Kent Euroclean Edge 28B Service Manual

Simple. Clean.

Edge 28B

SERVICE MANUAL

Kent model: 908 4703 010

1463165000(2)2009-02

SERVICE MANUAL

GENERAL INFORMATION ........................................................................................................................................ 3

CONVENTIONS .................................................................................................................................................... 3

MACHINE LIFTING ............................................................................................................................................... 3

MACHINE TRANSPORT ....................................................................................................................................... 3

OTHER AVAILABLE MANUALS ............................................................................................................................ 3

SAFETY ................................................................................................................................................................ 4

GENERAL INSTRUCTIONS ................................................................................................................................. 4

TECHNICAL DATA ................................................................................................................................................ 6

DIMENSIONS ......................................................................................................................................................... 7

MAINTENANCE .................................................................................................................................................... 8

SCHEDULED MAINTENANCE TABLE ................................................................................................................. 8

MACHINE NOMENCLATURE ............................................................................................................................... 9

SWEEPING SYSTEM .............................................................................................................................................. 11

SIDE BROOM HEIGHT CHECK AND ADJUSTMENT ........................................................................................ 11

SIDE BROOM DISASSEMBLY/ASSEMBLY ....................................................................................................... 12

MAIN BROOM HEIGHT CHECK AND ADJUSTMENT ....................................................................................... 13

MAIN BROOM DISASSEMBLY/ASSEMBLY ....................................................................................................... 14

MAIN MOTOR-TO-IDLER GEAR BELT DISASSEMBLY/ASSEMBLY (FOR MAIN BROOM) ............................. 15

MAIN BROOM BELT DISASSEMBLY/ASSEMBLY ............................................................................................. 16

SIDE BROOM MOTOR ELECTRICAL INPUT CHECK ....................................................................................... 17

SIDE BROOM MOTOR DISASSEMBLY/ASSEMBLY ......................................................................................... 18

TROUBLESHOOTING ........................................................................................................................................ 19

ENGLISH

SKIRT .......................................................................................................................................................................20

SKIRT HEIGHT AND OPERATION CHECK ........................................................................................................ 20

LEFT SIDE SKIRT DISASSEMBLY/ASSEMBLY ................................................................................................. 21

RIGHT SIDE SKIRT DISASSEMBLY/ASSEMBLY .............................................................................................. 22

REAR SKIRT DISASSEMBLY/ASSEMBLY ......................................................................................................... 23

FRONT SKIRT DISASSEMBLY/ASSEMBLY ...................................................................................................... 23

DUST AND DEBRIS COLLECTION SYSTEM ........................................................................................................ 24

DUST FILTER CLEANING AND INTEGRITY CHECK, HOPPER GASKET CHECK .......................................... 24

FILTER SHAKER OPERATION CHECK ............................................................................................................. 25

VACUUM SYSTEM MOTOR ELECTRICAL INPUT CHECK ............................................................................... 26

VACUUM SYSTEM MOTOR DISASSEMBLY/ASSEMBLY ................................................................................. 27

TROUBLESHOOTING ........................................................................................................................................ 27

DRIVE SYSTEM .......................................................................................................................................................28

DRIVE SYSTEM CONTROL CABLE ADJUSTMENT ......................................................................................... 28

DRIVING BELT DISASSEMBLY/ASSEMBLY ...................................................................................................... 29

TROUBLESHOOTING ........................................................................................................................................ 30

MAIN MOTOR .......................................................................................................................................................... 31

DRIVING BELT AND CLUTCH VISUAL INSPECTION AND ADJUSTMENT ...................................................... 31

MAIN MOTOR ELECTRICAL INPUT CHECK ..................................................................................................... 32

MAIN MOTOR CARBON BRUSH CHECK AND REPLACEMENT ..................................................................... 33

MAIN MOTOR DISASSEMBLY/ASSEMBLY ....................................................................................................... 34

TROUBLESHOOTING ........................................................................................................................................ 36

Edge 28B 1463165000(2)2009-02

1

ENGLISH

SERVICE MANUAL

2

1463165000(2)2009-02 Edge 28B

OTHER SYSTEMS ...................................................................................................................................................37

NUT AND SCREW TIGHTENING CHECK .......................................................................................................... 37

HOOD DISASSEMBLY/ASSEMBLY ................................................................................................................... 38

SIDE BROOM COVER DISASSEMBLY/ASSEMBLY ......................................................................................... 39

ELECTRICAL SYSTEM ........................................................................................................................................... 40

BATTERY CHARGER CABLE INTEGRITY CHECK ........................................................................................... 40

BATTERY CHARGING ........................................................................................................................................ 41

BATTERY DISASSEMBLY/ASSEMBLY .............................................................................................................. 41

HOOD SAFETY SWITCH OPERATION CHECK ................................................................................................ 42

LAMELLAR FUSE CHECK/REPLACEMENT ..................................................................................................... 42

TROUBLESHOOTING ........................................................................................................................................ 43

COMPONENT LAYOUT ...................................................................................................................................... 43

WIRING DIAGRAM ............................................................................................................................................. 44

CHARGER (CH1) CONNECTOR PINOUT .......................................................................................................... 45

GENERAL INFORMATION

SERVICE MANUAL

ENGLISH

Edge 28B 1463165000(2)2009-02

3

GENERAL INFORMATION

CONVENTIONS

Forward, backward, front, rear, left or right are intended with reference to the operator’s position, that is to say with the hands on

the handlebar.

MACHINE LIFTING

WARNING!

Do not work under the lifted machine without supporting it with safety stands.

MACHINE TRANSPORTATION

WARNING!

Before transporting the machine, make sure that:

All guards and hoods are closed –

The machine is off –

The machine is securely fastened to the means of transport. –

OTHER AVAILABLE MANUALS

The following manuals are available at Advance Literature Service Department:

Edge 28B, Spare Parts List – Kent Form Number 146 3087 000 –

Edge 28B, User Manual – Kent Form Number 146 3082 000 –

Installation Instruction for BATTERY ASSEMBLY – Kent Form Number 1463535000 –

GENERAL INFORMATION

ENGLISH

SERVICE MANUAL

4

1463165000(2)2009-02 Edge 28B

SAFETY

The following symbols indicate potentially dangerous situations. Always read this information carefully and take all necessary

precautions to safeguard people and property.

DANGER!

It indicates a dangerous situation with risk of death for the operator.

WARNING!

It indicates a potential risk of injury for people.

CAUTION!

It indicates a caution or a remark related to important or useful functions. Pay particular attention to the

paragraphs marked by this symbol.

NOTE

It indicates the necessity to refer to the User Manual before performing any procedure.

CONSULTATION

It indicates that it is necessary to consult the User Manual before performing any procedure.

GENERAL SAFETY PRECAUTIONS

Specic warnings and cautions to inform about potential damages to people and machine are shown below.

DANGER!

Before performing any maintenance/repair procedure on electrical components, disconnect the battery –

negative terminal.

The machine is only to be used by persons who have been adeguately instructed. Children or disabled –

people cannot use this machine.

Do not wear jewelry when working near electrical components. –

Keep the battery away from sparks, ames and incandescent material. –

Do not work under the lifted machine without supporting it with safety stands. –

Do not operate the machine near toxic, dangerous, ammable and/or explosive powders, liquids or –

vapours: This machine is not suitable for picking up hazardous dust.

GENERAL INFORMATION

SERVICE MANUAL

ENGLISH

Edge 28B 1463165000(2)2009-02

5

WARNING!

Carefully read all the instructions before carrying out any maintenance/repair procedure. –

Before using the battery charger, ensure that frequency and voltage values, shown on the machine –

serial number plate, match the electrical mains voltage.

Do not pull or carry the machine by the battery charger cable and never use the battery charger cable –

as a handle. Do not close a door on the battery charger cable, or pull the battery charger cable around

sharp edges or corners. Do not run the machine on the battery charger cable.

Keep the battery charger cable away from heated surfaces. –

Do not charge the batteries if the battery charger cable or the plug are damaged. –

If the battery charger cable is damaged, replace it. –

To reduce the risk of re, electric shock, or injury, do not leave the machine unattended when it is –

plugged in. Before performing any maintenance procedure, disconnect the battery charger cable from

the electrical mains.

If the machine is not working as it should, has been damaged, left outdoors or dropped into water, return –

it to Advance Service Center.

Do not smoke while charging the batteries. –

The machine left unattended are to be secured against unintentional movement. –

Always protect the machine against the sun, rain and bad weather, both under operation and inactivity –

condition. Store the machine indoors, in a dry place: This machine is for dry use only and is not to be

used or stored outdoors in wet conditions.

Before using the machine, close all doors and/or covers. –

Do not allow to be used as a toy. Close attention is necessary when used near children. –

Use only as shown in this Manual. Use only Advance recommended accessories. –

Take all necessary precautions to prevent hair, jewelry and loose clothes from being caught by the –

machine moving parts.

Do not wash the machine with direct or pressurised water jets, or with corrosive substances. Do not use –

compressed air to clean this type of machine.

While using this machine, take care not to cause warm to other people, and children especially. –

Do not put any can containing uids on the machine. –

The machine storage temperature must be between 0°C and +40°C. –

The machine working temperature must be between 0°C and +40°C. –

The humidity must be between 30% and 95%. –

Do not use the machine as a means of transport. –

Do not use on surfaces having a gradient exceeding that marked on the machine . –

Do not allow the brooms to operate while the machine is stationary to avoid damaging the oor. –

In case of re, possibly use a powder re extinguisher, not a water one. –

Do not bump into shelves or scaffoldings, especially where there is a risk of falling objects. –

Adjust the operation speed to suit the oor conditions. –

This machine cannot be used on roads or public streets. –

Do not remove or modify the plates afxed to the machine. –

Do not tamper with the machine safety guards and follow the ordinary maintenance instructions –

scrupulously.

Only use brushes provided with the machine or those specied in the instruction manual. The use of –

other brushes may impair safety.

In case of machine malfunctions, ensure that these are not due to lack of maintenance. Otherwise, –

request assistance from the authorised personnel or from an authorised Service Center.

To ensure machine proper and safe operation, perform the scheduled maintenance shown in the –

relevant chapter of this Manual.

If parts must be replaced, require ORIGINAL spare parts from a Dealer or Authorised Retailer. –

The machine must be disposed of properly, because of the presence of toxic-harmful materials –

(batteries, plastics, etc.), which are subject to standards that require disposal in special centers (see

Scrapping chapter in the User Manual).

GENERAL INFORMATION

ENGLISH

SERVICE MANUAL

6

1463165000(2)2009-02 Edge 28B

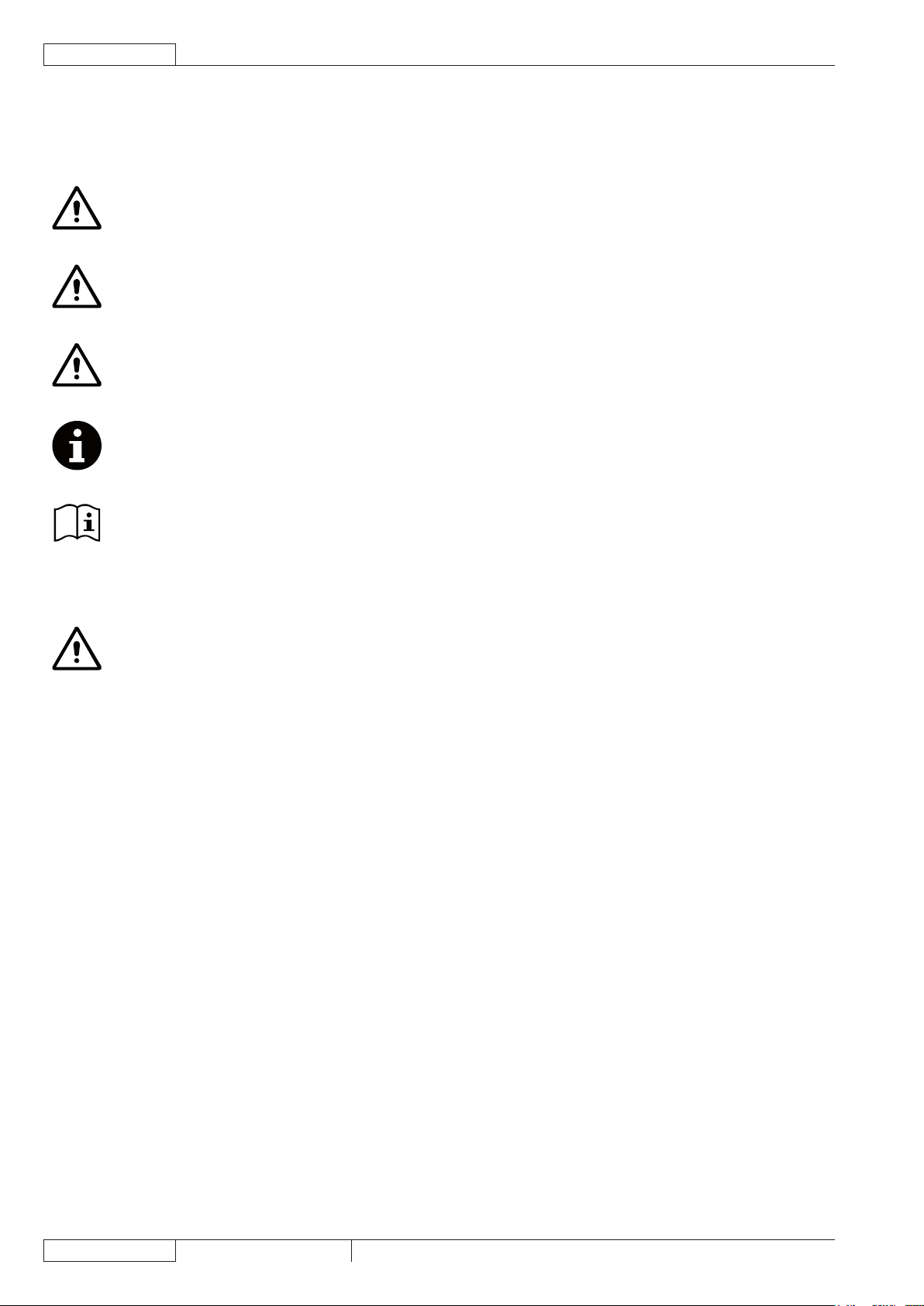

TECHNICAL DATA

General Values

Cleaning width (without side broom) 19.7 in (500 mm)

Cleaning width (with side broom) 28.3 in (720 mm)

Machine size with folded handlebar and without side broom (length x width x height) 39.3 x 31.4 x 19.7 in (998 x 797 x 501 mm)

Minimum distance from the ground (skirts not included) 1.0 in (25 mm)

Main broom size (diameter x length) 7.9 x 19.7 in (200 x 500 mm)

Side broom diameter 12.4 in (315 mm)

Main broom speed 335 rpm

Side broom speed 100 rpm

Gradeability 2%

Hopper capacity 15.8 US gal (60 litres)

Total machine weight with standard battery 167.5 lb (76 kg)

Front steering wheel size (diameter x length) 3.0 x 1.3 in (75 x 32 mm)

Rear wheel size (diameter x length) 11.8 x 1.8 in (300 x 45 mm)

Maximum drive speed 2.3 miles/h (3.7 km/h)

Sound pressure level at workstation (ISO 11201, ISO 4871) (LpA)

Machine output acoustic power (ISO 3744, ISO 4871) (LwA)

Vibration level at the operator’s arms (ISO 5349-1) (*)

59.3 ±3 dB(A)

78 dB(A)

<98.4 in/s

2

(< 2,5 m/s2)

(*) Under normal working conditions, on a level asphalt surface.

Electrical components Values

Electrical system voltage 12 V

Standard battery GEL, 12 V, 45 Ah

Battery charger 6 A

Main motor 200 W, 1,500 rpm

Side broom motor 40 W

Vacuum system motor 50 W

Dust vacuuming and ltering Values

Dust lter 5-10 µm (polyester)

Dust lter surface 10.8 ft2 (1 m

Main broom compartment vacuum 0.47 in H

2

)

O (12 mm H2O)

2

GENERAL INFORMATION

SERVICE MANUAL

ENGLISH

Edge 28B 1463165000(2)2009-02

7

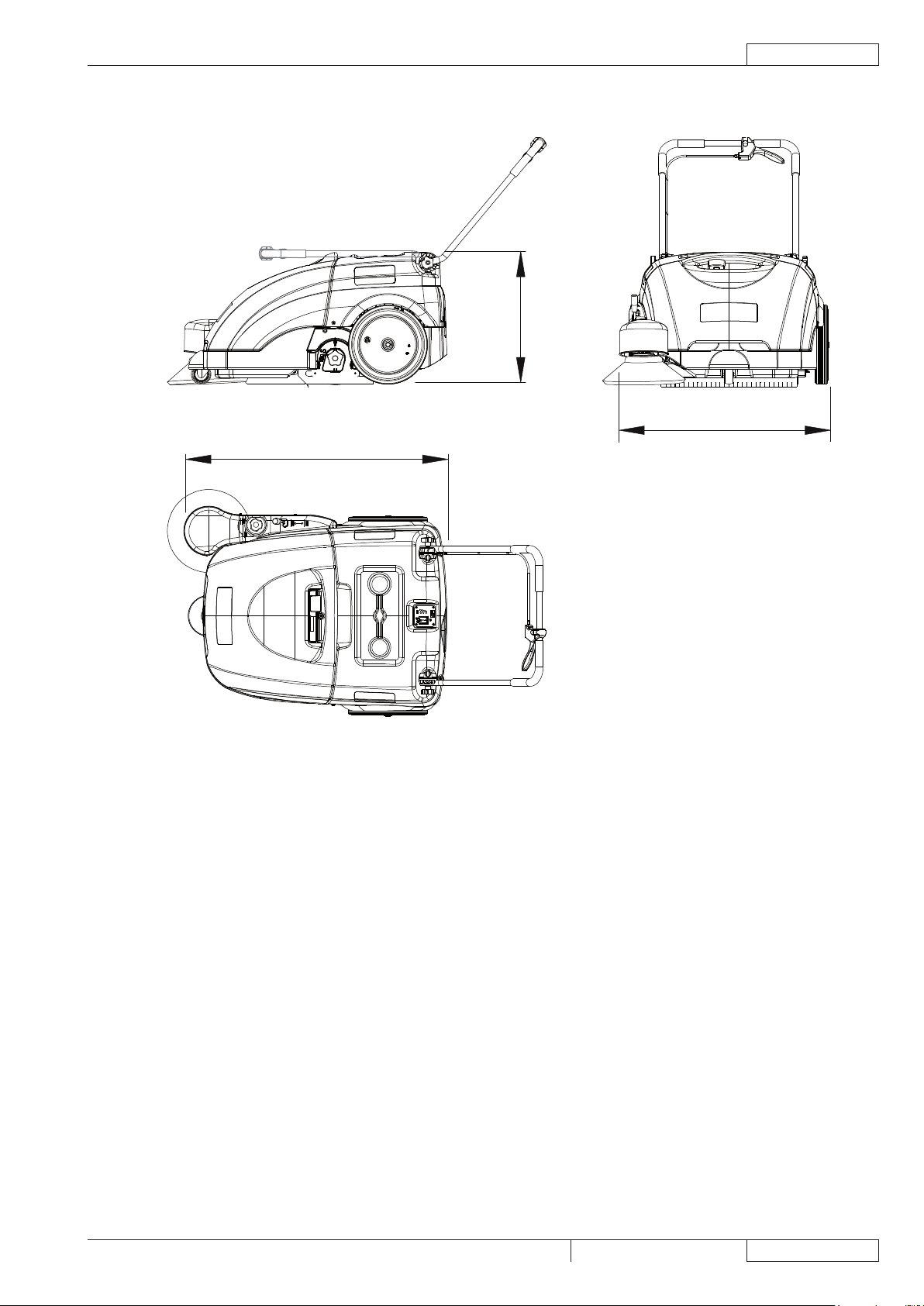

DIMENSIONS

998 mm (39.3 in)

501 mm (19.7 in)

797 mm (31.4 in)

S301584

GENERAL INFORMATION

ENGLISH

SERVICE MANUAL

8

1463165000(2)2009-02 Edge 28B

MAINTENANCE

The lifespan of the machine and its maximum operating safety are ensured by correct and regular maintenance.

The following table provides the scheduled maintenance. The intervals shown may vary according to particular working

conditions, which are to be dened by the person in charge of the maintenance.

The following paragraphs give further instructions about maintenance procedures listed in the Scheduled Maintenance Table.

NOTE

To perform maintenance procedures, the machine must be off and, if necessary, the batteries must be disconnected.

Moreover, carefully read the instructions in the Safety paragraph.

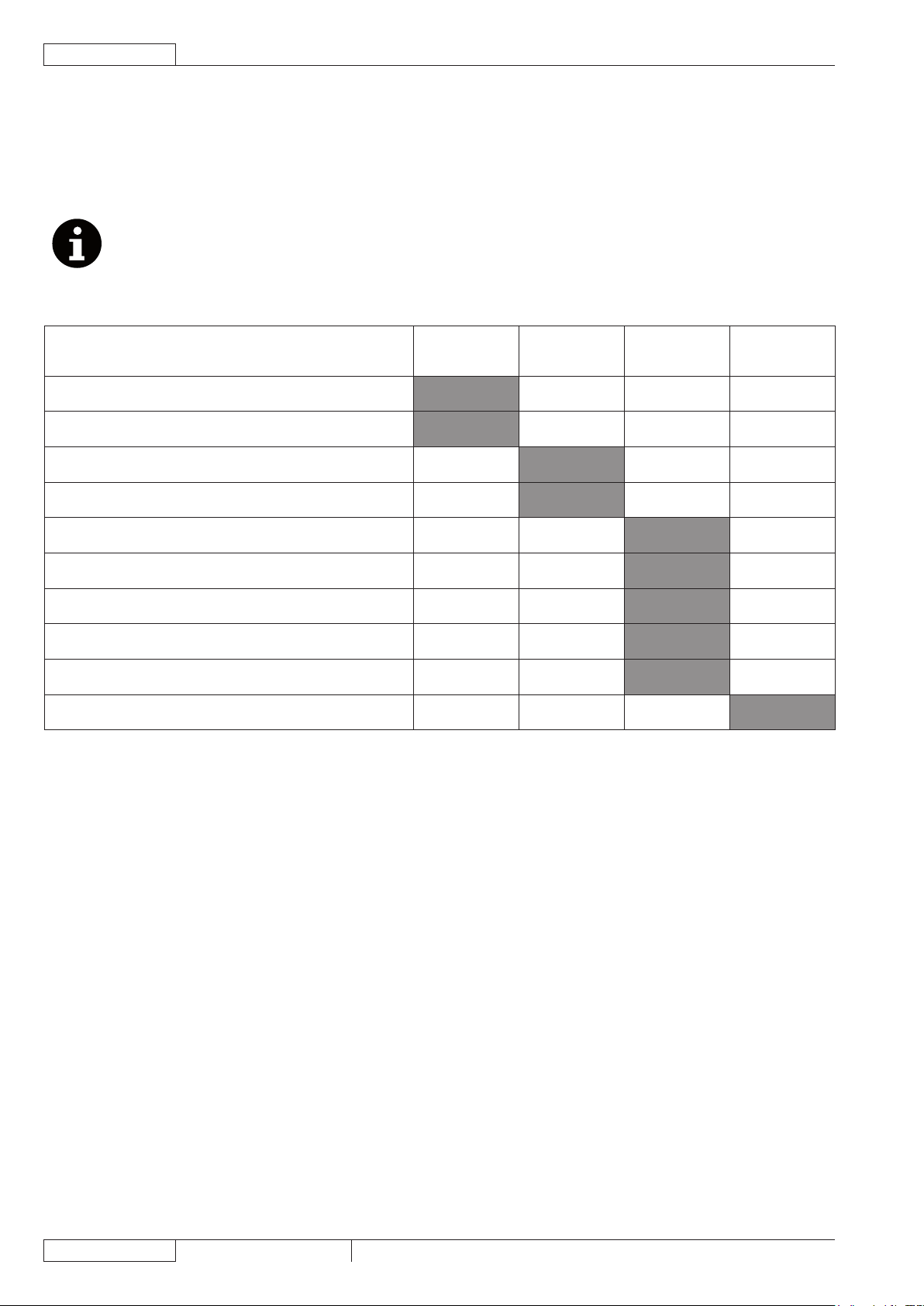

SCHEDULED MAINTENANCE TABLE

Procedure Every 10

hours

Battery charger cable check

Side and main broom height check and adjustment

Skirt height and operation check

Dust lter cleaning and integrity check

Hopper gasket check

Filter shaker operation check

Drive belt and wheel clutch visual inspection

Drive system belt tensioner adjustment

Nut and screw tightening check (1)

Motor carbon brush check or replacement

Every 50

hours

Every 200

(1): And after the rst 8 hours.

hours

Every 400

hours

GENERAL INFORMATION

SERVICE MANUAL

ENGLISH

Edge 28B 1463165000(2)2009-02

9

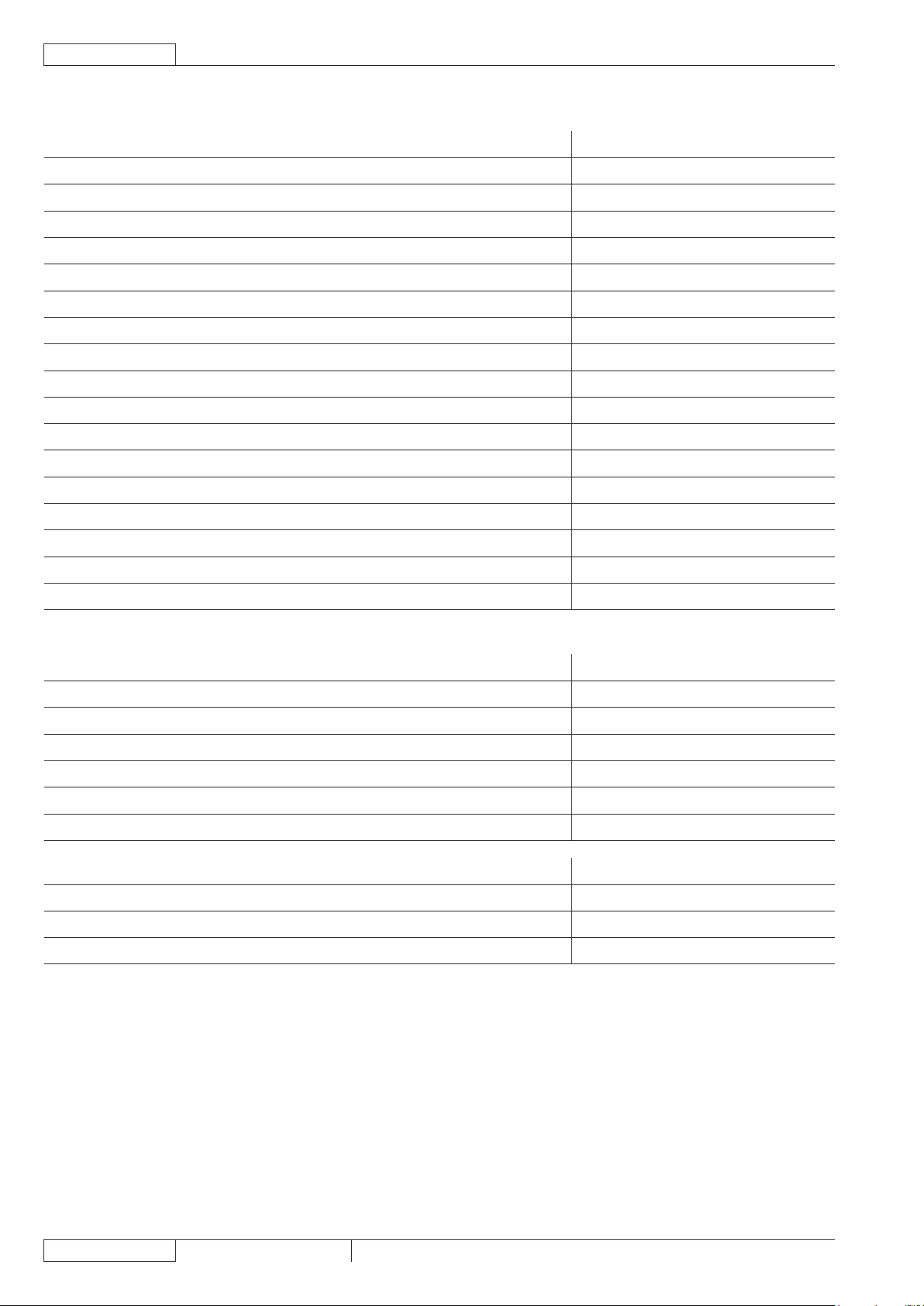

MACHINE NOMENCLATURE

Throughout this manual you will nd numbers in brackets – for example: (2). These numbers refer to the components shown in

these two nomenclature pages. Refer to these pages whenever it is necessary to identify a component mentioned in the text.

Main switch for vacuum system, main broom and side broom activation1.

Charged battery warning light (green)2.

Semi-discharged battery warning light (yellow)3.

Discharged battery warning light (red)4.

Drive control lever5.

Handlebar 6.

Handlebar adjusting knobs7.

Filter shaker knob8.

Hopper9.

Front steering wheel10.

Side broom11.

Side broom lifting/lowering lever12.

Side broom height adjusting knob13.

Main broom14.

Main broom height adjusting knobs15.

Rear driving wheels16.

Can holder17.

Battery charger cable18.

Battery charger cable housing19.

Side broom motor circuit breaker20.

Main motor circuit breaker21.

Battery22.

Dust lter23.

Side broom motor24.

Main motor25.

Drive system gear (clutch)26.

Vacuum fan27.

Battery charger - Function control28.

Vacuum system motor lamellar fuse (7.5 A)29.

Hood30.

Hopper upper handle31.

Hopper lower handles32.

Serial number plate/technical data/conformity certication33.

Side skirts34.

Front skirt35.

Rear skirt36.

Side broom cover37.

Drive system control cable adjuster38.

GENERAL INFORMATION

ENGLISH

SERVICE MANUAL

10

1463165000(2)2009-02 Edge 28B

5

6

7

17

31

8

14

7

30

36

9

11

32

29

10

34

13

16

15

12

34

35

15

16

23

24

25

27

22

28

26

38

38

37

18

20

19

33

21

1

2

3

4

S301584

SWEEPING SYSTEM

SERVICE MANUAL

ENGLISH

Edge 28B 1463165000(2)2009-02

11

SWEEPING SYSTEM

10

3

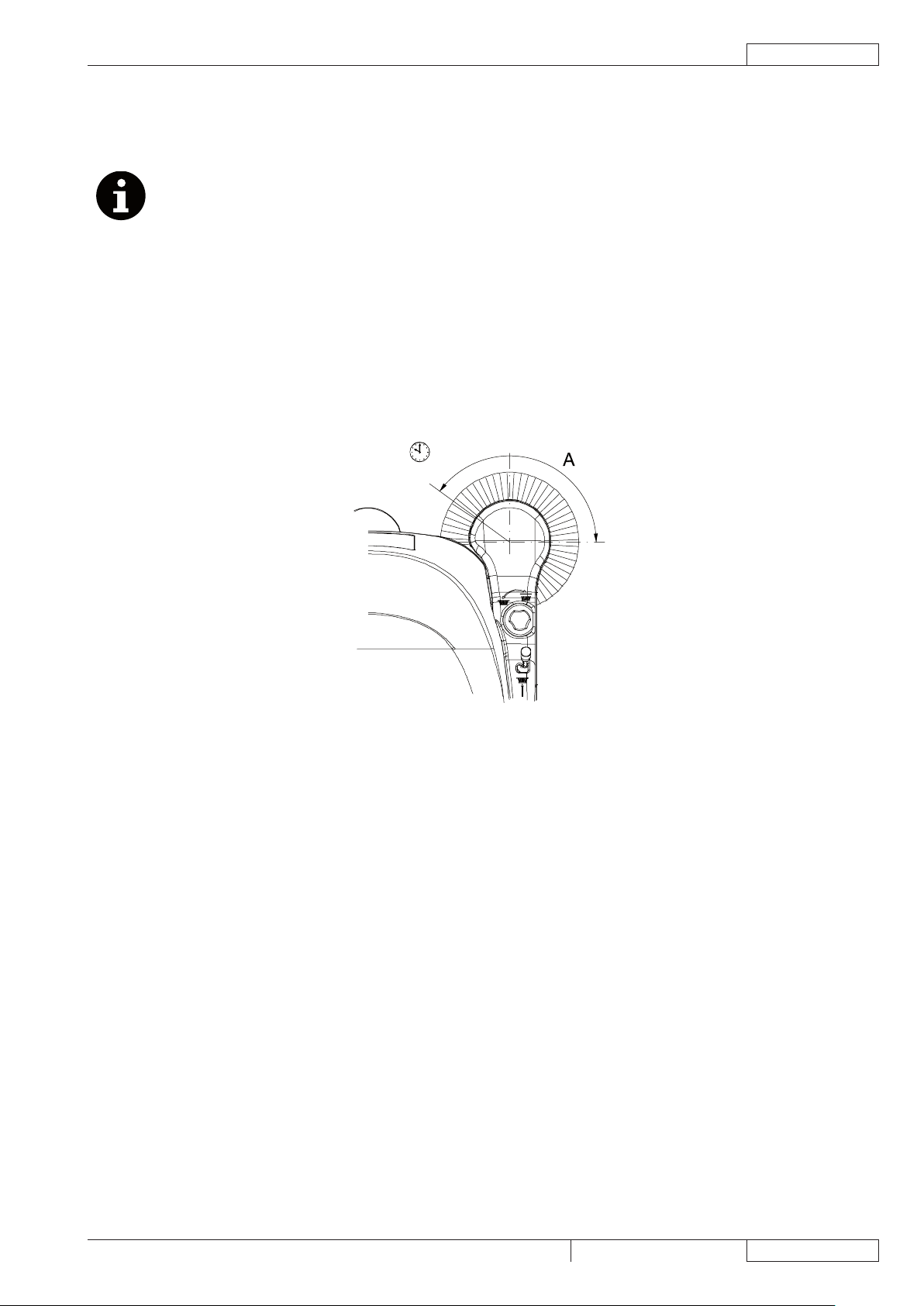

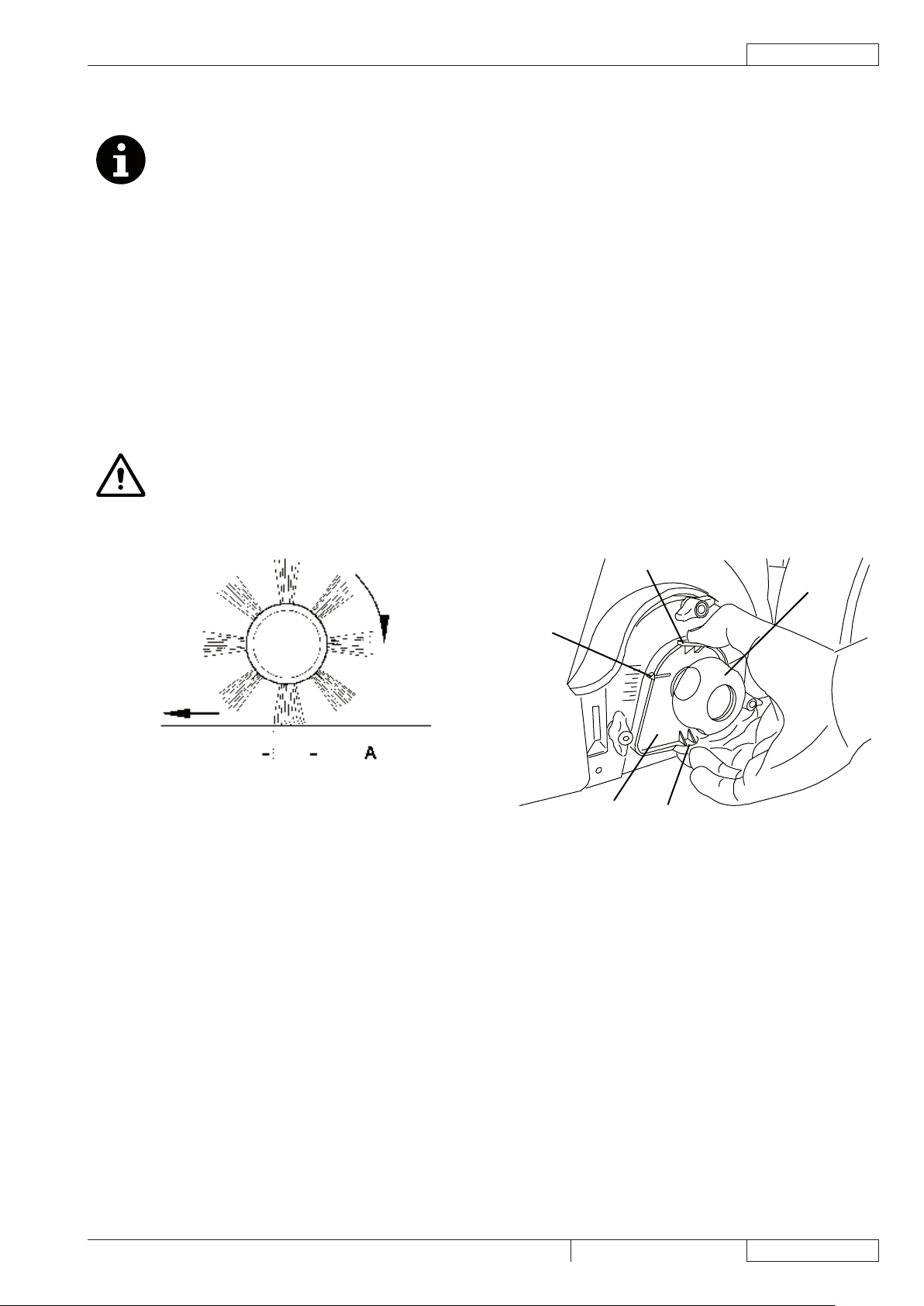

SIDE BROOM HEIGHT CHECK AND ADJUSTMENT

NOTE

Brooms of various hardness are available. This procedure is applicable to all types of brooms.

Check that the side broom is at the correct distance from the ground, according to the following procedure:1.

Drive the machine on a level ground and lower the side broom.•

Keep the machine stationary and turn on the side broom for a few seconds.•

Turn off the side broom by pressing the switch (1), then lift it and move the machine.•

Check if the size and orientation of the print left by the side broom are as shown in the gure (A, Fig. 1): the side broom •

must touch the ground along a circle arc ranging from “10 o’clock” position to “3 o’clock” position.

If the print is not within specications, it is necessary to adjust the broom height, according to the procedure shown in •

step 2.

Turn the knob (13) clockwise or counter-clockwise to adjust the broom height up or down.2.

Perform step 1 again to check that the side broom is at the correct distance from the ground.3.

When the broom is too worn and can no longer be adjusted, replace it according to the procedure shown in the relevant 4.

paragraph.

S301585

SWEEPING SYSTEM

ENGLISH

SERVICE MANUAL

12

1463165000(2)2009-02 Edge 28B

B

C

A

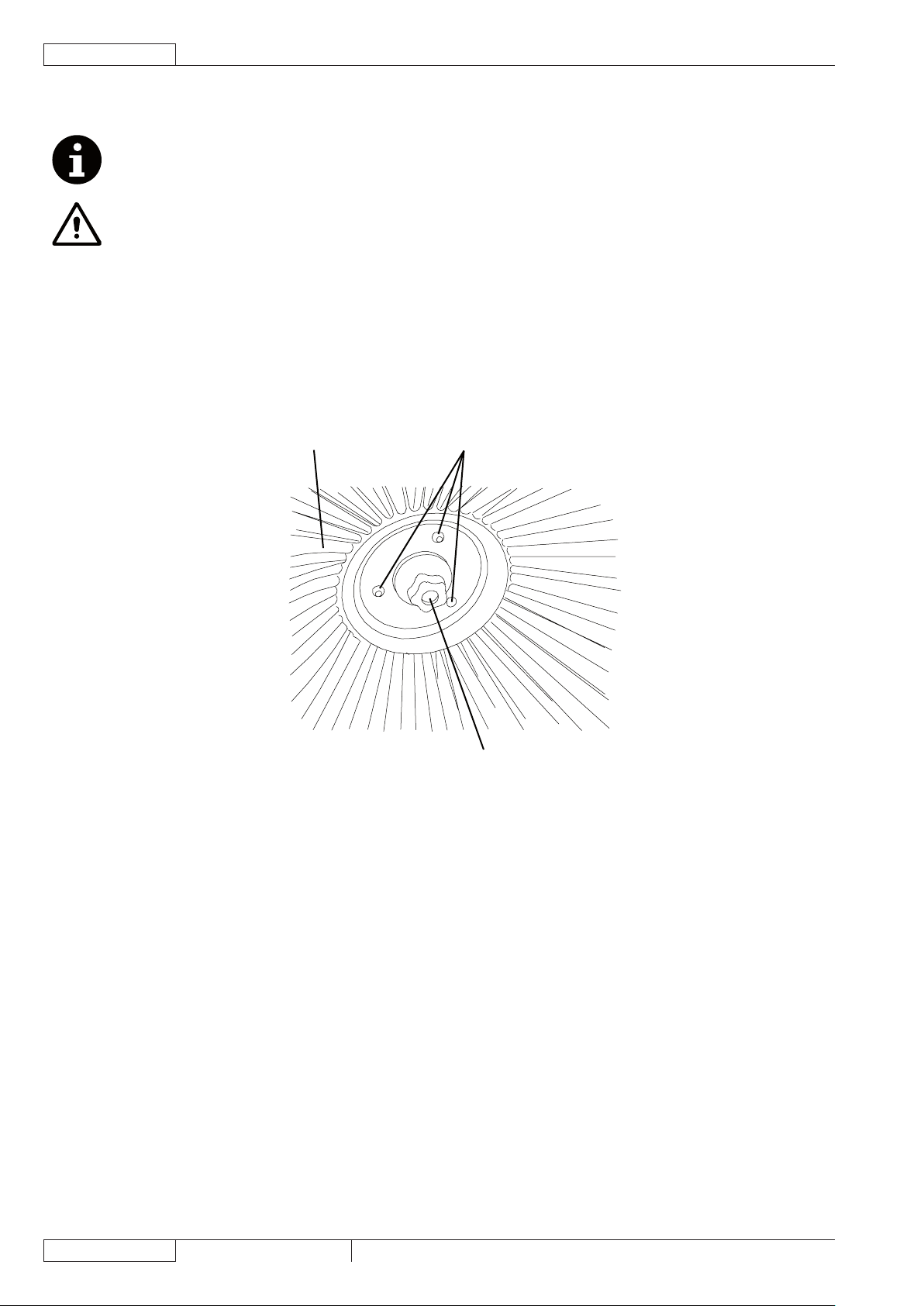

SIDE BROOM DISASSEMBLY/ASSEMBLY

NOTE

Brooms of various hardness are available. This procedure is applicable to all types of brooms.

CAUTION!

It is advisable to use protective gloves when replacing the side brooms because there can be sharp debris

between the bristles.

Disassembly

Drive the machine on a level ground.1.

Turn the main switch (1) to “0”.2.

Lift the side broom.3.

Loosen the knob (A) inside the side broom, then remove the broom (B) by disengaging it from the pins (C).4.

Assembly

Install the new broom on the machine engaging it on the pins (C), then tighten the knob (A).5.

Adjust the height of the new broom according to the procedure shown in the previous paragraph.6.

S301586

SWEEPING SYSTEM

SERVICE MANUAL

ENGLISH

Edge 28B 1463165000(2)2009-02

13

C

B

D

D

E

1.2 in - 2 in

3 cm - 5 cm

MAIN BROOM HEIGHT CHECK AND ADJUSTMENT

NOTE

Brooms of various hardness are available. This procedure is applicable to all types of brooms.

Check that the main broom is at the correct distance from the ground, according to the following procedure:1.

Drive the machine on a level ground.•

Keep the machine stationary and turn on the main broom for a few seconds.•

Turn off the main broom by pressing the switch (1), then move the machine.•

Check that the main broom print (A), along its length, is 1.2-2 in (3-5 cm) wide.•

If the print is not within specications, it is necessary to adjust the broom height, according to the procedure shown in •

step 2.

Turn the main switch (1) to “0”.2.

On both sides of the machine, loosen the knob (B).3.

Grasp the support (C) on the points (D) and move it upwards, then lift it or lower it to change the main broom height. For 4.

height variation, refer to the indicator (E). Then tighten the knob (B) on both sides of the machine.

Perform step 1 again to check that the main broom is at the correct distance from the ground.5.

When the broom is too worn and can no longer be adjusted, replace it according to the procedure shown in the relevant 6.

paragraph.

CAUTION!

An excessive print (larger than 5 cm) of the main broom can lead to machine malfunction and overheating of

moving and electric parts, thus reducing machine life.

Pay careful attention when performing the above-mentioned checks, and always use the machine according

to the indicated conditions.

S301587

Loading...

Loading...