Page 1

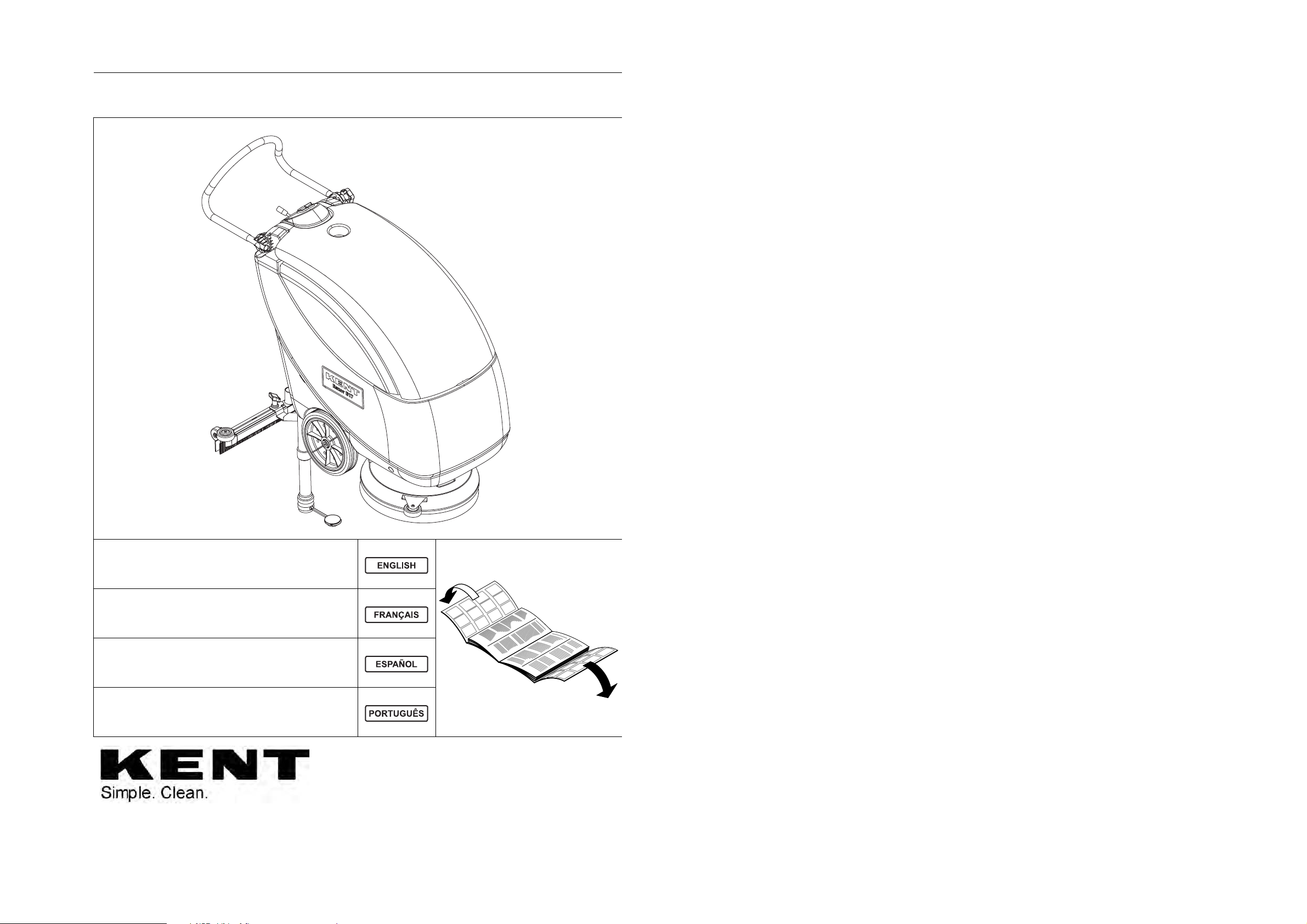

Razor E17

INSTRUCTIONS FOR USE

KENT model:

908 7113 020

INSTRUCTIONS D’UTILISATION

Modèle KENT:

908 7113 020

INSTRUCCIONES DE USO

Modelo KENT:

908 7113 020

INSTRUÇÕES DE USO

Modelo KENT:

908 7113 020

909 6311 000(1)2006-01

Page 2

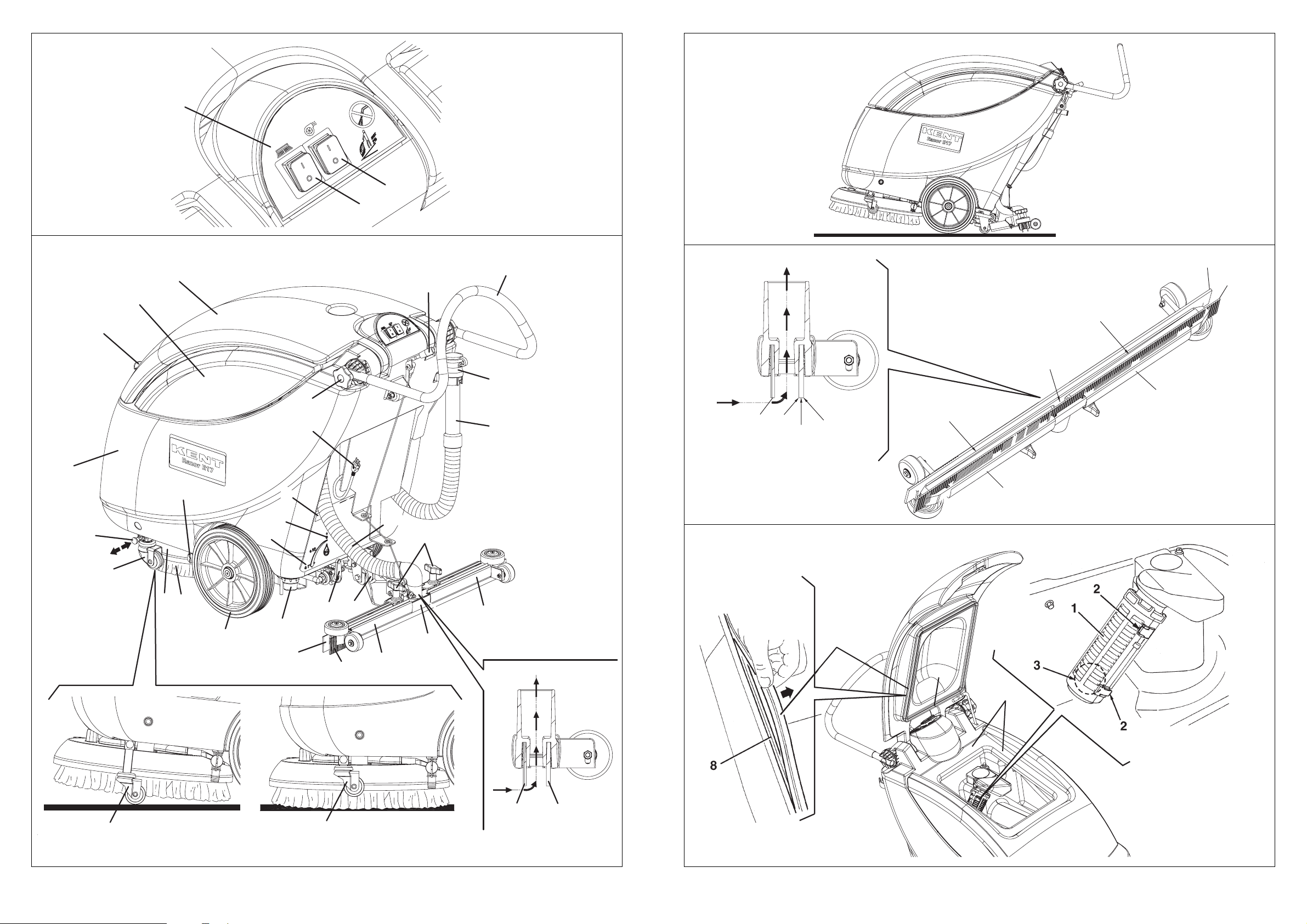

B

C

25

26

D

1

3

2

S311244

S311246

2

E

6

19

1

2

4

3

27

24

23

18

10 9

17

6

S311226

5b

5a

3

5

21

16

9

12

7

1

1

6

22

12

7

4

15

F

20

8

11

7

13

14

15

9

10

23a

23b

13 14

S311245

909 6311 000(1)2006-01

S311227

Page 3

INSTRUCTIONS FOR USE

INTRODUCTION ................................................................................................................................... 2

MANUAL PURPOSE AND CONTENTS ........................................................................................................... 2

TARGET ........................................................................................................................................................... 2

HOW TO KEEP THIS MANUAL ....................................................................................................................... 2

IDENTIFICATION DATA ................................................................................................................................... 2

OTHER REFERENCE MANUALS .................................................................................................................... 2

SPARE PARTS AND MAINTENANCE ............................................................................................................. 2

CHANGES AND IMPROVEMENTS ................................................................................................................. 2

SAFETY ................................................................................................................................................. 3

SYMBOLS ......................................................................................................................................................... 3

GENERAL INSTRUCTIONS ............................................................................................................................. 3

UNPACKING ......................................................................................................................................... 4

MACHINE DESCRIPTION ..................................................................................................................... 5

OPERATION CAPABILITIES ............................................................................................................................ 5

CONVENTIONS ................................................................................................................................................ 5

DESCRIPTION ................................................................................................................................................. 5

TECHNICAL DATA ........................................................................................................................................... 5

ACCESSORIES/OPTIONS ............................................................................................................................... 6

USE ........................................................................................................................................................ 6

BEFORE START-UP ........................................................................................................................................ 6

MACHINE START AND STOP ......................................................................................................................... 7

MACHINE OPERATION ................................................................................................................................... 7

MACHINE TRANSPORT/PARKING ................................................................................................................. 8

TANK EMPTYING ............................................................................................................................................. 8

AFTER USING THE MACHINE ........................................................................................................................ 8

RECOVERY WATER TANK REMOVAL ........................................................................................................... 8

MACHINE LONG INACTIVITY ......................................................................................................................... 8

FIRST PERIOD OF USE .................................................................................................................................. 8

MAINTENANCE .................................................................................................................................... 9

SCHEDULED MAINTENANCE TABLE ............................................................................................................ 9

SQUEEGEE CLEANING .................................................................................................................................. 9

SQUEEGEE BLADE CHECK AND REPLACEMENT ..................................................................................... 10

BRUSH CLEANING ........................................................................................................................................ 10

TANK AND VACUUM GRID CLEANING ........................................................................................................ 10

SOLUTION FILTER CLEANING ..................................................................................................................... 11

MACHINE SPEED ADJUSTMENT ................................................................................................................. 11

TROUBLESHOOTING ........................................................................................................................ 11

SCRAPPING ........................................................................................................................................ 12

Razor E17 — 909 6311 000(1)2006-01 1

Page 4

INSTRUCTIONS FOR USE

INTRODUCTION

MANUAL PURPOSE AND CONTENTS

The purpose of this Manual is to provide the customer with all

necessary information to use the machine properly in a safe

an autonomous way. It contains information about technical

data, operation, machine inactivity, maintenance, spare parts

and safety conditions.

Before carrying out any procedure on the machine, the

operators and qualified technicians must read this Manual

carefully. Contact an authorized KENT Service Center in case

of doubts concerning the interpretation of the instructions and

for any further information.

TARGET

This Manual is intended for operators and technicians

qualified to perform the machine maintenance.

The operators must not carry out operations reserved for

qualified technicians. KENT will not be answerable for

damages coming from the non-observance of this prohibition.

HOW TO KEEP THIS MANUAL

The Instructions for Use Manual must be kept near the

machine, inside an adequate case, away from liquids and

other substances that can cause damage to it.

OTHER REFERENCE MANUALS

– Spare Parts List, supplied with the machine.

– Service Manual (that can be consulted at KENT Service

Centers).

SPARE PARTS AND MAINTENANCE

All necessary operating, maintenance and repair procedures

must be carried out by qualified personnel or by KENT

Service Centers. Only original spare parts and accessories

must be used.

Call KENT for service or to order spare parts and

accessories, specifying the machine model and serial

number.

CHANGES AND IMPROVEMENTS

KENT constantly improves its products and reserves the right

to make changes and improvements at its discretion without

being obliged to apply such benefits to the machines

previously sold.

Any change and/or addition of accessory must be approved

and performed by KENT.

IDENTIFICATION DATA

The machine serial number and model are shown on the label

and can be read from the outside (1, Fig. C).

The machine model year is shown after the Date Code on the

serial plate (A06 means January 2006).

This information is useful when requiring machine spare

parts. Use the following table to write down the machine

identification data for any further reference.

MACHINE model ...........................................................

MACHINE serial number ...............................................

2 Razor E17 — 909 6311 000(1)2006-01

Page 5

SAFETY

The following symbols indicate potentially dangerous

situations. Always read this information carefully and take all

necessary precautions to safeguard people and property.

The operator's cooperation is essential in order to prevent

injury. No accident prevention program is effective without the

total cooperation of the person responsible for the machine

operation. Most of the accidents that may occur in a factory,

while working or moving around, are caused by failure to

comply with the simplest rules for exercising prudence. A

careful and prudent operator is the best guarantee against

accidents and is essential for successful completion of any

prevention program.

SYMBOLS

DANGER!

It indicates a dangerous situation with risk of

death for the operator.

WARNING!

It indicates a potential risk of injury for people.

CAUTION!

It indicates a caution or a remark related to

important or useful functions. Pay particular

attention to the paragraphs marked by this

symbol.

NOTE

GENERAL INSTRUCTIONS

Specific warnings and cautions to inform about potential

damages to people and machine are shown below.

– Before performing any maintenance/repair procedure,

– This machine must be used by properly trained and

– Do not wear jewels when working near electrical

– Do not operate the machine near toxic, dangerous,

It indicates the necessity to refer to the

Instructions for Use Manual before performing

any operation.

DANGER!

disconnect the power supply cable from the electrical

mains.

authorized personnel only. Children or disabled people

cannot use this machine.

components.

inflammable and/or explosive powders, liquids or

vapours.

INSTRUCTIONS FOR USE

WARNING!

– Carefully read all the instructions before carrying out any

maintenance/repair procedure.

– Before connecting the machine to the electrical mains,

make sure that the frequency and voltage shown in the

serial plate (1, Fig. C) match the mains voltage.

– To reduce the risk of fire, electric shock, or injury, do not

leave the machine unattended when it is plugged in.

Unplug the machine from the outlet when not in use and

before servicing.

– To avoid electric shock, do not expose to rain. Store the

machine indoors.

– Do not allow to be used as a toy. Close attention is

necessary when used near children.

– Use only as described in this Manual. Use only KENT's

recommended accessories.

– Do not use with damaged power supply cable or plug. If

the machine is not working as it should, has been

damaged, left outdoors or dropped into water, return it to

the Service Center.

– If the supply cable or the plug is worn or damaged, it

needs to be replaced at the Service Center.

– Do not pull or carry the machine by the supply cable;

never use the power supply cable as a handle. Do not

close a door on the supply cable, or pull the supply cable

around sharp edges or corners. Do not run the machine

on the supply cable. Keep the supply cable away from

heated surfaces.

– Do not unplug the machine by pulling the supply cable.

To unplug, grasp the plug, not the cable.

– Do not handle the plug or the machine with wet hands.

– Turn off all controls before unplugging.

– Take all necessary precautions to prevent hair, jewels

and loose dresses from being caught by the machine

moving and vacuuming devices.

– Do not work under the lifted machine without supporting

it with safety stands.

– Do not leave the machine unattended without being sure

that the machine cannot move independently.

– Do not use the machine on slopes with a gradient

exceeding the specifications.

– Do not wash the machine with direct or pressurized

water jets, or with corrosive substances.

Razor E17 — 909 6311 000(1)2006-01 3

Page 6

INSTRUCTIONS FOR USE

– Do not use the machine in particularly dusty areas.

– While using this machine, take care not to cause

damage to people.

– Do not put any can containing fluids on the machine.

– The storage temperature must be between +32°F and

+104°F (0°C and +40°C).

– The machine operating temperature must be between

+32°F and +104°F (0°C and +40°C).

– The humidity must be between 30% and 95%.

– Always protect the machine against the sun, rain and

bad weather, both under operation and inactivity

condition.

– Do not use the machine as a means of transport.

– Do not allow the brush to operate while the machine is

stationary to avoid damaging the floor.

– In case of fire, possibly use a powder fire extinguisher,

not a water one.

– Do not bump into shelves or scaffoldings, particularly

where there is a risk of falling objects.

– Do not tamper with the machine safety guards and follow

the ordinary maintenance instructions scrupulously.

– Do not remove or modify the plates affixed to the

machine.

– In case of machine malfunctions, ensure that these are

not caused by a lack of maintenance. Otherwise,

request assistance from the authorized personnel or

from an authorized Service Center.

– If parts must be replaced, require ORIGINAL spare parts

from a Dealer or Authorized Retailer.

– To ensure the proper and safe operation of the machine,

have the scheduled maintenance, detailed in the

relevant chapter of this Manual, performed by the

authorized personnel or an authorized Service Center.

– The machine must be disposed of properly, because of

the presence of toxic-harmful materials (plastic

materials, etc.), which are subject to standards that

require disposal in special centers (see Scrapping

chapter).

– If the machine is used according to the instructions, the

vibrations do not cause dangerous situations. The

machine vibration level is less than 98.42 in/s

(98/37/EEC - EN 1033/1995).

2

(2.5 m/s2)

– Do not allow any object to enter into the openings. Do

not use the machine if the openings are clogged. Always

keep the openings free from dust, hairs and any other

foreign material which could reduce the air flow.

– Do not pick up anything that is burning or smoking, such

as cigarettes, matches, or hot ashes.

– This machine cannot be used on roads or public streets.

– Pay attention during the machine transfers when

temperature is below freezing point. The water in the

recovery tank or in the hoses could freeze and seriously

damage the machine.

– Use only brushes and pads supplied with the machine or

specified in this Manual. Using other brushes or pads

could reduce safety.

– This machine is not suitable for picking up hazardous

materials.

– Dispose of machine or machine components according

to the law in force.

UNPACKING

To unpack the machine carefully follow the instructions on the

packing.

When the machine is delivered, check that the packing and

the machine were not damaged during transportation. In case

of visible damages, keep the packing and have it checked by

the Carrier that delivered it. Call the Carrier immediately to fill

in a damage claim.

Please check that the following items have been supplied with

the machine:

– Scrubber-dryer Instructions for Use Manual

– Scrubber-dryer Spare Parts List

– Supply cable extension

4 Razor E17 — 909 6311 000(1)2006-01

Page 7

INSTRUCTIONS FOR USE

MACHINE DESCRIPTION

OPERATION CAPABILITIES

This scrubber-dryer is used to clean (scrubbing and drying)

smooth and solid floors, in civil or industrial environment,

under safe operation conditions by a qualified operator.

The scrubber-dryer cannot be used for moquette and carpet

cleaning.

CONVENTIONS

Forward, backward, front, rear, right or left are intended

with reference to the operator’s position, that is to say with the

hands on the handlebar (2, Fig. C).

DESCRIPTION

Control panel

(See Fig. B)

1. Control panel

2. Brush/pad switch

3. Vacuum switch

Exterior rear view

(See Fig. C)

1. Serial number plate/technical data

2. Handlebar

3. Handlebar inclination adjusting knob

4. Solution flow control lever

5a. Solution flow control lever ECO position (water

“economy” usage, for a washing autonomy of 70-80

minutes).

5b. Maximum solution flow

5. Recovery water tank cover

6. Rear support wheel for transport/parking

7. Central wheels on fixed axle

8. Brush/pad

9. Brush/pad cover

10. Squeegee

11. Squeegee fixing handwheels

12. Front squeegee blade

13. Rear squeegee blade

14. Squeegee blade fixing springs

15. Recovery water drain hose

16. Recovery water drain hose bracket

17. Solution drain valve

18. Squeegee lifting/lowering lever

19. Solution filter

20. Power supply cable

21. Squeegee vacuum hose

22. Transport/parking device

23a. Transport/parking device activated

23b. Transport/parking device deactivated

23. Transport/parking device positioning pin

24. Brush/pad support (activated)

25. Recovery water tank

26. Solution tank

Under-tank front view

(See Fig. I)

1. Recovery water tank cover (open)

2. Recovery water tank cover gasket

3. Brush/pad support (activated)

4. Recovery water tank

5. Solution tank

6. Vacuum grid with automatic shut-off float

7. Recovery water drain hole

8. vacuum system motor

9. Brush/pad motor

10. Cover with brush/pad-holder coupling pin

11. Machine speed adjusting screw

12. Brush

13. Pad-holder

14. Pad

15. Terminal board box

16. Screw

17. Compensation hole

18. Cover stand (applied)

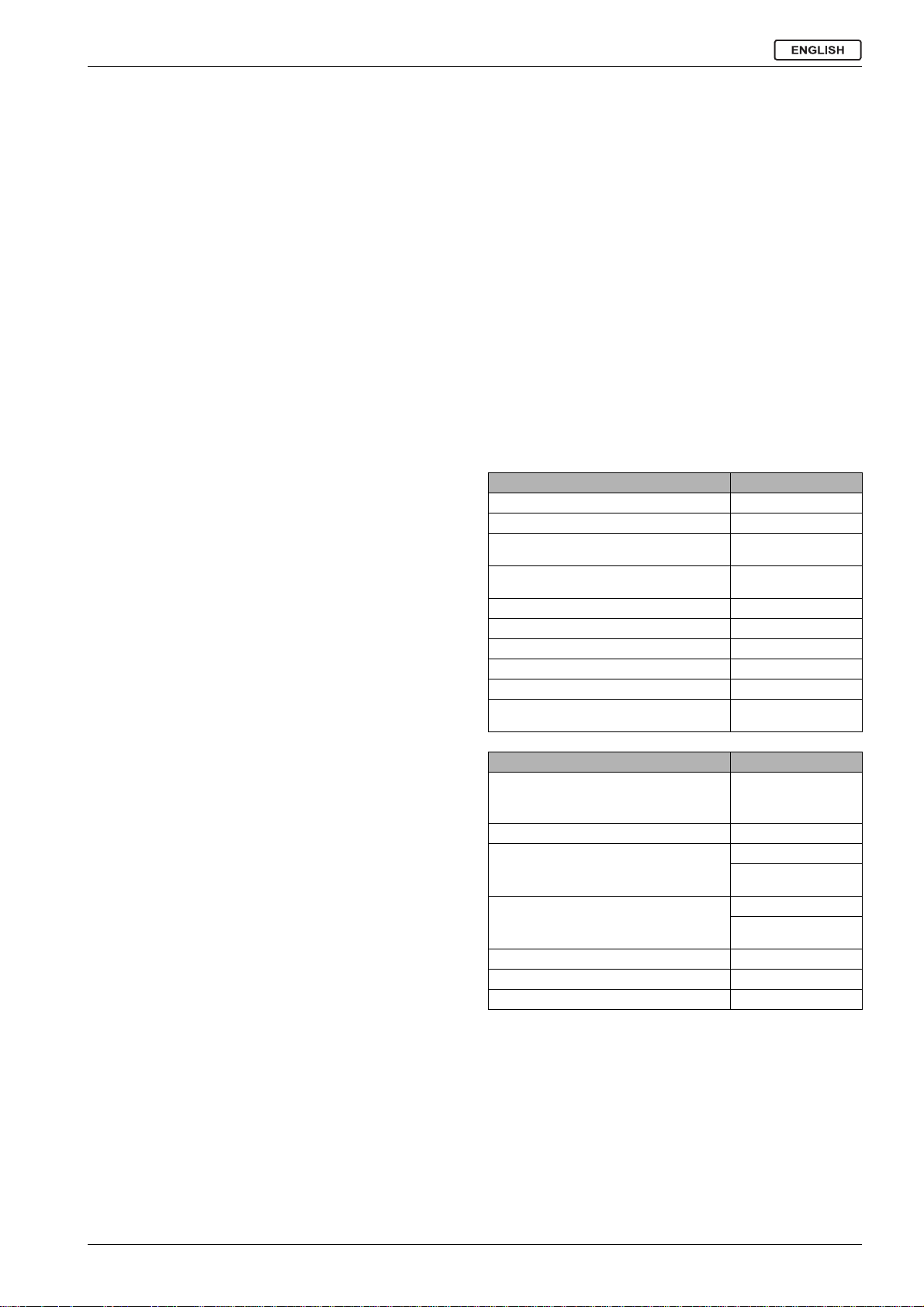

TECHNICAL DATA

General Values

Cleaning width 17.0 in (430 mm)

Machine width (without squeegee) 22.4 in (570 mm)

Minimum machine length with adjustable

handlebar

Minimum machine height with adjustable

handlebar

Squeegee width 28.3 in (720 mm)

Machine weight (with brush) 148.5 lbs (67.5 Kg)

Central (fixed axle) wheel diameter 9.8 in (250 mm)

Brush/pad diameter 17.0 in (430 mm)

Wheel pressure on the ground <0.5 N/mm

Brush/pad pressure on the ground (with

full tank)

Performance Values

Vacuum system capacity

Sound pressure level 76 dB(A)

vacuum system motor power

Brush/pad motor power

System voltage 230 V

Clean water tank capacity 8 gal (31 liters)

Recovery water tank capacity 7.9 gal (30 liters)

36.6 in (930 mm)

40.2/44.7 in

(1,020/1,135 mm)

61.6 lbs (28 Kg)

56.2 in H

O (1,316

2

mm H

550 W 50Hz

550 W 60Hz

(for US)

1,100 W 50Hz

550 W 60Hz

(for US)

2

2

O)

Razor E17 — 909 6311 000(1)2006-01 5

Page 8

INSTRUCTIONS FOR USE

Wiring diagram

(See Fig. K)

EV1: Water solenoid valve

FR: Frame

M1: Brush/pad motor

M2: vacuum system motor

PL: Plug

SW1: Brush/pad switch

SW2: Vacuum switch

Colour code:

BK: Black

BU: Blue

BN: Brown

GN: Green

GY: Grey

OG: Orange

PK: Pink

RD: Red

VT: Violet

WH: White

YE: Yellow

ACCESSORIES/OPTIONS

In addition to the standard components, the machine can be

equipped with the following accessories/options, according

the machine specific use:

– Brushes/pads of different materials.

For further information concerning the above-mentioned

optional accessories, contact an authorized Retailer.

USE

WARNING!

On some points of the machine there are some

adhesive plates indicating:

–DANGER

– WARNING

– CAUTION

–NOTE

While reading this Manual, the operator must pay particular

attention to the symbols shown on the plates.

Do not cover these plates for any reason and immediately

replace them if damaged.

BEFORE START-UP

Squeegee installation

1. Install the squeegee (11, Fig. C) and fix it by means of

the handwheels (12), then connect the vacuum hose

(22) to the squeegee.

Solution tank filling

2. Fill the solution tank (5, Fig. I) with a solution suitable for

the work to be carried out.

Do not fill the solution tank completely, leave few inches

from the edge.

Always follow the dilution instructions on the label of the

chemical product used to create the solution.

The solution temperature must not exceed 104°F

(40°C).

CAUTION!

Use only low-foam and non-flammable liquid

detergents, intended for automatic scrubber

applications.

NOTE

Use either the brush (12, Fig. I) or the

pad-holder (13) according to the type of floor to

be cleaned.

6 Razor E17 — 909 6311 000(1)2006-01

Page 9

INSTRUCTIONS FOR USE

Brush or pad-holder installation

3. Insert the positioning pin (24, Fig. C) and deactivate the

transport/parking device (23b).

4. Lift the brush/pad cover (10, Fig. C) by prying the

handlebar (2).

5. Place the brush (12, Fig. I) or the pad-holder (13) under

the cover.

6. Lower the cover (10, Fig. C) by means of the handlebar

(2).

7. Connect the power supply cable (21, Fig. C) to the

electrical mains.

8. Hook the brush/pad-holder by pressing the brush/pad

switch (2, Fig. B) for a few seconds.

If the hooking operation is difficult, manually rotate the

brush/pad-holder counter-clockwise (Fig. J).

Adjustments

9. Using the knob (3, Fig. C), adjust the handlebar (2) to the

most comfortable position.

MACHINE START AND STOP

Machine start

1. Prepare the machine according to the procedure shown

in the previous paragraph.

2. Lower the squeegee (11, Fig. C) by means of the lever

(19).

3. Turn the solution flow control lever (4, Fig. C) to one of

the following positions, according to the type of cleaning

to be carried out:

– ECO system: When the lever (4) is in the “ECO”

position (5a), the machine works in a special

condition of programmed water “economy” usage; as

the water flow is set and constant, the machine can

work with a washing autonomy of 70-80 minutes

[0.08 gal/min (0.3 liters/min) average].

– Variable system: When the lever is turned to the left

(variable flow), it is possible to increase the capacity

up to 0.26 gal/min (1 liter/min).

During machine operation, it is not possible to close

completely the water flow to the brushes.

4. While keeping one hand on the handlebar (2, Fig. C),

start the machine by turning the brush/pad switch and

the vacuum switch (2 and 3, Fig. B) to “I”.

Machine stop

5. Turn the brush/pad switch and the vacuum switch (2 and

3, Fig. B) to “0”.

6. Disconnect the power supply cable from the electrical

mains.

7. Lift the squeegee by means of the lever (19, Fig. C).

8. Insert the positioning pin (24, Fig. C) and lift the

brush/pad by activating the transport/parking device

(23a).

MACHINE OPERATION

1. Start the machine according to the procedure shown in

the previous paragraph.

2. While keeping both hands on the handlebar (2, Fig. C),

move the machine and start scrubbing/drying the floor.

CAUTION!

To avoid damaging the floor surface:

– Do not use the brush/pad without the

solution.

– When the machine is stopped, stop the

brush/pad by pressing the switch (2, Fig.

B).

CAUTION!

Before lifting the brush/pad, stop its rotation

by pressing the switch (2, Fig. B).

3. If necessary, adjust the solution flow sent to the brushes

by turning the lever (4, Fig. C).

Machine speed adjustment

4. The machine speed depends on the floor type and on

the choice of using brush or pad.

If necessary, it is possible to adjust the machine speed

by following the relevant procedure in the Maintenance

chapter.

Razor E17 — 909 6311 000(1)2006-01 7

Page 10

INSTRUCTIONS FOR USE

MACHINE TRANSPORT/PARKING

To transport/park the machine, proceed as follows.

1. Turn the brush/pad switch and the vacuum switch (2 and

3, Fig. B) to “0”.

2. Disconnect the power supply cable (21, Fig. C) from the

electrical mains, then wind it round its support.

3. Lift the squeegee by means of the lever (19, Fig. C).

4. Grasp the handlebar (2, Fig. C) and slightly lower it until

the rear wheel (7, Fig. C) comes into contact with the

floor (Fig. D). While holding the machine in this position,

push it to the transport/parking area.

5. After finishing the work, in order not to drag the

brush/pad on the floor and leave wet marks, remove the

brush/pad from the deck by using the release device (for

the procedure, see the After Using The Machine

paragraph), then place it on the support (3, Fig. I).

TANK EMPTYING

An automatic float shut-off system (6, Fig. I) stops the vacuum

system when the recovery water tank (4) is full.

The vacuum system deactivation is signalled by a sudden

increase in the vacuum system motor noise frequency.

When the recovery water tank (4, Fig. I) is full, empty it

according to the following procedure.

Recovery water tank emptying

1. Stop the machine by pressing the brush/pad and

vacuum switches (2 and 3, Fig. B).

2. Disconnect the power supply cable (21, Fig. C) from the

electrical mains, then wind it round its support.

3. Lift the squeegee by means of the lever (19, Fig. C).

4. Drive the machine to the appointed disposal area.

5. Insert the positioning pin (24, Fig. C) and lift the

brush/pad by activating the transport/parking device

(23a).

6. Empty the recovery water tank by means of the drain

hose (16, Fig. C).

Then, rinse the tank with clean water.

Solution tank emptying

7. Carry out steps 1 to 4.

8. Empty the solution tank by means of the drain valve (18,

Fig. C).

Then, rinse the tank with clean water.

AFTER USING THE MACHINE

After scrubbing-drying, before leaving the machine:

1. Remove the brush/pad-holder as follows:

– Lift the brush/pad, turn the brush/pad switch (2,

Fig. B) to “I” and, after a few seconds, to “0”, thus

releasing the brush/pad-holder.

2. Disconnect the power supply cable (21, Fig. C) from the

electrical mains, then wind it round its support.

3. Empty the tanks (4 and 5, Fig. I) according to the

procedure shown in the previous paragraph.

4. Perform the daily maintenance operations (see the

Maintenance chapter).

5. Store the machine in a clean and dry place, with the

brush/pad and the squeegee lifted or removed.

RECOVERY WATER TANK REMOVAL

To perform check and maintenance operations, it may be

necessary to remove the recovery water tank (1, Fig. H)

according to the following procedure.

1. Empty the recovery water tank (4, Fig. I) according to the

procedure shown in the relevant paragraph.

2. Drive the machine on a level ground.

3. Make sure that the power supply cable (21, Fig. C) is

disconnected from the electrical mains.

4. Disconnect the vacuum hose (22, Fig. C) from the

squeegee (11).

5. Disconnect the recovery water drain hose (16, Fig. C)

from the bracket (17).

6. Open the cover (6, Fig. C) and apply the cover stand (18,

Fig. I).

7. Grasp the recovery water tank (1, Fig. H) in the area (2)

and slightly raise it.

8. Disconnect the vacuum hose (3, Fig. H) from the tank,

then remove the tank (1) with the hoses (4) and (5).

MACHINE LONG INACTIVITY

If the machine is not going to be used for more than 30 days,

proceed as follows:

1. Perform the operations described in the After Using The

Machine paragraph.

2. Store the machine in a clean and dry place.

FIRST PERIOD OF USE

After the first period of use (first 8 hours) it is necessary to

check the fixing and connecting parts of the machine for

proper tightening. Check the visible parts for integrity and

leakage.

8 Razor E17 — 909 6311 000(1)2006-01

Page 11

INSTRUCTIONS FOR USE

MAINTENANCE

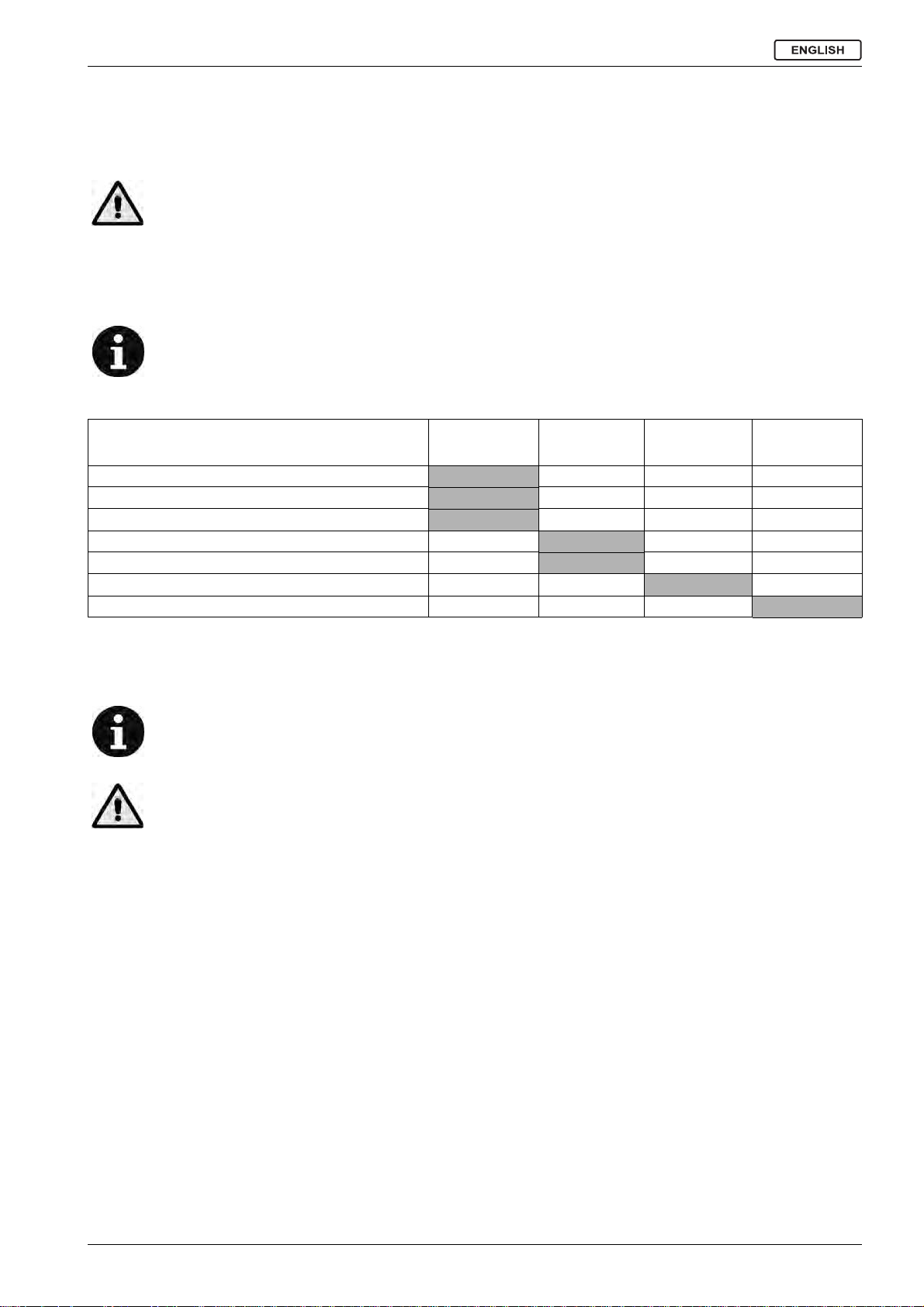

The lifespan of the machine and its maximum operating safety are ensured by correct and regular maintenance.

The following chart provides the scheduled maintenance. The intervals shown may vary according to particular working

conditions, which are to be defined by the person in charge of the maintenance.

WARNING!

Maintenance operations must be carried out with the machine switched off and the power supply cable

disconnected from the electrical mains.

Moreover, carefully read all the instructions in the Safety chapter.

All scheduled or extraordinary maintenance operations must be performed by qualified personnel, or by an authorized Service

Center.

This Manual describes only the easiest and most common maintenance procedures.

NOTE

For other maintenance procedures contained in the scheduled maintenance table, see the specific Service

Manual that can be consulted at any Service Center.

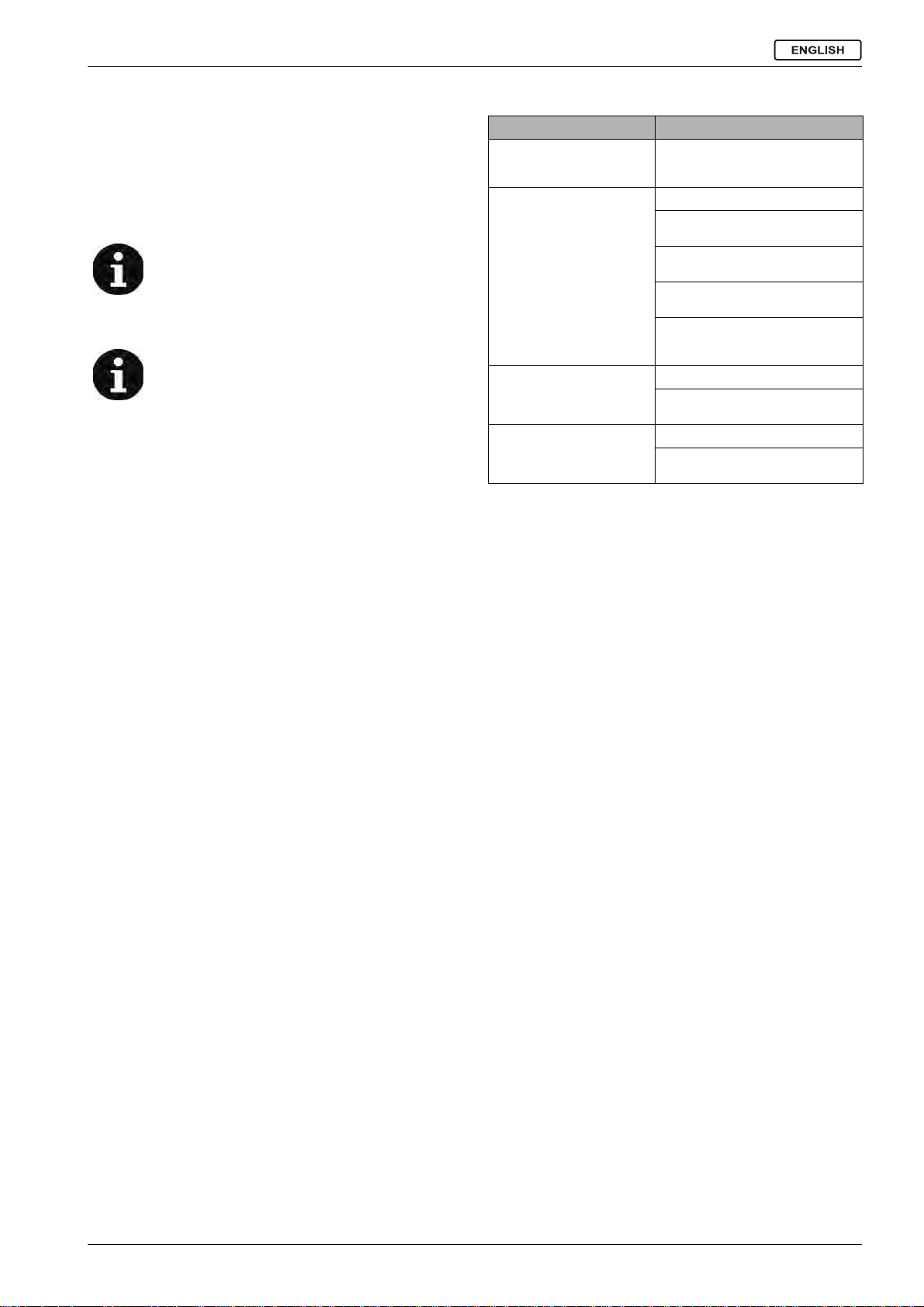

SCHEDULED MAINTENANCE TABLE

Operation

Squeegee cleaning

Brush cleaning

Tank and vacuum grid cleaning

Squeegee blade check and replacement

Solution filter cleaning

Screw and nut tightening check (1)

Vacuum system motor carbon brush check or replacement

Daily or after

using the

machine

Weekly

(1):And after the first 8 working hours

(2):This maintenance operation must be performed by KENT authorized Service Center.

Every six

months

Yearly

(2)

SQUEEGEE CLEANING

NOTE

The squeegee must be clean and its blades must be in good conditions in order to get a good drying.

CAUTION!

It is advisable to use protective gloves when cleaning the squeegee because there may be cutting debris.

1. Drive the machine on a level ground.

2. Make sure that the power supply cable (21, Fig. C) is disconnected from the electrical mains.

3. Lower the squeegee by means of the lever (19, Fig. C).

4. Disconnect the vacuum hose (22, Fig. C) from the squeegee.

5. Loosen the handwheels (12, Fig. C) and remove the squeegee (11).

6. Wash and clean the squeegee. In particular, clean the compartments (1, Fig. E) and the vacuum hole (2) from dirt and

debris.

7. Check the front blade (3) and the rear blade (4) for integrity, cuts and tears; otherwise replace them (see the procedure in

the next paragraph).

8. Assemble in the reverse order of disassembly.

Razor E17 — 909 6311 000(1)2006-01 9

Page 12

INSTRUCTIONS FOR USE

SQUEEGEE BLADE CHECK AND

REPLACEMENT

1. Clean the squeegee (according to the procedure shown

in the previous paragraph).

2. Check that the edges of the front (5, Fig. E) and rear

blades (12) lay down on the same level, along all their

length; otherwise adjust their height according to the

following procedure:

– Remove the fixing springs (6) and adjust the front

blade (3) and the rear blade (4).

– Reinstall the fixing springs on the properly

adjusted front and rear blades.

3. Check the front blade (3, Fig. E) and the rear blade (4)

for integrity, cuts and tears; otherwise replace them

according to the following procedure. Check that the

front corner (9) of the rear blade is not worn; otherwise,

overturn the blade to replace the worn corner with the

other one (7), provided that it is not worn. If the other

corner is worn too, replace the blade according to the

following procedure:

– Remove the fixing springs (6) and replace (or

overturn) the rear blade (4).

– Reinstall the fixing springs on the properly

adjusted front and rear blades.

4. Reinstall the squeegee (11, Fig. C) and screw down the

handwheels (12).

5. Connect the vacuum hose (22, Fig. C) to the squeegee

(11).

BRUSH CLEANING

NOTE

It is advisable to use protective gloves when

cleaning the brush because there may be

cutting debris.

TANK AND VACUUM GRID CLEANING

1. Drive the machine to the appointed disposal area.

2. Make sure that the power supply cable (21, Fig. C) is

disconnected from the electrical mains.

3. Lift the cover (1, Fig. I) and apply the cover stand (18,

Fig. I), then clean and wash the cover, the tanks (4 and

5) and the vacuum grid (6) with clean water.

Drain the water from the tanks by means of the drain

hose (16, Fig. C) and valve (18).

4. If necessary, release the retainers (2, Fig. F), open the

vacuum grid (1), remove the float (3), then carefully

clean and reinstall them.

5. Check the cover gasket (7, Fig. F) of the recovery water

tank for integrity.

NOTE

The gasket (7, Fig. F) creates vacuum in the

tank, which is necessary for vacuuming the

recovery water.

If necessary, replace the gasket (7) after removing it

from its housing (8).

When reassembling the new gasket, install the joint (9)

in the central area, as shown in the figure.

6. Check the gasket (7, Fig. F) bearing surface (10) for

integrity and sealing capabilities.

7. Check the compensation hole (28, Fig. C) for clogging.

NOTE

The hole (28, Fig. C) compensates the air in the

cover interspaces, thus allowing the creation

of vacuum in the recovery water tank.

8. Remove the cover stand (18, Fig. I) and close the

recovery water tank cover (1).

1. Remove the brush from the machine, according to the

procedure shown in the Use chapter.

2. Clean and wash the brush with water and detergent.

3. Check the brush bristles for integrity and wear; if

necessary, replace the brush.

10 Razor E17 — 909 6311 000(1)2006-01

Page 13

INSTRUCTIONS FOR USE

SOLUTION FILTER CLEANING

1. Empty the solution tank (5, Fig. I) according to the

procedure shown in the relevant paragraph.

2. Drive the machine on a level ground.

3. Make sure that the power supply cable (21, Fig. C) is

disconnected from the electrical mains.

4. Remove the transparent cover (1, Fig. G) and the filter

strainer (2); clean and reinstall them on the support (3).

NOTE

Properly install the filter strainer (2, Fig. G) in

the housing (4) of the support (3).

MACHINE SPEED ADJUSTMENT

NOTE

The machine speed depends on the floor type

and on the choice of using brush or pad.

The machine speed can be adjusted according

to the following procedure.

1. Remove the recovery water tank as shown in the Use

chapter.

2. Adjust the machine speed by means of the screw (11,

Fig. I), according to the following procedure:

– Loosen the screw (16, Fig. I) on the right side of

the machine, by turning it counter-clockwise;

– Turn the adjusting screw (11, Fig. I)

counter-clockwise to increase the machine speed;

– Turn the adjusting screw (11, Fig. I) clockwise to

decrease the machine speed;

– After adjusting, tighten the screw (16, Fig. I).

3. Install the recovery water tank as shown in the Use

chapter.

4. With the machine ready to operate, carry out hands-on

tests of the machine and, if other adjustments are

necessary, repeat steps 1 to 4.

TROUBLESHOOTING

TROUBLE REMEDY

No motor ignition

Insufficient dirty water

vacuuming

Insufficient solution flow to

the brush/pad

Squeegee-related marks

For further information refer to the Service Manual, available

at any KENT Service Center.

Power supply cable faulty or

disconnected from the electrical

mains

Recovery water tank full

Clogged vacuum grid or stuck closed

float

Vacuum hose disconnected from the

squeegee or faulty

Dirty squeegee, or worn or damaged

squeegee blades

Improperly closed recovery water

tank cover; worn gasket or clogged

compensation hole

Dirty solution filter

Dirty recovery water tank (clogged

drain hole)

Debris under the squeegee blades

Worn, chipped or torn squeegee

blades

Razor E17 — 909 6311 000(1)2006-01 11

Page 14

INSTRUCTIONS FOR USE

SCRAPPING

Have the machine scrapped by a qualified scrapper.

Before scrapping the machine, remove the following

components:

– Brushes

– Plastic hoses and components

– Electrical and electronic components

CAUTION!

Removed components must be disposed of

according to the law in force.

12 Razor E17 — 909 6311 000(1)2006-01

Page 15

INSTRUCTIONS D'UTILISATION

INTRODUCTION ................................................................................................................................... 2

BUT ET CONTENU DU MANUEL .................................................................................................................... 2

DESTINATAIRES ............................................................................................................................................. 2

CONSERVATION DU MANUEL ....................................................................................................................... 2

DONNEES D'IDENTIFICATION ....................................................................................................................... 2

AUTRES MANUELS DE REFERENCE ............................................................................................................ 2

PIECES DE RECHANGE ET ENTRETIEN ...................................................................................................... 2

MODIFICATIONS ET AMELIORATIONS ......................................................................................................... 2

SECURITE ............................................................................................................................................. 3

SYMBOLES ...................................................................................................................................................... 3

INSTRUCTIONS GENERALES ........................................................................................................................ 3

DEBALLAGE ......................................................................................................................................... 4

DESCRIPTION DE LA MACHINE ......................................................................................................... 5

CAPACITES OPERATIONNELLES .................................................................................................................. 5

CONVENTIONS ................................................................................................................................................ 5

DESCRIPTION ................................................................................................................................................. 5

CARACTERISTIQUES TECHNIQUES ............................................................................................................. 5

ACCESSOIRES/OPTIONS ............................................................................................................................... 6

UTILISATION ........................................................................................................................................ 6

AVANT LA MISE EN MARCHE ........................................................................................................................ 6

MISE EN MARCHE ET ARRET DE LA MACHINE ........................................................................................... 7

MACHINE AU TRAVAIL ................................................................................................................................... 7

TRANSPORT/STATIONNEMENT DE LA MACHINE ....................................................................................... 8

VIDANGE DES RESERVOIRS ......................................................................................................................... 8

APRES L'UTILISATION DE LA MACHINE ....................................................................................................... 8

DEPOSE DU RESERVOIR DE L'EAU DE RECUPERATION .......................................................................... 8

INACTIVITE PROLONGEE DE LA MACHINE ................................................................................................. 8

PREMIERE PERIODE D'UTILISATION ............................................................................................................ 8

ENTRETIEN ........................................................................................................................................... 9

PROGRAMME D'ENTRETIEN ......................................................................................................................... 9

NETTOYAGE DE L'EMBOUCHURE ................................................................................................................ 9

CONTROLE ET REMPLACEMENT DES LAMELLES EN CAOUTCHOUC DE L'EMBOUCHURE ............... 10

NETTOYAGE DE LA BROSSE ...................................................................................................................... 10

NETTOYAGE DES RESERVOIRS ET DE LA GRILLE D'ASPIRATION ........................................................ 10

NETTOYAGE DU FILTRE DE SOLUTION ..................................................................................................... 11

REGLAGE DE LA VITESSE D'AVANCE DE LA MACHINE ........................................................................... 11

DEPISTAGE DES PANNES ................................................................................................................ 11

MISE EN DECHARGE ......................................................................................................................... 12

Razor E17 — 909 6311 000(1)2006-01 1

Page 16

INSTRUCTIONS D'UTILISATION

INTRODUCTION

BUT ET CONTENU DU MANUEL

Ce manuel se propose de fournir au client toutes les

informations nécessaires afin qu’il puisse utiliser la machine

correctement et la gérer de la manière la plus autonome et

sûre. Il comprend des informations relatives à l’aspect

technique, le fonctionnement, l’arrêt de la machine,

l’entretien, les pièces de rechange et la sécurité.

Avant d’effectuer toute opération sur la machine, les

opérateurs et les techniciens chargés de l'entretien doivent

lire attentivement les instructions contenues dans ce texte.

En cas de doutes sur la correcte interprétation des

instructions, contacter un Service après-vente qualifié KENT

pour avoir plus de renseignements.

DESTINATAIRES

Ce manuel s’adresse à l’opérateur aussi bien qu’aux

techniciens préposés à l’entretien de la machine.

Les opérateurs ne doivent pas exécuter les opérations

réservées aux techniciens qualifiés. KENT ne répond pas des

dommages dus à l'inobservance de cette interdiction.

CONSERVATION DU MANUEL

Les Instructions d'utilisation doivent être gardées près de la

machine, dans une enveloppe spéciale et, surtout, loin de

liquides et de tout ce qui pourrait en compromettre l’état de

lisibilité.

AUTRES MANUELS DE REFERENCE

– Catalogue des pièces de rechange (livré avec la

machine).

– Manuel d’entretien (consultable auprès des Services

après-vente KENT).

PIECES DE RECHANGE ET ENTRETIEN

Pour toute nécessité relative à l’utilisation, l’entretien et, le

cas échéant, les réparations, il faut s’adresser au personnel

qualifié ou directement aux Services après-vente KENT, et il

ne faut utiliser que des pièces de rechange et accessoires

originaux.

Pour l’assistance ou la commande de pièces de rechange et

accessoires, contacter KENT en spécifiant toujours le modèle

et le numéro de série.

MODIFICATIONS ET AMELIORATIONS

Notre entreprise vise à un constant perfectionnement de ses

produits et se réserve le droit d’effectuer des modifications et

des améliorations, lorsqu’elles sont nécessaires, sans

l’obligation de modifier les machines précédemment

vendues.

Il est entendu que toute modification et/ou addition

d’accessoires doit toujours être approuvée et réalisée par

KENT.

DONNEES D'IDENTIFICATION

Le numéro de série et le modèle de votre machine sont

indiqués sur la plaque lisible de l'extérieur (1, Fig. C).

L'année de fabrication de votre machine est indiquée après le

code de la date sur le numéro de série de la machine (A06

signifie janvier 2006).

Ces informations sont nécessaires lors de la commande des

pièces de rechange de la machine. Utiliser l'espace

ci-dessous pour y noter les données d'identification de la

machine pour toute référence future.

Modèle de la MACHINE ................................................

Numéro de série de la MACHINE ..................................

2 Razor E17 — 909 6311 000(1)2006-01

Page 17

SECURITE

On utilise la symbologie suivante pour signaler les conditions

de danger potentielles. Lire attentivement ces informations et

prendre les précautions nécessaires pour protéger les

personnes et les choses.

Pour éviter tout accident la collaboration de l'opérateur est

essentielle. Aucun programme de prévention des accidents

du travail ne peut résulter efficace sans la totale collaboration

de la personne directement responsable du fonctionnement

de la machine. La plupart des accidents qui peuvent survenir

dans une entreprise, pendant le travail ou les déplacements,

sont dus à l’inobservance des plus simples règles de

prudence. Un opérateur attentif et prudent est la meilleure

garantie contre les accidents du travail et se révèle

indispensable pour compléter n’importe quel programme de

prévention.

SYMBOLES

DANGER !

Indique un danger qui comporte des risques,

ou même la mort, pour l’opérateur.

ATTENTION !

Indique une situation exposant les personnes

au risque de blessures.

AVERTISSEMENT !

Indique un avertissement ou une remarque sur

des fonctions clé ou utiles. Prêter la plus

grande attention aux segments de texte

marqués par ce symbole.

REMARQUE

INSTRUCTIONS GENERALES

Les avertissements et précautions spécifiques suivants

informent sur les potentiels risques de dommage à la

machine ou aux personnes.

– Débrancher le câble d'alimentation du réseau électrique,

– Cette machine doit être utilisée uniquement par un

– Ne pas porter de bijoux quand on travaille près de

– Ne pas opérer avec cette machine en présence de

Indique la nécessité de consulter les

Instructions d'utilisation avant toute opération.

DANGER !

avant d'effectuer toute opération d'entretien/réparation.

personnel adéquatement formé et autorisé. L’utilisation

de la machine est interdite aux enfants et aux personnes

handicapées.

composants électriques.

poudres, liquides ou vapeurs nuisibles, dangereux,

inflammables et/ou explosifs.

INSTRUCTIONS D'UTILISATION

ATTENTION !

– Avant d'effectuer toute activité d'entretien/réparation,

lire attentivement toutes les instructions qui concernent

l'entretien/réparation.

– Avant de brancher la machine au réseau électrique,

s'assurer que la fréquence et la tension indiquées sur la

plaque (1, Fig. C) coïncident avec la tension de réseau.

– Pour réduire le risque d'incendie, choc électrique ou

blessures, ne pas laisser la machine sans surveillance

lorsqu'elle est branchée au réseau électrique.

Débrancher la machine de la prise de courant lorsqu'on

n'utilise pas la machine et avant d'effectuer toute

opération d'entretien.

– Afin d'éviter le risque de choc électrique, ne pas exposer

la machine à la pluie. Garder la machine dans un endroit

couvert.

– Ne pas laisser que la machine est utilisée comme jouet.

Faire attention lorsque la machine est utilisée à

proximité des enfants.

– Ne pas utiliser à des fins autres que celles prévues dans

ce manuel. Utiliser seulement les accessoires

recommandés par KENT.

– Ne pas utiliser la machine si le câble d'alimentation ou la

fiche sont endommagés. Si la machine ne fonctionne

pas correctement, si elle est endommagée, laissée à

l'extérieur ou tombée dans l'eau, la porter auprès d'un

Service après-vente autorisé.

– Si le câble d'alimentation ou la fiche présentent des

traces d'abrasion ou s'ils sont endommagés, il est

nécessaire de les remplacer immédiatement dans un

Service après-vente autorisé.

– Ne pas utiliser le câble d'alimentation pour tirer ou

transporter la machine et ne pas utiliser le câble comme

poignée. Ne pas fermer de porte sur le câble

d'alimentation, ne pas tirer le câble sur des surfaces ou

coins tranchants. Ne pas faire passer la machine sur le

câble d'alimentation. Tenir le câble d'alimentation

éloigné des surfaces chaudes.

– Ne pas utiliser le câble d'alimentation pour débrancher la

machine de la prise de courant. Pour débrancher la

machine, saisir la fiche et non le câble.

– Ne pas toucher la prise de courant ou la machine avec

les mains mouillées.

– Eteindre toutes les commandes avant de débrancher la

machine de la prise de courant.

– Prendre les précautions convenables afin que les

cheveux, les bijoux et les parties non adhérentes des

vêtements ne soient pas capturés par les parties en

mouvement ou aspirantes de la machine.

– Ne pas travailler sous la machine soulevée, sans des

supports fixes de sécurité convenables.

– Avant de laisser la machine sans surveillance, veiller à

ce que celle-ci ne puisse pas bouger de façon

autonome.

– Ne pas utiliser sur des surfaces dont l'inclinaison est

supérieure à celle indiquée sur la machine.

– Ne pas laver la machine avec des jets d’eau directs ou

sous pression ou avec des substances corrosives.

Razor E17 — 909 6311 000(1)2006-01 3

Page 18

INSTRUCTIONS D'UTILISATION

– Ne pas utiliser la machine dans des endroits très

poussiéreux.

– Pendant l'utilisation de cette machine, faire attention à

sauvegarder l'intégrité des autres personnes.

– Ne pas poser de conteneurs de liquides sur la machine.

– La température de stockage doit être comprise entre

+32°F et +104°F (0°C et +40°C).

– La température de travail de la machine doit être

comprise entre 32°F et 104°F (0°C et +40°C).

– L’humidité doit être comprise entre 30% et 95%.

– Protéger toujours la machine du soleil, de la pluie et

d’autres intempéries, pendant le fonctionnement et en

état d’arrêt.

– Ne pas utiliser la machine comme moyen de transport.

– Ne pas faire travailler la brosse lorsque la machine est

arrêtée pour ne pas endommager le sol.

– En cas d’incendie, il est préférable d'utiliser un extincteur

à poudre, plutôt qu'un extincteur à eau.

– Ne pas heurter contre des étagères ou des

échafaudages, en particulier en cas de danger de chute

d’objets.

– Ne pas altérer pour aucune raison les protections

prévues pour la machine, respecter scrupuleusement

les instructions prévues pour l’entretien ordinaire.

– Ne pas enlever ou altérer les plaques apposées sur la

machine par KENT.

– S'assurer que les éventuelles anomalies de

fonctionnement de la machine ne dépendent pas du

manque d'entretien. En cas contraire, demander

l'intervention du personnel autorisé ou d'un Service

après-vente autorisé.

– En cas de remplacement de pièces, demander les

pièces de rechange D’ORIGINE à un Concessionnaire

ou Revendeur autorisé.

– Afin de garantir la sécurité et le bon fonctionnement de

la machine, faire effectuer l'entretien programmé prévu

au chapitre spécifique de ce manuel par du personnel

autorisé ou par un Service après-vente autorisé.

– Lors de la mise en décharge, la machine ne doit pas être

abandonnée par la présence de matériaux toxiques

(matériaux plastiques, etc.), sujets à des lois qui

prévoient l’élimination auprès de centres spéciaux (voir

le chapitre Mise en décharge).

– En conditions d’emploi conformes aux indications

d’utilisation correcte, les vibrations ne provoquent pas

de situations de danger. Le niveau de vibrations de la

machine est inférieur à 98.42 in/s

(98/37/EEC - EN 1033/1995).

2

(2.5 m/s2)

– Ne pas laisser entrer d'objets dans les ouvertures. Ne

pas utiliser la machine si les ouvertures sont bouchées ;

garder les ouvertures de la machine libres de poussière,

filasse, poils et tout autre corps étranger à même de

réduire le flux d'air.

– Ne pas ramasser des objets qui brûlent ou fument,

comme cigarettes, allumettes ou cendres chaudes.

– La machine n'est pas approuvée pour l'utilisation sur les

rues publiques.

– Faire attention pendant les déplacements de la machine

en conditions de températures inférieures au point de

congélation. L'eau présente dans le réservoir de

récupération ou dans les tuyaux pourrait se congeler et

endommager sérieusement la machine.

– Utiliser les brosses et les disques livrés avec la machine

et ceux spécifiés dans les Instructions d'utilisation.

L'utilisation d'autres brosses ou disques peut

compromettre la sécurité.

– La machine ne doit pas être utilisée pour ramasser des

matériaux dangereux.

– Effectuer la mise en décharge de la machine ou des

composants de la machine conformément aux normes

en vigueur.

DEBALLAGE

Pour déballer la machine, suivre attentivement les

instructions sur l'emballage.

Lors de la livraison de la machine, contrôler attentivement

que l’emballage et la machine n’ont pas été endommagés

pendant le transport. Si les dommages sont évidents, garder

l'emballage de façon qu'il puisse être examiné par le

transporteur qui l'a livré. Le contacter immédiatement pour

remplir une demande de dommages-intérêts.

Contrôler que les composants suivants sont livrés avec la

machine :

– Instructions d'utilisation de l'autolaveuse.

– Catalogue de pièces de rechange de

l'autolaveuse.

– Rallonge pour câble d'alimentation.

4 Razor E17 — 909 6311 000(1)2006-01

Page 19

INSTRUCTIONS D'UTILISATION

DESCRIPTION DE LA MACHINE

CAPACITES OPERATIONNELLES

L'autolaveuse est conçue et fabriquée pour le nettoyage

(lavage et séchage) de sols lisses et solides, en milieux civils

et industriels, en conditions de complète sécurité, par un

opérateur qualifié.

L'autolaveuse n'est pas adapte pour le lavage de tapis ou

moquettes.

CONVENTIONS

Toutes les références à en avant, en arrière, avant, arrière,

droit ou gauche indiquées dans ce manuel doivent être

considérées comme référées à l'opérateur en position de

conduite avec ses mains sur le guidon (2, Fig. C).

DESCRIPTION

Tableau de bord

(Voir Fig. B)

1. Tableau de bord

2. Bouton-poussoir de brosse/disque

3. Bouton-poussoir d'aspiration

Vue externe arrière

(Voir Fig. C)

1. Plaque avec numéro de série/données techniques

2. Guidon

3. Poignée de réglage inclinaison guidon

4. Levier de réglage flux de solution

5a. Position ECO du levier de réglage du flux de la solution

(emploi “économique” de l'eau, pour une autonomie de

lavage programmée de 70-80 minutes)

5b. Position de flux maximum de solution

5. Couvercle réservoir eau de récupération

6. Roue arrière d'appui pour transport/stationnement

7. Roues centrales sur axe fixe

8. Brosse/disque

9. Couverture de brosse/disque

10. Embouchure

11. Boutons de fixation embouchure

12. Lamelle en caoutchouc avant embouchure

13. Lamelle en caoutchouc arrière embouchure

14. Ressorts de fixation lamelles en caoutchouc

embouchure

15. Tuyau de vidange eau de récupération

16. Support tuyau de vidange eau de récupération

17. Soupape de vidange solution

18. Levier de soulèvement/abaissement embouchure

19. Filtre de solution

20. Câble d'alimentation

21. Tuyau d'aspiration embouchure

22. Dispositif de transport/stationnement

23a. Dispositif de transport/stationnement activé

23b. Dispositif de transport/stationnement désactivé

23. Goupille de positionnement dispositif de

transport/stationnement

24. Support de brosse/disque (en position d'utilisation)

25. Réservoir eau de récupération

26. Réservoir solution

Vue avant sous le réservoir

(Voir Fig. I)

1. Couvercle réservoir eau de récupération (ouvert)

2. Joint d'étanchéité couvercle réservoir eau de

récupération

3. Support de brosse/disque (en position d'utilisation)

4. Réservoir eau de récupération

5. Réservoir solution

6. Grille d'aspiration avec fermeture automatique à flotteur

7. Orifice de drainage eau de récupération

8. Moteur d'aspiration

9. Moteur de brosse/disque

10. Couverture avec queue d'accrochage pour

brosse/plateau

11. Vis de réglage vitesse d'avance machine

12. Brosse

13. Plateau

14. Disque

15. Boîte à bornes

16. Vis

17. Orifice de compensation

18. Support couvercle (en position d'activation)

CARACTERISTIQUES TECHNIQUES

Caractéristiques générales Valeurs

Largeur de lavage 17.0 in (430 mm)

Largeur machine sans embouchure 22.4 in (570 mm)

Longueur (minimum) machine avec

guidon réglable

Hauteur (minimum) machine avec guidon

réglable

Largeur embouchure 28.3 in (720 mm)

Poids machine (avec brosse) 67.5 Kg

Diamètre roues centrales sur axe fixe 9.8 in (250 mm)

Diamètre brosse/disque 17.0 in (430 mm)

Pression des roues au sol <0.5 N/mm

Pression de brosse/disque au sol (avec

réservoir plein)

Performances Valeurs

Aspiration

Niveau pression acoustique 76 dB(A)

Puissance moteur d'aspiration

Puissance moteur de brosse/disque

Tension du système 230 V

Contenance réservoir eau propre 8 gallons (31 litres)

Capacité réservoir eau de récupération 7.9 gallons (30 litres)

36.6 in (930 mm)

40.2/44.7 in

(1,020/1,135 mm)

61.6 lbs (28 Kg)

56.2 in H

(pour les États-Unis)

(pour les États-Unis)

O (1,316

2

mm H

O)

2

550 W 50Hz

550 W 60Hz

1,100 W 50Hz

550 W 60Hz

2

Razor E17 — 909 6311 000(1)2006-01 5

Page 20

INSTRUCTIONS D'UTILISATION

Schéma électrique

(Voir Fig. K)

EV1 : électrovanne eau

FR : cadre

M1 : moteur brosse/disque

M2 : moteur d'aspiration

PL : fiche

SW1 : interrupteur de brosse/disque

SW2 : interrupteur d'aspiration

Code des couleurs :

BK : Noir

BU : Bleu

BN : Marron

GN : Vert

GY : Gris

OG : Orange

PK : Rose

RD : Rouge

VT : Violet

WH : Blanc

YE : Jaune

ACCESSOIRES/OPTIONS

Outre les composants présents dans le modèle standard, la

machine peut être livrée avec les accessoires/options

suivants, selon l'emploi spécifique de la machine :

– brosses/disques de matériaux différents.

Pour de plus amples informations relatives aux accessoires

optionnels susmentionnés, s'adresser au revendeur agréé.

UTILISATION

ATTENTION !

Sur certains points de la machine sont

appliquées des plaques adhésives qui

indiquent :

–DANGER

– ATTENTION

– AVERTISSEMENT

–REMARQUE

Lors de la lecture de ce manuel, l'opérateur doit bien

comprendre le sens des symboles illustrés sur les plaques.

Ne pas couvrir les plaques et les remplacer immédiatement

en cas d'endommagement.

AVANT LA MISE EN MARCHE

Installation de l'embouchure

1. Reposer l'embouchure (11, Fig. C) et la fixer à l'aide des

boutons (12), puis connecter le tuyau d'aspiration (22) à

l'embouchure.

Remplissage du réservoir de solution

2. Remplir le réservoir de solution (5, Fig. I) avec une

solution adéquate au travail à effectuer.

Ne jamais remplir complètement le réservoir de

solution, mais laisser toujours quelques pouces du

bord.

Suivre toujours les instructions de dilution sur l'étiquette

du conteneur du produit chimique utilisé pour la

solution.

La température de la solution ne doit jamais être

supérieure à 32°F (40°C).

AVERTISSEMENT !

Utiliser exclusivement des détergents liquides

peu mousseux et non inflammables, adéquats

pour les machines utilisées.

REMARQUE

Selon le type de sol à nettoyer, il est possible

d'insérer la brosse (12, Fig. I) ou le plateau (13).

6 Razor E17 — 909 6311 000(1)2006-01

Page 21

INSTRUCTIONS D'UTILISATION

Installation de la brosse ou du plateau

3. Désactiver (23b, Fig. C) le dispositif de

transport/stationnement de la machine après avoir

reposé la goupille de positionnement (24).

4. Soulever la couverture de la brosse/disque (10, Fig. C)

en faisant levier sur le guidon (2).

5. Positionner la brosse (12, Fig. I) ou le plateau (13) sous

la couverture.

6. Baisser la couverture (10, Fig. C) au moyen du guidon

(2).

7. Brancher le câble d'alimentation (21, Fig. C) au réseau

électrique.

8. Appuyer sur le bouton-poussoir de brosse/disque (2,

Fig. B) pendant quelques secondes pour permettre

l'accrochage de la brosse/plateau.

En cas d'accrochage difficile, tourner manuellement la

brosse/plateau dans le sens inverse aux aiguilles d'une

montre (Fig. J).

Réglages

9. Régler le guidon (2, Fig. C) à la position la plus

confortable pour l'opérateur au moyen de la poignée (3).

MISE EN MARCHE ET ARRET DE LA MACHINE

Mise en marche de la machine

1. Préparer la machine comme indiqué au paragraphe

précédent.

2. Baisser l'embouchure (11, Fig. C) au moyen du levier

(19).

3. Positionner le levier de réglage du flux de solution (4,

Fig. C) dans une des positions suivantes, selon le type

de nettoyage à effectuer :

– Système ECO : en portant le levier (4) dans la

position “ECO” (ECO), la machine travaille en

condition d'emploi programmé de l'eau (économie) ;

en effet, puisque le flux est prédéterminé et constant,

la machine peut travailler avec une autonomie de

lavage de 70-80 minutes [0.08 gallons/min (0.3

litres/min) en moyenne].

– Système variable : en tournant le levier à gauche

(flux variable), il est possible d'augmenter le débit

jusqu'à un maximum de 0.26 gallons/min (1

litre/min).

En aucun cas il n'est possible de fermer complètement

le flux de l'eau aux brosses pendant le travail.

4. Tout en gardant une main sur le guidon (2, Fig. C),

démarrer la machine en positionnant les

boutons-poussoirs de brosse/disque et d'aspiration (2 et

3, Fig. B) sur “I”.

Arrêt de la machine

5. Positionner les boutons-poussoirs de brosse/disque et

d'aspiration (2 et 3, Fig. B) sur “0”.

6. Débrancher le câble d'alimentation du réseau électrique.

7. Soulever l'embouchure au moyen du levier (19, Fig. C).

8. Soulever la brosse/disque en activant (23a, Fig. C) le

dispositif de transport/stationnement de la machine

après avoir reposé la goupille de positionnement (24).

MACHINE AU TRAVAIL

1. Mettre la machine en marche comme prévu au

paragraphe précédent.

2. Tout en gardant les deux mains sur le guidon (2, Fig. C),

déplacer la machine et commencer le travail de

lavage/séchage du sol.

AVERTISSEMENT !

Afin d'éviter d'endommager la surface du sol à

nettoyer :

– ne pas utiliser la brosse/disque à sec.

– lorsque la machine est au repos, arrêter la

rotation de la brosse/disque au moyen du

bouton-poussoir (2, Fig. B).

AVERTISSEMENT !

Avant de soulever la brosse/disque, arrêter sa

rotation au moyen du bouton-poussoir (2, Fig.

B).

3. S'il est nécessaire, régler la quantité de solution qui

arrive à la brosse au moyen du levier (4, Fig. C).

Réglage de la vitesse d'avance de la machine

4. La vitesse d'avance de la machine varie selon le type de

sol à nettoyer et le choix d'utiliser la brosse ou le disque.

S'il est nécessaire, il est possible de régler la vitesse

d'avance en suivant la procédure au chapitre Entretien.

Razor E17 — 909 6311 000(1)2006-01 7

Page 22

INSTRUCTIONS D'UTILISATION

TRANSPORT/STATIONNEMENT DE LA

MACHINE

Pour le transport/stationnement de la machine, procéder

comme suit.

1. Positionner les boutons-poussoirs de brosse/disque et

d'aspiration (2 et 3, Fig. B) sur “0”.

2. Débrancher le câble d'alimentation (21, Fig. C) du

réseau électrique, et puis l'enrouler autour du support

correspondant.

3. Soulever l'embouchure au moyen du levier (19, Fig. C).

4. Saisir le guidon (2, Fig. C) et le baisser légèrement

jusqu'à ce que la roue arrière (7, Fig. C) touche le sol

(Fig. D). Tout en gardant la machine dans cette

condition, la pousser dans le lieu de

transport/stationnement.

5. Le travail effectué, afin de ne pas entraîner la

brosse/disque sur le sol et de ne pas laisser des traces

mouillées, déposer la brosse/disque de la tête à l'aide du

dispositif de décrochage (pour la procédure, voir le

paragraphe Après l'utilisation de la machine), et puis

l'appuyer sur le support (3, Fig. I).

VIDANGE DES RESERVOIRS

Un système de fermeture automatique à flotteur (6, Fig. I)

bloque le système d'aspiration lorsque le réservoir d'eau de

récupération (4) est plein.

Le blocage du système d'aspiration, dû au remplissage du

réservoir de l'eau de récupération, est signalé par

l'augmentation du bruit du moteur d'aspiration.

Lorsque le réservoir d'eau de récupération (4, Fig. I) est plein,

le vider en procédant comme suit.

Vidange du réservoir d'eau de récupération

1. Arrêter la machine à l'aide des boutons-poussoirs de

brosse/disque et d'aspiration (2 et 3, Fig. B).

2. Débrancher le câble d'alimentation (21, Fig. C) du

réseau électrique, et puis l'enrouler autour du support

correspondant.

3. Soulever l'embouchure au moyen du levier (19, Fig. C).

4. Pousser la machine dans la zone destinée à

l'écoulement.

5. Soulever la brosse/disque en activant (23a, Fig. C) le

dispositif de transport/stationnement de la machine

après avoir reposé la goupille de positionnement (24).

6. Vider le réservoir de l'eau de récupération au moyen du

tuyau de vidange (16, Fig. C).

Le travail effectué, rincer le réservoir à l'eau propre.

Vidange du réservoir de solution

7. Exécuter les étapes de 1 à 4 ci-dessus.

8. Vider le réservoir de solution à l'aide de la soupape de

vidange (18, Fig. C).

Le travail effectué, rincer le réservoir à l'eau propre.

APRES L'UTILISATION DE LA MACHINE

Le travail effectué, avant de laisser la machine :

1. Décrocher la brosse/plateau de la façon suivante :

– avec la brosse ou le disque soulevé, positionner le

bouton-poussoir de brosse/disque (2, Fig. B) sur

“I” et, après quelques secondes, le positionner à

nouveau sur “0” en détachant ainsi la

brosse/plateau.

2. Débrancher le câble d'alimentation (21, Fig. C) du

réseau électrique, et puis l'enrouler autour du support

correspondant.

3. Vider les réservoirs (4 et 5, Fig. I) comme indiqué au

paragraphe précédent.

4. Effectuer les opérations d'entretien prévues après

l'utilisation de la machine (voir le chapitre Entretien).

5. Garder la machine dans un endroit sec et propre, avec

la brosse/disque et l'embouchure soulevés ou déposés.

DEPOSE DU RESERVOIR DE L'EAU DE

RECUPERATION

Pour pouvoir effectuer toute opération de contrôle ou

entretien, il peut être nécessaire de déposer le réservoir d'eau

de récupération (1, Fig. H) ; procéder comme suit.

1. Vider le réservoir de l'eau de récupération (4, Fig. I),

comme indiqué au paragraphe spécifique.

2. Porter la machine sur un sol plat.

3. Vérifier que le câble d'alimentation (21, Fig. C) est

branché au réseau électrique.

4. Déconnecter le tuyau d'aspiration (22, Fig. C) de

l'embouchure (11).

5. Déconnecter le tuyau de vidange de l'eau de

récupération (16, Fig. C) du support correspondant (17).

6. Ouvrir le couvercle (6, Fig. C) et insérer le support du

couvercle (18, Fig. I).

7. Saisir le réservoir d'eau de récupération (1, Fig. H) dans

la zone (2) et le soulever légèrement.

8. Déconnecter le tuyau d'aspiration (3, Fig. H) du

réservoir, et puis déposer le réservoir (1) avec les tuyaux

(4) et (5).

INACTIVITE PROLONGEE DE LA MACHINE

Si on prévoit de ne pas utiliser la machine pendant plus de 30

jours, il est convenable d’effectuer les opérations suivantes :

1. Effectuer les opérations prévues au paragraphe Après

l'utilisation de la machine.

2. Garder la machine dans un endroit propre et sec.

PREMIERE PERIODE D'UTILISATION

Après la première période d'utilisation (les 8 premières

heures), il est nécessaire de contrôler le serrage des

éléments de fixation et de connexion de la machine. Vérifier

que les parties visibles sont intactes et sans pertes.

8 Razor E17 — 909 6311 000(1)2006-01

Page 23

INSTRUCTIONS D'UTILISATION

ENTRETIEN

La durée de vie de la machine et sa sécurité de fonctionnement sont garanties par un entretien soigné et régulier.

Veuillez trouver ci-dessous le plan récapitulatif d'entretien programmé. Les périodicités indiquées peuvent subir des variations

en fonction de conditions de travail particulières, à définir par le responsable de l'entretien.

ATTENTION !

Les opérations d'entretien doivent être exécutées avec la machine à l'arrêt et le câble d'alimentation

débranché du réseau électrique.

En outre, lire attentivement toutes les instructions du chapitre Sécurité.

Toutes les opérations d’entretien programmé ou extraordinaire doivent être effectuées par du personnel qualifié ou par un

Service après-vente autorisé.

Ce manuel ne contient que les opérations d'entretien les plus simples et les plus récurrentes.

REMARQUE

Pour les procédures des autres opérations d’entretien prévues par le plan récapitulatif d'entretien

programmé, se référer au manuel d’entretien consultable auprès des Services après-vente.

PROGRAMME D'ENTRETIEN

Opération

Nettoyage embouchure

Nettoyage brosse

Nettoyage réservoirs et grille d'aspiration

Contrôle et remplacement lamelles en caoutchouc

embouchure

Nettoyage filtre de solution

Contrôle serrage vis et écrous (1)

Contrôle et remplacement charbons moteur aspiration

(1):et après les 8 premières heures de travail

(2):pour ces opérations d'entretien, contacter un Service après-vente qualifié KENT.

Quotidienne ou

après l'utilisation

de la machine

Hebdomadaire Semestrielle Annuelle

(2)

NETTOYAGE DE L'EMBOUCHURE

REMARQUE

Pour un bon séchage, l'embouchure doit être propre et les lamelles en caoutchouc doivent être en bon état.

AVERTISSEMENT !

Lors du nettoyage de l'embouchure, il est conseillé de porter des gants de protection à cause de la présence

éventuelle de débris tranchants.

1. Porter la machine sur un sol plat.

2. Vérifier que le câble d'alimentation (21, Fig. C) est branché au réseau électrique.

3. Baisser l'embouchure au moyen du levier (19, Fig. C).

4. Déconnecter le tuyau d'aspiration (22, Fig. C) de l'embouchure.

5. Desserrer les boutons (12, Fig. C) et déposer l'embouchure (11).

6. Laver et nettoyer l'embouchure, en particulier éliminer toute trace de saleté et débris des compartiments de convoyage (1,

Fig. E) et de l'orifice d'aspiration (2).

7. Contrôler que la lamelle en caoutchouc avant (3) et la lamelle en caoutchouc arrière (4) sont intactes et qu'elles ne

présentent pas de coupures ou déchirures; en cas contraire, les remplacer (voir procédure au paragraphe suivant).

8. Pour la repose, procéder dans l'ordre inverse de la dépose.

Razor E17 — 909 6311 000(1)2006-01 9

Page 24

INSTRUCTIONS D'UTILISATION

CONTROLE ET REMPLACEMENT DES

LAMELLES EN CAOUTCHOUC DE

L'EMBOUCHURE

1. Nettoyer l'embouchure comme décrit au paragraphe

précédent.

2. Contrôler que les bords de la lamelle en caoutchouc

avant (5, Fig. E) et de la lamelle en caoutchouc arrière

(12) se posent simultanément sur un plan, sur toute leur

longueur ; en cas contraire, régler leur hauteur en

procédant comme suit :

– régler la lamelle en caoutchouc avant (3) et la

lamelle en caoutchouc arrière (4) après avoir

déposé les ressorts de fixation (6) ;

– reposer les ressorts de fixation sur les lamelles en

caoutchouc avant et arrière correctement réglés.

3. Contrôler que la lamelle en caoutchouc avant (3, Fig. E)

et la lamelle en caoutchouc arrière (4) sont intactes et

qu'elles ne présentent pas de coupures ou déchirures;

en cas contraire, les remplacer en procédant comme

suit. Contrôler aussi que l'arête de la lamelle en

caoutchouc arrière (9) n'est pas usée; en cas contraire,

renverser la lamelle, en remplaçant l'arête usée avec

l'autre arête (7), si elle est encore intacte. Si l'autre arête

est usée, remplacer la lamelle en caoutchouc, en

procédant comme suit :

– remplacer (ou renverser) la lamelle en

caoutchouc arrière (4) après avoir déposé les

ressorts de fixation (6) ;

– reposer les ressorts de fixation sur les lamelles en

caoutchouc avant et arrière correctement réglés.

4. Reposer l'embouchure (11, Fig. C) et serrer les boutons

(12).

5. Connecter le tuyau d'aspiration (22, Fig. C) à

l'embouchure (11).

NETTOYAGE DE LA BROSSE

REMARQUE

Lors du nettoyage de la brosse, il est conseillé