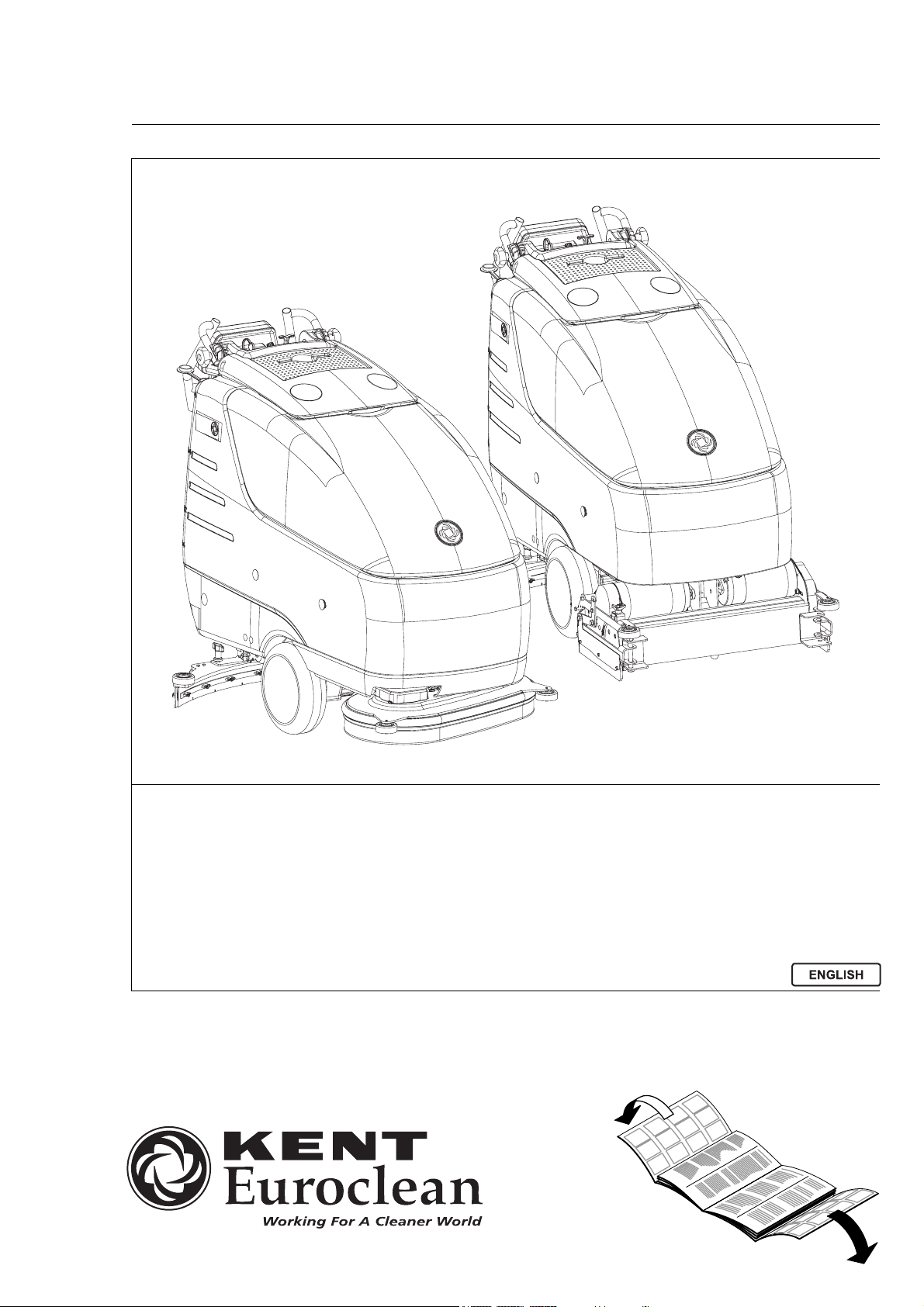

Kent Euroclean Razor Plus 28D Service Manual

Razor™ Plus 24D-26D-28D

SERVICE MANUAL

KENT/Euroclean models:

908 7041 020 - 908 7038 020 - 908 7039 020

909 5485 000(1)2004-08

SERVICE MANUAL

GENERAL INFORMATION ...................................................................................................... 3

MACHINE LIFTING ........................................................................................................................................... 3

MACHINE TRANSPORTATION ....................................................................................................................... 3

OTHER AVAILABLE MANUALS FOR RAZOR™ PLUS 24D-26D-28D ........................................................... 3

SAFETY ............................................................................................................................................................ 4

GENERAL SAFETY RULES ............................................................................................................................. 4

TECHNICAL DATA ........................................................................................................................................... 6

MAINTENANCE ................................................................................................................................................ 8

Scheduled Maintenance .............................................................................................................................. 8

SCHEDULED MAINTENANCE CHART ........................................................................................................... 8

MACHINE NOMENCLATURE .......................................................................................................................... 9

SOLUTION SUPPLY SYSTEM .............................................................................................. 13

SOLUTION TANK AND SUPPLY SYSTEM CLEANING ................................................................................ 13

SOLUTION FILTER CLEANING ..................................................................................................................... 13

SOLUTION FLOW SYSTEM SOLENOID VALVE/FAUCET/FILTER UNIT DISASSEMBLY .......................... 14

SOLUTION FLOW CONTROL CABLE AND LEVER DISASSEMBLY ........................................................... 16

SOLUTION FLOW CONTROL CABLE AND LEVER CHECK AND ADJUSTMENT ...................................... 18

TROUBLESHOOTING .................................................................................................................................... 19

Small amount of solution or no solution flows to the broom ....................................................................... 19

The solution flows to the broom even when the machine is off ................................................................. 19

The “ECO” system does not work .............................................................................................................. 19

SWEEPING SYSTEM ............................................................................................................ 20

BROOM CLEANING ....................................................................................................................................... 20

BROOM MOTOR ELECTRICAL INPUT CHECK ........................................................................................... 20

BROOM MOTOR CARBON BRUSH CHECK AND REPLACEMENT ............................................................ 22

BROOM MOTOR DISASSEMBLY .................................................................................................................. 23

BROOM ROTATION MICROSWITCH ADJUSTMENT .................................................................................. 25

ON-BOARD ADJUSTMENT OF THE BROOM DECK LIFTING/LOWERING ACTUATOR

LIMIT SWITCH POSITIONS ........................................................................................................................... 26

Lifted deck position inspection ................................................................................................................... 26

Lowered deck position inspection .............................................................................................................. 26

Extrapressure deck position inspection ..................................................................................................... 27

Reassembly ............................................................................................................................................... 27

ADJUSTMENT OF THE BROOM DECK LIFTING/LOWERING ACTUATOR LIMIT SWITCH

POSITIONS AT THE WORKBENCH .............................................................................................................. 29

DISASSEMBLY OF THE BROOM DECK LIFTING/LOWERING ACTUATOR LIMIT MICROSWITCHES ..... 30

BROOM DECK LIFTING/LOWERING ACTUATOR DISASSEMBLY ............................................................. 31

Disassembly ............................................................................................................................................... 31

Reassembly ............................................................................................................................................... 31

TROUBLESHOOTING .................................................................................................................................... 32

Open circuit ................................................................................................................................................ 32

None of the brooms rotates ....................................................................................................................... 32

One broom does not rotate ........................................................................................................................ 32

The brooms do not reach correctly the lifted, lowered or extrapressure position

(one or more positions are wrong) ............................................................................................................. 32

Razor™ Plus 24D-26D-28D — 909 5485 000(1)2004-08 1

SERVICE MANUAL

RECYCLING SYSTEM ........................................................................................................... 33

RECYCLING WATER TANK, VACUUM GRID WITH FLOAT AND RECYCLING WATER

FILTER CLEANING (OPTIONAL) ................................................................................................................... 33

VACUUM MOTOR ELECTRICAL INPUT CHECK .......................................................................................... 34

VACUUM MOTOR CARBON BRUSH CHECK AND REPLACEMENT .......................................................... 35

VACUUM MOTOR DISASSEMBLY ................................................................................................................ 36

SQUEEGEE CLEANING/CHECK AND BLADE REPLACEMENT .................................................................. 37

Disassembly and cleaning ......................................................................................................................... 37

Check and adjustment ............................................................................................................................... 37

TROUBLESHOOTING .................................................................................................................................... 38

The vacuum motor does not turn on .......................................................................................................... 38

The vacuum motor turns on, but it turns off after a few seconds ............................................................... 38

Insufficient or no dirty water vacuum ......................................................................................................... 38

The squeegee leaves lining or it does not pick up water ........................................................................... 38

DRIVE SYSTEM ..................................................................................................................... 39

DRIVE MOTOR ELECTRICAL INPUT CHECK .............................................................................................. 39

DRIVE MOTOR CARBON BRUSH CHECK AND REPLACEMENT ............................................................... 41

DRIVE MOTOR REMOVAL ............................................................................................................................ 42

POTENTIOMETER ADJUSTMENT ................................................................................................................ 43

DRIVE MICROSWITCH ADJUSTMENT ......................................................................................................... 44

TROUBLESHOOTING .................................................................................................................................... 45

Open circuit ................................................................................................................................................ 45

Drive motor: the fuse opens the circuit ...................................................................................................... 45

The machine does not move ...................................................................................................................... 45

Drive electronic board diagnostic LED ....................................................................................................... 45

ELECTRICAL SYSTEM .........................................................................................................46

BATTERY REMOVAL ..................................................................................................................................... 46

BATTERY MAINTENANCE AND RECHARGING .......................................................................................... 46

DRIVE ELECTRONIC BOARD REPLACEMENT ........................................................................................... 46

FUNCTION ELECTRONIC BOARD REPLACEMENT .................................................................................... 47

FUSE CHECK/REPLACEMENT ..................................................................................................................... 48

TROUBLESHOOTING .................................................................................................................................... 48

Function board connectors ........................................................................................................................ 49

Diagnostic LED on function board ............................................................................................................. 50

COMPONENT LAYOUT ................................................................................................................................. 52

WIRING DIAGRAM ......................................................................................................................................... 56

NOTE

Forward, backward, front, rear, left or right are intended with reference to the operator’s position.

2 Razor™ Plus 24D-26D-28D — 909 5485 000(1)2004-08

SERVICE MANUAL

GENERAL INFORMATION

GENERAL INFORMATION

MACHINE LIFTING

WARNING!

Do not work under the lifted machine, if it is not securely fixed.

MACHINE TRANSPORTATION

WARNING!

Before transporting the machine, ensure that:

• All doors and carters are closed.

• The ignition key is not inserted.

• The machine is firmly fastened to the means of transport.

OTHER AVAILABLE MANUALS FOR RAZOR™ PLUS 24D-26D-28D

The following manuals are available at KENT/Euroclean Literature Service Department:

– Spare Part List of Razor™ Plus 24D-24D-28D - KENT/Euroclean 909 5429 000.

– Instructions for Use of Razor™ Plus 24D-26D-28D - KENT/Euroclean 909 5428 000.

Razor™ Plus 24D-26D-28D — 909 5485 000(1)2004-08 3

SERVICE MANUAL

SAFETY

The following symbols indicate potentially dangerous situations. Always read this information carefully and take the

necessary precautions to protect people and objects.

DANGER!

It indicates a dangerous situation (risk of death) for the User.

WARNING!

It indicates the risk for people of being injured and for objects of being damaged.

CAUTION!

It indicates a caution or a remark related to important or useful functions. Pay particular attention to

the paragraphs marked by this symbol.

GENERAL SAFETY RULES

The following specific warnings and cautions inform you of any potential danger of damaging people or machines.

DANGER!

– Position the machine on a level ground; before performing any maintenance/repair procedures,

turn the machine ignition key to OFF position and disconnect the battery through the special

connector.

– This machine must be used by fully trained and authorized personnel only.

– Keep sparks, flames and other sources of ignition away from the battery. During the normal

operation explosive gases are released.

– Do not wear jewels when working near electrical components.

– Do not work under the lifted machine, if it is not securely fixed.

– Do not operate the machine near toxic, dangerous, inflammable and/or explosive powders,

liquids or vapors.

– Battery charging produces highly explosive hydrogen gas. Keep the tank assembly open during

battery charging and perform this procedure only in well-ventilated areas and away from naked

flames.

4 Razor™ Plus 24D-26D-28D — 909 5485 000(1)2004-08

SERVICE MANUAL

WARNING!

– Carefully read all maintenance/repair instructions before performing any maintenance/repair

procedure.

– Before using the battery charger, ensure that frequency and voltage values, indicated in the

machine serial number plate, match the mains voltage.

– Take all necessary precautions to prevent hair, jewels and loose clothes from being caught by the

machine moving and vacuuming parts.

– Do not smoke during battery charging.

– Before leaving the machine unattended, make sure that the machine cannot move and remove the

ignition key.

– Do not use the machine on surfaces with a gradient greater than the one indicated on the

machine.

– Do not wash the machine with direct or pressurized water jets, or with corrosive substances.

– Do not use the machine in particularly dusty areas.

– While using this machine, take care not to cause damage to other people.

– The storage temperature must be between +32°F and +104°F (0°C and +40°C).

– The machine operating temperature must be between +32°F and 104°F (0°C and +40°C).

– Humidity must be between 30% and 95%.

– Always protect the machine from the sun, rain and bad weather, when it is both in the operating

and stationary state.

– Do not use the machine as a means of transport.

– Do not use the machine on ramps or slopes with an inclination higher than 2%.

– Do not allow the broom to operate while the machine is stationary to avoid damaging the floor.

– In case of fire, possibly use a powder fire extinguisher, not a water fire extinguisher.

– Do not bump into shelves or scaffoldings, particularly where there is a risk of falling objects.

– Do not remove or modify the plates affixed to the machine.

– If parts must be replaced, contact an Authorized Dealer or Retailer for ORIGINAL spare parts.

– The machine must be disposed of properly, because of the presence of toxic-harmful materials

(batteries, etc.), which are subject to standards that require disposal in special centers (see

chapter “Scrapping”).

– Do not let any object enter the openings. Do not use the machine in case the openings are

clogged; always keep the openings free from dust, hairs and any other foreign material which

could reduce the air flow.

– This machine cannot be used on public roads or streets.

– Pay attention during the machine transfers when temperature is below the freezing point. The

water in the recycling tank or in the pipes could freeze and seriously damage the machine.

– Only use the brooms and pads/cylindrical brooms supplied with the machine and those specified

in the Instructions for Use Manuals. Using other brooms or pads/cylindrical brooms could reduce

safety.

Razor™ Plus 24D-26D-28D — 909 5485 000(1)2004-08 5

SERVICE MANUAL

TECHNICAL DATA

Dimensions 24D 26D 28D

Scrubbing width 24.0 in (610 mm) 26.0 in (660 mm) 29.0 in (740 mm)

Squeegee width 32.0 in (812 mm) 34.0 in (860 mm)

Machine length (max) 59 in (1,500 mm)

Machine height 42 in (1,065 mm)

Machine width without squeegee 26.0 in (658 mm) 26.8 in (681.5 mm) 30.0 in (758 mm)

Broom diameter 12.0 in (305 mm) 13.0 in (330 mm) 14.5 in (370 mm)

Fresh water tank capacity 21 gal (80 liters)

Dirty water tank capacity 21 gal (80 liters)

Weight without batteries and with empty tanks 264 lb (120 kg)

Front wheels on fixed axle Ø 10.5 in (267 mm)

Front wheels, specific ground pressure Less than 0.5 N/mm

Rear pivoting wheel Ø 3.9 in (100 mm)

2

Vacuum motor power 0.68 HP (500 W)

Rated power broom motor 0.54 HP (400 W)

Broom speed 0 to 220 rpm

Broom ground pressure 66 to 110 lb (30 to 50 kg) with gas spring

Drive motor power 0.27 HP (200 W)

Drive speed (variable) 0 to 3.2 mph (0 to 5.2 km/h)

Maximum gradient 2%

Sound pressure level (at the Operator's

position)

Standard batteries (with case) 24V 195Ah (WET)/24V 238Ah (WET)

Battery compartment dimensions (with case) 20.8 x 15.0 in, height 14.7 in (530 x 380 mm, height 375 mm)

Vacuum circuit 59.8 in H2O (1,520 mm H2O)

65 dBA

6 Razor™ Plus 24D-26D-28D — 909 5485 000(1)2004-08

SERVICE MANUAL

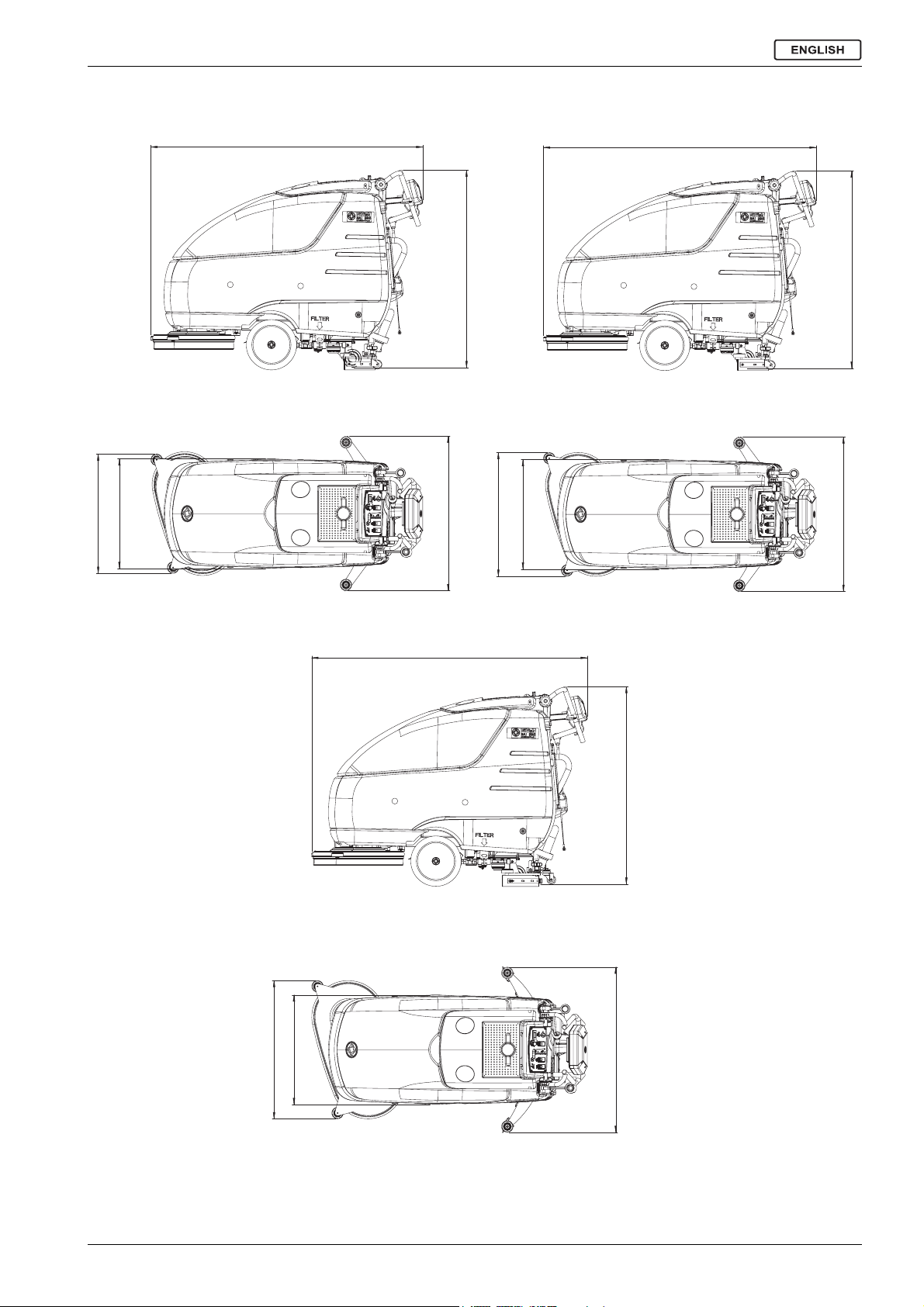

645

592

Razorô Plus 24D

1470

835

1067

669

592

Razorô Plus 26D

1473

1067

835

748

592

Razorô Plus 28D

1489

1067

893

S300617

Razor™ Plus 24D-26D-28D — 909 5485 000(1)2004-08 7

SERVICE MANUAL

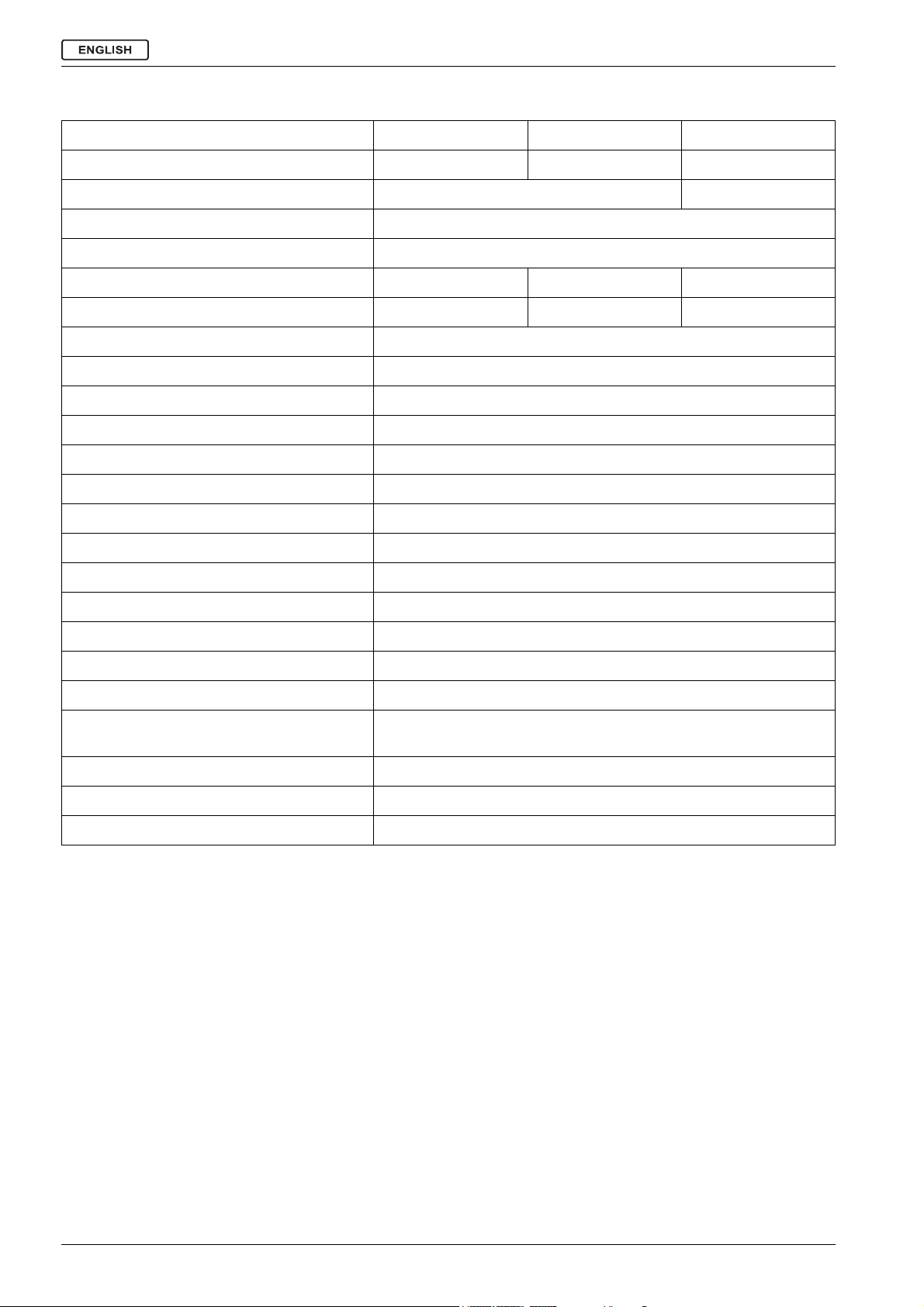

MAINTENANCE

Scheduled Maintenance

The lifespan of the machine and its maximum operating safety are ensured by regular maintenance.

WARNING!

See “GENERAL INFORMATION” and “SAFETY” paragraphs.

The following chart provides the Scheduled Maintenance. The intervals shown may vary according to particular working

conditions, which are to be defined by the person in charge of the maintenance.

For maintenance operation instructions, see the following paragraphs.

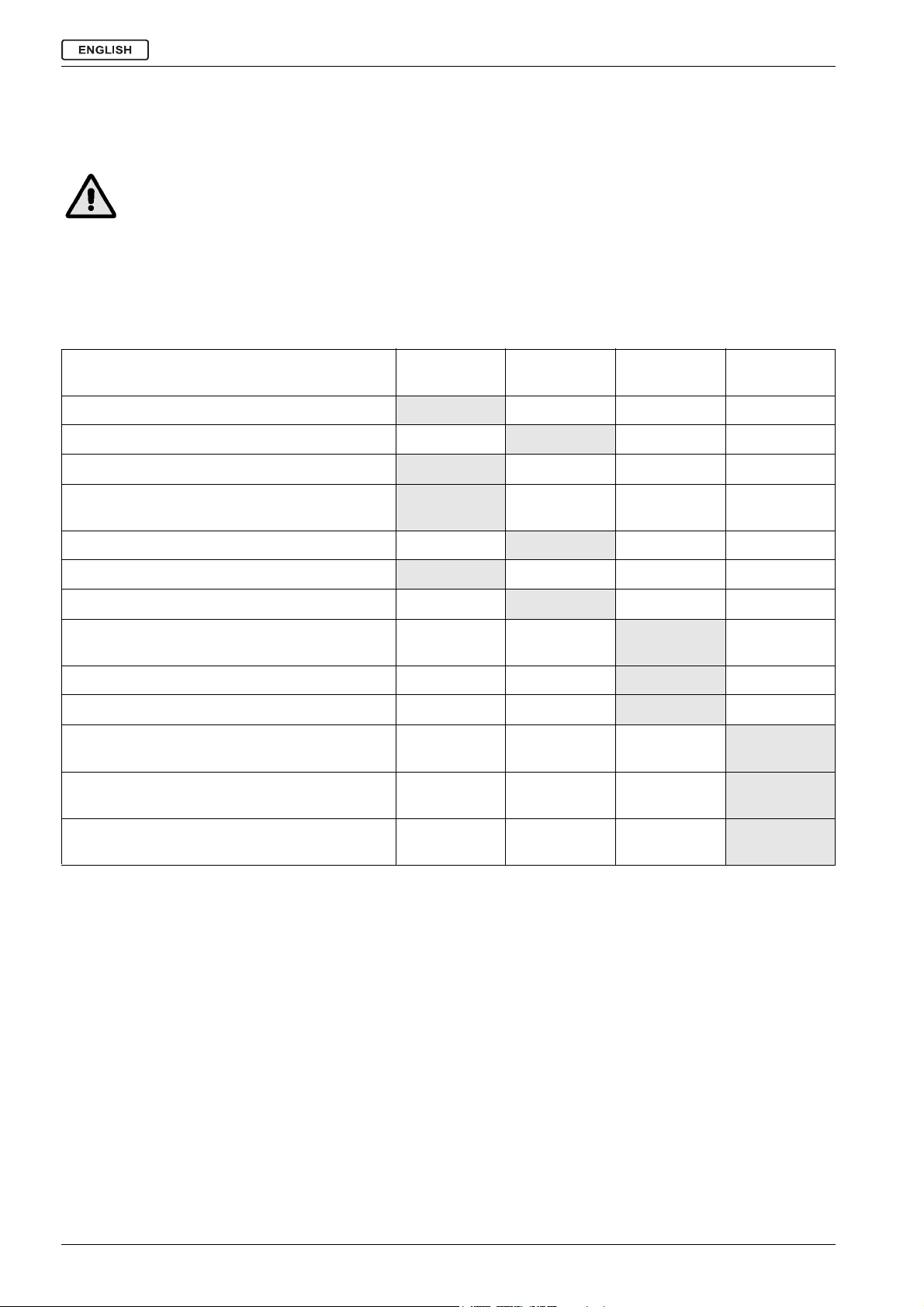

SCHEDULED MAINTENANCE CHART

Operation

Squeegee cleaning

Squeegee blade check (and replacement)

Broom/pad/cylindrical broom cleaning

Tank, vacuum grid with float and recycling water

filter cleaning (optional)

Solution filter cleaning

Battery charging

Lead (WET) battery liquid level check

Broom-holder deck lifting/lowering actuator

adjustment check

Vacuum motor seal efficiency check

Screw and nut tightening check

Broom/pad/cylindrical broom electric motor carbon

brush check or replacement

Vacuum electric motor carbon brush check or

replacement

Daily, after

machine use

Weekly

Every six

months

(1)

(1)

Yearly

Drive electric motor carbon brush check or

replacement

(1): and after the first 8 working hours

8 Razor™ Plus 24D-26D-28D — 909 5485 000(1)2004-08

SERVICE MANUAL

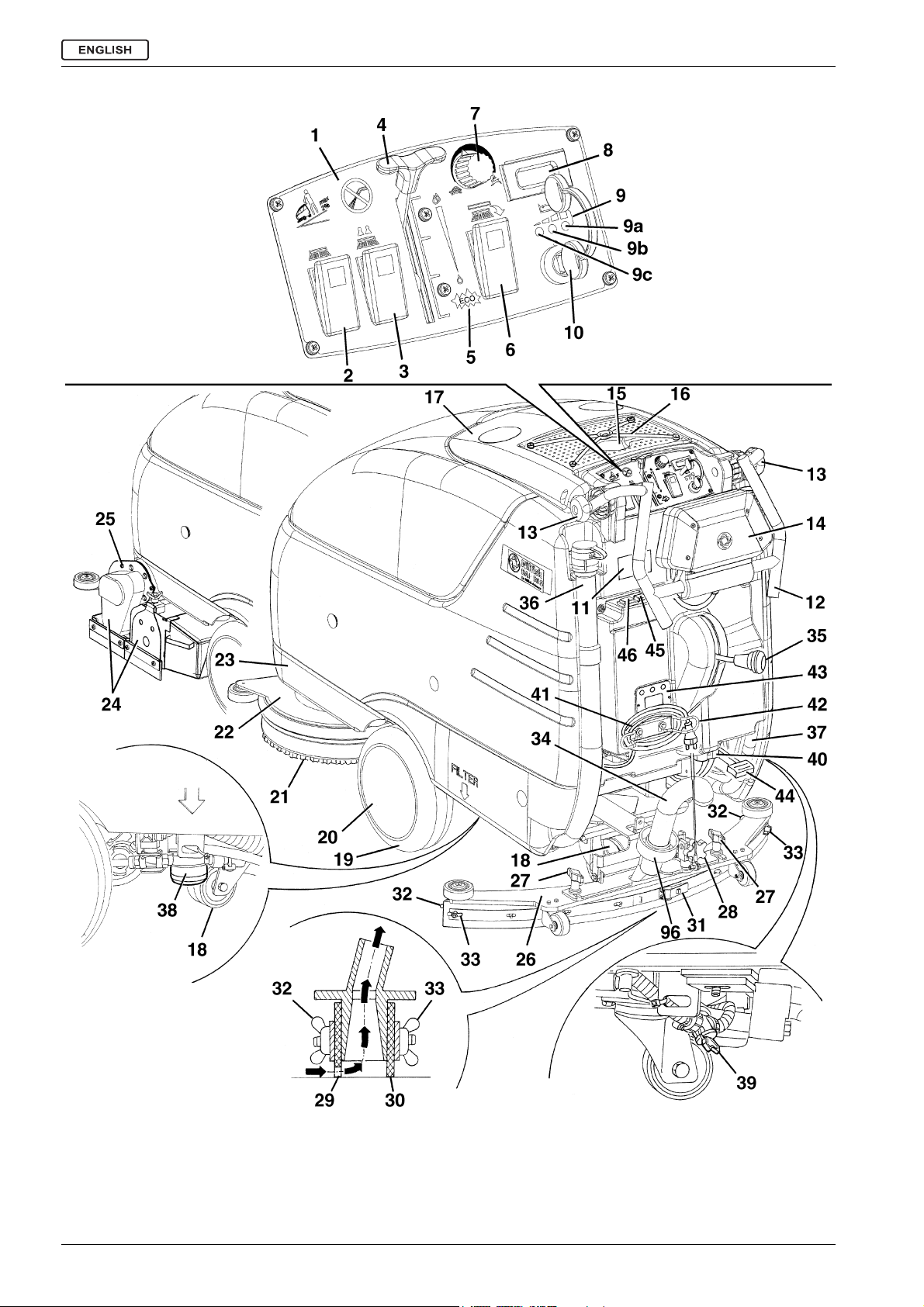

MACHINE NOMENCLATURE

Throughout this Manual you will find numbers in brackets – for example: (2). These numbers refer to the components

indicated in these two nomenclature pages. Refer to these pages whenever it will be necessary to identify a component

mentioned in the text.

1. Control panel and commands

2. Broom/pad/cylindrical broom-holder deck

lifting/lowering switch

3. Broom/pad extrapressure switch

4. Solution flow control lever

5. ECO position of the solution flow control lever (water

“economy” usage, for a washing autonomy of about 66

minutes)

6. Broom/pad control switch

7. Machine forward/reverse speed adjuster

8. Hour counter

9. Battery charge status indicator

9a. Green warning light (when ON: charged batteries)

9b. Yellow warning light (when ON: nearly discharged

batteries)

9c. Red warning light (when ON: discharged batteries)

10. Ignition key (0 - I)

11. Serial number plate / technical data

12. Machine handlebar

13. Handlebar inclination adjusting handles

14. Machine forward/reverse and broom/pad/cylindrical

broom rotation paddle

15. Glove compartment

16. Pocket

17. Tank cover

18. Rear pivoting wheel

19. Front wheels on fixed axle

20. Wheel cover

21. Broom or pad-holder with pad

22. Broom/pad-holder deck

23. Front spoiler

24. Cylindrical broom

25. Roller-holder deck

26. Squeegee

27. Squeegee fixing handwheels

28. Squeegee balance adjusting handwheel

29. Front squeegee blade

30. Rear squeegee blade

31. Rear blade fixing hook

32. Front squeegee blade fixing wing nuts

33. Rear squeegee blade fixing wing nuts

34. Squeegee vacuum pipe

35. Squeegee lifting lever

36. Recycling water drain pipe

37. Solution drain pipe

38. Solution filter

39. Solution faucet

40. Battery (red) connector

This connector also serves as EMERGENCY switch to

immediately stop all functions.

41. Battery charger cable

42. Battery charger cable holder

43. Battery charger data inspection window

44. Parking brake (optional)

45. Recycling water switch (optional)

46. Drive on/off switch

(for pushing/towing the machine)

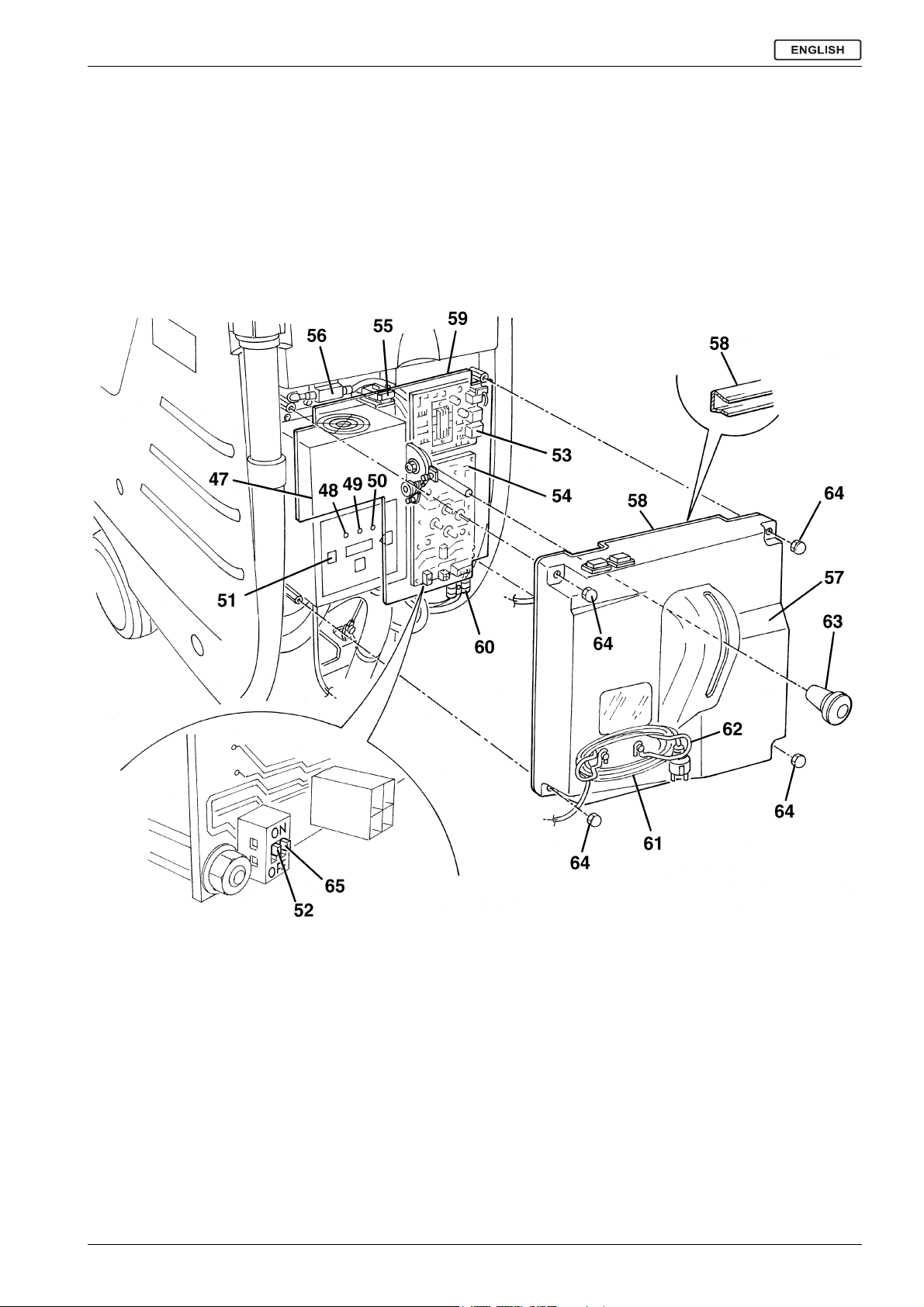

47. Electronic battery charger

48. Red warning light (when ON: battery charging)

49. Yellow warning light (when ON: battery charging almost

completed)

50. Green warning light (when ON: charged battery)

51. Lead (WET) or gel (GEL) battery selector switch,

positioned on the electronic battery charger

52. Lead (WET) or gel (GEL) battery selector switch,

located on the Function electronic board

53. Drive electronic board

54. Function electronic board

55. Drive electronic board protection fuse

56. Function electronic board protection fuse

57. Electrical component cover

58. Cover gasket

59. Rubber protection panel

60. Battery connector

61. Battery charger cable

62. Battery charger cable holder

63. Squeegee lifting lever handle

64. Cover fixing nuts

65. Vacuum automatic cut-off switch

66. Tank assembly release handwheel

67. Tank cover (open position)

68. Tank cover gasket

69. Compensation hole

70. Recycling water tank

71. Solution tank

72. Vacuum grid with float-type automatic shut-off

73. Vacuum motor

74. Broom/pad/cylindrical broom motors

75. Batteries

76. Battery caps

77. Possible battery assembly diagrams

78. Tank assembly (in lifted position)

79. Broom/pad-holder deck

80. Roller-holder deck

81. Broom/pad deck fixing handwheel

82. Broom/pad deck retaining split pins

83. Broom/disk motor connector

84. Broom

85. Pad-holder

86. Pad

87. Cylindrical brooms

88. Solution feed (removable) pipe

89. Battery case

90. Splash-guard

91. Vacuum motor seals

92. Recycling water filter (optional)

93. Solution tank marks

94. Solution drain pipe

95. Broom-holder deck lifting/lowering actuator

96. Vacuum pipe trap rubber

97. Recycling water floating switch (optional)

Razor™ Plus 24D-26D-28D — 909 5485 000(1)2004-08 9

SERVICE MANUAL

S300618

10 Razor™ Plus 24D-26D-28D — 909 5485 000(1)2004-08

SERVICE MANUAL

S300619

Razor™ Plus 24D-26D-28D — 909 5485 000(1)2004-08 11

SERVICE MANUAL

S300620

12 Razor™ Plus 24D-26D-28D — 909 5485 000(1)2004-08

SERVICE MANUAL

SOLUTION SUPPLY SYSTEM

SOLUTION SUPPLY SYSTEM

SOLUTION TANK AND SUPPLY SYSTEM CLEANING

1. Place the machine in the area designed for the solution and recycling water disposal.

2. Empty the solution tank (71) through the pipe (94).

3. Turn the solution flow control lever (4) to the wide-open position, then operate the machine until the solution inside

the machine runs out.

4. Turn the ignition key (10) to “0” position.

5. Wash the tank (71) by using fresh water.

6. Operate the machine until the solution inside the machine runs out.

7. Carry out the solution filter cleaning (see the following procedure).

SOLUTION FILTER CLEANING

1. Position the machine on a level ground.

2. Turn the ignition key (10) to “0” position.

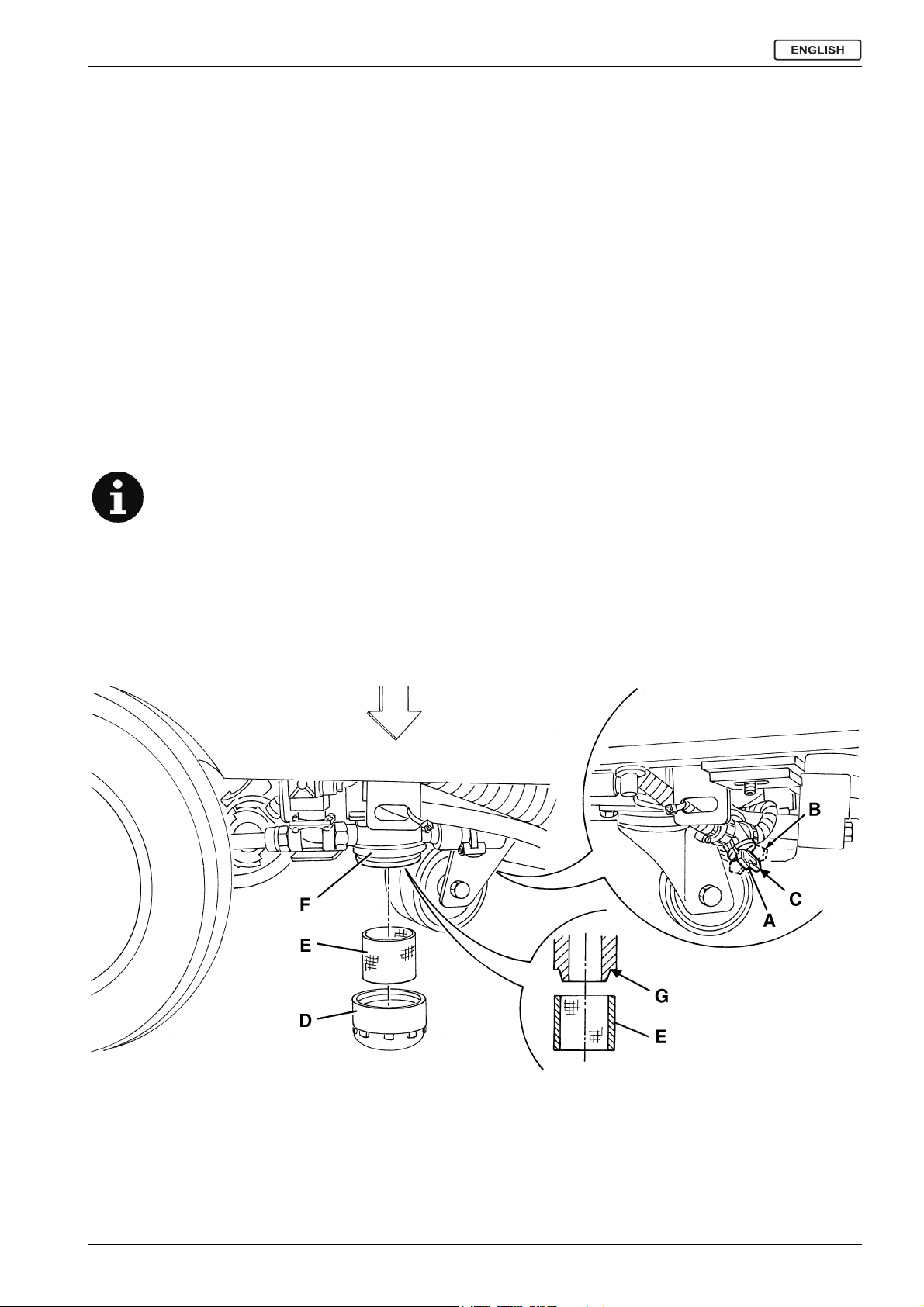

3. Close the solution faucet (A) from the right lower side of the machine. The faucet (A) is closed when it is in position

(B) as to the pipeline; it is open when it is in position (C).

4. Remove the transparent cover (D) and the strainer (E) from the left lower side of the machine (at the “FILTER”

mark); then clean and reinstall them on the holder (F).

NOTE

Correctly position the strainer (E) in the holder (F) housing (G).

5. Re-open the faucet (A).

Figure 1

S300621

Razor™ Plus 24D-26D-28D — 909 5485 000(1)2004-08 13

SERVICE MANUAL

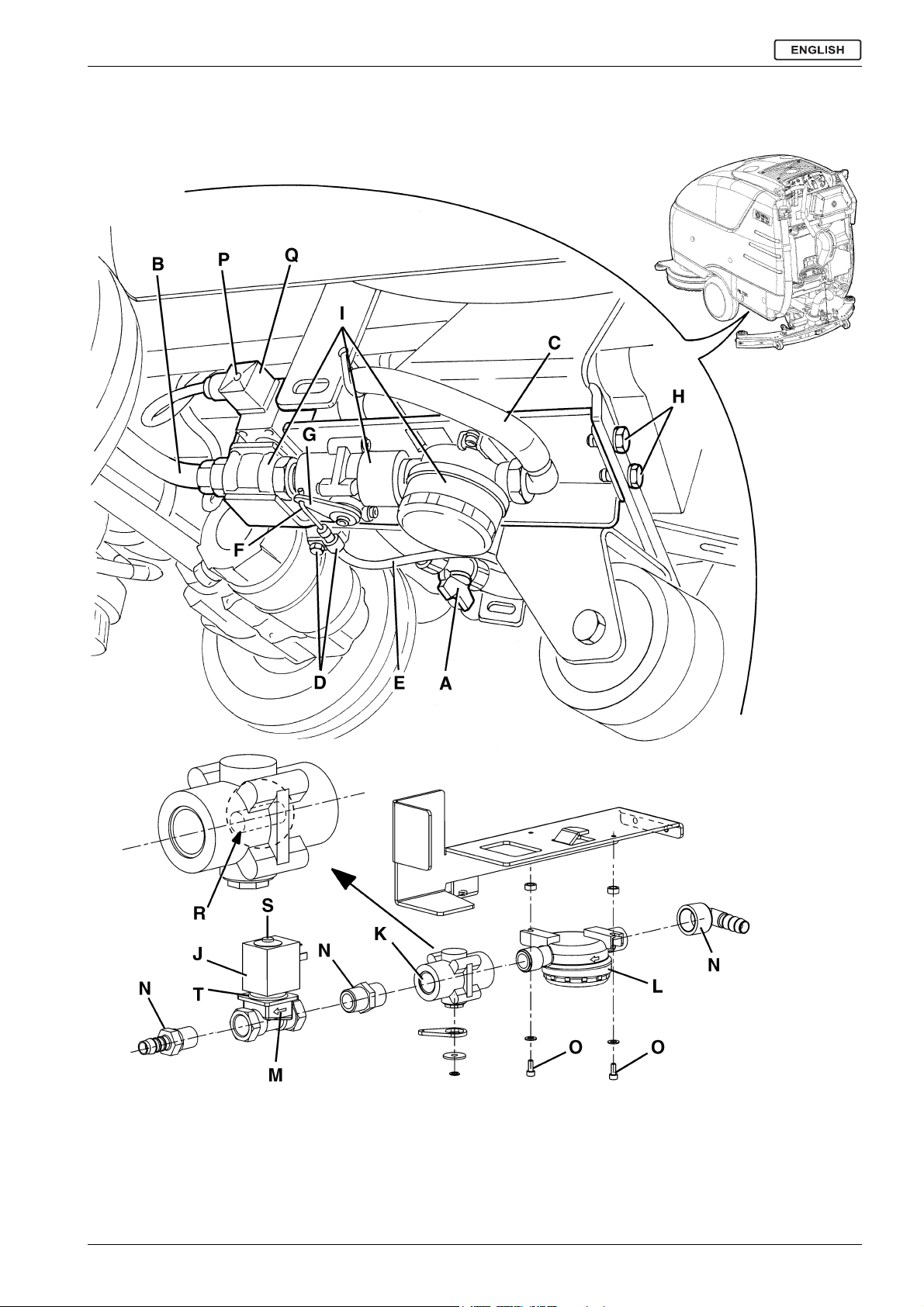

SOLUTION FLOW SYSTEM SOLENOID VALVE/FAUCET/FILTER UNIT DISASSEMBLY

1. Drain the recycling water, if any, from the related tank (70) by using the pipe (36).

2. Drain the solution, if any, from the related tank (71) by using the pipe (37).

3. Position the machine on a level ground.

4. Turn the ignition key (10) to “0” position.

5. Disconnect the battery connector (40).

6. Close the solution faucet (A) from the right lower side of the machine.

7. Slightly lift the machine left side and remove the hoses (B) and (C) from their fittings.

8. Mark the position of the clamp (D) on the faucet control cable sheath (E); loosen the clamp (D) and release the

sheath (E).

Remove the cable (F) from the lever (G).

NOTE

When reassembling, tighten the sheath (E) through the clamp (D) into its position, by using the

reference marks made before disassembly, not to change the adjustment of the faucet control.

9. Unscrew the screw (P) and disconnect the solenoid valve (Q).

10. Unscrew the fixing screws (H) of the solenoid valve-faucet-filter assembly holder.

11. Remove the solenoid valve-faucet-filter assembly (I).

12. Place the assembly on the workbench, and unscrew the fittings (N) / screws (O) to remove the solenoid valve (J) /

the faucet (K) / the filter unit (L).

13. If necessary, remove dirt or limestone from the solenoid valve (J) inner seal, after disassembling it according to the

following procedure:

– Loosen the retainer ring (S), then remove the coil.

– Unscrew the four solenoid valve fixing screws (T) and its seal.

– After cleaning the inner seal, reassemble the solenoid valve by carrying out the disassembly operations in the

reverse order. Make sure that you correctly replace the seal into its seat.

14. If necessary, remove dirt or limestone from the faucet (K); in particular, clean the solution “ECO” flow inner hole (R).

15. Reassemble by carrying out the disassembly operations in the reverse order.

NOTE

When reassembling the solenoid valve (D), the orientation of the arrow (M) must be as shown in the

figure (in the direction of the solution flow); furthermore, before installing the previously removed

fittings (N), clean the related threads and apply LOCTITE 572 sealant.

14 Razor™ Plus 24D-26D-28D — 909 5485 000(1)2004-08

Figure 2

SERVICE MANUAL

S300622

Razor™ Plus 24D-26D-28D — 909 5485 000(1)2004-08 15

SERVICE MANUAL

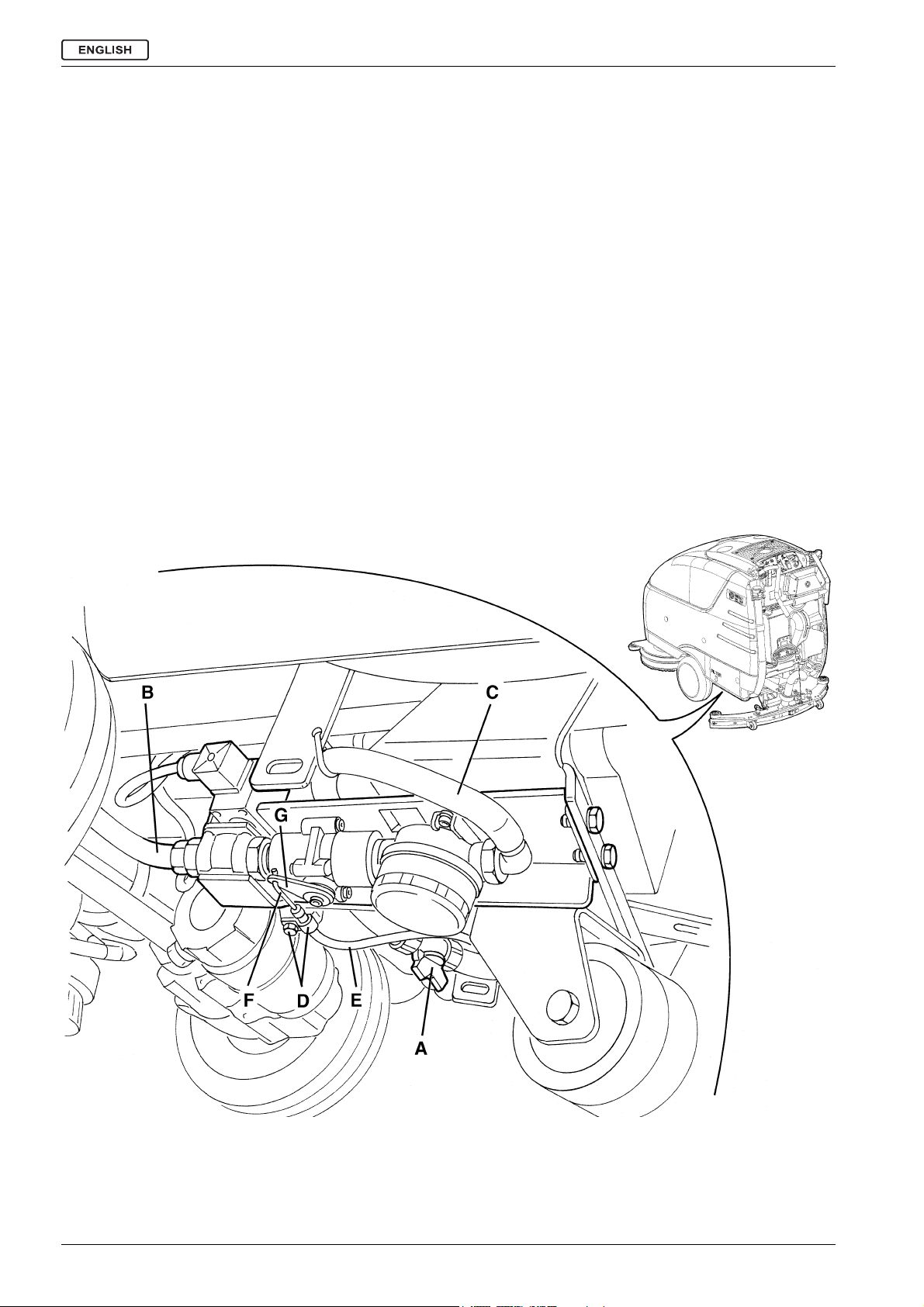

SOLUTION FLOW CONTROL CABLE AND LEVER DISASSEMBLY

1. Drain the recycling water, if any, from the related tank (70) by using the pipe (36).

2. Drain the solution, if any, from the related tank (71) by using the pipe (37).

3. Position the machine on a level ground.

4. Turn the ignition key (10) to “0” position.

5. Disconnect the battery connector (40).

6. Close the solution faucet (A) from the right lower side of the machine.

7. Slightly lift the machine left side and remove the hoses (B) and (C) from their fittings.

8. Loosen the clamp (D) and release the sheath (E).

9. Remove the cable (F) from the lever (G).

10. Connect a probe (cord or equivalent) to the cable end (F) (this operation is necessary to facilitate the insertion of

the cable inside the machine).

11. Lower the machine left side to the floor.

12. Remove the handle (H) from the lever (I), by using the control panel.

13. Unscrew the screws (J) and slightly lift the panel (K).

14. Unscrew the screws with the nut (L) and remove the lever assembly (I) from the panel (K).

15. Take the control cable (M) and the lever out of the machine, leaving the probe in its place (to facilitate the control

cable insertion).

16. Reassemble by carrying out the disassembly operations in the reverse order, by placing the clamp (D) on the sheath

(E) without tightening it.

17. Perform the Cable Adjustment, as described in the following procedure.

Figure 3

S300623

16 Razor™ Plus 24D-26D-28D — 909 5485 000(1)2004-08

Figure 4

SERVICE MANUAL

S300624

Razor™ Plus 24D-26D-28D — 909 5485 000(1)2004-08 17

Loading...

Loading...