Page 1

Model 220,230

Programming Manual

Contains IEEE Programming Information

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of I year

from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable

batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio.

You will be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service

facility. Repairs will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for

the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or

misuse of any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from

battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS

INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE

OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY

PERSON, OR DAMAGE TO PROPERTY.

Keithley Instruments, Inc. l 28775 Aurora Road l Cleveland, OH 44139 l 440-248-0400 l Fax: 440-248-6168 l http:Nwww.keithley.com

BELGIUM:

CHINA:

FRANCE:

GERMANY:

GREAT BRITAIN:

INDIA:

ITALY

NETHERLANDS:

SWITZERLAND:

TAIWAN:

Keithley Instruments B.V.

Keithley Instruments China

Keithley Instruments Sari

Keithlev Instruments GmbH

Keith& Instruments Ltd

Keithley Instruments GmbH

Keithley Instruments s.r.1.

Keithley Instruments B.V.

Keithley Instruments SA

Keithley Instruments Taiwan

Bergensesteenweg 709 * B-1600 Sint-Pieters-Leeuw * 02/363 00 40. Fax: 02/363 00 64

Yuan Chen Xin Building, Room 705 l 12Yumin Road, Dewi, Madian l Beijing loo029 l 861@62022886 l Fax.: 861@62022892

B.P. 60.3, alICe des Garays l 91122 Palaiseau C&x * 01 64 53 20 20 * Fax: 01 60 I 1 77 26

Lundsberger Strwe 65 l D-821 10 Germering * 089/84 93 07-40 - Fax: 089/84 93 07-34

The Minster l 58 Portman Road * Reading, Berkshire RG30 IEA * 01 IS-9 57 56 66 * Fax: 01 IS-9 59 64 69

Flat 28. WILOCRISSA l 14. Rest House Crescent * Bangalore S60001 l 91-EO-509-1320121 -Fax: 91-80-509-1322

Viale S. Gimignano. 38 * 20146 Milano l 02/48 30 30 08 * Rx: 02/48 30 22 74

Postbus 559 l 4200AN Gorinchem * 0183-635333 *Fax: 0183-630821

Kriesbachsvasse 4 * 8600 Diibendorf*OI-821 94 44 l Fax: 01-820 3081

1 FI. 85 PO Ai Street * Hsinchu, Taiwan, R.O.C. - 886-3572-9077 * Fax: 886-3572-903

1 o/99

Page 3

Model 220 Programmable Current Source

Model 230 Programmable Current Source

Programming Manual

01982, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Third Printing, May 2000

Document Number: 220-900-01 Rev. C

Page 4

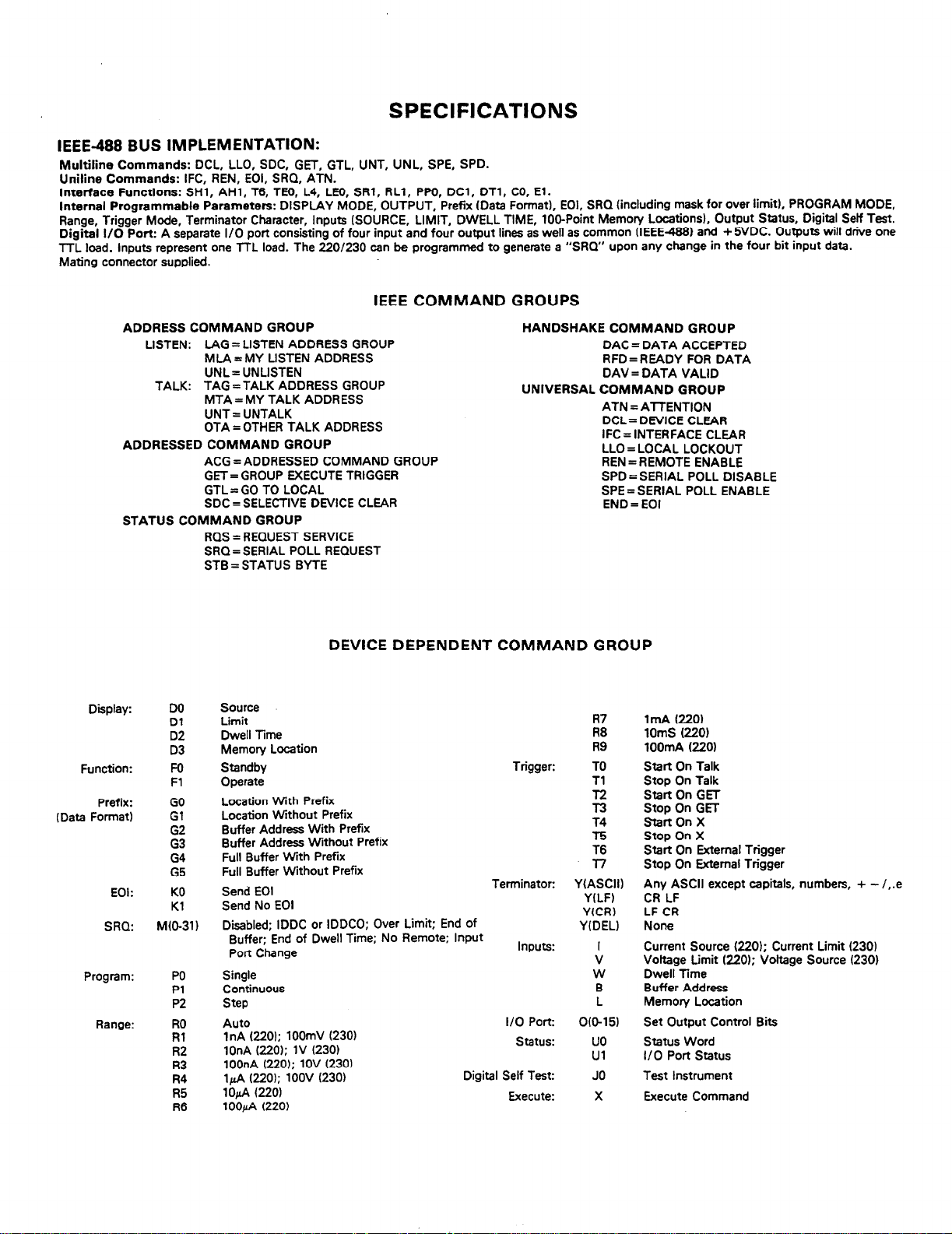

SPECIFICATIONS

IEEE-488 BUS IMPLEMENTATION:

Multiline Commands: DCL, LLO, SDC, GET, GTL, UNT, UNL, SPE, SPD.

Uniline Commands: IFC, REN, EOI, SRQ, ATN.

Interface Functions: SHl, AHl, T6, TE6, L4, LH), SRl, RLl, PW, DCl, DTl, CO, El.

Internal Programmable Parameters: DISPLAY MODE, OUTPUT, Prefix (Data Format), EOl, SRQ (including mask for over limit), PROGRAM MODE,

Range, Trigger Mode, Terminator Character, Inputs (SOURCE, LIMIT, DWELL TIME, 106Point Memory Locations), Output Status, Digital Self Test.

Digital l/O Port: A separate I/O port consisting of four input and four output lines as well as common (IEEE4881 and + 5VDC. Outputs will drive one

TTL load. Inputs represent one TTL load. The 220/230 can be programmed to generate a “SRQ” upon any change in the four bit input data.

Mating connector supplied.

IEEE COMMAND GROUPS

ADDRESS COMMAND GROUP

LISTEN: LAG = LISTEN ADDRESS GROUP

MLA = MY LISTEN ADDRESS

UNL= UNLISTEN

TALK: TAG =TALK ADDRESS GROUP

MTA = MY TALK ADDRESS

UNT = UNTALK

OTA=OTHER TALK ADDRESS

ADDRESSED COMMAND GROUP

ACG = ADDRESSED COMMAND GROUP

GET= GROUP EXECUTE TRIGGER

GTL = GO TO LOCAL

SDC = SELECTIVE DEVICE CLEAR

STATUS COMMAND GROUP

RQS = REQUEST SERVICE

SRQ= SERIAL POLL REQUEST

STB = STATUS BYTE

HANDSHAKE COMMAND GROUP

DAC = DATA ACCEPTED

RFD=READY FOR DATA

DAV = DATA VALID

UNIVERSAL COMMAND GROUP

ATN = ATTENTION

DCL= DEVICE CLEAR

IFC = INTERFACE CLEAR

LLO = LOCAL LOCKOUT

REN = REMOTE ENABLE

SPD = SERIAL POLL DISABLE

SPE = SERIAL POLL ENABLE

END = EOI

Display:

Function:

Prefix:

(Data Format)

EOI:

SRQ:

Program:

Range:

DO

Dl

D2

D3

Fo

Fl

GO

Gl

G2

G3

G4

G5

KO

Kl

M(O-31)

PO

Pl

P2

RO

Rl

R2

I?3

R4

R5

R6

DEVICE DEPENDENT COMMAND GROUP

Source

Limit

Dwell Time

Memory Location

Standby

Operate

Location With Prefix

Location Without Prefix

Buffer Address With Prefix

Buffer Address Without Prefix

Full Buffer With Prefix

Full Buffer Without Prefix

Send EOI

Send No EOI

Disabled: IDDC or IDDCO: Over Limit: End of

Buffer;‘End of Dwell Time; No Remote; Input

Port Change

Single

Continuous

Step

Auto

1nA (220); 100mV (230)

1OnA (220): 1V (230)

100nA (220); 1OV (230)

14 (220); 1OOV (230)

1ofi f220)

100&A (220)

Trigger:

Terminator:

Inputs:

I/O Port:

status:

Digital Self Test:

Execute:

R7

R8

R9

TO

Tl

T4

T5

T6

3-7

YIASCII)

YILF)

YfCR)

Y(DEL)

V

W

B

0015)

uo

Ul

JO

X

1mA (220)

1OmS (220)

lOOmA (220)

Start On Talk

Stop On Talk

Start On GET

Stop On GET

StartOnX

Stop On X

Start On External Trigger

Stop On External Trigger

Any ASCII except capitals, numbers, + - /,.e

CR LF

LF CR

None

Current Source (220); Current Limit (230)

Vottage Limit (220); Voltage Source (230)

Dwell Time

Buffer Address

Memory Location

Set Output Control Bits

Status Word

I/O Port status

Execute Command

Page 5

Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read the operating information

carefully before using the product.

The types of product users are:

Responsible body is the individual or group responsible for the use

and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be

trained in electrical safety procedures and proper use of the instrument. They must be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel perform routine procedures on the product

to keep it operating, for example, setting the line voltage or replacing consumable materials. Maintenance procedures are described in

the manual. The procedures explicitly state if the operator may perform them. Otherwise, they should be performed only by service

personnel.

Service personnel are trained to work on live circuits, and perform

safe installations and repairs of products. Only properly trained service personnel may perform installation and service procedures.

Users of this product must bc protcctcd from electric shock at all

times. The responsible body must ensure that users arc prevented

access and/or insulated from every connection point. In some cases,

connections must be exposed to potential human contact. Product

users in these circumstances must bc trained to protect thcmsclves

from the risk of electric shock. If the circuit is capable ofopcrating

at or above 1000 volts. no conductive part of the circuit may be

exposed.

As described in the Intcmational Electrotechnical Commission

(IEC) Standard IEC 664, digital multimctcr measuring circuits

(e.g., Keithley Models I75A, 199,2000,2001, 2002. and 2010) arc

Installation Category II. All other instruments’ signal terminals arc

Installation Category I and must not bc connected to mains.

Do not connect switching cards directly to unlimited power circuits.

They are intended to bc used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connccted to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear. cracks, or breaks

before each use.

For maximum safety, do not touch the product, test cables. or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the cntirc test system and discharge

any capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connectorjacks or test fixtures. The

American National Standards Institute (ANSI) states that a shock

hazard exists when voltage levels greater than 30V RMS, 42.4V

peak, or 60VDC are present. A good safety practice is to expect

that hazardous voltage is present in any unknown circuit before

measuring.

Do not touch any object that could provide a current path to the

common side of the circuit under test or power line (earth) ground.

Always make measurements with dry hands while standing on a

dry, insulated surface capable of withstanding the voltage being

measured.

Page 6

The instrument and accessories must be used in accordance with its

specifications and operating instructions or the safety of the equipment may be impaired.

The WARNING heading in a manual explains dangers that might

result in personal injury or death. Always read the associated information very carefully before performing the indicated procedure.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard.

Chassis connections must only be used as shield connections fat

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is ap-

plied to the device under test. Safe operation requires the use of a

lid interlock.

Ifa@

screw is present, connect it to safety earth ground using the

wire recommended in the user documentation.

The !

symbol on an instrument indicates that the user should re-

a

fer to the operating instructions located in the manual.

The

symbol on an instrument shows that it can source or mea-

A

sure 1000 volts or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to

avoid personal contact with these voltages.

The CAUTION heading in a manual explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

Instrumentation and accessories shall not bc conncctcd to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

To maintain protection from electric shock and fire, replacement

components in mains circuits, including the power transformer, test

Icads. and input jacks, must be purchased from Keithlcy Instruments. Standard fuses, with applicable national safety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may bc purchased from other suppliers as

long as they are equivalent to the original component. (Note that se-

lectcd parts should be purchased only through Keithley Instruments

to maintain accuracy and functionality of the product.) If you arc

unsure about the applicability of a replacement component, call a

Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild. water based

cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill

on the instrument. Products that consist of a circuit board with no

case or chassis (e.g., data acquisition board for installation into a

computer) should never require cleaning if handled according to in-

structions. If the board becomes contaminated and operation is af-

fected, the board should be returned to the factory for proper

cleaning/servicing.

Rev. IO/99

Page 7

TABLE OF CONTENTS

Paragraph

1 .I

1.2

1.3

1.4

1.5

1.6

1.7

2.1

2.2

2.3

2.3.1

2.3.2

2.3.3

2.4

2.4.1

2.4.2

2.4.3

2.4.4

2.4.5

2.5

2.6

2.6.1

2.6.2

2.6.3

3.1

3.2

3.2.1

3.2.2

3.2.3

3.2.4

3.3

3.3.1

3.3.2

3.3.3

3.3.4

4.1

4.2

4.2.1

4.2.2

4.2.3

4.2.4

4.2.5

4.2.6

4.2.7

4.2.8

4.3

4.3.1

4.3.2

4.3.3

4.3.4

4.3.5

4.3.6

4.3.7

SECTION 1 - GENERAL INFORMATlON

introduction

Model 220 and 230 IEEE Interface Features..

Warranty Information.. ...................................................................................................................................................................................

Manual Addenda.. .........................................................................................................................................................................................

Safety Symbols and Terms ...........................................................................................................................................................................

Using the Model 220/230 Programming Manual. ..........................................................................................................................................

IEEE Specifications

SECTION 2 - AN OVERVIEW OF THE IEEE-488 BUS

Introduction

Bus Description.. ...........................................................................................................................................................................................

IEEE-488 Bus Lines.. ....................................................................................................................................................................................

Bus Commands.. ...........................................................................................................................................................................................

Command Codes

Command Sequences

SECTION 3 - SYSTEM CONFIGURATION

Introduction ...................................................................................................................................................................................................

Hardware Considerations.. ............................................................................................................................................................................

Software Considerations.. .............................................................................................................................................................................

SECTION 4 - OPERATION

Introduction ...................................................................................................................................................................................................

General Bus Commands.. .............................................................................................................................................................................

Device-Dependent Command Programming ................................................................................................................................................

Title Page

...................................................................................................................................................................................................

..............................................................................................................................................

.......................................................................................................................................................................................

............................................................................................

Bus Management Lines

Handshake Lines ..................................................................................................................................................................................

Data Lines

Uniline Commands..

Universal Commands..

Addressed Commands

Unaddressed Commands .....................................................................................................................................................................

Device-Dependent Commands.. ...........................................................................................................................................................

Addressed Command Sequence.. ........................................................................................................................................................

Universal Command Sequence ............................................................................................................................................................

Device-Dependent Command Sequence

Typical Systems

Bus Connections ..................................................................................................................................................................................

Primary Address Selection

Digital I/O Port.. .....................................................................................................................................................................................

Controller Interface Routines ................................................................................................................................................................

HP-85 BASIC Statements..

Interface Function Codes ......................................................................................................................................................................

Model 220/230 Interface Commands. ...................................................................................................................................................

REN (Remote Enable) ..........................................................................................................................................................................

IFC (Interface Clear). .............................................................................................................................................................................

LLO (Local Lockout). .............................................................................................................................................................................

GTL (Go To Local). ................................................................................................................................................................................

DCL (Device Clear). ..............................................................................................................................................................................

SDC (Selective Device Clear). ..............................................................................................................................................................

GET (Group Execute Trigger) ...............................................................................................................................................................

Serial Polling (SPE, SPD) .....................................................................................................................................................................

Execute (X)

Display Mode (D) ..................................................................................................................................................................................

Inputs (I, V, W, L, B). ..............................................................................................................................................................................

I/O Port (0) ...........................................................................................................................................................................................

Function (F). ..........................................................................................................................................................................................

Data Format (G). ...................................................................................................................................................................................

EOI Programming (K) ...........................................................................................................................................................................

.............................................................................................................................................................................................

..........................................................................................................................................................................................

...........................................................................................................................................................................................

........................................................................................................................................................................

..............................................................................................................................................................................

.........................................................................................................................................................................

.........................................................................................................................................................................

..................................................................................................................................................................................

.............................................................................................................................................

....................................................................................................................................................................................

...................................................................................................................................................................

...................................................................................................................................................................

. ......................................................................................................

1-l

l-l

l-l

l-l

l-1

l-l

1-l

2-l

2-l

2-l

2-l

2-2

2-2

2-3

2-3

2-3

2-3

2-3

2-3

2-4

2-4

2-6

2-6

2-6

3-1

3-1

3-l

3-l

3-3

3-4

3-4

3-4

3-5

3-5

3-6

4-l

4-l

4-l

4-l

4-2

4-2

4-2

4-3

4-3

4-3

4-4

4-6

4-6

4-6

4-8

4-8

4-8

4-10

Page 8

TABLE OF CONTENTS (CONT.)

Paragraph

4.3.8

4.3.9

4.3.10

4.3.11

4.3.12

4.3.13

4.3.14

4.4

4.4.1

4.4.2

4.4.3

4.5

4.5.1

4.5.2

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5.8

5.9

5.10

5.11

Front Panel

Waveform

SECTION 5 - IEEE COMMAND FLOW CHARTS

Introduction ...................................................................................................................................................................................................

DCL (Device Clear).

IFC (Interface Clear)

REN

Serial

UNL

UNT (Untalk)

GET

GTL

SPC (Selective Device Clear)

Device-Dependent Commands..

Title

SRQ Mode (M) and Status Byte Format..

Program Mode (P)

Range (R) .............................................................................................................................................................................................

Trigger Mode (T) ...................................................................................................................................................................................

Programmable Terminator (Y). ..............................................................................................................................................................

Status Word (U) ....................................................................................................................................................................................

Digital Self-Test (J). ...............................................................................................................................................................................

Error Messages .........................................................................................................................................................................

IDDC Error.. ..........................................................................................................................................................................................

IDDCO Error .........................................................................................................................................................................................

No Remote Error..

Programs

Sine Wave Approximation .....................................................................................................................................................................

Ramp Simulation.. .................................................................................................................................................................................

(Remote Enable) ..................................................................................................................................................................................

Polling (SPE, SPD)

(Unlisten). ..............................................................................................................................................................................................

.................................................................................................................................................................................................

(Group Execute Trigger).

(Go To Local). ........................................................................................................................................................................................

................................................................................................................................................................................

.................................................................................................................................................................................

......................................................................................................................................................................................

......................................................................................................................................................................................

.....................................................................................................................................................................................

.............................................................................................................................................................................

.......................................................................................................................................................................

.......................................................................................................................................................................

...................................................................................................................................................................

.............................................................................................................................................

Page

4-10

4-13

4-13

4-14

4-15

4-15

4-17

4-17

4-18

4-18

4-18

4-18

4-18

4-19

5-1

5-1

5-1

5-1

5-2

5-2

5-3

5-3

5-4

5-4

5-4

ii

Page 9

LIST OF TABLES

Table

2-l

2-2

2-3

2-4

3-l

3-2

3-3

3-4

3-5

3-6

4-1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

4-10

Figure

Title Page

IEEE-488 Bus Command

Hexadecimal and

Typical Addressed Command Sequence ...................................................................................................................................................... 2-6

Typical Device-Dependent Command Sequence..

IEEE Contact Designations..

Primary Address Switch Positions ................................................................................................................................................................ 3-3

Digital I/O Port Pin Assignments

HP-85 IEEE-488 Basic Statements .............................................................................................................................................................. 3-5

Model 220/230 Interface Function Codes .....................................................................................................................................................

IEEE Command

General Bus Command..

Default Values (Status on

Device-Dependent Command Summary

Model 220 and 230 Display Mode Commands .............................................................................................................................................

Input Command Summary

l/O Port Command Parameters

SRQ Commands and Conditions

Status Byte Data and Error Conditions. ........................................................................................................................................................

Range Commands

I/O Port Status Values..

Groups ...............................................................................................................................................................................

Summary

Decimal Command

...............................................................................................................................................................................

Power Up and After SDC or DCL) .......................................................................................................................

............................................................................................................................................................................

........................................................................................................................................................................................

.................................................................................................................................................................................

............................................................................................................................................................. 2-4

.........................................................................................................................................................................

...................................................................................................................................................................

.....................................................................................................................................................................

..................................................................................................................................................................

...............................................................................................................................................

Codes

........................................................................................................................................

......................................................................................................................................................

2-4

2-6

3-2

3-4

3-6

3-6

4-l

4-3

4-5

4-6

4-7

4-8

4-11

4-12

4-13

4-16

LIST OF FIGURES

Title Page

2-l

2-2

2-3

3-1

3.2

3-3

3-4

3-5

3-6

3-7

3-8

4-1

4-2

4-3

4-4

4-5

4-6

5-1

5-2

5-3

5-4

5-5

5-6

5-7

5-8

5-9

5-10

IEEE Bus Configuration

IEEE Handshake Sequence.. ........................................................................................................................................................................

Command Codes

System Types

IEEE-488 Connector..

IEEE-488 Connections..

Rear Panel of Model 220 or 230 Showing IEEE Connectors and Switches

Contact Assignments..

Typical IEEE-488 Bus Driver (One of 16). .....................................................................................................................................................

Primary Address Switches (Address = 12 Shown)

Digital I/O Port Pin Assignments.. .................................................................................................................................................................

Model 220 and

SRQ Mask Format ........................................................................................................................................................................................

Status Byte Format

Status Word Format (Default Values Shown)

I/O Status Format (Default Values

Front Panel Error Messages

DCL Command Flow Chart

IFC Command

REN Command Flow Chart ..........................................................................................................................................................................

Serial Poll Flow Chart..

UNL Command Flow Chart..

UNT Command

GET Command Flow Chart.

GTL Command

SDC Command

Device-Dependent Command Flow Chart ....................................................................................................................................................

................................................................................................................................................................................................

230 Data

Flow Chart

................................................................................................................................................................................

.........................................................................................................................................................................................

...................................................................................................................................................................................

................................................................................................................................................................................

..................................................................................................................................................................................

.......................................................................................................................................

Formats.. ...............................................................................................................................................................

.......................................................................................................................................................................................

Shown).

.........................................................................................................................................................................

...........................................................................................................................................................................

............................................................................................................................................................................

..................................................................................................................................................................................

.........................................................................................................................................................................

Flow Chart.. .........................................................................................................................................................................

Flow Chart..

Flow Chart

..........................................................................................................................................................................

.........................................................................................................................................................................

..........................................................................................................................................................................

................................................................................................................................................

...................................................................................................................................................

.................................................................................................

2-2

2-2

2-5

3-l

3-l

3-2

3-2

3-2

3-3

3-3

3-4

4-9

4-12

4-12

4-l 6

4-16

4-l 8

5-l

5-l

5-2

5-2

5-3

5-3

5-4

5-4

5-5

5-5

iii/iv

Page 10

SECTION 1

GENERAL INFORMATION

1.1 INTRODUCTION

The Model 220 programmable current source, and the

Model 230 programmable voltage source are each supplied

with a standard IEEE-488 interface. This interface adds an

extra measure of versatility by allowing the transmission of

data and commands over the IEEE-488 bus. The built-in

IEEE interface provides all the logic necessary to interface

the Models 220 and 230 to the bus using standard

IEEE-488-1978 protocol. Additionally, the interface board

incorporates a separate digital I/O port that may be used to

interface the Models 220 and 230 to other digital instrumentation.

1.2 MODEL 220 AND 230 IEEE INTERFACE FEATURES

Important IEEE-488 interface features include:

1. IEEE-4881978 Standard. The Model 220 or 230 communicates with other instrumentation using the same

IEEE488-1978 standards.

2. Standard IEEE Connector. A standard IEEE-488 connector is available on the rear panel of the instrument for

easy connection to the IEEE bus.

3. Simple Primary Address Selection. The primary address

of the Model 220 or 230 may be easily changed by using

the five address switches on the rear panel of the instrument.

4. Digital I/O port. The interface also includes a digital I/O

port which has separate 4-bit input and output connections. Port status may be read and controlled through

commands given over the IEEE bus.

5. Programming Versatility. All Model 220/230 operation is

supported by IEEE programming. In addition, numerous

other IEEE commands add operating features not available from the front panel.

1.3 WARRANTY INFORMATION

Warranty information may be found inside the front cover of

this manual. Should it become necessary to exercise the

warranty, contact your nearest Keithley representative or

the factory to determine the proper course of action.

Keithley Instruments, Inc. maintains service facilities in the

United States, United Kingdom, and throughout Europe.

Addresses for these facilities may be found inside the front

cover of this manual. Information concerning the application, operation, or service of your instrument may be

directed to the applications engineer at any of these

locations.

1.4 MANUAL ADDENDA

Information concerning improvements or changes to the

instrument which occur after the printing of this manual

may be found on an addendum included with this manual.

Be sure to review these changes before attempting to program the instrument.

1.5 SAFETY SYMBOLS AND TERMS

The following safety symbols and terms are used in this

manual and may be found on the Model 220 and 230:

The symbol ’

user should refer to the operating instructions.

The symbol

potential of 1OOOV or more may be present on the

terminal(s). Standard safety precautions should be observed when such dangerous voltages are encountered.

information associated with the WARNING heading explains dangers that could result in personal injury or death.

Information following the CAUTION heading explains

hazards that could damage the instrument.

1.6 USING THE MODEL 220/230 PROGRAMMING

MANUAL

This manual contains all the information necessary to con-

nect the Model 220 or 230 to the IEEE488 bus and program

the instrument from a separate bus controller. Not included

in this manual is information concerning front panel operation, servicing, or maintenance of the instrument {including

the interface board itself). For those aspects, refer to the

Model 220 or 230 Instruction Manual.

This programming manual is divided into the following

sections:

1. Section 2 contains a general description of the IEEE-488

bus and its commands.

2. information necessary to connect the instrument to the

bus and set the primary address is contained in Section 3.

Also, digital I/O port information can be found in this

section.

3. The bulk of the programming information may be found

in Section 4. General bus commands as well as commands unique to the Models 220 and 230 are covered in

detail.

4. Section 5 contains IEEE command flow charts, which

could be helpful in some applications.

1.7 IEEE SPECIFICATIONS

A complete list of IEEE specifications is presented immediately preceding this section.

Q

on the instrument indicates that the

on the instrument indicates that a

l-1/1-2

Page 11

SECTION 2

AN OVERVIEW OF THE IEEE-488 BUS

2.1 INTRODUCTDON

The IEEE-488 bus is an instrumentation data bus adopted by

the IEEE WWitute of Electrical and Electronic Engineers) in

1975 and given the IEEE488 designation. The most recent

revision of bus standards was made in 1978; hence the complete description for current bus standards is the

IEEE-488-1978 designation.

This section gives a brief description of the general bus

structure along with an outline of bus commands. The information presented here is not intended to be an in-depth

description of what is truly a very complex set of standards.

More complete information on the IEEE-488 bus, which is

also frequently referred to as the GPIB (General Purpose

Interface Bus), is available from the IEEE and a variety of

other sources.

2.2 BUS DESCRIPTION

The IEEE-488 bus was designed as a parallel data transfer

medium to optimize data transfer without using an excessive number of bus lines. In keeping with this goal, the bus

has only eight data lines that are used for both data and

some commands. Five bus management lines and three

handshake lines round out the complement of signal lines.

Since the bus is of parallel design, all devices connected to

the bus have the same information available simultaneously.

Exactly what is done with the information by each device

depends on many factors, including device capabilities.

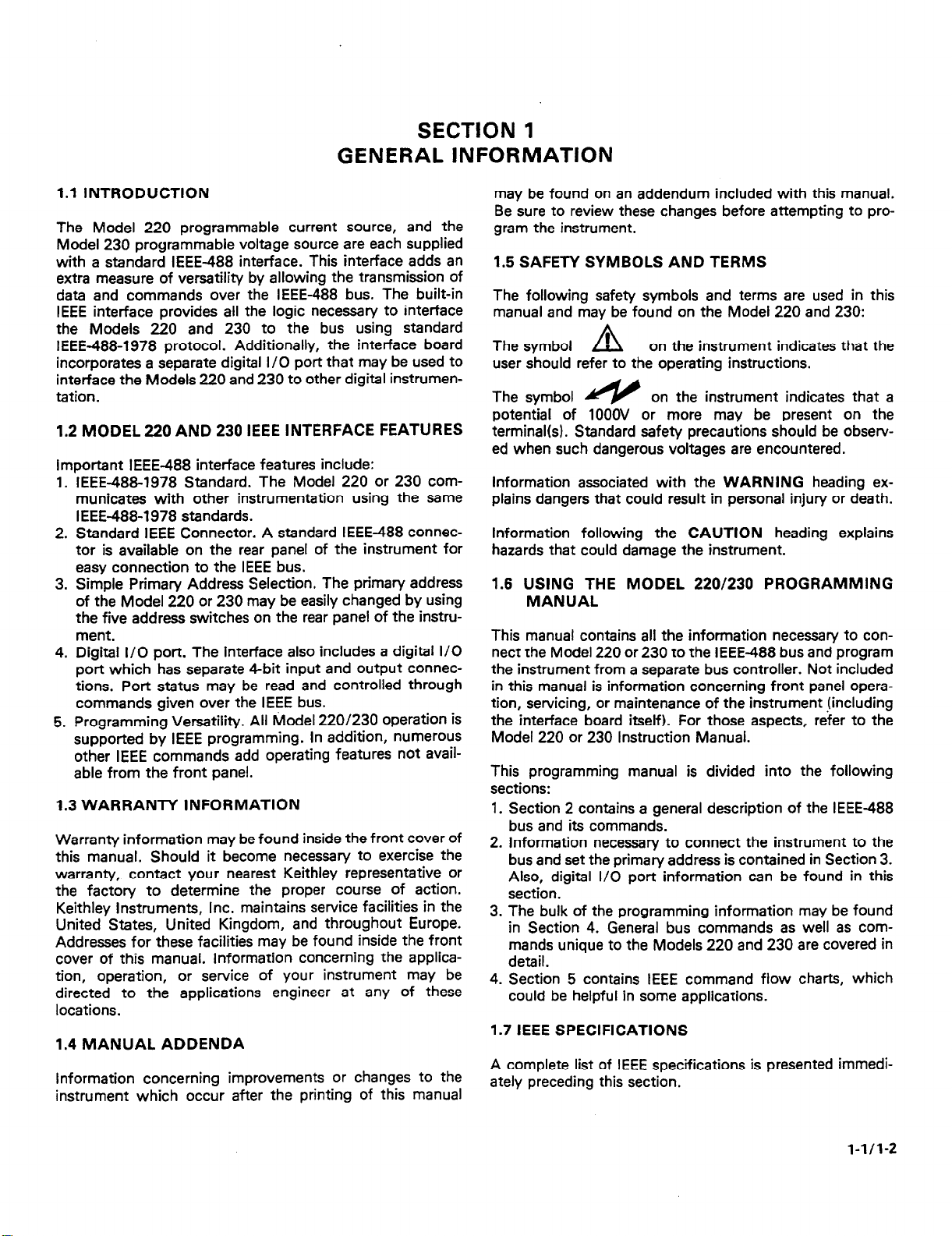

A typical bus configuration for controlled operation is

shown in Figure 2-1. The typical system will have one controller and one or more instruments to which commands are

given and, in most cases, from which data is received.

Generally, there are three categories that describe device

operation. These designations include: controller; talker:

listener.

The controller does what its name implies: it controls other

devices on the bus. A talker sends data, while a listener

receives data. Depending on the instrument, a particular

device may be a talker only, a listener only, or both a talker

and a listener.

Any given system can have only one controller (control may

be passed to an appropriate device through a special com-

mand), but any number of talkers or listeners may be present up to the hardware constraints of the bus. Generally,

the bus is limited to 15 devices, but this number may be

reduced if higher than normal data transfer rates are

required or if longer than normal cables are used.

Several devices may be commanded to listen at once, but

only one device may be a talker at any given time. Otherwise, communications would be scrambled much like an

individual’s trying to pick out a single conversation out of a

large crowd.

Before a device can talk or listen, it must be appropriately

addressed. Devices are selected on the basis of their primary

address; the addressed device is sent a talk or listen com-

mand derived from its primary address. Normally, each

device on the bus has a unique primary address so that each

may be addressed individually.

Once the device is addressed to talk or listen, appropriate

bus transactions are set to take place. For example, if an

instrument is addressed to talk, it will usually place its data

on the bus one byte at a time. The listening device will then

read this information, and the appropriate software can then

be used to channel the information to the desired location.

2.3 IEEE-488 BUS LINES

The signal lines on the IEEE-488 bus are grouped into three

general categories. The data lines handle bus information,

while the handshake and bus management lines ensure that

proper data transfer and bus operation takes place. Each of

the bus lines is active low so that approximately zero volts is

a logic one. The following paragraphs describe the purpose

of these lines, which are shown in Figure 2-l.

2.3.1 Bus Management Lines

The bus management group is made up of five signal-lines

that help ensure an orderly transfer of data. These lines are

used to send the uniline commands described in paragraph

2.4.

1. ATN (Attention)-The ATN line is one of the more important management lines. The state of the ATN line determines whether controller information on the data bus is to

be considered data or a multiline command as described

in paragraph 2.4.

2. IFC (Interface Clear)-Setting the IFC line true (low)

causes the bus to go to a known state by sending the IFC

command.

3. REN (Remote Enable)-Setting the REN line low sends

the REN command. This sets up instruments on the bus

for remote operation.

4. EOI (End Or Identify)-The EOI line is used to send the

EOI command that usually terminates a multi-byte

transfer sequence.

5. SRQ (Service Request)-The SRQ line is set low by a

device when it requires service from the controller.

2-1

Page 12

TALK.LISTEN.

AN0 dt5NTR0~

(COMPUTER) E

I

l

DEVICE 2

ABLE TO

TALK AND E

DEVICE 3

I

DEVICE 4

ONLY AELti

TO TALK

I

TO OTHER DEVICES

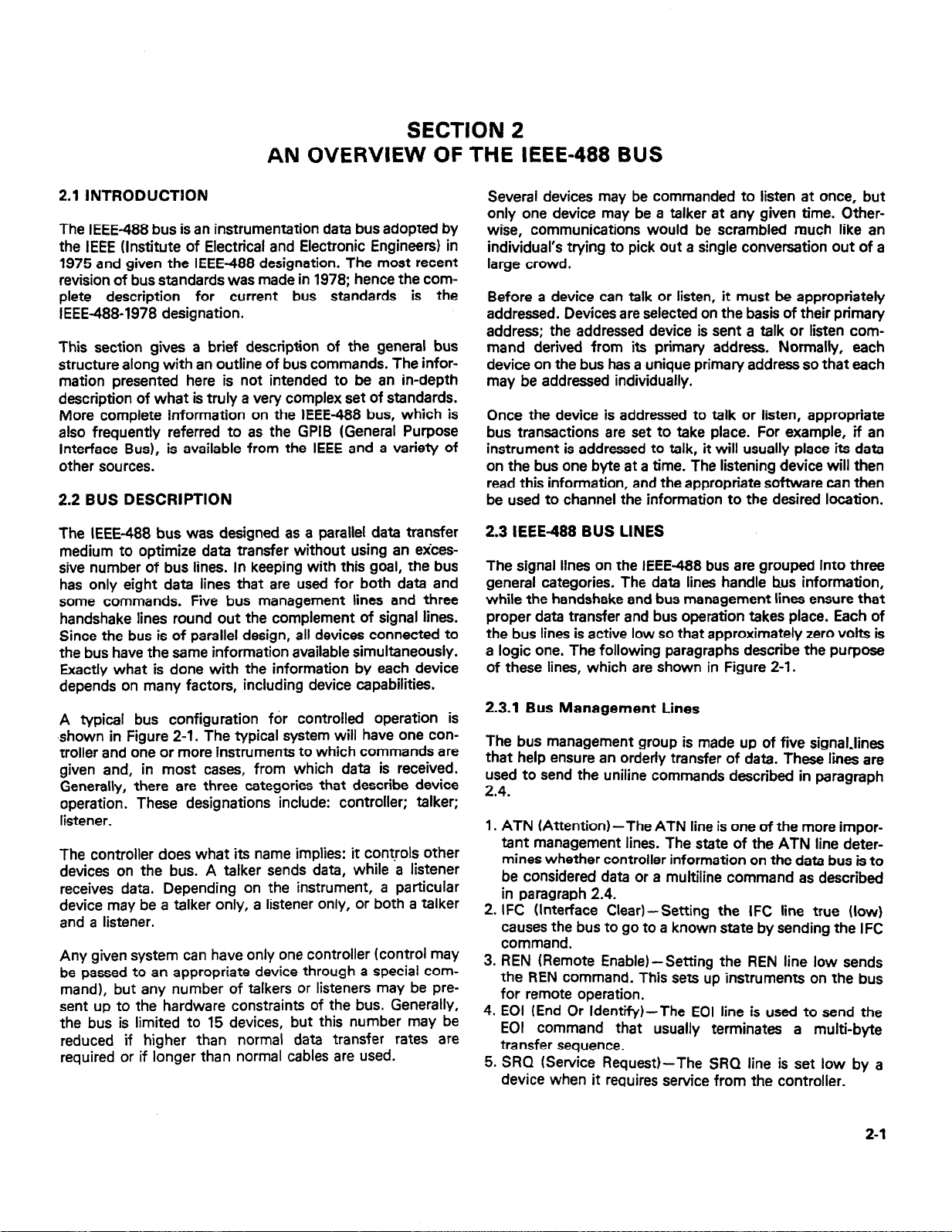

The complete handshake sequence for one data byte is

shown in Figure 2-2. Once data is on the bus, the source

checks to see that NRFD is high, indicating that all devices

on the bus are ready for data. At the same time NDAC

should be low from the previous byte transfer. If these conditions are not met, the source must then wait until the

NRFD and NDAC lines have the correct status. If the source

is a controller, NRFD and NDAC must remain stable for at

DATA BUS

)

4

least 100ns after ATN is set low. Because of the possibility

of bus hang up, some controllers have time-out routines to

display error messages if the handshake sequence stops for

any reason.

lllll

Once the NRFD and NDAC lines are properly set, the source

sets the DAV line low, indicating that data on the bus is now

DATA BYTE

TRANSFER

CONTROL

--

valid. The NRFD line then goes low; the NDAC line goes

high once all devices on the bus have accepted the data.

Each device will release the NDAC line at its own rate, but

the NDAC line will not go high until the slowest device has

accepted the data byte.

After the NDAC line goes high, the source then sets the

GENERAL

INTERFACE

MANAGEMENT

DAV line high to indicate that the data on the bus is no

longer valid. At this point, the NDAC line returns to its low

state. Finally, the NFRD line is released by each of the

devices at their own rates, until the NFRD line finally goes

high when the slowest device is ready, and the bus is set to

repeat the sequence with the next data byte.

The sequence just described is used to transfer both data

and multiline commands. The state of the ATN line determines whether the data bus contains data or commands as

described in paragraph 2.4.

1 =E) BUS MANAGEMENT I

EOI 1

1.220/230

Figure 2-1. IEEE Bus Configuration

2.3.2 Handshake Lines

The bus uses three handshake lines that operate in an interlocked sequence. This method ensures reliable data transfer

regardless of the transfer rate. Generally, data transfer will

occur at a rate determined by the slowest active device on

the bus.

One of the handshake lines is controlled by the data source,

while the remaining two lines are controlled by accepting

devices. The three bus handshake lines are:

1. DAV (Data Valid)-The source controls the state of the

DAV line.

2. NRFD (Not Ready For Data)-The acceptor controls the

state of the NRFD line.

3. NDAC (Not Data Accepted)-The acceptor also controls

the NDAC line.

2.3.3 Data Lines

The IEEE-488 bus uses the eight data lines that allow data to

be transmitted and received in a bit-parallel, byte-serial manner. These eight lines use the convention DIOI through

D108 instead of the more common DO through D7 binary

terminology, The data lines are bidirectional and, as with the

remaining bus signal lines, low is true.

OAV

NRFO

NoAC

VALID

I

I

I

/ ’ j/j ’ ACCEPTOR

I

DATA DATA

TRANSFER

BEGIN

---

I

I

TRANSFER

END

SOURCE

ACCEPTOR

2.210~233

Figure 2-2. IEEE Handshake Sequence

2-2

Page 13

2.4 BUS COMMANDS

While the hardware aspects of bus is essential, the interface

would be essentially worthless without appropriate com-

mands to control communications between the various

instruments on the bus. This section briefly describes the

purpose of the bus commands, which are grouped into the

following three general catagories:

1. Uniline commands: Sent by setting the associated bus

line low.

2. Multiline commands: General bus commands which are

sent over the data lines with the ATN line low.

3. Device-dependent commands: Special commands that

depend on device configuration; sent over the data lines

with ATN high.

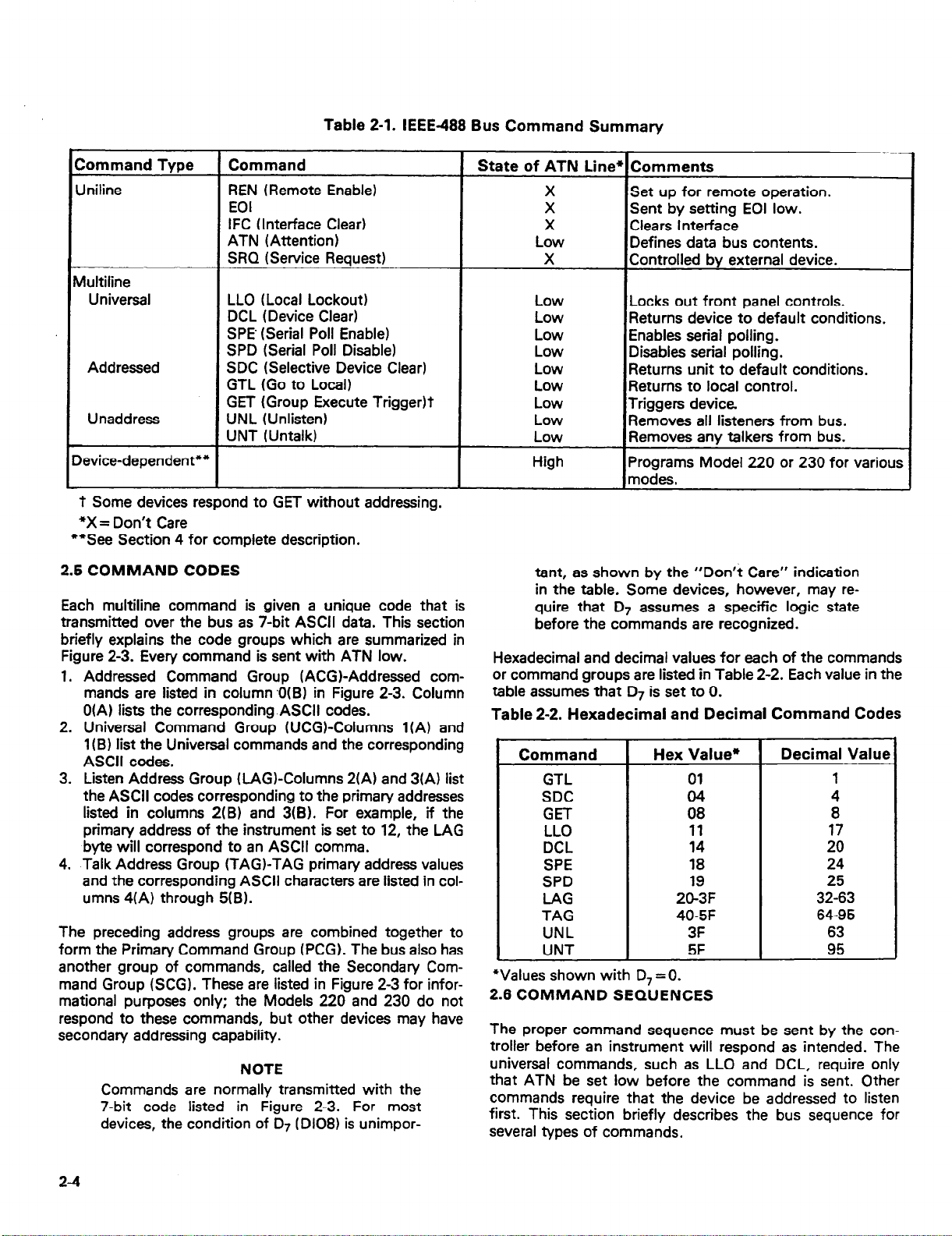

These commands are summarized in Table 2-l.

2.4.1 Uniline Commands

Uniline commands are sent by setting the associated bus

line low. The ATN, IFC, and REN commands are asserted

only by the system controller. The SRQ command is sent by

an external device. The EOI command may be sent by either

the controller or an’external device depending on the direction of data transfer. The following is a brief description of

each command.

1. REN (Remote Enable)-When the controller sends the

REN command,the instrument will be set up for remote

operation. Generally, the REN command should be sent

before attempting to program instruments over the bus.

2. EOI (End Or Identify)-The EOI command is used to

positively identify the last byte in a multi-byte transfer

sequence. This allows variable length data words to be

transmitted easily.

3. IFC (Interface Clear)-The IFC command is sent to clear

the bus and set devices to a known state. Although

device configurations differ, the IFC command usually

places instruments in the talk and listen idle states.

4. ATN (Attention)-The controller sends ATN while

transmitting addresses or multiline commands. Devicedependent commands are sent with the ATN line high

(false).

5. SRQ (Service Request)-The SRQ command is asserted

by an external device when it requires service from the

controller. If more than one device is present, a serial

polling sequence, as described in Section 4, must be used to determine which device has requested service.

2.4.2 Universal Commands

Universal commands are multiline commands that require

no addressing. All instrumentation equipped to implement

the command will do so simultaneously when the command

is transmitted over the bus. As with all multiline commands,

the universal commands are sent over the data lines with

ATN low.

1. LLO (Local Lockout)-The LLO command is used to lock

out front panel controls on devices so equipped.

2. DCL (Device Clear)-After a DCL is sent, instrumentation

equipped to implement the command will revert to a

known state. Usually, instruments return to their powerup conditions.

3. SPE (Serial Poll Enable)-The SPE command is the first

step in the serial polling sequence, which is used to

determine which instrument has requested service with

the SRQ command.

4. SPD (Serial Poll Disable)-The SPD command is sent by

the controller to remove all instrumentation on the bus

from the serial poll mode.

2.4.3 Addressed Commands

Addressed commands are multiline commands that must be

preceded by a listen command derived from the device’s

primary address before the instrument will respond. Only

the addressed device will respond to each of these

commands:

1. SDC (Selective Device Clear)-The SDC command performs essentially the same function as the DCL command except that only the addressed device will respond.

Instruments usually return to their default conditions

when the SDC command is sent.

2. GTL(Go To Local)-The GTL command is used to remove

instruments from the remote mode of operation. Also,

front panel control operation will usually be restored if

the LLO command was previously sent.

3. GET (Group Execute Trigger)-The GET command is used

to trigger devices to perform a specific action that

depends on device configuration. Although GET is

considered to be an addressed command, many devices

respond to GET without being addressed.

2.4.4 Unaddressed Commands

The two unaddressed commands are used by the controller

to remove all talkers and listeners from the bus simultaneously. ATN is low when these multiline commands are

asserted.

1. UNL (Unlistenj-All listeners are removed from the bus at

once when the UNL command is placed on the bus.

2. UNT (Untalkj-The controller sends the UNT command to

clear the bus of any talkers.

2.4.5 Device-Dependent Commands

The meaning of the device-dependent commands is determined by instrument configuration. Generally, these commands are sent as one or more ASCII characters that tell the

device to perform a specific function. For example, FO is

sent to the Model 220 or 230 to place the instrument in the

standby mode. For complete information on using these

commands with the Model 220 or 230, refer to Section 4.

The IEEE-488 bus treats device-dependent commands as

data in that ATN is high (false) when the commands are

transmitted.

2-3

Page 14

Table 2-1. IEEE488 Bus Command Summary

Command Tvoe

Jniline

Aultiline

Universal

Addressed

Unaddress

C

Device-dependent**

1

- _ -- .

‘t Some devices respond to GET without addressing.

*X = Don’t Care

**See Section 4 for complete description.

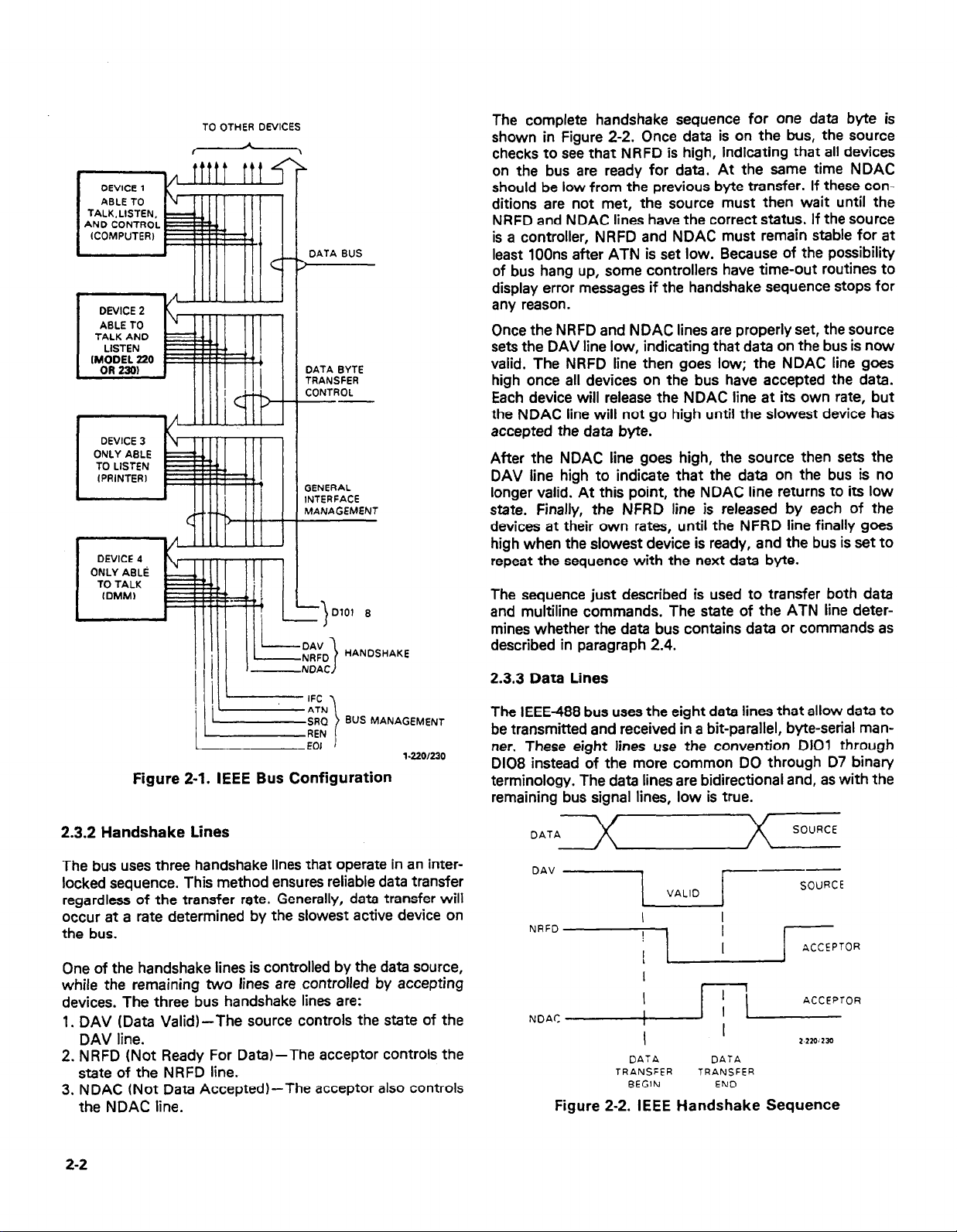

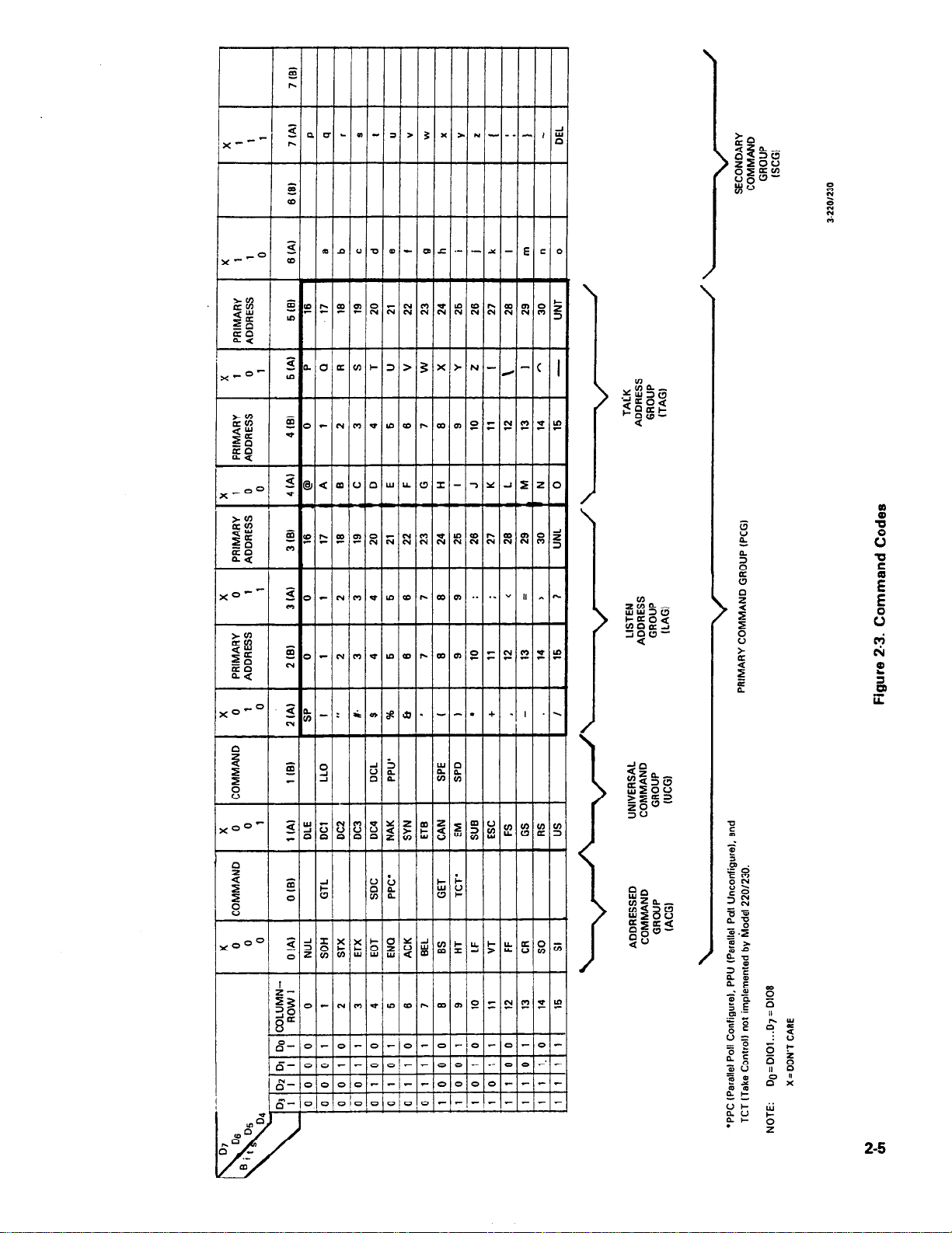

2.5 COMMAND CODES

Each multiline command is given a unique code that is

transmitted over the bus as 7-bit ASCII data. This section

briefly explains the code groups which are summarized in

Figure 2-3. Every command is sent with ATN low.

1. Addressed Command Group (ACGI-Addressed commands are listed in column ,0(B) in Figure 2-3. Column

O(A) lists the corresponding ASCII codes.

2. Universal Command Group WCGI-Columns l(A) and

1 (BI list the Universal commands and the corresponding

ASCII codes.

3. Listen Address Group (LAGKolumns 2(A) and 3(A) list

the ASCII codes corresponding to the primary addresses

listed in columns 2(B) and 3(B). For example, if the

primary address of the instrument is set to 12, the LAG

byte will correspond to an ASCII comma.

4. Talk Address Group (TAG)-TAG primary address values

and the corresponding ASCII characters are listed in columns 4(A) through 5(B).

The preceding address groups are combined together to

form the Primary Command Group (PCG). The bus also has

another group of commands, called the Secondary Com-

mand Group (SCG). These are listed in Figure 2-3 for informational purposes only; the Models 220 and 230 do not

respond to these commands, but other devices may have

secondary addressing capability.

Commands are normally transmitted with the

7-bit code listed in Figure 2-3. For most

devices, the condition of 07 (Dl08) is unimpor-

1 Command

REN (Remote Enable)

EOI

IFC (Interface Clear)

ATN (Attention)

SRQ (Service Request)

LLO (Local Lockout)

DCL (Device Clear)

SPE’ (Serial Poll Enable)

SPD (Serial Poll Disable)

SDC (Selective Device Clear)

GTL (Go to Local)

GET (Group Execute TriggerIt

UNL KInlisten)

UNT (Untalk)

I

I

NOTE

1 State of ATN Line

X

X

X

Low

X

tant, as shown by the “Don’t Care” indication

in the table. Some devices, however, may require that 07 assumes a specific logic state

before the commands are recognized.

Hexadecimal and decimal values for each of the commands

or command groups are listed in Table 2-2. Each value in the

table assumes that D7 is set to 0.

Table 2-2. Hexadecimal and Decimal Command Codes

Command

GTL

SDC

GET

LLO

DCL

SPE

SPD

LAG

TAG

UNL

UNT

*Values shown with D, = 0.

2.6 COMMAND SEQUENCES

The proper command sequence must be sent by the con-

troller before an instrument will respond as intended. The

universal commands, such as LLO and DCL, require only

that ATN be set low before the command is sent. Other

commands require that the device be addressed to listen

first. This section briefly describes the bus sequence for

several types of commands.

Comments

Set up for remote operation.

Sent by setting EOI low.

Clears Interface

Defines data bus contents.

Controlled bv external device.

/Locks out front panel controls.

‘Returns device to default conditions.

Enables serial polling.

Disables serial polling.

Returns unit to default conditions.

Returns to local control.

Triggers device.

Removes all listeners from bus.

Removes any talkers from bus.

Programs Model 220 or 230 for various

modes.

Hex Value*

01

04

08

11

14

18

19

20-3F

40-5F

3F

5F

Decimal Value

1

4

8

17

20

24

25

32-63

64-95

63

95

24

Page 15

a”

k

2-5

Page 16

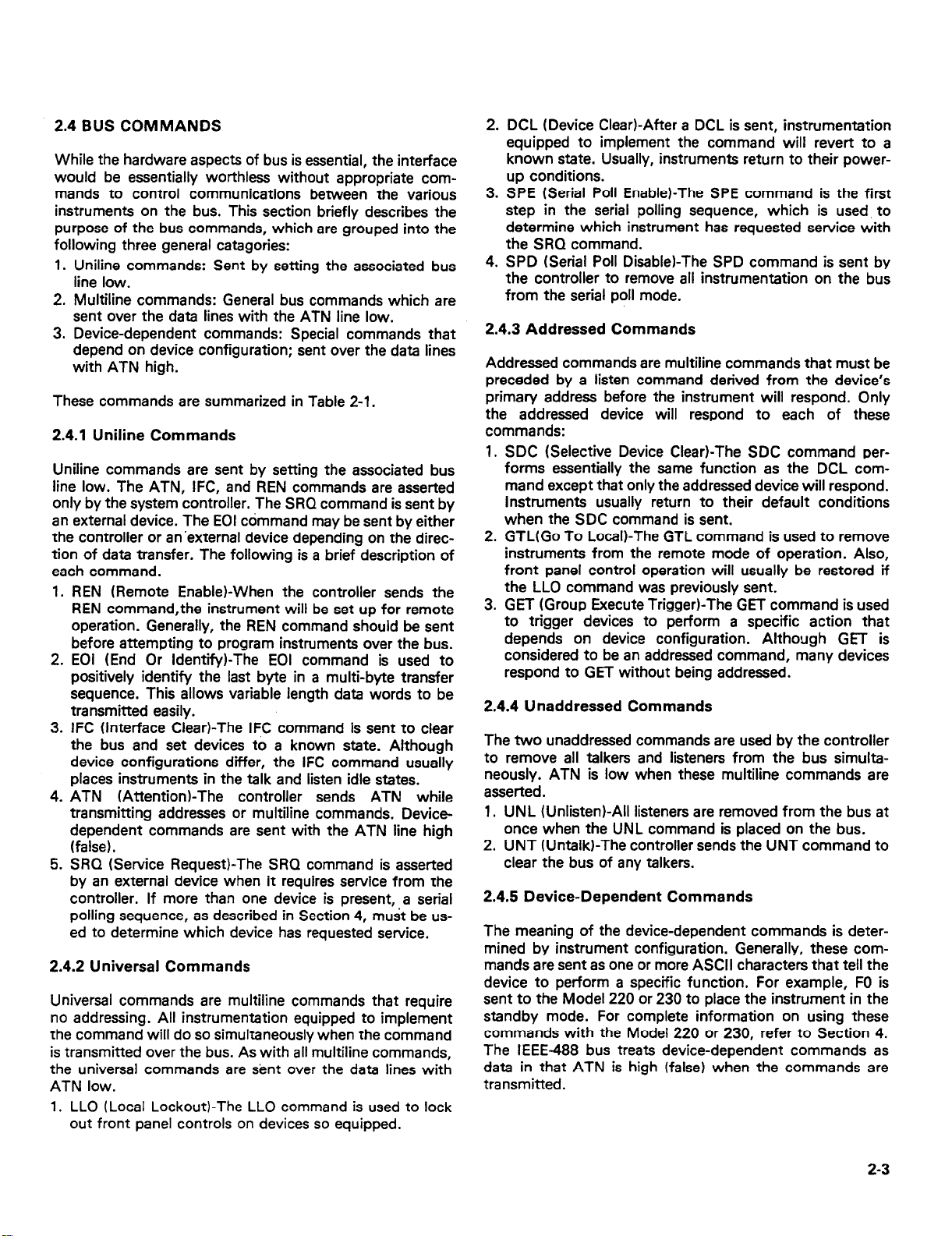

2.6.1 Addressed Command Sequence

Before a device will respond to one of these commands, it

must receive a LAG command derived from its primary

address. Table 2-3 shows a typical sequence for the SDC

command. The LAG command assumes that the instrument

is set at a primary address of 12.

Note that an UNL command is transmitted before the LAG,

SDC sequence. This is generally done to remove all other

listeners from the bus first so that only the addressed device

responds.

2.6.2 Universal Command Sequence

The universal commands are sent by setting ATN low and

then placing the command byte on the bus. For example,

the following gives the LLO command:

ATN*LLO

Table 2-3. Typical Addressed Command Sequence

Note that both the ATN and LLO commands are on the bus

simultaneously. Also, addressing is not necessary.

2.6.3 Device-Dependent Command Sequence

Device-dependent commands are transmitted with ATN

high. However, the device must be addressed to listen first

before the commands are transmitted. Table 24 shows the

sequence for the following command:

FOX

This command, which sets the Model 220 or 230 to the

standby mode, is described in detail in Section 4.

Step

1 UNL set low ? 3F 63

2 LAG” stays low

3 SDC stays low 04 4

4 Returns high

*Assumes primary address= 12.

Table 24. Typical Device-Dependent Command Sequence

1 Step 1 Command 1 ATN State

Command

ATN State

Data Bus

ASCII Hex Decimal

2c 44

EbT

Data Bus

ASCII Hex

1 1 1 g pi&w;

*Assumes primary address= 12.

Decimal

63

44

70

48

88

r

2-6

Page 17

SECTION 3

SYSTEM CONFIGURATION

3.1 INTRODUCTION

There are two operating aspects to almost any digital interface. The IEEE488 standard is no exception to this rule. Not

only must the hardware meet certain standards, but all

devices, including the controller, must have appropriate

software. This section deals with important hardware and

software aspects of bus operation. Also included is information pertaining to the Model 220/230 digital I/O port.

3.2 HARDWARE CONSIDERATIONS

Before the Model 220 or 230 can be used .with the IEEE488

bus, the instrument must be connected to the bus with a

suitable connector. Also, the primary address must be properly selected as described in this section.

3.2.1 Typical Systems

The IEEE488 bus is a parallel interface system. As a result,

adding more devices is simply a matter of using more cables

to make the desired connections. Because of this flexibility,

system complexity can range from the very simple to extremely complex.

Figure 3-l shows two typical system configurations. Figure

3-l(a) shows the simplest possible controlled system. The

controller is used to send commands to the instrument,

which sends data back to the controller.

The system becomes more complex in Figure 3-l(b), where

additional instrumentation is added. Depending on programming, all data may be routed through the controller, or

it may be transmitted directly from one instrument to

another.

For very complex applications, a much larger computer can

be used. Tape drives or disks can then be used to store data.

3.2.2 Bus Connections

The Model 220 or 230 is connected to the bus through an

IEEE488 connector which is shown in Figure 3-2. This connector is designed to be stacked to allow a number of

parallel connections on one instrument.

f

\

220 OR 230

(Al SIMPLE SYSTEM

CONTROLLER

(El ADDITIONAL INSTRUMENTATION

Figure 3-l. System Types

CONTROLLER

4-220/230

S-220/230

Figure 3-2. IEEE488 Connector

NOTE

To avoid possible mechanical damage, it is

recommended that no more than three connectors be stacked on any one instrument. Otherwise, the resulting strain may cause internal

damage.

A typical connecting scheme for the bus is shown in Figure

3-3. Each cable normally has the standard IEEE connector

on each end. The Keithley Model 7008 cable, which is six

feet in length, is ideal for this purpose. Once the connec-

tions are made, the screws should be tightened securely.

For the location of the connector on the rear panel of the

Model 220 or 230, refer to Figure 34.

3-1

Page 18

Instrument

Instrument

Figure 3-3. IEEE-488 Connections

1 01

Al

A2

A3

A4

a

DIGITAL l/O

Figure 3-4. Rear Panel of Model 220 or 230 Showing

IEEE Connectors and Switches

NOTE

The IEEE-488 bus is limited to a maximum of

15 devices, including the controller. Also, the

maximum cable length is 20 meters. Failure to

observe these limits will probably result in

erratic bus operation.

Custom cables may be constructed using the information in

Table 3-l and Figure 3-5. Table 3-l lists the contact assignments for the various bus lines, while Figure 3-5 shows

contact designations. Contacts 18 through 24 are return

lines for the indicated signal lines, and the cable shield is

connected to contact 12. Each ground line is connected to

digital common in the Model 220 or 230, but contact 12

within the instrument is left unconnected to avoid ground

loops.

Table 3-1. IEEE Contact Designations

Contact

Number

1

2

3

4

5 EOI (24)*

6 DAV

7

8

9

10

11 ATN

12

13

14

15

16

17 REN (24)*

18 Gnd, (6)*

19 Gnd, (7)*

20

21 Gnd, (9)*

22 Gnd, (lo)*

23 Gnd, (1 l)*

24

l Numbers in parentheses refer to signal ground return of referenced

contact number. EOI and REN signal lines return on contact 24.

** The cable shield is normally connected to contact 12. This shield

should be connected to ground only at the controller end to avoid

ground loop problems.

CONTACT 13

IEEE-488

Designation

DlOl

D102

D103

0104

NRFD

NDAC

IFC

SRQ

SHIELD**

Dl05

D106

D107

D108

Gnd, (8)*

Gnd, LOGIC

Type

Data

Data

Data

Data

Management

Handshake

Handshake

Handshake

Management

Management

Management

Ground

Data

Data

Data

Data

Management

Ground

Ground

Ground

Ground

Ground

Ground

Ground

CONTACT 24

NOTE

The connector supplied with the Hewlett-

Packard 85 HP-B interface will require the use

of the Keithley Model 7010 IEEE cable adapter.

The HP-B cable connector has an unusually

large shoulder that prevents the cable

connector from seating properly on the IEEE

connector on the rear panel of the Model 220

or 230. Connectors on other cables, including

those on the Keithley Model 7008, should seat

properly without this adapter.

3-2

CONTACT 1

CONTACT 12

Figure 3-5. Contact Assignments

Page 19

A typical signal line bus driver is shown in Figure 3-6. With

the configuration shown, the driver has bidirectional

capability. When the I/O control line is high, the line is configured as an output line. When the control line is low, the

driver is set up for input operation. Note that not all signal

lines have bidirectional capability. Some lines, such as ATN,

will always be configured as an ouput line in the controller

and as an input line for all other devices on the bus.

DATA

LINE ’

I/O

CONTROL >

Figure 3-6. Typical IEEE-488 Bus Driver (One of 16)

3.2.3 Primary Address Selection

The Model 220 or 230 must receive a listen command

before it will respond to addressed commands. Similarly,

the instrument must receive a talk command before it will

transmit its data string, status word, or status byte. These

listen and talk commands are derived from the instrument’s

primary address. The Model 220 is shipped from the factory

with a primary address of 12. The factory set value for the

primary address of the Model 230 is 13. The primary address

may be set to any value between 0 and 30 as long as address

conflicts with other bus instruments are avoided. This may

be done by placing the primary address switches, which are

shown in Figure 3-7, in the desired positions. Note that the

primary address of the instrument must agree with the address specified in the controller’s programming language.

The primary address switch positions are read

only upon power-up. If the address is changed,

the Model 220 or 230 must be turned off and

then powered up again before the new address

can be used. The primary address is shown on

the display for a short period after power-up as

follows: IE nn, where nn represents the primary

address value.

7

0

NOTE

--o 51017

OUTPUT

%?20/230

Table 3-2. Primary Address Switch Positions

Primary Address

(Decimal Value)

0

1

z

4

5

6

7

:

10

11

12’

13””

14

15

18

17

18

19

20

21

22

23

24

25

26

;;

29

30

*Model 220 factory set value.

**Model 230 factory set value.

NOTE: Primary Address 31 (11111) is reserved for UNL and

UNT commands and should not be used.

T

Switch Positions

A5 A4 A3

-

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

1

0

1

0

0

1

0

1

:,

1

0

1

0

1

0

1

1

1

1

1

1

1

1

0

0

0

0

:

0

0

1

0

0

1

1

0

0

1

:,

1

1

ii

0

1

1

1

1

1

1

1

-

-

A2

-T

0

1

1

0

0

1

1

0

0

1

1

0

0

1

1

0

0

1

1

0

0

1

il

0

1

1

0

0

1

-

Al

0

1

0

1

0

1

0

:,

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

:,

:,

1

0

- J

1 0

Figure 3-7 shows the correct positions for the Model 220

factory set value of 12; if a different address is required, the

primary address may be changed as outlined in Table 3-2.

NOTE

If other instrumentation is also connected to

the bus, be sure that each device has a different

primary address. If this precaution is not

observed, erratic bus operation will probably

result.

l/230

Figure 3-7. Primary Address Switches (Address = 12

Shown)

3-3

Page 20

The primary address switches are binary weighted; Al is

the least significant bit, while A5 the most significant bit.