VHF FM TRANSCEIVER

TK-2212/2217

SERVICE MANUAL

Antenna

(T90-1036-05): TK-2212(K,M)

(T90-1050-05): TK-2217(M3)

(KRA-26: Option) TK-2217 (M)

Knob (CH selector)

(K29-9345-04)

Knob (Volume)

(K29-9309-03)

Cabinet assy

(A02-3894-13)

Key top

Knob (PTT)

(K29-9308-13)

(K29-9346-02)

© 2005-1 PRINTED IN JAPAN

B51-8715-00 (S) 971

CONTENTS

GENERAL ............................................................. 2

SYSTEM SET-UP ................................................. 2

OPERATING FEATURES ..................................... 3

REALIGNMENT .................................................... 4

DISASSEMBLY FOR REPAIR .............................. 9

CIRCUIT DESCRIPTION .....................................12

SEMICONDUCTOR DATA .................................16

COMPONENTS DESCRIPTION ......................... 17

TERMINAL FUNCTION ...................................... 17

PARTS LIST ........................................................ 18

EXPLODED VIEW............................................... 24

PACKING ............................................................25

ADJUSTMENT ...................................................26

PC BOARD

TX-RX UNIT (X57-7120-XX) ......................... 32

SCHEMATIC DIAGRAM..................................... 36

BLOCK DIAGRAM .............................................. 40

LEVEL DIAGRAM ............................................... 42

KSC-31 / KNB-29N / KBH-10 ............................ 43

SPECIFICATIONS ............................BACK COVER

Button Knob

(Side1/Side2)

(K29-9307-13)

Photo is TK-2212.

TK-2217(M) :

Does not come with antenna.

Antenna is available as an option.

This product uses Lead Free solder

TK-2212/2217

GENERAL / SYSTEM SET-UP

INTRODUCTION

SCOPE OF THIS MANUAL

This manual is intended for use by experienced technicians

familiar with similar types of commercial grade communications

equipment. It contains all required service information for the

equipment and is current as of the publication date. Changes

which may occur after publication are covered by either Service

Bulletins or Manual Revisions. These are issued as required.

ORDERING REPLACEMENT PARTS

When ordering replacement parts or equipment information,

the full part identification number should be included. This

applies to all parts, components, kits, or chassis. If the part

number is not known, include the chassis or kit number of

which it is a part, and a sufficient description of the required

component for proper identification.

Unit

Model

& destination

TK-2212

TK-2217

TK-2217

TX-RX Unit Frequency range Remarks

K,M

X57-7120-10 136~174MHz IF1 : 38.85MHz

M

M3 X57-7120-21 216~223MHz

LOC : 38.4MHz

PERSONAL SAFETY

The following precautions are recommended for personal

safety:

●

DO NOT transmit until all RF connectors are verified secure

and any open connectors are properly terminated.

●

SHUT OFF and DO NOT operate this equipment near

electrical blasting caps or in an explosive atmosphere.

●

This equipment should be serviced by a qualified technician

only.

SERVICE

This transceiver is designed for easy servicing. Refer to

the schematic diagrams, printed circuit board views, and

alignment procedures contained within.

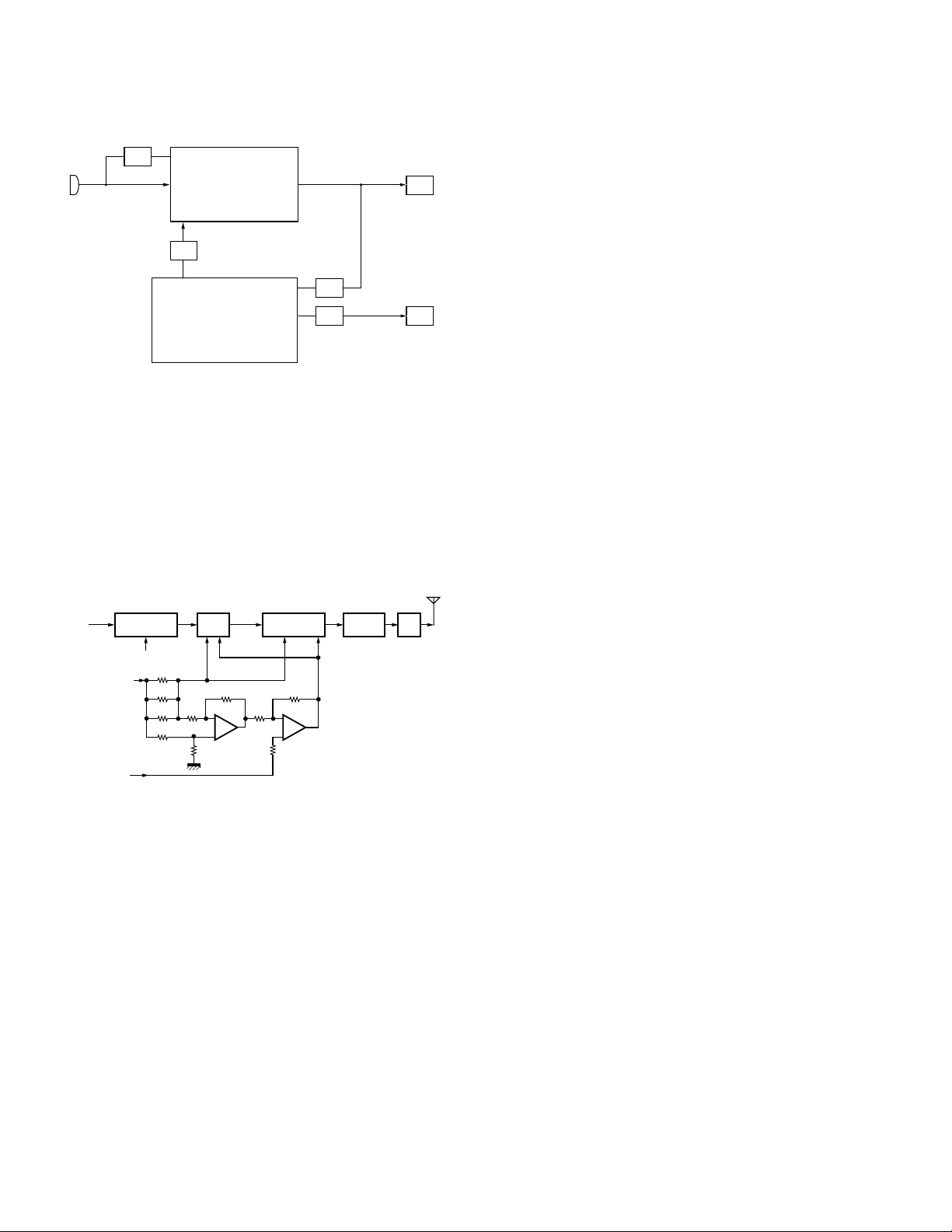

SYSTEM SET-UP

Merchandise received

License and frequency allocated by FCC

Choose the type of transceiver

Transceiver programming

Are you using the optional antenna?

Are you using the speaker microphone?

NO

NO

Delivery

Frequency range (MHz) RF power Type

TX/RX 136~174

TX/RX 136~174

TX/RX 216~223

A personal computer (IBM PC or compatible), programming

interface (KPG-22), and programming software (KPG-100D)

are required for programming.

(The frequency, TX power HI/LOW, and signaling data are programmed

for the transceiver.)

YES

YES

KRA-22 or KRA-26

Optional antenna

KMC-17 or KMC-21

Speaker microphone

(Option)

5.0W

5.0W

5.0W

TK-2212 (K,M)

TK-2217 (M)

TK-2217 (M3)

2

TK-2212/2217

OPERATING FEATURES

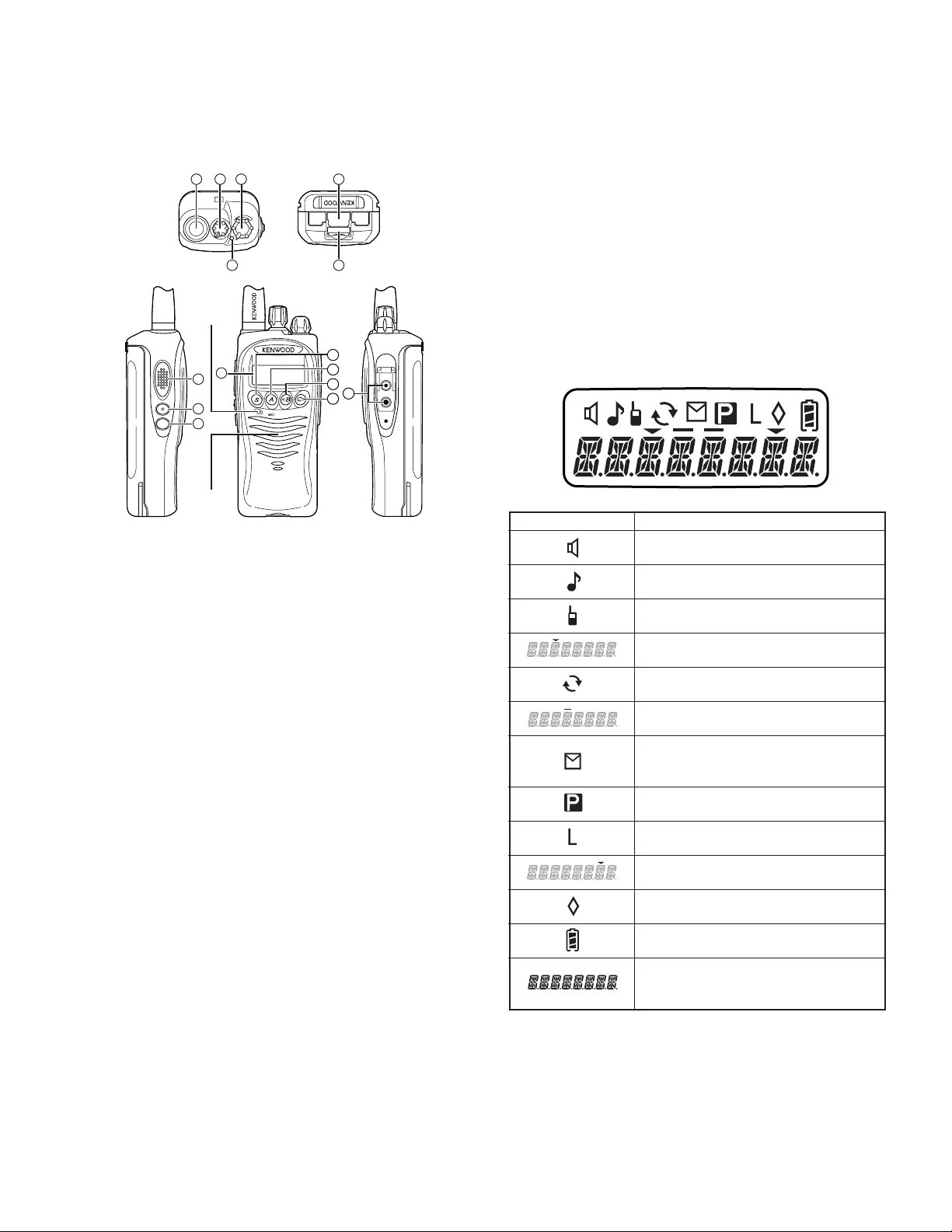

1. Controls and Functions

123 5

1

4

Microphone

10

7

8

9

Speaker

1 Antenna connector

Connect an antenna here.

2 Selector

Your dealer can program the selector as either Zone Up/

Down (default setting) or Channel Up/Down. Rotate the

selector to select a zone or channel.

3 Power switch/ Volume control

Turn clockwise to switch ON the transceiver. Rotate to

adjust the volume. Turn counterclockwise fully to switch

OFF the transceiver.

4 Transmit/ Busy/ Call indicator

This LED lights red while transmitting and green while receiving a call. The LED flashes orange while receiving an

encoded call (i.e. Code Squelch, etc.) and red when the

battery power is low while transmitting.

5 Release Latch

Press the release latch to unlock and remove the battery

pack.

6 Safety Catch

Lock this catch to avoid accidentally pressing the release

latch and removing the battery pack.

7 PTT (Push-to-Talk) switch

Press this switch, then speak into the microphone to call a

station.

8 Side 1 key

Press to activate its programmable function. The default

setting is Squelch Off Momentary.

9 Side 2 key

Press to activate its programmable function. The default

setting is Lamp.

0 Display

Refer to the display.

! S key

Press to activate its programmable function. The default

setting is None (no function).

6

11

12

13

15

14

@ A key

Press to activate its programmable function. The default

setting is None (no function).

# <B key

Press to activate its programmable function. The default

setting is Channel Down.

$ C> key

Press to activate its programmable function. The default

setting is Channel Up.

% Speaker/ Microphone jacks

Connect an optional speaker/ microphone or headset here.

Otherwise, keep the supplied cap in place.

2. Display

Indicator Description

Appears when the key programmed as

Monitor or Squelch Off is pressed.

Appears when you receive a Code Squelch

call or transmit using Code Squelch.

Appears while using the Talk Around

function.

The selected zone is added to the

scanning sequence.

Appears while scanning.

Appears while using the VOX function

Appears when a message is stored in the

transceiver stack memory. Appears and

blinks when a new message has arrived.

The selected channel is set as a Priority

channel.

Appears while using low transmit power

on the selected channel.

The selected channel is added to the

scanning sequence.

Appears when the Scrambler function has

been activated.

Displays the current battery status (full/

sufficent/ low/ requires charging).

Displays the currently selected zone and

channel number or the channel name. Also

displays FleetSync messages.

3

TK-2212/2217

REALIGNMENT

REALIGNMENT

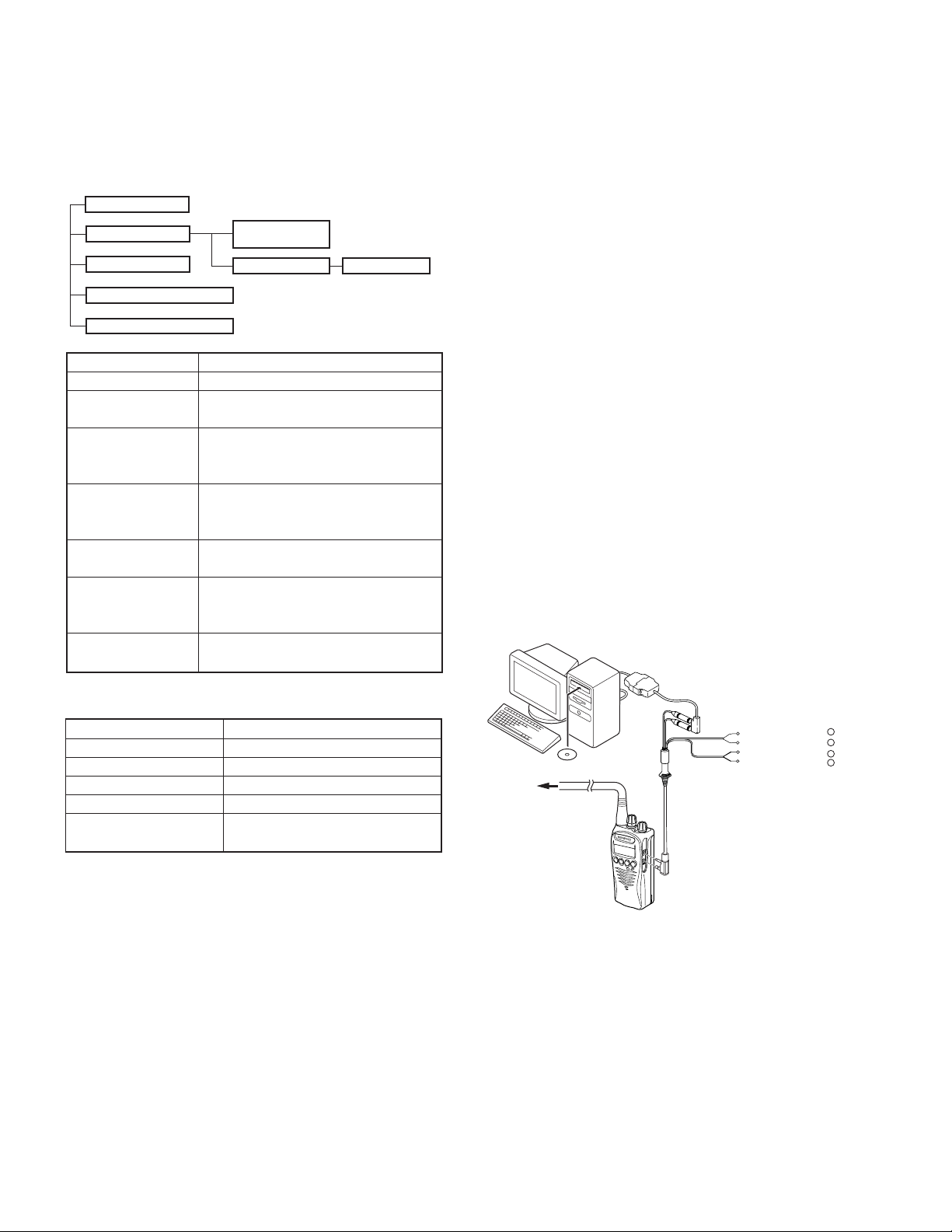

1. Modes

User mode

PC mode

Clone mode

Self programming mode

Firmware version information

Mode Function

User mode For normal use.

PC mode Used for communication between the

Data programming Used to read and write frequency data

mode

PC test mode Used to check the transceiver using

Clone mode Used to transfer programming data

Self programming You can program the frequency,

mode signaling and other functions using

Firmware version Used to confirm the internal firmware

information version.

Data programming

mode

PC test mode

transceiver and PC (IBM compatible).

and other features to and from the

transceiver.

the PC.

This feature is included in the FPU.

from one transceiver to another.

only the transceiver.

PC tuning mode

2. How to Enter Each Mode

Mode Operation

User mode Power ON

PC mode Received commands from PC

Clone mode [<B]+Power ON (Two seconds)

Self programming mode

Firmware version [Side1]+[Side2]+Power ON

information (Two seconds)

[S]+Power ON (Two seconds)

When data is transmitting from the transceiver, the red

LED lights.

When data is received by the transceiver, the green LED

lights.

Notes:

• The data stored in the personal computer must match the

model type when it is written into the EEPROM.

• Change the TK-2212/2217 to PC mode, then attach the

interface cable.

3-3. KPG-22 description

(PC programming interface cable: Option)

The KPG-22 is required to interface the TK-2212/2217 with

the computer. It has a circuit in its D-subconnector (25-pin)

case that converts the RS-232C logic level to the TTL level.

The KPG-22 connects the SP/MIC connector of the TK-2212/

2217 to the computer’s RS-232C serial port.

3-4. Programming software description

KPG-100D is the programming software for TK-2212/2217

supplied on a CD-ROM. This software runs under Windows

98, ME, Windows 2000 or XP on an IBM-PC or compatible

machine.

The data can be input to or read from TK-2212/2217 and

edited on the screen. The programmed or edited data can be

printed out. It is also possible to tune the transceiver.

IBM-PC

KPG-22

RF Power meter

or SSG

KPG-100D

Tuning cable

(E30-3216-05)

Gray +

Gray/Black –

1.5D-XV Lead wire +

1.5D-XV Shield wire –

SP

}

MIC

}

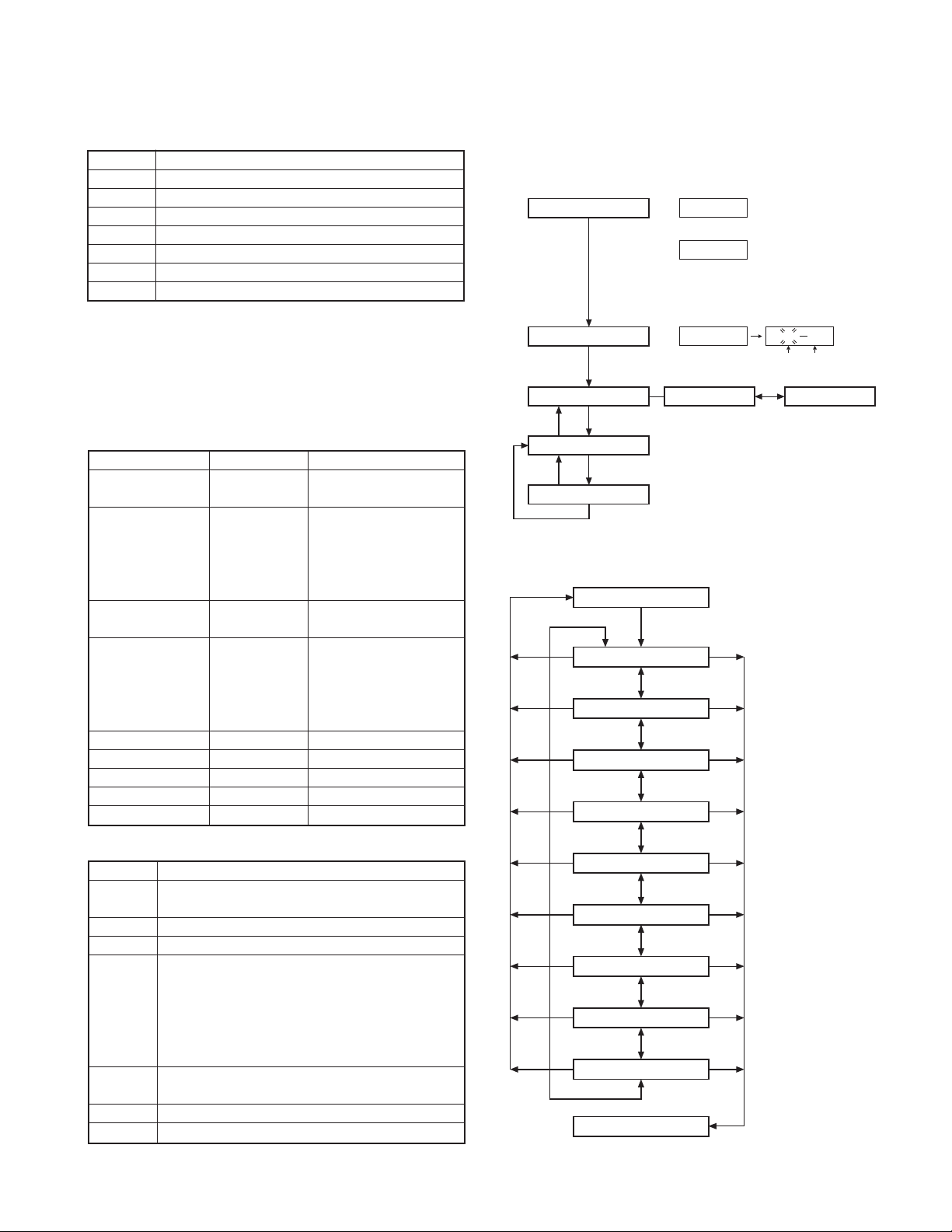

3. PC Mode

3-1. Preface

The TK-2212/2217 transceivers are programmed using a

personal computer, a programming interface (KPG-22) and

programming software (KPG-100D).

The programming software can be used with an IBM PC

or compatible. Figure 1 shows the setup of an IBM PC for

programming.

3-2. Connection procedure

1. Connect the TK-2212/2217 to the personal computer with

the interface cable.

2. When the POWER is switched on, user mode can be

entered immediately. When the PC sends a command,

the transceiver enters PC mode. In the PC mode,

"PROGRAM" is displayed on the LCD.

4

Fig. 1

4. Clone Mode

4-1. Outline

"Clone Mode" copies the transceiver data to another

transceiver.

The dealer can copy the transceiver data to another

transceiver even without the use of a personal computer.

4-2. Example

The transceiver can copy the programming data to one or

more transceivers via RF communication.

The clone master and clone slave/s must be in Clone mode.

REALIGNMENT

TK-2212/2217

4-3. Operation

1. To switch the clone slave/s to Clone mode, press and hold

the [<B] key while turning the transceiver power ON.

2. Wait for 2 seconds. “CLONE” appears on the LCD, followed

by “FRQTBL 1”.

3. Select a channel table number using the [Selector] knob.

4. To switch the clone master to Clone mode, press and hold

the [<B] key while turning the transceiver power ON.

5. Wait for 2 seconds. “CLONE” appears on the LCD, followed

by “FRQTBL 1”.

6.

Select the same channel table number as the clone slave/s.

7. Press the [S] key on the clone master to begin data

transmission. When the clone slave starts to receive data,

the green LED will light and “CLONING” will appear on

the LCD. The master unit will display “MASTER”.

8. When the clone master finishes sending data, a

“confirmation” tone will sound and “COMPLETE” will

appear on the LCD. If data transmission failed while cloning,

the Slave unit will produced an error tone and “CLONE

NG” will appear on the LCD.

9. If the cloning fails, no data will be available in the Slave unit

when it is returned to User mode.

10.When the cloning is successful, the Slave unit's "Scan" and

"Key lock" functions will return to their default values (Scan

= OFF, Key lock = OFF).

11.The master will remain in clone mode after cloning. The

slave unit will return to user mode after a successful cloning.

Notes:

• The dealer can clone data to two or more transceivers by

repeating the above procedures.

• If the transceivers Clone Mode is configured as "Disabled",

the transceiver cannot enter Clone mode.

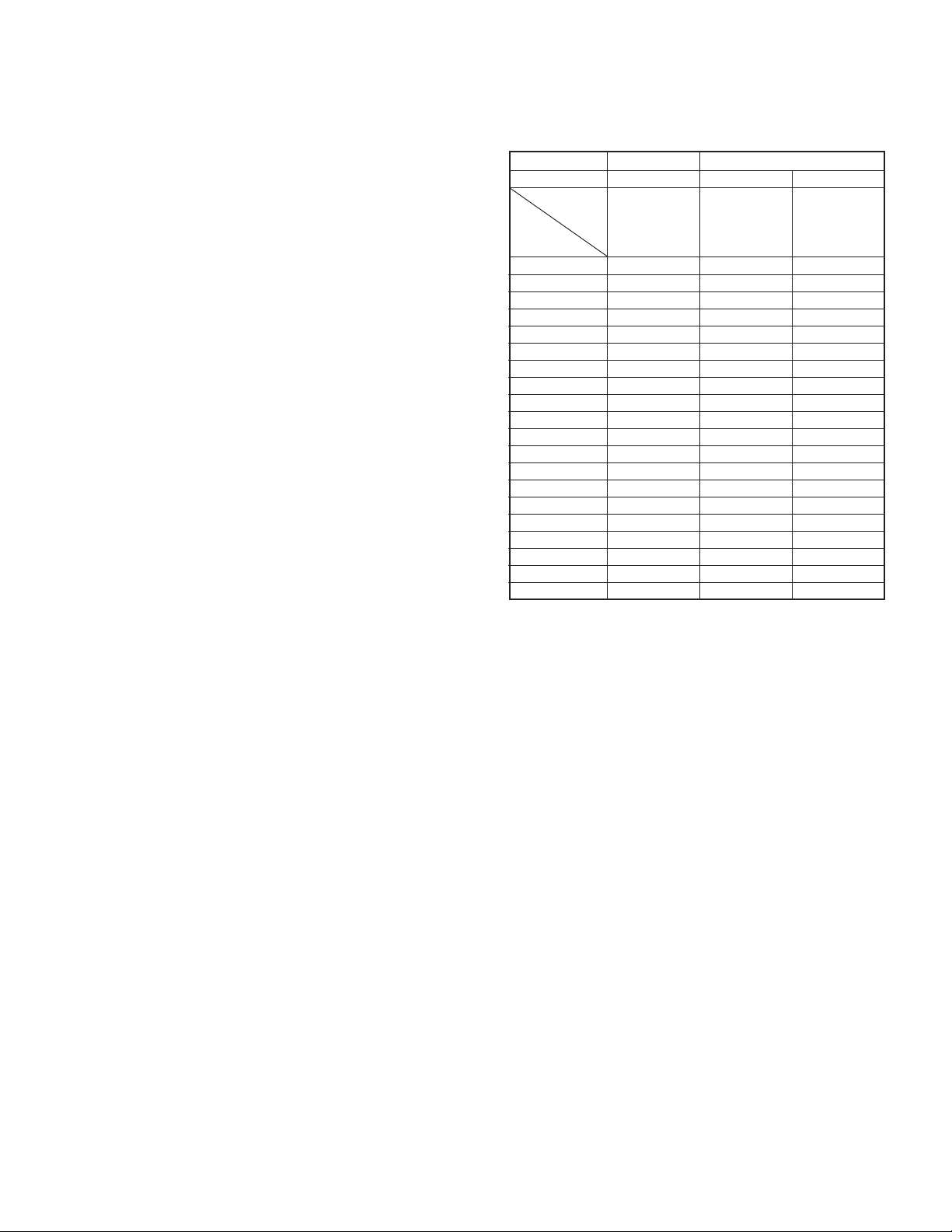

• The table shown below will cover the frequency tables used

for wireless cloning.

•Clone mode cannot be entered in battery low state.

•A unit cannot be a "Master Unit" if it is unprogrammed. If

the [S] key is pressed, an "error" tone will sound.

• Once a unit is set to be the Master, it cannot be a slave

after the data has been transmitted. This protects the data

in the Master unit.

• MSK signaling is used in cloning.

• Electronic interface may cause a failure in data transfer

during Wireless Clone, such as when waveforms or

electromagnetics are being performed at the workbench.

• Clone mode can be used ONLY by the authorized service

personnel.

• The Clone mode setting must be configured as "Disable"

before being delivered to the end-user.

• To clone, replace the antenna from both the master

transceiver and the slave transceiver with a dummy

load.

• The transmit output power is automatically set to Low

in Clone mode.

Cloning Frequency Table

MODEL TK-2212 TK-2217

Type K, M M M3

Operating

Clone Frequency

Frequency

Table

1 136.000 136.000 216.000

2 138.000 138.000 216.350

3 140.000 140.000 216.700

4 142.000 142.000 217.050

5 144.000 144.000 217.400

6 146.000 146.000 217.750

7 148.000 148.000 218.100

8 150.000 150.000 218.450

9 152.000 152.000 218.800

10 154.000 154.000 219.150

11 156.000 156.000 219.500

12 158.000 158.000 219.850

13 160.000 160.000 220.200

14 162.000 162.000 220.550

15 164.000 164.000 220.900

16 166.000 166.000 221.250

17 168.000 168.000 221.600

18 170.000 170.000 221.950

19 172.000 172.000 222.300

20 174.000 174.000 222.650

(MHz)

136~174 136~174 216~223

4-4. Adding the Data Password

If the Data password is set to the transceiver, you must

enter the password to activate a clone mode. The maximum

length of the password is 6 digits.

The following describes how to enter the password.

1. Press and hold the [S] key for 2 seconds while turning the

transceiver power on.

2. “CLN.LOCK.R”(When the Read authorization password is

set to the transceiver.) / “CLN.LOCK.W” (When the

Overwrite password is set to the transceiver.) is displayed

on the LCD.

3. If the [selector] knob is rotated while “CLN.LOCK.R”/

“CLN.LOCK.W” is displayed, the number (0 to 9) flashes

on the LCD.

When you press the [C>] key, the currently selected

number is determined.

If you press the [A] key, the least digit of the password is

deleted.

If you press the [S] key after entering the password in this

procedure, “FRQTBL 1” is displayed if the entered

password is correct.

If the password is incorrect, “CLN.LOCK.R”/

“CLN.LOCK.W” is redisplayed.

5

TK-2212/2217

REALIGNMENT

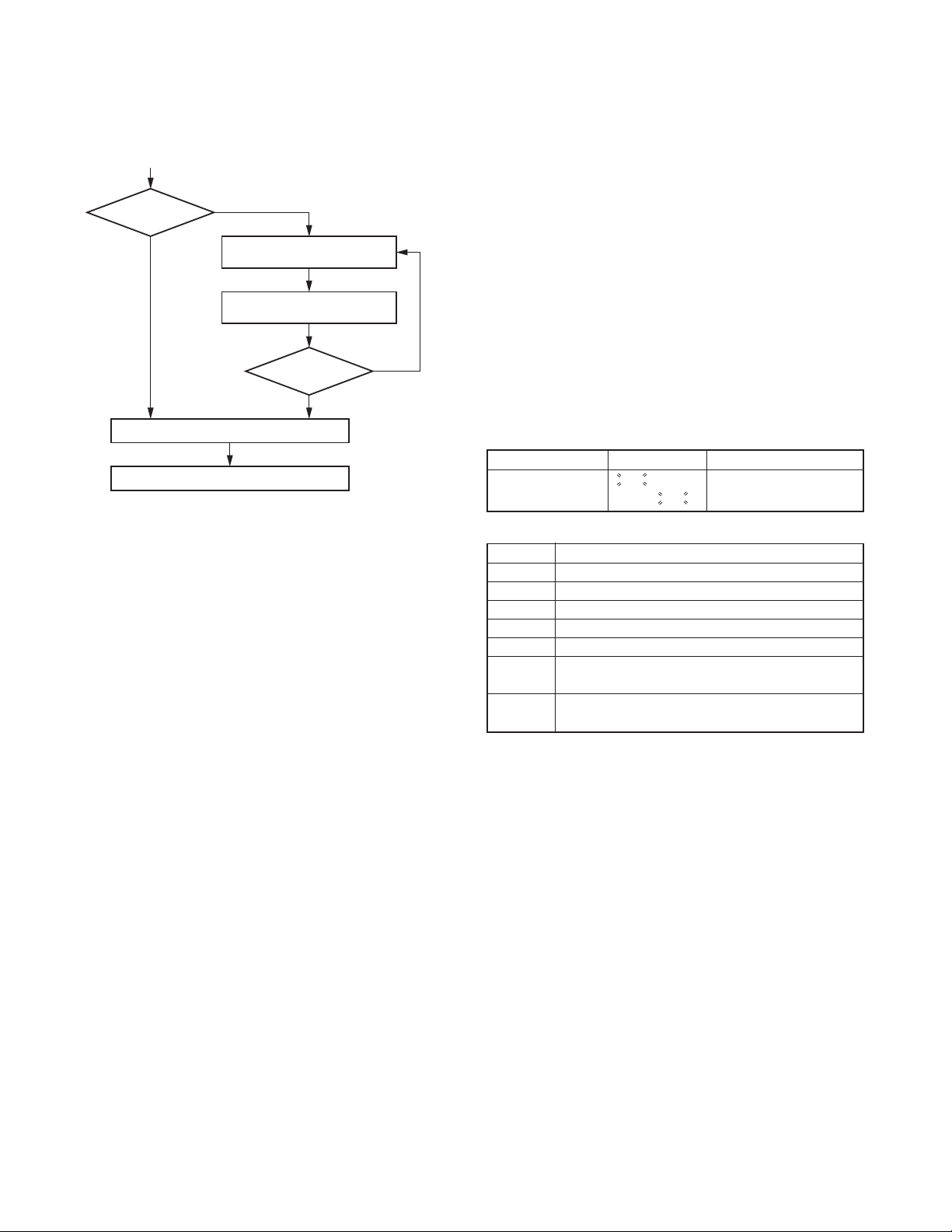

■ Flow Chart (Master transceiver)

[<B]+Power ON

Is Data

password

set?

No

Ye s

"CLN.LOCK.R”/“CLN.LOCK.W”

Clone mode

Start the clone function

is displayed.

Enter the password and

then press the [S] key.

Is password

[S]

correct?

No

Ye s

5. Self Programming Mode

Write mode for frequency data and signaling, etc. To be

used ONLY by the authorized service person maintaining the

user's equipment. After programming, reset the FPU to the

"Self- Programming" disabled mode. Transceivers CANNOT be

delivered to the end-user in the self-programming mode.

5-1. Enter to the Self Programming Mode

Press and hold the [S] key for 2 seconds while turning the

transceiver power on.

When the transceiver enters in the self programming mode,

"1- 1" is displayed 2 seconds after "SELF " is displayed.

Note :

This mode (self programming mode) cannot be set when it

has been disabled with the FPU.

If you press the [A] key, the least digit of the password is

deleted.

If you press the [S] key after entering the password in this

procedure, "SELF" is displayed if the entered password is

correct.

If the password is incorrect, "SLF.LOCK.R"/ "SLF.LOCK.W"

is redisplayed.

5-3. Channel Selection Mode

In this mode, the Zone or Channel can be selected.

Press and hold the [S] key for 2 seconds while turning the

transceiver power on to enter self programming mode. When

the transceiver enters in the self programming mode, the

transceiver automatically enters the Channel Selection mode.

2 seconds after displaying "SELF", "1- 1" appears on the LCD.

The setup item for channel selection mode is as follows.

Setup item Display Remarks

Select ∗∗∗ - ∗∗∗ Zone: 1~128

Zone/Channel ∗∗∗ - ∗∗∗ Channel: 1~128

Key operation

Key Key Function

[Selector] Toggle between Zone selection and Channel selection.

[Side1] No action

[Side2] No action

[S] Enter the Item Selection mode

[A] Error tone sounds

[<B] Decrement the blinking Zone/Channel number by 1.

Press and hold to decrement in steps of 10.

[C>] Increment the blinking Zone/Channel number by 1.

Press and hold to decrement in steps of 10.

Note :

If a non-existing Zone-Channel is selected and the memory

for all 128 channels is already filled, an error tone will sound

and "MEM.FULL" will appear on the LCD for 2 seconds.

5-2. Adding the Data Password

If the Data password is set to the transceiver, you must

enter the password to activate a self programming mode. The

maximum length of the password is 6 digits.

The following describes how to enter the password.

1. Press and hold the [S] key for 2 seconds while turning the

transceiver power on.

2. "SLF.LOCK.R"(When the Read authorization password is

set to the transceiver.) / "SLF.LOCK.W" (When the

Overwrite password is set to the transceiver.) is displayed

on the LCD.

3. If the [selector] knob is rotated while "SLF.LOCK.R"/

"SLF.LOCK.W" is displayed, the number (0 to 9) flashes on

the LCD.

When you press the [C>] key, the currently selected

number is determined.

6

5-4. Item Selection Mode

In this mode, the following items can be selected.

• RX frequency

• RX signaling

• TX frequency

• TX signaling

•Wide/ Narrow

• RF power Hi/Low

• Scan Del/Add

• Beat shift on/off

• Compander on/off

When the [S] key is pressed in the Channel Selection mode,

the transceiver enters the Item Selection mode.

REALIGNMENT

[S]+Power ON

Read authorization password /

Overwrite password entry (6 digits)

Self programming mode SELF

Zone

II

Channel selection mode

Data password

Display

SLF.LOCK.R

When the Read

authorization password is

set to the transceiver.

[<B] : Zone/Channel number decrement

[C>] : Zone/Channel number increment

When the Overwrite

authorization password is

set to the transceiver.

SLF.LOCK.W

or

[S]

Item selection mode

[S]

[Selector]

[A]

Item setting mode

[S][A]

Zone selection Channel selection

Channel

[S]

TK-2212/2217

Key operation

Key Key Function

[Selector] The selected item changes

[Side1] No action

[Side2] No action

[S] Enter the Item Setting mode

[A] Return to the Channel Selection mode

[<B] Error tone sounds

[C>] Error tone sounds

5-5. Item Setting Mode

In this mode, the selected item in the Item Selection mode

can be programmed.

When the [S] key is pressed in the Item Selection mode,

the transceiver enters the Item Setting mode.

The setup items for item setting mode are as follows.

Setup item Display Remarks

1.RX frequency 1. RX FREQ→Receive frequency

2.RX signaling 2. RX SIG

3.TX frequency 3. TX FREQ

4.TX signaling 4. TX SIG

5. Wide / Narrow 5. BAND ∗ W / N

6.

RF power Hi / Low

7.Scan Del / Add 7. SCN ∗∗∗ DEL / ADD

8.Beat shift on / off 8. SF T ∗∗∗ ON / OFF

9.

Compander on / off

Key operation

Key Key Function

[Selector] Changing the selection item (RX/ TX frequency and

[Side1] No action

[Side2] No action

[S] • Store the current settings and return to the Item

[A] Abort the current settings and return to the Item

[<B] Toggle/ Decrease the blinking value.

[C>] Toggle/ Increase the blinking value.

RX/ TX signaling only)

Selection mode.

•A MHz digit of the frequency blinks.

(RX/ TX frequency only)

• The icon of the current signaling configuration blinks.

(RX/ TX signaling only)

Selection mode without backup.

∗∗∗.∗∗∗∗∗

TONE OFF/

QT ∗∗∗.∗ /

DQT∗∗∗N/

DQT∗∗∗I

∗∗∗.∗∗∗∗∗

TONE OFF/

QT ∗∗∗.∗ /

DQT∗∗∗N/

DQT∗∗∗I

6. PWR ∗∗∗ HI / LOW

9. CMP ∗∗∗ ON / OFF

100.00000~280.00000MHz

→

Receive QT/DQT

→

Transmit frequency

100.00000~280.00000MHz

→

Transmit QT/DQT

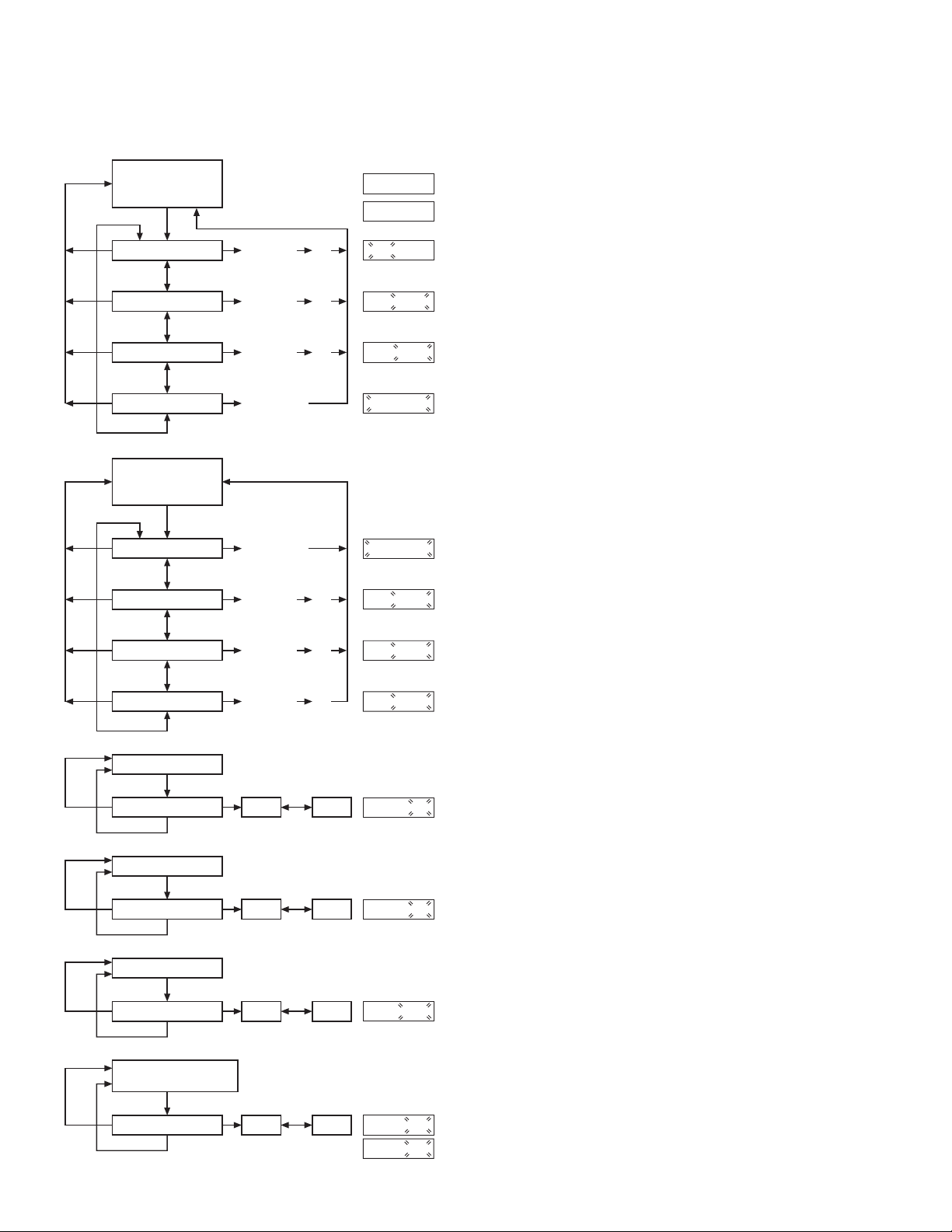

5-6. Self Programming Mode flow chart

■ Channel selection mode flow chart

■ Item selection mode flow chart

Channel selection mode

[S]

[A]

[A]

[A]

[A]

[A]

1. RX frequency

[Selector]

2. RX signaling

[Selector]

3. TX frequency

[Selector]

4. TX signaling

[Selector]

5. Wide / Narrow

[Selector]

6. RF power Hi / Low

[Selector]

7. Scan Del / Add

[Selector]

8. Beat shift on / off

[Selector]

9. Compander on / off

[Selector]

Item setting mode

[S]

[S]

[S][A]

[S]

[S][A]

[S]

[S][A]

[S]

[S][A]

7

TK-2212/2217

REALIGNMENT

■ Item setting mode flow chart

[1. RX frequency] or

[3. TX frequency]

[S]

[A]

[A]

[A]

[A]

[A]

[A]

[A]

[A]

MHz setting

[Selector]

KHz setting

[Selector]

Channel step

[Selector]

Frequency clear

[Selector]

[2. RX signaling] or

[4. TX signaling]

[S]

OFF

[Selector]

QT

[Selector]

DQT N

[Selector]

DQT I

[Selector]

[<B] / [C>] [S]

[<B] / [C>] [S]

[<B] / [C>] [S]

[S] : Cleared

[S] : Tone off

[<B] / [C>] [S]

[<B] / [C>] [S]

[<B] / [C>] [S]

Current

setting value

Value is not set

Display

136.00000

--------

136. 00000

136. 00000

STP 5.00K

--------

Display

TONE OFF

67.0QT

023NDQT

023 IDQT

6. Firmware Version Information

Turn the transceiver ON with the [Side1] and [Side2] keys

held down. Then, the version is displayed during holding the

[Side1] and [Side2] keys.

8

[A]:Not

stored

[A]:Not

stored

[A]:Not

stored

[A]:Not

stored

5. Wide / Narrow

[S]

Wide / Narrow selection Wide

[S] : Stored

6. RF power Hi / Low

[S]

Hi / Low selection Hi Low

[S] : Stored

7. Scan Del / Add

[S]

Del / Add selection Del Add

[S] : Stored

[8. Beat shift on / off] or

[9. Compander on / off]

[S]

on / off selection on off

[S] : Stored

[<B] / [C>]

Narrow

[<B] / [C>]

[<B] / [C>]

[<B] / [C>]

Display

W5.BAND

Display

HI6.PWR

Display

ADD7.SCN

Display

ON8.SFT or

ON9.CMP

TK-2212/2217

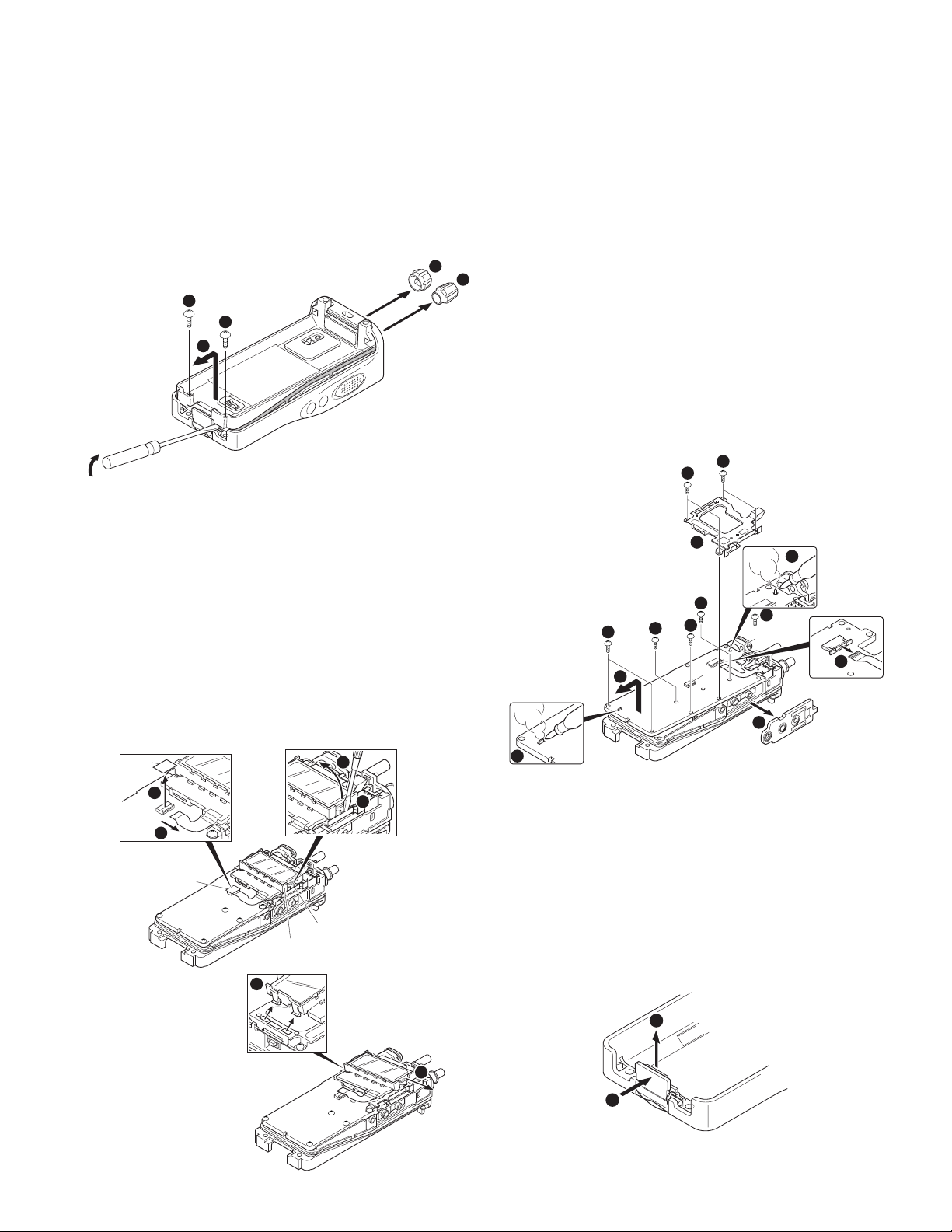

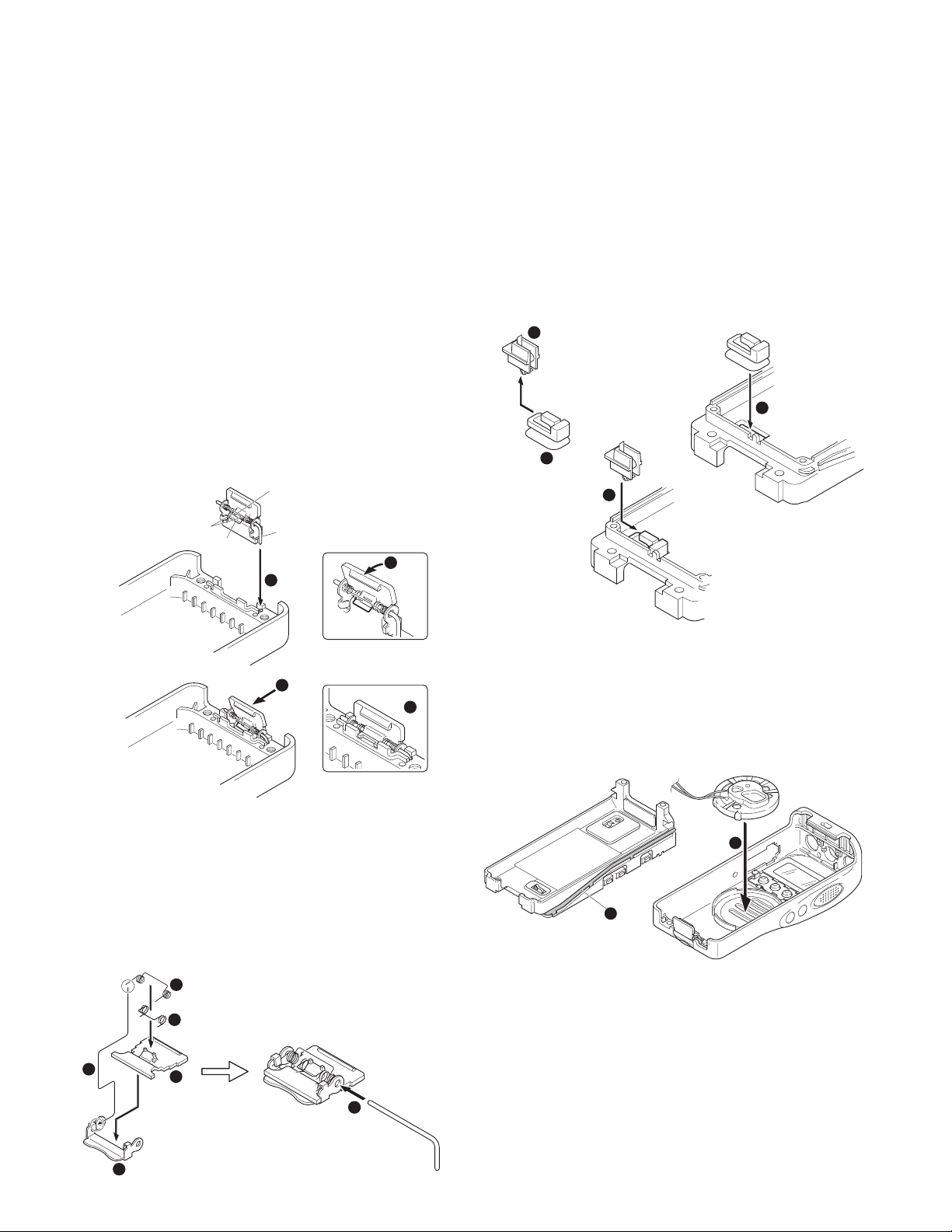

DISASSEMBLY FOR REPAIR

Disassembly Procedure

■ Removing the case assembly from the chassis.

1. Remove the volume knob z and channel knob x.

2. Remove the two screws

3. Lift and remove the chassis from the case assembly

(Use a flat-blade screwdriver to easily lift the chassis.)

3

3

4

■ Removing the LCD ASSY from the mounting

hardware

1. Remove the sheet attached to the flat cable connector z.

2. Remove the FPC from the flat cable connector

Note: Be careful not to forget to attach the sheet after the

LCD ASSY is reassembled.

3. Insert a flat-head screwdriver on the right side of the

illumination guide

the right side of the illumination guide from the mounting

hardware

4. Slide the LCD ASSY

the left side of the illumination guide are removed from the

mounting hardware

Sheet

v

.

, then lever the screwdriver to remove

c

b

n

.

c

v

1

.

x

to the right so that the two tabs on

.

4

■ Removing the TX-RX unit from the chassis.

1. Remove the packing m from the SP / MIC jack of the TXRX unit.

2. Remove the eleven screws

.

2

3. Remove the mounting hardware

4. Remove the solder of the antenna terminal with a soldering

iron

.

/

5. Remove the solder of the positive terminal with a soldering

iron

.

Ω

Note: You can remove the TX-RX unit from the chassis without

removing the solder at the positive terminal. However,

in this case, you can not attach the packing (G53-1605-

03) that is on the positive terminal to the chassis in

assembling. So, it is advisable to remove the solder on

the positive terminal first.

6. Remove the FPC from the flat cable connector

7. Lift and remove the TX-RX unit from the chassis

8

8

13

11

fixing the TX-RX unit.

,

of the SP / MIC.

.

8

8

9

8

8

8

7

.

≈

.

ç

10

12

1

2

Sheet

Mounting hardware

Illumination guide

6

3

■ Removing the battery release lever from the case

assembly.

1. Press the upper part of the lever toward the inside of the

case assembly. One side of the shaft will be removed

2. Lift and remove the battery release lever from the case

assembly

Note: Scratch and widen the glue hole if there is difficulty in

removing the other end of the shaft.

No glue is required when you reassemble the battery

release lever.

5

x

.

2

1

z

.

9

TK-2212/2217

DISASSEMBLY FOR REPAIR

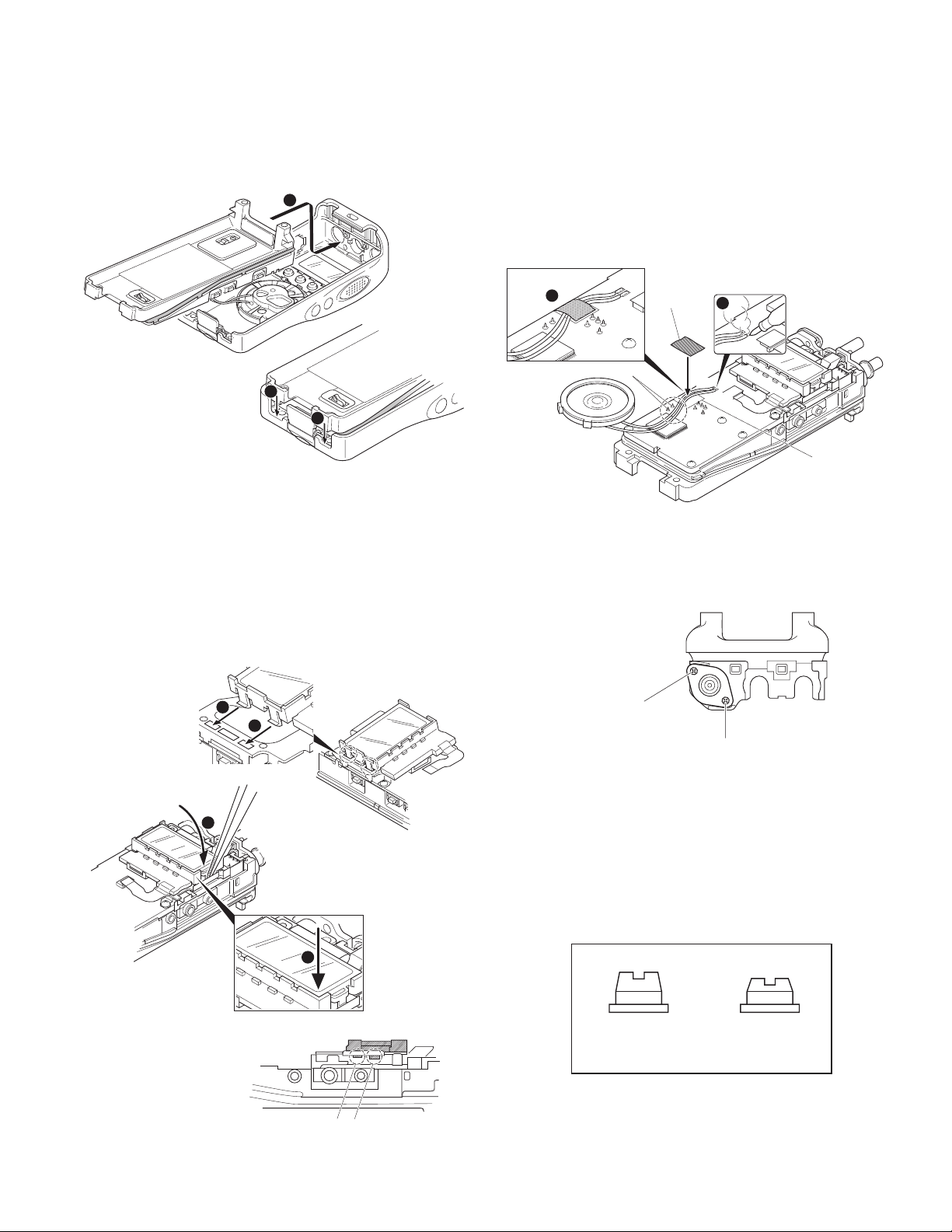

Precautions for Reassembly

■ Attaching the battery release lever to the case

assembly.

1. Insert one side of the shaft into the hole at the lever fitting

section on the case assembly

Note: The thin spring (G01-4543-04) should be positioned

above the two tabs of the lever.

2. Tilt the battery release lever slightly forward

thick spring (G01-4542-04) is positioned below the case

surface.

3.

With the thick spring positioned below the case surface, attach

the other side of the shaft to the case assembly by pressing

the battery release lever

Note: Be careful not to tilt the battery release lever too

forward.

If the battery release lever is pushed in this state where

the two tabs come below the case surface, there is a

possibility of damaging the two tabs.

Tw o tabs

A thick spring

c

.

z

, so that the

x

until it snaps into place v.

A thin spring

Shaft

2

1

■ Attaching the positive terminal to the chassis.

Always attach the positive terminal to the chassis, using

the following procedures, before mounting the TX-RX unit

onto the chassis.

1. Remove the holder assembly

the positive terminal.

2. Mount the packing of the positive terminal into the chassis

hole

3. Mount the holder assembly into the packing of the positive

terminal

2

c

.

.

v

1

4

from the packing z of

x

3

3

4

■ Assembling the battery release lever

1. Place the lever x onto the stopper z.

2. Place the thick spring

3. Hook the right and left ends of the thin spring

tabs of the stopper, then place the thin spring onto the

lever

4. Slide the shaft through the hole of the stopper and lever

5

b

.

4

3

2

onto the lever.

c

6

onto the

v

n

■ Mounting the chassis to the case assembly.

1. Confirm that the waterproof packing attached to the

circumference of the chassis is securely inserted in the

groove of the chassis

2. Attach the speaker to the speaker recess of the case

assembly

.

Confirm that the

waterproof packing is

securely inserted in the

groove of the chassis.

3. Insert the upper part of the chassis into the case assembly

.

c

Note: Take care that the speaker lead wire is not caught by

the microphone element.

4. Press the chassis

attach them.

. Make sure the speaker is securely inserted.

x

1

.

z

2

and the case assembly together to

v

10

1

TK-2212/2217

DISASSEMBLY FOR REPAIR

Note: If the packing of the SP / MIC does not come to the

correct position after attaching the chassis to the case

assembly, reposition the packing with your fingers.

3

4

4

■ LCD ASSY Installation Procedure

1. Insert the two tabs on the left side of the illumination guide

into the matching slots of the mounting hardware

2. Insert the tab on the right side of the illumination guide into

the mounting hardware using a pair of tweezers

press the illumination guide down until it snaps into place

.

c

3. Ensure that the tab of the illumination guide is fully inserted

into the mounting hardware.

x

z

, then

.

■ Connecting the speaker wires to the TX-RX unit

1. To connect the speaker wires, solder them to the speaker

terminals of the TX-RX unit

2. Align the speaker wires as shown in figure, making sure to

avoid the legs of the discriminator.

3. Attach the fibrous sheet to the speaker wires as shown by

the silk print on the TX-RX unit

2

legs of the discriminator

Fibrous sheet

z

SP-

.

x

1

SP+

.

Silk print

■ Attaching the antenna receptacle to the chassis.

Screw the antenna receptacle to the chassis in the order

shown in the drawing so that the antenna receptacle comes

to the center of the case hole.

1

1

2

3

Ensure that the tab of the illumination guide

is fully inserted into the mounting hardware.

Tighten this screw first.

Tighten this screw second.

■ The nuts of the volume knob and channel knob

Note that the shapes, colors and heights of nuts of the

volume knob and channel knob are different from one

another. (The nut of volume knob is silver, and the nut of

channel knob is gold)

Use the following jig when removing the nuts of the

volume knob and channel knob.

●

Jig (Part No. : W05-1012-00)

Volume Knob

(Silver)

Channel Knob

(Gold)

11

TK-2212/2217

CIRCUIT DESCRIPTION

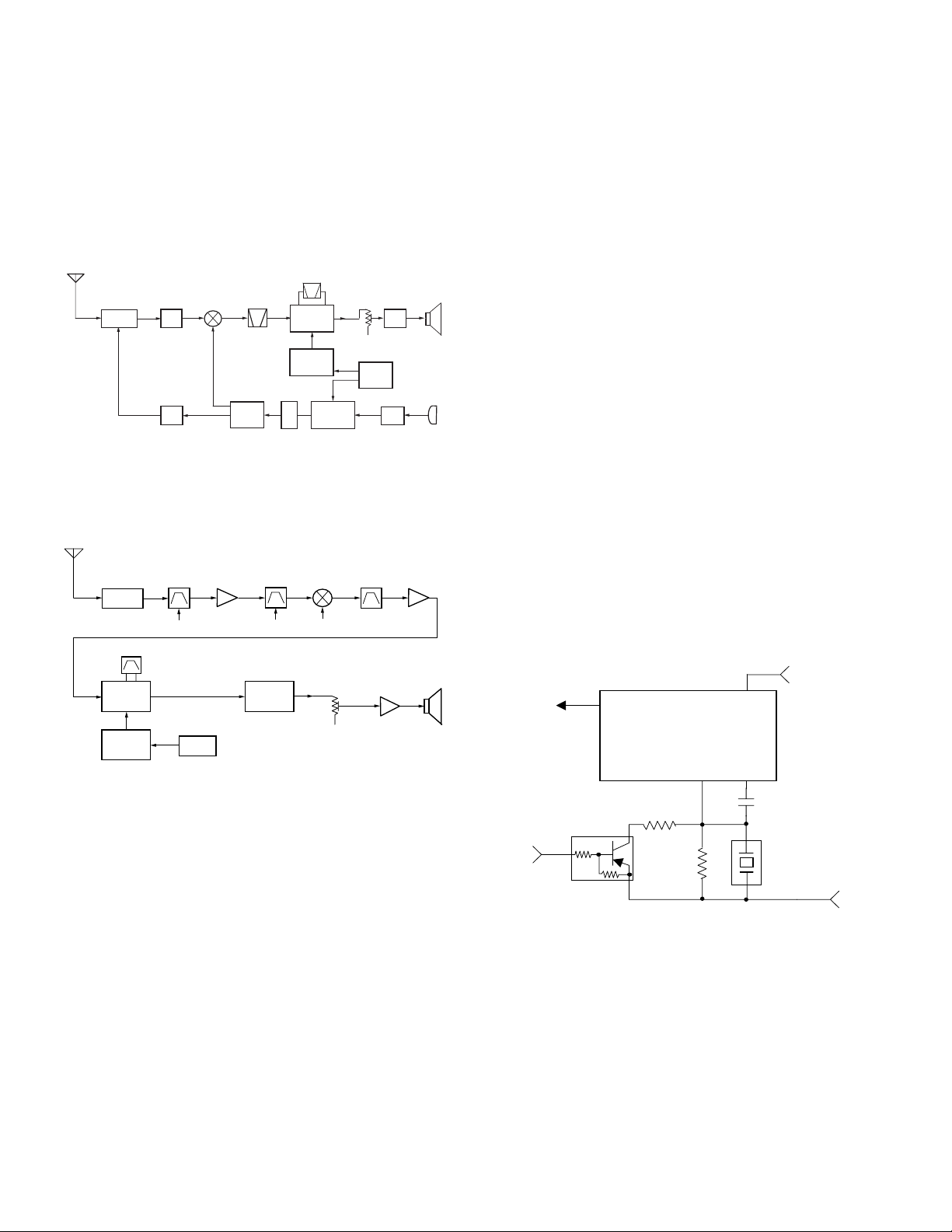

1. Frequency Configuration

The receiver utilizes double conversion. The first IF is 38.85

MHz and the second IF is 450 kHz. The first local oscillator

signal is supplied from the PLL circuit.

The PLL circuit in the transmitter generates the necessary

frequencies. Fig. 1 shows the frequencies.

ANT

216 ~ 223MHz (TK-2217(M3))

ANT SW

RF

AMP

TX:136 ~ 174MHz

(TK-2212(K,M) TK-2217(M))

216 ~ 223MHz

(TK-2217(M3))

TX

AMP

MCF

38.85MHz

RX: 174.85 ~ 212.85MHz

(TK-2212(K,M) TK-2217(M))

254.85 ~ 261.85MHz

(TK-2217(M3))

RF

AMP

IF SYSTEM

38.4MHz

X3 multiply

1/2

CF

450kHz

PLL

VCO

TCXO

AF

AMP

MIC

AMP

12.8MHz

136 ~ 174MHz (TK-2212(K,M) TK-2217(M))

TX/RX:

Fig. 1 Frequency configuration

2. Receiver

The frequency configuration of the receiver is shown in Fig. 2.

ANT

RF AMP

Q205

BPF

ANT SW

TUNE

IC201

IF,MIX,DET

Q1

X3 multiply

2nd Local

CF201

X1

TCXO

IC301

AQUA-L

12.8MHz

Fig. 2 Receiver section

1) Front End (RF AMP)

The signal coming from the antenna passes through the

transmit/receive switching diode circuit, (D103,D104,D105

and D106) passes through a BPF (L214 and L213), and is

amplified by the RF amplifier (Q205).

The resulting signal passes through a BPF (L209 and L211)

and goes to the mixer. These BPFs are adjusted by variable

capacitors (D203,D204,D205 and D206). The input voltage

to the variable capacitor is regulated by voltage output from

the microprocessor (IC405).

2) First Mixer

The signal from the front end is mixed with the first local

oscillator signal generated in the PLL circuit by Q1 to

produce a first IF frequency of 38.85 MHz.

The resulting signal passes through the XF201 MCF to cut

the adjacent spurious and provide the opitimun

characteristics, such as adjacent frequency selectivity.

BPF

TUNE

MIXER

Q204

1st Local

AF VOL

MCF

XF201

IC302

AF PA

IF AMP

Q203

MIC

SP

3) IF Amplifier Circuit

The first IF signal is passed through a four-pole monolithic

crystal filter (XF201) to remove the adjacent channel signal.

The filtered first IF signal is amplified by the first IF amplifier

(Q203) and then applied to the lF system IC (IC201). The

IF system IC provides a second mixer, second local

oscillator, limiting amplifier, quadrature detector and RSSI

(Received Signal Strength Indicator). The second mixer

SP

mixes the first IF signal with the 38.4MHz of the second

local oscillator output (TCXO X1) and produces the second

IF signal of 450kHz.

The second IF signal is passed through the ceramic filter

(CF201) to remove the adjacent channel signal. The filtered

second IF signal is amplified by the limiting amplifier and

demodulated by the quadrature detector with the ceramic

discriminator (CD201). The demodulated signal is routed

to the audio circuit.

4) Wide/Narrow Switching Circuit

Narrow and Wide settings can be made for each channel

by switching the demodulation level.

The WIDE (low level) and NARROW (high level) data is

output from IC405, pin 45.

When a WIDE (low level) data is received, Q202 turn on.

When a NARROW (high level) data is received, Q202 turn off.

Q202 turns on/off with the Wide/Narrow data and the

IC201 detector output level is switched to maintain a

constant output level during wide or narrow signals.

Q203

RX_W/N

(IC405)

L : Wide

H : Narrow

AFOUT

Q202

R211

R213

QUAD

IFOUT

C214

IC201

FM IF SYSTEM

CD201

5R

Fig. 3 Wide/Narrow switching circuit

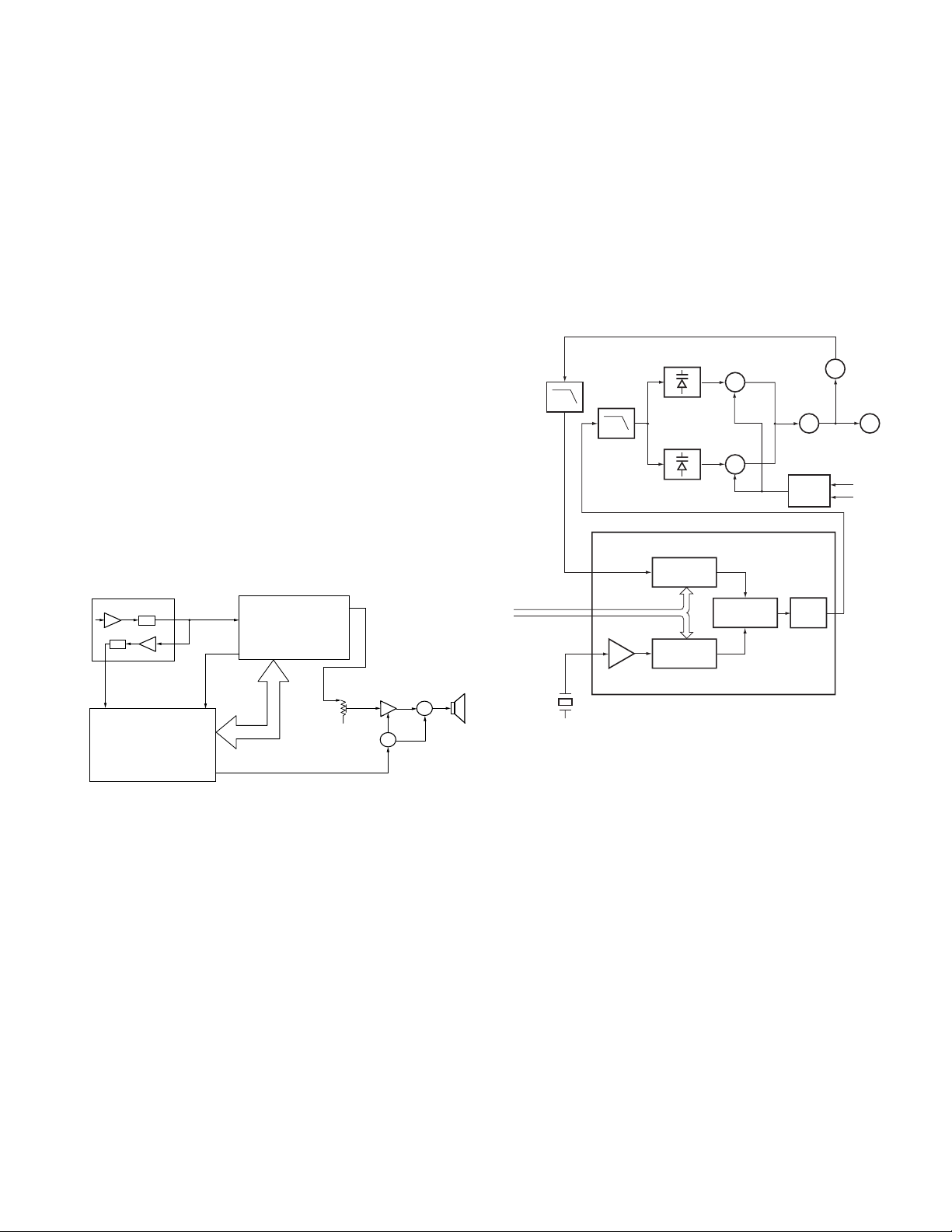

5) Audio Amplifier Circuit

The demodulated signal from IC201 goes to AF amplifier

through IC301.

The signal then goes through an AF volume control , and

is routed to an audio power amplifier (IC302) where it is

amplified and output to the speaker.

12

TK-2212/2217

RECEIVE SIGNALING

PLL DATA

X1

12.8MHz

REF OSC

1M

1N

PLL IC IC1

PHASE

COMPARATOR

CHARGE

PUMP

LPF

5kHz/6.25kHz

D4, 7

D5, 9

Q4

TX VCO

Q3

RX VCO

Q6

BUFF AMP

IC2

1/2

Q2

BUFFER

Q5, 7

T/R SW

5kHz/6.25kHz

LPF

RX

TX

CIRCUIT DESCRIPTION

6) Squelch

Part of the AF signal from the IC enters the FM IC (IC201)

again, and the noise component is amplified and rectified

by a filter and an amplifier to produce a DC voltage

corresponding to the noise level.

The DC signal from the FM IC goes to the analog port of

the microprocessor (IC405). IC405 determines whether

to output sounds from the speaker by checking whether

the input voltage is higher or lower than the preset value.

To output sounds from the speaker, IC405 sends a high

signal to the SP MUTE line and turns IC302 on through

Q303,Q304,Q305,Q306 and Q316. (See Fig. 4)

7) Receive Signaling

(1) QT/DQT

The output signal from FM IC(IC201) enters the

microprocessor(IC405) through IC301. IC405 determines

whether the QT or DQT matches the preset value, and

controls the SP MUTE and the speaker output sounds

according to the squelch results.

(2) MSK (Fleet Sync)

The MSK input signal from the FM IC goes to pin 31 of IC 301.

The signal is demodulated by MSK demodulator in IC 301.

The demodulated data goes to the CPU for processing.

RECEIVE SIGNALING

FM IF IC201

IF Amp

SIGNAL

DTMF

QT/DQT

IC301

AQUA-L

to the VCO to control the oscillator frequency. (See Fig. 5)

2) VCO

The operating frequency is generated by Q4 in transmit

mode and Q3 in receive mode. The oscillator frequency is

controlled by applying the VCO control voltage, obtained

from the phase comparator, to the varactor diodes (D4 and

D7 in transmit mode and D5 and D9 in receive mode). The

RX pin is set high in receive mode causing Q5 turn on.

The TX pin is set high in transmit mode. The outputs from

Q3 and Q4 are amplified by Q6 and sent to the RF amplifiers.

Q306,316

IC302

SW

AF PA

Q303,304,305

SW

BUSY

CPU

IC405

QT/DQT IN

AF CONT

CLK,DATA,

STD,LOADN

Fig. 4 AF amplifier and squelch

(3) DTMF

The DTMF input signal from the FM IC (IC201) goes to

IC301. The decoded information is then processed by the

CPU.

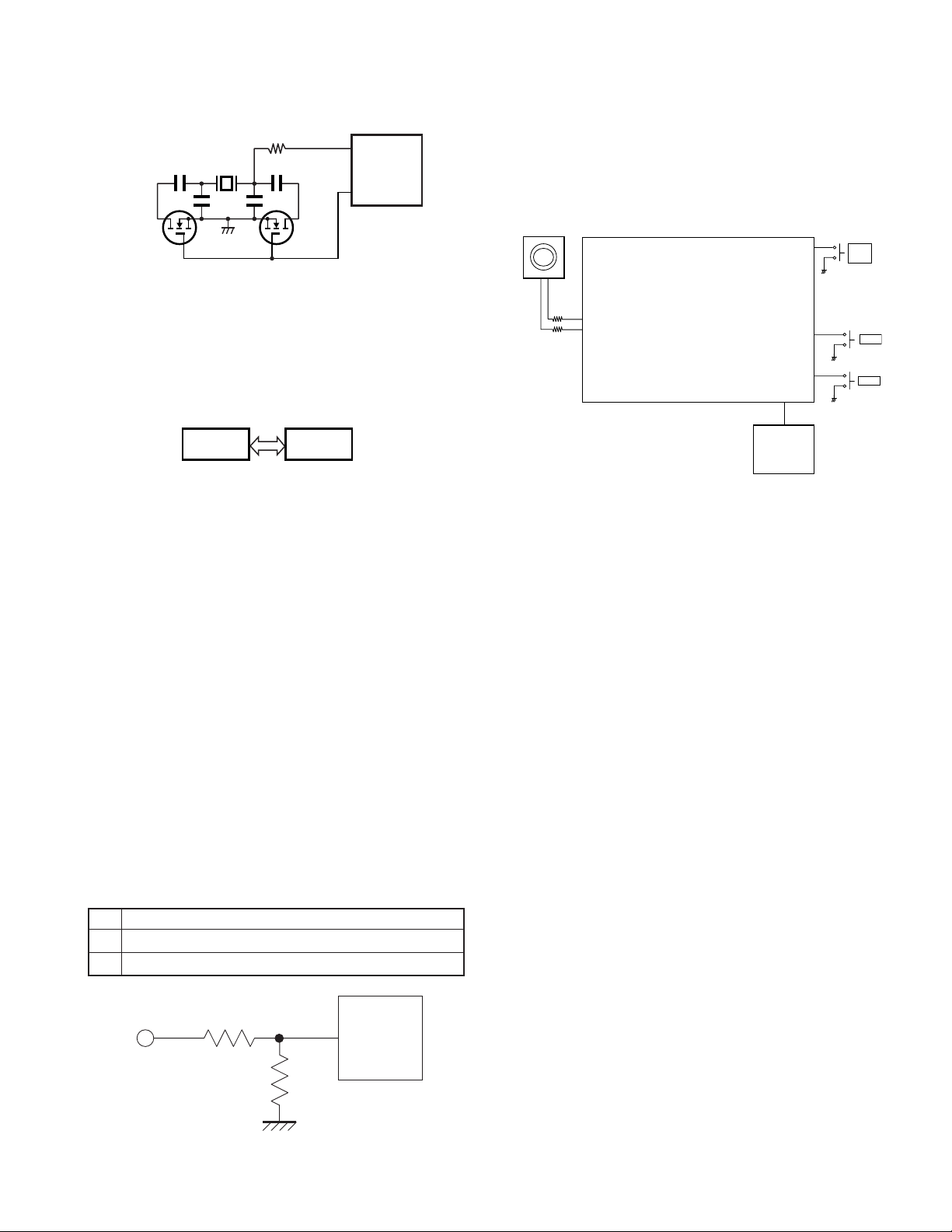

3. PLL Frequency Synthesizer

The PLL circuit generates the first local oscillator signal for

reception and the RF signal for transmission.

1) PLL

The frequency step of the PLL circuit is K,M: 2.5, 5, 6.25 or

7.5kHz, M3: 2.5 or 5kHz.

A 12.8MHz reference oscillator signal is divided at IC1 by a

fixed counter to produce an oscillator (VCO) output signal

which is buffer amplified by Q2 then divided in IC1 by a

programmable counter. The divided signal is compared in

phase with the 5 or 6.25kHz reference signal from the phase

comparator in IC1. The output signal from the phase

comparator is filtered through a low-pass filter and passed

SP

Fig. 5 PLL circuit

3) Unlock Detector

If a pulse signal appears at the LD pin of IC1, an unlock

condition occurs, and the DC voltage obtained from C4,R5

and D1 causes the voltage applied to the microprocessor

to go low. When the microprocessor detects this condition,

the transmitter is disabled, ignoring the push-to-talk switch

input signal.

4. Transmitter System

1) Microphone Amplifier

The signal from the microphone passes through the IC301.

When encoding DTMF, it is turned OFF for muting the

microphone input signal by IC301.

The signal passes through the Audio processor (IC301) for

the maximum deviation adjustment, and goes to the VCO

modulation input.

13

TK-2212/2217

T

CIRCUIT DESCRIPTION

IC301

MIC

AGC

LPF

DTMF

AQUA-L

IC405

CPU

QTVCO

QTTCXO

LPF

LPF

Fig. 6 Microphone amplifier

2) Drive and Final Amplifier

The signal from the T/R switch (D101 is on) is amplified by

the pre-drive (Q102) and the drive amplifier (Q103) to 50mW.

The output of the drive amplifier is amplified by the RF power

amplifier (Q106) to 5.0W (1W when the power is low). The

RF power amplifier consists of two MOS FET stages. The

output of the RF power amplifier is then passed through

the harmonic filter (LPF) and antenna switch (D103 and

D104) and applied to the antenna terminal.

D103

From

T/R SW

(D101)

PCTV

(IC405)

Q102

Pre-DRIVE

AMP

5T

+B

R127

R128

R129

Q103 Q106

DRIVE

AMP

IC101

(1/2)

RF

POWER AMP

VDD

IC101

(2/2)

D104

ANT

SW

VGVGVD

Fig. 7 Drive and final amplifier and APC circuit

3) APC Circuit

The APC circuit always monitors the current flowing through

the RF power amplifier (Q106) and keeps a constant current.

The voltage drop at R127, R128 and R129 is caused by the

current flowing through the RF power amplifier and this

voltage is applied to the differential amplifier IC101(1/2).

IC101(2/2) compares the output voltage of IC101(1/2) with

the reference voltage from IC405. The output of IC101(2/2)

controls the VG of the RF power amplifier and drive amplifier

to make both voltages the same.

The change of power high/low is carried out by the change

of the reference voltage.

The QT,DQT data of the QTVCO Line is output from pin 24

of the CPU. The signal passes through a low pass CR filter,

VCO

mixes with the audio signal, and goes to the VCO modulation

input. TX deviation is adjusted by the CPU.

(2) DTMF

High-speed data is output from pin 2 of the CPU. The signal

passes through a low-pass CR filter, and provides a TX and

X1

TCXO

SP out tone, and is then applied to the audio processor

(IC301). The signal is mixed with the audio signal and goes

to the VCO.

TX deviation is adjusted by the CPU.

(3) MSK (Fleet Sync)

Fleet Sync utilizes 1200bps and 2400bps MSK signal is

output from pin 6 of IC301. And is routed to the VCO.

When encoding MSK, the microphone input signal is muted.

5. Power Supply

There are four 5V power supplies 5M,5C,5R, and 5T. 5M

for microprocessor is always output while the power is on.

5M is always output, but turns off when the power is turned

off to prevent malfunction of the microprocessor.

5C is a common 5V and is output when SAVE is not set to

AN

OFF.

5R is 5V for reception and output during reception.

LPF

5T is 5V for transmission and output during transmission.

6. Control Circuit

The control circuit consists of a microprocessor (IC405) and

its peripheral circuits. It controls the TX-RX unit and transfers

data to the Display unit. IC405 mainly performs the following:

(1) Switching between transmission and reception by the

PTT signal input.

(2) Reading system, group, frequency, and program data

from the memory circuit.

(3) Sending frequency program data to the PLL.

(4) Controlling squelch on/off by the DC voltage from the

squelch circuit.

(5) Controlling the audio mute circuit by the decode data input.

(6) Transmitting tone and encode data.

1) Frequency Shift Circuit

The microprocessor (IC405) operates at a clock of

7.3728MHz. This oscillator has a circuit that shifts the

frequency by BEAT SHIFT SW (Q407,Q408).

A beat sound may be able to be evaded from generation if

“Beat Shift” is set to ON when it is generated in the internal

spurious transmission modulated sound of a transceiver.

4) Encode Signaling

(1) QT/DQT

QT,DQT data of the QTTCXO Line is output from pin 28 of

the CPU. The signal passes through a low-pass CR filter

and goes to the TCXO(X1).

14

TK-2212/2217

CIRCUIT DESCRIPTION

11

XOUT

Q408

H:OFF

L:ON

X3

Q407

H:OFF

L:ON

8

IC405

BSHIFT

Fig. 8 Frequency shift circuit

2) Memory Circuit

Memory circuit consists of the CPU (IC405) and an EEPROM

(IC406). An EEPROM has a capacity of 64k bits that contains

the transceiver control program for the CPU and data such

as transceiver channels and operating features.

IC405

CPU

IC406

EEPROM

Fig. 9 Memory circuit

3) Low Battery Warning

The battery voltage is checked by the microprocessor.

The transceiver generates a warning tone when the battery

voltage falls below the warning voltage (2) shown in the

table.

7. Control System

LCD, Keys and channel selector circuit.

The signal from the keys and channel selector are directly

input to the microprocessor, as shown in fig. 11.

Channel selector

49

EN1

71

EN2

IC405

Fig. 11 Control system

CPU

LCD

ASSY

PTT

SIDE 1

SIDE 2

27

74

75

PTT

SW

SW1

SW2

(1) The red LED blinks when the battery voltage falls below

the voltage (1) shown in the table during transmission.

Transmission is still allowed.

Note:

The transceiver checks the battery voltage during reception

even when, in the FPU, the Battery Warning status function

is set to “While Transmitting” (default setting).

However, the LED does not blink during reception. The red

LED blinks during transmission. The transceiver is still

usable.

(2) The transceiver immediately stops transmission when

the battery voltage falls below the voltage (2) shown in

the table. A warning tone sounds while the PTT switch

is pressed.

Ni-MH Battery

(1) 6.2[V]

(2) 5.8[V]

SB

R404

88

R406

IC405

BATT

CPU

Fig. 10 Low battery warning

15

Loading...

Loading...