Kenwood KD-CCMP-21-V Service Manual

CD AUTO CHANGER PLAYER

KDC-CMP2 1V

SERVICE MANUAL

© 2004-3 PRINTED IN JAPAN

B53-0163-00 (N) 428

The MECHANISM OPERATION is the same as model KDC-C660.

Please refer to the service manual of model KDC-C660 (B51-7105-00).

When transporting this model, always attach CAUTION CARD and STEPPED SCREW (for transportation).

Service jig

For initial position setting

Parts No.

W05-0635-00

Cord with plug

(E30-4291-05)

(E30-4711-05)

(E30-6358-05)

Tray

(J99-0614-01)

Bracket (L)

(J19-5018-03)

Holder assy

(J19-5146-02)

Bracket (R)

(J19-5019-03)

Screw set

(N99-1645-15)

Cord with pinjack

(E30-6351-05)

2

BU14V

5V AVR BU5V

BU3.3V

BU2.5V

SW

5V AVR

D5V (SW)

8V AVR

SW

5V REG (A)

SRV8V

BU

DETECT

A5V

NJM2880U33 SW3.3V

TR

SW5V

UPC2926T SW2.6V

SHIFT

LEVEL

CONTROL IC

MICROPROCESSOR

AUDIO DAC HD74LV157AT-EAUDIO MUTE

LIM SW

LIM SW

SW

RESET

EEP-ROM

L.P.S

ARM SW

EJ SW

MG SW

N/PAL SW

SERVO,DSP

DECODER

MP3/WMA

VCD

DECODER

VIDEO AMP

DRAM

FLASH ROM

DC MOTOR

DRIVER

BTL

TR COIL

SLED

FO COIL

ELEVATOR

LO-EJ

SPINDLE/

CB

A

E

F

PD

HOT

IC4 IC15

CQ RF,

MECHANISM

AUDIO

OUT

VIDEO

OUT

IC5

IC8

IC9

IC7

IC11

IC12 IC15

SYSTEM

IC1

IC2

Q90,91 IC14

NJM2890

M1

M2

M3

CHCLK

REQH

REQC

DATAH

DATAC

CHCON

CHRST

CHMUTE

N/PAL

PON

PON

PON

D5V (SW)

16MHz

PON

BU3.3V

BU5V

A5V

A or B

PON

PON

BU3.3V

DATA SEL

12.5MHz

BU5V

GND

16.934MHz

SW3.3V

BU3.3V BU2.5V

AB

SW5V

SW2.6V

75 470u

SW5V

27MHz

XTAL

SRV8V

10

C16M

BCLK,DATA,LRCK

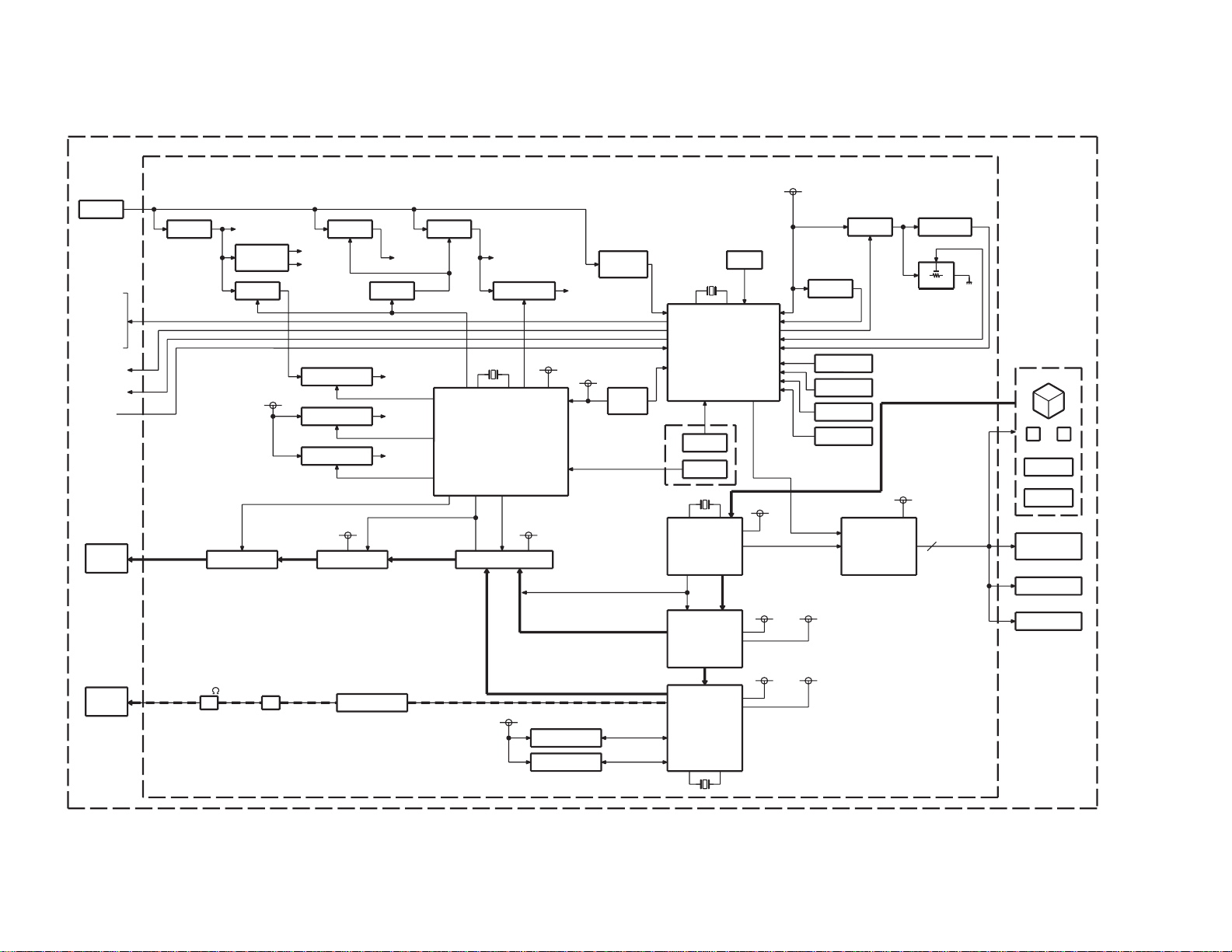

CD PLAYER UNIT (X32-5650-00)

(X13- )

PICKUP ASSY

MECHANISM ASSY (X92-4950-00)

DPU1

KDC-CMP2 1V

BLOCK DIAGRAM

KDC-CMP2 1V

COMPONENTS DESCRIPTION

● CD PLAYER UNIT (X32-5650-00)

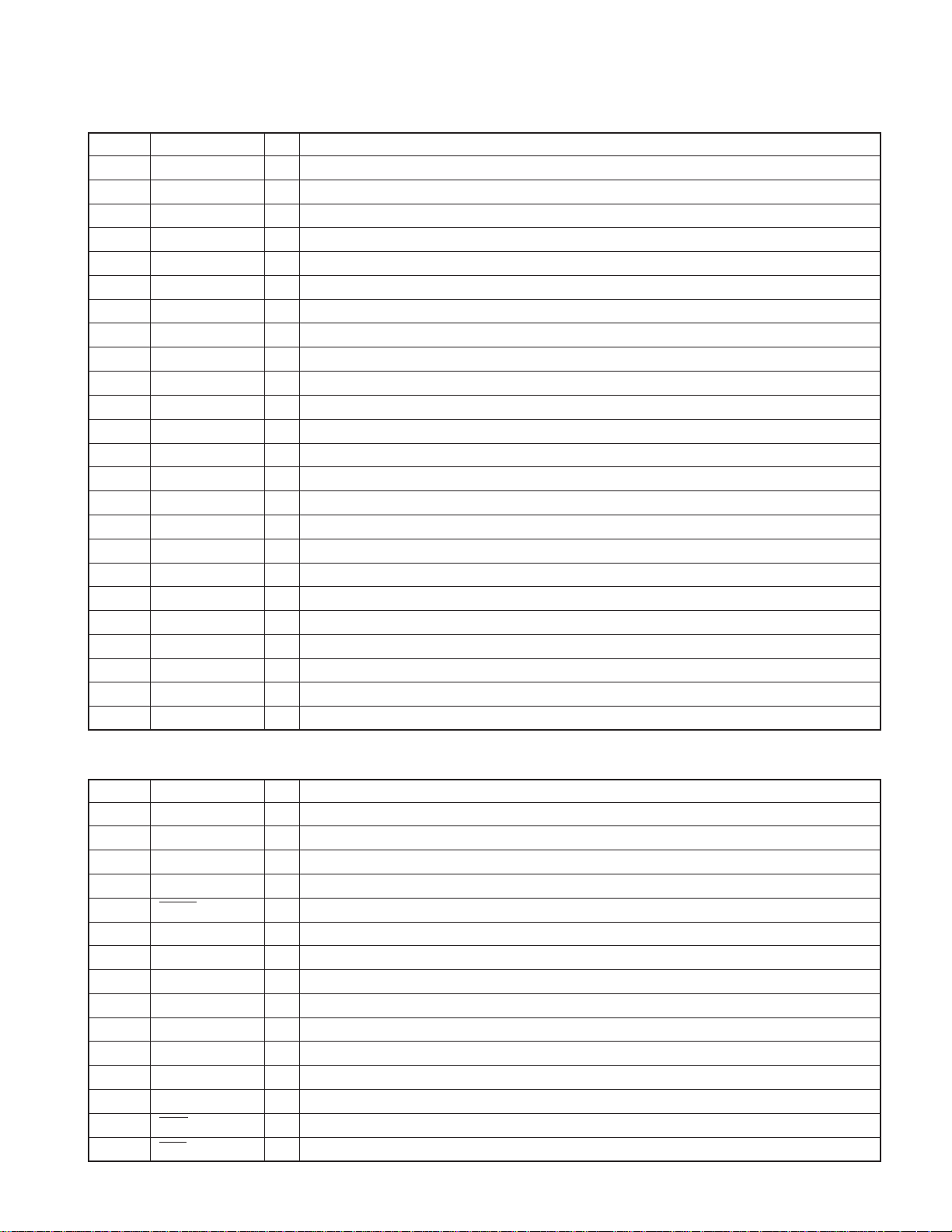

Ref. No. Application / Function Operation / Condition / Compatibility

IC1 Reset IC System microprocessor reset control IC

IC2 System microprocessor Communication to head unit and control for mechanism control IC

IC3 EEPROM LPS data backup memory (for MD position)

IC4 Mechanism control IC Control for Mechanism assy, servo IC and MP3/WMA decoder

IC5 Video amp Video amp for composite video signal

IC6 AVR 2.6V (for IC7 VCC)

IC7 Video decoder Video CD decoder IC

IC8 DRAM For playback video data

IC9 Flash ROM Program memory for VCD decode

IC10 Selector Select for VCD line or MP3/WMA data line

IC11 Decoder MP3/WMA decoder IC

IC12 CD servo IC RF amplifier built in digital servo and data processor IC

IC13 AVR 5.0V (for audio and IC14 VDD)

IC14 Audio DAC Audio DA converter

IC15 Motor driver Focusing coil, tracking coil, spindle motor and sled motor driver

IC16 AVR 5.0V (for IC7 VDD)

IC17 AVR 3.3V, 2.5V (for BU), IC4, IC11 VDD

IC18 AVR 3.3v (for IC12 VDD)

Q1,2 SW AVR 8V control SW

Q3,6 SW AVR 6.2V control SW

Q5 Driver AVR 5V driver

Q7 SW Select for 8V and 7V voltage

Q8 Driver AVR 6.2V driver

Q11 Driver AVR 8V driver

Q12 BU det Backup line voltage detector

Q20 Parking det Parking SW detector

Q21 Reset SW Reset control SW (for system microprocessor)

Q22 SW Changer muting control

Q23 SW Changer control SW

Q24 SW AVR 5V control SW

Q25,26 Level shift Voltage level shift (5.0V →3.3V, 3.3V→5.0V)

Q27,28 Audio muting SW Q27 (for Lch), Q28 (for Rch)

Q40 SW System reset for IC4

Q52 SW System reset for IC7

Q70 Selector SW Selector IC control SW

Q71 VC SW Control for Q73

Q72 LD SW Control for APC

Q73 VC SW Eccentric disc SW (for sub beam F)

Q90~93 Audio muting SW Q90,93 (Rch), Q91,92 (Lch)

Q100 Vref selector Select for internal Verf or external Vref

3

KDC-CMP2 1V

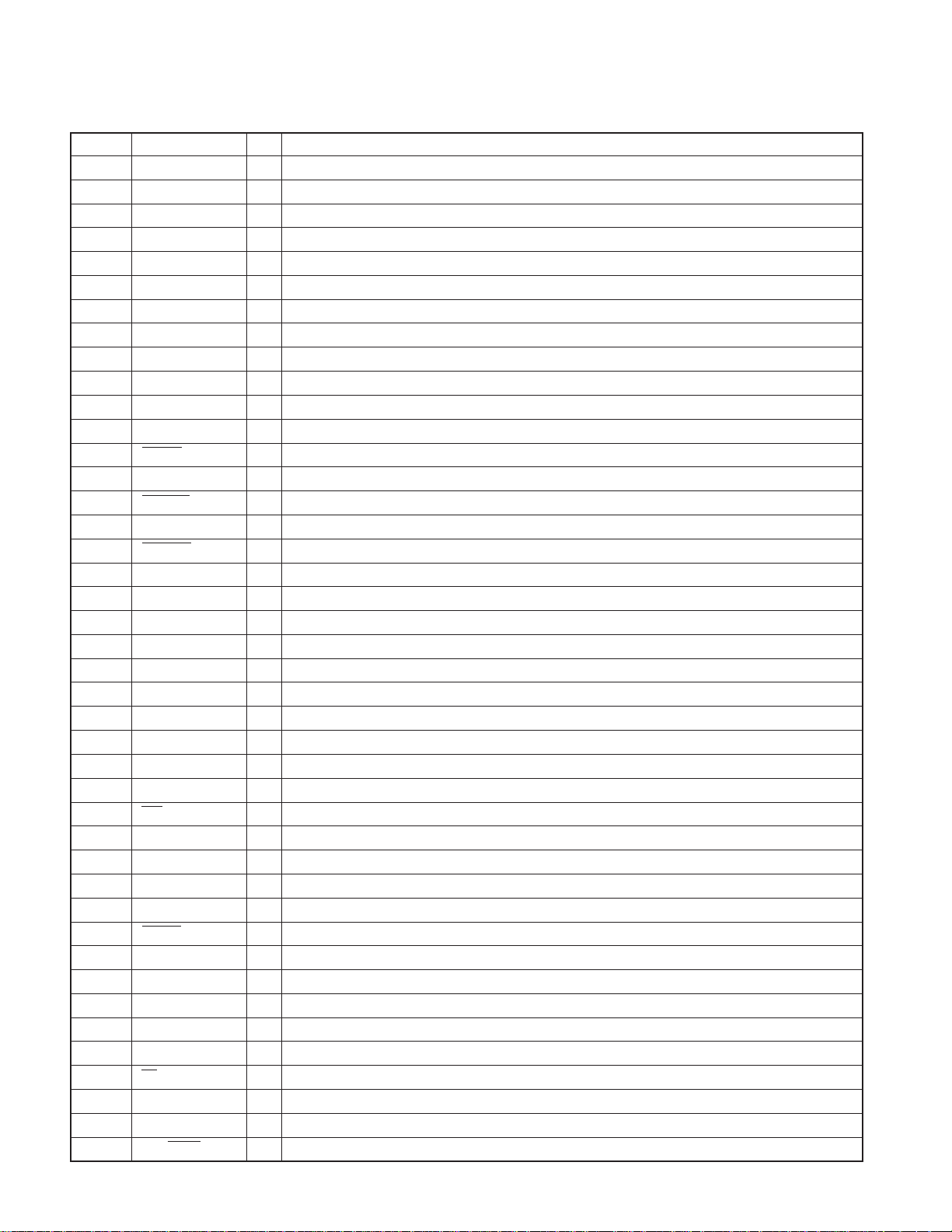

MICROCOMPUTER’S TERMINAL DESCRIPTION

● SYSTEM MICROPROCESSOR : 784214AGC-204 (X32: IC2)

Pin No. Pin Name I/O Description / Processing Operation

1 PON O Power control output terminal (L : AVR power ON)

2NCONC (open)

3/MSTOP O Mechanism stop signal output terminal (L : Mechanism stop, H : NORMAL)

4PARK SW I Parking SW detect input terminal (H : Monitor ON, L : Monitor OFF)

5 NTSC/PAL I NTSC/PAL select terminal (H : PAL, L : NTSC)

6 RST O Servo IC reset signal output terminal (L : Reset)

7 /MUTEIN L I Lch muting signal input terminal (L : Muting ON)

8 /MUTEIN R I Rch muting signal input terminal (L : Muting ON)

9 VDD - BU5V (for ADC)

10 X2 - X’tal 12.5MHz

11 X1 - X’tal 12.5MHz

12 VSS - GND

13,14 XT2,XT1 - NC

15 /RESET I Reset signal input terminal (L : Reset)

16 NC - NC

17 MGSW I Magazine in SW input terminal (H : Magazine pack in)

18 EJSW I Eject SW input terminal (H : Eject SW ON)

19 COMMSW I Select for OLD or NEW 5L line system control

20 NC - NC

21 CH-CON I Changer control for Head unit (H : System ON)

22 BUDET I Backup line voltage detect input terminal (H : Momentary power down)

23 AVDD - VDD for A/D converter (BU5V)

24 AVREF0 I Vref for A/D converter (Sys 5V)

25 HOT I Rise in temperature detect input terminal (Detect level : 4V (90°C))

26 LPS I Mechanical deck position detect input terminal

27 LOESW I Loading in SW input terminal (L : Loading complete)

28 NC - NC

29 TOFF I Tracking OFF mode detect terminal (H : Tracking OFF)

30 SRVSEL I Servo active mode terminal (No mechanism movement, H : Servo active mode)

31 SLNSA I SLED non-sensitive area ON/OFF terminal (L : Seld non-sensitive ON)

32 ADJSEL I Servo automatic adjustment ON/OFF terminal (L : Servo adjustment ON)

33 AVSS - GND

34,35 NC - NC

36 AVREF1 I Vref for A/D converter (BU 5V)

37~39 NC - NC

40 DATAH I Data input terminal (for Head unit)

41 DATAC O Data output terminal (for Changer unit)

42 HCLK I/O Communication clock (for Head unit)

43 REQC O Communication request to Head unit

44 CHMUTE O Audio muting signal to Head unit (L : Muting ON)

45 /MUTE L O Lch audio muting signal output terminal (L : Muting ON)

4

KDC-CMP2 1V

MICROCOMPUTER’S TERMINAL DESCRIPTION

Pin No. Pin Name I/O Description / Processing Operation

46 /MUTE R O Rch audio muting signal output terminal (L : Muting ON)

47~71 NC - NC

72 VSS - VSS

73~75 NC - NC

76 ELVADJ I Mechanism deck position adjustment mode select terminal (L : Adjustment mode)

77~80 NC - NC

81 VDD - VDD (BU 5V)

82 NC - NC

83 REQH Communication request from Head unit

84 SP/LO+ O Spindle/Loading motor control terminal

85 SP/LO- O Spindle/Loading motor control terminal

86 ELV+ O Elevator motor control terminal

87 ELV- O Elevator motor control terminal

88,89 NC - NC

90,91 TEST1,TEST2 I Test mode terminal

92 8V/7V O Mechanism driver IC control terminal

93 EEPWR I EEPROM writing mode control terminal (H : Writing, L : NORMAL)

94 TEST/VPP I Flash ROM program mode control terminal

95 DATA I/O Serial data communication to mechanism control IC

96 /CLK I/O Serial clock communication to mechanism control IC

97 SDA I/O EEPROM data I/O terminal

98 SCL O EEPROM clock output terminal

99 NC - NC

100 ARMSW I ARM SW detector (H : Arm SW ON)

● MECHANISM CONTROL IC : 91CW12AFG-5DN4 (X32 : IC4)

Pin No. Pin Name I/O Description / Processing Operation

1 VREFL I Reference V input terminal (for ADC)

2AVSS - GND (for ADC)

3AVCC - BU3.3V (for ADC)

4NCONC (open)

5 20RST O Reset control terminal (for decoder, L : RESET, H : NORMAL)

6 20ACK I Acknowledge signal input terminal (for decoder)

7 20STBY O Stand-by control terminal (for decoder, H : STAND BY, L : NORMAL)

8,9 NC O NC (open)

10 20INT I Interrupt signal input terminal (for decoder)

11 FOGUP I Focus gain interrupt input terminal (H : Fo gain UP, L : NORMAL)

12 LZM I 0bit MUTE detect (Lch) (L : MUTE OFF, H : MUTE ON)

13 RZM I 0bit MUTE detect (Rch) (L : MUTE OFF, H : MUTE ON)

14,15 NC O NC

16 20CS O Chip select signal output terminal (for decoder)

17 20LP O Latch pules signal output terminal (for decoder)

5

KDC-CMP2 1V

MICROCOMPUTER’S TERMINAL DESCRIPTION

Pin No. Pin Name I/O Description / Processing Operation

18 20TXD0 I/O Serial data signal output terminal (for decoder)

19 20RXD0 I Serial data signal input terminal (for decoder)

20 20SCLK0 O Serial data clock output terminal (for decoder)

21 DSPTXD1 O Serial data signal output terminal (for DSP)

22 DSPRXD1 I Serial data signal input terminal (for DSP)

23 DSPSCLK1 O Serial data clock output terminal (for DSP)

24 AM0 I Select for ROM mode (H : NORMAL, L : External ROM mode)

25 DVCC - BU3.3V

26 X2 O X’tal 16MHz

27 DVSS - GND

28 X1 I X’tal 16MHz

29 AM1 I Fixed H

30 RESET I Reset input terminal (L : RESET, H : NORMAL)

31~34 NC O NC

35 DSPSTB O Data strobe signal output terminal (for DSP)

36 DSPA0 O Command, parameter select signal (for DSP) (H : Parameter, L : Command)

37 DSPRST O Reset control output terminal (for DSP)

38 DSPINT I Interrupt signal input terminal (for DSP) (H : Interrupt)

39 /DAC RESET O Reset signal output terminal (for DSP) (L : RESET, H : NORMAL)

40 SEARCH O Search condition output terminal (H : Search, L : NORMAL)

41 LOE/LIM_SW I SLT SW detect input terminal (H : Inside)

42~45 NC O NC

46 PONE5 O +5V power supply control (for video) (H : POWER ON)

47 PONE2.5 O +2.5V power supply control (for video) (H : POWER ON)

48~60 NC O NC

61 /DAC PD O DAC RESET (L : RESET, H : NORMAL)

62 DVSS - GND

63 NMI I Request for non maskable interrupt signal input terminal

64 DVCC - +VCC

65 DAC MUTE O DAC MUTE control terminal (H : MUTE, L : MUTE OFF)

66 DAC PON O Audio power supply (for DXM6550) (H : Power ON)

67 PONA5 O +5V Audio power supply (for DXM6550) (H : Power ON)

68 ESRST O Reset signal output terminal (for ES3890) (L : RESET, H : NORMAL)

69 VMUTE O VIDEO MUTE control terminal (H : MUTE, L : MUTE OFF)

70 NC O NC

71 SELINT O Video/Audio select output terminal (H : NORMAL, L : Interrupt)

72 ASEL0 O Audio signal output select terminal 0 (00 : STEREO, 01 : Lch)

73 ASEL1 O Audio signal output select terminal 0 (10 : Rch, 11 : Not function)

74 NT/PAL O NTSC/PAL selector (L : NTSC, H : PAL)

75 DATASEL O 20F/ES3890 output select (H : 20F, L : ES3890)

76,77 NC O NC

78 NC (BOOT) I Flash memory writing terminal (L : Writing, H : NORMAL)

6

KDC-CMP2 1V

MICROCOMPUTER’S TERMINAL DESCRIPTION

Pin No. Pin Name I/O Description / Processing Operation

79,80 NC O NC

81 POND3.3 O D3.3V POWER ON control terminal (H : POWER ON)

82 MUTEL O Audio muting control terminal (Lch)

83 MUTER O Audio muting control terminal (Rch)

84 SDA I/O I2C data (for system microprocessor)

85 SCL I/O I2C clock(for system microprocessor)

86 MSTOP I Interrupt for stand-by condition (L : STOP, H : NORMAL)

87 NC O NC

88 DMUTE O Driver muting (L : MUTE ON, H : MUTE OFF)

89 DVCC - VDD

90 NC O NC

91 DVSS - GND

92~94 NC I NC

95 VCDSEL I Video CD operation control terminal

96 ASEL I Audio output polarity control terminal (H : Reversal output, L : Normal output)

97 CHSEL I Destination input terminal (H : Changer, L : Normal)

98 SEL0 I Destination input terminal (L,L : DXM-6540, L,H : DXM6550)

99 SEL1 I Destination input terminal (H,H : DXM6560)

100 VREFH I Reference voltage input terminal (for ADC : BU3.3V)

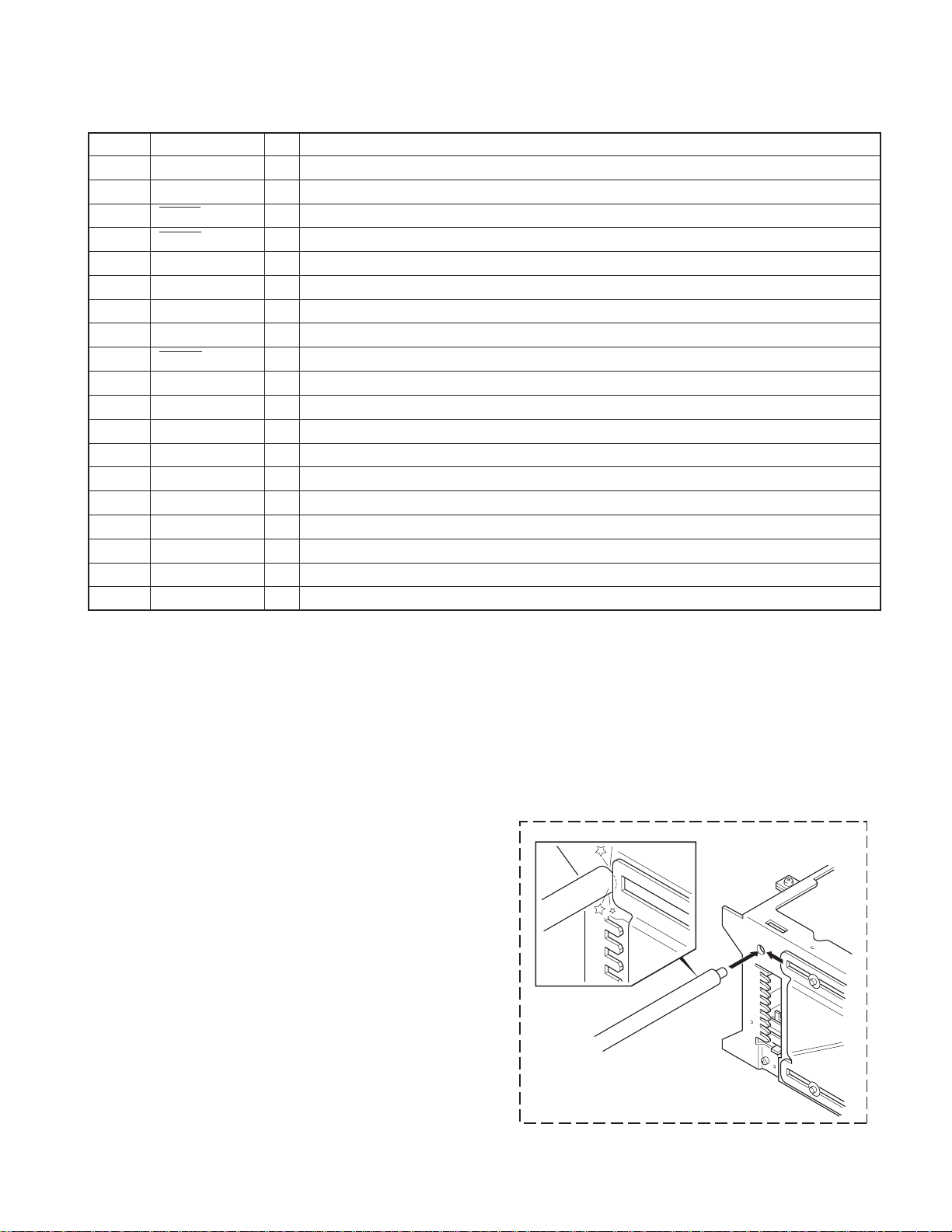

ADJUSTMENT

● L.P.S. initial position adjustment procedure

1. Connect the changer to the HEAD UNIT (H/U).

2. While holding the magazine eject button of the changer,

press the reset button of the H/U.

3. After about 3 seconds, release the magazine eject button.

4. Press the SRC button of the H/U to enter the CD-CH mode,

and the H/U's display section indicates “E-88”.

5. Move the mechanism deck to around the 1st stage b y pressing the DISC- or DISC+ button.

6. Insert the adjustment tool (W05-0635-00) into the tool hole

on the changer mechanism.

7. Then press the DISC+ button to move the mechanism dec k

until the mechanism’s slider hits the adjustment tool.

8. When the motor locks (stops), press the REPEAT key of

the H/U.

When the REPEAT key is pressed, the mechanism moves

automatically to the 1st stage and the initial position adjustment completes. (The data is written in the EEPROM at

this time.)

W05-0635-00

7

Loading...

Loading...