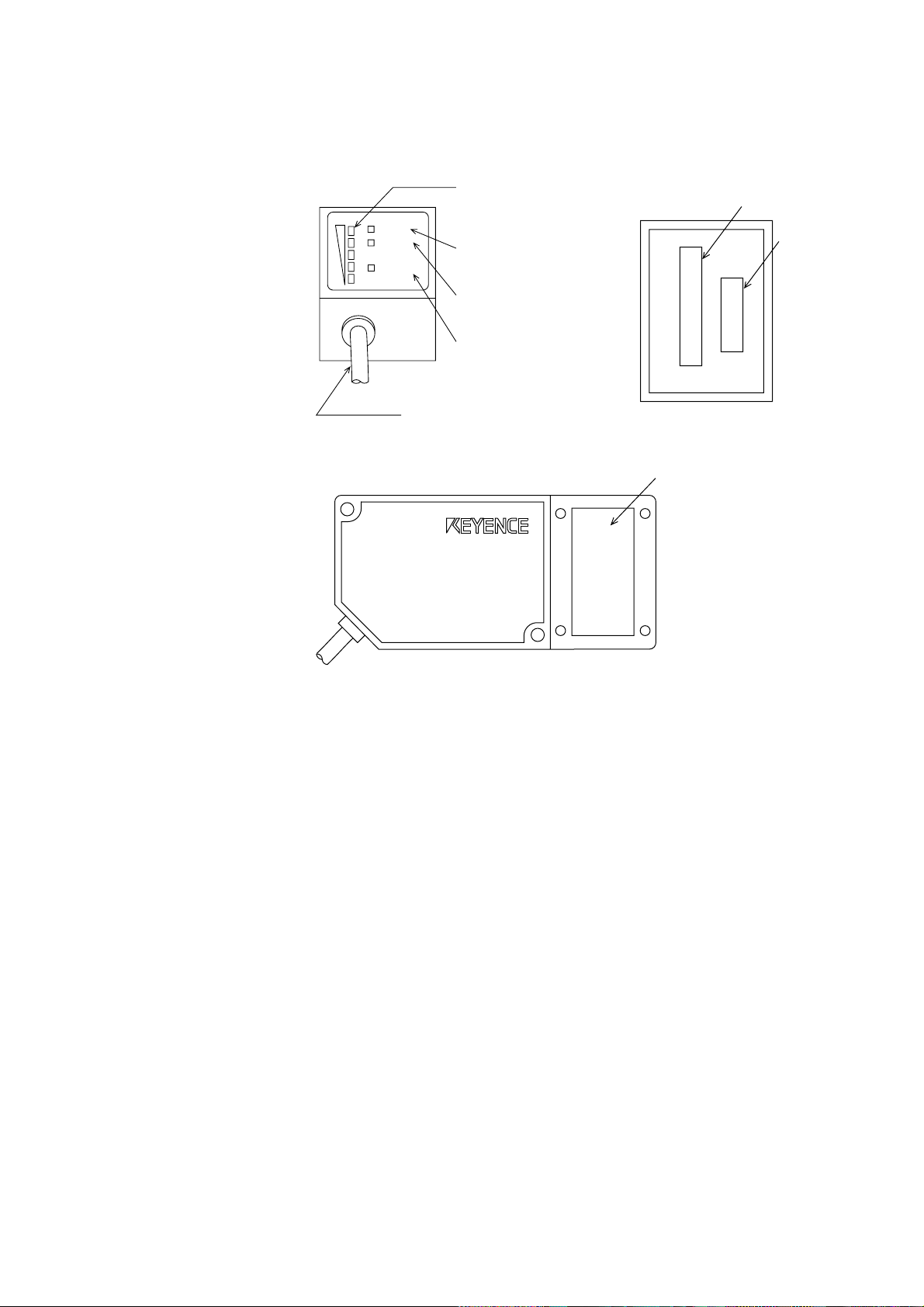

Parts and Functions .......................................................................................................xvi

BL-500/501/500H/501H .................................................................................................................................xvi

BL-550/551/550H/551H .................................................................................................................................xvi

Chapter 1: Connection and Installation

BL-500 Connections ..........................................................................................................2

Wire colors and signal types ............................................................................................................................ 2

Power supply wiring ......................................................................................................................................... 2

Connecting shielded cables ............................................................................................................................. 2

Wiring I/O ......................................................................................................................................................... 2

RS-232C Connections ..................................................................................................................................... 3

Installing the BL-500 Series ..............................................................................................5

Chapter 2: Functions for Reading Operation

Read Operation ..................................................................................................................8

Scanning method ............................................................................................................................................. 8

Data-send mode ............................................................................................................................................... 9

Read modes .....................................................................................................................10

Single label read mode .................................................................................................................................. 10

Multi-label read mode 1 (Multi 1) .................................................................................................................... 10

Multi-label read mode 2 (Multi 2) .................................................................................................................... 11

Multi-label read mode 3 (Multi 3) .................................................................................................................... 11

Label orientation mode ...................................................................................................14

Test Mode .........................................................................................................................15

STABILITY LEDs ..............................................................................................................17

Preset Function (Compare with:) ...................................................................................19

What is the preset function? ........................................................................................................................... 19

Wildcard symbols (“!” and “?”) ........................................................................................................................19

Additional Information ....................................................................................................20

Max. Code Length (Designated Digit )

Output Function ...............................................................................................................22

iii

Page 5

Chapter 3: Setup Software

Controlling the BL-500 .................................................................................................... 24

Setup Software Requirements ....................................................................................................................... 24

Operating Procedure ...................................................................................................... 26

Outline of Operation ....................................................................................................................................... 26

Setup Software Operating Procedure ........................................................................... 27

File Operation ................................................................................................................................................ 28

Main setting screen ........................................................................................................................................ 30

CODE39 setup ............................................................................................................................................... 31

ITF setup ........................................................................................................................................................ 32

Setup for Industrial 2 of 5 and COOP 2 of 5 .................................................................................................. 32

Codabar setup ............................................................................................................................................... 33

UPC/EAN setup ............................................................................................................................................. 34

CODE128 setup ............................................................................................................................................. 34

Timing setting ................................................................................................................................................. 35

Communication setting .................................................................................................................................. 36

Communication strings setup ......................................................................................................................... 36

Other setting .................................................................................................................................................. 37

Sending Settings ............................................................................................................................................ 38

Version Display .............................................................................................................................................. 38

List of Error Messages ................................................................................................... 39

How to Use Terminal Software ...................................................................................... 40

Chapter 4: Serial Communication (RS-232C/RS-422A)

Serial Communication .................................................................................................... 44

Communication Setup .................................................................................................................................... 44

Details on Data Communication .................................................................................... 45

Communication Protocols(Hardware handshaking) ....................................................................................... 45

Capacity of Transmission Buffer .................................................................................................................... 46

Read Data Format ......................................................................................................................................... 46

Read Error Code ............................................................................................................................................ 47

Command Communication ............................................................................................ 48

Setup of Direct Control Commands ............................................................................................................... 48

Explanation of Direct Control Commands ...................................................................................................... 49

Details on Parameter Setting Commands ...................................................................................................... 50

Response Error Code .................................................................................................................................... 52

Description of Parameter Setting Commands ................................................................................................ 52

Appendix

Specifications .................................................................................................................. 60

Raster Scan Specifications ............................................................................................................................ 61

Reading Range Characteristics (Typical) ..................................................................... 62

Angular Characteristics (Typical) .................................................................................. 66

Dimensions ...................................................................................................................... 67

Example Program for Serial Communication ............................................................... 69

Troubleshooting .............................................................................................................. 70

CODE128 Specifications ................................................................................................ 72

ASCII Code Table ............................................................................................................ 73

Default Settings ...............................................................................................................74

iv

Page 6

BL-U1 Power Supply

Introduction ......................................................................................................................80

Conventions .....................................................................................................................80

System Configuration .....................................................................................................81

Using the RS-232C and RS-422A .................................................................................................................. 81

Using the RS-485 multidrop link ..................................................................................................................... 81

Other Options .................................................................................................................................................81

BL-U1 .............................................................................................................................................................82

BL-U1 Connections .........................................................................................................83

Connecting the AC power supply ...................................................................................................................83

Connecting the BL-U1 to a BL series .............................................................................................................83

Setting the BL-U1 DIP switches ..................................................................................................................... 84

Function and wiring on the I/O terminal block ................................................................................................ 85

RS-232C port pin assignment ........................................................................................................................ 86

RS-232C port wiring .......................................................................................................................................87

RS-422A port wiring ....................................................................................................................................... 87

Wiring the RS-485 (multidrop link) .................................................................................................................88

Installation ........................................................................................................................89

Precautions before use .................................................................................................................................. 89

Installing the BL-U1 ........................................................................................................................................90

Outline of Multidrop Link ................................................................................................91

Multidrop Link .................................................................................................................................................91

System Configuration .....................................................................................................................................91

Setup and Connection Procedures ................................................................................92

Communication ................................................................................................................93

Outline of Communication types .................................................................................................................... 93

Communication Format ..................................................................................................................................93

Details on Data Communication ..................................................................................................................... 95

Details of Command Communication ............................................................................................................. 97

Precautions for Programming ........................................................................................99

BL-U1 Specifications .....................................................................................................100

WARRANTIES .................................................................................................................103

v

Page 7

vi

Page 8

Safety Precautions

This User’s Manual describes the operation and functions of the BL-500. Read

this manual carefully to ensure safe use and maximum performance from your

BL-500.

The BL-500 uses a semiconductor laser as the light source. Before using the

product, see “Laser Safety Precautions” on page 3 to learn the safe and correct

method of using the reader.

Symbols

The following symbols alert you to important messages. Be sure to read these

messages carefully.

WARNING

CAUTION

Note

General precautions

Failure to follow instructions may lead to injury. (electric shock, burn, etc.)

Failure to follow instructions may lead to product damage.

Provides additional information on proper operation.

Any reference to the BL-500 in this manual refers to information on all products in

the BL-500 series. When refering to specific product information, the product

name exclusively will be used.

• The BL-500 uses a semiconductor laser as the light source. Before using the

product, see “Handling a Laser Product” on page 3 to learn the safe and correct method of using the reader.

• Do not use the BL-500 as a controller for equipment which could potentially

harm a person.

• Be sure to match the polarities (+ and -) of the power supply when soldering

the connections. Reversing the polarities will damage the unit.

• Do not disassemble the BL-500. Doing so may make repair impossible.

• The BL-500 is a precision instrument. Dropping the unit could damaged it.

Exercise caution when moving or installing.

• Be sure that there is no water, oil or dust on the optical pickup. Such obstructions can cause read errors. Clean the pickup by gently wiping with a soft lens

cloth soaked with water.

vii

Page 9

CAUTIONCAUTION

AVOID EXPOSURE

Laser radiation is emitted

from this aperture.

Laser radiationDo not stare into beam.

Semiconductor laser

Maximum output

Pulse duration

Class II laser product

CAUTION-Laser radiation when

open. Do not stare into beam.

670nm

1.2mW

70µsec

CAUTIONCAUTION

Laser radiationDo not stare into beam.

Semiconductor laser

Maximum output

Pulse duration

Class II laser product

CAUTION-Laser radiation when

open. Do not stare into beam.

670nm

1.2mW

70µsec

LASER RADIATION

DO NOT STARE INTO BEAM

IN CONFORMITY TO IEC825 1 11, 1993

CLASS2 LASER PRODUCT

MAXIMUM OUTPUT

PULSE DURATION

EMITTED WAVELENGTH

1.2mW

127µs

670nm

LASER RADIATION

DO NOT STARE INTO BEAM

CAUTION

LASER RADIATION

WHEN OPEN. DO NOT

STARE INTO BEAM.

IN CONFORMITY TO IEC825 1 11, 1993

CLASS2 LASER PRODUCT

MAXIMUM OUTPUT

PULSE DURATION

EMITTED WAVELENGTH

1.2mW

127µs

670nm

LASERSTRAHLUNG

NICHT IN DEN STRAHL BLICKEN

NACH ENTWARF DIN EN 60825-1 07.1994

LASER KLASSE 2

MAXIMUM LEIGTUNG

PULSDAUER

WELLENLÄNGE

1.2mW

127µs

670nm

LASERSTRAHLUNG

NICHT IN DEN STRAHL BLICKEN

VORSICHT

LASERSTRAHLUNG

WENN ABDECKUNG

GEOFFNET. NICHT IN

DEN STRAHL BUCKEN.

NACH ENTWARF DIN EN 60825-1.1994

LASER KLASSE 2

MAXIMUM LEISTUNG

PULSDAUER

WELLENLÄNGE

1.2mW

127µs

670nm

CAUTION – Laser radiation

when open.

Do not stare into beam.

AVOID EXPOSURE

Laser radiation is emitted

from this aperture.

CAUTION

LASER RADIATION

WHEN OPEN. DO NOT

STARE INTO BEAM.

VORSICHT

LASERSTRAHLUNG

WENN ABDECKUNG

GEOFFNET. NICHT IN

DEN STRAHL BLICKEN.

CAUTION

LASER RADIATION

WHEN OPEN. DO NOT

STARE INTO BEAM.

VORSICHT

LASERSTRAHLUNG

WENN ABDECKUNG

GEOFFNET. NICHT IN

DEN STRAHL BUCKEN.

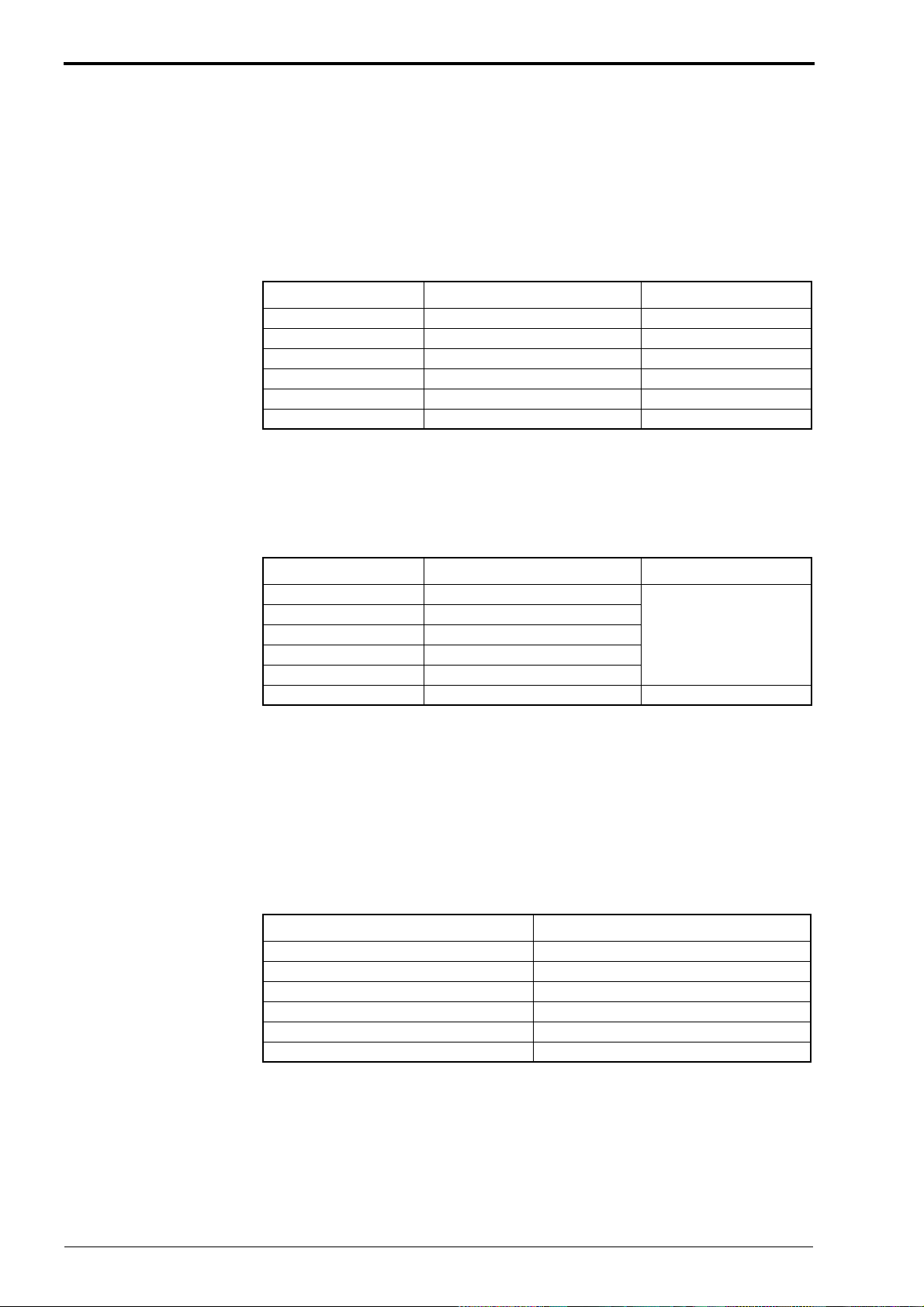

Laser Safety Precautions

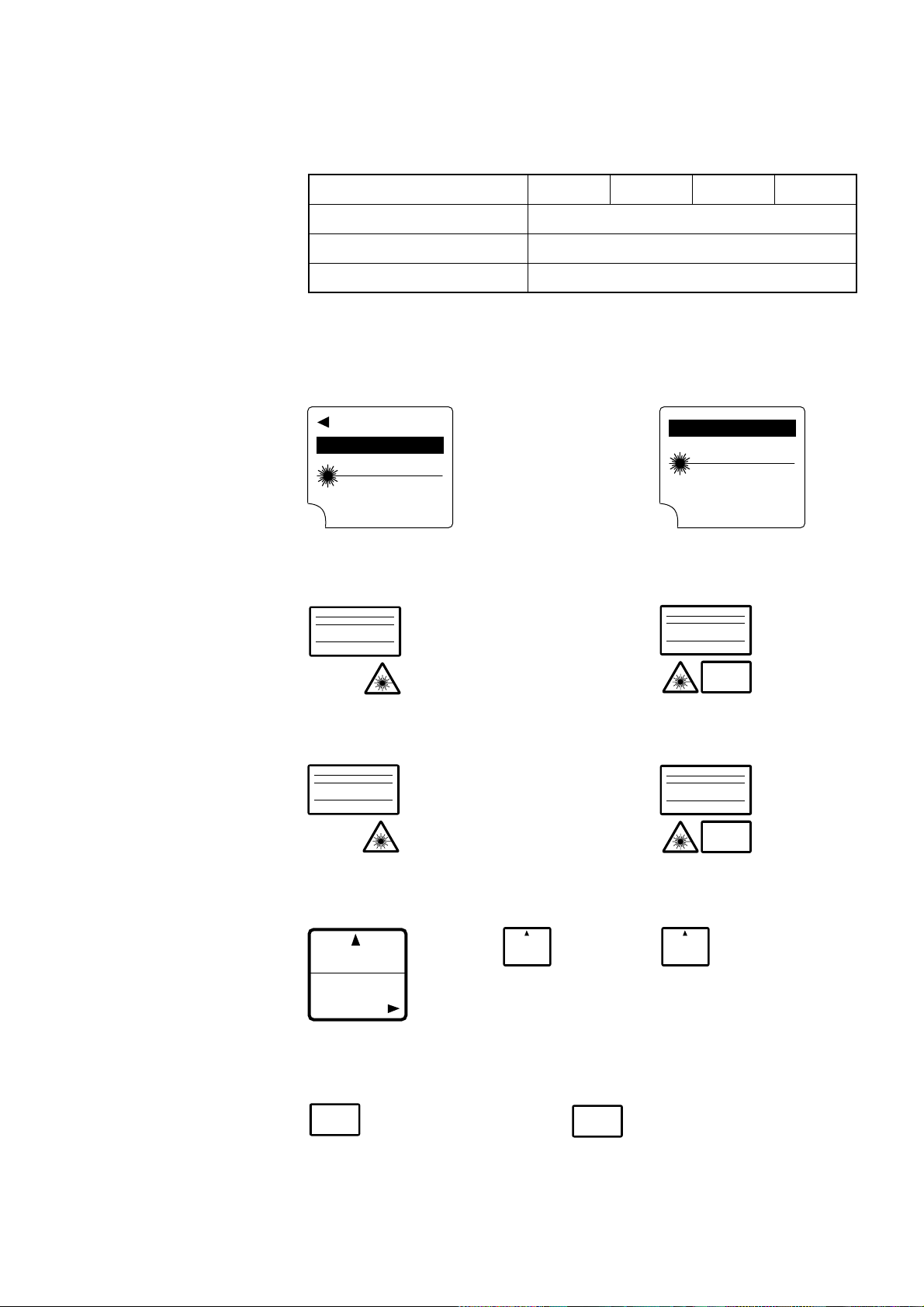

Classification

Warning labels

Model

FDA

IEC 825-1, 11 1993

DIN EN 60825-1 07.1994

BL-500(H) BL-501(H) BL-550(H) BL-551(H)

Class II

Class 2

Klasse 2

FDA Class II

BL-500/501/500H/501H BL-550/551/550H/551H

IEC Class 2

BL-500/501/500H/501H BL-550/551/550H/551H

DIN Klasse 2

BL-500/501/500H/501H BL-550/551/550H/551H

Aperture label

FDA Class II IEC Class 2 DIN Klasse 2

Protective housing label

IEC Class 2 DIN Klasse 2

viii

Page 10

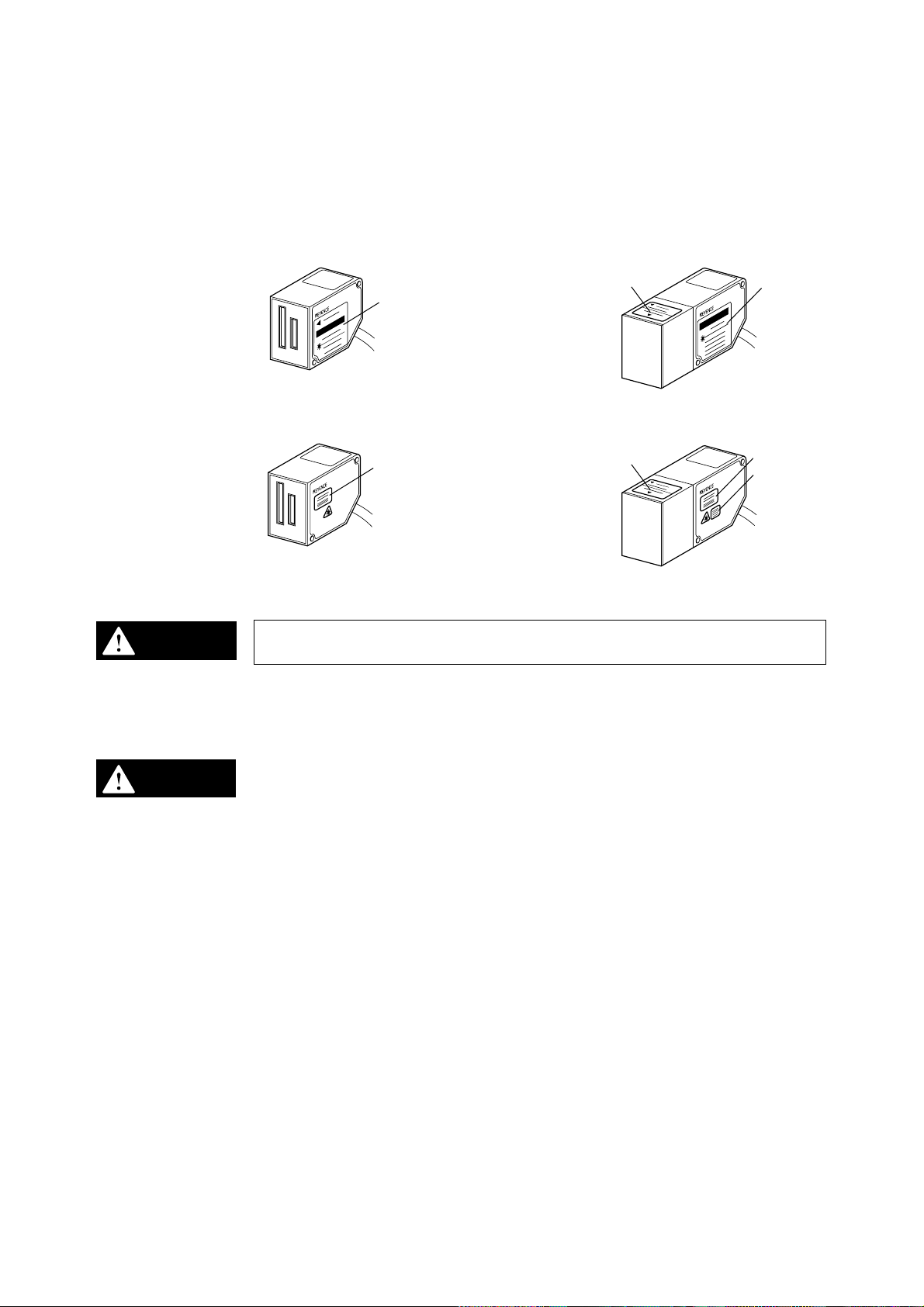

Label location

The following label positions are recommended.

FDA Warning labels are attached to the sensor head as shown below. The IEC/

DIN Warning labels are packaged with the BL-500 series. Affix the Warning labels

on the sensor head as shown below.

FDA

BL-500/501/500(H)/501(H) BL-550/551/550(H)/551(H)

)

CAUTION

2

)

1

CAUTION

)

1

IEC

BL-500/501/500(H)/501(H) BL-550/551/550(H)/551(H)

)

)

)

1

2

1

)

3

Safety consideration

CAUTION

WARNING

Use of controls or adjustment, or the performance of procedures other than those

specified herein, may result in hazardous radiation exposure.

The laser beam is not harmful to the skin. There is, therefore, no danger in exposing arms or hands to the beam. The only possible health hazard is in exposing the

eyes to the laser beam. Damage to the eyes can occur if the operator stares directly into the beam.

Following the safety precautions below to ensure operator safety:

• Operate the BL-500 series only according to the procedures described in

• Do not disassemble the sensor head.

• Do not look directly at the laser beam.

• Protective enclosure

• Protective goggles

• Stop laser emissions before cleaning the laser emission port.

• Chek the laser beam path.

this instruction manual.

Otherwise, injury may occur due to exposure to the laser beam.

Laser emission from the BL-500 series is not automatically stopped if the sensor head is disassembled. If you disassemb le the sensor head f or inspection or

repair, you may be exposed to the laser beam. If the BL-500 series malfunctions, contact KEYENCE immediately.

Looking directly at the laser beam may result in serious eye injury.

We recommend that you install a protectiv e enclosure around the sensor head

to prevent any person from getting near the sensor head during operation.

We recommend that you wear protective goggles when using the BL-500

series.

Failure to stop the laser emission may expose eyes to the laser beam.

To prevent exposure to the laser beam due to specular or diffuse reflection,

install a screen which offers the appropriate reflectance and temperature characteristics to interrupt the reflected laser beam. Do not install the BL-500

series in such a way that the laser beam passes at eye height.

ix

Page 11

Safety features

The BL series is provided with the following safety features. Make sure these features function correctly before making any measurement.

1. LASER ON alarm LED

A visible LED that informs you that the laser beam is being emitted, or is about to

be emitted, at least 3 seconds after power is provided to the amplifier and the sensor head.

2. Laser emission delay

Laser emission only starts when the LED has been ON/lit for at least 3 seconds,

thus decreasing the possibility of laser exposure.

3. Laser Stop function

By sending the laser stop command (see page 18) to the BL-500, you can disabled laser emission. When working near the laser pickup, use the laser can disabled laser emission. When working near the laser pickup, use the laser stop

command to protect you from direct exposure to laser beam. When this command

is activated, the top LED of the STABILITY LEDS blinks.

Unpacking

How to use the Laser Stop command

Laser stop mode can be invoked by transmitting the serial command from the

host computer to the unit.

To execute the Laser stop command, use the following instruction.

LOCK [CR]

To cancel Laser stop, use the following instruction.

UNLOCK [CR]

When either above instruction is properly processed, the BL-500 series returns

the following message to the host computer.

OK [CR]

There are two packages: A BL-500 package and a software package.

Each package contains the following components. Be sure to check the items

against the checklist below:

BL-500 package

BL-500 unit 1

Mounting bracket 1

Mounting bracket screw (32 mm) 2

Laser warning label 1

Instruction manual 1

Setup software (BL-50H1E) and user’s manual

Setup software floppy disk (3.5-inch) 1

User’s Manual (this document) 1

Note

x

The setup software and user’s manual are not included in the BL-500 package.

You can order the software package, free of charge, separately.

Page 12

System Configuration

Note

RS-232C null modem cable

OP-22149 (1.5 m) + OP-25057

(25- to 9-pin adapter)

BL-500

5VDC

Power-supply unit*

Trigger input

Timing sensor

OK/NG

output

PLC etc.

RS-232C

BL-50H1E

Setup software

3.5-inch version

WINDOWS 3.1

The 5 VDC power supply unit must be purchased separately.

The optional BL-U1 or BL-U2 power supply is also available.

IBM PC/AT

or compatible

Laser Bar-Code Reader Model Types:

Model

BL-500

BL-501 Raster

BL-550

BL-551 Raster

BL-500H

BL-501H Raster

BL-550H

BL-551H Raster

The readable bar width is the range in which narrow-group bar codes can be read.

Reading direction Scanning method Readable bar width

Front

Side

Front

Side

Other Options

BL-U1:.................. 5 VDC power supply (100 to 240 VAC input)

(with built-in RS-232C, RS-422A, RS-485 ports)

See page 79 for details.

OP-22149: ...........RS-232C null modem cable (1.5 m) for BL-U1

OP-25057.............25- to 9-pin adapter

BL-U2:.................. 5VDC power supply (24 VDC input)

(with built-in RS-232C port)

See the BL-U2 manual for details.

Single

Single

Single

Single

0.25 to 1.0 mm

(Standard type)

0.125 to 0.5 mm

(High-resolution type)

OP-27937: ...........RS-232C null modem cable (2 m) with 9-pin connector for BL-

U2

xi

Page 13

Parts and Functions

Optical pickup

Laser

light source

OK/NG

TIMING

LASER ON

STB

STABILITY LED

Indicates the reading stability or

the unit’s operation status (see P.

33 to P. 34).

OK/NG LED

OK output: Lights in green

NG output: Lights in red

TIMING LED

Lights when the timing input turns

ON.

LASER ON LED

Lights when the laser turns ON.

Cable (2 m)

Optical pickup/

light source

BL-500/501/500H/501H

BL-550/551/550H/551H

xii

For LED names, see the BL-500/501(H) User’s Manual.

Page 14

Chapter 1

Connection and Installation

Page 15

BL-500

Shield —

Black GND

Shield —

Black GND

BL-500

Ceramic capacitor

(Withdraw voltage 0.5 k to

1.0 kVDC, Capacity 0.1 µF,

non-polarity)

GND

TIM

Yellow

Black

5 VDC

10KΩ

4.7

KΩ

1.1 BL-500 Connections

1.1 BL-500 Connections

1.1.1 Wire colors and signal types

The following wires extend from the BL-500. Solder the required wires to a connector to connect the BL-500 to a computer/controller.

Wire Color

Shield

Purple RSBrown RD (RXD) Receive data Input

Pink RS (RTS) Request to send (always on) Output

Blue CS (CTS) Request to receive Input

Black GND (SG)

Yellow TIM Trigger input Input

White OK OK output Output

Gray NG NG output Output

Red + 5V + 5V power supply input Input

1.1.2 Power supply wiring

CAUTION

• Be sure to match the polarities of the power supply when soldering the connections. Reversing the polarities will damage the unit.

• Make sure that the power supply provides a stable 5 VDC ± 5%. If the power

supply does not function in the above range, it can damage the unit.

• Do not use a power cable longer that 2 meters. A long power cable can cause

a voltage drop, preventing the BL-500 from starting properly.

• If the power supply is UL rated, it must provide Class 2 output.

Symbol Description Signal Direction

Shield Connect to ground (SG) ——

232C

SD (TXD) Send data Output

Ground (common ground for

respective signals)

BL-500

+5V

GND

Red

Black

+

——

5 VDC

1.1.3 Connecting shielded cables

For optimum reading performance, connect the BL-500’s shielded cable to GND

(black) directly or through a condenser.

• Using a capacitor provides a more stable operation.

1.1.4 Wiring I/O

Trigger (TIM) input

The trigger input is used to signal the BL-500 to start reading (Start laser emission).

The trigger input is a non-voltage input (TTL input is also available).

2

Page 16

3

1.1 BL-500 Connections

OK/NG output

This output signals whether the readout data is the same as the preset data.

When no preset data has been registered, the signal indicates bar code read status. It is an NPN open-collector output.

BL-500

1.1.5 RS-232C Connections

Note

This BL-500 setup software applies to port 1 and port 2 only.

Communication cannot be performed with other ports.

When using a D-sub 9-pin connector:

Use a metallic connector housing for the D-sub 9-pin connector. Connect the

shielded cable with the connector housing.

PC

Load

+

–

2

RD

SD

3

RS

7

CS

8

SG

5

ER

4

DR

6

OK/NG

1kΩ

Internal circuit

BL-500

Shield Connector case

Shield

SD

Purple

RD

Blown

CS

Blue

RS

Pink

GND

Black

+5V

Red

+

5 VDC

Write/Gray

Black

GND

*Rated load: 24 VDC

(30 mA) max.

D-sub 9-pin (male)

# 4-40 screw

Note

When using a D-sub 25-pin connector:

BL-500

Shield FG

Shield

Blown

RD

SD

Purple

CS

Blue

RS

Pink

GND

Black

+5V

Red

+

5 VDC

PC

1

2

SD

RD

3

RS

4

CS

5

SG

7

DR

6

ER

20

D-sub 25-pin (male)

M 2..6 screw

Be sure the BL-500’s shielded cable is properly connected. Refer to “1.1.3 Connecting shielded cables” in the User’s Manual.

Page 17

Optical

pickup

Light

source

Object

Bar code

s

1.1 BL-500 Connections

Hints on correct use

Trigger (TIM) input

Set the trigger input to be long enough to allow the laser beam to cover the entire

bar code.

If the trigger input needs to be on for only a short period of time, select one-shot

mode.

Influence from mirror surface

If a mirror surface (metallic surface) is near the bar code and the laser beam reflects off the mirror, the BL-500 may cause a read error. Protect the unit from the

influence of a mirror surface by covering the surface or changing the bar code label position.

Bar code pitch

Do not place several bar codes in the field of the laser beam, unless you are in

multi-label read mode (Multi 3).

If you use multi-label read mode (multi 3), the BL-500 can simultaneously read 2

to 4 bar codes in the field of the laser beam.

Influence from photoelectric sensor

When using a photoelectric sensor to control trigger, block the sensor beam so it

does not enter the BL-500 optical pickup.

The beam from the photoelectric sensor can interfere with the BL-500, deteriorating reading performance. If this case, reposition the photoelectric sensor.

When a bar code is stained or partially missing

Use a raster scan reader (BL-501/551(H)) when a bar code is stained or partially

missing. This raster scan readers scan several portions of the bar code. Normal

portions of the bar code, even with stained or missing portions, can be read by

the BL-501/551(H).

Scan

4

Page 18

1.2 Installing the BL-500 Series

1.2 Installing the BL-500 Series

Installation method

Use the mounting holes on the side panel to install the unit.

Using the supplied mounting brackets

Install the BL-500 Series as shown in the figures below.

• Select screws of the proper length by checking the thickness of the plate used

for mounting. (The screws provided are for use with the mounting bracket.)

• For the mounting hole diameter, see page 66.

(BL-500/501/500H/501H)

M3 screws

(BL-550/551/550H/551H)

M3 screws

Optical pickup/

light source

• Use the set screw to secure the mounting bracket to the unit.

• See page 68 for mounting bracket dimensions.

• The mounting bracket for the front type (BL-500/501(H)) differs from that for

the side type (BL-550/551(H)). The correct bracket is provided with your unit.

Installation with no mounting bracket

• (BL-500/501/500H/501H)(BL-550/551/550H/551H)Prepare M3 male screws

M3 nuts

M3 screws

separately.

• Although the mounting holes are on both sides of the unit, only one side should

be mounted.

• For the mounting hole diameter, see page 66.

M3 screws

M3 nuts

5

Page 19

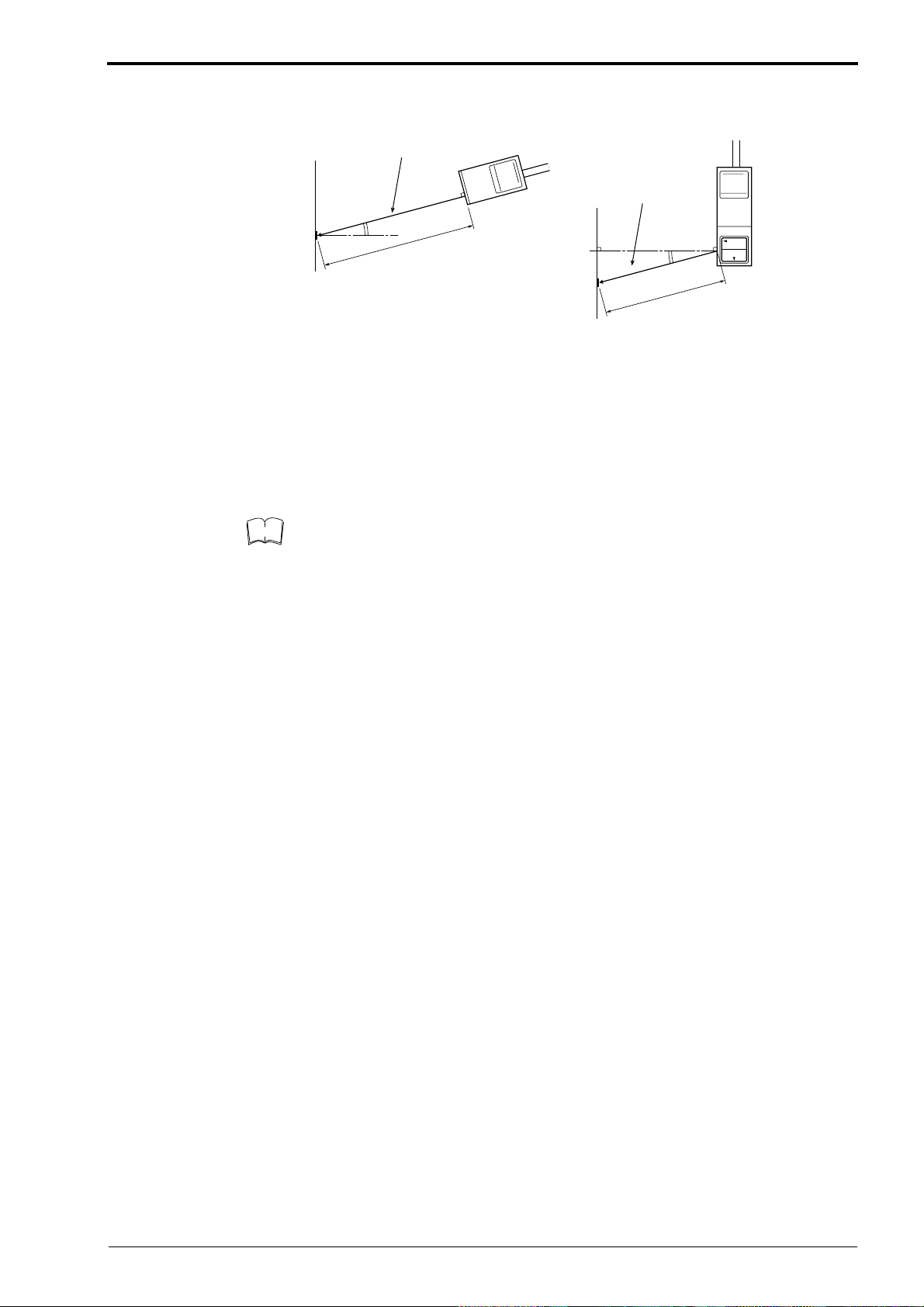

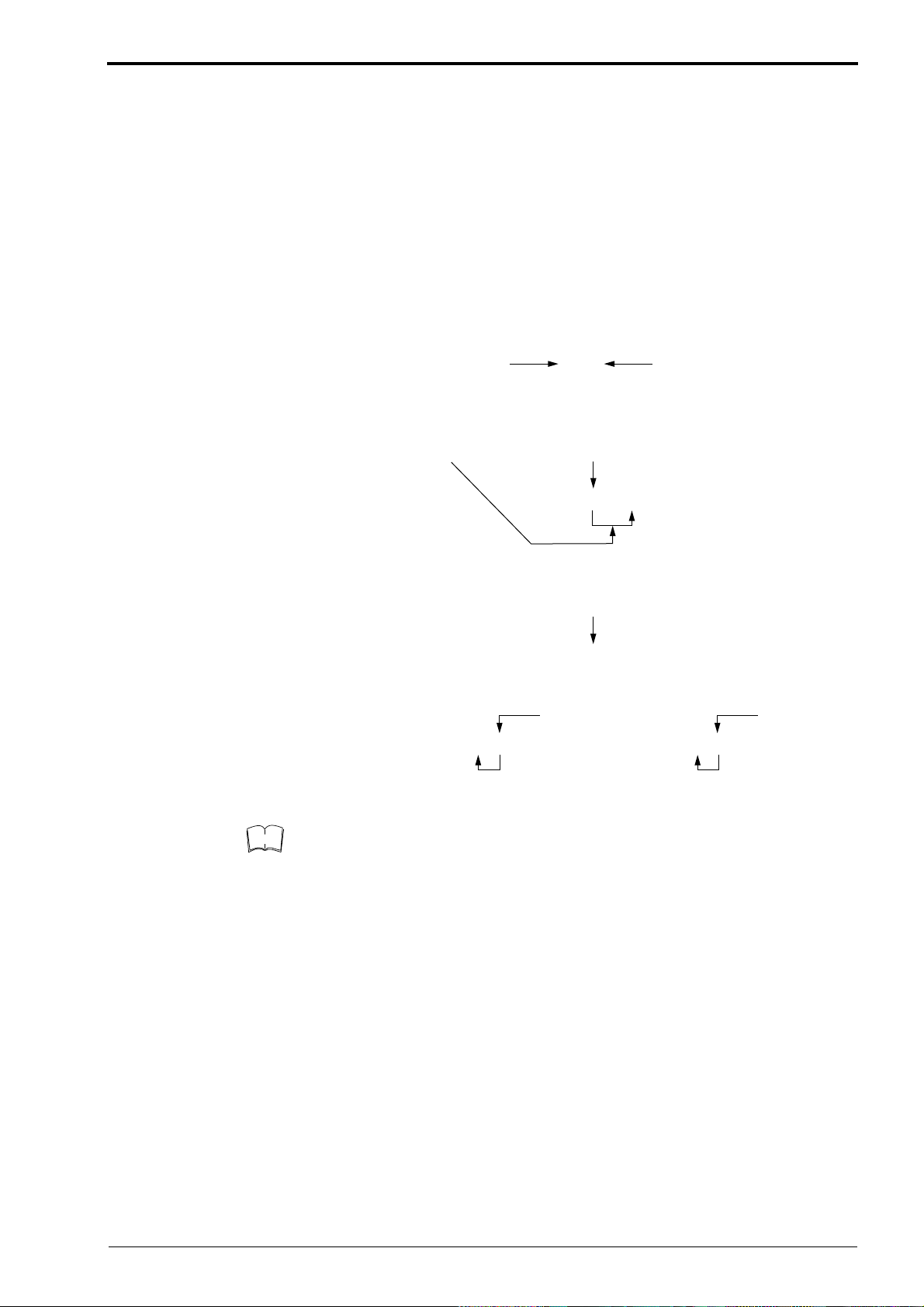

15°

Laser beam

Reading distance

BL

-

500

BL-550

*Reading distance = 120 mm

Reading distance

15°

Laser beam

*Reading distance = 95 mm

1.2 Installing the BL-500 Series

Mounting angle and mounting distance

BL-500/501/500H/501H BL-550/551/550H/551H

Set the angle and reading distance by referring to the read range characteristics

and angle characteristics described on page 62 and 66.

The allowable reading distance and angle may vary depending on the narrow bar

width of the bar code, the bar code size, and the readability of the bar code. Set

these parameters after performing a test read of the required bar code using the

unit.

Note

Do not set the unit at an angle at which the laser beam is perpendicular to the surface of the bar code. The beam will be fully reflected into the reader, making correct reading impossible (see page 66).

The laser radiation angle differs between the front and side type units. The optimal mounting angle differs depending on the type.

The reading check test mode (see page 15) allows you to set the optimal reading

position.

6

Page 20

Chapter 2

Functions for Reading Operation

Page 21

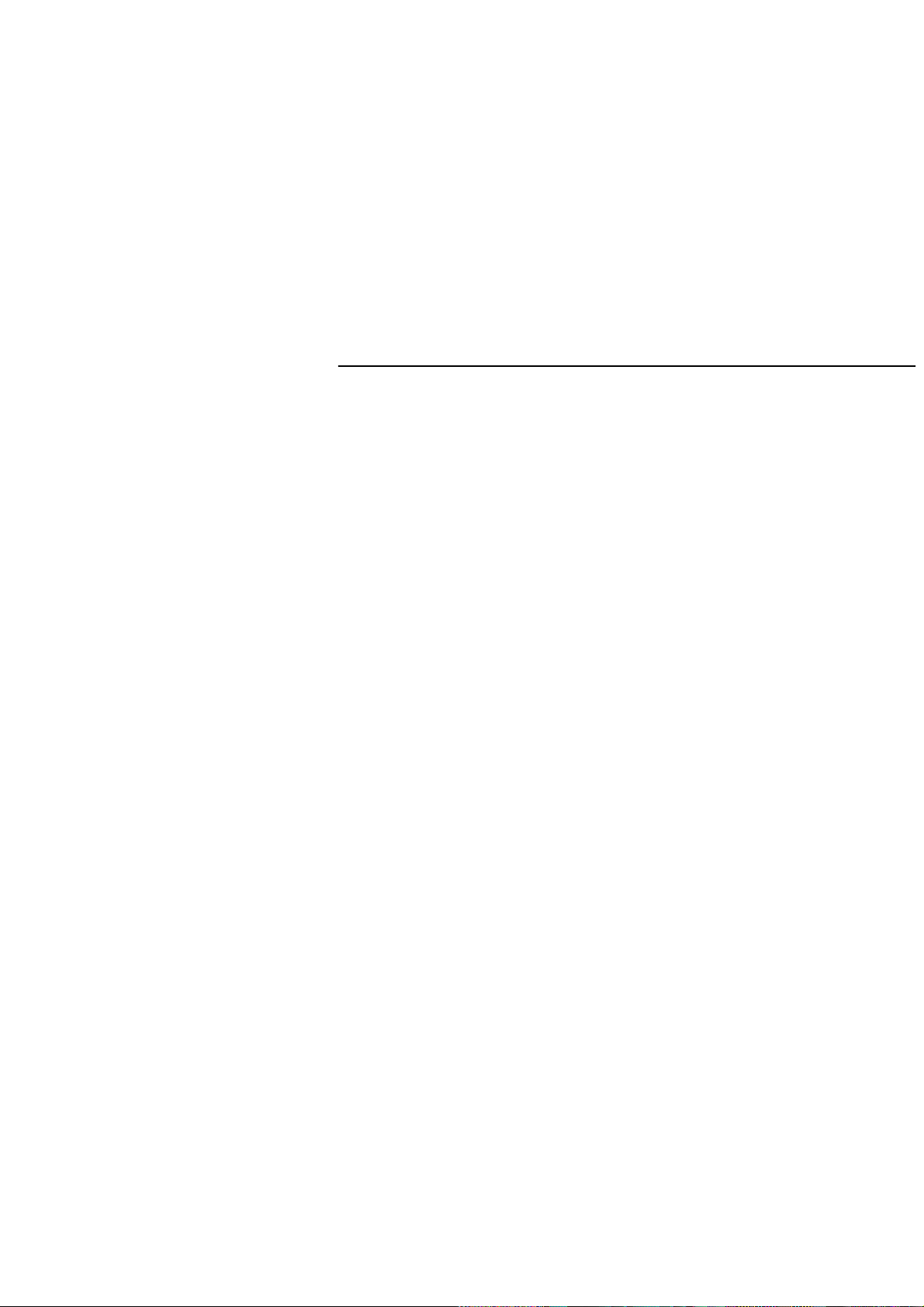

Trigger input

Bar code

Laser beams

Communication time

OK/NG output OK/NG NG

<Succeed to read> <Fail to read>

*2

*1

*3

*4

*5

Data bits + (1: If parity is used) + Start/stop bit

Baud rate

(code length of data to be sent + Header/

number of characters in delimeter)

X

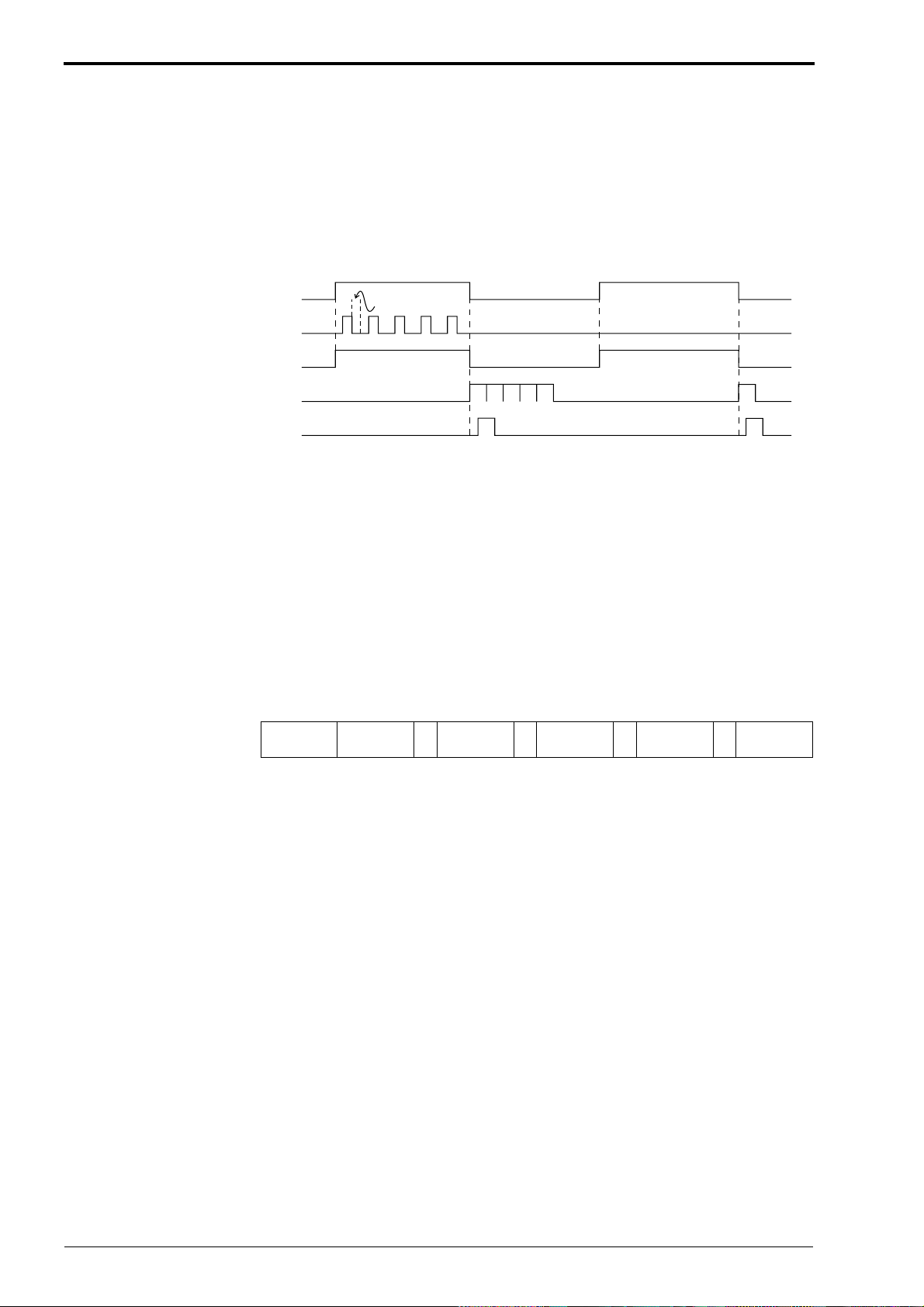

2.1 Read Operation

2.1 Read Operation

2.1.1 Scanning method

There are two methods for triggering the BL-500 to read bar codes; the “Level signal” method and the “One-shot signal” method. The example given for these two

methods uses the “single label read mode” (see page 10), which reads one bar

code while trigger input turns on once, and uses the “after read” as the data-send

mode (see page 9).

Level signal trigger

When the trigger input turns on, laser emission begins and the the unit begins

reading. The laser turns off after reaching the specified decode count. Then, the

unit sends the readout data.

CAUTION

1. Set trigger input so that it stays on long enough for the laser beam to cover

the entire bar code.

2. After the trigger input exceeds the preset input time, the laser begins to emit.

3. The communication time can be obtained from the following expression:

4. The length of time that the OK/NG output is on can be changed to between

10 ms and 2.55 s.

5. The OK/NG output turns on 5 ms after the data has been read (or trigger

input turns off in case of reading failure).

5 seconds after the power switch turns on or an UNLOCK command (see

page 50) is sent, the unit will not start reading a bar code by turning on the trigger

input.

8

Page 22

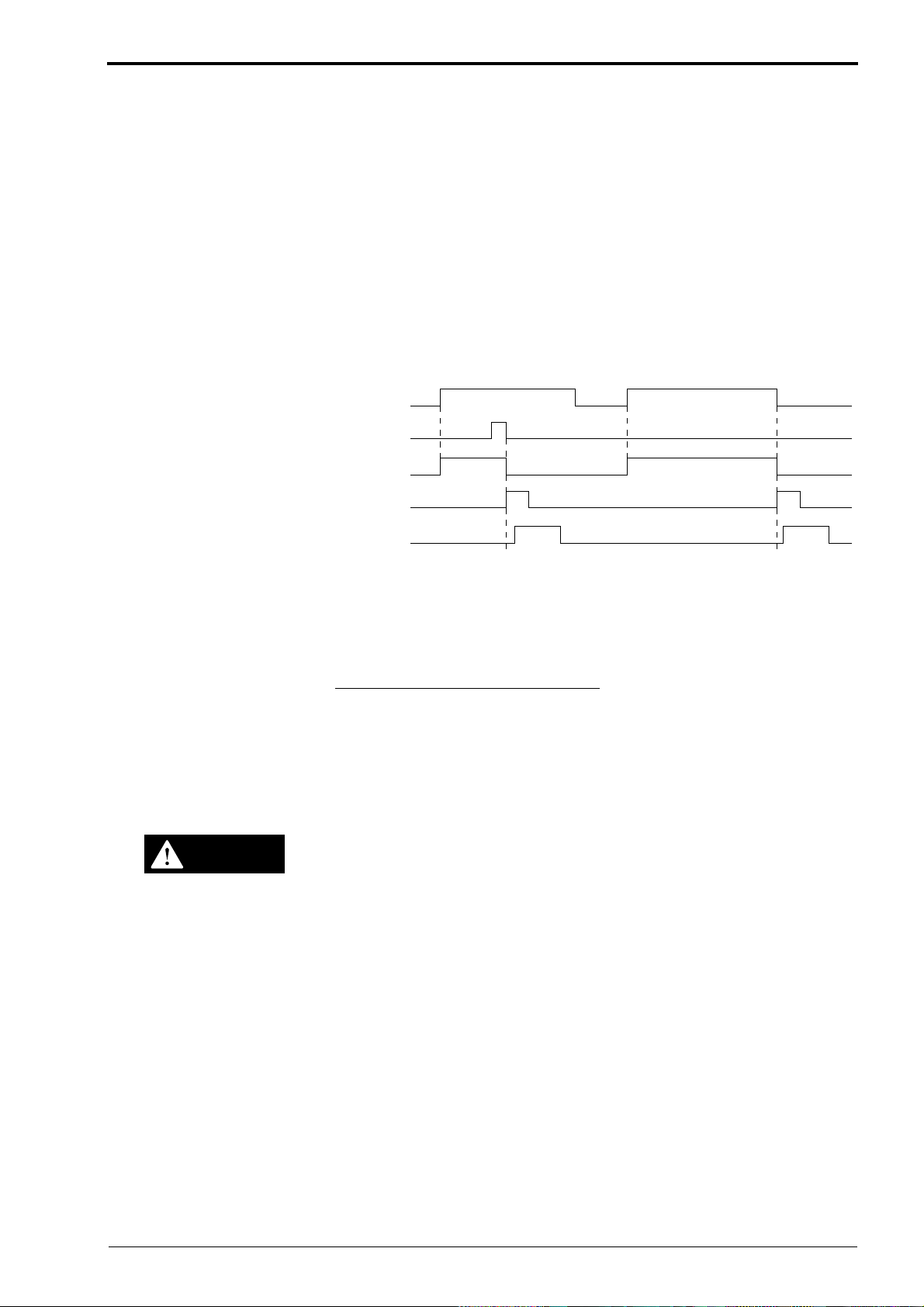

One-shot signal trigger

2.1 Read Operation

The unit detects the rising edge of the trigger input and starts reading bar codes

for the preset input time. The laser beam turns off after reaching the specified decode count and the unit sends the readout data.

The remaining actions are the same as those for level signal trigger.

<Succeed to read> <Fail to read>

Trigger input

*1

Bar code

Laser beams

Communication time

OK/NG output

1. After the trigger input exceeds the preset input times, the laser begins to

Note

• The BL-500 can read up to 4 types of bar codes without changing the bar code

type setting (see page 30).

• For general operation, see "Level signal trigger"

• Choose “One-shot signal trigger” when the trigger input signal is very short or

you want to set the input time.

2.1.2 Data-send mode

In the single label read mode only, you can select from the two data send modes

(OK/NG output on trigger) described below: In the multi-label read mode, you can

only select the “send after reading” mode.

Send after read

The unit outputs the communication and OK/NG signals after a sucessful read

(trigger output turns on as many times as the preset decode count). This is the

same operation as in the time chart described in “1.1 Scanning method”. Normally, this is the method you should use.

emit.

Preset input time

OK/NG NG

Preset input time

Send at trigger input

The unit outputs the communication and OK/NG signal when the trigger input

turns off (or the preset input time has passed if one-shot signal trigger is selected).

OK/NG

<Fail to read>

NG

<Succeed to read>

Trigger input

Bar code

Laser beams

Communication time

OK/NG output

9

Page 23

BL-500

OK/NG

STB

TIMING

LASER ON

Repeat reading time

OK

NG

<Succeed to read> <Fail to read>

Trigger input

Bar code

Laser beams

Communication time

OK/NG output

OK OK OK

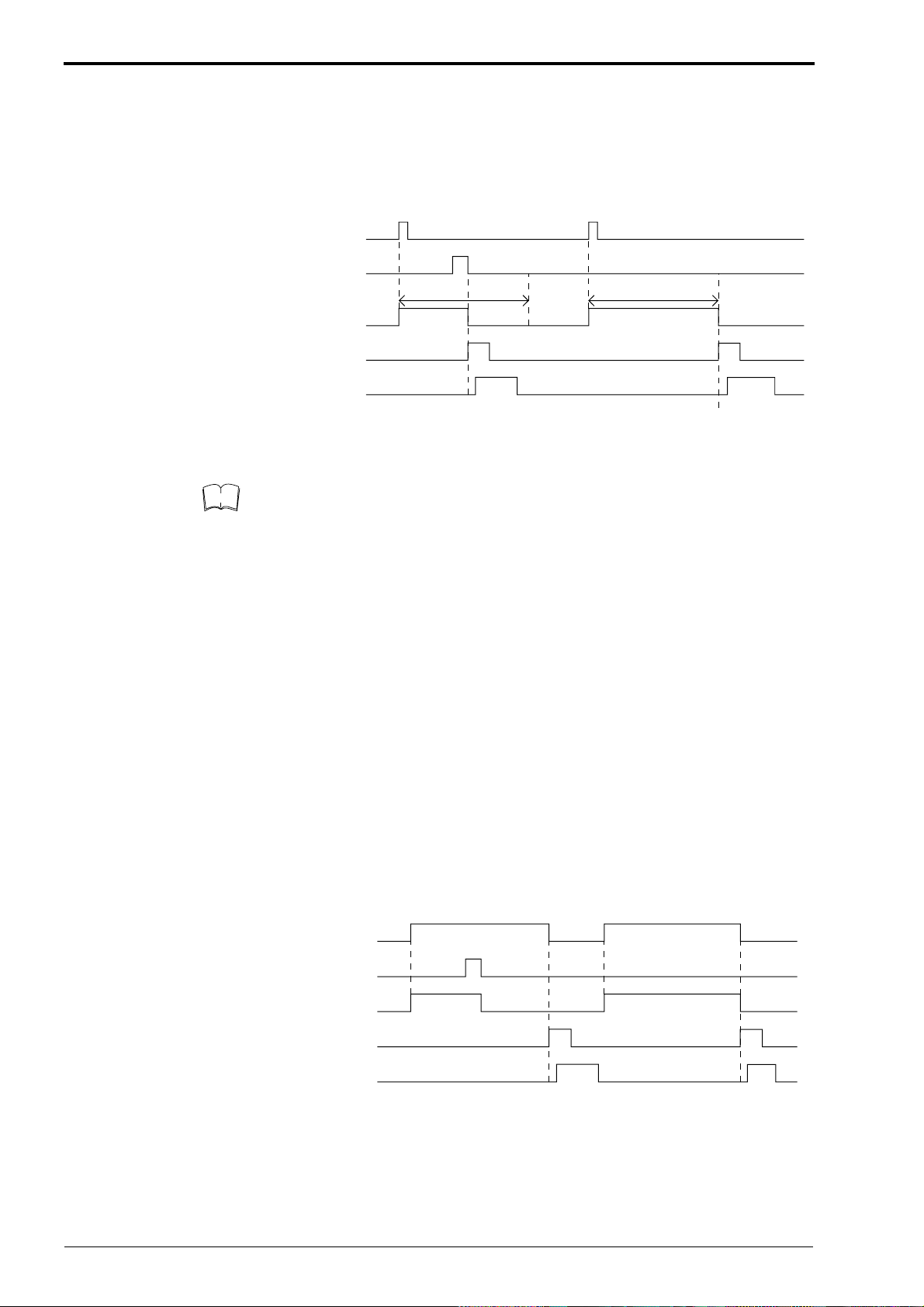

2.2 Read modes

2.2 Read modes

The BL-500 provides 4 types of read modes.

2.2.1 Single label read mode

This mode allows the unit to read one bar code during one trigger input signal.

The operation and timing chart are described on page 8.

2.2.2 Multi-label read mode 1 (Multi 1)

This mode allows the unit to read several bar codes printed on one label as shown

below during one trigger input signal. The unit outputs the readout data sequentially.

Multi-label read mode 1 operation

In the multi-label read mode 1, the unit reads several bar codes continuously, and

outputs them sequentially as it reads while laser beam remains on and trigger input turns on after bar codes have been read (or during the preset input time if oneshot signal trigger is selected).

To prevent the unit from reading the same bar code twice, the time for one bar

code to pass across the laser beam’s field and read, plus the repeat reading time

must be set (100 ms to 25.5 s). During the repeat reading time, the unit cannot

read the same bar code repeatedly, but can read different bar codes.

A reading error is issued only when the unit cannot read any bar code while the

trigger input is on.

For OK/NG output, “OK” turns on every time the unit reads a bar code and “NG”

turns on if the unit fails to read a bar code. (Comparison to the preset data is not

performed.)

10

Page 24

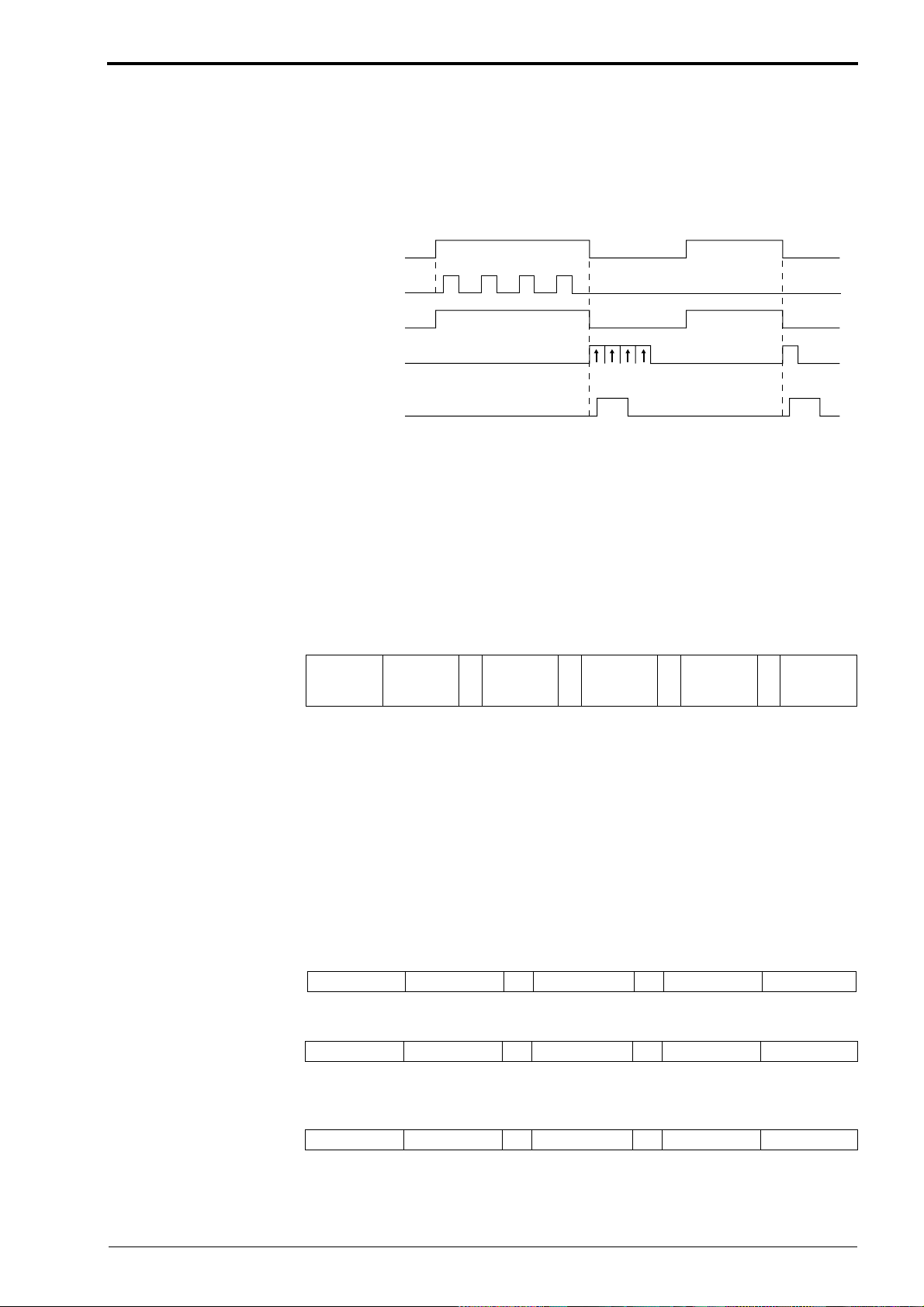

2.2.3 Multi-label read mode 2 (Multi 2)

As with multi 1 mode, this mode allows the unit to read several bar codes continuously while the trigger input is on. (The number of bar codes that can be read

depends on the buffer capacity. See page 46.) The difference between the two

modes is that multi 2 modesends all the readout data at one time after the trigger

input turns off.

Multi-label read mode 2 operation

<Succeed to read> <Fail to read>

Trigger input

Bar code

Laser beams

Repeat reading

time

12345

2.2 Read modes

Communication time

OK/NG output

Reading data format

12345

OK

NG

Multi 2 mode allows the unit to read several bar codes while the trigger input is on

(or during the preset input time if one-shot signal trigger is selected) and sends all

the readout data at one time after the trigger input turns off (or after the preset

input time is expired if one-shot signal trigger is selected).

To prevent the unit from reading the same bar code twice, the time for one bar

code to pass across the laser beam’s field and read, plus the repeat reading time

must be set (100 ms to 25.5 s). During the repeat reading time, the unit cannot

read the same bar code repeatedly, but can read different bar codes.

For OK/NG output, after trigger input turns off, “OK” turns on if the unit reads at

least one bar code and “NG” turns on if the unit fails to read a bar code. (Comparison to the preset data is not performed.)

Header

1st

data

2nd

,

data

3rd

,

data

4th

,

data

, Delimeter

Each data packet is separated by a comma (, : 2CH) (intermediate delimiter).

The unit sends as many data packets the number of bar codes read.

See page 46 for “header string” and “delimeter”.

2.2.4 Multi-label read mode 3 (Multi 3)

As described in multi-label read modes 1 and 2, this mode also allows the unit to

read several bar codes (up to 4 codes) while the trigger input is on.

The unit sends the readout data at one time according to a specified sequence

after the trigger input turns off. When up to 4 codes are in the laser beam’s field,

the unit can simultaneously reads all of them.

11

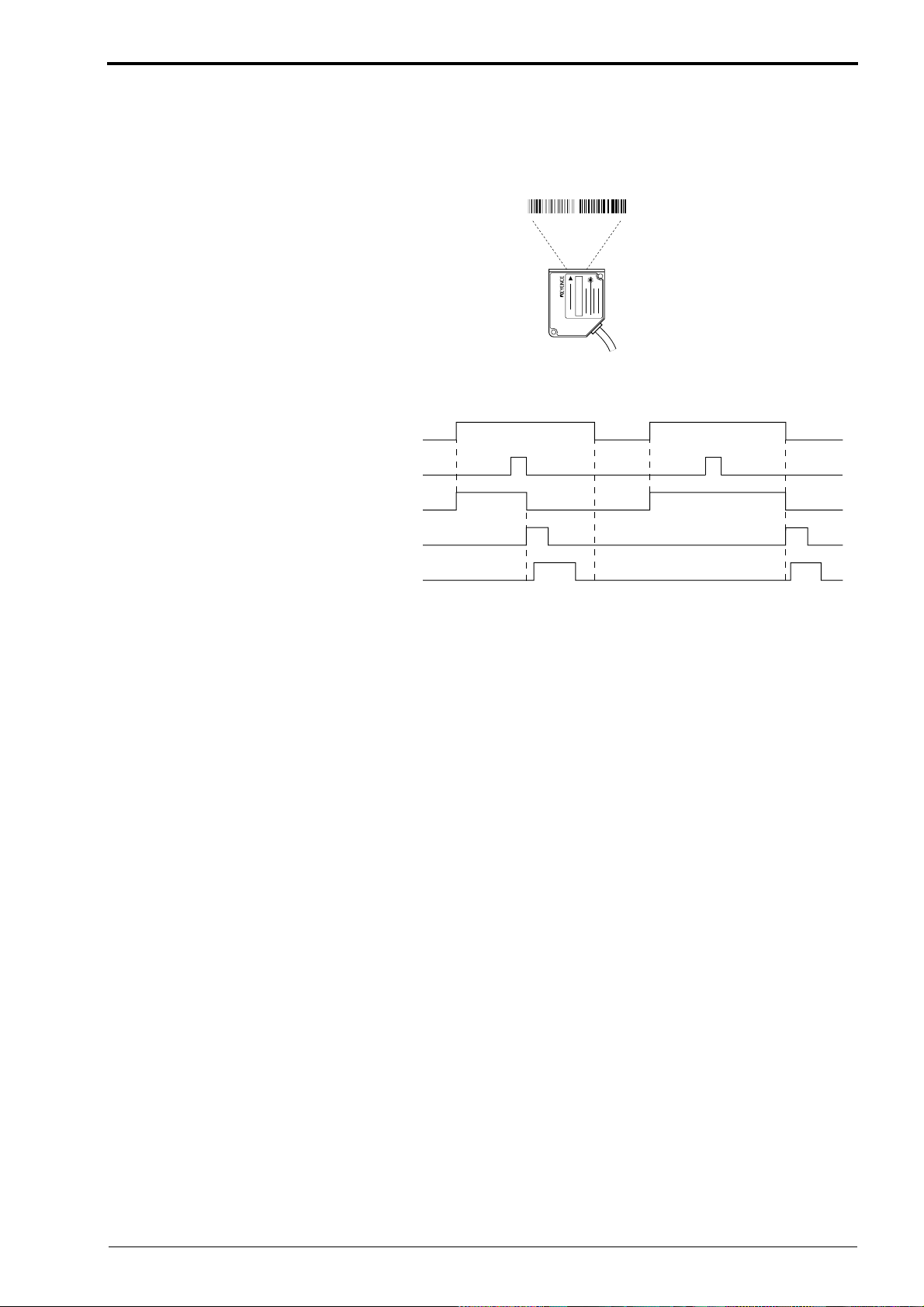

Page 25

OK

Trigger input

Bar Code

Laser beams

Communication time

OK/NG output

Code 1 Code 2 Code 3 Code 4

Code 1

Code 2

Code 3

Code 4

NG

2.2 Read modes

Operation of multi-label read mode 3

This mode allows the unit to continuously read each one of 4 bar code types

“Code 1”, “Code 2”, “Code 3”, and “Code 4” as specified in the “code setup” of the

setup software (see page 30). If 3 types are specified in the “code setup”, the unit

reads 3 bar codes (each of 3 types). If 2 types are specified, the unit reads 2 bar

codes.

The following time chart is given.

The above example chart is with all four codes specified in the “code setup” of the

setup software.

• The bar code reading sequence is not fixed.

• The unit communicates the readout data in the order of Code 1 to Code 4.

After the trigger input turns off, the unit sends all the data at one time.

• For OK/NG output, “OK” turns on if the unit reads all the specified Codes 1 to 4

and “NG” turns on if the unit fails to read at least one bar code. (Comparison to

the preset data is not performed.)

Reading data format

Example Suppose that the following codes are specified:

Header

Data read

from Code

1

Data read

from Code

,

Data read

from Code

2

,

3

Data read

from Code

,

4

, Delimeter

• Each data packet is separated by a comma (, : 2CH) (intermediate delimiter).

• If an read error occurs on any one of Codes 1 to 4, or the corresponding bar

code does not exist, “ERROR” (see page 47 for the reading error codes),

instead of the read data is sent.

• See page 46 for “header string” and “delimeter”.

Code 1 --- CODE39, 10 digits

Code 2 --- EAN/UPC, 13 digits

Code 3 --- None

Code 4 --- CODE39, 8 digits

When the unit successfully reads all 3 types of codes:

Header ABCDE12345 , 4901234567894 , KEYENCE Delimeter

When the unit fails to read Code 1 (CODE39, 10 digits)

Header ERROR , 4901234567894 , KEYENCE Delimeter

12

When the unit fails to read Code 1 (CODE39, 10 digits) and Code 4 (CODE39, 8

digits)

Header ERROR , 4901234567894 , ERROR Delimeter

When the same type of data having the same digits is specified to all Codes 1 to

4, the unit sends the data in the reading order.

Page 26

13

Example

Suppose that the following codes are specified:

Code 1 --- CODE39, 7 digits

Code 2 --- CODE39, 7 digits

Code 3 --- CODE39, 7 digits

Code 4 --- CODE39, 7 digits

2.2 Read modes

Note

Header

The unit cannot read the bar code having the same content twice while trigger input turns on once.

ABCD123 , XYZ3333 , 1234567 , KEYENCE , Delimeter

Page 27

4 9000000

4 9000000

Forward orientation Reverse orientation

OK/NG

NG

<Specified orientation>

<Non-specified orientation>

Trigger input

Bar code

Laser beams

Communication time

OK/NG output

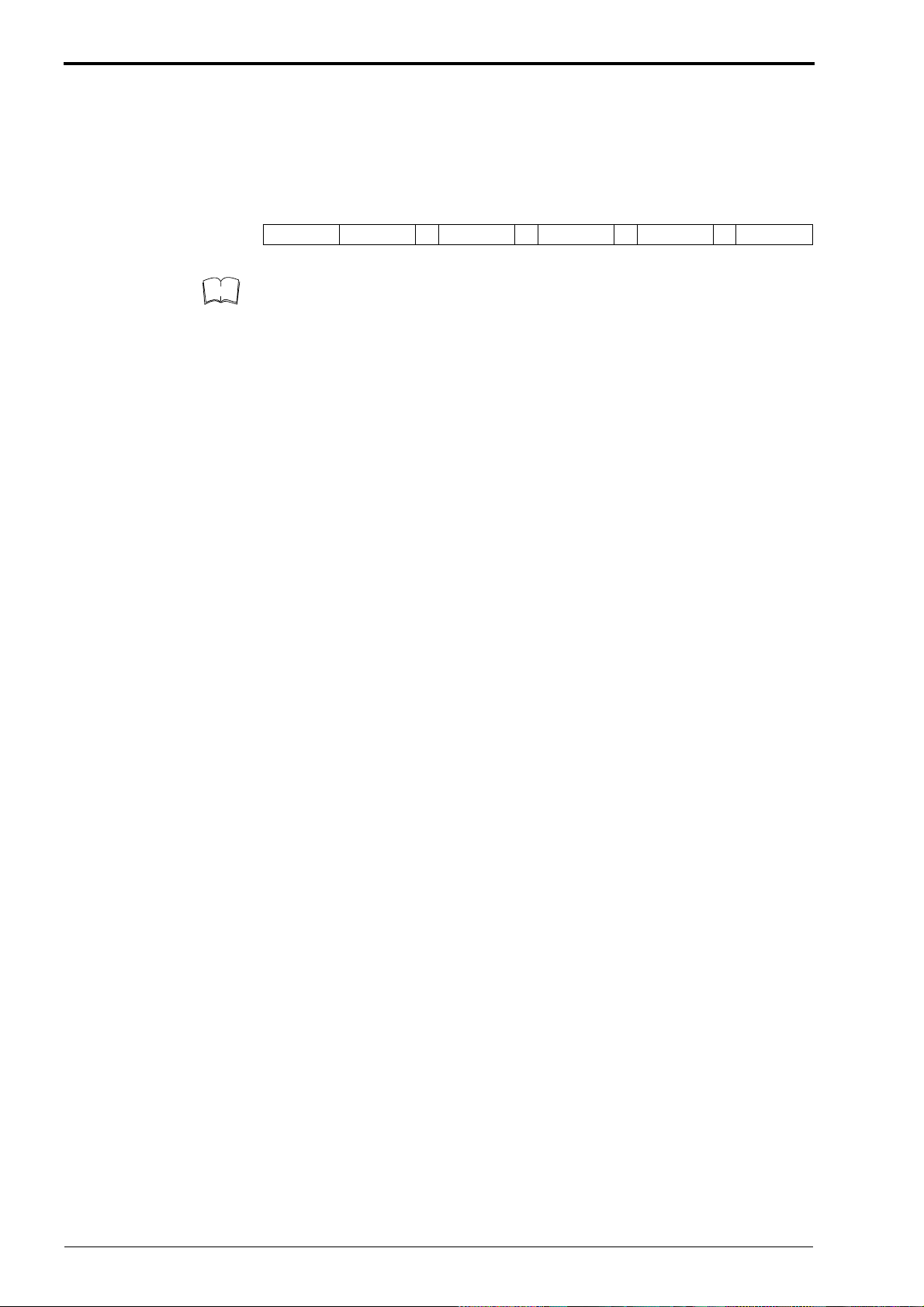

2.3 Label orientation mode

2.3 Label orientation mode

As shown below, this mode allows the unit to read bar codes only in the specified

orientation when bar code labels are moving both in the forward and reverse orientations.

Normally, the unit can read bar codes regardless of the orientation.

An reading error is issued when the unit reads a bar code label running in the orientation which is not specified.

The above chart applies to the single label read mode. You can also use this

mode together with the desired multi-label read mode. However, in any case, the

unit reads bar codes running in the specified orientation only.

You can specify the orientation individually for Codes 1 to 4, such as specifying

“forward orientation” for Code 1, and “reverse orientation” for Code 2.

14

Page 28

2.4 Test Mode

2.4 Test Mode

Test mode can be used for the bar code reading test. Because trigger input is not

required, this mode allows you to perform a reading test easily. You can select

one of the following 3 methods to enter the test mode.

Send the command

Enter test mode by sending the serial command for the test mode (TEST1,

TEST2). Commands should be entered in all uppercase characters.

Turning on trigger input

You can use the BL-500 to switch to test mode by turning on the trigger input (see

page 35). If you select this method to enter the test mode, trigger input is disabled

to ensure normal operation.

Turning on power supply

You can set the BL-500 to enter test mode by turning on the power supply (see

page 35).

Note

When you try to enter the test mode by turning on trigger input, you cannot use

the serial command to enter the test mode.

The following 2 types of test modes are available:

Reading rate check mode

The unit scans a bar code100 times and analyzes how many times it can decode

the scanned data (reading rate). This mode is useful in the following cases:

• When adjusting the mounting distance and angle

• When verifying the reading stability of the bar code to be used

• The analyzed result will be output anytime (every 100 scans) using the follow-

ing format:

• Although an OK/NG signal is not output, the OK/NG LED lights (see page 17).

Tact check mode

In this test mode, the unit counts how many scans can be decoded (the decode

count) while reading one bar code.

This mode is useful when testing which line speed can be expected when actually

implementing the BL-500 system on the line.

• The analyzed data is output using the following format 0.2 seconds after the

bar code has passed the laser beam’s field.

Readout data

Delimiter

: m %

m = 0 to 100 (zero-suppressed)

Readout data

• The unit continues to read a bar code while the code is in the laser beam’s field

and does not output the result. If the laser beam does not detect a bar code for

0.2 seconds, the unit stops scanning and outputs the result.

• If the unit reads the same bar code twice within the 0.2 seconds, the unit cannot separate the bar codes and will add to the read count. However, the unit

can continuously reads different bar codes within the 0.2 seconds by recognizing the delimiter.

Delimiter

: m

m = 1 to 999 (zero-suppressed)

15

Page 29

2.4 Test Mode

16

• The read count can be up to 9999.

• Although an OK/NG signal is not output, the OK/NG LED lights (see page 17).

Note

When the unit is running in test mode, the laser beam remains on, which can

shorten the laser’s service life.

Select the test mode only when you need to perform a test read.

Avoid long emission times.

When using the “additional information” (see page 20 to 21) in the test mode, the

selected data is added in the same manner as in the normal operation mode.

However, only when selecting the reading rate check mode, the decode count

and scan count are not added to the analyzed results.

Page 30

2.5 STABILITY LEDs

STABILITY LEDs allow you to easily check reading stability and operation status.

Indication of reading stability

When reading rate check mode is selected

STABILITY LEDs light according to the reading rate shown in the table below. Although, in the test mode, the unit does not output an OK/NG singnal, the OK/NG

LED lights as below. (Comparison to the preset data is not performed.)

2.5 STABILITY LEDs

Reading rate

81 to 100%

61 to 80% 4 LEDs light Green

41 to 60% 3 LEDs light Green

21 to 40% 2 LEDs light Green

1 to 20% 1 LED lights Green

0% —— Red

STABILITY LED OK/NG LED

5 LEDs light Green

When tact check mode is selected

STABILITY LEDs light according to the scan count (decode count), which indicates the number of successful reads, as shown in the table below.

Although, in the test mode, the unit does not output an OK/NG signal, OK/NG LED

lights as below. (Comparison to the preset data is not performed.)

Decode count

100 or more

50 to 99 4 LEDs light

10 to 49 3 LEDs light

5 to 9 2 LEDs light

1 to 4 1 LED lights

0 —— Red

STABILITY LED OK/NG LED

5 LEDs light

Green (decode counts are

equal to or greater than

the preset match count)

Red (decode counts are

less than the preset

match count)

When normal read mode is selected

When you select multi-label read mode 1 or 2 (see page 10 to 11), or the send

mode is set to “after trigger input” (see page 9), or you select the decode count

adding function (see page 20), STABILITY LEDs light according to the decode

count as shown in the table below.

However, If you do not select “use STABILITY LED” in the setup software (see

page 37), STABILITY LEDs do not light in normal read mode.

ON/NG output (ON/NG LED) turns on/off normally according to the result of a

comparison to the preset data.

Decode count

100 or more

50 to 99 4 LEDs light

10 to 49 3 LEDs light

5 to 9 2 LEDs light

1 to 4 1 LED lights

0 ——

STABILITY LED

5 LEDs light

17

Page 31

2.5 STABILITY LEDs

Unit operation status display

STABILITY LEDs indicate the following information in addition to reading stability.

Power-on

LEDs turn on sequentially from the bottom. The unit cannot read bar codes while

STABILITY LEDs are lit (for 5 seconds).

During setup (see page 49)

All the STABILITY LEDs blink.

Using “Laser stop” function (by sending LOCK; see page 50)

The top LED blinks. When resetting “laser stop” (by sending UNLOCK ), the

LEDs light in the same manner as at power-on.

Unit error

The 2nd or 3rd LED from the top blinks. The unit may have failed. Contact your

nearest KEYENCE office or distributor.

18

Page 32

2.6 Preset Function (Compare with:)

2.6 Preset Function (Compare with:)

2.6.1 What is the preset function?

The BL-500 can store one bar codeas preset data. It compares the preset data to

the bar code data actually read and outputs an OK/NG signal to whether there is

a match.

Using the BL-500 preset function, you can prevent the wrong products from entering the line without using a PC.

If no preset data is registered, the unit outputs OK when it successfully reads a

bar code and NG when it fails to read a bar code.

• See page 8 to 14 for output timing.

• Use the setup software and serial command to register the preset data (see

page 37 and page 58).

?:

!:

Note

• The bar code actually read can be compared to the preset data only in the single label read mode.

• See page 72 if you want to use CODE128.

2.6.2 Wildcard symbols (“!” and “?”)

Using “!” and “?” in the preset data allows for flexible settings.

Does not define numeric values (characters) of certain digit(s) of the bar code.

Ignores numeric values and symbols within the dot box and recognizes the bar codes

as the same group.

4912 3456

4912 5256

4912 AB5 6

When using “?” data as “4912??56”, 2

digits positioned in “??” can contain

any numeric values (or characters),

expanding the allowable range. Identifies all the bar codes to be OK as

long as the beginning or ending

strings match.

4912 3456

4912 C

4912

When using “!” as “4912!”, any bar

code which begins with “4912” will be

OK. When using “!” as “!4912”, any

bar code which ends with “4912” will

be OK.

Setting examples 1. “ABC?” ABCD (OK), ABC3 (OK), ABC (NG), ABCDE (NG)

2. “ABC!” ABCD (OK), ABC3 (OK), ABC (OK), ABCDE (OK), AB (NB)

3. “?????” Any 5-digit bar code will be OK.

4. “!CDE” ABCDE (OK), 3CDE (OK), CDE (OK), ABBDE (NG), ADE (NG)

5. “A!E” ABCDE (OK), A3CE (OK), ABCD (NG), AE (OK)

Note

You can use “!” only once in the setting.

If you do not register preset data, “!” is automatically registered. Therefore, when

the unit sucessfully reads a bar code, “OK” is output; when the unit fails to read,

“NG” is output.

You cannot use the “*” character as a wild card symbol with the BL series.

19

Page 33

2.7 Additional Information

m = 1 to 999 (zero-suppressed)

The value is zero-suppressed.

Delimiters

Readout data

: d / s

t = 0 :Code39

1 :ITF

2 :Industrial 2 of 5

3 :Codabar

4 :EAN/UPC (A•E)

5 :CODE 128

6 :COOP 2 of 5

7 :Read error

Delimiter

t

:

Readout data

2.7 Additional Information

When sending the bar code data, you can add the following data to the readout

data.

Additional information types

Decode match count add function

Adds the number of successful scans during one bar code reading (decode

count) to the end of the readout data (up to 9999 count). However, this decode

count is never less than the preset decoding match count.

• This function can be used to check reading stability and code label quality.

When using this function, output turns on at a different time from normal operation.

• In single label read mode, output turns on after one bar code has been read

(after trigger input turns off). Even if you set the data-send to “after read”, the

data is forced sent after trigger input turns off.

• In multi-label read mode 1, a bar code passes across the laser beam’s field,

after repeat read time, and is finally output.

• In multi-label read mode 2 or 3, operation is the same as when you do not use

the decode match count adding function.

Delimiter

Readout data

The value is zero-suppressed.

:

d

d = [Decoding match count] to

9999: Decode count

Code type add function

Scan count add function (valid only when using the read count add function)

Adds the number of scans, including when no bar code exists, to the end of the

decode count (up to 9999).

Adds the bar code type before the readout data .

20

Page 34

label orientation add function

Adds the orientation of bar code travel before the readout data.

Order of additional information

If you select to include all the additional information functions, they appear in the

following order:

2.7 Additional Information

Delimiter

r

:

r =F :Forward

R :Reverse

If an read error occurs, this information is not added.

Forward orientation Reverse orientation

4 9000000

Readout data

4 9000000

21

Note

Code type

:

label

orientation

: Readout data :

Decode match

count

: Scan count

You can change the delimiter as desired (one character), except the delimiter of

the scan count.

Page 35

2.8 Max. Code Length (Designated Digit ) Output Function

4 9 1 2 3 4 5 6

Forward Reverse

4 9 1 2 3 4 5 6

3 digits starting from 5th digit by counting forward

4 9 1 2 3 4 5 6

5th digit by counting forward

1 5 8 4 2 3 4 2 1

5 8 4 2 3 4 2 1

2.8 Max. Code Length (Designated Digit )

Output Function

This function allows you to output the designated digit(s) as desired from the

readout bar code data. For example, from bar code data “49123456”, you can extract “1234” for output.

Setting digits to be output

Set the digits to be output as shown below. Individually set the digits for codes 1

to 4.

1. Set the direction to designate.

Set from which direction you want to start counting.

2. Set how many digits you want to designate for output starting from the designation start digit in (2) (designation effective digits).

The actual setting order is (1) (3) (2).

3. Set from which digit you want to begin designation (destination start digit).

Example Designating and outputting “34” from bar codes “158423421” and “58423421”

Designate 2 digits starting from 3rd digit by counting reversely.

Note

• Regardless of the designated direction, the data is output forward in the com-

munication application.

• When the bar code group includes those having different digits, take special

care on the designated direction when setting the digits to be output.

• When comparing to the preset data, all the digits of the bar code are used.

22

Page 36

Chapter 3

Setup Software

Page 37

3.1 Controlling the BL-500

3.1 Controlling the BL-500

The BL-500 can be controlled by computer using an RS-232C serial communication with Windows™ Terminal software or using BL-500 Setup Software. This

chapter describes how to set the BL-500 using the BL-500 setup software. For

more information on using the serial communication, see “Chapter 4” on page 43.

3.1.1 Setup Software Requirements

The BL-500 Setup Software for Windows operates in the following environments:

Personal Computer

IBM PC/AT or compatible model (100% compatible)

CPU: 80386 or higher

Memory: 4 MB or more

Floppy drive: One or more 3.5 inch drives

RS-232C: One serial port (COM 1 or COM 2)

DOS: Windows 3.1

* The BL-500 Setup Software applies to COM 1 and COM 2 only.

Starting the setup

software

1. Prepare the following items before starting.

• BL-500

• Power supply unit for BL-500 (5 VDC) or the BL-U1/BL-U2

• RS-232C cable described on p. 2 to 4 in this manual

• Setup software

• Personal computer

• Mouse

2. Connect the PC with the BL-500 or BL-U1/BL-U2 using the RS-232C cable.

3. Set the DIP switches on the BL-U1 to RS-232C when you use the BL-U1.

4. Install the setup software.

Turn the PC’s power switch ON to start Windows.

5. Insert the setup software into the floppy disk drive.

6. Select F

ile - Run on the menu bar of the program manager.

24

7. When the following screen appears, type the name of the floppy disk drive

and the name of the installed file “SETUP” in the “Command Line”. After typing the above, click on the OK button.

Example When the floppy disk drive name is A, type as follows:

A:\SETUP

Then, the target directory for installation is displayed.

“C:\BL500”

is displayed.

Page 38

25

3.1 Controlling the BL-500

8. To accept the directory name, click on the OK button.

To change the directory name, click on the column displying the directory

name, type a desired directory name using the keyboard, and click on the OK

button.

9. After the installation is completed, the “KEYENCE Barcode Reader” window

is created in the program manager. In this window, icon “BL50WIN” is created.

10. To start the setup software, double-click on the “BL50WIN” icon.

Note

11. After the setup software gets started, the following screen appears:

When using a monochrome display on a laptop PC, the display appears in reverse video. To make the display clearer, set the laptop’s display to reverse video

and then restart the setup software.

Page 39

3.2 Operating Procedure

3.2 Operating Procedure

3.2.1 Outline of Operation

To operate the setup software, place the mouse pointer on the item to be

changed, and click the left button of the mouse.

Use the Down Arrow button to select an item from a list. Place the mouse pointer

on a desired item, and click on the item.

Click on the Option button to select one of several items.

In the above settings, Read mode is set to “Single” and Data-send is set for “At

trigger input.”

The Check Box is used to enable special functions. An “X” in the Check Box indicates that a function has been enabled.

In the above settings, “Inspect check-digit[Modulus43]” is enabled.

To enter characters or a value in a field, insert the mouse pointer over the field.

The pointer will change to a cursor. Click inside the field and type in the desired

value.

If the specified value exceeds the setting range, an error message will appear

26

To shift to a different screen, click the mouse cursor one of the buttons in the window. For example to return to the previous screen, click on the button.

Page 40

3.3 Setup Software Operating Procedure

3.3 Setup Software Operating Procedure

After the setup software is started, the following screen (main setting screen) is

displayed.

The function of each display is as follows.

Title (Name of the current setting screen)

Menu bar (*)

Parameter

Current file name

The initial file name is “Untitled. CFG”.

Setting screen selector buttons

The setup software provides the following setting screens according to the parameters.

Main setting [Main]

• Type of the bar code to be read

• Read mode and its setup

• Decoding match count

• Additional information

Setting details for the specified code type [Code setup]

• Setting No. of bar code length, inspection of check-digit, etc.

Trigger input setup [Setup Trigger input]

• Setting the operation mode and the trigger input

• Selecting the test mode starting method

• Setting characters for the trigger ON/OFF command

Communication parameters [Setup comm]

• Setting the baud rate, data bits, stop bit and parity

• Setting the protocol

• Setting the Communication strings (header string, delimiter, read error code,

etc.)

Utility [Utility]

• Indication of the STABILITY LED

• Duration of OK/NG output

• Registration of preset data

For the operating procedure, see “Setup Software Operating Procedure” on

page 27.

For the error messages displayed during operation, see page 39.

27

Page 41

3.3 Setup Software Operating Procedure

Menu Bar

The following operations can be performed using the menu bar.

File Menu (Alt+F)

Specifies a file name/Saves a file.

Exits the setup software.

Send Settings (Alt+S)

Sends settings to the BL-500.

Info (Alt+I)

Indicates the version number of this software.

3.3.1 File Operation

The following is the procedure for specifying a file name, saving a file or exiting

the setup software.

Click on F

The following menu appears.

ile in the menu bar.

New

New

Cancels the current setting file and calls the initial setting.

Open

Calls the previously stored file.

Save As

Saves a file with a specified file name.

Save

Saves a file.

Exit

Exits the setup software.

1. Click on New.

The following message appears.

2. To cancel the current settings and call the initial setting, click on the OK button. If you wish not to execute this operation, click on Cancel

.

28

Page 42

3.3 Setup Software Operating Procedure

Open

1. Click on Open .

2. The following screen is displayed for selection of the file to be read.

Directory selection

list

File name

entry column

File selection

list

Drive selection

list

Select a desired file from those listed in the file selection column, and click on

the OK button.

If you wish to cancel this operation, click on the Cancel button.

To change the directory or drive, select a desired directory or drive in the di-

rectory/drive selection column.

3. When you click on the OK button on the above screen, the following message appears.

Save As

To cancel the current setting and call a new file, click on the OK button. If you

wish not to execute this operation, click on the Cancel button.

1. Click on Save As .

2. The “Save As” screen appears.

3. Click in the file name entry field and type a file name using the keyboard.

Type a file name of up to 8 characters. Be sure to add extension “CFG” to the

file name.

29

Page 43

3.3 Setup Software Operating Procedure

Example When the file name is “TEST”:

1. Click on the file name entry column.

2. Enter “TEST. CFG” as the file name .

3. Click on the OK button.

If you wish cancel this operation, click on the Cancel button.

To change the directory or drive, select a desired directory or drive in the

directory/drive selection column.

4. If the specified file name has already been stored, the following message will

appear.

To save the setting by overwriting the existing file, click on the OK button. If

you wish not to save the setting, click on the Cancel button.

30

Save

Exit

A file name must be entered before the file can be saved

1. Click on Save . The file will be saved.

1. Click on Exit .

The following message appears.

2. To exit the setup softw are, clic k on the OK button. If y ou wish cancel, clic k on

Cancel .

Save the current settings before exiting the setup software.

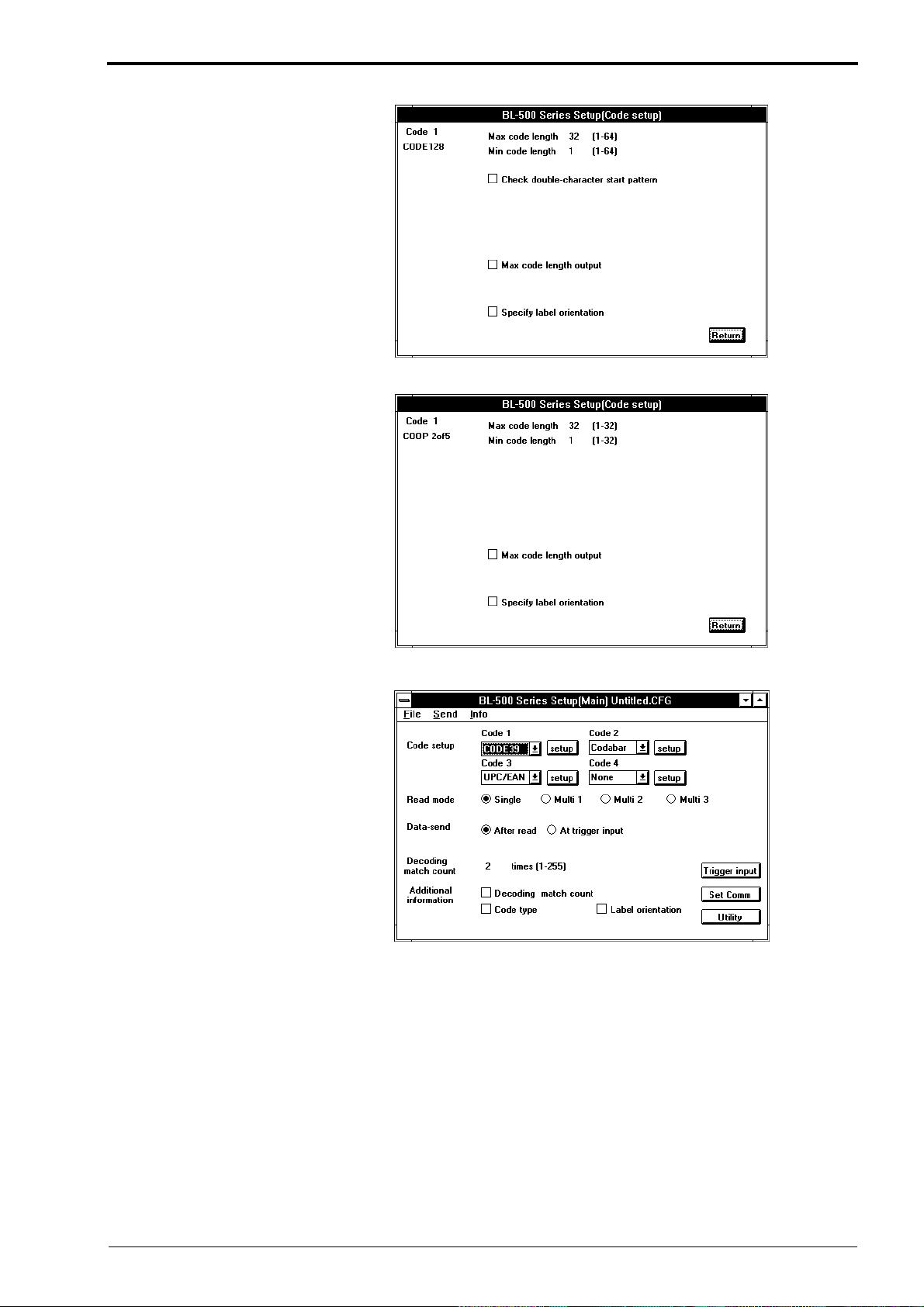

3.3.2 Main setting screen

1. Place the mouse cursor at the item to be changed and click it, or move to the

target item by pressing [TAB] . Then, change the setting using [Space] .

2. To codes 1 to 4, specify the types of bar codes to be read.

If you specify 4 different types of bar codes, the BL-500 can read them without changing the settings.

3. To set the code length or the inspect for check-digit, click Setup or press

[ENTER] to move to the setup screen for each code (see page 31 to 34).

Page 44

31

3.3 Setup Software Operating Procedure

4. When selecting Single for Read mode, the following appears on the screen:

When selecting Multi 1 or Multi 2, the following appears on the screen:

Set the time within the range from 1 to 255 (100 ms to 25.5 s).

When selecting Multi 3, none of the above information appears.

5. In the Additional information field, you can select one or more items. However, the scan count is given only when the decode count is selected.

Note

Read mode --> Page 10

Data-send --> Page 9

Repeating-reading time --> Page 10

Decoding match count --> Page 8

Additional information --> Page 20

3.3.3 CODE39 setup

When setting CODE39 to any one of codes 1 to 4 and trying to set details, this

setting screen appears.

1. Place the mouse cursor at the item to be changed and click it, or move to the

target item by pressing [TAB] . Then, change the setting using [Space] .

2. Setting Max code length and Min code length allows the BL-500 to read bar

codes having the specified range of digits. If you want to read bar codes with

the specific code length, set the same value to both Max code length and

Min code length.

The allowable setting range is 3 to 32 digits including the start/stop character.

3. When you select Send start/stop character, * is added to the data when

being sent.

Page 45

3.3 Setup Software Operating Procedure

4. When you select Inspect check-digit, the following information appears:

The above setting sends the data together with the check-digit.

Modulus 43 is used to calculate the check-digit.

5. When you select Max code length output, the following information appears:

Set Effective and Starting from 1 to 32.

6. When you select Specify label orientation, the following information appears:

32

Note

3.3.4 ITF setup

7. Click the Return button or press [ENTER] to return to the main setting

screen.

Max. code length output --> Page 22

Specify label orientation --> Page 14

1. Setup is the same as the CODE39 setup. However, ITF does not have Start/

stop character.

2. Set code length using a even value within the range from 2 to 32.

3. Modulus 10/Weight3 is used to calculate the check-digit.

Note

When reading the standard distribution code (bar code on the corrugated fiberboard box), set the code length to 14 or 16 and select the Inspect check-digit.

3.3.5 Setup for Industrial 2 of 5 and COOP 2 of 5

1. Setup is the same as the CODE39 setup. However, a start/stop character

and Inspect check-digit are not provided.

2. Set code length within the range from 1 to 32.

Page 46

3.3.6 Codabar setup

1. Set code length from 3 to 32 including the start/stop character.

2. When you select Send start/stop character, A, B, C, and D are added to the

3.3 Setup Software Operating Procedure

data to be sent.

In this case, the following information appears:

You can select lowercase or uppercase for the start/stop character.

3. When you select Inspect check-digit, the following information appears:

Specify the check-digit calculation method and whether or not the check-digit

is sent.

4. Set the other parameters in the same manner as for CODE39.

33

Page 47

3.3 Setup Software Operating Procedure

3.3.7 UPC/EAN setup

1. Select Read EAN 8 code, Read UPC-A[EAN13] code or Read UPC-E to

enable to read.

If you select Read UPC-A[EAN13] code, the following information appears,

asking you to select which digits you want to output on UPC-A.

2. You can use the same setting procedure as f or CODE39 f or Max code length

• Although the check-digit parameter is not provided on the screen, the system

internally calculates it using modulus 10/Weight3. (The calculated data is

sent.)

3.3.8 CODE128 setup

If you select Read UPC-E, the following information appears, asking if you

want to send data with the leading zero-suppressed.

output and Specify label orientation. However, the setting range of Effective

and Starting in Max code length output is limited to the code length of the

readout UPC/E code.

34

1. The setting range of code length depends on the start character type CODEA to C (see page 72).

• CODE-A and B --- 1 to 32

• CODE-C --- 2 to 64

The code length does not include the start/stop character or check-digit. Also,

FNC1 to 4 (function codes), SHIFT, and CODE-A to C are excluded from the

code length.

Page 48

2. Check that the double-character start pattern is regulated in the UPC/EAN128 standard. It means the combination of start character (CODE-C) and

FNC1 (function code 1). The standard specifies that the UPC/EAN-128 bar