Page 1

KE1TH

LEY

1

NSTRUMENTS

Model

Model

Service

236

237

Source

High

Manual

Measure

Voltage

i

Unit

Source

and

Measure

Unit

Contains

Publication

Document

‚

1

T

Ij

Servicing

Date:

October

Number:

F

fl

LI

r

Lt

U

1991

236-902-01

‘

fl

u

i

ii

Information

D

Rev.

n

UI

ri

LILIU

n

for

_I

j

rn

the

o

i

i

Model

236/237

Page 2

Keithley

period

Instraments,

year

of

1

from

Inc.

date

warrants

shipment.

of

this

WAR

product

RANTY

tobefree

from

defects

in

material

and

workmanship

for

a

Keithley

Instruments,

rechargeable

During

the

fective.

To

exercise

Cieveland,

prepaid,

tion

prepaid.

least

This

ten

Repaired

days.

90

warranty

consent,

chargeable

instructions.

WARRANTY

THIS

IMPLIED

ANY

REMEDIES

batteries,

warranty

warranty,

this

You

Ohio.

indicated

to

the

or

not

does

or

misuse

batteries,

WARRANTY

PROVIDED

Inc.

diskettes,

period,

will

replaced

apply

of

damage

IN

15

warrants

we

write

given

be

service

products

to

product

any

from

LIEU

HEREIN

following

the

documentation.

and

our

at

your

facility.

are

option,

local

assistance

Repairs

warranted

will,

or

call

prompt

LIMITATION

defects

OF

OF

resulting

part.

leakage,

OTHER

This

or

battery

ALL

MERCHANTABILITY

BUYER‘S

ARE

for

items

either

Keithley

OF

from

90

repair

representative,

and

return

for

be

made

the

will

WARRANTY

product

warranty

problems

or

WARRANTIES,

OR

AND

SOLE

days

from

or

replace

instructions.

and

balance

modification

also

does

arising

EXPRESSED

FTTNESS

EXCLUSIVE

the

or

the

of

not

from

date

any

contact

product

the

apply

FOR

shipment:

of

product

Keithley

the

Send

retuined,

original

without

normal

warranty

Keithley‘s

to

fuses,

wear

TMPLIED,

OR

PARTICULAR

A

REMEDIES.

that

proves

headquarters

product,

software,

failure

or

probes,

cables,

be

to

transporta

transportation

period,

express

or

writ

non-re

follow

to

INCLU1JIMG

THE

USE.

de

in

at

NEITHER

DIRECT,

AN

USE

THE

OF

BEEN

ADVISED

SHALL

AGES

LOSSES

SUSTAINED

KEITH

Instruments

AUSTRIA:

FRANCE

GERMANY:

GREAT

BRITAIN:

ITALY:

JAPAN:

NETHERLANDS:

SWITZERLAND:

TAIWAN:

KEITHLEY

INDIRECT,

ITS

OF

IN

INCLTJ1JE,

LEY

Division,

Keithley

Keithley

Keithley

Keithley

Keithley

Keithley

Keithley

Keithley

Keithley

INSTRUMENTS,

SPECIAL,

INSTRUMENTS

ADVANCE

BUT

THE

AS

Instruments

Instruments

Instruments

Instruments,

Instruments

Instruments

Instruments

Instruments

Instruments

Instruments,

GesmbH

SARL•3

GmbH

Ltd.

SRL

Far

BV

SA

Taiwan

Keithley

OF

ARE

RESULT

Rosenhugeistrasse

•

Allee

•

Landsberger

Minster•58

•

The

•

Viele

S.

•

East

KK

•

Avelingen

•

Kriesbachstrasse

•

Room

INC.

INCIDENTAL

SOFTWARE

AND

POSSIBILITY

THE

LIMITED

NOT

INJURY

OF

28775

•

Inc.

BP.

•

Garays

des

Gimignano

Sumiyoshi

West

1105,

Str.

65

Portman

38

24

49•4202

4

•

8600

Floor,

llth

•

•

Bldg.,

NOR

Aurora

A-1J20

12

•

•

60

D-8034

Road

20146

Room

Gorinchem

MS

Dubendorf

No.

ANY

T0

Road

91121

Germering

Reading,

•

Milano

201

147

•

ITS

OF

CONSEQUENTIAL

OR

IF

EVEN

SUCH

OF

COSTS

TO:

PERSON,

ANY

•

Cieveland,

•

0222-804-6548

Wien

Palaiseau

•

02-48303008

2-24-2

•

•

Postbus

•

01-821-9444

Section

•

Berkshire

Cedex

089-849307-0

•

Sumiyoshi-Cho

559

Fax:

•

2,

Chien

•

RG3

Fax:

4200

•

01-820-3081

Kuo

EMPLOYEES

KEITHLEY

DAMAGES.

REMOVAL

OF

DAMAGE

OR

44139•(216)

Ohio

Fax:

0222-804-3597

•

01-60-11-51-55

Fax:

•

1EA•0734-575666

02-48302274

AN Gorinchem

North

089-84930759

Naka-Ku,

•

•

Road

Fax:

•

Taipei,

SHALL

BE

DAMAGES

INSTRUMENTS,

SUCH

EXCLUDED

INSTALLATION,

AND

TO

81-45-201-2246

•

231

•

R.O.C.

•

Fax:

•

886-2-509-4-465

01-60-11-77-26

Fax: 0734-596469

•

Yohohama

•

01830-35333

Taiwan

248-0400

LIABLE

ARISING

INC.,

DAM

PROPERTY.

(216)

•

248-6168

Fax:

81-45-201-2247

Fax:

•

Fax:

01830-30821

FOR

01ff

HAS

886-2-509-4473

Page 3

Service

Manual

Model

Model

237

High

236

Voltage

Source

Measure

Source

Unit

Measure

Unit

.

%

Rlght$

Instruments,

Reserved

Ohio,

01990,

.

.

Keitbley

AU

.

hsträmen6DfrIson•

cieveland,

DocumentNnbec236-902-O1

U. S.

Inc.

A.

Page 4

All

Keithley

Other

brand

products

and

product

are

trademarks

names

are

trademarks

or

registered

trademarks

or

registered

of

Keithley

trademarks

Instruments,

their

respective

of

Inc.

holders.

Page 5

BESCHEINIGUNG

DES

HERSTELLERS/IMPORTEURS

etwirdbescheinigt,(da3)/dasMODEL

mit

dieses

Bestimmungen

den

Gerates

angezeigt

der

und

Vfg

die

geraumt.

Einhaltung

Die

Fur

DIESES

ANWENDUNGSFALL

GEPRUEFI

UNGUENSTIGEN

WERDEN.

J

Beschaffung

die

DER

Keithley

der

GERAET

EST

HiER

DIE

DIESES

GERAET

Instruments,

betreffenden

richifger

WURDE

Me1eitungen

SOWOHL

NACHBILDET,

IS

JEDOCH

UMSTAENDEN

EJHALTUNG

BETRIEBEN

Incorporated

CERTIFICATE

1046/1984

Berechtigung

funkentstort

BesUnimungen

ist

ELN

AUF

MOEGUCH,

BEI

ANDEREN

DER

FUNKENTSTOERBEST1UNGEN

WWD,

23

6/237

zur

setzt

der

Befreiber

DIE

IST

BY

MANUFACTURER/IMPORTER

/238

ist.

Uberprufung

vordus,

ALS

AUCH

EHALTUNG

DASS

GERAETEKOMBIATIONEN

DER

SOUCE

Der

Deutschen

der

Serie

da,

(dass)

geschirmte

verantworificK

EllER

DER

D

FUNKENTSTOERBEST1UNGEN

BETREIBER

MEASURE

Bundespost

auf

VERANTWORTLICH.

UNIT

wurde

Einhaltung

Me1eitungen

ANLAGE,

FUNKENTSTOERBESTfUNGEN

DIE

SER

inUbereinsümmung

das

Inverkehrbringen

der

Bestimmungen

verwendet

EEN

NICHT

GESAMTEN

E1GEHALTEN

NORMALEN

ANLAGE,

ein

werden.

UNR

istocerUfy

This

accordancewith

in

ence

is

ifons.

Compliance

curing

nils

TION

TION

put

being

the

EQUIPMENT

REQUIREMENTS

CONDITIONS).

CERTAIN

BLE

FOR

Keithley

that

the

the

on

the

market

with

applicable

appropriate

and

cables.

HAS

Born

HOWEVER,

UNFAVORABLE

COWLIANCE

Insfruments,

provisions

that

they

regulations

BEEN

TESTED

INDWIDUALLY

lT

CONDITIONS

OF

HIS

PARTICULAR

Incorporated

ofVfg

1046/1984.

have been

depends

CONCERNJG

IS

POSSIBLE

R

The

given

the

on

the use

AND

ON

THAT

OTFR

STALLATIONS.

STALLATION.

GermanPostal

right

of

COWLIANCE

THESE

inspect

to

shielded

SYSTEM

RFI

cables.ltis

i

Services

the

WITH

LEVEL

REQUIREMENTS

lT

series

the

(TO

IS

havebeen

for

user

THE

SIULATE

THE

shielded againstradio

advised

compliance

who

is

RELEVANT

thatthis

with

responsible

RFI

NORMAL

NOT

ARE

USER

WHO

MET

IS

RESPONSI

interfer

device

regu1a

the

for

PROTEC

OPERA

UNDER

pro

Page 6

Page 7

The

The

are

famifiar

before

following

Model

using

safety

236/237

with

the

instrument.

precautions

Source

the

safety

SAFETY

should

Measure Unit

precautions

observed

be

is

intended

requiredtoavoid

PRECAUTIONS

before

for

using

Model

usebyqualified

possible

injury. Read

236/237

personnel

over

Source

who

the

Measure

recognize

Operator‘s

Units

shock

manual

hazards

carefully

and

Exercise

Measure

voltagelevels

is

lnspect

For

power

necting

eration

Do

(earth)

standing

Do

tions

present

the

maximum

is

cables

requires

not

touch

ground.

not

exceed

and

extreme

Unit

in

applied

the

operation

caution

connector

greater

any

unknown

connecting

safety,

to

the

orjumpers.

the

any

object

Always make

voltage

the maximum

when

jacks.

than

30V

circuit

cables,

do

not

circuit

Also,

useofthe

which

being

measured,

section

a

shock

hazardispresent.

The

American

RMS

or4Z4Vpeak

before

test

touch

under

keep

lid

interlock.

could

measurementswith

signal

of

the

instruction

leads,

the

test.

the

provide

levels

measuring.

and

Source

Turn

test

of

National

arc

jumpers

Measure

off

all

fixture

a

current

dry

the

test

manual.

Lethal

voltages

Standards

present.

for

Unit,

power and

lid

closed

pathtothe common

hands

fixture,

A

possible

test

while

while

shown

as

Institute

good

wear,

discharge any

standing

maybepresent

(ANSI)

safetypractice

cracks,orbreaks

fixture,

power

on

test

is

sideofthe

on

the

rear

on

states

thatashock

istoexpect

before

cablesorany

capacitors before

appliedtothe

circuit

a

dry,

insulated

panel

and

the test

fixture

thathazardous

each use.

other

connecting

device

as

under

under

surface

definedinthe

or

the

hazard

instruments

exists

or

test.

testorpower

capable

Source

when

voltage

while

discon

Safe

op

line

of

with

specifica

Connect

Instrumentation

The

Operator‘s

When

PUT

hazard,

test

the

symbolon

a

Model

terminals

always

fixture.

Manuals

236/237

when

turn

screw

and

accessories

a

Model237

for

the

offall

of

the

test

indicates

detailed

is

programmed

unitisin

power

fixftire

should not

operation

operate

before

to

safety

be

connectedtohumans.

that

1000V

information.

for

remote

regardiess

connecting

earth

ground using

or

more

sensing,

of

the

or

disconnecting

may

be

presentonthe

hazardous

programmed

cables to

#18

voltage

voltage

AWG

may

the

or

larger

terminals.

be

present

or

current.

Source

wire

(supplied

Refer

to

on

the

To

avoidapossible

MeasureUnit

accesso).

the

Mode1236/237

SENSE

or

and

the

associated

OUT

shock

Page 8

Page 9

PRCAUTIONS

Ii

faut

observer

pareils

Lappareildemesuredesourcedumod1e

par

et

des blessures

dutiliser

Ii

tion.

test

Linstitut

ddlectrocution

pointe

dre

Avant

cordons dc

cass6s.

Pour

dc testoules

connecteur

tre sur

avantdcbrancher

maintenir

pareiL

danger.

Ne

cöt6

toujours

face

Ne

mc

donn6es

Les

personnes.

Le

pr6sents

Avec

peut

Cette

circuits

tion

d&ecteur

sion.11faut

sources

Pour

tous

mesure

de

personnes

des

familires

sont

faut

ou

ä

pas

pas

montr6

instrumentsetles

symbole

possibles.IIfaut

linstrument.

faire

extr8mement

tensions

Des

les

dans

National

sont

prdsentes.

des

tensions

chaque

test

le

maximumdcs6curitd,nepas

cäbles

d‘instrument

1‘arrt

toutes

ferm6

Ii

verrouiller

laut

toucher

communducircuitäessayer

sacheetisol6e

les

faire

d6passer

surlepanneau

techniques

dans

les

le

dtecteur

produire

tension

peut

extrieurs.Iifaut

soient

correctement

loign.

sassurer

externes

les

dispositifsdctestäplusieurs

les

modles

SOMMAIRE

LOCAL

(LOCAL):Met

fonctionnement

GROUPE

OPERATION

ou

MESURE

mesure

FONCTION

ouenbalayage.

DE

(OPERATE):Met

dattente.

SOURCE

lintensit6ouchoisit

(PUNCflON):choisit

DE

SCURIT

les

pr&autions

de

source

qualifi6es

avec

les

mortelles

fichesdcconnecteursdelappareildemesuredcsource.

Amricain

quand

des

Une

dangereuses

utilisation,iifaut

les

et

fils

dc testdclappareildcmesuredcsourceoutout

les

alimentations

ou

ddbrancher

le

couvercledudispositif

nimporte

mesures

capabledcsupporterlatension

les

niveaux

et

des

accessoires

sur

le

mod6le

terminaux.

loign

tensions

des

causer

JAMAIS

NE

dalimentation.

236/237/238 soit

DES

touchesdupanneau

des

SOURCE

(SOURCE MEASURE):Choisit

s&urit

de

236/237/238.

qui reconnaissent

pr6cautions

lirelemanuel

attention quand

peuvent

tensions

bonne habitude

dc

quand

le

couvercle

quel

avec

maximumdcsignauxdclinstrument,

arri6reetcomme indiqu6

op6rations

237

en

des

toujours

branchs

toujours

de

de

8tre

Normes

des

sup6rieuresä30VRMS

avantdcmesureruncircuit

v6rifier

connexion

des

marche,uncordondedtection

morteilesäOUTPUT

blessuresoula

que

toucher

le

circuitäessayer est

et d6charger

les

cäblesoules

pour

qui

objet

la

ou ä

mains

du

ne doivent

indique

s‘assurer

avantdcmete

changer

d&harger

appareils

tous en

COMMANDES

lappareilenfonctionnement

lappareilenpositiondcfonctionnement

lintensit6

dc

fonctionnementencourant continu

le

suivantes

s6curitd

ne

pourrait

masse

s6chesense

manueldclinstrument.

que

frontal.

avant

236/237/238

les

risques

ndcessaires

de

l‘opdrateur

ii

pr6sentes

(ANSI)

dc test

les

marcheousoit

la

risques

a

des

y

dansledispositif

dit

quil

de

s&urit

les

cäblesdcconnexion,

soient

pas

les

connecteurs,

sous

les

tous

fils.Iifaut

pendant

obtenir

une

fournirunpassage

lalimentation.

dc

tenant

mesurer.

ä

danslasection

pas

8tre

branchds

1000Vou

sourceetmesure

plus

HI

mortetendommager

les

cordons de

que

branchements

et/ou

verrouill6s,iilaut

localetr6tablit

tensiondcsource

la

dutiliser

doit

d6lectrocution

avec

y

ou

est

us6s,

tension.

condensateurs

le

utilisation sans

peuvent

et GUARD.

en

dbrancher

tous

les

tre

utilis6

pour

6viter

soin

avant

d6lectrocu-

un

risque

a

42,4

V

satten-

dc

inconnu.

fissur6s

dispositif

le

autre

Met-

aussi

lap

test dc

Ii

faut

sur

une

sur

com

sur

tre

ouvert

dtec

marche

sous

ten

garder

arr8tds.

la

tension

ap

de

dc

les

ou

des

des

les

les

le

CONFORMIT1

mesurelaplage.

mutateur

GROUPEDEMESURES

TEMPS

taelleenappuyant

ENTER.

SAUVEGARDE

lignedcbase.

supprim6eetle

FILTRE

ifitrationenappuyant

dc

AUTOPLAGE

aveclaplus

plage

GROUPE

CREER

les

boutonsdcSELECT

sur

ENTER.

balayageetle

dc

MODIFIER

pointsdcbalayage

balayage,

le

d6lais

sourceachang6

plagedcla

AJOUT

au

sur APPEND

boutons

ENTER.

balayageetle

PAPPEL

mesuresetla

mutateur

les

avantdcfaire

GROUPE

PRIPARATION

commutateur

le

et ENTER

MÄNUEL

tant

puyer

bus

GROUPE

le

Commutateur

fonctionnement,

en

CHOIX

mentdcremplacement

des

Clavier

les

le

MENU

dc

dimplicite

lalimentation

Aussi

et

param6tres.

indique

surlebouton

IEEE-488ouune

RECALL

donnes

donn6es

fonctionnement:

utilisd

(COMPLIANCE):Vdrifie

Changerleniveau

rotatifoule

(TIME)

(FILTER)

DE

(CREATE)

Utiliser

(MODIFY):Affiche

les

clavier

source.

(APPEND)

SELECT

Utiliserlecommutateur

(RECALL)

rotatif

DE

pour

(MANUAL)

D‘ENTRE

(SELECT):Ccs

dc

:

Toutes

num6riques.

(MENU)

(marche/arrt(

pour

ciavier

V6rifielap6riode

:

sur

les

(SUPPRESS):Sauvegarde

lectures suivantes

Les

niveau

r6el

Affiche

:

sur

(AUTORANGE)

grande

sensibilitd

BALAYAGE

Choisitunbalayageetd6finit

:

pour

le

commutateur

clavier

pour

sauvegard6s. Utiliser

boutons

fait

quune

rotatif

commande

SELECT

et ENTER

utffiser

les

Ajouteunbalayageäun

:

afficherlebalayage

pour changerletype

ciavier

pour

Affiche

:

pour

dur6e

choisirlepointetles

pour

Affiche

seulement

balayage.

le

DCLENCHEMENT

(SETUP):V6rifie

rotatif

pour

changer

les

:

Le

stimulationdcd6clenchement

MANUAL,

entr6e

DE

Commande

:

r6gle

les

valeurs

laffichage

boutons

et

balayage.

touchesduclavier

les

pour

Utilis6

:

d6lais

Hz/60

faire

Hz(

les

(50

actueletla

ensuite

dint6gration.

boutons

du

ldtat

les

changer

pour

boutons

les

chaque

afficher

param6tres.

voyantdcd6clenchement

quandenRECALL,

du

auto-tests,

dc

seront

signal.

ifitre

du

boutons

:

Permet

pour

le

rotatif

les

changer.

les

valeursdcla

pour

changer

SELECTetENTER

actuel

rotatif

changer.

les

paramtresdcla

pointdcbalayage.

les

l6tat

les

une commandedcddclenchement

externedcd6clenchement(.

DONNES

laffichagedcdiffdrents

la

dc

des

choisissent

vdrifier

ou

courant

ddtection

ladresse

et

niveaudcconformit

plage

appuyer

sur

SELECT,

la

conversion

la

diff6rence

mesure.

dc

SELECT

dc

lappareildcse

ä

faire

une

balayage,

type

dc

pour

bouton pour

le

la

choisir

valeurs.Sila

les

balayage

et

ses

balayage,

dc

afficher

pour

boutons

valeursdclii

actuel

du

paramtres

source

et

dc

donn6es dc

paramtres

les

commandent

(sauf

MENU(

changer

continu

(0ä65

(locale/loign6e(

IEEE-488(0ä

en

utilisantlecom

ENTER.

Changer

valeurdcsourceetdc

d6clenchement,

la

s6lection

ensuite

appuyer

suivante comme

entrelavaleur

Changer

ensuite

sur

mettre

mesure.

param6tres.

ses

ensuite

afficher

les

paramtres

sourceetdc

choisirlepoint

valeurdcla

pour

existant.

param6tres.

source,

SELECT

conformitd et

les

appuyer

ensuite

les

param6tres

les

valeurs

Utiliser

pour

source et

les

touches

MANUAL

est n6cessaire

param6tres dc

balayage.

dc

fonctionne

entrentouannulent

conditions

secondes(

frquence

30

lii

quantit6

ENTER.

dans

Utiliser

appuyer

ddlais

changer

Appuyer

Utiliser

com

le

afficher

d6lais

du

Utiliser

SELECT

digno

(ap

sur

quand

laffichage

suivantes

d6lais

secondes(.

et

ac

sur

la

des

dc

la

les

sur

dc

des

le

dc

Page 10

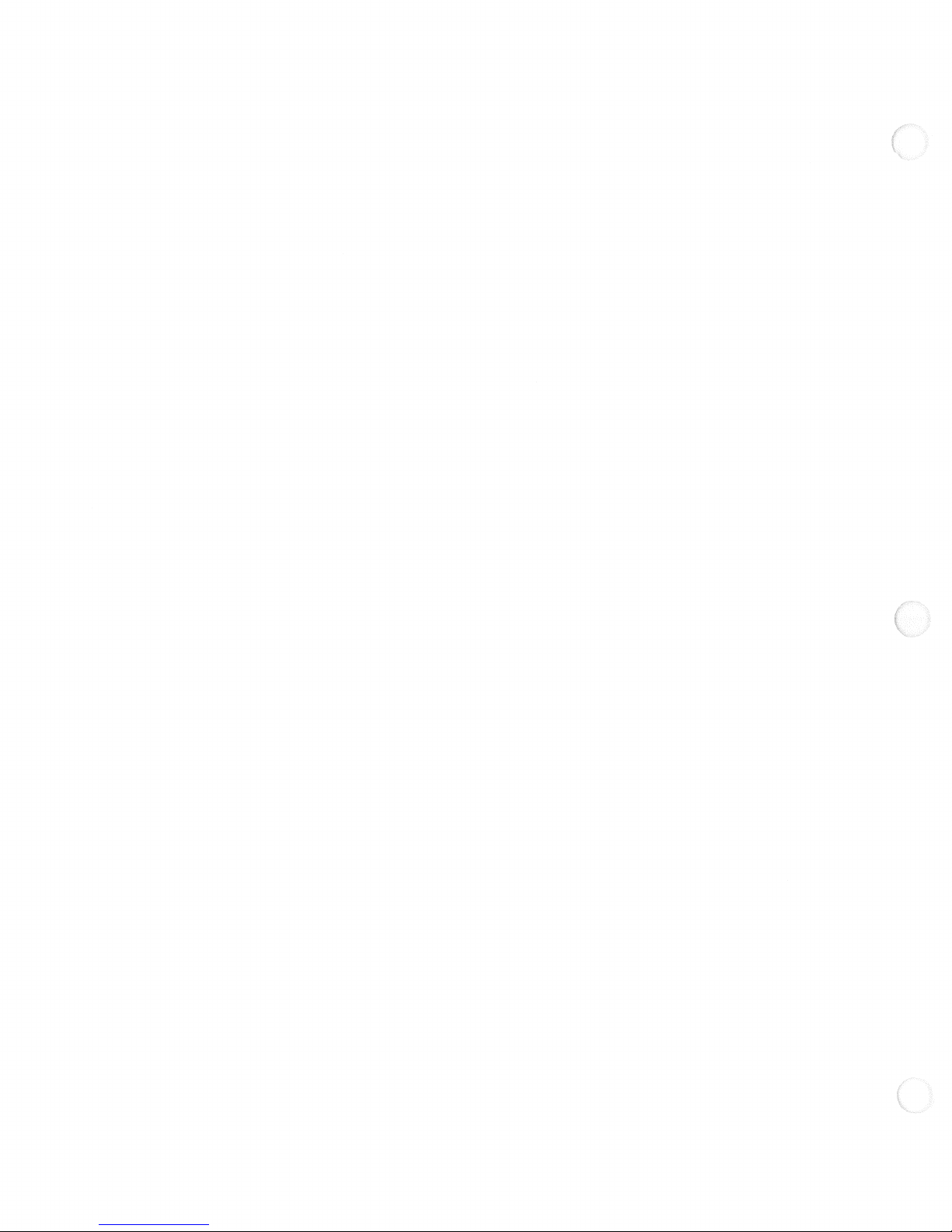

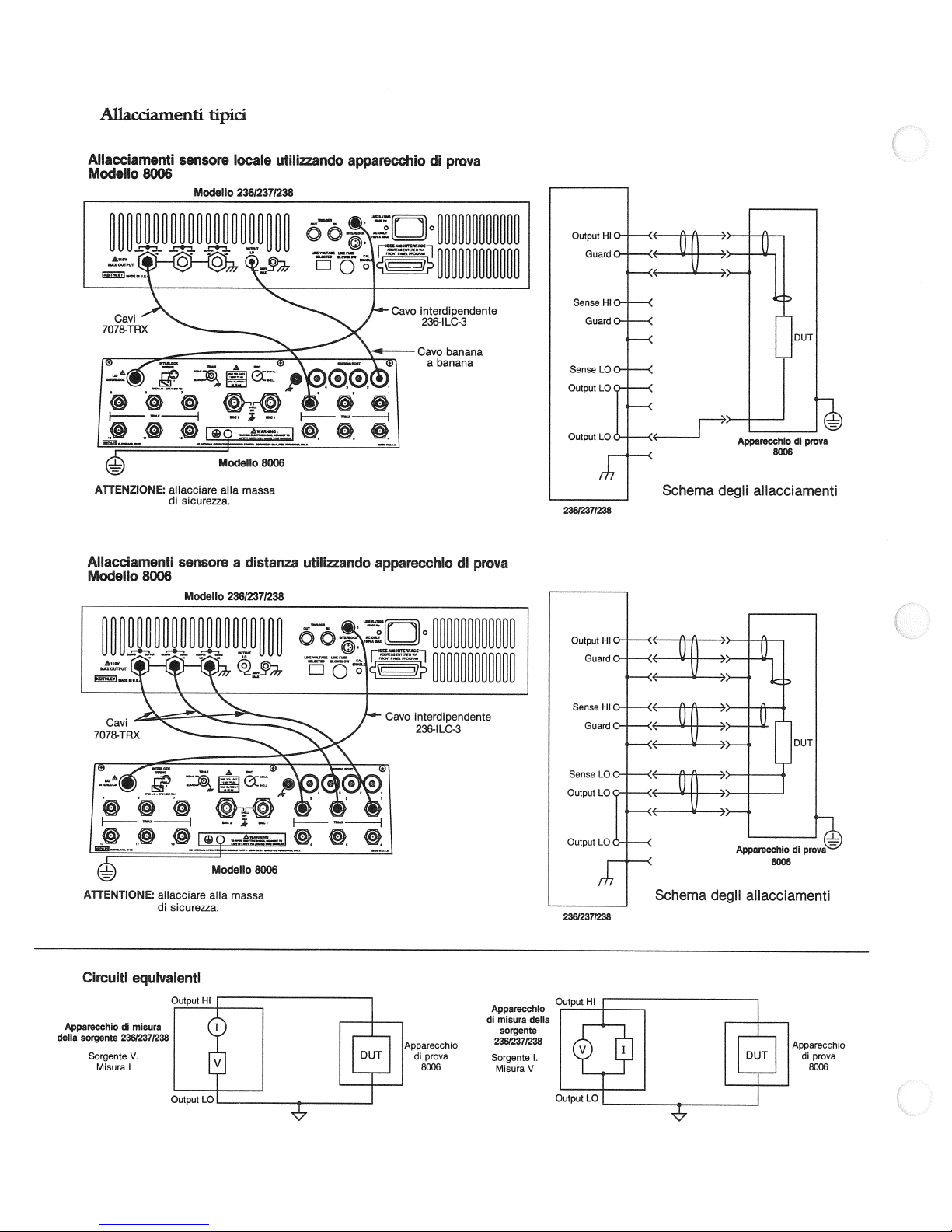

Branchements

typiques

Branchements

mod&e

8006

r•

—.

7o;8-TRx

c»

F—

ATTENTION

Branchements

mod&e

test

de

0

:

Brancher

de

scurit.

de

8006

dtection

ModIe

—

dtection

Mode

23812371238

0

A

Modele

une

masse

23612371238

locale

8006

Ioigne

en

ÖÖ

f—

utilisant

en

—

utlUsant

le

ri

Cäble

236-ILC-3

Cäbledebanane

0

un

dispositif

ä

verrou

äbanane

dispositif

de

de

test

23612371238

Schma

branchement

de

ATTENTION

Circuits

:

Brancher

de

scurit.

quivaIents

une

masse

Dispositif

de

test

8006

Apparell

source

de

de

mesure

23612371238

Source

MesureV

1.

23612371238

Sortle

Soie

eve

basse!

Schma

de

branchement

Dispositif

1

de

test

8006

Page 11

SICHERHEITSHINWEISE

Vor

Sie

Das Quellenmeßgerät

qualifiziertes

mit den

möglichen

Gerätes

Bei

ten.

sind

tional

gefahr

oder

nahme

vor

Prüfen

Brücken auf

Berühren

schlüsse,

Geräten,

Stellen

Kabel

Testanschlußdeckel

Strom

Deckelschlosses,

Berühren

samen

darstellt,

während

zu

Überschreiten

Höchstwerte,

des

Geräte

Das

Anschlüssen

Ist

sungsdraht

GUARD.

führen

Sie

sind,

die

daß

Bei

Sie

Gebrauch

dem

folgende

bitte

Personal

Sicherheitsvorkehrungen

Verletzung getroffen

lesen

Sie

bitte

bestehender

An

Stromschlaggefahr

Testvorrichtung

der

möglicherweise

Standard

dann

42,4

dem

ist

Messen

Sie

Institute

besteht,

Volt

Spitzenleistung

die

Vermutung,

vor

jeder

eine

mögliche

Sie

zur

Prüfvorrichtungen,

während

Sie

den

Stromabund

Brücken

oder

versorgt

wird.

Sie

keinen

Seite

deszuprüfenden

Nehmen

Sie

auf

messende

einer

Spannung

Sie

nicht

außerdem

die

Bedienerhandbuchs

und

Zubehör

Zeichen

auf

mehr

ferngesteuerte

die

immer

Anschlüsse

Sie

Prüfsystemen

entweder

und

bevor

externe

zu

Diese

die

darauf,

Sie

alle

tödlichen

Spannung

externen

die

NIEMALS

Stromquellen

für

Modelle

der

Quellenmeßgeräte

Sicherheitshinweise.

Modell

gedacht, das

Bedienerhandbuch

das

oder

tödliche

Spannungen

(ANSI)

wenn

die

gefährliche

Benutzung

Abnutzung,

maximalen

Prüfkabel

prüfende

der

zu

anschließen

geschlossen,

sichere

Der

Gegenstand,

Messungen

Sie

die

trockenen,

ausgelegt

die

auf

im

beschrieben

nicht

sollten

einem

Modell

1000V

als

vorhanden

Erfassung

kann

Teile

daß

die

ferngesteuerte

unter

mehrfache,

236/237/238

KONTROLLBEGRIFFE

LOKAL

(LOCAL):

kungstastenfunktion wieder

QUELLENGRUPPE

BETRIEB

(OPERATE):

QUELLENMESSUNG

nung

und

FUNKTION

Bringt

Meßstrom

(FUNCTION):

Gerät

Bringt

(SOURCE

Quellenstrom

oder

her.

GerätinBetrieb

Bestimmt

Modelle

236/237/238

eine

vertraut

werden

für

ist

Stromschlaggefahr

die

ist,

müssen.

sorgfältig

lassen

Sie

den

bitte

Anschlüssen

vorhanden.

darauf

weist

hin,

Spannungswerte

betragen.

daßinjedem

alle

Sicherheit

entladen

Eine

unbekannten

Spannung

Verbindungskabel,

oder

Risse

Brüche.

nicht

Verbindungenzuanderen

oder

Stromkreis

Sie

alle

mit

Kondensatoren

besteht.

oder trennen. Halten

während

Stromkreises

isolierten

Betrieb

der

immer

das

erfordert

Stromleitung

eine

oder

mit

Oberfläche

ist.

der

Rückseite

Kapitel

des

‘Technische

sind.

mit

Menschen

237

weist

darauf

sein

können,

aktiviert,soführt

Spannungen

bei

Verletzungen

des

Stromkreises beschädigen.

Erfassungsdrähte

Erfassung

Stromspannung

immer entladen

miteinander

in

Lokal-Modus

an

verbundene

oder

ab.

oder

MEASURE):

Meßspannung.

und

Gleichstrom

236/237/238

Gebrauch

den

Verhinderung

zur

dem

Vor

Gebrauch

durch.

äußerste

Vorsicht

Quellenmeßgeräts

des

American

Das

eine

daß

höher

gute

Stromschlag-

als

Sicherheitsmaß

Prüfkabel

Quellenmeßgerätan

die

versorgt wird.

Strom

außerdem

Sie

prüfende

zu

die

Benutzung

Stromkabelmasse

der

trockenen

stehen

Gerätes

vorgegebenen

Daten

und

verbunden

hin,

daßandiesen

ein

offener

OUTPUT

den

oder

richtig

anescMossen

aktivieren.

Achten

undloder

Geräte

und

stellt

Standby.

Bestimmt

oder

Quellenspan

Durchlaufbetrieb.

beachten

durch

erkennt

einer

30

Volt

RMS

Stromkreis

bevor

‚

Gerät

zur

gemein-

Händen

die

‚

für

Betrieb“

sein.

Erfas

III

herbei-

Tod

Achten

Andern

darauf,

Sie

trennen.

stellen

Frontabdek

und

des

wal

Na-

und

den

mit

des

vor,

und

Sie

Sie

die

ÜBEREINSTIMMUNG

mung

und den

Bereich,

indem

dann

ENTER

(COMPLJANCE):

Meßbereich.

Sie

den

drücken.

MESSGRUPPE

(TIME):

ZEIT

Einstellung,

ENTER

UNTERDRÜCKEN

Grundwert.

dem

unterdrückten

FILTER

indem

AUTOBEREICH

findlichsten

indem

drücken.

Alle

(FILTER):

Sie

einen

Bereich

Prüft

Integrationszeitraum.

Sie

einen

(SUPPRESS):

folgenden

Wert

Gibt

Status

der

SELECT

(AUTORANGE):

für

DURCHLAUFGRUPPE

BESTL\JMEN

Parameter. Bedienen

zu

ändern

um

die

(CREATE):

Sie

und

drücken

Durchlaufparameter

ändern.

ÄNDERN

cherten

laufpunkt zu

zögernngswerte

Wertezuändern.

SELECT

ANI-IANG

weiteren

Durchlauf

die

den

feld,umsie

RÜCKRUF

chene

um

der

Durchlauf

(MODIFY):

Durchlaufpunkte

bestimmen;

zu

Knöpfe

(AFPEND):

hinzu.

dessen Parameter.

und

Durchlaufart

Drehknopf,

zu

um

ändern.

(RECALL):

für

Zeit

den

Parameter.

jeden

Punktzubestimmen

Zeigt

an.

Zeigt

bestimmen,

Wurde

und

ENTER,umden

Fügt

Drücken

zu

ändern

die

Zeigt

Durchlaufpunkt

nur

AUSLÖSERGRUPPE

VORGABEN

den

Drehknopf

Tasten

HANDBETRIEB

zeigt

Knopf,

(SETLJF):

zur

Anderung

daß

an,

Triggerbefehl

Prüft

Anzeige

zur

der

(MANUAL):

Triggerimpuls

ein

über

gabetrigger).

DATENEINGABEGRUPPE

Drehknopf:

uellen-

Q

RECALL-Modus—die

WAHL

gewählt

daten

und

(SELECT):

und-wennimRECALL-Modus—die

geregelt.

Tastenjeld:

numerische

geben

MENÜ

(MENU):

ändern:

zu

oder

lungsverzögerung

Hz)

Hz/60

rung

von Selbstprüfungen.

die

Regelt

Ubereinstimmungswerte

Mit

diesen

Tastenfeldknöpfe

Alle

Daten

Dient

Gleichstromverzögerung

(an/aus)

IEEE-488

und

Sie

ändern

Drehknopf

der

die gegenwärtige

oder

SELECT

Speichert

Ablesungen

und

des

Knöpfe

dem

tatsächlichen

Meßfilters

sind

betätigen

Ermöglicht

die

vorzunehmende

sich

Sie

Bestimmt

der

dann

einen

SELECT

ENTER.

anzuzeigen

Quellen-

an.

die

der

und

Benutzen

SELECT

und

das

Quellenwert

Knöpfe,umdie

Quellenbereichzuändern.

einem

bereits

Sie

APPEND,

Benutzen

drücken

und

Durchlaufparameter

Quellenparameter,

an.

und

SELECT

die

Quellen-

und

gegenwärtigen

der Parameter

Parameter.

Eine

leuchtende

nötig

IEEE-488

Anzeige

Anzeige

ein

dazu,

Erfassung

‚

Adresse

Vielfachleitung

verschiedener

Durchlaufdaten.

der

Knöpfen

oder

werden andere

Ausnahme

(mit

löschen

folgende

(lokal/ferngesteuert)‚Frequenz

(0

bis

Prüft

das

die

Sie

Knöpfe

nächste

dann

Stufe

Tastenfeld

ändern

betätigen

Differenz

die

der

die

Umwandlung

Signalwert.

wieder.

ändern

Sie

und

ENTER

es

dem

Gerät,

Messungzuwählen.

Durchlauf

Knöpfe,

Benutzen

das

und

die

um

Sie

den

Tastenfeld,umsie

Verzögerungswerte

Sie

den

Knopf,

um

Quellen-oder

Tastenfeld

ENTER,umdie

und

geändert,sobenutzen

die

ENTER.

Durchlauf

der

SELECT

und

existierenden

erscheint

so

Sie

Sie

dann

anzuzeigen

Meßwerte

Benutzen

Sie

Knöpfe

den

zur

Verzögerungswerte

Triggerstatus.

und

SELECT

die

MANUAL

(Druck

ist

auf

den

oder

Betriebsparameter,

ein

und

regelt—wenn

Betriebsparameter

Anzeige

von

MENÜ/MENU)

diese.

Betriebsbedingungen

bis65sek),

(0

30).Dient

auch

Übereinstim

Stufe

oder

bedienen

gegenwärtige

und

dann

zwischen

den

Wert,

drücken,

den

emp

und

dessen

Durchlaufart

Drehknopf,

der

gespei

den

Durch-

Sie

einen

gegenwärtige

Knöpfe,

Benutzen

das

Tasten-

verstri

und

Drehknopf,

Wiedergabe

vor

dem

Benutzen

und

ENTER

Triggerleuchte

MANUAL

externer

Durchlauf-

der

zu

prüfen

Grundeinstel

Durchfüh

zur

den

und

als

zu

Ver

die

um

Sie

Sie

Ein-

stellt

im

(50

Page 12

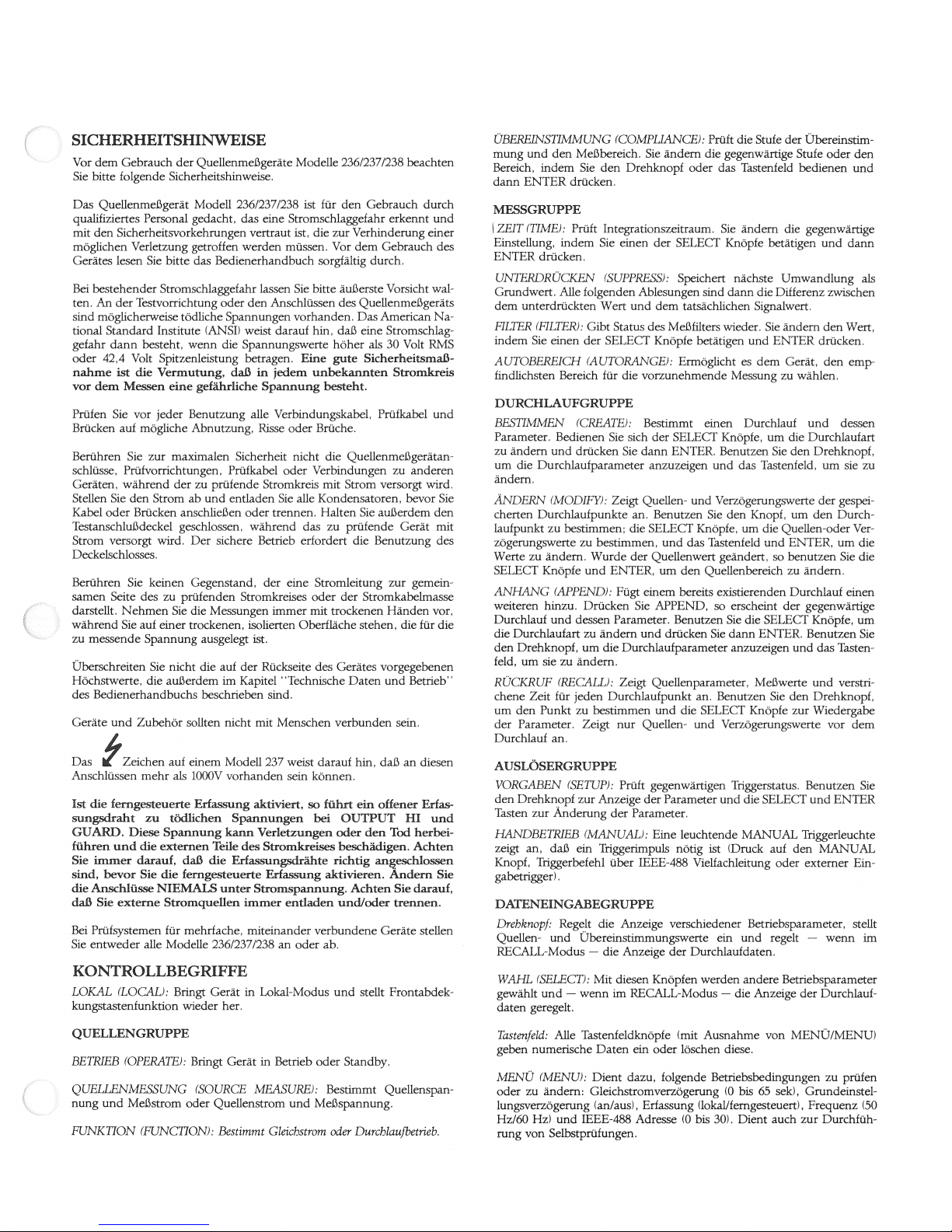

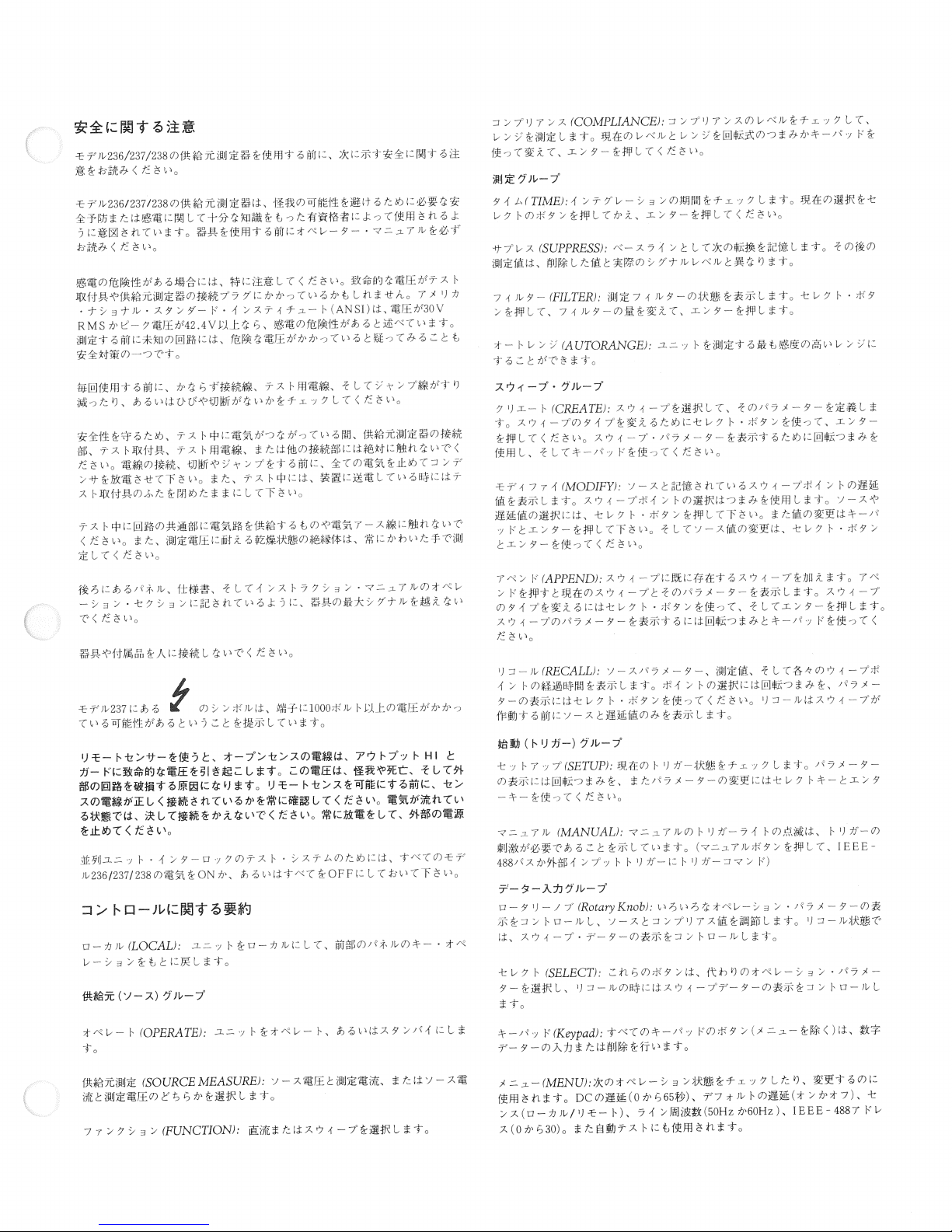

Gebräuchliche

Lokale

Erfassungsanschlüsse

8006

Prüfgerät

ACHTUNG:

An

angesch‘ossen.

Anschlüsse

ModeN

23612371238

Modell

Sicherheitsmasse

8006

bei

Verwendung

von

Modell

236/237/238

Ferngesteuerte

ACHTUNG:

An

angeschlossen.

Äquivalente

Erfassungsanschlüsse

Modell

23612371238

Modell

Sicherhetsmasse

Stromkreise

8006

bei

Vetwendung

von

Prüfgerät

Modell

236/237/238

8006

23612371238

meßgerät

Quelle

Messung

QueNen

V

1

8006

Prüf

gerät

23612371238

meßgerät

Quelle

Messung

QueHen

1

V

8006

Prüf

gerät

Page 13

PRECAUZIONI

osservare

Bisogna

apparecchi

L‘apparecchio

zato

zione

evitare

manuale

delettrocuzione.

di

1‘Istituto

trocuzione

RMS o

tensioni

Prima

tondiprova

Perunmassimo

misura

connettore

completamente

allacciare

chio

sione.

un‘operazione

Non

al

pre

isolate,

Non

sul

manuale

Gli

di

personale

da

sono

e

eventuali

delloperatore

necessario

provaonei

nazionale

allorch

42,4V.

pericolose

delluso

ediponti

di

sorgente,

quando

slacciare

0

dellapparecchio

L‘uso

alcun

toccare

comune

lato

effettuati

capacidisostenere

superare

pannello

posteriore

‘istruzione.

d

strumenti

misura

di

al

procedere

connettori

E

di

lailmentazione

del

privadipericoli.

dcl

conlemani

i

livelli

gli

e

DI

SICUREZZA

le

seguenti

misura

di

sorgente

di

sorgente

precauzioni

quallficatoingrado

corrente

danni

alla

prima

con

Potrebbero

delle

persona.

d‘utilizzare

estrema

esservi

dell‘Apparecchio

americano

vi

buona

prima

necessario

sicurezza,

sono

abitudine

non

dei

liveffi

di

misurare

verificare

accusino

non

l‘apparecchio

II

circuito di

ponti.

cavi

e

di

aUorchIIdispositivo

prova

dispositivo di

ehe

oggetto

potrebbe

circuitoinprova

asciutte

la

tensione

dci

massimi

accessori

e

come

definito

nun vanno

236/237I238

tipo

di

precauzioni

Bisogna

attenzione

delle

regolamenti

massimi

di

sicurezza

un

cheicavi

tracce

toccare

di

prova,

prova

scaricare

e

Bisogna

sicurezza

fomire

alla

o

rimanendo

ehe

segnali

ndr

allacciati

sicurezza

leggere

prima

dovrä

i

rischi

con

sicurezza

di

236/237/238

riconoscere

di

1apparecchio.

quando

letali

tensioni

di

misura

sorgente.

di

(ANSI)

vokaggio

di

attendersi

circuito

sconosciuto.

connessione,

di

di usura,

i

connettori

sotto

tutti

inoltre

massa.

si

incrinature

cavidiprova

i

tensione.

i

condensatori

tenere

in

coperchio

sul

passaggio

un

1

rilevamenti

su

superfici

vuole

misurare.

dell‘apparecchio

prova

dell‘apparecchio,

specifichecduso

sezione

alla

persona.

di

usare

essere

utiliz

delettrocu

necessarie

attenzione

vi

sono

rischi

nell‘apparecchio

Secondo

c‘

superiori

30

a

delet

rischio

cMvisiano

i

condut

avarie.

o

alcun altro

o

Interrompere

prima

ii

chiuso

copen

sotto

garantisce

di

tensione

vanno

asciutte

come

indicato

per

ten

sem

gli

cd

dcl

misura

e

commutatore

la

sele

ENTER.

linea

come

II

valore

fra

II

CONFORMITA (COMPLIANCE):

la

gamma.

Cambiare

rotatorio0sul

GRUPPO

TEMPO

1

zione

DI

(TIME):

attuale

PROTEZIONE

di

soppresso

FILTRO

titativo

base.

leggende

Le

cd

(FILTER):

ffltraggio

di

agendosupulsante

ii

livelloela

II

tasto,

quindi

MISURA

Verifica

(SUPPRESS):

successive

reale

livebo

Indica

in

agendo

premere

ii

periodo

Protegge

dcl

stato

sul

Verifica

gamma

ENTER.

d‘integrazione.

SELECT,

la

conversione

consisteranno

segnale.

dcl

ffltro

pulsante

livello

II

attuali

quindi

nella

di

SELECT,

di

agendo

su

seguente

defferenza

misura.

conformitä

sul

Cambiare

quello

CambiareIIquan

quindisuquello

ENTER.

V

AUTOGAMMA

gamma

GRUPPO

CREARE

dci

virsi

di

premere

parametri

di

MODIFICARE

puntidiscansione

scegliere

della

sorgente

il

valore

per

cambiare

AGGIUNGERE

esistente.

suoi

parametri.

sinne,

quindi

i

dicare

RJCHIAIvIO

misura,

commutatore

indicare

di

prima

(AUTORANGE):

piü

sensibile

DI SCANSIONE

(CREATE):

pulsanti

SELECT

ENTER.

la

tastiera

e

(MODIFY):

II

punto

di

dcl

o

della

sorgente

la

gamma

(APPEND):

Premendo

Servirsi

premere

parametri

elatastiera

(RECALL):

tempo

cd

II

rotatorio

i

parametri.

effetturare

per

Sceglie

Servirsi

per

protetti.

scansione,

ritardo,latastiera

della

l‘APPEND

dci

ENTER.

trascorso

per

Indica

la

scansione.

effettuare

una

per

dcl

cambiarli.

Indica

Servirsi

mutato,

sorgente.

Aggiunge

pulsanti

Servirsi

per

Indica

per

scegliere

soitanto

Permette

scansione

cambiare

commutatore

i

i

pulsanti

agire

vengono

i

parametri

ciascun

all‘apparecchiodiporsi

lii

misura.

enedefinisce

tipodiscansione,

II

della

valori

commutatore

dcl

SELECT

cd

ENTER

puisanti

sui

scansione

una

indicati

SELECT

per

dcl

commutatore

cambiarli.

della

punto

puntoedci

un

i

valori

della

i

parametri.

rotatorio

per

sorgenteedcl

per

scegliere

cambiare

per

SELECT

una

ad

la

scansione

cambiare

ii

rotatorio

sorgente,

scansione.

di

pulsanti

sorgente

sulla

Sen

quindi

indicare

ritardo

dci

rotatorio per

ii

valore

i

valori.

cd

ENTER

scansione

attuale

cd

tipo

di scan-

in-

per

vaiori di

i

dcl

Servirsi

dcl

per

ritardo

SELECT

e

i

Se

i

Ii

simbolo

esservi

Col

telesensore

produrre

causare lesioni

puö

sempre

primadiattivare

tensione.

sione

Per

i

i

modeffi

ti

SOMMARIO

LOCALE

sul modem

una

tensione

attivato,unconduttore

delle

tensioni

i

conduttori

che

ii

Accertarsidiscaricare

esterne.

dispositivi

provaadapparecchi

di

236/237/238

DEI

(LOCAL):

superioreai1000

letaliaOUTPUT

o

morte

telesensore.

in

Avvia

ristabilisceilfunzionamento

GRUPPO

OPERAZIONE

zione

MISURA

della

misura

FUNZIONE

0

a

DELLA SORGENTE

d‘attesa,

DELM

sorgente

la

tensione.

e

(FLTNCT1ON):

scansione.

(OPERATE):

SORGENTE

ne misura

237

staadindicare

danneggiare

e

di

sensore

Non

e/o slacciare

funzione

o

COMANDI

l‘apparecchio

dcl

tasti

a

l‘apparecchio

Mette

(SOURCE

l‘intensitä,

II

Sceglie

ehe

V.

di

sensore

HI

e

GUARD.

i

circuiti

appositamente

siano

sostituire

MAIiconnettori

sempre

multipli,

sarä necessario

fermarli tutti.

in

funzionamento

pannello

anteriore.

MEASURE):

l‘intensitä

o

sceglie

funzionamento

sui

aperto

in

funzione

a

terminali

Tale

esterni.

sorgenti

le

Sceglie

della

corrente

potrebbe

in

grado

tensione

Accertarsi

allacciati

sotto

di

tenere

locale

in

o

tensione

la

sorgente

continua

ten

tut-

posi

SGANCIO

GRUPPO

PREPARAZIONE

dcl

di

ENTER

MANUALE

sta

MANUAL,

ando

GRUPPO

Commutatore

zionamento,

zionediRECALL,

SELEZIONE

zionamento

e

zione

Tastiera:

canceflano

MENU

condizioni

secondi)

e

frequenza

secondi)

DI

commutatore

per

cambiare

(MANUAL):

indicare

ad

comando

estero).

D‘IMMISSIONE

aiterni

dci

dati

Tutti

i

dati

(MENU):

di

ritardo

‚

di

.

Utilizzati

(SETUP):

rotatorio

parimetri.

i

la

necessitä

di sgancio

rotatorio:

regola

Comanda

valori

i

comanda

(SELECT):

nella

e,

di

scansione.

tasti

i

della

numerici.

Viene

funzionamento:

per

default

alimentazione

anche

Verificainstato attuale

per

Ii

lampeggiare

di

indicare

stimolo

uno

sulla

i

parametri,

della

sbarra

DATI

l‘indicazione

sorgente

della

iindicazione

Tali

pulsanti

dci

scelgono

posizionediRECALL,

(eccetto

tastiera

per

ritardo

verificare

della

utilizzato

(avvio/arresto)

‚

(5OHz/6OHz)

effettuare

per

e

auto-prove.

spia

sgancio

di

IEEE-488,

di

di

conformitä

e

dati

II

corrente

‚

sensore

l‘indirizzo

sgancio.

dem

dci tasti

e

di

sgancio

(premere

sgancio

o

parametridifun

van

scansione.

di

i

parametri

comandano

MENU)

cambiare

o

continua

(iocale/a

IEEE-488(0a

Servirsi

SELECT

MANUAL

pulsante

a

nella

e,

di

l‘indica

immettono

seguenti

le

(0

distanza),

com

posi

fun

a

cd

o

65

30

Page 14

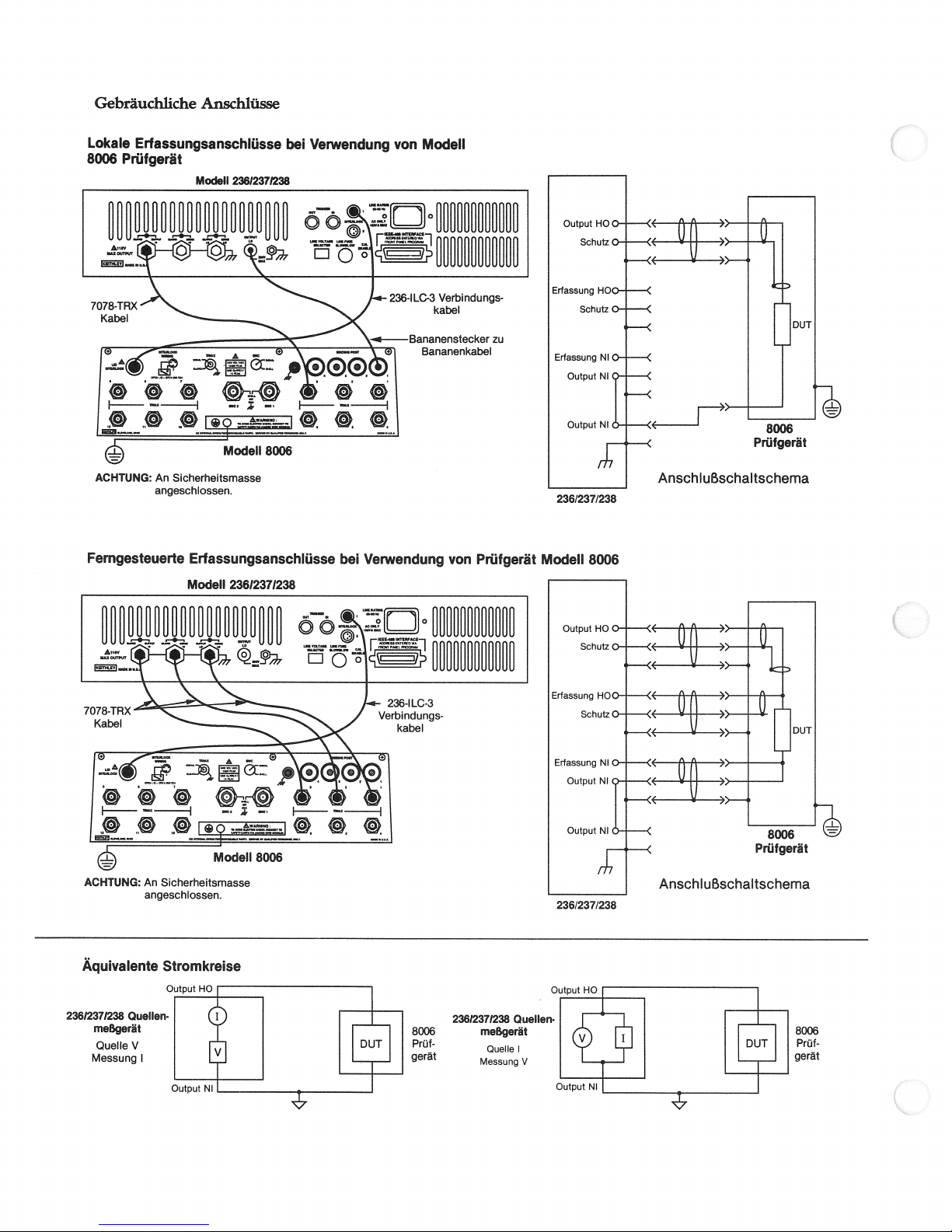

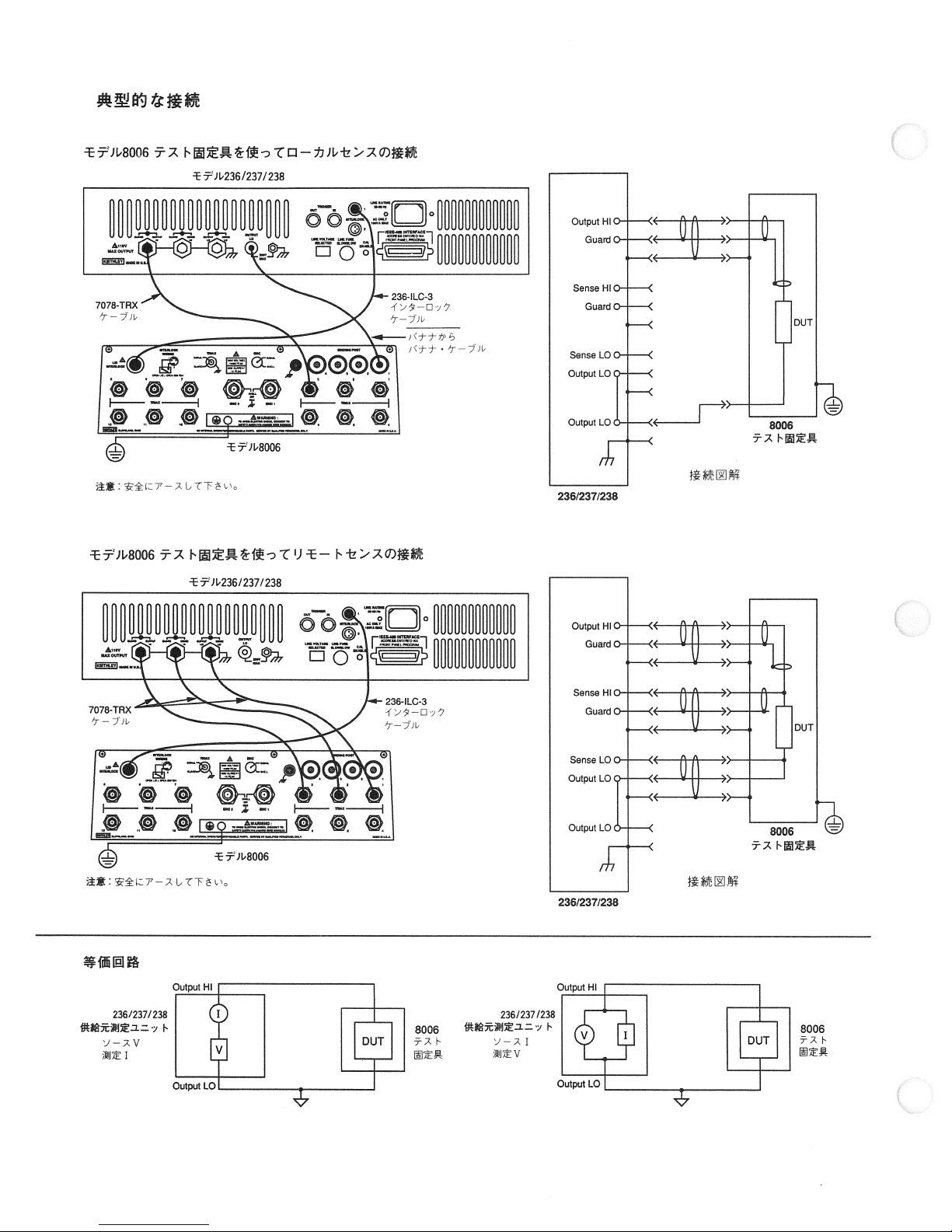

Allacdamenti

üpid

Allacciamenti

Modello

re

7O78TRX

H—

8006

‘———H

L@

AflENZIONE

Allacciamenti

Modello

8006

sensore

Modelto

°

allacciare

di

scurezza.

sensore

Modello

locale

23612371238

°

‘

ModeUo

alla

massa

a

distanza

23612371238

utillzzando

»‚

8006

apparecchio

ÖÖ

.ØØ

F—

—

utilizzando

di

ri

intercpendente

Cavo

Cavgna

1

apparecchio

prova

di

prova

23612371238

Schema

degli

allacciamenti

AflENTONE:

Circuiti

AppareccNo

defla

sorgente

Sorgente

Misura

aflacciare

di

equivalenti

misura

di

23612371238

V.

1

sicurezza.

afla

massa

Apparecchio

di

misura

sorgente

23612371238

Sorgente

Misura

della

V

1.

23612371238

Schema

degli

allacciamenti

Apparecchio

1

di

prova

8006

Page 15

‘H

ALl

{

11

!1

Li

JJ

%

s

i

L

pz

+

i;

r

)C/D

v

Tj

;1c;

L*

g4

j

+J

i

-‘

<z

‚N.E

\j

‚

N/)r

N

‘,\

-

L

‚

:

r

-:

‘-J

\

Nt

\-

-

-j

N

:

O\

-D

—

N

$

-\J

\

\

.‘-

j

‚

\

N

>

t

\

\

«

J

-\J

-)

J

+

J

‘<,

=

<4

s

\-

6

:‘

N

4

-‘

.

‘

4

4*64*

-

.

‚

N

-‚

\

4

N

‚U:frL

\N

1GG-

(

‚

J-

\

J

0

‚6

a<

i

N

;

NS

‚L

m

N

:

-j

-

‘

J

jL

46

\-

*1:;:;

lJ4+

*u)

‚;

Zt

U

A4+6

1%::pE\/

i

-Eu

->

L)

‚

HL

h

$

‚

-;

\

L}t

g

•_)

-

s

‚

1-

ApE

jn

-

-+

.-(

‘

-

4‘

--

IJj

L

ia‘i)

—-)

‚4G

--

4J

1J

J

N

N

r<JIk

_)

r<

r

-

)

<

*

J

‚

-

&

J

/

\

-

r

--

z

-‚-

-

4

Q

z

}

N

.

->-

__)

6\

--

:

-.

N

>

-

.

<--

\J

4.

-

)

\J

rjj>

I4

zI

K

AJ•‘

J

N

4j

‘

J

J

T

L

N

..

‚

-

:

‚—

J

\

\

.

4

--j

J

‘-

.

1

-\

4

-J

k)*

‚6

4

.LL

\7

_J

-\

«

6

-

\

4

)

<\

i

--

*

\\

N

‚

s

N

/

!

.

:

u

“

n

‘,\

IH

‘

-J

N

-%‚

Q

1

JD

0

.:

—

R

N

-

(J-

_j

‘,\

z

r‘

j

6

—

0

‚

-)

‘

j_

‚

4

:;

i

L1L

N

b

‚

;

k

-

4

4

*

4

‚

\J

\

(b

;

)

*6

—)

L

‚\

÷

kU

J

—

£<

N

N

N

0

N

j

.

<

a

6

-R

-

Z

6c)

-L

*6

-

0

:\

n

jj-

N

-6

N:

-4i

r1

\

f6

-

\

*

/

c

s

ZN

‚\

j

I

±

I

‚k

‚\A

r

1-

+6

d

‚

%

N

Page 16

0)

dl

CO

9‘

>.4

-7-

:11111

l}

rH

9

t1

>.4

3

0

a

99

0-0

CD

Co

a

0

cD

99

111

CD

0,

.—

0

—

-

‘-4

Ok

H

>.4

9‘

>

;jw

rH

lj

(J

Co

dl

dl

oo(

3

-.3

(‚3

0)

3

$

41

2

99

H1

g)

o

99

co

OCf)

c

cD

00

99

111

0

c

0

v

19

H

_-4—1

‘-4

H

Co

7_

1

<

>J

4

ii

w—

<>

—

r%)

0)

(‚3

0

>1

flll

>

Page 17

MEDIDAS

Es

necesario

medidores

El

medidor

nal

experimentado

conocedor

y

lidad

dc

antes de

Tener

sumo cuidado

mortal

voltaje

fuente.

dor

de

(ANSI)

de

voltaje

medidadeseguridad

cualquier

Inspeccionar

puente

Para

mäxima

DE

SEGURIDAD

tomar

las

de

fuente

modelo

medidasdeseguridad

modelos

236/237/238

capazdereconocer

de

las

lesiones.

este

instrumento.

medidas

Leer

sufrir

usar

cuando

presente

en

El

establece

en

Instituto

que

son

circuito

busca

existe peligro

superioresa30VRMSode

es

anticiparla

desconocido

los

cablesdeconexiön,

de

posible

seguridad,

no tocar

de

cablesdepruebaocualquier

aplica

corriente

conectar

probador

La

operaciön

No

tocar

lado

comün

el&trica.

superficie

una

corriente

el&tricaalcircuito

el&tricaydescargar

cablesocables

puente.

mientrasseaplica

segura

requiere

ningün

objeto

dcl

Siempre

que

circuito

sometidoapruebaotierra

tomar

las

secayaislada

do

exceder

los

No

cl

panel

en

operaciön

No

se

El

simbolo

nales

puede

Coneidetector

darä

por

SALIDA

puede

je

teriores

bien

conectados

biar

las

asegurar

energla

Para

los

deberä

desenergizados,

todos

RESUMEN

LOCAL

ciones

GRUPO

OPERAR

niveles

mäximos

traseroycomo

dcl

manual

dc

instrucciones.

deben

conectar

haber

resultado

los

que

apareceencl

presente

remoto

la

apariciön de

instrumentos

habilitado,

ALTAyde GUARDA (OUTPUT

causar

lesioneseindusolamuerte,

Siempre

asegurar

antesdehabffitareidetector

conexiones

de

descargar

estando

y/o

externas.

sistemasdcprueba

manteneryasea

(LOCAL):

dcl

panel

todos

DE

LOS

Poneeiinstrumentoenlocalyrestablece

frontal.

DELAFUENTE

(OPERATE):

Pone

reserva.

MEDIDA

dc

FUENTE

(SOURCE

fuenteycorriente dc

medida.

FUNCION

(FUNCTION):

antesdeusar

los

236/237/238.

ser

usado

estä

diseüado

los

peligros

manual

peigro

requeridas para

del

de electrochoque.

de seguridad

el

exista

los

enchufes conectores

Normalizaciones

de electrochoque

crestadc42,4V.

presencia de

antesdetomar

conductores

desgaste,

otro

los

Tambin,

los

conector de

que

capacitores

grietasoroturas

conectores

estä

se

mantener

corrientealdispositivo

cl

usodcun

pudiera

enclavamiento dc

proporcionar

para

de

operador

del

Nacional

voltajes

mediciones

de

del

medidor, probador,

instrumento

probando.

antesdeconectarodes-

que

un

paso dc corriente

por

los

electrochoques

evitarlaposibi

cuidadosamente

Podria

probador

Norteamericano

cuando

los

Una

peliosos

pruebaycables

antes dc

mientras

Cortar

cerradalatapa

estä

se

probando.

lii

dcl cabledcenergla

con

las

manos

secas

mediciones

capazdcresistirclvoltaje

dc

seüal

dcl

y

modelo

instrumento,

las

especificaciones

accesorios

237

indica

se

define en

que

se

como

a seres

queenlos

dc

estä

secciön

y

humanos.

1000Vomäs.

conductordcdetecciön

un

voltajes

mortales

HI

que

los

conductores

la

energla

e1ctrica

desconectar la

interconectadosdcmedidores

los

modelos

236/237/238

y

dafiar

y

remoto.

fuentes

enlaconexiön

GUARD).

los

de

detecciön

NUNCA

aplicada

suministro

dc

energizados,

Este

circuitos

mültiples,

CONTROLES

unidadenestadodcfuncionamientoodc

la

MEASURE):

medida,

Sclecciona

corriente

o

operaciön

Selecciona

dc

cc

fuenteytensiön

dc

o

tensiön

barrido.

primaria

aparatos

perso

haber

medi

o

niveles

buena

cada

toda

tapa.

pie

sobre

midien

indica

se

termi

abierto

volta

estn

Siempre

las

opera

uso.

cam

en

dcl

dc

ex-

DOCILIDAD

medida.

dc

0

tecladoyluego

GRUPO

TIEMPO

en

curso

ENTER

SUPRIMIR

ciöndclfneadcbase.

cl

valor

FILTRO

tidaddcifitraciön

AUTOGAMA

margen mäs

GRUPO

CREAR

los

botones

se

la

ENTER.

cl

teclado

y

MODIHCAR

los

puntos

cl

punto

dc

rctardo,

al

valordcfuente

cl

margen dclafuente

AGREGAR

pulsar APPEND

botones

TER.

teclado

LLAMAR

mediciön

rilla

giratoria

parämetros.

dc

ejecutarse

GRUPO DE

dc

PREPARACION

rador.

SELECT

MANUAL

ca

quc

dc

se

o

comando

parador

GRUPO

Perilla

operaciön,

modo

SELECCIONAR

racionales

sualizaciöndclos

Teclado:

(registrar)

o

dc

MENU

operaciön:

dc

defecto

(ines

ejccutar

(COMPLIANCE):

nivelymargenencurso

Cambiar

DE

(TIME):

pulsando

ei

pulsar

MEDICION

Verifica

los

ENTER.

elperiododcintegraciön.

botones

(ENTRAR).

(SUPPRESS):

suprimido

(FILTER):

Guarda

Las

lecturas subsiguientes

cl

nivel

y

realdcla

Indicaclestado

pulsando

los

(AUTORANGE):

sensible

para

tomar una

DE

BARRIDO

(CREATE):

Usarlaperilla

dc

dc barrido,

SELECT

Usarlaperilla

para

(RECALL):

y

Seleccionaunbarrido

SELECT

para

para

cambiarlos.

(MODIF):

barrido

registradosenla

los

cl

tccladoyla

cambiö,

(APPEND):

visualizaclbarrido

se

para

giratoria

cambiarlos.

Visualiza

tiempo

elegir

para

Visualiza

barrido.

cl

transcurrido

los

cl

cambiareitipo dc

giratoria

Visualiza

botones

tecla

usar

los

dc

energta.

Aüadeunbarrido

cambiarcltipodcbarrido

para

elpunto

valores

DISPARADORES

Usarlaperilla

(SETUP):

ENTER

y

(MANUAL): La

requiereunimpulsodcdisparo

se

disparo

dc

entrada

dc

DE ENTRADA

giratorja:

Controlalavisualizaciöndclos

ajusta

RECALL,

controla

(SELECT):

alternativos

Verfficalacondiciönoestado

giratoria

cambiar

para

luz destellante

sobrelabarra

exterior).

DE

los

valores

dc fuenteydc

la

visualizaciöndclos

Estos

cuando

y,

datosdcbarrido.

botones

Se

datos

usa

dcl teclado

numeticos.

para

verfficarocambiar

cc(0a

Todos

los

anular

0

(MF.NU):

retardo

(activado/desactivado)

Hz),ydirecciön

Hz/60

(50

autopruebas.

Verificaclniveldcdocilidadyei

conlaayuda

Cambiar

SELECT

la

conversiön

(SELECCIONAR)yluego

siguiente

como

seränladiferencia

seflal.

dcl

filtrodcmediciön.

SELECTyluego

botones

Permitealaparato

Cambiar

ENTER.

pasarala

medida.

define

sus

parämetros.

en

seguida pulsar

y

parämetros

los

retardoydc

dc

Usarlaperilla

elegirclvalor

cambiar

los

barridoyaexistente.

parämetros.

seguida

en

y

parämetros

dc barridoycl

dclafuente,

dc barrido.

para

retardo

solamente

para

los

SELECT

ENTER

botones

visualizar

los

parämetros

para

ylos

dc

y

barrido

visualizar

valores

memoria.

para

para

SELECTyENTER

a

un

en cursoysus

los

cada

punto

SELECT

botones

fuenteydc

actual dcl

para

visualizar

los

parämetros.

colectora

los

dcl

disparador

(pulsaciön

o

bus

parämetros,

MANUAL

dcl

botön

IEEE-488,oun

DATOS

distintos

parämetros

docilidad,ycuando

datos

dc barrido.

botones

estäenmodo

segundos)

65

detecciön

‚

IEEE-488

seleccionan

(excepto

‚

(local/remota)

(0a30).

RECALL,

MENU)

las

retardo

los

parämetros

controlan

sirven

siguientes

predetermmnado

frecuencia

‚

Tambin

margen

dclaperilla

la

selecciön

una

mcdi-

entre

la

can

gama

Usar

dc barrido

fuente

dc

para

elegir

dc fuente

valores.Sicl

cambiar

para

Usar

los

EN

pulsar

los

valores

dc

Usarlape

visualizar

los

antes

dispa

las

tcclas

mdi-

MANUAL,

dis

dc

estä

en

ope

vi-

la

para

entrar

condiciones

per

dc

usa

para

se

o

o

Al

Page 18

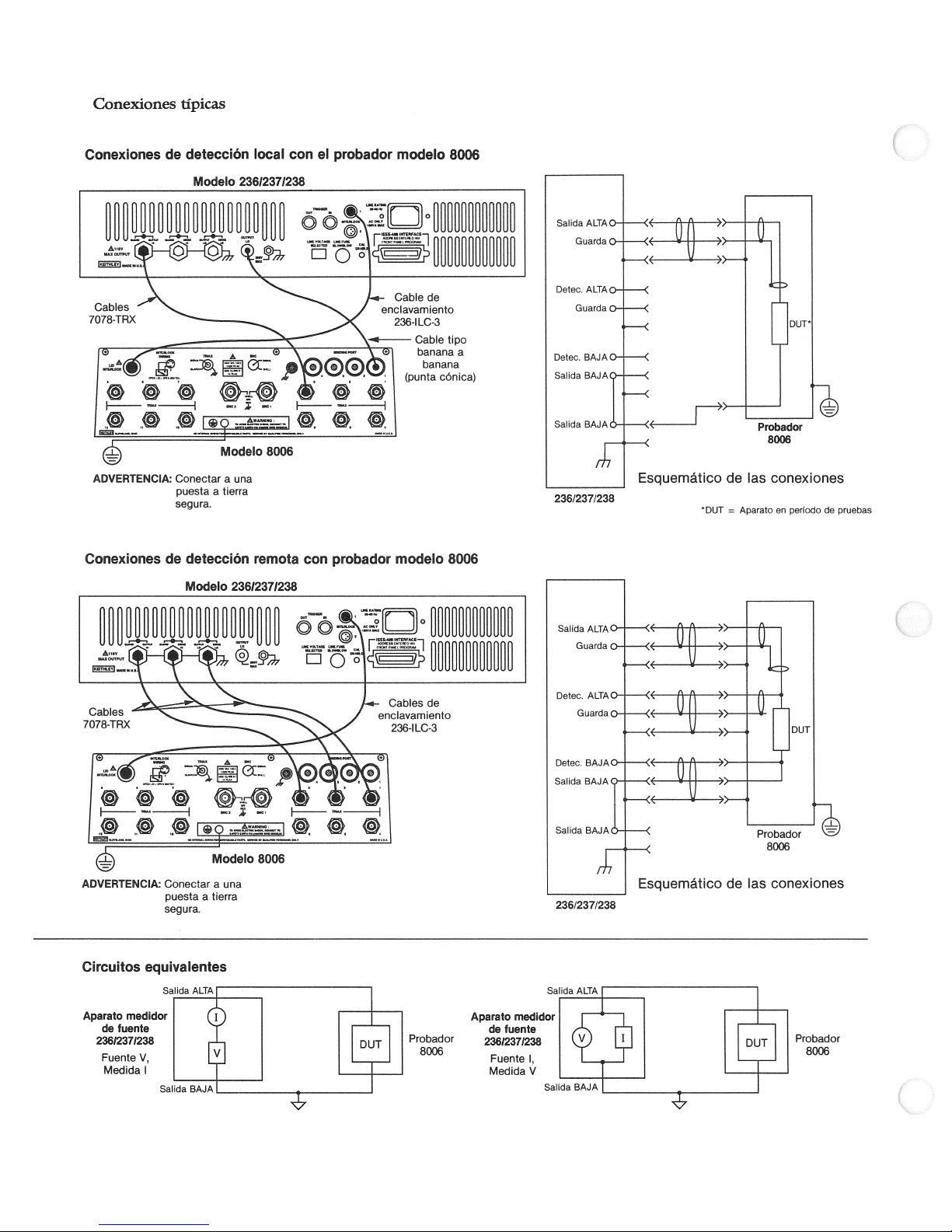

Conexiones

Conexiones

1

ffpicas

detecciön

de

Modelo

23612371238

Mod&o

local

8006

con

ei

probador

modeio

8006

Probador

8006

ADVERTENCA:

Conexiones de

ADVERTENCA:

Conectar

puesta

a

segura.

detecciön

Modeio

Modelo

Conectar

puestaatierra

segura.

a

una

a

flerra

remota con

23612371238

8006

una

probador

modeio

8006

236/237/238

236/237/238

Esquemätico

*DUT

de las

=

conexiones

Aparatoenperiodo

de

pruebas

Circuitos

Aparato

23612371238

fuente

de

Fuente

Medida

equivalentes

Satida

medidor

V,

Probador

8006

fuente

de

23612371238

Fuente

1,

Medida

V

Probador

8006

Page 19

SPECI

FICATIONS

SOURCEMEASURE

or

sources

rent,

FUNCTION:

source-measure

Can

current

be

used

unit.

UNIT:

SOURCEDELAY-MEASURE

Source

SourceDe1ayMeasure

Default

Delay

Default

User

Delay:

Delay:

Fixed

Additional

delay

pacitance.

MEASURE:

Integration

Fast

Medium

Line

Elapsed

measurement

Cycle

Time:

Time:

416

4

16,67

20.00

Measures

complete

RANGING:

Auto-ranging

Source:

using

grammable

Measure:

of

COMPLIANCE

FILTER:

2,

4,8,16,or32,

SUPPRESS:

ings.

MENU:

Remote

DATA

ENTRY:

rotary

Auto

Takes

Subtracts

Measurement

DC

Sense,

n

through

dial

and

in

SWEEP

or

fixed

value.

measurements,

selectable).

displayed

50/60Hz,

Numeric

TRIGGER:

Input

and

Internal,

measure

battery

open puts

Output:

sequenceortrigger

External

button),

Stores

one

full

values,

backup.

with

Use

instrumentinstandby.

IEEE-488

elapsed

MEASURE

Origin:

TRIGGER

MEMORY:

and

ium

INTERLOCK:

closed;

Sources

while

as

DC

voltage

measuring

sourceormeter,sweep

CYCLE:

Delay

for

instrument

delay

for

device

isec.

msec.

msec.

msec.

and

for

(60

(50

stores

each

stepofsweep.

Hz)

Hz)

keypad

SELET

function.

range.

Fixed

keys

range

caiculates

measurement

Delay,

Address,

for

any

(including

bus

times,

Default

detented

or

phaseofSOURCE-DELAY

output

(TALK,

and

IEEE

keypad

Set

sweep (upto1000

test fixture or

while

vo1tage

Cycle

Measure

J

Inteation

settling.

test

under

digit

4

digit

5

digit

5

time

from

entry;

fixed

(DC

function).

selection

and

outputs

from

Delay

Seif

Tests.

rotary

of

at end

front

panel

GET,

points)

sweep parameters.

external

switch.

measuring

source,

L

Time

or system

resolution

resolution

resolution

sweep trigger

selection

range

Fully

madebychoice

average

subsequent

On/Off,

“X“).

ofsource,

Local/

dial.

sweep.

MANUAL

delay,

Normally

or

read

cur

pro-

(n

Lith

full

ca

to

=

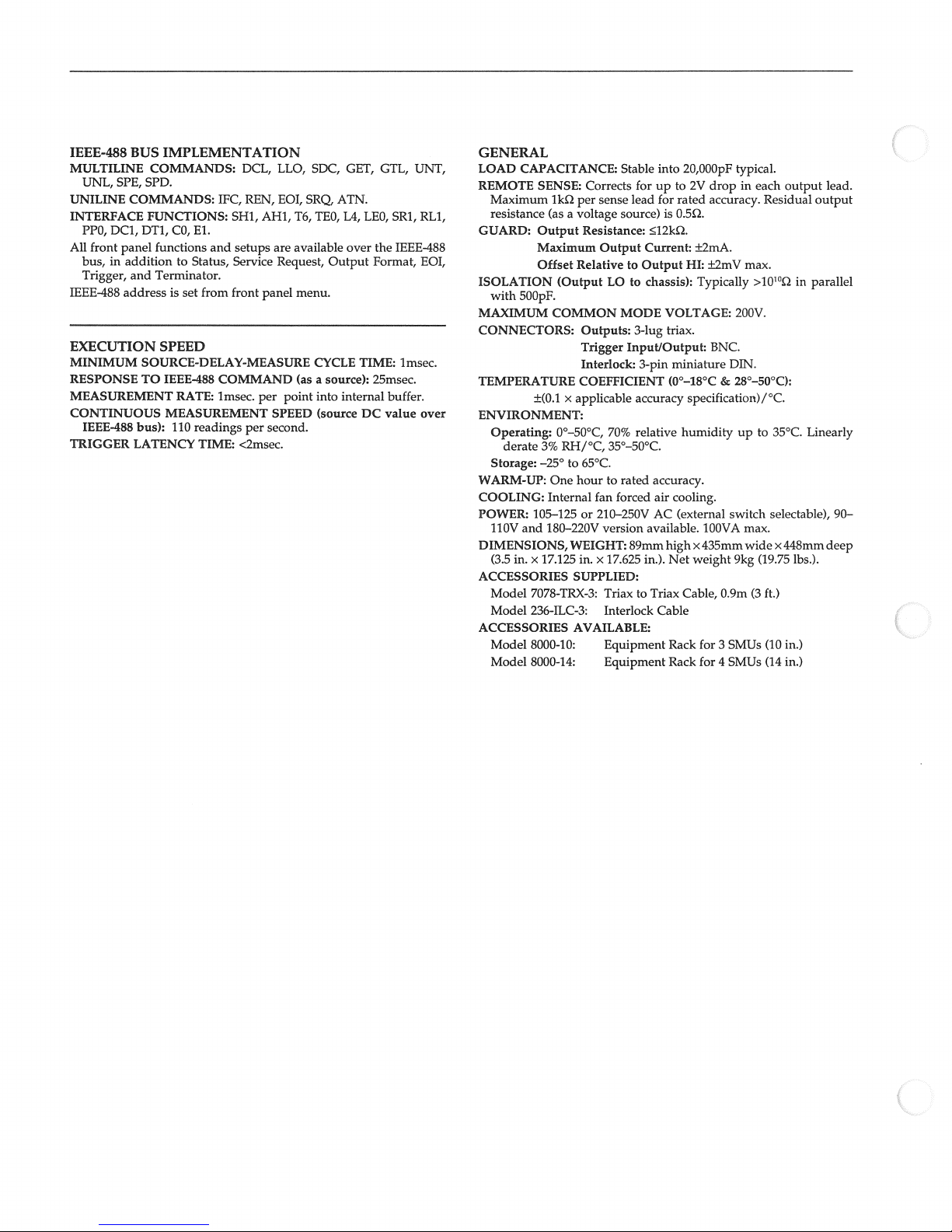

VOLTAGE

SOURCE

RANGE

(Max.

Value)

±1.1000W

±11.000V

±110.00V10mV

±1100.0V3100

10

=

‘n

1

Specifications

of

2

Assumes

3

1100V

COMPLIANCE:

Maximum:

Minimum:

Accuracy,

NOISE

WIDEBAND

OVERSHOOT:

SETTLING

NMRR:

CMRR:

selected).

INPUT

CURRENT

RANGE

(Max.

Value)

±10000

±10.000

±10000

±1.0000tA100

±10000

±10000

±1.0000mA100

±10.000

±10000

STEP

SIZE

100

1

Output

current

Fiill

range.

on selected

scale

apply

remote

range

availableonModel

Step

(p-p):

TIME:

>60dB

>120dBatDC,50or

IMPEDANCE

SOURCE

STEP

SIZE

nA

100fA±(0.3

nA

nA

10

iA

tA

10

mA1iA

mA

10

V

ACCURACY

(1

18°-28°C)

iV

±(O033%+650

+

[Io/IF]

mV

±(O033%+

±(O.033%+

mV

±(O04

%+24OmV)

current

for 5-digit

seine

for

1>1OOtA.

Bipolar

current

±lOOmA

±0.1%

NOISE:

Size:

<0.01%

at5O

(except ±lOmA

of

range,

Same

0.1

(110V

<500j.tsec.

or

60Hz

(asavoltmeter):

1

ACCURACY

(1

18°—28°C)

1

pA

pA

pA

1nA±(0.05%÷

nA

nA

tA

%+450

%+

±(0.3

±(0.21%+

±(0.05%+200

±(0.05%+

±(0.05%+200

±(0.05%+

%+

±(0.1

Year,

tV

X

450jtV)

2.4mV)

24mV)

range

resolution.

only.

237

limit

except

as

current

Range

110v—1100v

11

1.1

V

20MHz,

to

step,

0.01%

to

(LINE

60Hz

Year,

fA)

pA)

2

20

pA)

pA)

2

nA)

20

nA)

nA)

A)

2

jiA)

20

MEASURE

RESOLUTION

4-Digit

5-Digit

1

10

For

set

on

0.5%

tV

mV

mV

mV

1100V

10

100

10

4-digit

with

1.1V

of

jiV

iV

1

mV

mV

resolution

single

range

range.

100

100

source.

0,1—10Hz

<

V

lOmA

CYCLE

(LINE

RESOLUTION