Kenwood DPSE-9 Service manual

COMPACT DISK PLAYER

60

repeat 7

¢4

1 ¡

timespace

compact disc player DP-SE7

on/standby

D.R.I.V.E.

'

OPTICAL

SYSTEM

CONTROL

DIGITAL OUT

PLAY OUT

R

L

DP-SE7/SE7(G)/SE9

SERVICE MANUAL

(HM-701)

©1997-10/B51-5371-00 (K/K) 3191

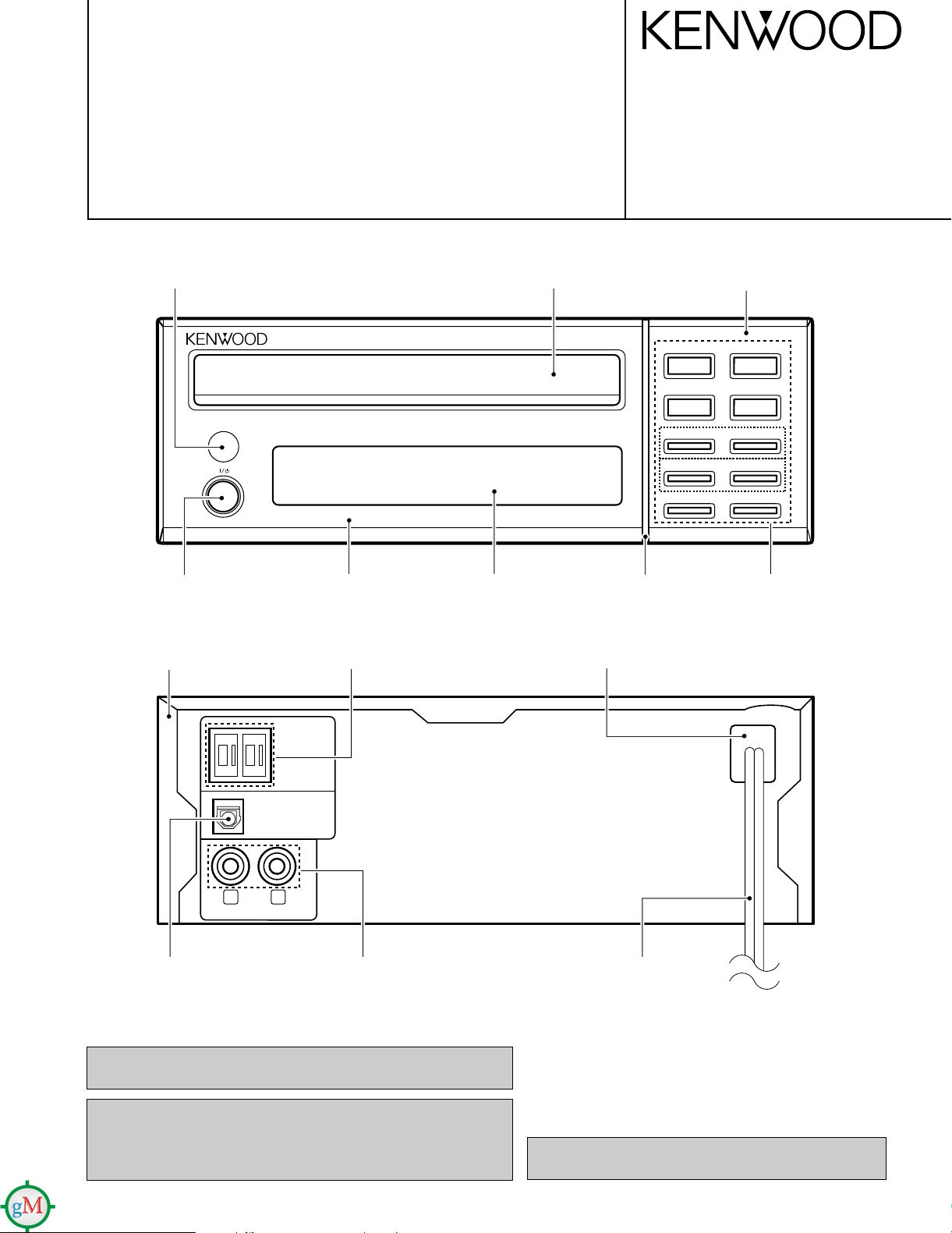

Indicator

(B12-0318-04)

Knob

(K29-6744-04)

Metallic cabinet

(A01-3321-01)

Panel *

(A60-)

Rectangular receptacle

(E08-0312-05)

Panel

(A29-0872-03)

Front glass

(B10-2372-03)

Escutcheon

(B07-2363-04)

Power cord bushing

(J42-0083-05)

Panel *

(A60-)

Knob

(K29-6743-03)

Oscillating module

(W02-1114-05)

Phono jack

(E63-0122-05)

In compliance with Federal Regulations, following are reproductions of

labels on, or inside the product relating to laser product safety.

KENWOOD-Crop. certifies this equipment conforms to DHHS Regulations

No. 21 DFR 1040. 10, Chapter 1, Subchapter J.

DANGER : Laser radiation when open and interlock defeated.

AVOID DIRECT EXPOSURE TO BEAM

AC power cord *

(E30-)

Illustration is DP-SE7Mtype.

* Refer to parts list on page 17.

Refer to DP-SA7 service manual (B51-5243-00) if you require

Disassembly for repair in detail.

DP-SE7/SE7(G)/SE9

CONTENTS / EXTERNAL VIEW

Contents

CONTENTS / EXTERNAL VIEW............................... 2

CIRCUIT DESCRIPTION............................................3

ADJUSTMENT............................................................6

PC BOARD ................................................................ 7

SCHEMATIC DIAGRAM............................................ 9

EXPLODED VIEW ....................................................15

PARTS LIST..............................................................17

SPECIFICATIONS ......................................Back cover

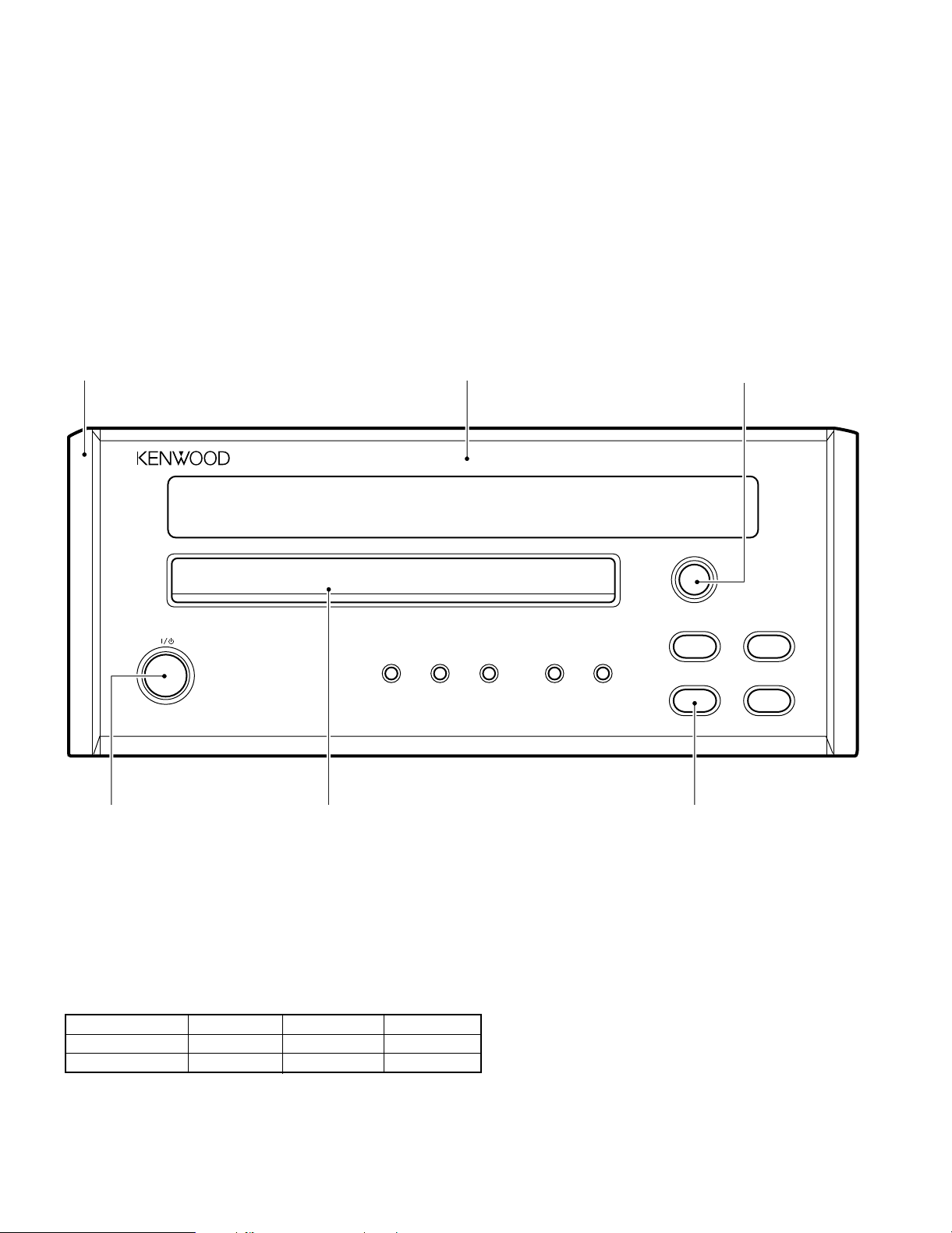

Side plate

(A50-1303-12)

on/standby

compact disc player

Panel

(A60-1266-02)

DP-SE9

'

time space repeat 1 ¡

D.R.I.V.E. with 24 bit D/A conversion

24 bit fine D.R.I.V.E.

Knob

(K29-6742-04)

0

7

4 ¢

6

Knob

(K29-6741-04)

Panel

(A29-0871-03)

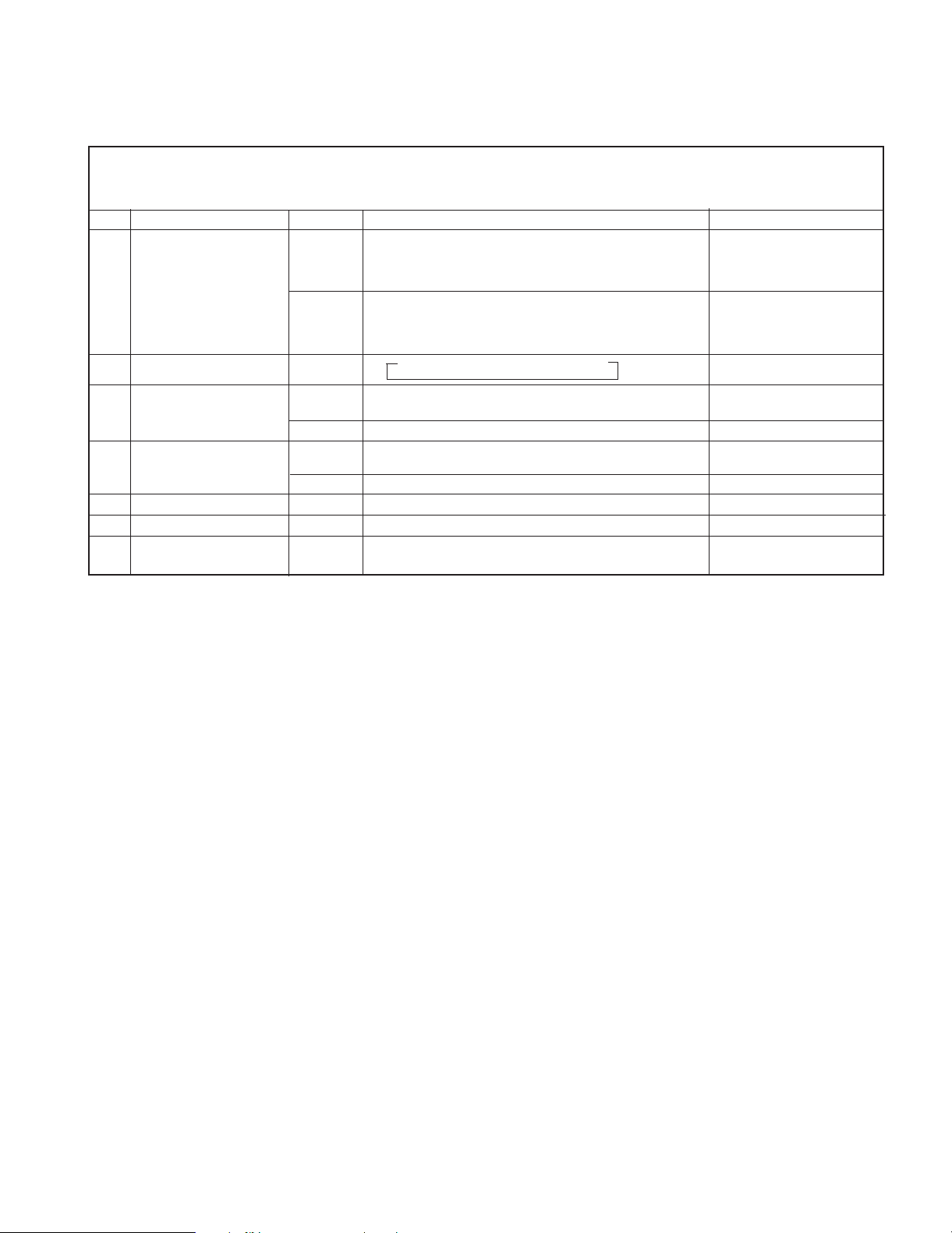

System configuration

SYSTEM NAME RECEIVER CD PLAYER SPEAKER

HM-701 R-SE7 DP-SE7 LS-SE7

HM-901 R-SE9 DP-SE9 LS-SE9

2

Knob

(K29-6766-04)

Illustration is DP-SE9.

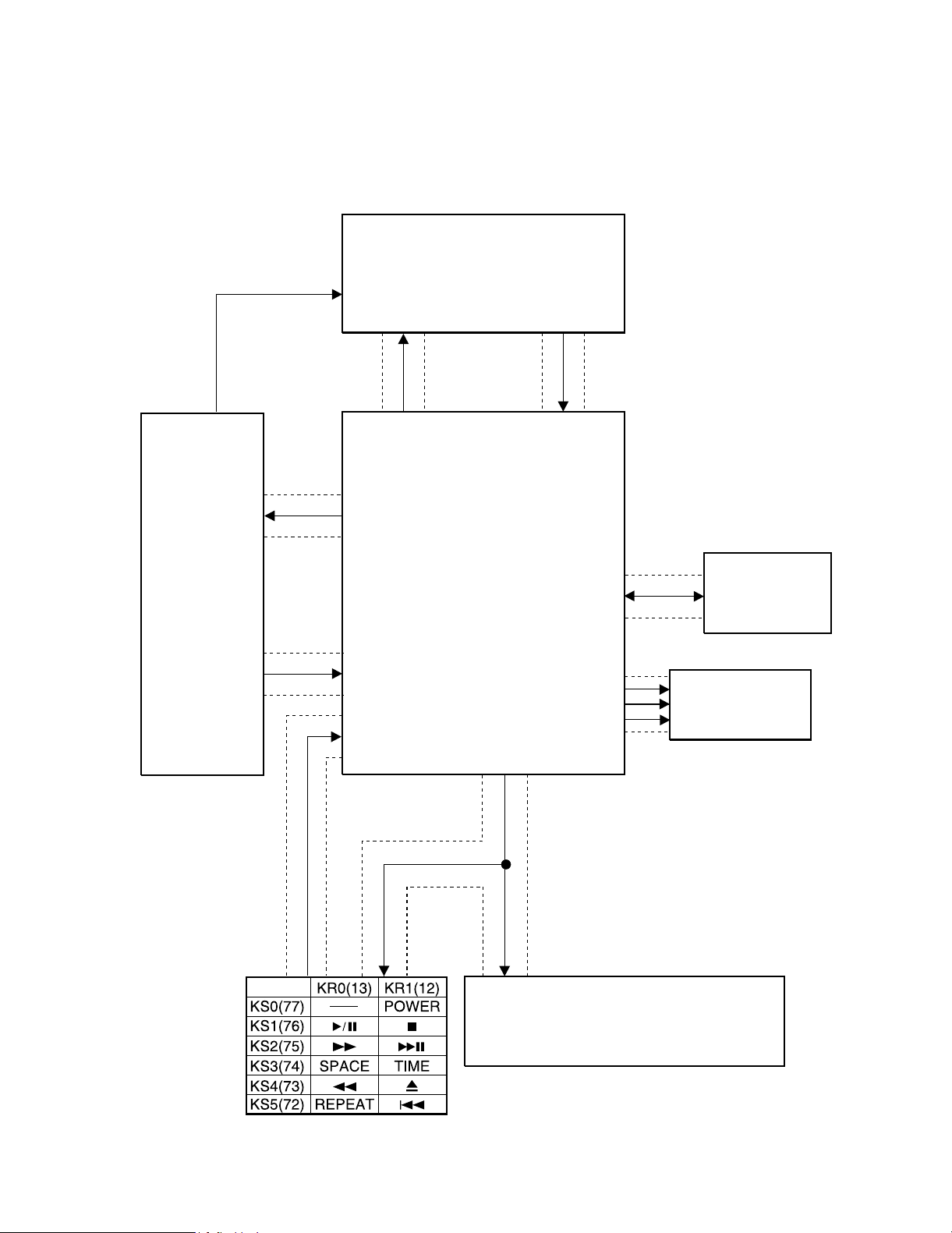

CIRCUIT DESCRIPTION

(X32) IC2

KAN03

213BGN

8-BT-207GK

µPD78044FGF

SDATA

SBUSY

(X25) IC5

CLK, DTA, LAT

S. CLK M. ON

MUTE XLON

SENSE

SCOR

SUBQ

(SLTSW)

(FOK , GFS)

SGATE

SCK

SDT

KR0,KR1

SLT SW

Seg key scm pin

KSL-

CD mecha

MOTOR CONTROL

TERMINAL

SWITCH INPUT

X 2

KEY INPUT

X 2

GRID X 8

SEGMENT X 12

SYSTEM

SERIAL

SIGNAL

D.S.P.

CXD 2507AQ

6

KEY MATRIX

1. Microprocessor

1-1. Microprocessor periphery block diagram

DP-SE7/SE7(G)/SE9

3

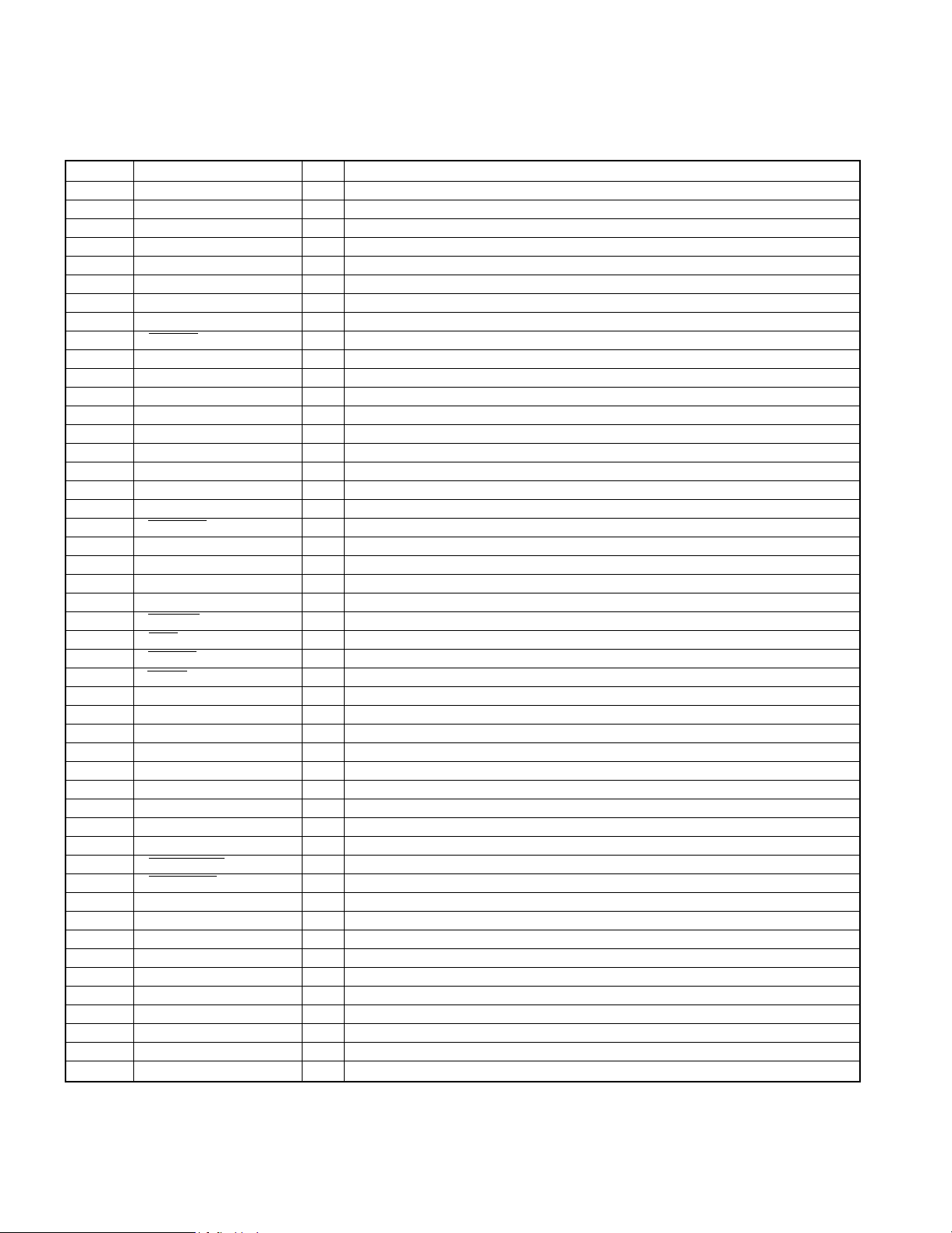

DP-SE7/SE7(G)/SE9

CIRCUIT DESCRIPTION

1-2 Pin description

(uPD78044FGF-071 : X25, IC4)

PIN No. PIN NAME I/O DESCRIPTION

1~7 Grid 2G~8G O FL Digit control (Grid 2G~8G)

8 Vdd O Power supply (+5)

9 SQCK O Q-data read clock output.

10 STBY O Not use (OPEN)

11 SUBQ I Q-data (or SLT SW) input

12 KR 1 I Key return input 1

13 KR 0 I Key return input 0

14~16 NC I Not use (PULL DOWN)

17 RESET I Reset input

18, 19 NC I Not use (PULL DOWN)

20 AVss – Not use (GND)

21~24 NC I Not use (PULL DOWN)

25 SDT O Enable output to KAN03

26 SCK O Clock output to KAN03

27 S GATE O Data output for KAN03

28 NC I Not use

29 AVdd – Not use (+5V)

30 AVref – Not use (GND)

31 DEFECT I Scratch disk compel sat

32 XT2 – Not use (OPEN)

33 Vss – GND

34 X1 I System clock

35 X2 – System clock

36 RMUTE O Analog mute

37 CLK O CXD2507AQ clock output

38 LATCH O CXD2507AQ latch output

39 DATA O CXD2507AQ data output

40 SENSE I SENSE/GFS/F.OK input

41 D.S O Not use

42 S.DATA I/O Serial DATA I/O

43 S.BUSY I/O Serial BUSY I/O

44 SCOR I Sub-code synch detect

45 NC I Not use (PULL DOWN)

46 M.ON O Focus lock compensation

47 REMOCON I REMOCON

48 Vpp – GND

49 CLOSE SW I Tray close (L : close)

50 OPEN SW I Tray open (L : open)

51 NC I Not use (PULL DOWN)

52 Vdd – Power supply (+5V)

53 OPEN MOTOR O Motor [OPEN] (H : OPEN/T.U.DOWN)

54 CLOSE MOTOR O Motor [CLOSE] (H : CLOSE/T.U.UP)

55~64 NC O Not use (OPEN)

65~70 Sa~Sf O FL Segment (SEG Sa~Sf)

71 Vlord – FL driver power supply (-30V)

72~77 SEG Sg~Sl/KS 5~0 O FL Segment Sg~Sl and key scan (KS5~KS0)

78, 79 NC O Not use (open)

80 GRID 1G O FL digit (Grid 1G)

4

DP-SE7/SE7(G)/SE9

CIRCUIT DESCRIPTION

2. Test mode

MODE "0 0" : Use for Test or alignment

Setting the test mode : While pressing the "REPEAT" key, plug the AC cord

into wall output.

No. Key Display Operation Remarks

(1)Focus servo.........................................ON

03 (2) Tracking servo ....................................OFF

1 PLAY/ PAUSE (3) Feed servo .........................................OFF

6 (1) Focus servo.........................................ON

05 (2) Tracking servo.....................................ON

(3) Feed servo..........................................ON

2 UP ¢

3 FB 1

4 FF ¡ 01 Pick manual feed(inside = outside)

5 STOP 7 01 Pick-up initialize

6 OPEN / CLOSE 0 Tray open / close

7 DOWN 4 01

01 Pick manual feed (outside = inside)

05 FB operation is available

05 FF operation is available

All display ON = All display OFF

Cancel the test mode, and

return to normal mode.

TE-adjustment

F-GAIN / T-GAIN

FE-B adjustment

Stop mode only

Time display goes off

Stop mode only

Time display goes off

Play track No.01

5

DP-SE7/SE7(G)/SE9

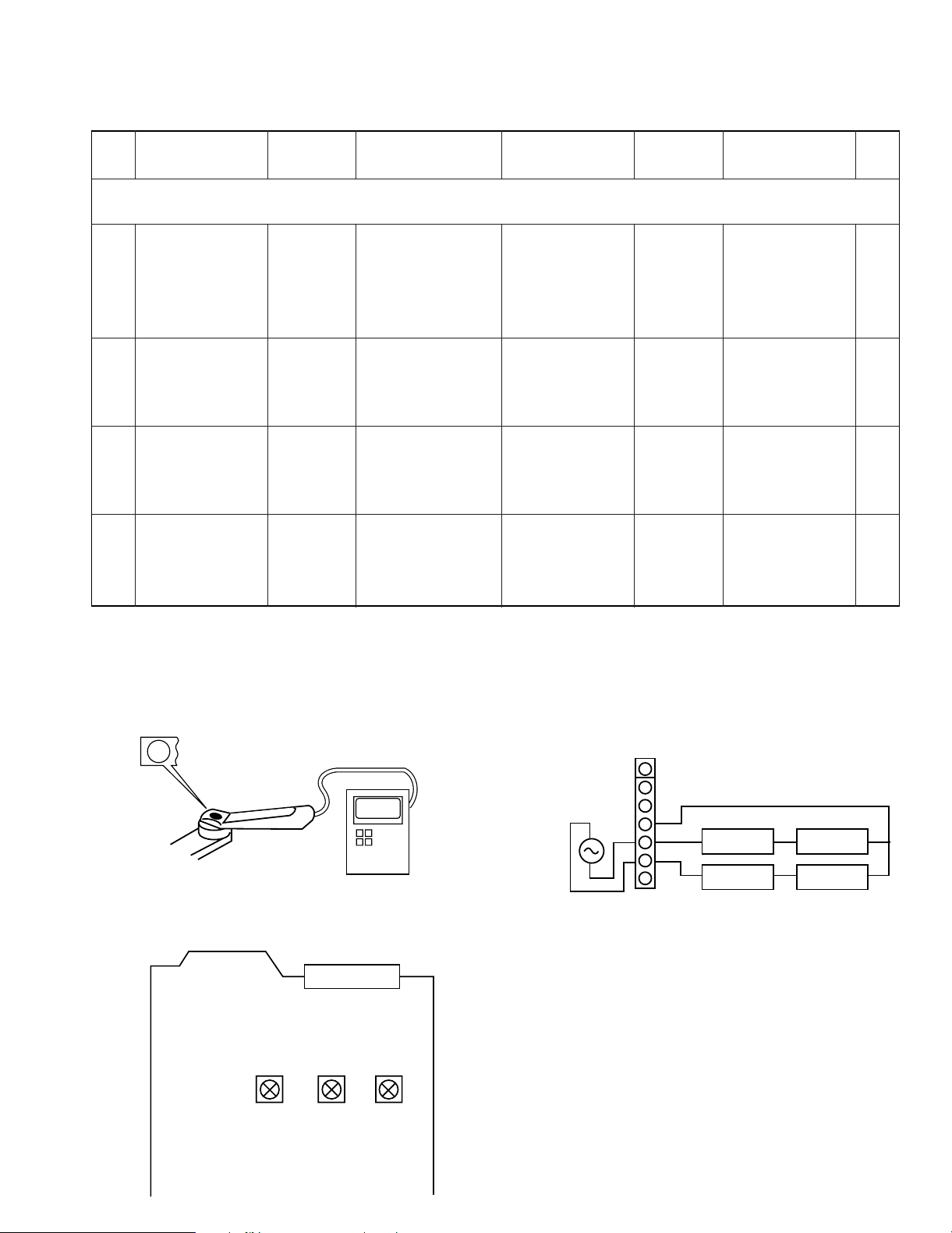

ADJUSTMENT

No. ITEM

While pressing the "REPEAT" key, turn the AC ON.

{ Refer to test mode (MODE 0 0) }

1 LASER POWER

FOCUS ERROR

2

3

Note:

Type 4 disc : SONY YEDS-18 Test Disc or equivalent.(KTD-0

LPF: Around 47 kΩ+ 390 pF or so.

Step 1~4 are in Test Mode.

BIAS

TRACKING ERROR

BALANCE

INPUT

SETTINGS

−

Test disc

Type 4

Test disc

Type 4

Test disc

Type 4

Apply signal of

1.2 kHz,

50mVrms to

CN3 pin 5-6.

OUTPUT

SETTINGS

Apply the sensor section

of optical power meter

on the pickup lens.

Connect an oscilloscope

as follows.

CH1 : RF (CN3 pin 1)

CH2 : TE (CN3 pin 6)

Connect an oscilloscope

as follows.

CH1 : RF (CN3 pin 1)

CH2 : TE (CN3 pin 6)

Connect a LPF to CN3

pin 5-6 to which you

connect an oscilloscope

or AC voltmeters.

✽)

PLAYER

SETTINGS

Press the

PLAY/PAUSE key,

then confirm that the

LED is "03".

Press the

/PAUSE

PLAY

then confirm that the

LED is "05".

Press the

PLAY/PAUSE key,

then confirm that the

LED

Press the

PLAY/PAUSE key,

then confirm that the

LED

key,

is "03".

is "05".

ALIGNMENT

POINTS

−

FE BIAS

VR2

TE BALANCE

VR1

TRACKING

GAIN

VR3

ALIGN

FOR

On the power from

0.08 to 0.15 mW,

when the diffraction

grating is correctly

aligned with the RF

level of 0.6 Vp-p or

more.

Optimum eye pattern

Symmetry between

upper and lower

patterns

Two VTVMs should

read the same value.

FIG.

(a)

(e)4 TRACKING GAIN

Pickup

ALIGNMENT POINTS

T-GAIN

VR3 VR1 VR2

0.08 ~ 0.15 mW

Optical power meter

CN1

TE-B FE-B

(e)Tracking gainn(a)Laser power

1.2 kHz

50 mVrms

CN3

1

RF

2

FE1

FE2

3

_

+

VC

4

TE2

5

TE1

6

7

S.S

L.P.F.

L.P.F.

VC

+

VTVM

+

VTVM

6

Loading...

Loading...