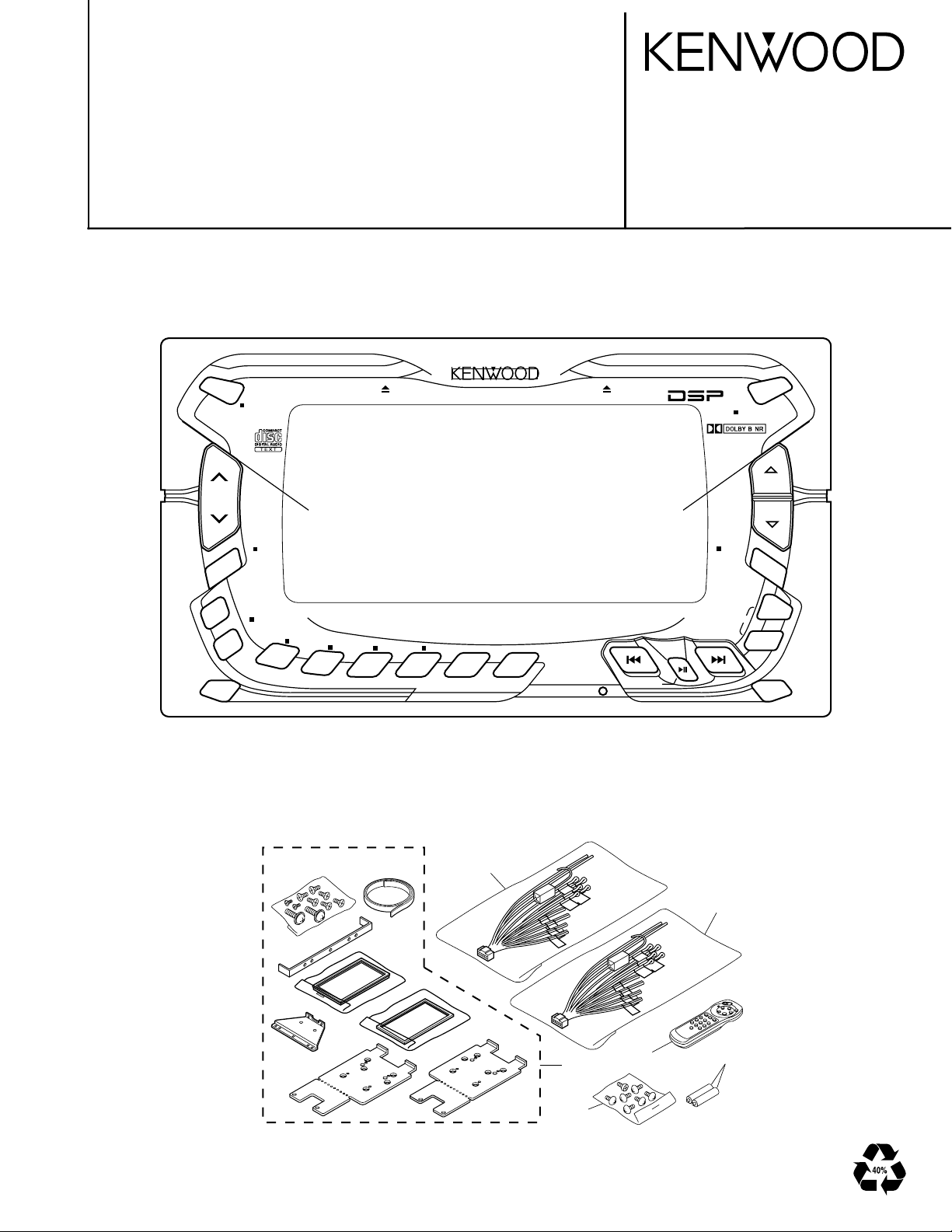

Kenwood DPX-5010 Service manual

CD CASSETTE DSP RECEIVER

DPX-5010

SERVICE MANUAL

Refer to the service manual "D40-1132-05" (B51-7505-00)

for CASSETTE MECHANISM ASSY's information.

CD OPEN/CLOSE TAPE OPEN/CLOSE

© 2000-8 PRINTED IN JAPAN

B51-7663-00 (N) 1714

DSP

ATT

EQ

DISP

D

I

S

C

DIR AUD

DPX-5010

OFF PWR

VOLUME LAST ANGLE

CRSC SBF

NAME.S

SCROLL

B NR

7

1

D

I

R

E

C

T

SCN

8

2

COMPRESSION

KBS

RDM/B.S

9 0

34

SFC

POSITION

DBB

SFC LEVEL

REP M.RDM/MTL

ROOM SIZE

D.S

56

DIGITAL SIGNAL PROCESSOR

DIGITAL X,OVER

CD CASSETTE

DSP RECEIVER

MEMORY

PROGRAM

DISC

OFF

SRC

RETURN

ANGLE

FNC

FM

AM—

+

The following reference numbers with accessory parts are the same reference numbers

used on EXPLODED VIEW and PARTS LIST.

DC1

205

210

RM1

DC1

711

DPX -50 10

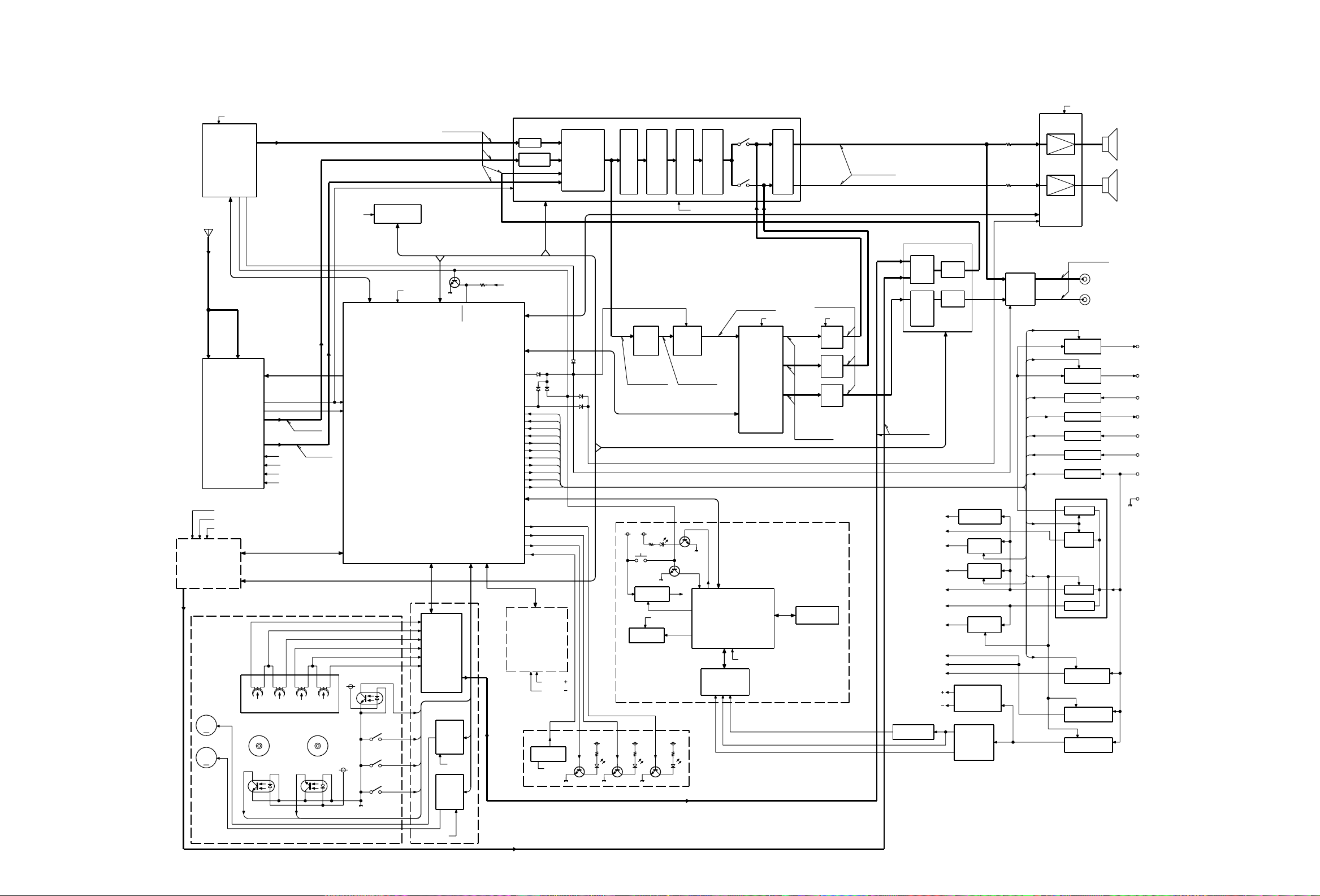

BLOCK DIAGRAM .................................................................................... 3

MICROCOMPUTER’S TERMINAL DESCRIPTION .................................. 5

PANEL MECHANISM DESCRIPTION....................................................... 9

TEST MODE / ADJUSTMENT................................................................. 11

PC BOARD .............................................................................................. 12

SCHEMATIC DIAGRAM .......................................................................... 21

EXPLODED VIEW ................................................................................... 30

PARTS LIST............................................................................................. 34

SPECIFICATIONS ............................................................... BACK COVER

CONTENTS

2

ANT.

CD MECHA

AUDIO OUT

CASSETTE

MECHA

MAIN

SUB

AM ANT

A2

M

M

B.U

MD/CD

CHANGER

FM DET OUT

AM DET OUT

BU 5V

AUD +B

SRV +B

SW1-3

AMUTE

MRST

MSTOP

LO/EJ

MOTOR

SDA

SCL

CLK

DATA

FM ANT

REQ

FSD

FM SD

Takeup Reel

F/E

CE

FWD

Lch

REELT

PON 5V

AUD +B

FM +B

AM +B

REV

Lch

PLAY HEAD

FM

FWD

::400mV

REELS

AM

160mV

REV

RchRch

Supply Reel

PON 5V

PLL CLK

PLL DATA

PLL CE

PLL REQ

FSD

FM SD

SW1-3

AMUTE

MRST

MSTOP

LO/EJ

MOTOR

IC14

REQC

REQH

DATA C

CH CLK

CH CON

DOLBY UNIT

(X30-3000-00)

MODE

PACK DET

STBY

PACK IN

E2PROM

DATA H

BU 5V

SYSTEM u-COM

MSC

MTL

MUSIC

EQ-MUTE

FWD/REV

DOLBY

F-IN(L)

VREF(L)

R-IN(L)

F-IN(R)

VREF(R)

R-IN(R)

HA12216F

IC2,Q4

CD CH

TAPE

FM

AM

SCL

SDA

FREEL

A OUT

MAIN

MOTOR

DRIVER

2SB

SUB

MOTOR

DRIVER

RREEL

PACK DET

IC1

BU

DPX -50 10 DPX-50 1 0

BLOCK DIAGRAM

PM DET

PM

OPEN-SW

PWIC STBY

PWIC SVR

DSP WRQ

DSP WRDY

PW MUTE

LINE MUTE

LED LOGO

LED TAPE

IC2

ISO

NC. MPX

+6dB

BU 5V

IC1

BEEP

TEST

DSP RST

DSP PD

DSP SO

DSP CLK

MUTE

BU DET

ACC DET

SMALL

ANT CON

P CON

P ON

FM

AM

ILLUM

FL PON

SCDATA

MCDATA

CTS

RTS

SC-CON

LED CD

CD PACK

REFCON

PANEL MECHA

SDA

PM DET

PM-MODE

OPEN-SW

MOTOR

MOTOR

CD PACK

PON 5V

SCL

CD CH

TAPE

FM

AM

INPUT

SEL

+2dB

:

+4dB

:

+0dB

:

+4dB

:

ILL+B ILL+B

E VOL, TONE, NC, MPX

SOFT

VOL

MUTE

Buff

1511mV

:

475mV

:

798mV

254mV

:

DOWN

-12.4dB

CD CH

TAPE

FM :

AM

ILL +BBU 5V

RST SW

SW 5V

5V SW

DTB123YK

SW 5V

IC3

REMOCON

ILL+B

TRE

MUTE&

LEVEL

-0.5dB

CD CH

TAPE

FM :

AM :

AUD +B

:

363mV

:

114mV

192mV

61mV

ED1

BASS

PANEL u-COM

VFD

CD CHFM:

TAPE

:

:

AM :

IC8

DSP

(+2.4-3dB)

DSP RST

DSP PD

DSP WRQ

DSP WRDY

DSP SO

DSP CLK

BU 5V

342mV

108mV

180mV

58mV

IC1

DSP 5V

1200mV

:

300mV

:

400mV

:

160mV

:

RESET

SUB+

MAIN

MODE 1-3

SUB-

REFCON

VOL

TAPE

+15dB

OTHER

+11dB

FRONT

REAR

CD CH

TAPE

FM

AM :

FRONT

LPF

BUFF

9dB

REAR

LPF

BUFF

9dB

N/F or

REAR

LPF

BUFF

9dB

IC9-11

319mV

CD CH

:

100mV

TAPE

:

169mV

:

59mV

AMFM:

SWITCH UNIT

(X25-8330-11)

KEY MATRIX

:

900mV

:

283mV

:

475mV

151mV

AUD +B

CD CH

TAPE

FM::

AM

:

3193mV

:

1593mV

1687mV

537mV

CD

TAPE

IC5

::1200mV

VDD

HPF MUX

AMP

TAPE

+15dB

OTHER

+11dB

300mV

DSP(A) 3.3V

DSP(D) 3.3V

FM +B

AM +B

AUDIO +B

BU 5V

PON 5V

CD SRV +B

MOTOR +B

ILL +B

MOTOR

MOTOR

FL

SDA

VOL

SCL

IC17

A1

IC18

DSP3.3V AVR

FM8V SW

AM8V SW

5V SW

PANEL

MOTOR1

DRIVER

+B

DC/DC

FAC

MUTE

-0.5dB

FM

AM

IC12

PWR AMP

TEST

STBY

SVR

BEEP

ANT CON

P CON

LINE MUTE

AMP-CTRL

SMALL

ACC DET

B.U DET

P ON

P ON2

L4943

ILLUM

B. U

CD CH

:

3014mV

TAPE

:

1503mV

:

1592mV

AMFM:

507mV

FRONT

PRE OUT

REAR/NON FAD

PRE OUT

ANT CON

P CON

LINE MUTE

AMP-CTRL

SMALL DET

ACC DET

BU DET

SW 14V

DSP3.3V

AVR

A8V AVR

D5V AVR

ILL +B AVR

SRV +B AVR

DC/DC +B SW

IC3

Q16

FRONT

SP OUT

REAR

SP OUT

ANT CON

P CON

LINE MUTE

AMP-CTRL

SMALL

ACC

B. U

GND

MOTOR +B

3 4

DPX -50 10

MICROCOMPUTER’S TERMINAL DESCRIPTION

(X14-) IC1 : System µ-com

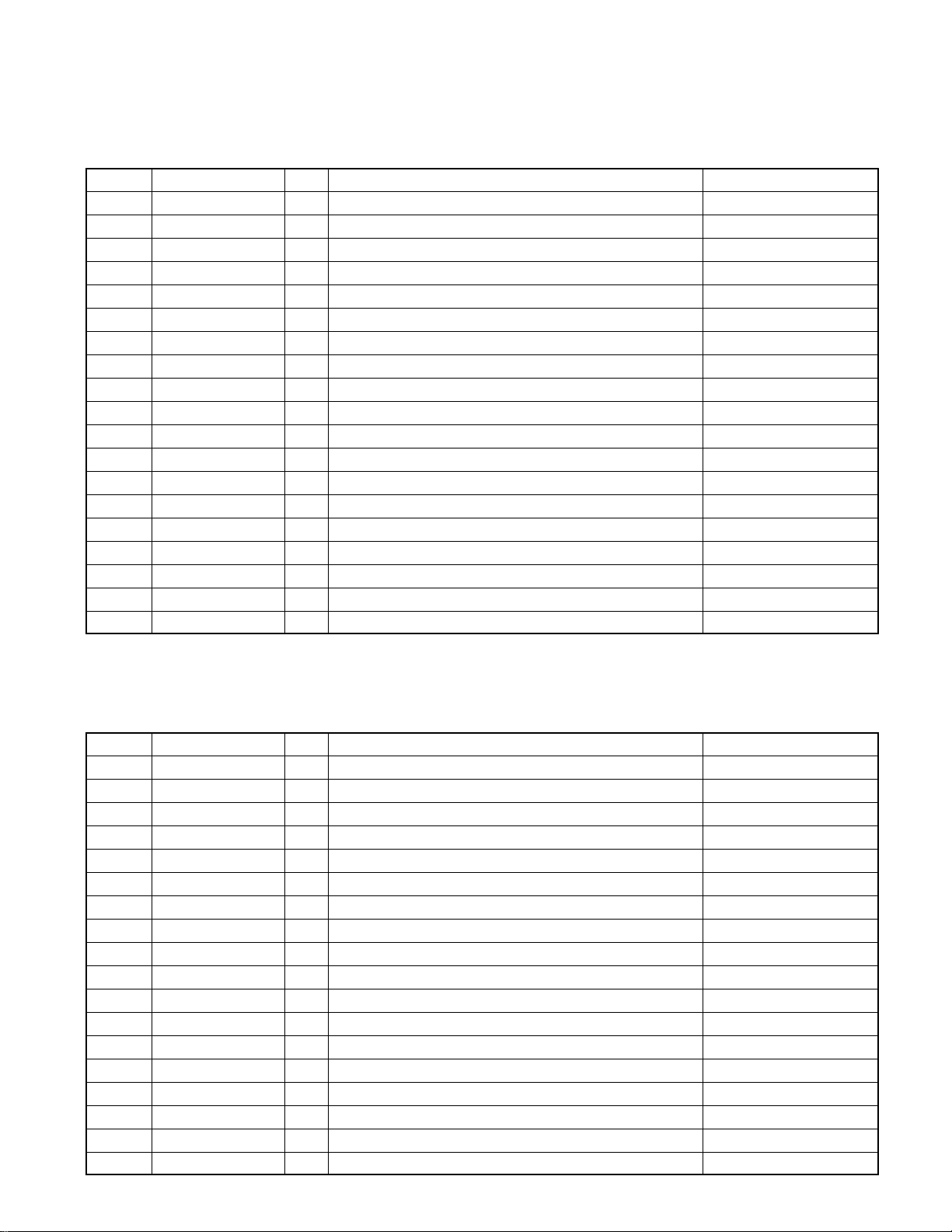

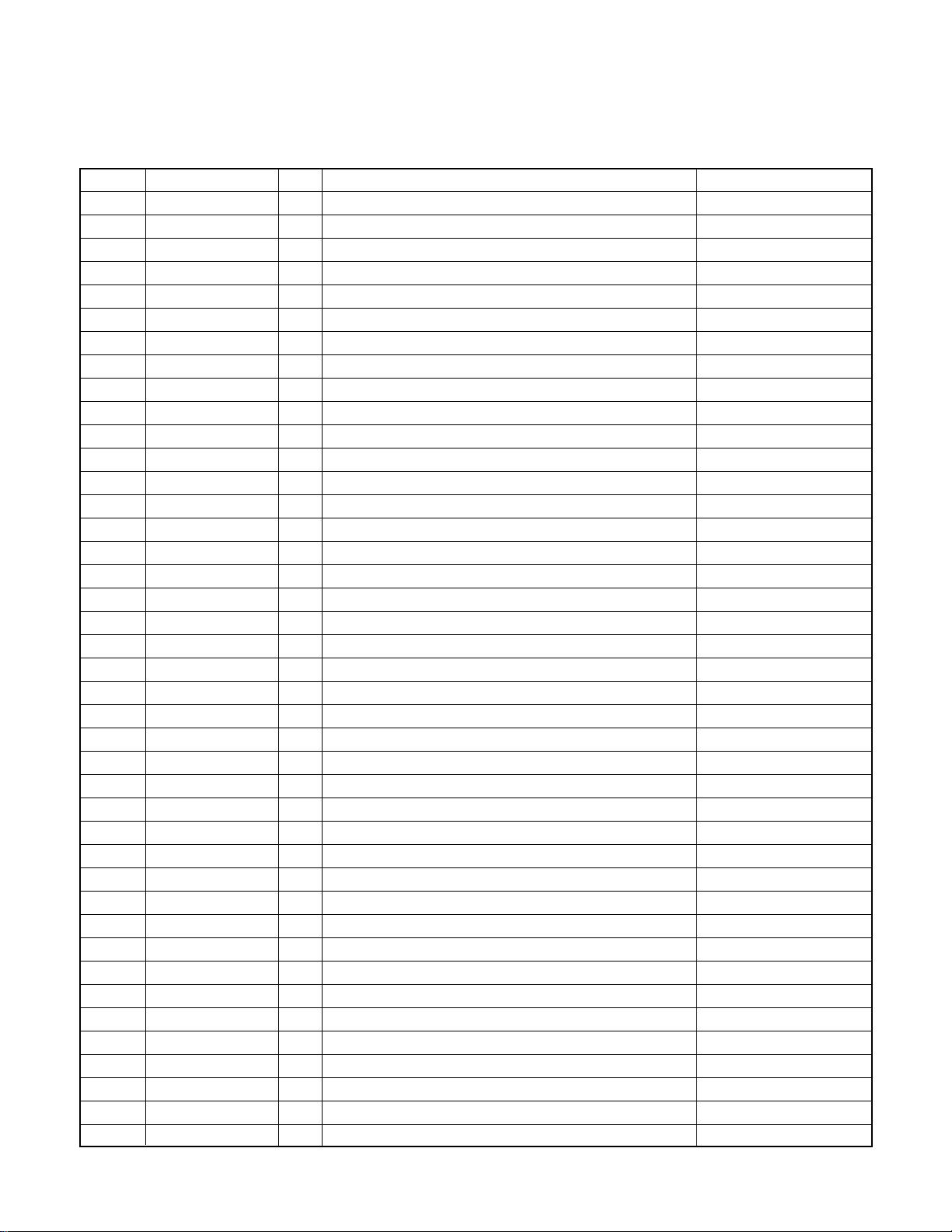

Pin Pin Name I/O Description Processing Operation

1 DSP RVDT O DSP data output

2 DSP_CLK O DSP clock output

3 CHCON1 O External CH1 selection H: CH1, L: Others

4 CHCON2 O External CH2 selection H: CH2, L: Others

5 DATAH O External CH data output

6 DATAC I External CH data input

7 CHCLK I/O External CH clock input/output

8 BYTE I External data bus width switching

9 CNVss I Processor mode switching

10 DSP_REDY I DSP write request

11 DSP_RST O DSP Reset

12 Reset I Reset input L: Reset

13 Xout O Main system clock output

14 Vss I Power input

15 Xin I Main system clock input

16 Vcc I Power input

17 NC I Not in use

18 SP INT I Spectrum analyzer reception permission

19 B U DET I B.U detection H: Power down

20 REQC I External CH reception request

21 REQH O External CH transmission request H: On

22 PANT O Power antennal control H: On

23 PCON O External amp power control H: On

24 PON O Power control H: On

25 LAMP O Lamp control H: On

26 AMP_CTRL O External amp control H: On

27 A CC DET I ACC detection H: ACC off

28 B UZZ O Beep ouput

29 SCL O IC2 clock ouput

30 SDA I/O IC2 data input/output

31 PN MC DATA * O Panel µ-com communication data output

32 PN SC DATA I Panel µ-com communication data input

33 PN RTS O Panel µ-com communication control

34 PN CTS I Panel µ-com communication control

35 PMOT1 O Panel motor control

36 PMOT2 O Panel motor control

37 REFCON O A/D reference voltage output

38 PMDET I Panel mechanism detection

39 OPEN SW I Panel full-open detection L: Panel full-open

40 PM VR O Panel mechanism voltage congrol H: 5.1V, L: 7.2V

41 PN SCCON O Panel µ-com communication control line

H: Panel Microcomputer stop

5

DPX -50 10

MICROCOMPUTER’S TERMINAL DESCRIPTION

(X14-) IC1 : System µ-com

Pin Pin Name I/O Description Processing Operation

42 MUTE O MUTE H: MUTE on

43 LED CD O LED CD display H: On

44 LED TAPE O LED T APE display H: On

45 LED LOGO O LED LOGO display H: On

46 SP_REQ O SPANA data output request to panel microcomputer

47 CD_SW3 I CD mechanism SW3 detection

48 CD MOTOR O CD loading motor control H: On

49 CD_LO/EJ I/O Loading/Eject control L: Loading direction

50 CD_MSTOP O CD mecha controller stop L: Stop

51 CD_MRST O CD mecha controller reset L: Reset

52 CD_AMUTE I CD mute request H: Mute request

53 CD_SW1 I CD mecha SW1 detection

54 CD_SW2 I CD mecha SW2 detection

55 TA DOLBY O Dolby selection SW H: DOLBY on

56 TA MTL O Metal selection SW H: Metal, L: Normal

57 TA_F/R O Play direction selection SW H: RWD, L: FWD

58 TA MUSIC I Between-music detection input SW L: Music

59 TP MSC O Casettee between-music selection SW L: FF&REV

60 TA EQ MUTE O EQ music selection SW H: MUTE on

61 SEL1 I IC2III noise cancellation selection

62 Vec - Power input

63 NC O Not in use L: Fixed

64 Vss - Power input

65 SEL2 I IC2III noise cancellation selection

66 SEL3 I Location switching H: M, L: J

67 NC O Not in use. L: Fixed.

68 PACK_DET I PACK detection SW L: PACK

69 TA_MODE1 I Cassette MODE1 detection SW

70 TA_MODE2 I Cassette MODE2 detection SW

71 TA_MODE3 I Cassette MODE3 detection SW

72 TA_SMOTOR1 O Cassette sub motor control 1

73 TA_SMOTOR2 O Cassette sub motor control 2

74 TA_MOTOR O Cassette main motor control H: On

75 NC O Not in use. L: Fixed.

76 PLL CLK O PLL clock ouput

77 PLL DATA I/O PLL data input/output

78 PLL_CE O PLL selection

79 FMSD I FM station detection H: Station

80 PLL_REQ O PLL seek selection L: In seek

81 FM+B O FM Power H: FM

H: Eject direction

6

DPX -50 10

MICROCOMPUTER’S TERMINAL DESCRIPTION

(X14-) IC1 : System µ-com

Pin Pin Name I/O Description Processing Operation

82 AM+B O AM Power L: AM

83 PMUTE O Power IC MUTE control H: MUTE on

84 ILLUMI I Illumination detecton L: Dimmer on

85 LINE_MUTE I External MUTE request L: Line MUTE on

86 PCON_IN I External amp peak current control H: Protection on

87 NC O Not in use. L: Fixed.

88 PWIC SVR O Power IC control H: On

89 TEST O Power IC control L: In test mode

90 PWIC_STBY O Power IC standby H: On

91 F_REEL I Reel pulse (FWD) detection SW Vth: 2.5V

92 R_REEL I Reel pulse (RWD) detection SW Vth: 2.5V

93 TAPE_DET I Tape detection H: Tape (A/D input)

94 CD_DET I CD detection sensor input H: CD (AD input)

95 PMODE I Panel position sensor input (AD input)

96 Avss I Analog po wer input

97 FSD OUT I S-meter input H: Station (AD input)

98 Vref - A-D reference voltage input

99 Avcc I Analog po wer input

100 DSP_XLAT O DSP write request

(X25-) IC1 : Panel µ-com

Pin Pin Name I/O Description Processing Operation

1~3 NC O Not in use

4 REMO O Remote signal input

5 NC O Not in use

6 SP DATA O Spectrum analyzer data input

7 SP CLK O Spectrum analyzer clock input

8 BYTE - External data bus width selection

9 CNVss - Processor mode selection

10,11 NC O Not in use

12 RESET - Reset input

13 Xout - Main system clock output

14 Vss - Power input

15 Xin - Main system clock input

16 Vcc O Power input

17,18 NC O Not in use

19 SP REQ I Spectrum analyzer data input request

20 PN SC CON I System µ-com communication control line

21~23 NC O Not in use

24 GBK O FL dot section data blanking output

7

DPX -50 10

MICROCOMPUTER’S TERMINAL DESCRIPTION

(X25-) IC1 : Panel µ-com

Pin Pin Name I/O Description Processing Operation

25 GLAT O FL dot section data latch ouput

26~30 NC O Not in use

31 PN_SC_DATA O System µ-com communication data output

32 PN_MC_DATA O System µ-com communication data input

33 PN RTS O System µ-com communication control line

34 PN CYTS I System µ-com communication control line

35,36 NC O Not in use

37 GCLK O FL dot section clock output

38~61 NC O Not in use

62 Vcc - Power input

63 NC O Not in use

64 Vss - Power input

65 LED4 G O 4 key illumination (green) control H: On

66 LED4 A O 4 k ey illumination (red) control H: On

67 LED3 G O 3 key illumination (green) control H: On

68 LED3 A O 3 k ey illumination (red) control H: On

69 LED2 G O 2 key illumination (green) control H: On

70 LED2 A O 2 k ey illumination (red) control H: On

71 LED1 G O 1 key illumination (green) control H: On

72 LED1 A O 1 k ey illumination (red) control H: On

73 KR4 I Key Return signal input 4

74 KR3 I Key Return signal input 3

75 KR0 I Key Return signal input 0

76 KS4 O Key Scan output 4

77 KS3 O Key Scan output 3

78 KS2 O Key Scan output 2

79 KS1 O Key Scan output 1

80 KS0 O Key Scan output 0

81~88 NC O Not in use

89 KR5 I Key Return signal input 5

90 PON O Periferal IC pow er control H: On

91 KR1 I Key Return signal input 1

92 KR2 I Key Return signal input 2

93 TAPE_EJECT O TAPE EJECT key illumination selection L: Blue

94 CD_EJECT O CD EJECT key illumination selection L: Blue

95 NC O Not in use

96 A vss - Analog power input

97 SP_INT O Spectrum analyz er data control request

98 Vref - A-D referece voltage input

99 A vcc - Analog power input

100 NC O Not in use

8

1

2

3

4

312

304

308

304

309

320

321

316

303

302

305

DPX -50 1 0

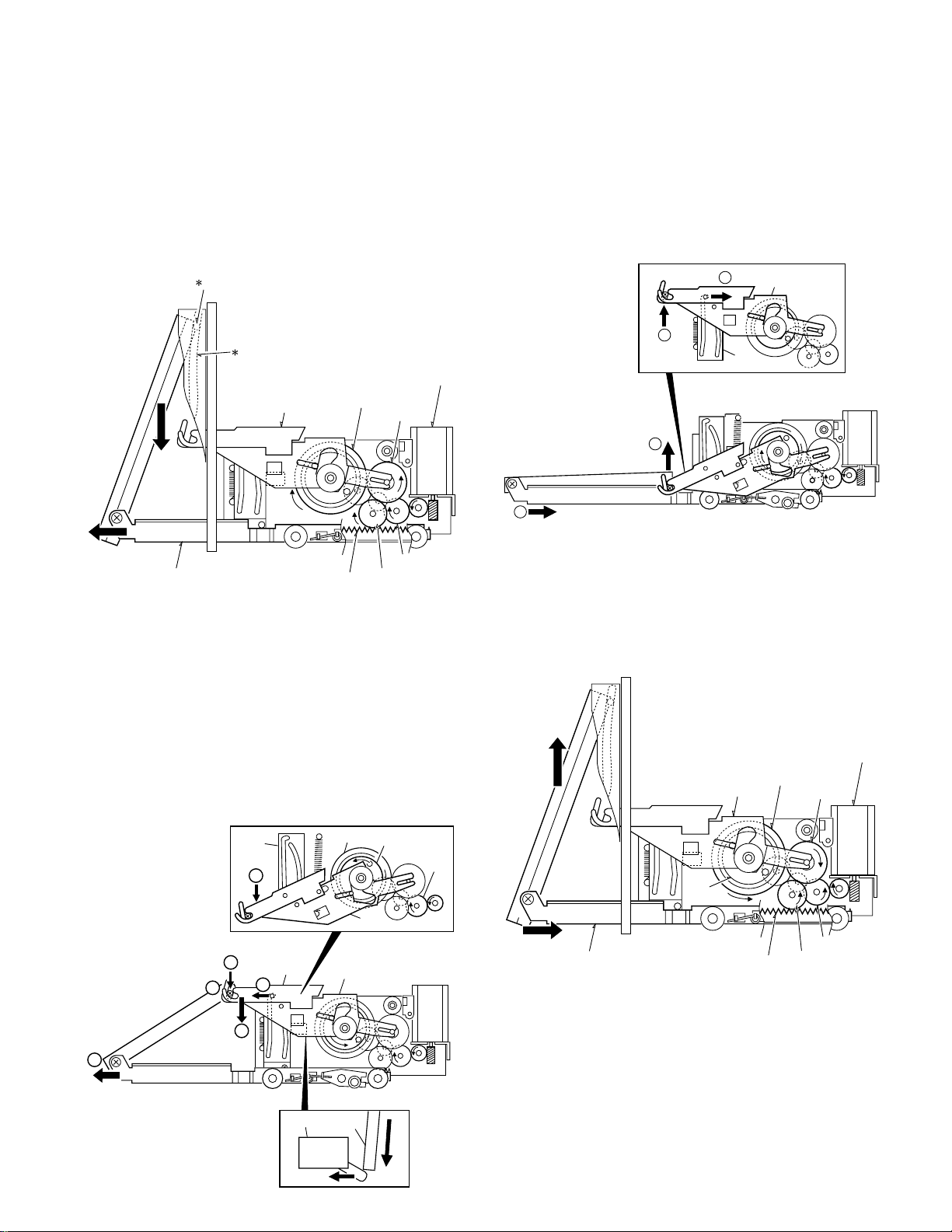

PANEL MECHANISM DESCRIPTION

A.Panel Opening

1. When Open button(switch) is pressed, the motor (305)

rotates.

2. The rotation of the motor is transmitted forward through

the rack gear (316) via the gears (320-322)

3. When the rack gear (316) moves, the panel (PA1) goes

down.

4. (1) The upper side of the panel pushed on the arm as-

sembly (304) by the pin (✽2) and the groove of the

rail (✽3).

(2) The lock on the lever (A) is let go and the arm assem-

bly (304) goes down.

(3) When this happens, the planetary gear (303) rotates.

5. When the arm assembly goes down to the open position,

the switch (341) is turned on. When the switch (341) is

turned on, the motor stops after 950ms.

302

2

3

305

316

308

309

320

321

304

B. Closing Behavior

1. The motor rotates in reverse direction.

2. The arm assembly (304) goes up. When the lever (A) goes

into the lock position of the rail (312), the arm assembly

(304) stops going up.

3. When the arm assembly (304) stops, by the rotation of

the planetary gear (303), the motor rotation pushes the

rack gear (316) backward via the gears (320-322).

4. By the close position information of the LPS (342), the

motor (305) stops after 200mS.

308

304

304

303

320

304

C. Angle Behavior

1. By the position information of the LPS (342), the panel

angle is controlled.

312

3

1

2

4

A

2

3

341

9

342

314

3

342

316

301

305

4

DPX -50 1 0

D.Assembly (Close Position)

1. Align the arm assembly with the pin of the planetary gear

(303).

2. Assembly these to the sub-chassis (306) along with the

rail (312).

3. Align lever (314) hole and the hold of the chassis (301).

4. Lead wires of LPS should be kept in place with a tape so

that they would not interfere with rack gear (316).

2

312

1

PANEL MECHANISM DESCRIPTION

1

304

306

2

325

1

303

308

309

10

DPX -50 10

TEST MODE / ADJUSTMENT

■ How to enter the text mode

While pressing on 1 and 3 keys, press the RESET key.

■ Panel Mechanism Adjustment

The mechanism detects the open/close position of the panel

and writes it to the E2PROM.

■ Starting on the test mode

Major initial positions

•

When booted with everything off, the test mode starts up.

• The valueof the volume is –40dB (indication is 15).

• FL lamps all light up.

• The diversity is off.

• Position: All.

• EQ: Flat

• COMPRESSOR: OFF

• SPE/ANA: PEAK HOLD

■ All display lamps lighting up

Since there are many segments on the display section,

bridging with other segments can be confirmed. By track up/

down keys, grids and segments can be lighted up individually.

■

Opening/Closing Time of the Panel Mechanism

When each time the Angle/Retune button is pressed, time

is displayed after going into the tuner mode. From the maximum angle to return, it takes about 1.2S.

■ CD Mechanism Panel Disk Detection

Sensor behavior for detecting whether there is CD disk or

not can be checked. When the sensor is closed off after a

disk is inserted, it beeps four times.

■

FM S-Meter Adjustment (Stop Adjustment and others)

Method:

SG Output: Set to 35dBµ 98.1MHz. (with no modulation)

During the above text mode, when Preset 1 and Preset 6.

are pressed at the same time, the adjustment begins. When

adjustments is completed normally , OK is displayed and there

will be one beep of 2kHz. In this case the stop adjustment

values will be between 15~25dBµ.

When the S-meter value is outside of the standard system

control values, NG is displayed and the initial value of the

system control is written in the E2PROM.

■ AM Stop Adjustment

Method:

SG Output: Set to 35dBµ 999kHz. (with no modulation)

During the above text mode, when Preset 1 and Preset 6.

are pressed at the same time, the adjustment begins. When

adjustments is completed normally , OK is displayed and there

will be one beep of 2kHz. In this case the stop adjustment

values will be between 30~43dBµ .

When the S-meter value is outside of the standard system

control values, NG is displayed and the initial value of the

system control is written in the E2PROM.

[ How to enter the test mode ]

After entering the above-mentioned test mode, switch over

to the tuner mode. Then, press on the TI knob for some time

and the unit will go into panel mechanism test mode, which

is indicated by STAND-BY display.

Method:

Each time Open/Close key (*key) of the remote controller

is pressed, full-open and full-close positions are registered.

(There will be OPEN ENTRY/ CLOSE ENTRY display and

three beeps are sound.)

Releasing:

When TI key is pressed, the unit goes back to the previous

test mode. Pressing the reset key will take the unit to the

initial condition.

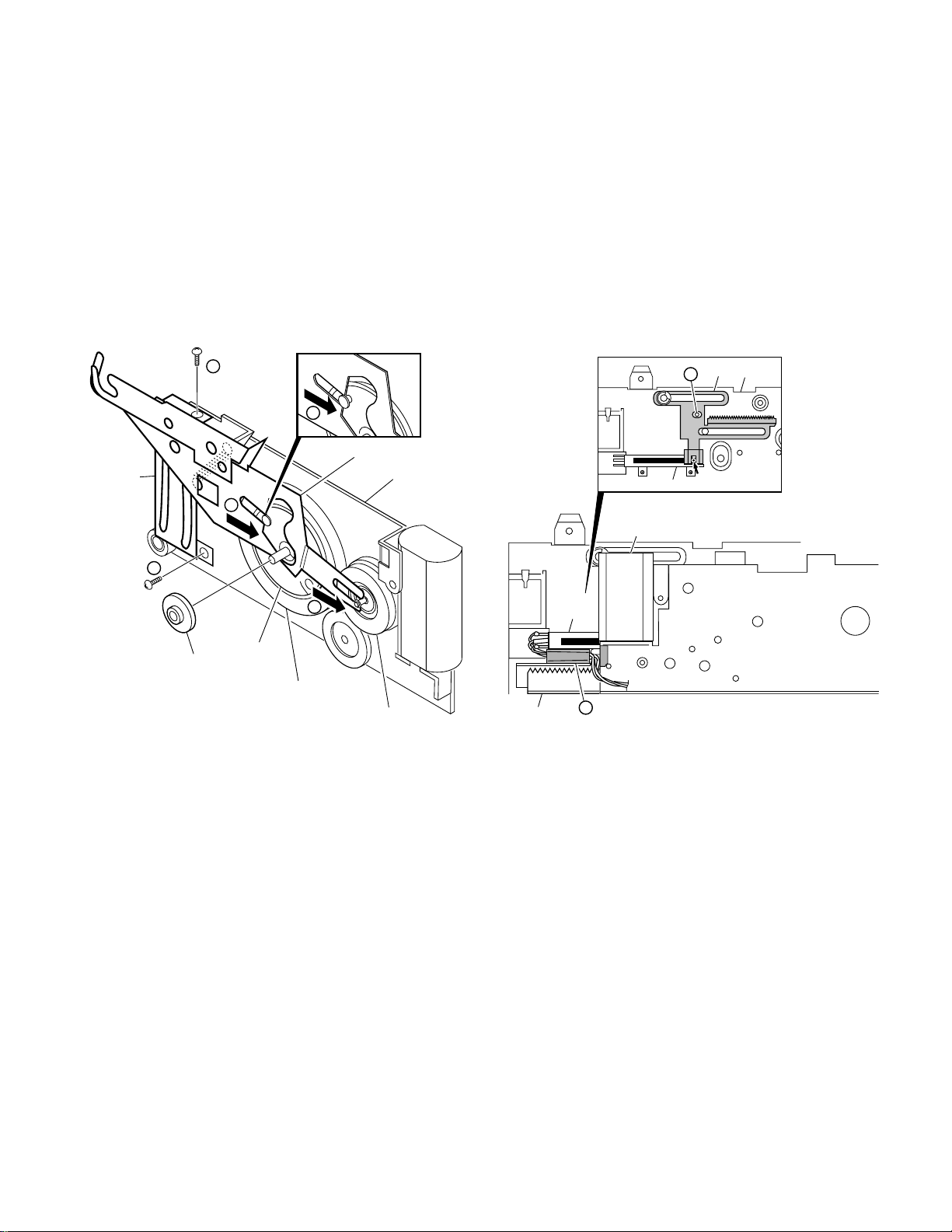

■ DOLBY Adjustment

Using the extension cord (W05-0755-00), separate the

mechanism from the unit. Play the TCC-130 and adjust the

test round value to 300mV with the VR1, 2 on the X30 Board.

(Refer to the PC BOARD.) Balance with FWD and REV.

■ Releasing the Security Code

The unit will go into release mode when Preset 6 is pressed

while Preset 1 is being pressed. The character “C” is displayed at the right end of the character display. At this point,

input KCAR by using 1, 2, 3, and 4 key of the remote controller. Confirm with PLAY/PAUSE key and the security code will

be released.

■

The bass boost function of the amplifier can be remote

control from the unit. This is a one-way communication, using one control line. The control is made with pulse widths of

the three kinds of communication data. Five cycle pulses are

generated from the unit side and when there are three consecutive successes, comm unication is established. The pulse

widths are as shown below and the cycle is 200ms.

HI: 100ms

LOW: 70ms

OFF: 40ms

Specifications for the Amplifier Control Terminal

11

11

A B C D E

1

2

3

4

5

6

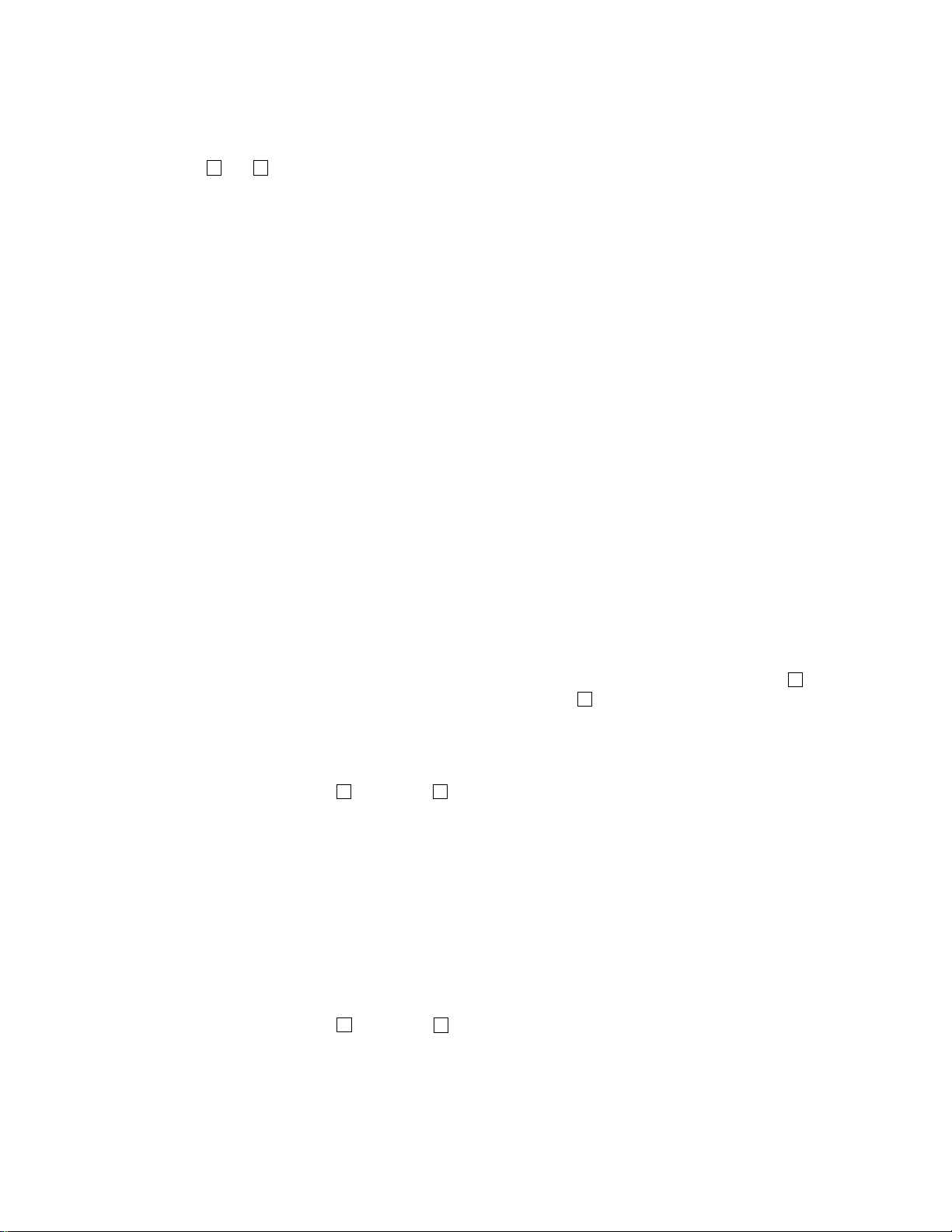

PC BOARD

(COMPONENT SIDE VIEW)

DOLBY NISE REDUCTION UNIT

X30-3000-00 (J74-0940-22)

BE

GND

L

Q5

14

D1

R19

BE

R18

BU

R27

CN2

2

J8

R13

24

J7

C15

1

23

R

J6

R16

J5

R10

C6

R17

J9

C10

R8

R1

1

C25

9

R15

J3

C8

R6

C1

Q4

J2

W2

R12

15

C20

11

10

C28

C4

R4

W4

2

8

J4

C12

W3

W1

C26

C2

R2

C19

CN3

20

1

W9

J1

R25

IC1

CN4

R23

Q1

EB

21

40

W5

R24

C22

R26

S1

C3

R3

D2

W8

R22

R21

C21

C16

C7

31

C23

EB

30

W7

C11

R14

C13

W6

10

R20

IC2

1

C18

C17

Q2

C9

R11

R9

C5

R7

C14

J10

R5

C27

Rch

VR2

VR1

Lch

(FOIL SIDE VIEW)

DOLBY NOISE REDUCTION UNIT

X30-3000-00 (J74-0940-22)

Q5

14

C20

W1

2

8

9

J2

J3

J4

W2

11

10

C8

R12

W3

C26

C28

C4

R4

W4

C1

51

EB

Q4

1

C10

R1

C25

R16

J5

R10

D1

BE

R18

R17

R15

J9

J6

R13

C6

J7

R8

R6

VR1

Lch

J10

10

1

R11

R9

C5

R7

VR2

R20

IC2

C14

R5

Rch

W6

C18

Q2

C9

C17

C27

R22

R21

C21

R14

C13

CN4

R24

C22

R23

C19

J1

D2

C23

CN3

C16

Q1

E

E

B

B

C12

R26

C7

30

31

R25

20

21

IC1

1

40

C11

S1

W9

W8

C3

C2

R2

R3

W5

W7

R19

CN2

J8

C15

2

24

R27

BU

1

GND

L

23

R

CN1

X30-3000-00

IC Q Address

15B

7

23B

14B

IC Q Address

24B

42B

52B

Refer to the schematic diagram f or the

values of resistors and capacitors.

X30-3000-00

CN1

IC Q Address

IC Q Address

15D

23D

14D

24D

42E

52E

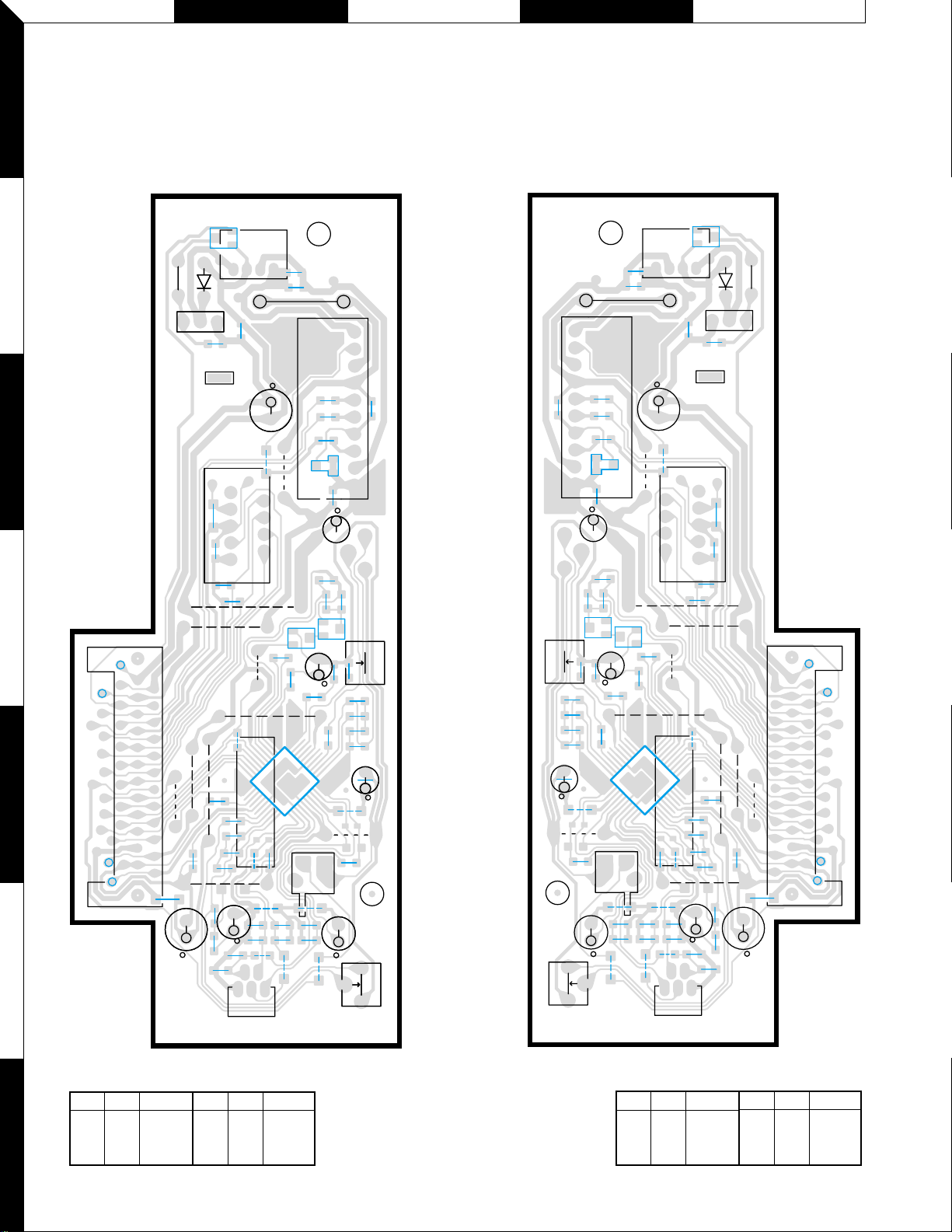

12

F G H I J K L M N O

1

2

3

4

5

6

7

PC BOARD (COMPONENT SIDE VIEW)

SYNTHESIZER UNIT

X14-602x-xx (J74-0920-52)

J1

16

8

C221

25

C220

24

C234

C235

D39

C222

R196

R195

IC12

EB

Q49

2

1

TH1

Q48

EB

R197

R207

R208

C38

14

IC3

R20

C15

C10

R19

R17

R23

C11

R22

R21

R24

2

Q15

R25

B

B

E

E

E

Q17

Q16

C32

Q22

B

D16

E

E

B

Q24

BE

Q25

R31

C42

R35

A1

15

1

B

C17

C20

C33

C31

B

Q23

C233

E

R32

7

1

D49

D42

D46

D44

D47

C14

C12

C9

C26

C24

R26

22

D14

BE

C35

C34

C47

2

C40

L1

C36

D48

C19

Q28

C21

CN3

C41

R10

D43

C16

EB

BEBE

D17

C7

C22

Q29

9

R199

D45

21

R34

R33

B

E

1

1

C27

R4

D9

R204

R42

Q14

Q27

D8

EB

Q26

D50

R13

D7

R198

Q50

C2

R203

D10

R43

D18

C8

Q9

Q13

R201

R202

C13

D11

C39

R14

L10

W1

BE

R200

C232

E

R36

D2

Q12

B

EB

C23

C151

C254

R306

1

D1

R12

C229

D3

IC18

IGO

C167

R305

C264

Q10

R18

C231

EB

C150

C263

Q54

Q53

D23

C1

R9

R27

R1

L29

R301

IC15

R259

EBE

EBE

R8

EB

Q11

Q1

C240

R7

C230

BE

X2

A2

D4

R41

D24

4

R3

C3

5

Q55

CN5

C6

C241

R219

R226

R233

C246

1

R16

R5

R2

C242

R218

C243

EBE

L5

C5

D6

R44

R6

C4

R212

R315

8

R249

Q5

E

Q2

BE

R227

R251

1

R239

C64

B

EB

R214

CP3

EB

Q52

C244

CP5

R234

R240

R53

L4

D40

R221

R325

Q4

EB

D5

R216

R211

R210

R326

R324

R222

R228

R328

R241

C66

L7

BE

Q3

R213

R248

R232

R323

30

R304

CP13

R242

R243

R244

C71

R247

1

31

R319

D25

Q6

C256

CP6

100

C255

C245

R220

R250

29

R238

R308

IC1

R246

R224

R229

C253

R245

C63

Q32

R215

R307

R309

R296

C74

R45

C73

EB

R312

R223

R314

R303

R318

R317

R253

EB

Q51

Q35

R237

C257

R310

R316

CP7

C72

L6

B

R51

BE

R50

R49

R217

R225

CP4

C248

R273

C262

C249

R298

R300

CP8

R252

R322

R327

4

31

B

CP14

81

R278

R311

R302

1

4

IC14

Q34

E

C261

80

R283

R282

R286

51

50

5

D41

E

R52

C77

Q33

C76

CP9

R284

R280

R276

R321

R313

IC16

5

Q60

C146

D26

C187

8

C177

C157

C212

D30

R90

5

C173

C158

R182

Q46

R91

R151

C145

C149

L20

D35

C216 C217

R190

R186

E

D38

C84

Q37

EB

C111

C110

C123

C185

C196

R160

R143

R162

R139

R137

C92

D34

R76

C91

R111

B

Q41

R109

C135

R40

C50

R183

B

R71

R166

R164

C190

E

R107

R191

R187

E

B

C82

Q38

BE

C116

23

C109

33

C108

C199

4

C194

C192

C93

R75

R110

BE

R106

25

Q36

BE

C214

C215

R189

R188

R285

C69

CN2

15

J3

D12

C210

R184 R185

R180

B

C218

D37

EB

R181

Q44

E

Q45

C211

242

14

C113

C75

R47

R46

R48

C68

C67

L8

123

C70

24

L9

C100

IC5

C101

C184

R136

R135

C155

L18

C104

C122

C153

L17

100

C56

1

R150

R142

C178

4

C176

R138

X1

C143

1

C189

IC10

C172

R113

31

L19

C166

C163

C114

L30

C179

30

1

C259

R320

8

C258

C247

EB

R231

R265

R275

CP12

Q59

R264

CP10

R268

R272

CP11

EB

R269

R271

C260

R274

R281

R279

L28

L27

R270

R277

C169

CP1

C251

C102

C103

R144

R134

C168

CP2

C165

C182

C159

C252

C124

R152

R140

L12

C140

4

C180

C174

C170

L14

C141

C164

1

L13

80

CP16

C188

51

IC9

C175

50

28

C186

R153

C171

C148

C152

C142

C160

C161

81

C105

8

5

C154

C144

R114

L16

C106

C125

C183

R145

C181

R141

L15

R112

C156

IC8

C162

D15

D13

C219

C213

Q47

C88

C83

R63

D27

R65

C85

C86

D32

R95

D33

R94

C117

22

C119

IC2

R92

C198

C107

1

8

R167

IC11

R165

5

C195

C193

C191

R77

C90

C94

18

IC13

C133

4

C132

R100

Q42

C128

5

R102

R108

C134

8

R104

C130

C55

C52

IC17

C53

1

D21

R69

C81

C118

12

4434

C197

R161

R163

IC7

5

R61

D29

R96

19

C51

R64

R66

R67

R68

C87

C121

11

1

C112

C95

C126

R101

4

R105

1

C131

CN1

C54

13

C120

D36

C129

R103

14

R62

J2

C96

D31

C127

R60

R70

D28

X14-602x-xx

IC Q Address

15I

24L

34G

54K

76L

86K

95K

10 5K

11 5L

12 3G

13 6L

14 6J

15 6I

16 6J

17 7L

18 5H

14I

24I

33I

53I

63I

93H

10 3H

11 3H

12 5H

13 5H

14 5H

15 5G

16 5G

17 5G

IC Q Address

23 5G

24 5G

25 5G

26 6H

27 5H

28 5G

29 5G

32 3I

33 3J

34 2J

35 2J

36 7L

37 3K

38 3L

41 6K

42 6L

44 2K

45 2K

46 2K

47 2L

48 4G

49 3G

50 4H

51 6I

52 5I

53 6H

54 6H

55 6I

59 6J

60 6J

22 5G

Refer to the schematic diagram for the values of resistors and capacitors.

14

Loading...

Loading...