Kent Euroclean Razor SV17 Operation Manual

Razor SV17

Simple. Clean.

INSTRUCTION FOR USE

KENT model: 908 7112 020

INSTRUCTIONS D’UTILISATION

Modèle KENT: 908 7112 020

INSTRUCCIONES DE USO

Modelo KENT: 908 7112 020

INSTRUÇÕES DE USO

Modelo KENT: 908 7112 020

ENGLISH

FRANÇAIS

ESPAÑOL

PORTUGUÊS

909 6309 000(3)2009-11

INSTRUCTIONS FOR USE

ENGLISH

TABLE OF CONTENTS

INTRODUCTION .............................................................................................................................................................. 2

MANUAL PURPOSE AND CONTENTS .......................................................................................................................................... 2

TARGET ........................................................................................................................................................................................... 2

HOW TO KEEP THIS MANUAL ....................................................................................................................................................... 2

IDENTIFICATION DATA ................................................................................................................................................................... 2

OTHER REFERENCE MANUALS ................................................................................................................................................... 2

SPARE PARTS AND MAINTENANCE ............................................................................................................................................. 2

CHANGES AND IMPROVEMENTS ................................................................................................................................................ 2

OPERATION CAPABILITIES ........................................................................................................................................................... 2

CONVENTIONS .............................................................................................................................................................................. 2

UNPACKING/DELIVERY ................................................................................................................................................. 3

SAFETY ...........................................................................................................................................................................3

SYMBOLS ....................................................................................................................................................................................... 3

GENERAL INSTRUCTIONS ............................................................................................................................................................ 3

MACHINE DESCRIPTION ............................................................................................................................................... 5

MACHINE STRUCTURE ................................................................................................................................................................. 5

CONTROL PANEL ........................................................................................................................................................................... 7

ACCESSORIES/OPTIONS .............................................................................................................................................................. 7

TECHNICAL DATA ........................................................................................................................................................................... 8

WIRING DIAGRAM .......................................................................................................................................................................... 9

USE ................................................................................................................................................................................ 10

BATTERY CHECK/SETTING ON A NEW MACHINE .................................................................................................................... 10

GEL BATTERY SETTING, INSTALLATION AND CHARGING ...................................................................................................... 10

BEFORE MACHINE START-UP .....................................................................................................................................................11

MACHINE START AND STOP ....................................................................................................................................................... 12

MACHINE OPERATION (SCRUBBING/DRYING) ......................................................................................................................... 13

MACHINE TRANSPORT/PARKING .............................................................................................................................................. 14

TANK EMPTYING .......................................................................................................................................................................... 14

AFTER USING THE MACHINE ..................................................................................................................................................... 14

RECOVERY TANK REMOVAL ...................................................................................................................................................... 15

MACHINE LONG INACTIVITY ...................................................................................................................................................... 15

FIRST PERIOD OF USE ............................................................................................................................................................... 15

MAINTENANCE ............................................................................................................................................................. 16

SCHEDULED MAINTENANCE TABLE ......................................................................................................................................... 16

SQUEEGEE CLEANING ............................................................................................................................................................... 17

SQUEEGEE BLADE CHECK AND REPLACEMENT .................................................................................................................... 17

BRUSH CLEANING ....................................................................................................................................................................... 18

TANK AND VACUUM GRID CLEANING .......................................................................................................................................18

SOLUTION FILTER CLEANING .................................................................................................................................................... 19

MACHINE SPEED ADJUSTMENT ................................................................................................................................................ 19

BATTERY CHARGING .................................................................................................................................................................. 20

FUSE CHECK/REPLACEMENT .................................................................................................................................................... 21

TROUBLESHOOTING ................................................................................................................................................... 22

SCRAPPING .................................................................................................................................................................. 22

Razor SV17 909 6309 000(3)2009-11

1

ENGLISH

INSTRUCTIONS FOR USE

2

909 6309 000(3)2009-11 Razor SV17

INTRODUCTION

NOTE

The numbers in brackets refer to the components shown in Machine Description chapter.

MANUAL PURPOSE AND CONTENTS

The purpose of this Manual is to provide the operator with all necessary information to use the machine properly, in a safe and

autonomous way. It contains information about technical data, operation, machine inactivity, maintenance, spare parts and safety

conditions.

Before carrying out any procedure on the machine, the operators and qualied technicians must read this Manual carefully. Contact

an authorized KENT Service Center in case of doubts regarding the interpretation of the instructions and for any further information.

TARGET

This Manual is intended for operators and technicians qualied to perform the machine maintenance.

The operators must not perform procedures reserved for qualied technicians. KENT will not be answerable for damages coming

from the non-observance of this prohibition.

HOW TO KEEP THIS MANUAL

The Instructions for Use Manual must be kept near the machine, inside an adequate case, away from liquids and other substances

that can cause damage to it.

IDENTIFICATION DATA

The machine model and serial number are marked on the label and can be read from the outside (1).

The machine model year is shown after the Date Code on the serial plate (A09 means January 2009).

This information is useful when requiring machine spare parts. Use the following table to write down the machine identication data

for any further reference.

MACHINE model ...............................................................................

MACHINE serial number ...................................................................

OTHER REFERENCE MANUALS

Electronic Battery Charger Manual, which is to be considered as integral part of this Manual. –

Spare Parts List (supplied with the machine) –

Service Manual (that can be consulted at KENT Service Centers) –

SPARE PARTS AND MAINTENANCE

All necessary operating, maintenance and repair procedures must be carried out by qualied personnel or by KENT Service

Centers. Only original spare parts and accessories must be used.

Call KENT for service or to order spare parts and accessories, specifying the machine model and serial number.

CHANGES AND IMPROVEMENTS

KENT constantly improves its products and reserves the right to make changes and improvements at its discretion without being

obliged to apply such benets to the machines previously sold.

Any change and/or addition of accessories must be approved and performed by KENT.

OPERATION CAPABILITIES

These scrubber-dryers are used to clean (scrubbing and drying) smooth and solid oors, in civil or industrial environment, under

safe operation conditions by a qualied operator.

The scrubber-dryers cannot be used for moquette and carpet cleaning.

CONVENTIONS

Forward, backward, front, rear, left or right are intended with reference to the operator position, that is to say with the hands on the

handlebar (2).

INSTRUCTIONS FOR USE

ENGLISH

Razor SV17 909 6309 000(3)2009-11

3

UNPACKING/DELIVERY

To unpack the machine, carefully follow the instructions on the packing.

When the machine is delivered, check that the packing and the machine were not damaged during transportation.

In case of visible damages, keep the packing and have it checked by the carrier that delivered it. Call the carrier immediately to ll

in a damage claim.

Please check that the following items have been supplied with the machine:

Technical documents: –

Scrubber-dryer Instructions for Use•

Electronic Battery Charger Manual•

Scrubber-dryer Spare Parts List•

No. 1 40 A lamellar fuse –

No. 4 battery terminal caps –

SAFETY

The following symbols indicate potentially dangerous situations. Always read this information carefully and take all necessary

precautions to safeguard people and property.

The operator’s cooperation is essential in order to prevent injury. No accident prevention program is effective without the total

cooperation of the person responsible for the machine operation. Most of the accidents that may occur in a factory, while working

or moving around, are caused by failure to comply with the simplest rules for exercising prudence. A careful and prudent operator is

the best guarantee against accidents and is essential for successful completion of any prevention program.

SYMBOLS

DANGER!

It indicates a dangerous situation with risk of death for the operator.

WARNING!

It indicates a potential risk of injury for people.

CAUTION!

It indicates a caution or a remark related to important or useful functions.

Pay careful attention to the paragraphs marked by this symbol.

NOTE

It indicates a remark related to important or useful functions.

CONSULTATION

It indicates the necessity to refer to the Instructions for Use before performing any procedure.

GENERAL INSTRUCTIONS

Specic warnings and cautions to inform about potential damages to people and machine are shown below.

DANGER!

Before performing any maintenance, repair, cleaning or replacement procedure, turn the main switch to “0” –

and, if necessary, disconnect the battery.

This machine must be used by properly trained operators only. Children or disabled people cannot use this –

machine.

Do not wear jewelry when working near electrical components. –

Do not operate the machine near toxic, dangerous, ammable and/or explosive powders, liquids or vapors: –

This machine is not suitable for collecting dangerous powders.

During battery charging, remove the recovery tank and perform this procedure in well-ventilated areas and –

away from bare ames.

ENGLISH

INSTRUCTIONS FOR USE

4

909 6309 000(3)2009-11 Razor SV17

WARNING!

Before using the battery charger, ensure that frequency and voltage values, indicated on the machine serial –

number plate, match the electrical mains voltage.

Do not pull or carry the machine by the battery charger cable and never use the battery charger cable as –

a handle. Do not close a door on the battery charger cable, or pull the battery charger cable around sharp

edges or corners. Do not run the machine on the battery charger cable. Keep the battery charger cable away

from heated surfaces.

Do not charge the batteries if the battery charger cable or the plug are damaged. If the machine is not –

working as it should, has been damaged, left outdoors or dropped into water, return it to the Service Center.

To reduce the risk of re, electric shock, or injury, do not leave the machine unattended when it is plugged –

in. Before performing any maintenance procedure, disconnect the battery charger cable from the electrical

mains.

Do not smoke while charging the batteries. –

Do not leave the machine unattended without being sure that it cannot move independently. –

Always protect the machine against the sun, rain and bad weather, both under operation and inactivity –

condition. Store the machine indoors, in a dry place: This machine must be used in dry conditions, it must

not be used or kept outdoors in wet conditions.

Before using the machine, close all doors and/or covers. –

Do not allow to be used as a toy. Close attention is necessary when used near children. –

Use only as shown in this Manual. Use only KENT recommended accessories. –

Take all necessary precautions to prevent hair, jewelry and loose clothes from being caught by the machine –

moving parts.

Do not leave the machine unattended without being sure that it cannot move independently. –

Do not use the machine on slopes with a gradient exceeding the specications. –

While using this machine, take care not to cause damage to people or objects. –

Do not bump into shelves or scaffoldings, especially where there is a risk of falling objects. –

Do not put any can containing uids on the machine. –

The machine working temperature must be between +32°F and +104°F (0°C and +40°C). –

The machine storage temperature must be between +32°F and +104°F (0°C and +40°C). –

The humidity must be between 30% and 95%. –

When using oor cleaning detergents, follow the instructions on the labels of the detergent bottles. –

To handle oor cleaning detergents, wear suitable gloves and protections. –

Do not use the machine as a means of transport. –

Do not use the machine on incline. –

Do not allow the brushes to operate while the machine is stationary to avoid damaging the oor. –

In case of re, use a powder re extinguisher, not a water one. –

Do not tamper with the machine safety guards and follow the ordinary maintenance instructions –

scrupulously.

Do not allow any object to enter into the openings. Do not use the machine if the openings are clogged. –

Always keep the openings free from dust, hairs and any other foreign material which could reduce the air

ow.

Do not remove or modify the plates afxed to the machine. –

This machine cannot be used on roads or public streets. –

Pay attention during machine transportation when temperature is below freezing point. The water in the –

recovery tank or in the hoses could freeze and seriously damage the machine.

Use the brushes and pads supplied with the machine and those specied in the Instructions for Use Manual. –

Using other brushes or pads could reduce safety.

In case of machine malfunctions, ensure that these are not due to lack of maintenance. Otherwise, request –

assistance from the authorized personnel or from an authorized Service Center.

If parts must be replaced, require ORIGINAL spare parts from an Otherwise Dealer or Retailer. –

To ensure machine proper and safe operation, the scheduled maintenance shown in the relevant chapter of –

this Manual, must be performed by the authorized personnel or by an authorized Service Center.

Carefully read all the instructions before performing any maintenance/repair procedure. –

Do not wash the machine with direct or pressurized water jets, or with corrosive substances. –

The machine must be disposed of properly, because of the presence of toxic-harmful materials (batteries, –

etc.), which are subject to standards that require disposal in special centers (see Scrapping chapter).

INSTRUCTIONS FOR USE

ENGLISH

Razor SV17 909 6309 000(3)2009-11

5

14

13

32

30

31

6

3

19

2

17

16

25

26

18

24

23 10

9

8

13

14

15

11

15

12

22

7

4

5b

5a

1

21

27

28

29

23a

23b

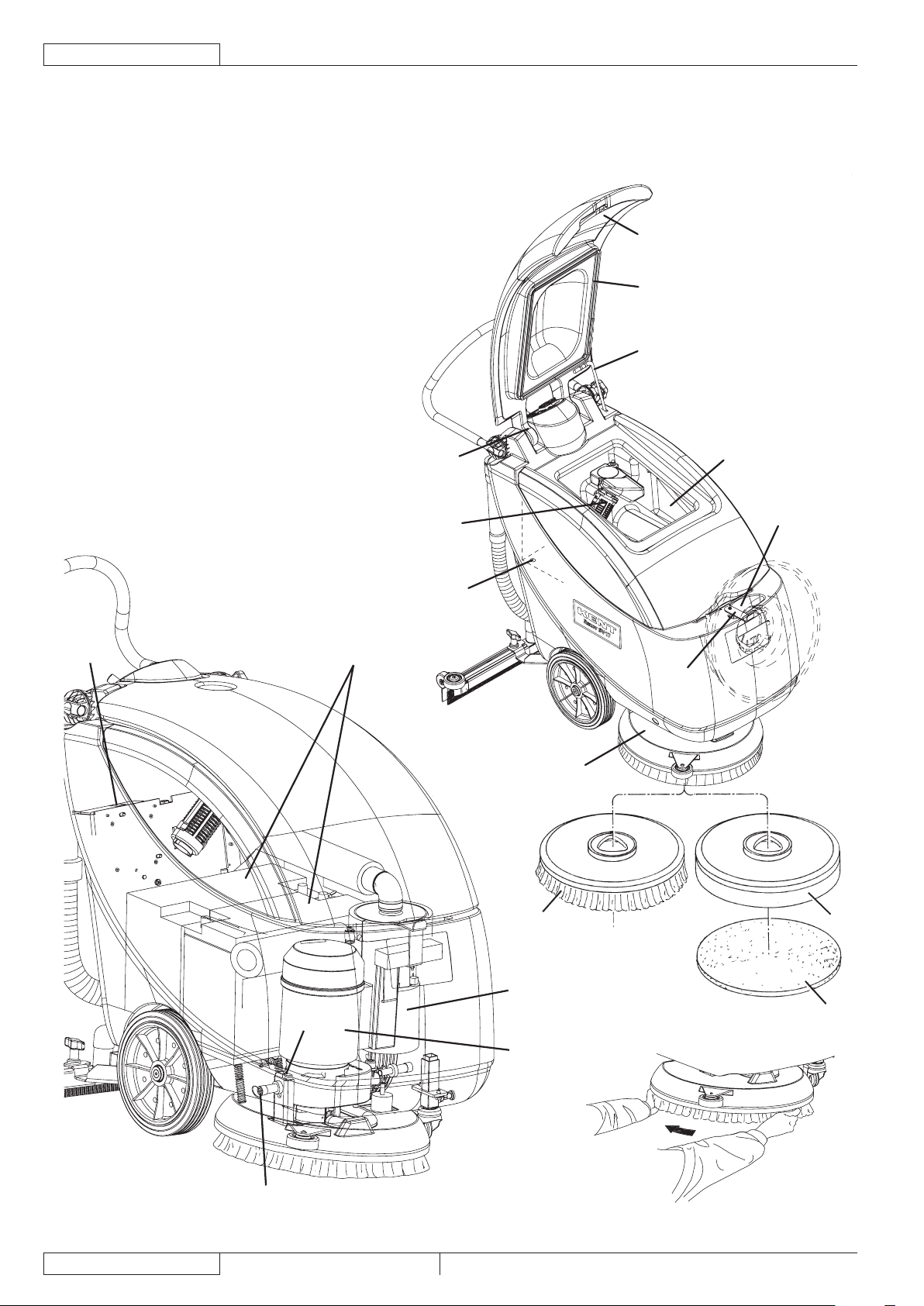

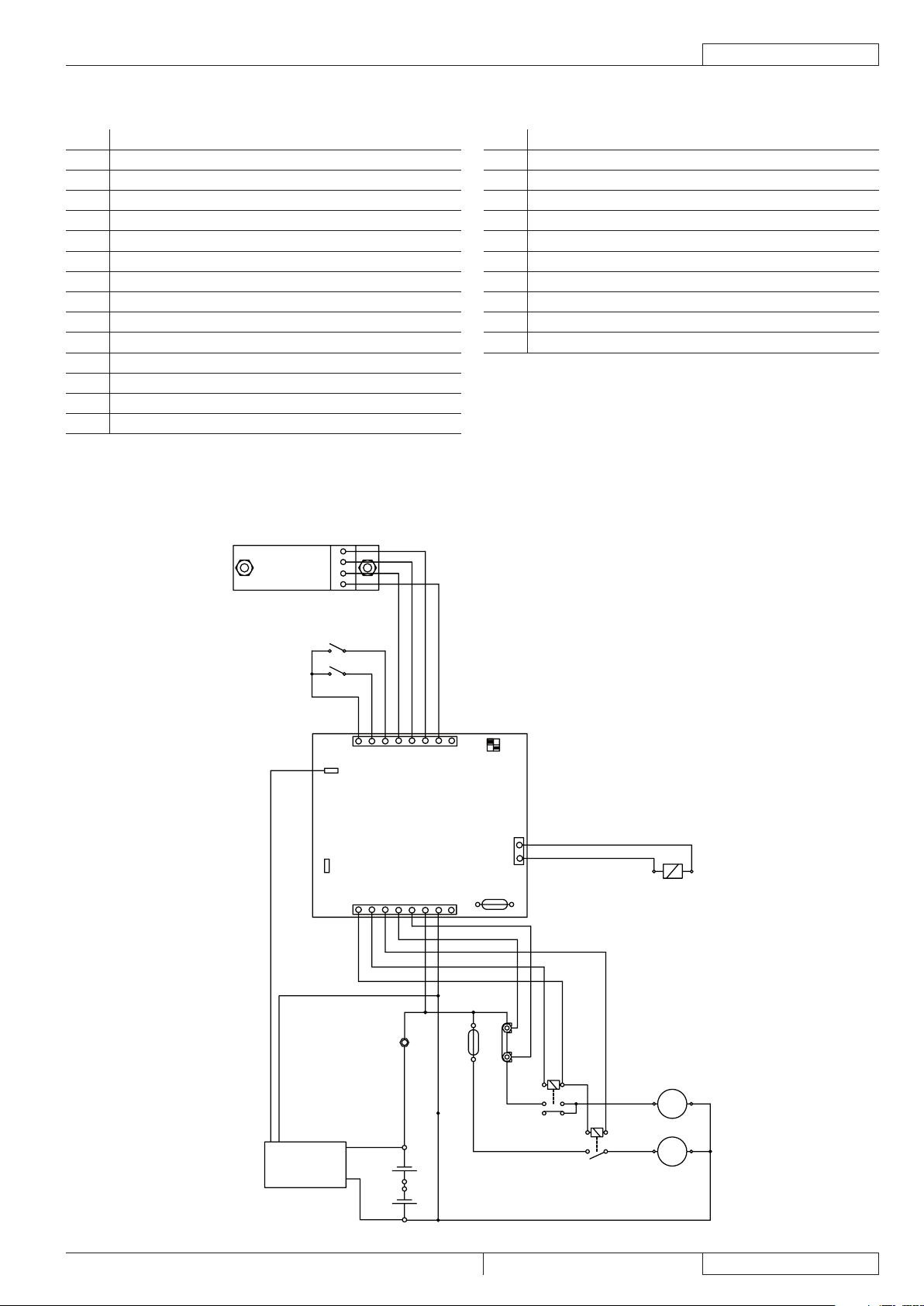

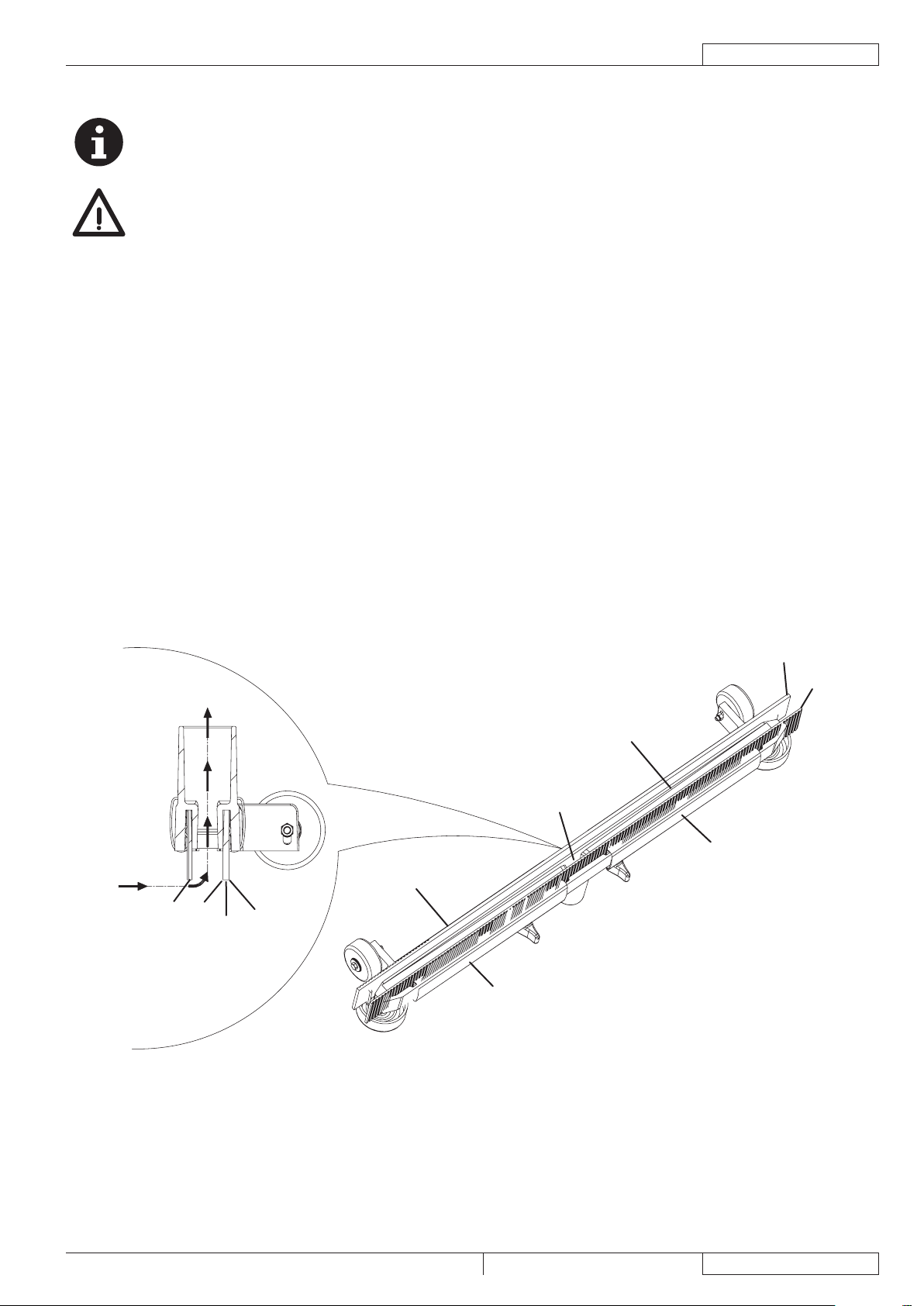

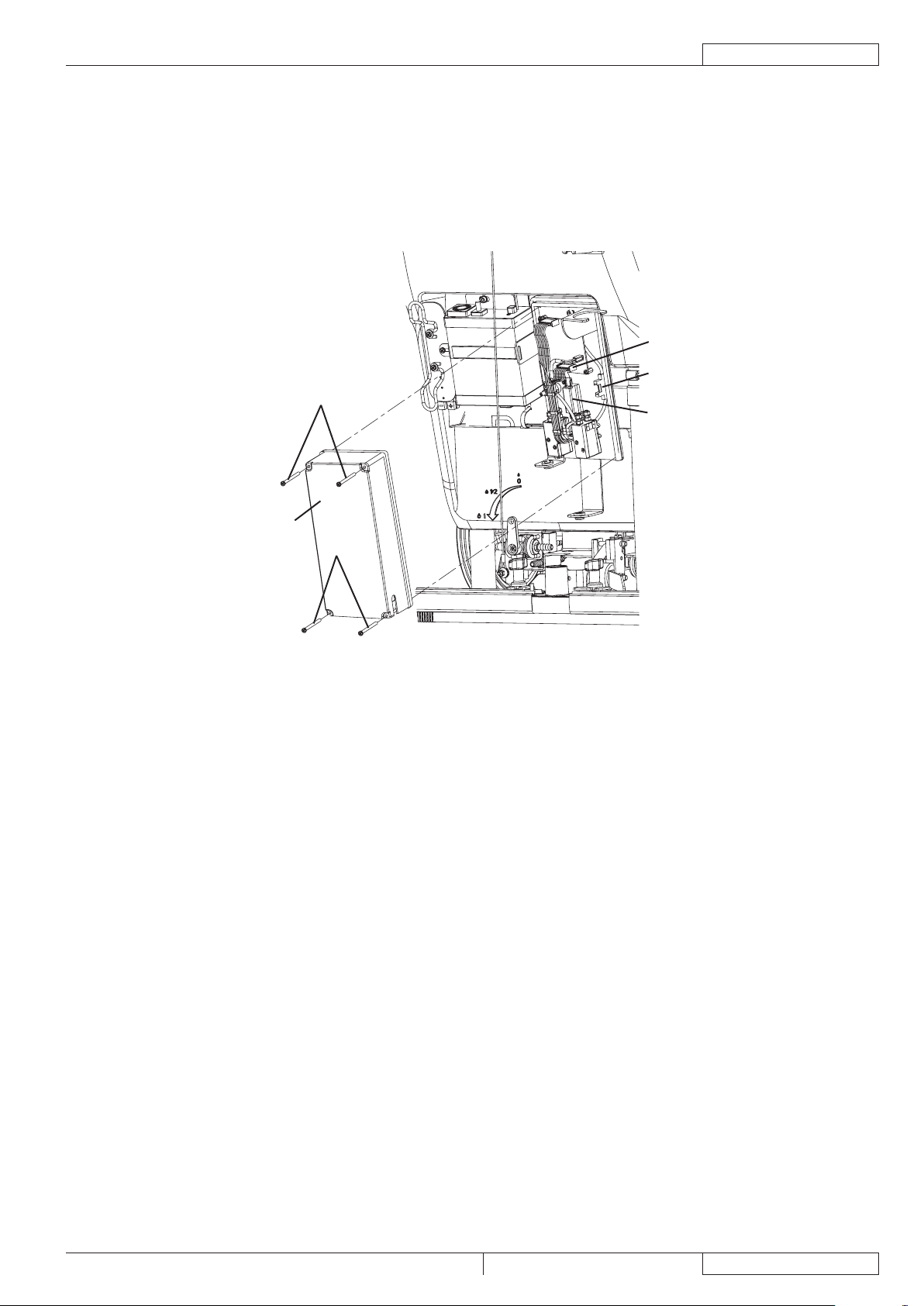

MACHINE DESCRIPTION

MACHINE STRUCTURE

Serial number plate/technical data1.

Handlebar2.

Handlebar inclination adjusting knob3.

Solution ow control lever4.

Solution ow control lever in Smart solution position (water 5.

“economy” usage, for a washing autonomy set to 70-80

minutes)

Recovery water tank cover6.

Rear support wheel for transport/parking7.

Central wheels on xed axle8.

Brush/pad9.

Brush/pad cover10.

Squeegee11.

Squeegee mounting handwheels12.

Front squeegee blade13.

Rear squeegee blade14.

Squeegee blade mounting springs15.

Recovery water drain hose16.

Recovery water drain hose bracket17.

Solution drain valve18.

Squeegee lifting/lowering lever19.

Solution lter20.

Battery charger-electrical mains connecting cable21.

Squeegee vacuum hose22.

Transport/parking device23.

Transport/parking device (engaged)23a.

Transport/parking device (disengaged)23b.

Transport/parking device positioning pin24.

Electrical component box25.

Battery charger26.

Battery charger warning lights27.

Danger label28.

Squeegee bumper wheel29.

Brush/pad support30.

Recovery tank31.

Solution tank32.

S311239K

ENGLISH

INSTRUCTIONS FOR USE

6

909 6309 000(3)2009-11 Razor SV17

41

42

59

58

46

47

44

45

52

43

50

53

57

51

49

48

60

54 55

56

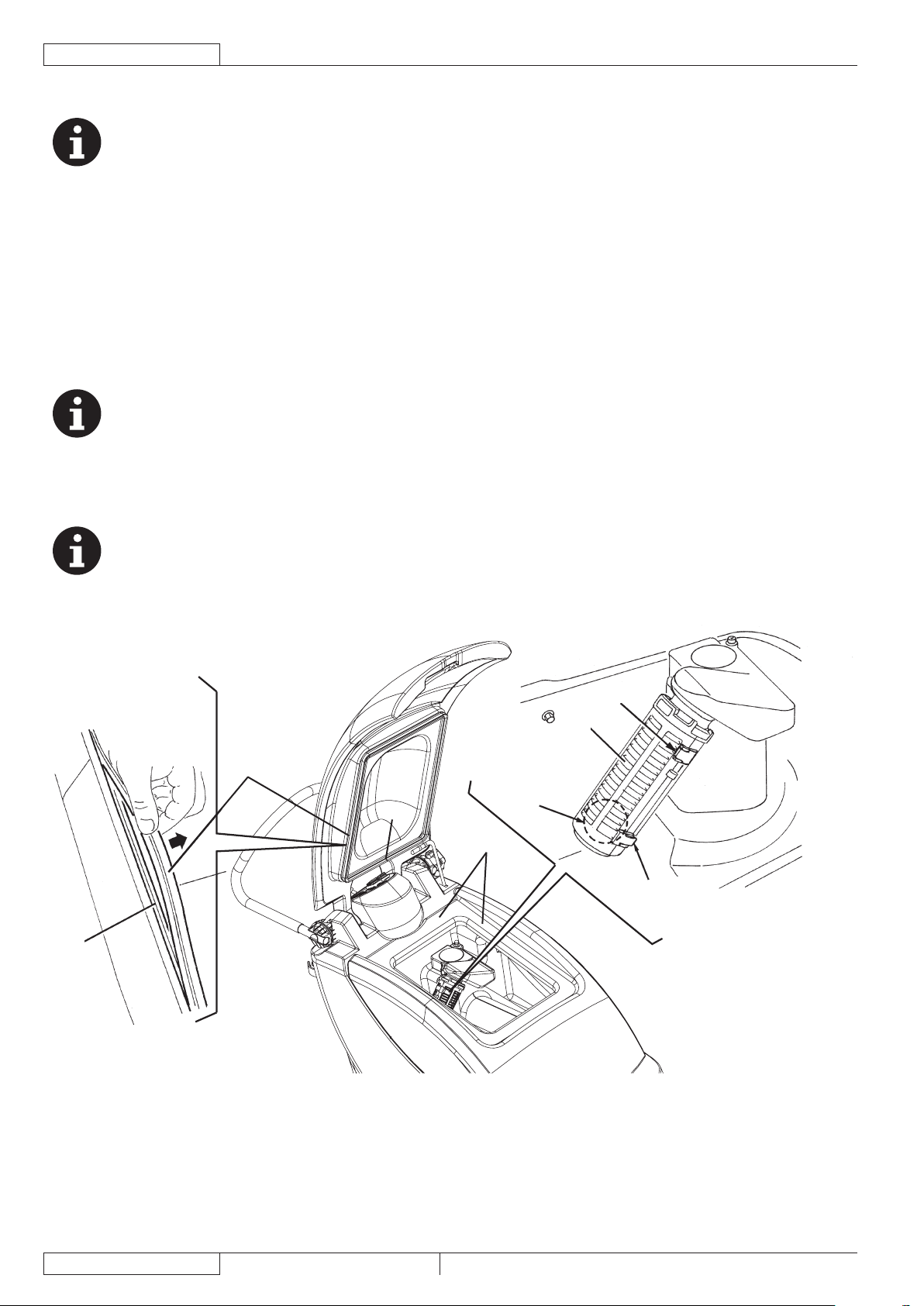

MACHINE STRUCTURE (Continues)

Recovery water tank cover (open)41.

Recovery water tank cover gasket42.

Brush/pad support43.

Recovery tank compartment44.

Solution tank ller neck45.

Vacuum grid with automatic shut-off oat46.

Recovery water drain hole47.

Vacuum system motor48.

Brush/pad motor49.

Batteries50.

Battery installation diagram51.

Deck with brush/pad-holder coupling pin52.

Machine speed adjustment screw53.

Brush54.

Pad-holder55.

Pad56.

Screw57.

Compensation hole58.

Cover support rod (engaged)59.

Brush/pad-holder engagement rotation direction60.

S311243K

INSTRUCTIONS FOR USE

ENGLISH

Razor SV17 909 6309 000(3)2009-11

7

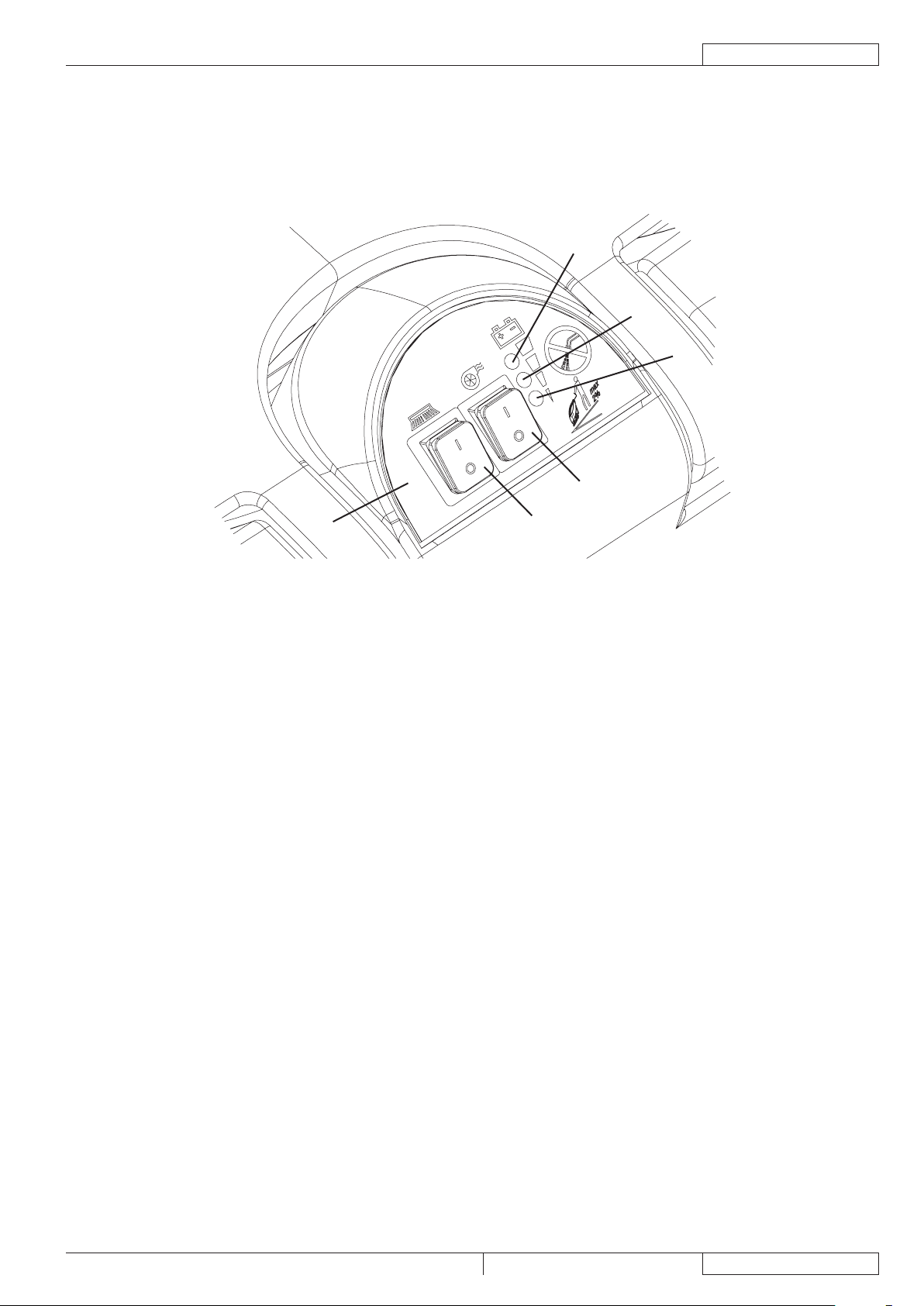

CONTROL PANEL

62

63

64

61

65

66

Control panel61.

Charged battery warning light (green)62.

Semi-discharged battery warning light (yellow)63.

Discharged battery warning light (red)64.

Brush/pad switch65.

Vacuum switch66.

ACCESSORIES/OPTIONS

In addition to the standard components, the machine can be equipped with the following accessories/options, according the

machine specic use:

Brushes/pads of different materials –

Curved squeegee –

For further information concerning the optional accessories, contact an authorized Retailer.

S311238K

ENGLISH

INSTRUCTIONS FOR USE

8

909 6309 000(3)2009-11 Razor SV17

TECHNICAL DATA

General Values

Machine length with folded handlebar 44 in (1,120 mm)

Machine width with squeegee 28.3 in (720 mm)

Machine width without squeegee 22.4 in (570 mm)

Min/max machine height with adjustable handlebar 33.8 - 43.5 in (860 - 1,105 mm)

Total machine weight 158,7 lb (72 kg)

Minimum turning radius 29.5 in (750 mm)

Cleaning width 16.9 in (430 mm)

Battery compartment size 13.7x13.7x10.2 in (350x350x260 mm)

Central wheel diameter 9.8 in (250 mm)

Brush/pad diameter 16.9 - 17 in (430 - 432 mm)

2

Rear wheel pressure on the oor 145 psi (1.0 N/mm

Front wheel pressure on the oor 275.5 psi (1.9 N/mm

Brush/pad pressure on the oor 79.3 lb (36 kg)

Performance Values

Vacuuming 41.5 inH

O (1,055 mmH2O)

2

Brush/pad-holder motor speed 135 rpm

Sound pressure level at workstation (ISO 11201, ISO 4871) (LpA) 65 dB(A) ± 3 dB(A)

Machine sound pressure level (ISO 3744, ISO 4871) (LwA) 89 dB(A)

Vibration level at the operator’s arms (ISO 5349-1) < 98.4 in/s

2

Vacuum system motor power 0.5 HP (370 W)

Brush/pad motor power 0.7 HP (520 W)

Gradeability 2%

Battery voltage 24 V

Standard batteries 12 V, 70 Ah (GEL)

Clean water tank capacity 8.2 gal (31 liters)

Recovery tank capacity 7.7 gal (29 liters)

)

2

)

(< 2.5 m/s2)

INSTRUCTIONS FOR USE

ENGLISH

Razor SV17 909 6309 000(3)2009-11

9

F3

CH1

BK

RD

BN

V-

IS1

F2

YE

CFBA430

BKBU BN RD

BK

EB1

PKWHOGBNBU GY

EB2

SW1

SW2

RD

ES1

BU

ES2

F1

YE

BN

M2

BU

M1

RD

RD

OR WH

EV1

Pb/Gel

SWITCH

RD

GY

BK

RD

RD

BK

909 5604 000

Rev. A

+

-

+

-

CT

1

BL

S-BT VT S+ V-

BL

V+

8

CH

1

SC LRSVSB LY LG

KY

LC

8

Ch

NO Ch

W-

W+

Gel

Pb

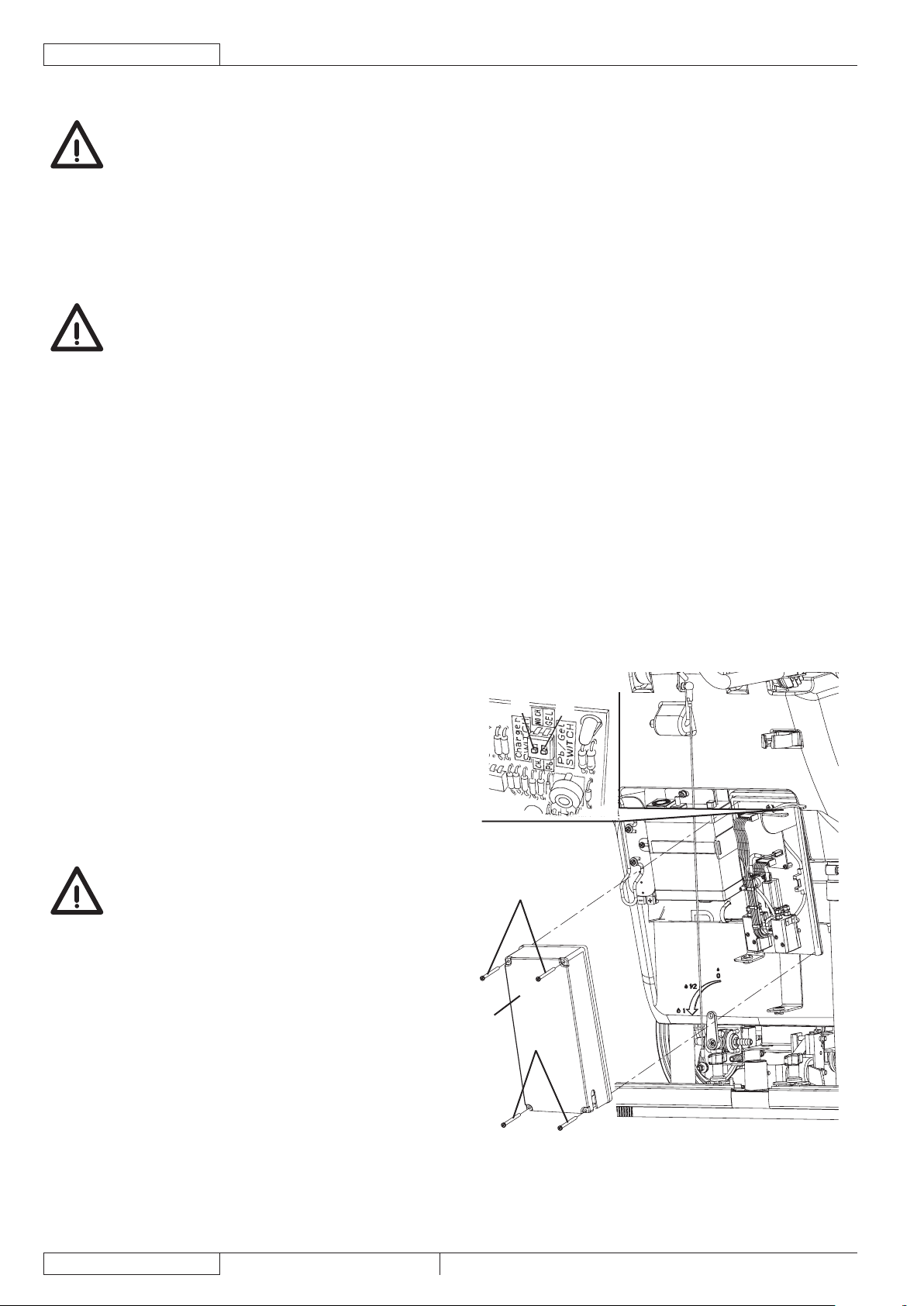

WIRING DIAGRAM

Key

CH1 Battery charger

C1 Battery charger connector

EB1 Electronic board (CF BA430)

EB2 Electronic board led (CF BALED)

ES1 Brush/pad-holder switch

ES2 Vacuum system switch

EV1 Water solenoid valve

F1 Brush fuse (40 A)

F2 Vacuum system fuse (40 A)

F3 Solenoid valve and electronic board fuse (5 A)

IS1 Negative insulator

M1 Brush/pad-holder motor

M2 Vacuum system motor

SW1 Brush/pad-holder switch

SW2 Vacuum system switch

Colour codes

BK Black

BU Blue

BN Brown

GN Green

GY Grey

OG Orange

PK Pink

RD Red

VT Violet

WH White

YE Yellow

S310228

ENGLISH

INSTRUCTIONS FOR USE

10

909 6309 000(3)2009-11 Razor SV17

B

A

A

C

D

USE

WARNING!

On some points of the machine there are some adhesive plates indicating:

DANGER –

WARNING –

CAUTION –

CONSULTATION –

While reading this Manual, the operator must pay particular attention to the symbols shown on the plates.

Do not cover these plates for any reason and immediately replace them if damaged.

BATTERY CHECK/SETTING ON A NEW MACHINE

WARNING!

The electric components of the machine can be seriously damaged if the batteries are either improperly installed

or connected. The batteries must be installed by qualied personnel only. Check the batteries for damage before

installation. Handle the batteries with great care. Install the battery terminal protection caps supplied with the

machine.

The machine requires two 12 V batteries, connected according to the diagram (28).

The machine can be supplied in one of the following modes:

GEL batteries already installed on the machine

Start the machine by pressing the brush/pad-holder and vacuum system switches (65 and 66). If the green warning light (62) –

turns on, the batteries are ready to be used.

If the yellow or red warning light (63 or 64) turns on, the batteries must be charged (see the procedure in Maintenance –

chapter).

Without batteries

Buy appropriate batteries [See the Technical Data paragraph and the diagram (28)]. For battery choice and installation, apply –

to qualied battery Retailers.

Set the machine and the battery charger according to the type of batteries installed (WET or GEL), according to the procedure –

shown in the following paragraph.

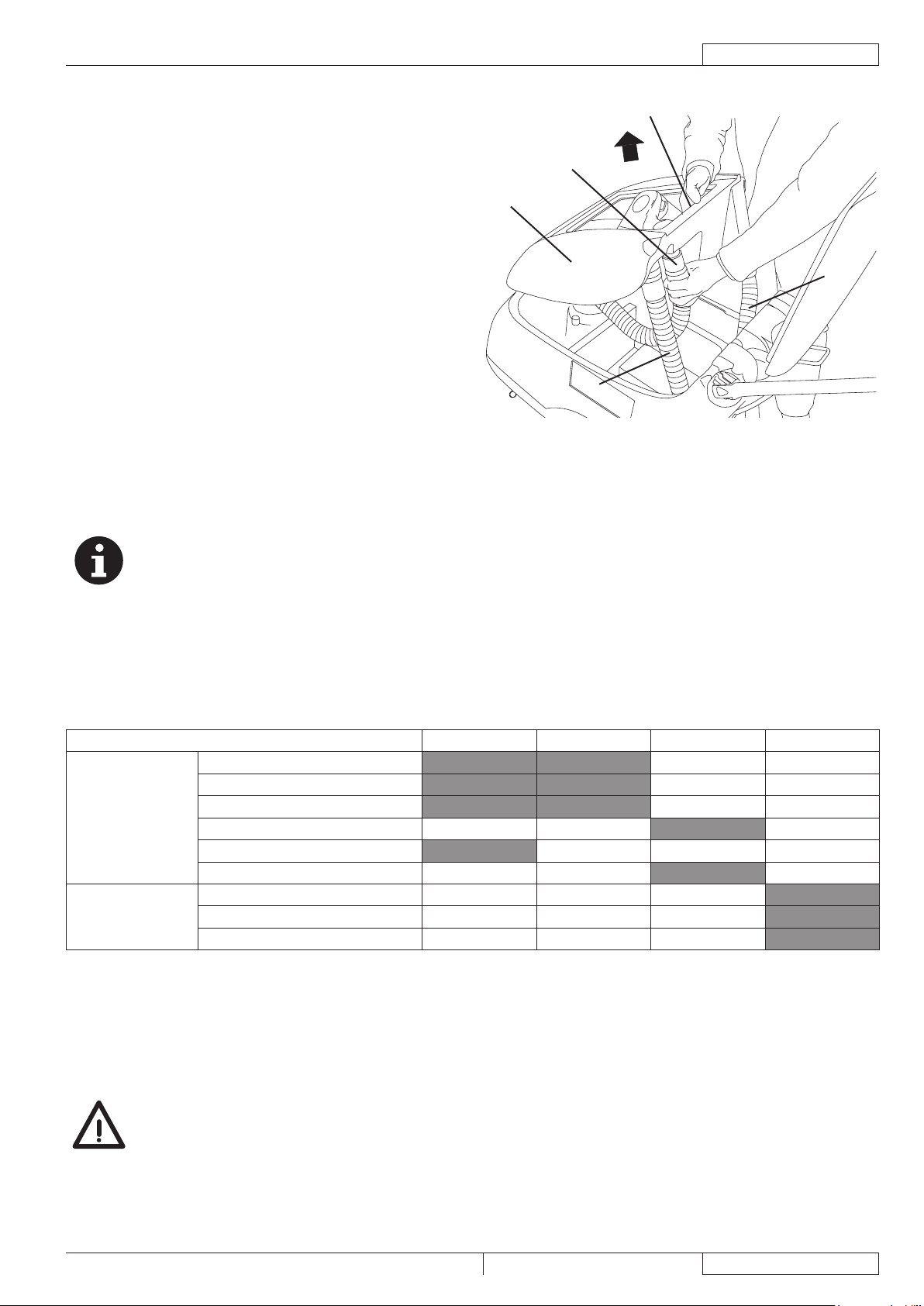

BATTERY TYPE SETTING (WET OR GEL)

Set the electronic board of the machine according to the type of

batteries installed (WET or GEL) as shown below:

Machine setting

Check that the battery connector (29) is disconnected.1.

The machine factory setting is for GEL batteries. If this 2.

setting corresponds to the type of batteries installed, go to

step 6. Otherwise, perform steps 3, 4 and 5 too.

Remove the screws (A, Fig. 1), then remove the electrical 3.

component box cover (B).

Turn the microswitch (C) to WET position.4.

WARNING!

Do not move/set the adjacent switch (D).

Reinstall the electric component box cover (B) and tighten 5.

the screws (A).

Figure 1

S311243B

INSTRUCTIONS FOR USE

ENGLISH

Razor SV17 909 6309 000(3)2009-11

11

Battery installation

A

C

B

D

E

Disconnect the vacuum hose (22) from the squeegee (11).6.

Disconnect the recovery water drain hose (16) from the 7.

bracket (17).

Open the cover (6).8.

Grasp the recovery tank (A, Fig. 2) in the area (B) and 9.

slightly raise it.

Disconnect the vacuum hose (C) from the tank, then 10.

remove the tank (A) with the hoses (D) and (E).

Install the batteries on the machine according to the 11.

diagram (28).

Install the tank (A, Fig. 2) by performing steps 6 to 10 in 12.

the reverse order.

Battery charging

Charge the batteries (see the procedure in Maintenance 13.

chapter).

BEFORE MACHINE START-UP

Figure 2

S310233 A

Brush or pad-holder installation

NOTE

Use either the brush (54) or the pad-holder (55) according to the type of oor to be cleaned.

Insert the positioning pin (24) and disengage the machine transport/parking device (23b).1.

Lift the brush/pad-holder deck (10) by prying the handlebar (2).2.

Place the brush (54) or the pad-holder (55) under the deck.3.

Lower the deck (10) by using the handlebar (2).4.

Engage the brush/pad-holder by pressing the brush/pad switch (65) for a few seconds. If the procedure is difcult, manually 5.

turn the brush/pad-holder counter-clockwise (60).

Brush/pad application guide (suggestions only)

Types of brushes available Midlite Grit 180 Midgrit 240 Prolite Union Mix

Concrete

Terrazzo oor

General cleaning

Polishing

Ceramic tiles/quarrystones

Marble

Vinyl tiles

Rubber tiles

Rubber tiles

Marble

Vinyl tiles

Squeegee installation

Install the squeegee (11) and fasten it with the handwheels (12), then connect the vacuum hose (22) to the squeegee.6.

Solution tank lling

Open the recovery water tank cover (41) and engage the support rod (59).7.

Use the ller neck (45) to ll the tank (32) with a solution suitable for the work to be performed. Do not ll the solution tank 8.

completely, leave a few centimetres from the edge. Always follow the dilution instructions on the label of the chemical product

used to prepare the solution. The solution temperature must not exceed 104°F (40°C).

CAUTION!

Use only low-foam and non-ammable detergents, intended for automatic scrubber applications.

Adjustments

Adjust the handlebar (2) with the knobs (3) to reach a comfortable position.9.

ENGLISH

INSTRUCTIONS FOR USE

12

909 6309 000(3)2009-11 Razor SV17

A

B

MACHINE START AND STOP

Starting the machine

Prepare the machine as shown in the previous paragraph.1.

Lower the squeegee (11) with the lever (19).2.

Turn the solution ow control lever (4) to a position between the minimum limit (5a) and maximum limit (5b). In no case it is 3.

possible to close completely the water ow to the brushes during operation.

While keeping the hand on the handlebar (2), start the machine by turning the brush/pad-holder switch and the vacuum system 4.

switch (65 and 66) to “I”.

NOTE

If the green warning light (62) turns on, the batteries are ready to be used. If the yellow or red warning light (63 or 64)

turns on, the batteries must be charged (see the procedure in Maintenance chapter).

Stopping the machine

Turn the brush/pad-holder switch and the vacuum system switch (65 and 66) to “0”.5.

Lift the squeegee with the lever (19).6.

Insert the positioning pin (24) and lift the brush/pad-holder by engaging the transport/parking device (23a).7.

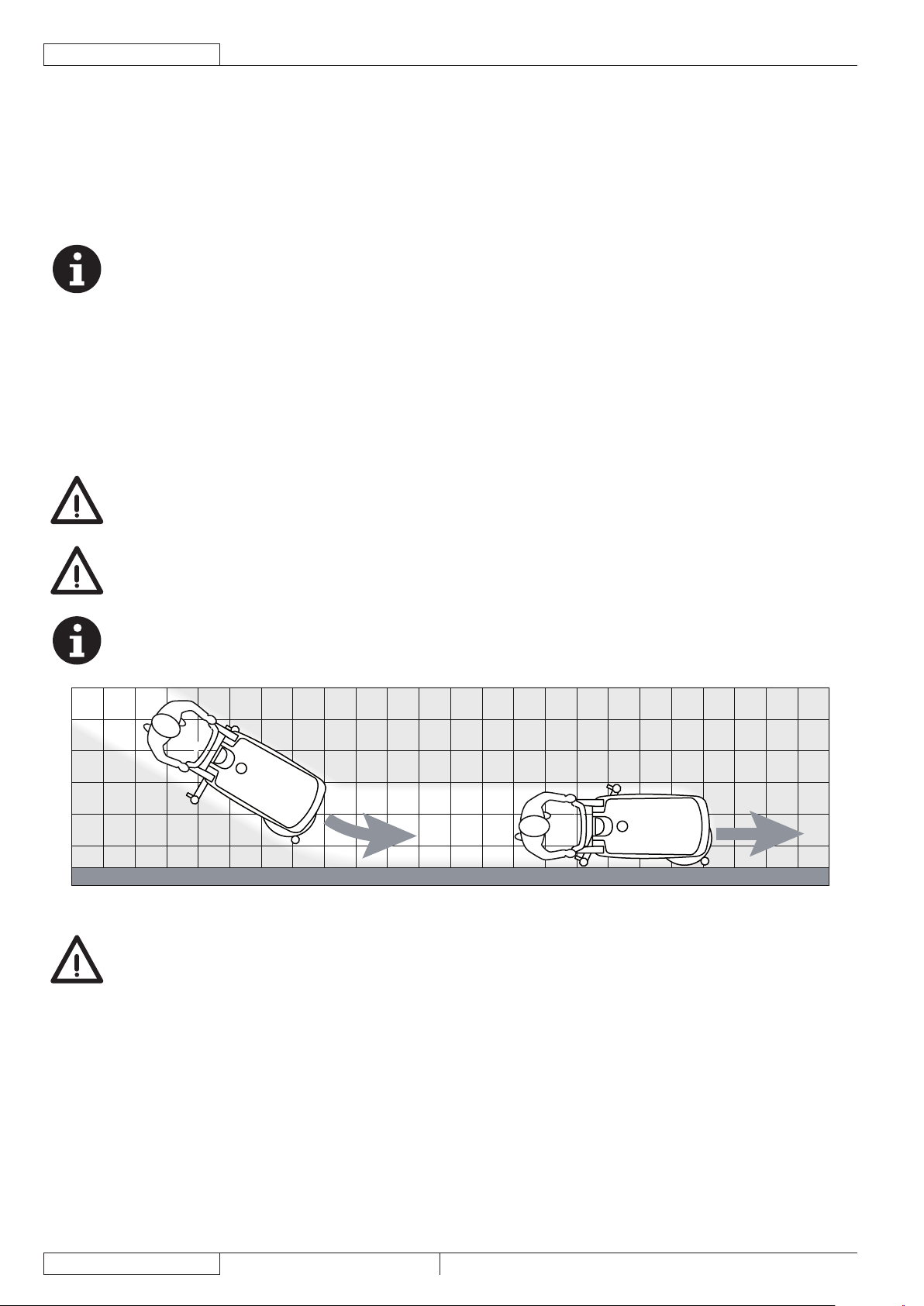

MACHINE OPERATION (SCRUBBING/DRYING)

Start the machine as shown in the previous paragraph.1.

While keeping both hands on the handlebar (2), move the machine and start scrubbing/drying the oor.2.

If necessary, adjust the solution quantity by using the lever (4).3.

CAUTION!

To avoid damaging the oor surface, do not use the brushes without the solution and, when the machine is not

operating, stop the brush/pad-holder by pressing the switch (65).

CAUTION!

Before lifting the brush/pad, turn it off by pressing the switch (65).

NOTE

For correct scrubbing/drying of oors at the sides of the walls, KENT suggests to go near the walls with the right side of

the machine as shown in gure 3.

Figure 3

P100160A

CAUTION!

In case of brush/pad-holder motor overload, due to foreign bodies which prevent them from turning, or to

excessively aggressive oors/brushes, the safety system stops the brush/pad-holder after about one minute of

continuous overload.

The overload is shown by the three warning lights (62, 63, 64) ashing simultaneously.

If the overload persists, the brush/pad-holder stops.

To start scrubbing again after a brush/pad-holder stop due to overload, stop the machine by turning the brush/

pad-holder switch and the vacuum system switch (65 and 66) to “0”. Turn on the machine by turning the brush/

pad-holder switch and the vacuum system switch (65 and 66) to “I”.

INSTRUCTIONS FOR USE

ENGLISH

Razor SV17 909 6309 000(3)2009-11

13

Battery discharge during operation

Until the green warning light (62) stays on, the batteries allow the machine to work normally. When the green warning light 4.

(62) turns off and the yellow (63) and red (64) warning lights turn on in sequence, it is necessary to charge the battery as the

machine residual autonomy is at the minimum level.

WARNING!

Do not use the machine with discharged batteries, to avoid damaging the batteries and reducing the battery life.

Machine speed adjustment

The machine speed varies according to the type of oor to be cleaned and the choice of using the brush or the pad. If 5.

necessary, it is possible to adjust the machine speed, according to the procedure shown in Maintenance chapter.

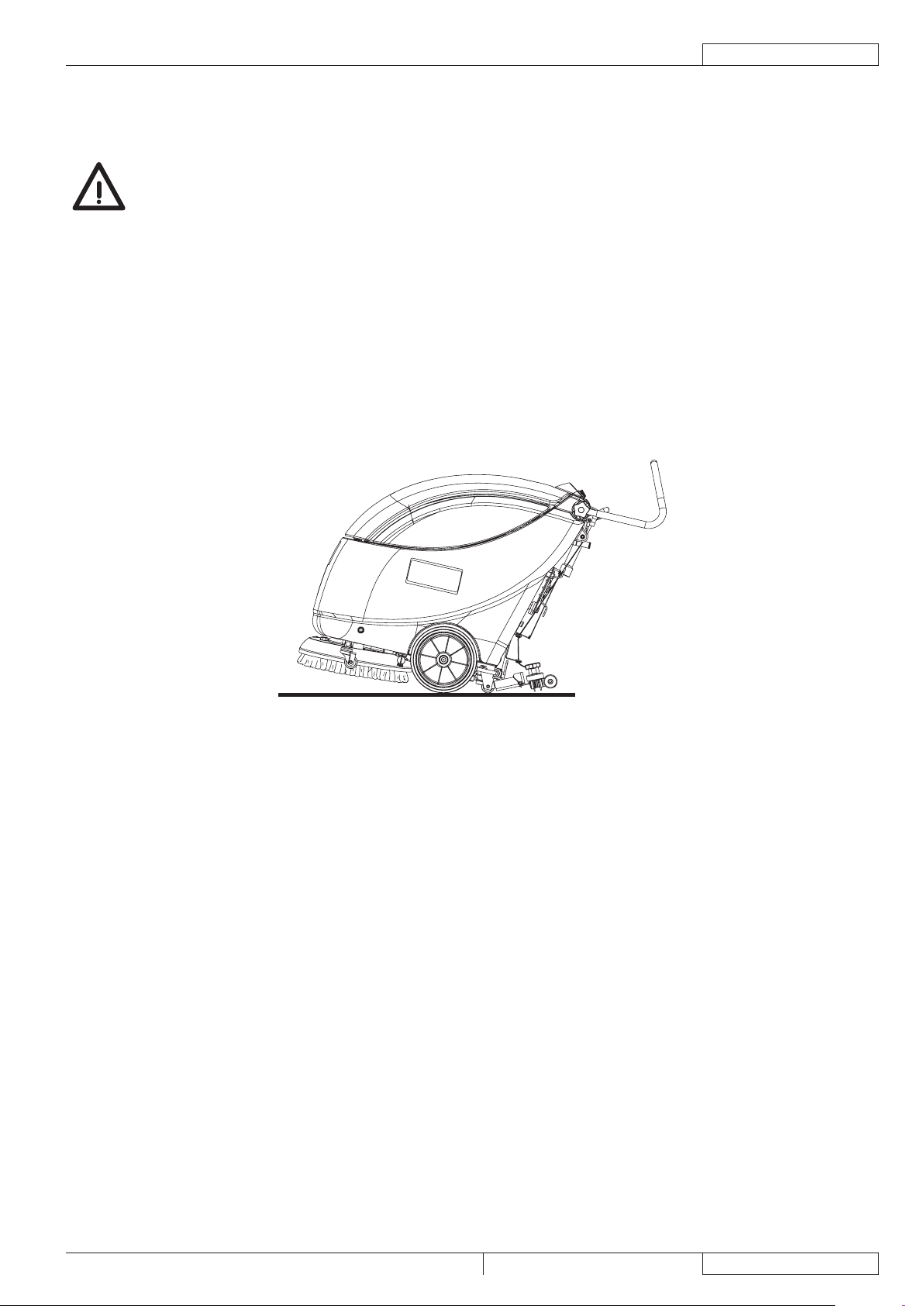

MACHINE TRANSPORT/PARKING

To transport/park the machine, proceed as follows.

Turn the brush/pad-holder switch and the vacuum system switch (65 and 66) to “0”.1.

Lift the squeegee with the lever (19).2.

Grasp the handlebar (2) and slightly lower it until the rear wheel (7) comes into contact with the oor (Fig. 4). While holding the 3.

machine in this position, drive it to the transport/parking area.

In order not to drag the brush/pad on the oor and leave wet marks, when nishing working, remove the brush/pad-holder from 4.

the deck by using the release device (see the procedure in After Using The Machine paragraph), then place it on the support

(30).

Figure 4

S311225A

ENGLISH

INSTRUCTIONS FOR USE

14

909 6309 000(3)2009-11 Razor SV17

TANK EMPTYING

An automatic oat shut-off system (44) turns off the vacuum system when the recovery tank (31) is full.

The vacuum system shutdown, due to the recovery tank lling, is signalled by an increase in the vacuum system motor noise,

moreover the oor is not dried.

CAUTION!

If the vacuum system turns off accidentally (for example, when the oat is activated because of a sudden

machine movement), to resume the operation: turn off the vacuum system by pressing the switch (66), then

open the cover (6) and check that the oat inside the grid (46) has gone down to the water level. Then close the

cover (6) and turn on the vacuum system by pressing the switch (66).

When the recovery tank (31) is full, empty it according to the following procedure.

Recovery tank emptying

Start the machine by pressing the brush/pad-holder and vacuum system switches (65 and 66).1.

Lift the squeegee with the lever (19).2.

Drive the machine to the appointed disposal area.3.

Insert the positioning pin (24) and lift the brush/pad-holder by engaging the transport/parking device (23a).4.

Empty the recovery tank with the drain hose (16). Then, rinse the tank with clean water.5.

Solution tank emptying

Perform steps 1 to 4.6.

Empty the solution tank by using the drain valve (18). Then, rinse the tank with clean water.7.

AFTER USING THE MACHINE

After working, before leaving the machine:

Remove the brush/pad-holder as follows:1.

With the brush/pad-holder lifted, turn the brush/pad-holder switch (65) to “I” and, after a few seconds, back to “0”, thus •

releasing the brush/pad-holder.

Empty the tanks (31 and 32) as shown in the previous paragraph.2.

Perform the daily maintenance procedures (see the Maintenance chapter).3.

Store the machine in a clean and dry place, with the brush/pad-holder and the squeegee lifted or removed.4.

INSTRUCTIONS FOR USE

ENGLISH

Razor SV17 909 6309 000(3)2009-11

15

A

C

B

D

E

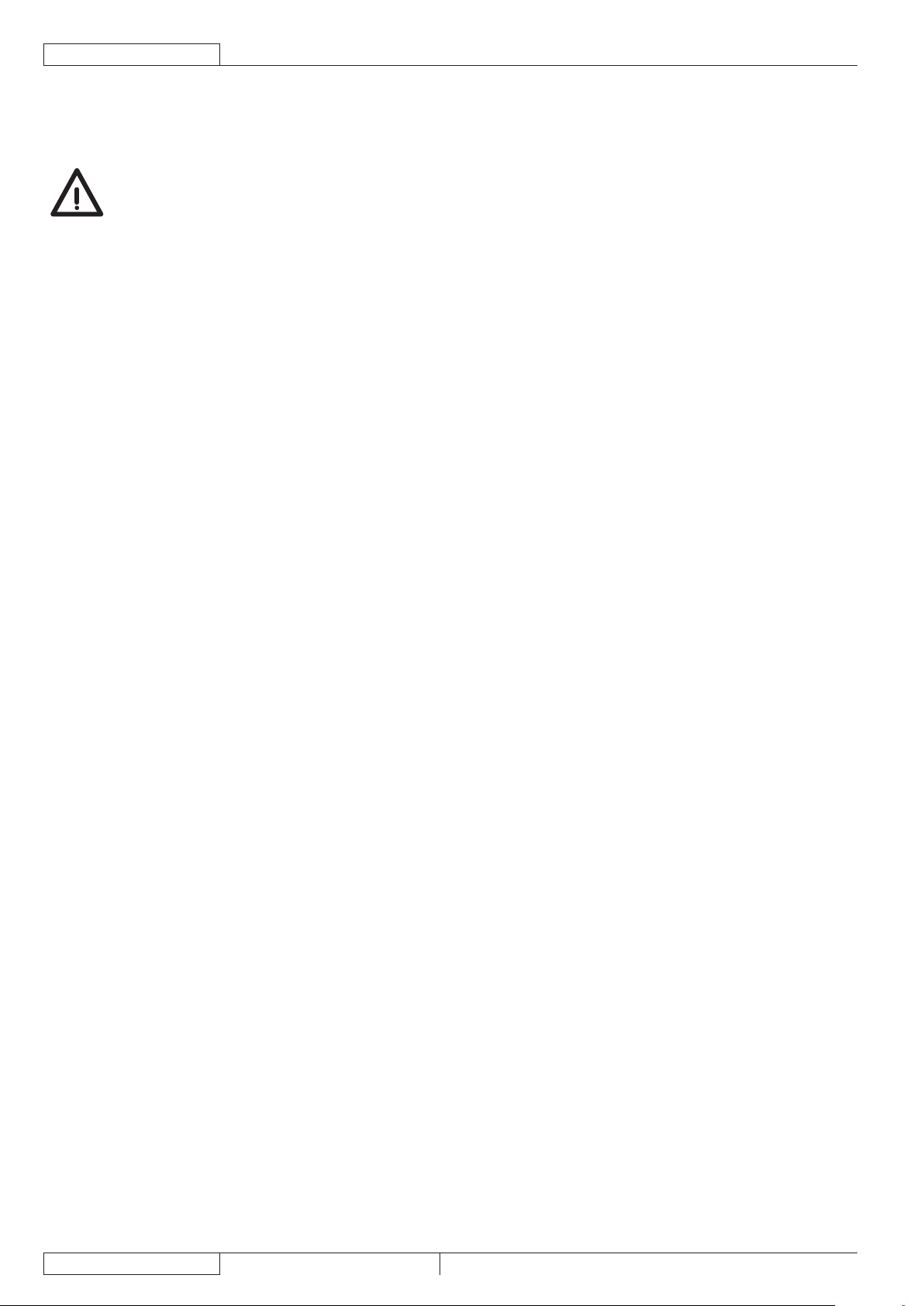

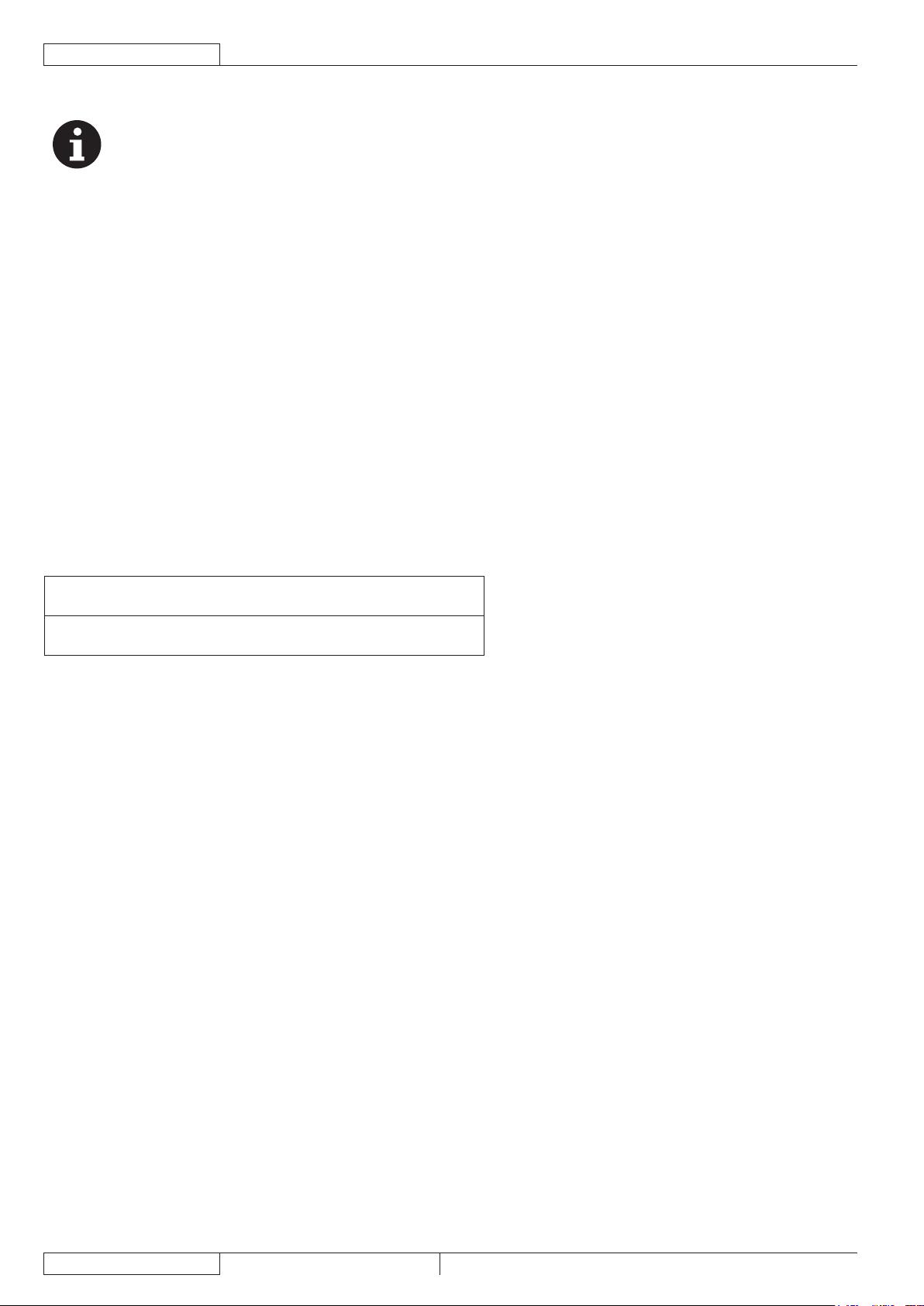

RECOVERY TANK REMOVAL

To check or charge the lead (WET) batteries, or to perform other procedures, it may be necessary to remove the recovery tank (31)

as shown below.

Empty the recovery tank (31) as shown in the relevant paragraph.1.

Drive the machine on a level oor.2.

Make sure that the switches (65 and 66) are turned to “0”.3.

Disconnect the vacuum hose (22) from the squeegee (11).4.

Disconnect the recovery water drain hose (16) from the bracket (17).5.

Open the cover (6).6.

Grasp the recovery tank (A, Fig. 5) in the area (B) and slightly raise it.7.

Disconnect the vacuum hose (C) from the tank, then remove the tank (A) with the hoses (D) and (E).8.

Figure 5

S310233 A

MACHINE LONG INACTIVITY

If the machine is not going to be used for more than 30 days, proceed as follows:

Perform the procedures shown in After Using the Machine paragraph.1.

Remove the recovery tank (31) as shown in the previous paragraph, and then disconnect the battery negative terminals (10).2.

Install the recovery water tank (A).3.

Store the machine in a clean and dry place.4.

FIRST PERIOD OF USE

After the rst 8 hours, check the machine fastening and connecting parts for proper tightening. Check the visible parts for integrity

and leakage.

ENGLISH

INSTRUCTIONS FOR USE

16

909 6309 000(3)2009-11 Razor SV17

MAINTENANCE

The lifespan of the machine and its maximum operating safety are ensured by correct and regular maintenance. The following chart

provides the scheduled maintenance. The intervals shown may vary according to particular working conditions, which are to be

dened by the person in charge of the maintenance.

WARNING!

Maintenance procedures must be performed with the machine switched off and the batteries/battery charger

cable disconnected.

Moreover, carefully read the instructions in the Safety chapter.

All scheduled or extraordinary maintenance procedures must be performed by qualied personnel, or by an authorised Service

Center. This Manual describes only the easier and most common maintenance procedures.

NOTE

For other maintenance procedures shown in the Scheduled Maintenance Table, refer to the Service Manual that can be

consulted at any Service Center.

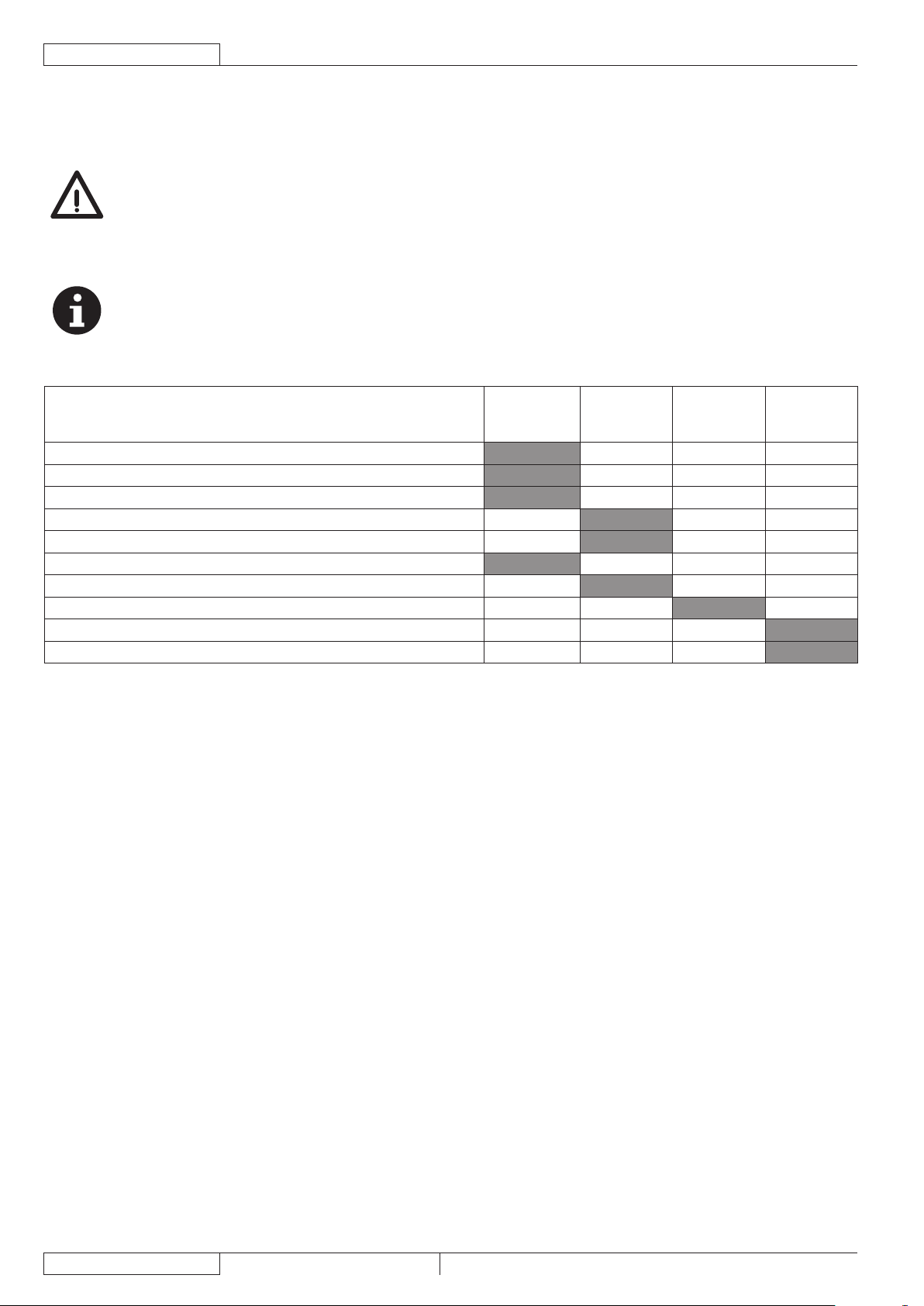

SCHEDULED MAINTENANCE TABLE

Procedure

Squeegee cleaning

Brush cleaning

Tank and vacuum grid cleaning

Squeegee blade check and replacement

Solution lter cleaning

Battery charging

WET battery uid level check

Screw and nut tightening check (1)

Brush motor carbon brush check and replacement (2)

Vacuum system motor carbon brush check and replacement (2)

Daily, after

using the

machine

Weekly

Every six

months

Yearly

And after the rst 8 working hours.(1)

This maintenance procedure must be performed by KENT authorised Service Center.(2)

INSTRUCTIONS FOR USE

ENGLISH

Razor SV17 909 6309 000(3)2009-11

17

I

G

A

EH

B

A

F

F

D

C

SQUEEGEE CLEANING

NOTE

The squeegee must be clean and its blades must be in good conditions in order to get a good drying.

WARNING!

It is advisable to wear protective gloves when cleaning the squeegee because there may be sharp debris.

Drive the machine on a level oor.1.

Make sure that the switches (65 and 66) are turned to “0”.2.

Lower the squeegee with the lever (19).3.

Disconnect the vacuum hose (22) from the squeegee.4.

Loosen the handwheels (12) and remove the squeegee (11).5.

Wash and clean the squeegee. In particular, clean the compartments (A, Fig. 6) and the vacuum hole (B) from dirt and debris.6.

Check the front blade (C) and the rear blade (D) for integrity, cuts and tears; if necessary replace them (see the procedure in 7.

the following paragraph).

Assemble the components in the reverse order of disassembly.8.

SQUEEGEE BLADE CHECK AND REPLACEMENT

Clean the squeegee as shown in the previous paragraph.1.

Check that the front blade edges (E, Fig. 6) and the rear blade edges (I) lay down on the same level, along their length; if 2.

necessary adjust the height according to the following procedure:

Remove the mounting springs (F), then adjust the front blade (C) and the rear blade (D).•

Install the mounting springs on the front and rear blades.•

Check the front blade (C) and rear blade (D) for integrity, cuts and tears; if necessary replace them as shown below. Also 3.

check the front corner (H) of the rear blade for wear; if it is worn, overturn the blade to replace the worn corner with the other

one (I), if it is integral. If the other corner is worn too, replace the blade according to the following procedure:

Remove the mounting springs (F) and then replace (or overturn) the rear blade (D).•

Install the mounting springs on the front and rear blades.•

Install the squeegee (11) and screw tighten the handwheels (12).4.

Connect the vacuum hose (22) to the squeegee (11).5.

Figure 6

S310230A

ENGLISH

INSTRUCTIONS FOR USE

18

909 6309 000(3)2009-11 Razor SV17

C

B

B

A

D

F

G

E

BRUSH CLEANING

NOTE

It is advisable to wear protective gloves when cleaning the brushes because there may be sharp debris.

Remove the brush, as shown in Use chapter.1.

Clean the brush with water and detergent.2.

Check the brush bristles for integrity and wear; if necessary, replace the brush.3.

TANK AND VACUUM GRID CLEANING

Drive the machine to the appointed disposal area.1.

Make sure that the switches (65 and 66) are turned to “0”.2.

Open the cover (6), then clean and wash the cover, the tanks (31 and 32) and the vacuum grid (46) with clean water. Drain the 3.

water from the tanks with the drain hose (16) and the valve (18).

If necessary, release the fasteners (B, Fig. 7) and open the grid (A); recover the oat (C), clean all the components and then 4.

reinstall them.

Check the recovery tank cover gasket (D) for integrity.5.

NOTE

The gasket (D) creates vacuum in the tank that is necessary for vacuuming the recovery water.

If necessary replace the gasket (D) by removing it from its housing (E). When assembling the new gasket, install the joint (F) in

the rear central area, as shown in the gure.

Check the seating surface (D) of the gasket (G) for integrity and sealing capabilities.6.

Check the compensation hole (58) for clogging.7.

NOTE

The hole (58), allowing to compensate the air in the cover air gap, contributes to create vacuum in the tank.

Close the recovery tank cover (6).8.

Figure 7

S311227A

INSTRUCTIONS FOR USE

ENGLISH

Razor SV17 909 6309 000(3)2009-11

19

SOLUTION FILTER CLEANING

C

B

A

B

D

Empty the solution tank (32) as shown in the relevant paragraph.1.

Drive the machine on a level oor.2.

Make sure that the switches (65 and 66) are turned to “0”.3.

Remove the transparent cover (A, Fig. 8), then remove the lter strainer (B). Clean and install them on the support (C).4.

NOTE

The lter strainer (B) must be correctly positioned on the housing (D) of the support (C).

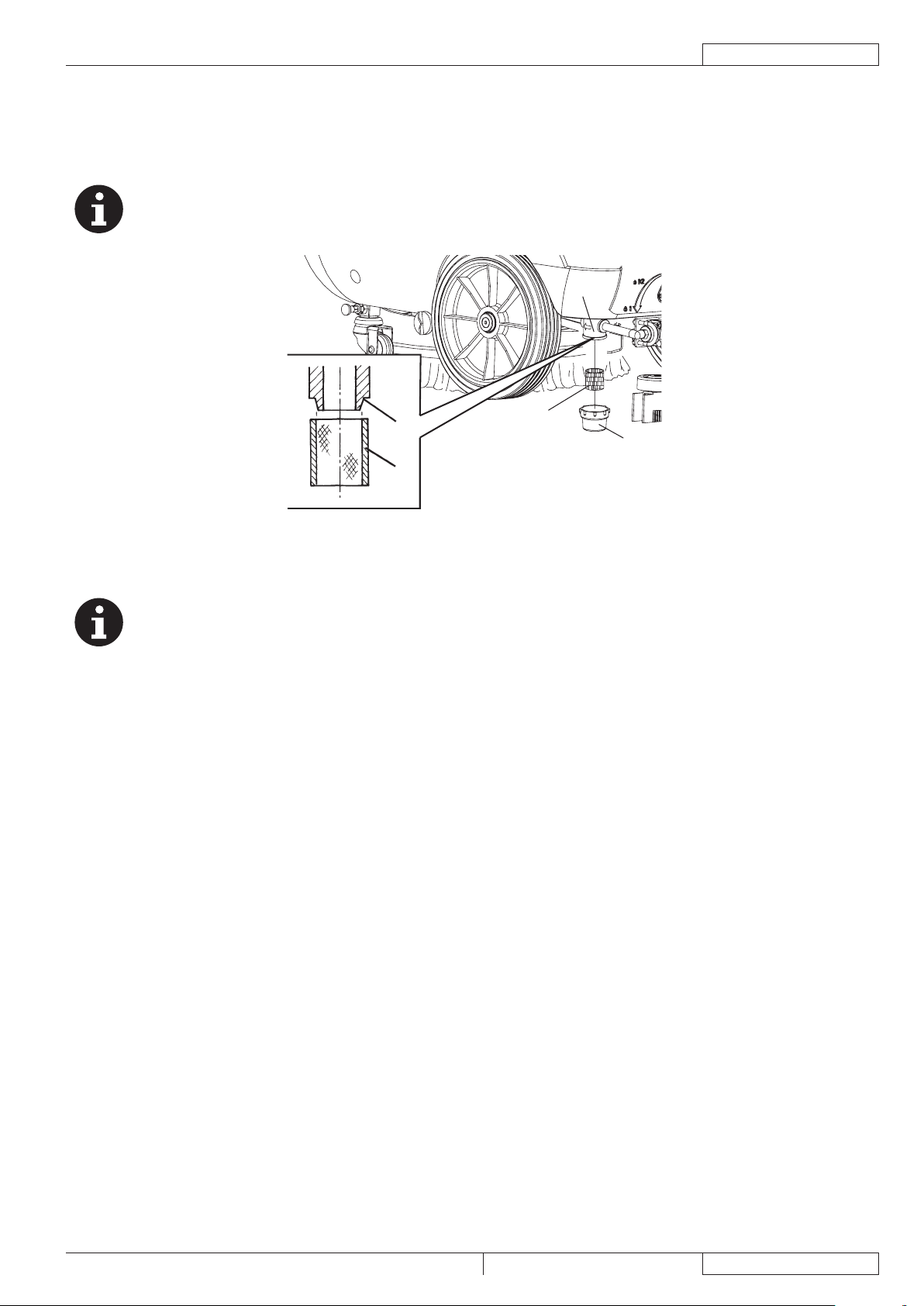

MACHINE SPEED ADJUSTMENT

NOTE

The machine speed varies according to the type of oor to be cleaned and the choice of using the brush or the pad.

If necessary, perform the following procedure.

Remove the recovery tank as shown in Use chapter.1.

Adjust the machine speed with the screw (53) as shown below:2.

Loosen the screw (57), on the right side of the machine, by turning it counter-clockwise.•

Turn the adjusting screw (53) counter-clockwise to increase the machine speed.•

Turn the adjusting screw (53) clockwise to decrease the machine speed.•

After adjusting, tighten the screw (57).•

Install the recovery tank as shown in Use chapter.3.

With the machine ready to operate, perform hands-on tests of the machine and, if other adjustments are necessary, repeat 4.

steps 1 to 4.

Figure 8

S310232A

ENGLISH

INSTRUCTIONS FOR USE

20

909 6309 000(3)2009-11 Razor SV17

A

C

B

D

E

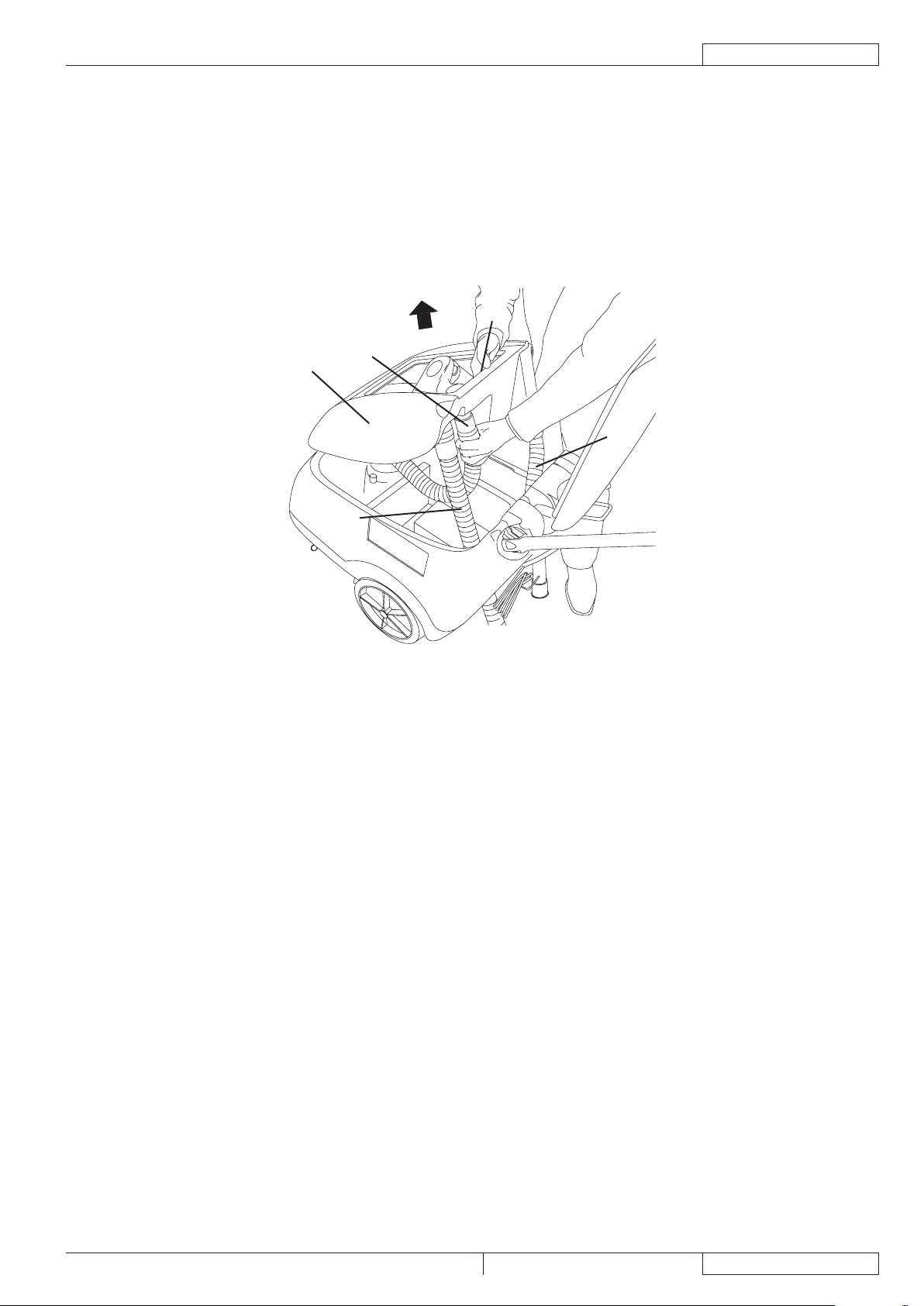

BATTERY CHARGING

NOTE

Charge the batteries when the yellow or red warning light (63 or 64) turns on, or at the end of every working cycle.

Keeping the batteries charged make their life last longer.

CAUTION!

When the batteries are discharged, charge them as soon as possible, as that condition makes their life shorter.

Check for battery charge at least once a week.

CAUTION!

When using lead (WET) batteries, battery charging produces highly explosive hydrogen gas. Charge the

batteries in well-ventilated areas and away from naked ames.

Do not smoke while charging the batteries.

Do not reinstall the recovery tank until the battery charging cycle is over.

WARNING!

Pay careful attention when charging WET batteries as there may be battery uid leakages. The battery uid is

corrosive. If it comes in contact with skin or eyes, rinse thoroughly with water and consult a physician.

Drive the machine on a level oor.1.

Connect the battery charger cable (21) to the electrical mains (the electrical mains voltage and frequency must be compatible 2.

with the battery charger values shown on the relevant Manual).

NOTE

When the battery charger is connected to the electrical mains, all machine functions are automatically cut off.

The green warning light (27) ashes when the battery charger is charging the batteries.

When the green warning light (27) stays on, the battery charging cycle is over.3.

When the battery charging is completed, disconnect the battery charger cable (21) from the electrical mains and wind it round 4.

its housing.

Now the machine is ready to be used.5.

Hold the recovery tank (A, Fig. 9) and place it on the machine as shown. Connect the suction hose (C) to the tank, then lower 6.

it in the original position.

Connect the suction hose (22) to the squeegee (11).7.

Close the cover (6)8.

NOTE

For further information about the operation of the battery charger (26), see the relevant Manual.

Figure 9

S310233 A

INSTRUCTIONS FOR USE

ENGLISH

Razor SV17 909 6309 000(3)2009-11

21

FUSE CHECK/REPLACEMENT

B

A

A

C

D

E

Remove the recovery tank as shown in Use chapter.1.

Disconnect the battery negative terminals (50).2.

Remove the screws (A, Fig. 10), then carefully remove the electrical component box cover (B).3.

Check/replace the following fuses:4.

Brush (40 A) (C)•

Vacuum system (40 A) (D)•

Solenoid valve and electronic board (5 A) (E)•

Install the components in the reverse order of removal.5.

Figure 10

S311230B

ENGLISH

INSTRUCTIONS FOR USE

TROUBLESHOOTING

Trouble Possible Cause Remedy

The motors do not turn on; no warning light turns

on

The warning lights (62, 63, 64) ash

simultaneously

The vacuum system motor does not turn on The fuse is blown Replace

The dirty water vacuuming is insufcient

The solution ow is insufcient The solution lter (20) is dirty Clean

The squeegee leaves marks on the oor

The battery terminals (50) are disconnected Connect

The batteries (50) are discharged Charge

The brush motor is overloaded Use a different kind of brush

There are foreign materials (tangled threads,

etc.) preventing the brush from rotating

The recovery water tank (31) is full Empty

The vacuum grid (46) is clogged or the oat

is closing

The vacuum hose (22) is disconnected from

the squeegee (11) or it is damaged

The squeegee (11) is dirty, or the squeegee

blades (13, 14) are worn or damaged

The recovery water tank cover (6) is not

properly closed, or the gasket (42) is

damaged

The recovery water tank (31) is dirty (clogged

drain hole)

There is debris under the squeegee blades

(13, 14)

The squeegee blades (13, 14) are worn,

chipped or torn

Clean the brush hub

Clean the grid and check the oat

Connect

Clean the squeegee or replace the blades

Check and/or clean the seating surface or

replace the gasket

Clean

Remove the debris

Replace the blades

For further information refer to the Service Manual, available at any KENT Service Center.

SCRAPPING

Have the machine scrapped by a qualied scrapper.

Before scrapping the machine, remove and separate the following materials, which must be disposed of properly according to the

Law in force:

Battery –

Brushes –

Plastic hoses and components –

Electrical and electronic components (*) –

Refer to the nearest KENT Center especially when scrapping electrical and electronic components.(*)

22

909 6309 000(3)2009-11 Razor SV17

INSTRUCTIONS D’UTILISATION

FRANÇAIS

TABLE DES MATIERES

INTRODUCTION .............................................................................................................................................................. 2

BUT ET CONTENU DU MANUEL ................................................................................................................................................... 2

DESTINATAIRES ............................................................................................................................................................................. 2

CONSERVATION DU MANUEL ....................................................................................................................................................... 2

DONNEES D’IDENTIFICATION ...................................................................................................................................................... 2

AUTRES MANUELS DE REFERENCE ........................................................................................................................................... 2

PIECES DE RECHANGE ET ENTRETIEN ..................................................................................................................................... 2

MODIFICATIONS ET AMELIORATIONS ......................................................................................................................................... 2

CAPACITES OPERATIONNELLES ................................................................................................................................................. 2

CONVENTIONS .............................................................................................................................................................................. 2

DEBALLAGE / LIVRAISON ............................................................................................................................................. 3

SECURITE .......................................................................................................................................................................3

SYMBOLES UTILISES .................................................................................................................................................................... 3

INSTRUCTIONS GENERALES ....................................................................................................................................................... 3

DESCRIPTION DE LA MACHINE ...................................................................................................................................5

STRUCTURE DE LA MACHINE ...................................................................................................................................................... 5

TABLEAU DE BORD .......................................................................................................................................................................7

ACCESSOIRES / OPTIONS ............................................................................................................................................................ 7

CARACTERISTIQUES TECHNIQUES ............................................................................................................................................ 8

SCHEMA ELECTRIQUE ..................................................................................................................................................................9

UTILISATION ................................................................................................................................................................. 10

CONTROLE / PREPARATION DE LA BATTERIE SUR UNE MACHINE NEUVE ......................................................................... 10

ETABLISSEMENT (GEL), INSTALLATION ET CHARGEMENT DES BATTERIES....................................................................... 10

AVANT LA MISE EN MARCHE DE LA MACHINE ..........................................................................................................................11

MISE EN MARCHE ET ARRET DE LA MACHINE ........................................................................................................................ 12

MACHINE AU TRAVAIL (LAVAGE / SECHAGE) ........................................................................................................................... 13

TRANSPORT / STATIONNEMENT DE LA MACHINE ................................................................................................................... 14

VIDANGE DES RESERVOIRS ...................................................................................................................................................... 14

APRES L’UTILISATION DE LA MACHINE .................................................................................................................................... 14

DEPOSE DU RESERVOIR DE L’EAU DE RECUPERATION ....................................................................................................... 15

INACTIVITE PROLONGEE DE LA MACHINE .............................................................................................................................. 15

PREMIERE PERIODE D’UTILISATION ......................................................................................................................................... 15

ENTRETIEN ................................................................................................................................................................... 16

PLAN D’ENTRETIEN PROGRAMME ............................................................................................................................................ 16

NETTOYAGE DE L’EMBOUCHURE ............................................................................................................................................. 17

CONTROLE ET REMPLACEMENT DES LAMELLES EN CAOUTCHOUC DE L’EMBOUCHURE .............................................. 17

NETTOYAGE DE LA BROSSE ...................................................................................................................................................... 18

NETTOYAGE DES RESERVOIRS ET DE LA GRILLE D’ASPIRATION ........................................................................................ 18

NETTOYAGE DU FILTRE DE LA SOLUTION ............................................................................................................................... 19

REGLAGE DE LA VITESSE D’AVANCE DE LA MACHINE ........................................................................................................... 19

CHARGEMENT DES BATTERIES ................................................................................................................................................ 20

CONTROLE / REMPLACEMENT DES FUSIBLES ....................................................................................................................... 21

DEPISTAGE DES PANNES ........................................................................................................................................... 22

MISE A LA FERRAILLE ................................................................................................................................................. 22

Razor SV17 909 6309 000(3)2009-11

1

FRANÇAIS

INSTRUCTIONS D’UTILISATION

2

909 6309 000(3)2009-11 Razor SV17

INTRODUCTION

REMARQUE

Les nombres entre parenthèses se réfèrent aux composants indiqués au chapitre Description de la machine.

BUT ET CONTENU DU MANUEL

Ce manuel se propose de fournir à l’opérateur toutes les informations nécessaires an qu’il puisse utiliser la machine correctement

et la gérer de la manière la plus autonome et sûre. Il comprend des informations concernant l’aspect technique, la sécurité, le

fonctionnement, l’arrêt de la machine, l’entretien, les pièces de rechange et la mise à la ferraille.

Avant d’effectuer toute opération sur la machine, les opérateurs et les techniciens qualiés doivent lire attentivement les instructions

contenues dans ce manuel. En cas de doutes sur la correcte interprétation des instructions, contacter KENT pour avoir plus de

renseignements.

DESTINATAIRES

Ce manuel s’adresse aux opérateurs aussi bien qu’aux techniciens préposés à l’entretien de la machine.

Les opérateurs ne doivent pas exécuter les opérations réservées aux techniciens qualiés. KENT ne répond pas des dommages

dus à l’inobservance de cette interdiction.

CONSERVATION DU MANUEL

Le Manuel opérateur doit être gardé près de la machine, dans une enveloppe spéciale et, surtout, loin de liquides et de tout ce qui

pourrait en compromettre l’état de lisibilité.

DONNEES D’IDENTIFICATION

Le numéro de série et le modèle de la machine sont indiqués sur la plaque (1).

L’année de fabrication de la machine est indiquée par les deux premiers chiffres du numéro de série de la machine.

Ces informations sont nécessaires lors de la commande des pièces de rechange de la machine. Utiliser l’espace suivant pour noter

les données d’identication de la machine.

Modèle de la MACHINE ....................................................................

Numéro de série de la MACHINE ......................................................

AUTRES MANUELS DE REFERENCE

Manuel du chargeur de batterie électronique, si équipé, qui constitue une partie intégrante de ce manuel –

Catalogue de pièces de rechange (livré avec la machine) –

Manuel d’entretien (consultable auprès des Services après-vente KENT) –

PIECES DE RECHANGE ET ENTRETIEN

Pour toute nécessité concernant l’emploi, l’entretien et la réparation, s’adresser au personnel qualié ou directement aux Services

après-vente KENT. N’utiliser que des pièces de rechange et accessoires d’origine.

Pour l’assistance ou la commande de pièces de rechange et accessoires, contacter KENT en spéciant toujours le modèle et le

numéro de série.

MODIFICATIONS ET AMELIORATIONS

KENT vise à un constant perfectionnement de ses produits et se réserve le droit d’effectuer des modications et des améliorations

lorsqu’elle le considère nécessaire sans l’obligation de modier les machines précédemment vendues.

Il est entendu que toute modication et / ou addition d’accessoires doit toujours être approuvée et réalisée par KENT.

CAPACITES OPERATIONNELLES

Les autolaveuses sont conçues et fabriquées pour le nettoyage (lavage et séchage) de sols lisses et solides, en milieux civils et

industriels, en conditions de complète sécurité, par un opérateur qualié.

Les autolaveuses ne sont pas adaptées au lavage de tapis ou de moquettes.

CONVENTIONS

Toutes les références à en avant, en arrière, avant, arrière, droite ou gauche indiquées dans ce manuel doivent être considérées

comme référées à l’opérateur en position de conduite, les mains sur le guidon (2).

INSTRUCTIONS D’UTILISATION

FRANÇAIS

Razor SV17 909 6309 000(3)2009-11

3

DEBALLAGE / LIVRAISON

Pour déballer la machine, suivre attentivement les instructions sur l’emballage.

Lors de la livraison de la machine, contrôler attentivement que l’emballage et la machine n’ont pas été endommagés pendant le

transport.

Si les dommages sont évidents, garder l’emballage de façon qu’il puisse être examiné par le transporteur qui l’a livré. Contacter

immédiatement le transporteur pour remplir une demande de dommages-intérêts.

Contrôler que les composants suivants sont livrés avec la machine :

Documentation technique : –

Manuel d’utilisation de l’autolaveuse•

Manuel du chargeur de batterie électronique•

Catalogue de pièces de rechange de l’autolaveuse•

N° 1 fusible lamellaire de 40 A –

N° 2 panneaux de batteries –

SECURITE

On utilise les symboles suivants pour signaler les conditions de danger potentielles. Lire attentivement ces informations et prendre

les précautions nécessaires pour protéger les personnes et les choses.

Pour éviter tout accident, la collaboration de l’opérateur est essentielle. Aucun programme de prévention des accidents du travail

ne peut résulter efcace sans la totale collaboration de la personne directement responsable du fonctionnement de la machine. La

plupart des accidents qui peuvent survenir dans une entreprise, pendant le travail ou les déplacements, sont dus à l’inobservance

des plus simples règles de prudence. Un opérateur attentif et prudent est la meilleure garantie contre les accidents du travail et se

révèle indispensable pour compléter n’importe quel programme de prévention.

SYMBOLES UTILISES

DANGER !

Indique une situation dangereuse exposant l’opérateur au risque de blessures graves, voire mortelles.

ATTENTION !

Indique une situation exposant les personnes au risque de blessures.

AVERTISSEMENT !

Indique un avertissement ou une remarque sur des fonctions clé ou utiles.

Prêter la plus grande attention aux segments de texte marqués par ce symbole.

REMARQUE

Indique une remarque sur des fonctions clé ou utiles.

CONSULTATION

Indique la nécessité de consulter ce Guide rapide avant toute opération.

INSTRUCTIONS GENERALES

Les avertissements et précautions spéciques suivants informent sur les potentiels dangers de dommages matériels ou blessures.

DANGER !

Avant d’effectuer toute opération de nettoyage, d’entretien et de remplacement des composants de la –

machine, positionner les interrupteurs généraux de la machine sur “0” et, si besoin est, débrancher la

batterie.

Cette machine doit être utilisée uniquement par le personnel adéquatement formé. L’utilisation de la machine –

est interdite aux enfants et aux personnes handicapées.

Ne pas porter de bijoux quand on travaille près de composants électriques. –

Ne pas opérer avec cette machine en présence de poudres, liquides ou vapeurs nuisibles, dangereux, –

inammables et / ou explosifs : la machine ne doit pas être utilisée pour ramasser des matériaux dangereux.

Déposer le réservoir d’eau de récupération pendant le cycle de rechargement des batteries et effectuer cette –

opération dans un endroit bien aéré et loin de ammes libres.

FRANÇAIS

INSTRUCTIONS D’UTILISATION

4

909 6309 000(3)2009-11 Razor SV17

ATTENTION !

Avant d’utiliser le chargeur de batterie, s’assurer que la fréquence et la tension indiquées sur la plaque avec –

numéro de série coïncident avec la tension du réseau.

Ne pas utiliser le câble du chargeur de batterie pour tirer ou transporter la machine et ne pas utiliser le câble –

comme poignée. Ne pas fermer de porte sur le câble du chargeur de batterie, ne pas tirer le câble sur des

surfaces ou coins tranchants. Ne pas faire passer la machine sur le câble du chargeur de batterie. Tenir le

câble du chargeur de batterie éloigné des surfaces chaudes.

Ne pas charger les batteries de la machine si le câble du chargeur ou la che sont endommagés. Si la –

machine ne fonctionne pas correctement, si elle est endommagée, laissée à l’extérieur ou tombée dans l’eau,

l’amener auprès d’un Service après-vente agréé.

Pour réduire le risque d’incendie, chocs électriques ou blessures, ne pas laisser la machine sans –

surveillance lorsqu’elle est branchée au réseau électrique. Débrancher le câble du chargeur de batterie du

réseau électrique avant d’effectuer toute opération d’entretien.

Ne pas fumer pendant le chargement des batteries. –

Avant de laisser la machine sans surveillance, veiller à ce que celle-ci ne puisse pas bouger de façon –

autonome.

Protéger toujours la machine du soleil, de la pluie et d’autres intempéries, pendant le fonctionnement et en –

état d’arrêt. Garder la machine dans un endroit couvert et sec : elle a été conçue pour l’utilisation à sec, par

conséquent elle ne doit pas être utilisée ou gardée dehors, dans des conditions d’humidité.

Avant d’utiliser la machine, fermer tous les portillons et / ou couvercles. –

Ne pas laisser que la machine est utilisée comme jouet. Faire attention lorsque la machine est utilisée à –

proximité des enfants.

Ne pas utiliser à des ns autres que celles prévues dans ce manuel. Utiliser seulement les accessoires –

recommandés par KENT.

Prendre les précautions convenables an que les cheveux, les bijoux, les parties non adhérentes des –

vêtements ne soient pas capturés par les parties en mouvement de la machine.

Avant de laisser la machine sans surveillance, veiller à ce que celle-ci ne puisse pas bouger de façon –

autonome.

Ne pas utiliser la machine dans des endroits très poussiéreux. –

Pendant l’utilisation de la machine, faire attention à sauvegarder l’intégrité des personnes et des choses. –

Ne pas heurter contre des étagères ou des échafaudages, en particulier en cas de danger de chute d’objets. –

Ne pas poser de conteneurs de liquides sur la machine, utiliser le porte-boissons spécial. –

La température de travail de la machine doit être comprise entre 32°F et 104°F (0°C et +40°C). –

La température de stockage de la machine doit être comprise entre 32°F et 104°F (0°C et +40°C). –

L’humidité doit être comprise entre 30% et 95%. –

Pendant l’utilisation de détergents pour le nettoyage des sols, suivre toujours les instructions et les –

avertissements indiqués sur les étiquettes des acons.

Avant la manipulation de détergents pour le nettoyage des sols, mettre les gants et les vêtements de –

protection adéquats.

Ne pas utiliser la machine comme moyen de transport. –

Ne pas utiliser la machine sur des surfaces en pente. –

Ne pas faire travailler les brosses lorsque la machine est arrêtée pour ne pas endommager le sol. –

En cas d’incendie, il est préférable d’utiliser un extincteur à poudre, plutôt qu’un extincteur à eau. –

Ne pas altérer pour aucune raison les protections prévues pour la machine, respecter scrupuleusement les –

instructions prévues pour l’entretien ordinaire.

Ne pas laisser entrer d’objets dans les ouvertures. Ne pas utiliser la machine si les ouvertures sont –

obstruées. Garder les ouvertures de la machine libres de poussière, lasse, poils et tout autre corps étranger

à même de réduire le ux d’air.

Ne pas enlever ou altérer les plaques apposées sur la machine. –

La machine n’est pas approuvée pour l’utilisation sur la voie publique. –

Faire attention pendant les déplacements de la machine en conditions de températures inférieures au point –

de congélation. L’eau présente dans le réservoir de l’eau de récupération ou dans les tuyaux pourrait se

congeler et endommager sérieusement la machine.

Utiliser les brosses et les disques livrés avec la machine et ceux spéciés dans le Manuel opérateur. –

L’utilisation de brosses ou disques différents peut compromettre la sécurité.

S’assurer que les éventuelles anomalies de fonctionnement de la machine ne dépendent pas du manque –

d’entretien. En cas contraire, demander l’intervention du personnel autorisé ou d’un Service après-vente

autorisé.

En cas de remplacement de pièces, demander les pièces de rechange D’ORIGINE à un Concessionnaire ou –

Revendeur autorisé.

An de garantir la sécurité et le bon fonctionnement de la machine, faire effectuer l’entretien programmé –

prévu au chapitre spécique de ce manuel par du personnel autorisé ou par un Service après-vente autorisé.

Avant d’effectuer toute opération d’entretien / réparation, lire attentivement toutes les instructions qui –

concernent l’entretien / réparation.

Ne pas laver la machine avec des jets d’eau directs ou sous pression ou avec des substances corrosives. –

Lors de la mise à la ferraille, la machine ne doit pas être abandonnée par la présence de matériaux toxiques –

(batteries, etc.), sujets à des lois qui prévoient l’élimination auprès de centres spéciaux (voir le chapitre Mise

à la ferraille).

Loading...

Loading...