Page 1

Model 2002Multimeter

Calibration Manual

A GREATER MEASURE OF CONFIDENCE

Page 2

Model 2002 Multimeter

Calibration Manual

©1994, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Fourth Printing, May 2004

Document Number: 2002-905-01 Rev. D

Page 3

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this manual. The Revision

Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are released between Revisions, contain important change information that the user should incorporate immediately into the manual. Addenda are numbered sequentially. When a new Revision is created, all Addenda associated with the previous Revision of the manual are

incorporated into the new Revision of the manual. Each new Revision includes a revised copy of this print history page.

Revision A (Document Number 2002-905-01) ....................................................................................... April 1994

Addendum A(Document Number 2002-905-02)................................................................................. October 1995

Addendum A(Document Number 2002-905-03)....................................................................................... July 1996

Revision B (Document Number 2002-905-01) ........................................................................................ June 1998

Revision C (Document Number 2002-905-01) ...............................................................................November 2000

Revision D (Document Number 2002-905-01) ........................................................................................ May 2004

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand and product names are trademarks or registered trademarks of their respective holders

Page 4

Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read and follow all installation,

operation, and maintenance information carefully before using the

product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use

and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be

trained in electrical safety procedures and proper use of the instrument. They must be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel perform routine procedures on the product

to keep it operating properly, for example, setting the line voltage

or replacing consumable materials. Maintenance procedures are described in the manual. The procedures explicitly state if the operator

may perform them. Otherwise, they should be performed only by

service personnel.

Service personnel are trained to work on live circuits, and perform

safe installations and repairs of products. Only properly trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that

are rated Measurement Category I and Measurement Category II, as

described in the International Electrotechnical Commission (IEC)

Standard IEC 60664. Most measurement, control, and data I/O signals are Measurement Category I and must not be directly connected to mains voltage or to voltage sources with high transient overvoltages. Measurement Category II connections require protection

for high transient over-voltages often associated with local AC

mains connections. Assume all measurement, control, and data I/O

connections are for connection to Category I sources unless otherwise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connector jacks or test fixtures.

The American National Standards Institute (ANSI) states that a

shock hazard exists when voltage levels greater than 30V RMS,

42.4V peak, or 60VDC are present. A good safety practice is to ex-

pect that hazardous voltage is present in any unknown circuit

before measuring.

Operators of this product must be protected from electric shock at

all times. The responsible body must ensure that operators are prevented access and/or insulated from every connection point. In

some cases, connections must be exposed to potential human contact. Product operators in these circumstances must be trained to

protect themselves from the risk of electric shock. If the circuit is

capable of operating at or above 1000 volts, no conductive part of

the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

When installing equipment where access to the main power cord is

restricted, such as rack mounting, a separate main input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always

make measurements with dry hands while standing on a dry, insulated

surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its

specifications and operating instructions or the safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and

accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard.

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a

lid interlock.

5/03

Page 5

If a screw is present, connect it to safety earth ground using the

wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to

avoid personal contact with these voltages.

The symbol indicates a connection terminal to the equipment

frame.

The WARNING heading in a manual explains dangers that might

result in personal injury or death. Always read the associated information very carefully before performing the indicated procedure.

The CAUTION heading in a manual explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

To maintain protection from electric shock and fire, replacement

components in mains circuits, including the power transformer, test

leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as

long as they are equivalent to the original component. (Note that selected parts should be purchased only through Keithley Instruments

to maintain accuracy and functionality of the product.) If you are

unsure about the applicability of a replacement component, call a

Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based

cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill

on the instrument. Products that consist of a circuit board with no

case or chassis (e.g., data acquisition board for installation into a

computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for proper

cleaning/servicing.

Page 6

Table of Contents

1 Performance Verification

1.1 Introduction......................................................................................................................................................... 1-1

1.2 Environmental conditions ................................................................................................................................... 1-1

1.3 Warm-up period .................................................................................................................................................. 1-1

1.4 Line power .......................................................................................................................................................... 1-2

1.5 Recommended test equipment ............................................................................................................................ 1-2

1.6 Verification limits ............................................................................................................................................... 1-2

1.6.1 Reading limit calculation example.............................................................................................................. 1-2

1.6.2 Additional derating factors.......................................................................................................................... 1-2

1.7 Restoring default conditions ............................................................................................................................... 1-2

1.8 Verification procedures....................................................................................................................................... 1-4

1.8.1 DC volts verification................................................................................................................................... 1-4

1.8.2 AC volts verification................................................................................................................................... 1-6

1.8.3 DC current verification ............................................................................................................................. 1-11

1.8.4 AC current verification ............................................................................................................................. 1-12

1.8.5 Resistance verification .............................................................................................................................. 1-13

1.8.6 Frequency accuracy verification ............................................................................................................... 1-15

1.8.7 Temperature reading checks ..................................................................................................................... 1-17

2 Calibration

2.1 Introduction......................................................................................................................................................... 2-1

2.2 Environmental conditions ................................................................................................................................... 2-2

2.3 Warm-up period .................................................................................................................................................. 2-2

2.4 Line power .......................................................................................................................................................... 2-2

2.5 Calibration lock................................................................................................................................................... 2-2

2.5.1 Comprehensive calibration lock.................................................................................................................. 2-2

2.5.2 Low-level calibration lock .......................................................................................................................... 2-2

2.5.3 IEEE-488 bus calibration lock status .......................................................................................................... 2-2

2.6 IEEE-488 bus calibration commands.................................................................................................................. 2-2

2.7 Calibration errors ................................................................................................................................................ 2-4

2.7.1 Front panel error reporting.......................................................................................................................... 2-4

2.7.2 IEEE-488 bus error reporting...................................................................................................................... 2-4

2.8 Comprehensive calibration ................................................................................................................................. 2-4

2.8.1 Recommended equipment for comprehensive calibration.......................................................................... 2-4

2.8.2 Front panel comprehensive calibration ....................................................................................................... 2-4

2.8.3 IEEE-488 bus comprehensive calibration................................................................................................... 2-9

2.9 AC self-calibration............................................................................................................................................ 2-12

2.9.1 Front panel AC calibration........................................................................................................................ 2-12

2.9.2 IEEE-488 bus AC self-calibration ............................................................................................................ 2-13

i

Page 7

2.10 Low-level calibration......................................................................................................................................... 2-13

2.10.1 Recommended equipment for low-level calibration ................................................................................. 2-13

2.10.2 Low-level calibration summary................................................................................................................. 2-13

2.10.3 Front panel low-level calibration procedure.............................................................................................. 2-16

2.10.4 IEEE-488 bus low-level calibration procedure ......................................................................................... 2-20

2.11 Single-point calibration ..................................................................................................................................... 2-24

2.11.1 Front panel single-point calibration........................................................................................................... 2-24

2.11.2 IEEE-488 bus single-point calibration ...................................................................................................... 2-24

3 Calibration Command Reference

3.1 Introduction ......................................................................................................................................................... 3-1

3.2 Commands........................................................................................................................................................... 3-1

3.2.1 Command summary..................................................................................................................................... 3-1

3.3 :CALibration:PROTected Subsystem ................................................................................................................. 3-3

3.3.1 :INIT ............................................................................................................................................................ 3-3

3.3.2 :LOCK ......................................................................................................................................................... 3-3

3.3.3 :SWITch?..................................................................................................................................................... 3-4

3.3.4 :SAVE.......................................................................................................................................................... 3-4

3.3.5 :DATA? ....................................................................................................................................................... 3-4

3.3.6 :DATE ......................................................................................................................................................... 3-5

3.3.7 :NDUE......................................................................................................................................................... 3-5

3.3.8 :DC .............................................................................................................................................................. 3-6

3.3.9 :LLEVel..................................................................................................................................................... 3-11

3.4 :CALibration:UNPRotected Subsystem............................................................................................................ 3-13

3.4.1 :ACCompensation ..................................................................................................................................... 3-13

3.5 Bus error reporting ............................................................................................................................................ 3-13

3.5.1 Calibration error summary ........................................................................................................................ 3-13

3.5.2 Detecting Calibration Errors...................................................................................................................... 3-13

3.6 Detecting calibration step completion ............................................................................................................... 3-14

3.6.1 Using the *OPC? Query ............................................................................................................................ 3-14

3.6.2 Using the *OPC command ........................................................................................................................ 3-14

3.6.3 Generating an SRQ on calibration complete ............................................................................................. 3-14

APPENDICES

A Specifications ............................................................................................................................................. A-1

B Calibration Programs .................................................................................................................................. B-1

C Calibration Messages.................................................................................................................................. C-1

D Calibration Command Summary................................................................................................................ D-1

ii

Page 8

List of Illustrations

1 Performance Verification

Figure 1-1 Connections for DC volts verification ........................................................................................................ 1-5

Figure 1-2 Connections for AC volts verification (all except 2MHz) .......................................................................... 1-7

Figure 1-3 Connections for 2MHz AC volts verification ............................................................................................. 1-7

Figure 1-4 Connections for DC current verification................................................................................................... 1-11

Figure 1-5 Connections for AC current verification................................................................................................... 1-12

Figure 1-6 Connections for resistance verification (20 Ω -2M Ω ranges)..................................................................... 1-14

Figure 1-7 Connections for resistance verification (20M Ω and 200M Ω ranges)....................................................... 1-14

Figure 1-8 1G Ω resistor test box construction............................................................................................................ 1-15

Figure 1-9 Connections for frequency accuracy verification ..................................................................................... 1-16

2 Calibration

Figure 2-1 Low-thermal short connections................................................................................................................... 2-5

Figure 2-2 Calibrator connections for DC volts and ohms portion of comprehensive calibration............................... 2-6

Figure 2-3 Connections for amps comprehensive calibration ...................................................................................... 2-8

Figure 2-4 Calibrator voltage connections.................................................................................................................. 2-18

Figure 2-5 Synthesizer connections............................................................................................................................ 2-20

APPENDICES

Figure B-1 Low-thermal short connections.................................................................................................................. B-3

Figure B-2 Connections for comprehensive calibration............................................................................................... B-4

Figure B-3 Calibrator voltage connections................................................................................................................... B-4

Figure B-4 Calibrator current connections ................................................................................................................... B-4

Figure B-5 Synthesizer connections............................................................................................................................. B-5

iii

Page 9

iv

Page 10

List of Tables

1 Performance Verification

Table 1-1 Recommended Test Equipment for Performance Verification.................................................................. 1-3

Table 1-2 Limits for DCV verification....................................................................................................................... 1-5

Table 1-3 Limits for normal mode AC voltage verification....................................................................................... 1-8

Table 1-4 Limits for low-frequency mode AC voltage verification........................................................................... 1-9

Table 1-5 Limits for AC peak voltage verification .................................................................................................. 1-10

Table 1-6 Limits for DC current verification ........................................................................................................... 1-11

Table 1-7 Limits for AC current verification ........................................................................................................... 1-13

Table 1-8 Limits for resistance verification (20 Ω -200M Ω ranges) ......................................................................... 1-15

Table 1-9 Limits for resistance verification (1G Ω range)........................................................................................ 1-15

Table 1-10 Frequency verification limits ................................................................................................................... 1-16

Table 1-11 Thermocouple temperature reading checks ............................................................................................. 1-17

Table 1-12 RTD probe temperature reading checks................................................................................................... 1-18

2 Calibration

Table 2-1 IEEE-488 bus calibration command summary .......................................................................................... 2-3

Table 2-2 Recommended equipment for comprehensive calibration......................................................................... 2-4

Table 2-3 Front panel comprehensive calibration summary ...................................................................................... 2-5

Table 2-4 IEEE-488 bus comprehensive calibration summary.................................................................................. 2-9

Table 2-5 Ohms calibration summary ...................................................................................................................... 2-11

Table 2-6 Amps calibration summary ...................................................................................................................... 2-12

Table 2-7 Recommended equipment for low-level calibration................................................................................ 2-14

Table 2-8 Low-level calibration summary ............................................................................................................... 2-15

Table 2-9 Ohms calibration summary ...................................................................................................................... 2-22

Table 2-10 Amps calibration summary ...................................................................................................................... 2-22

3 Calibration Command Reference

Table 3-1 IEEE-488 bus calibration command summary .......................................................................................... 3-2

Table 3-2 Comprehensive calibration commands ...................................................................................................... 3-6

Table 3-3 Low-level calibration commands............................................................................................................. 3-11

Appendices

Table B-1 Recommended equipment for comprehensive calibration......................................................................... B-2

Table B-2 Recommended equipment for low-level calibration.................................................................................. B-2

Table C-1 Calibration error messages......................................................................................................................... C-2

Table C-2 Calibration constants returned by :CAL:PROT:DATA? query................................................................. C-4

Table D-1 Calibration commands ............................................................................................................................... D-1

v

Page 11

vi

Page 12

Performance Verification

1

1.1 Introduction

The procedures in this section are intended to verify that

Model 2002 accuracy is within the limits stated in the instrument one-year accuracy specifications. These procedures can

be performed when the instrument is first received to ensure

that no damage or misadjustment has occurred during shipment. Verification may also be performed whenever there is

a question of instrument accuracy, or following calibration,

if desired.

NOTE

If the instrument is still under warranty,

and its performance is outside specified

limits, contact your Keithley representative or the factory to determine the correct

course of action.

This section includes the following:

1.2 Environmental conditions: Covers the temperature

and humidity limits for verification.

1.3 Warm-up period: Describes the length of time the

Model 2002 should be allowed to warm up before

testing.

1.4 Line power: Covers power line voltage ranges during

testing.

1.5 Recommended equipment: Summarizes recom-

mended equipment and pertinent specifications.

1.6 Verification limits: Explains how reading limits were

calculated.

1.7 Restoring factory default conditions: Gives step-by-

step procedures for restoring default conditions before

each test procedure.

1.8 Verification procedures: Details procedures to verify

measurement accuracy of all Model 2002 measurement functions.

1.2 Environmental conditions

Verification measurements should be made at an ambient

temperature of 18–28°C (65–82°F), and at a relative humidity of less than 80% unless otherwise noted.

1.3 Warm-up period

The Model 2002 must be allowed to warm up for the

following time period before performing the verification

procedures:

• DC volts and ohms: four hours

• AC volts, AC current, DC current: one hour

If the instrument has been subjected to temperature extremes

(outside the range stated in paragraph 1.2), allow additional

time for internal temperatures to stabilize. Typically, it takes

one additional hour to stabilize a unit that is 10°C (18°F) outside the specified temperature range.

The test equipment should also be allowed to warm up for

the minimum period specified by the manufacturer.

1-1

Page 13

Performance Verification

×

1.4 Line power

The Model 2002 should be tested while operating from a line

voltage in the range of 90–134V or 180–250V at a frequency

of 50, 60, or 400Hz.

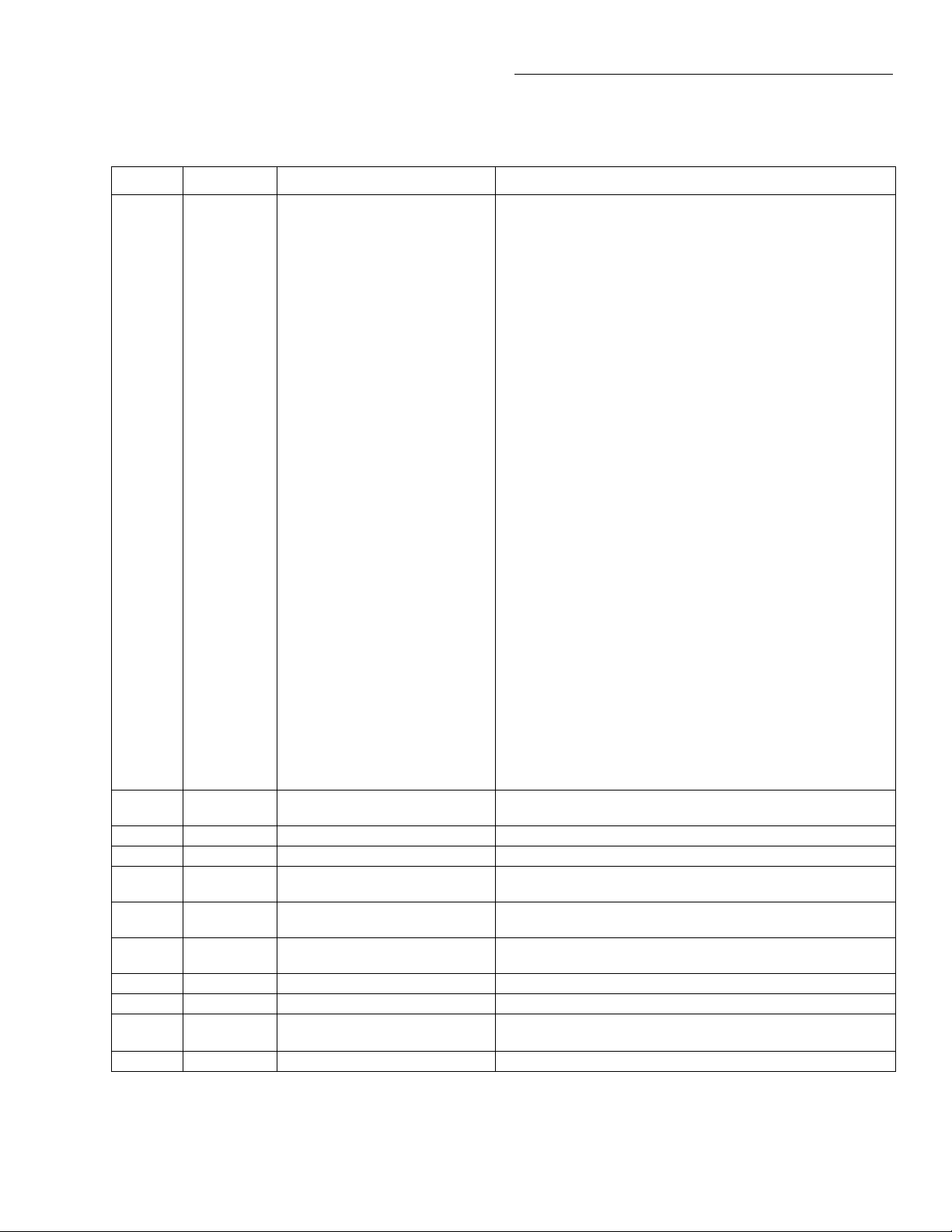

1.5 Recommended test equipment

Table 1-1 lists all test equipment required for verification.

Alternate equipment may be used as long as that equipment

has specifications at least as good as those listed in the table.

NOTE

The calibrator listed in Table 1-1 is sufficiently accurate to verify Model 2002

accuracy to total factory calibration uncertainty. It is not accurate enough to verify

Model 2002 relative accuracy specifications alone.

1.6 Verification limits

The verification limits stated in this section have been calculated using the Model 2002 one-year relative accuracy specifications and the total absolute uncertainty of the factory

recommended calibrator (see Table 1-1). DCV, DCI, and

ohms limits also include factory calibration uncertainty. (See

specifications.) Those who are using calibration sources with

better absolute uncertainty should recalculate the limits using the Model 2002 relative accuracy specifications, the absolute uncertainty specifications of the calibration sources,

and factory calibration uncertainty (DCV, DCI, and ohms).

1.6.1 Reading limit calculation example

As an example of how reading limits are calculated, assume

that the 20VDC range is being tested using a 19V input value, and the various specifications are as follows:

• Model 2002 relative accuracy: ±(10ppm of reading +

0.15ppm of range)

• Model 2002 factory calibration uncertainty: ±2.6ppm

of reading

• Calibrator total absolute uncertainty at 19V output:

±5.4ppm

The calculated limits are:

Reading limits = 19V ± [(19V × (10ppm + 2.6ppm)) + (20V

0.15ppm) + 19V × 5.4ppm]

Reading limits = 19V ± 0.000345V

Reading limits = 18.999655V to 19.000345V

1.6.2 Additional derating factors

Certain functions and ranges are subject to certain derating

factors that must be included when calculating reading

limits. For example, coupling errors must be added to lowfrequency AC limits, while AC voltage limits for inputs

above 100V are subject to additional derating factors.

Always read the associated specification notes to determine

if any derating factors apply before calculating reading

limits.

1.7 Restoring default conditions

Before performing each performance verification procedure,

restore instrument bench default conditions as follows:

1. From the normal display mode, press the MENU key.

The instrument will display the following:

MAIN MENU

SAVESETUP GPIB CALIBRATION

2. Select SAVESETUP, and press ENTER. The following

will be displayed:

SETUP MENU

SAVE RESTORE POWERON RESET

3. Select RESET, and press ENTER. The display will then

appear as follows:

RESET ORIGINAL DFLTS

BENCH GPIB

4. Select BENCH, then press ENTER. The following will

be displayed:

RESETTING INSTRUMENT

ENTER to confirm; EXIT to abort

5. Press ENTER again to confirm instrument reset. The instrument will return to the normal display with bench

defaults restored.

1-2

Page 14

Performance Verification

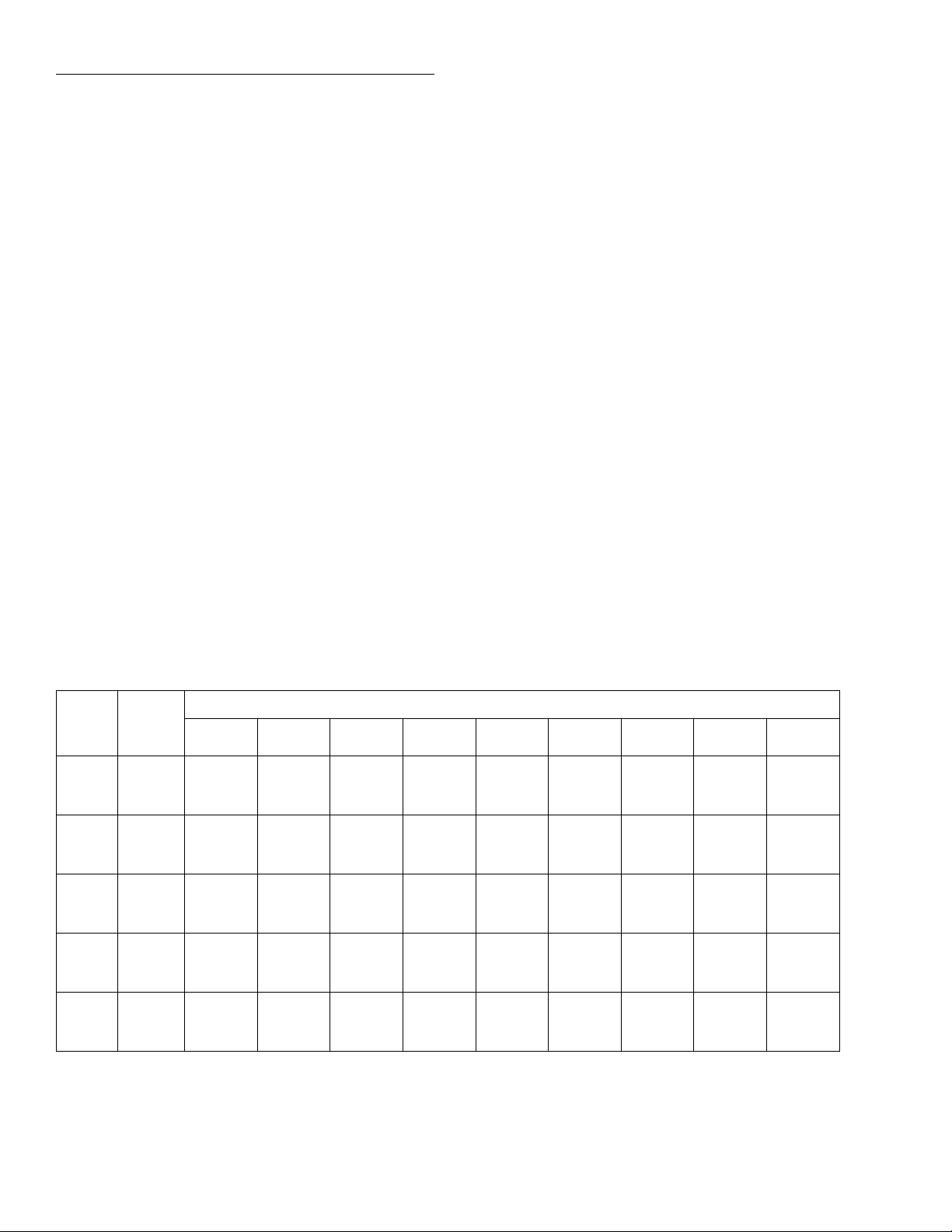

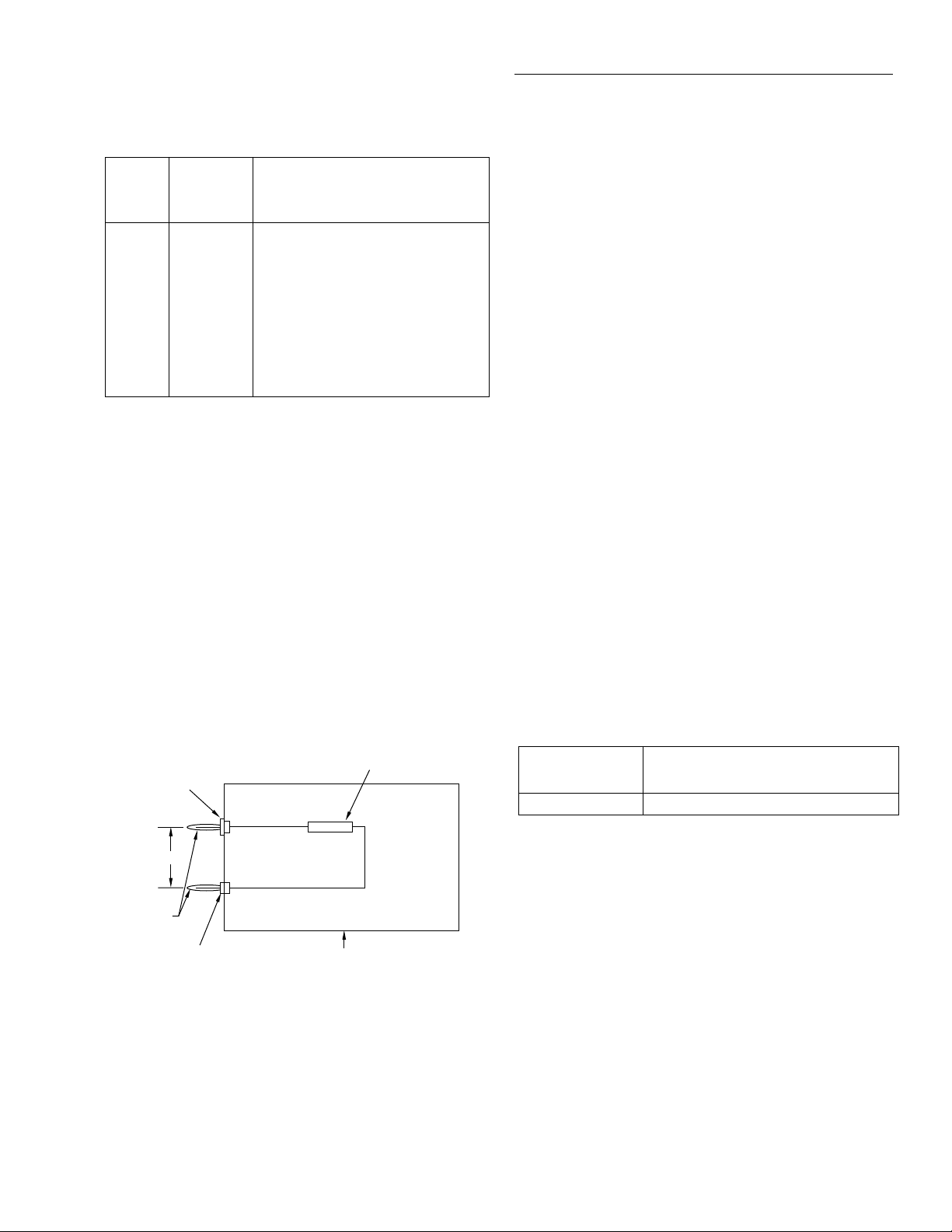

Table 1-1

Recommended Test Equipment for Performance Verification

Mfg. Model Description Specifications*

Fluke 5700A Calibrator ±5ppm basic uncertainty.

DC Voltage:

190mV: ±11ppm

1.9V: ±7ppm

19V: ±5ppm

190V: ±7ppm

1000V: ±9ppm

AC Voltage, 10Hz-1MHz

(40Hz-20kHz specifications):

190mV: ±150ppm

1.9V: ±78ppm

19V: ±78ppm

190V: ±85ppm

750V: ±85ppm (50Hz-1kHz)

DC current:

190µA: ±103ppm

1.9mA: ±55ppm

19mA: ±55ppm

190mA: ±65ppm

1.9A: ±96ppm

AC Current, 40Hz-10kHz

(40Hz-1kHz specifications):

190µA: ±245ppm

1.9mA: ±160ppm

19mA: ±160ppm

190mA: ±170ppm

1.9A: ±670ppm

Resistance:

19Ω: ±26ppm

190Ω: ±17ppm

1.9kΩ: ±12ppm

19kΩ: ±11ppm

190kΩ: ±13ppm

1.9MΩ: ±19ppm

19MΩ: ±47ppm

100MΩ: ±120ppm

Fluke 5725A Amplifier AC Voltage, 1kHz-10kHz:

Fluke 5700A-03 Wideband AC option 190mV ± 0.22%, 1.9V ± 0.3% @ 2MHz

Fluke 5440A-7002 Low-thermal cable set

Keithley CA-18-1 Low-capacitance cable Low-capacitance dual banana to dual banana shielded cable (for

Keithley R-289-1G 1GΩ resistor NOTE: Resistor should be characterized to within ±1,000ppm and

Metal component box (for 1GΩ

resistor)

Banana plugs (2) for test box One insulated, one non-insulated.

Keithley 3940 Multifunction Synthesizer 1Hz-15MHz, ±5ppm

General

Radio

— — Megaohmmeter 1GΩ, ±0.5%

* 90-day calibrator specifications shown include total absolute uncertainty at specified output.

1433-T Precision Decade Resistance Box 10-400Ω, ±0.02%

750V: ±85ppm

ACV), 1.2m (4 ft.) in length.

mounted in shielded test box (see procedure).

1-3

Page 15

Performance Verification

1.8 Verification procedures

The following paragraphs contain procedures for verifying

instrument accuracy specifications for the following measuring functions:

• DC volts

• AC volts

• DC current

• AC current

• Resistance

• Frequency

• Temperature

NOTE

The following verification procedures are

intended to verify the accuracy of the

Model 2002 and include reading limits

based on the Model 2002 relative accuracy

specifications and the total uncertainty of

the recommended calibrator. DCV, DCI,

and ohms limits include factory calibration uncertainty.

1.8.1 DC volts verification

DC voltage accuracy is verified by applying accurate DC

voltages from a calibrator to the Model 2002 input and verifying that the displayed readings fall within specified ranges.

Follow the steps below to verify DCV measurement

accuracy.

CAUTION

Do not exceed 1100V peak between INPUT HI and INPUT LO, or instrument

damage may occur.

1. Connect the Model 2002 to the calibrator, as shown in

Figure 1-1. Be sure to connect calibrator HI to Model

2002 INPUT HI and calibrator LO to Model 2002

INPUT LO as shown.

NOTE

Use shielded, low-thermal connections

when testing the 200mV and 2V ranges to

avoid errors caused by noise or thermal

offsets. Connect the shield to calibrator

output LO.

If the Model 2002 is out of specifications and not under warranty, refer to the calibration procedures in Section 2.

WARNING

The maximum common-mode voltage

(voltage between INPUT LO and chassis ground) is 500V peak. Exceeding this

value may cause a breakdown in insulation, creating a shock hazard. Some of

the procedures in this section may

expose you to dangerous voltages. Use

standard safety precautions when such

dangerous voltages are encountered to

avoid personal injury caused by electric

shock.

NOTE

Do not connect test equipment to the

Model 2002 through a scanner or other

switching equipment.

2. Turn on the Model 2002 and the calibrator, and allow

a four-hour warm-up period before making

measurements.

3. Restore Model 2002 factory default conditions, as

explained in paragraph 1.7.

4. Set Model 2002 operating modes as follows:

A. From normal display, press CONFIG then DCV.

B. Select SPEED, then press ENTER.

C. Select HIACCURACY, then press ENTER.

D. Select FILTER, then press ENTER.

E. Select AVERAGING, then press ENTER.

F. Using the cursor and range keys, set the averaging

parameter to 10 readings, then press ENTER.

G. Press EXIT to return to normal display.

5. Select the Model 2002 200mV DC range. (If the FILT

annunciator is off, press the FILTER key to enable the

filter.)

NOTE

Do not use auto-ranging for any of the verification tests because auto-range hysteresis may cause the Model 2002 to be on an

incorrect range.

1-4

Page 16

Performance Verification

6. Set the calibrator output to 0.00000mVDC, and allow

the reading to settle.

7. Enable the Model 2002 REL mode. Leave REL enabled

for the remainder of the DC volts verification test.

8. Set the calibrator output to +190.00000mVDC, and

allow the reading to settle.

9. Verify that the Model 2002 reading is within the limits

summarized in Table 1-2.

10. Repeat steps 8 and 9 for the remaining ranges and voltages listed in Table 1-2.

11. Repeat the procedure for each of the ranges with negative voltages of the same magnitude as those listed in

Table 1-2.

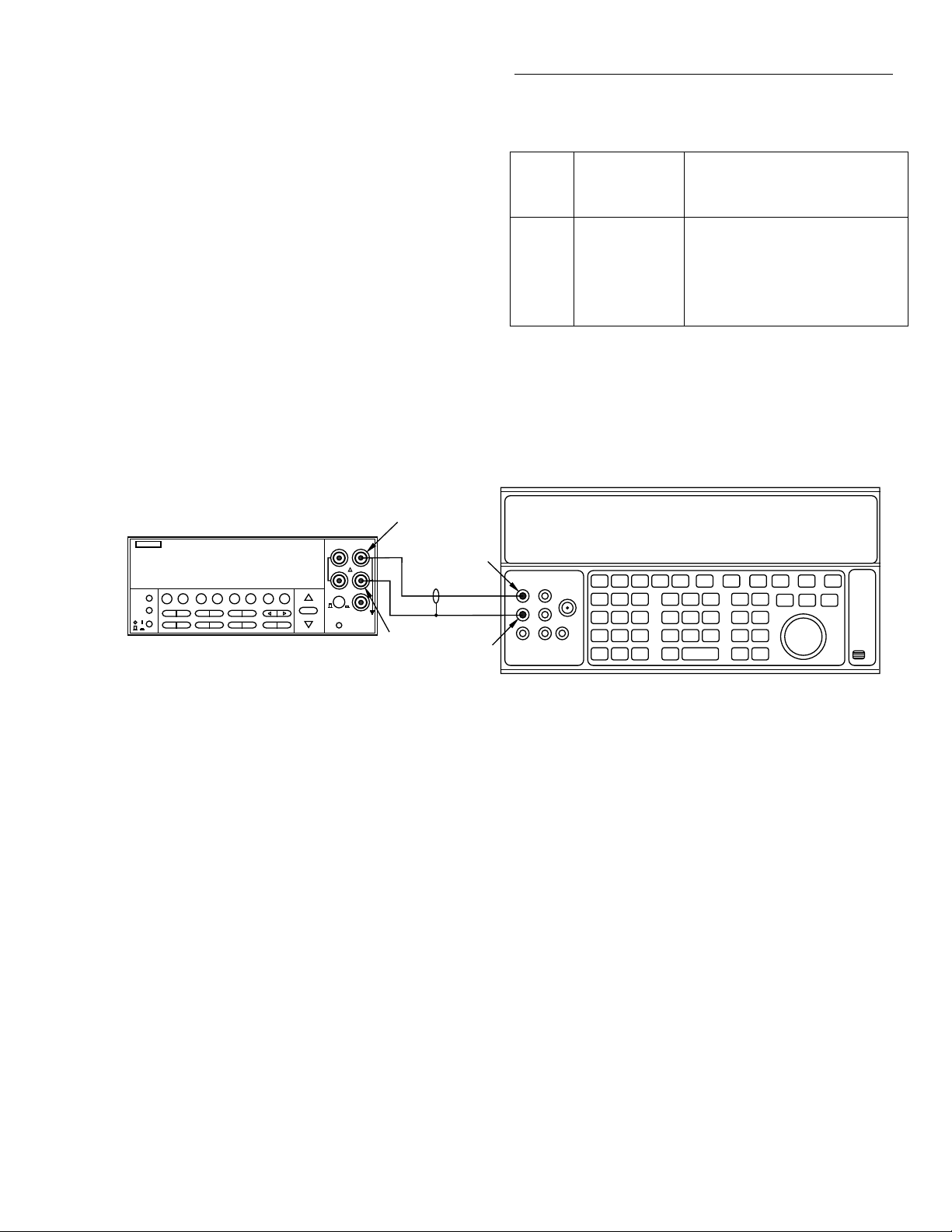

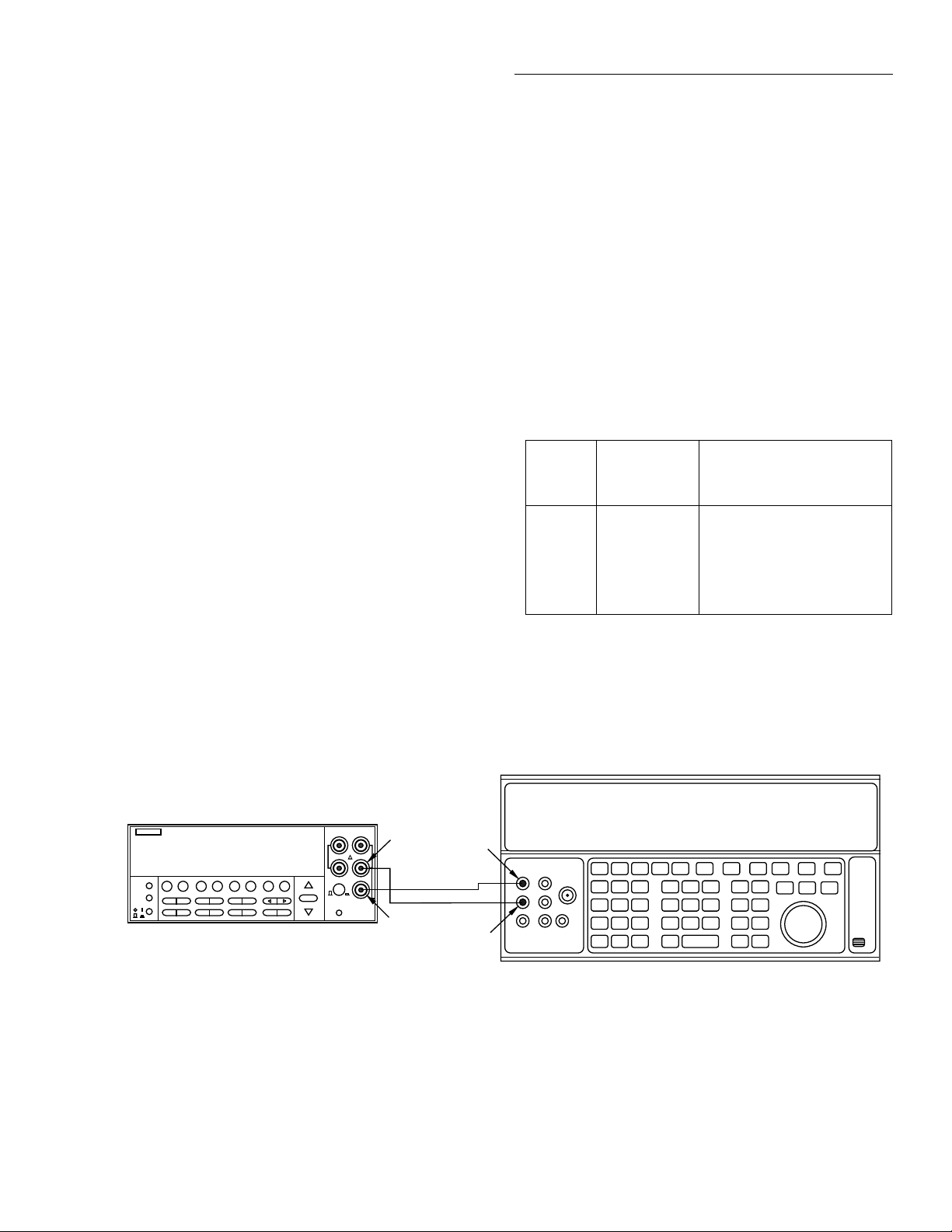

Input HI

Model 2002

Output HI

Table 1-2

Limits for DCV verification

2002

DCV

Range

Applied DC

Voltage

Reading Limits

(1 year, 18° to 28°C)

200mV 190.000000mV 189.991911mV to 190.008089mV

2V 1.90000000V 1.89996058 to 1.90003942V

20V 19.0000000V 18.9996550V to 19.0003450V

200V 190.000000V 189.993691V to 190.006309V

1000V 1000.0000V 999.94640V to 1000.05360V

NOTES:

1. Repeat procedure for negative voltages of same magnitude.

2. Reading limits shown include total absolute uncertainty of recommended

calibrator (see Table 1-1) and factory calibration uncertainty (see

specifications).

5700A Calibrator (Output DC Voltage)

2002 MULTIMETER

Figure 1-1

Connections for DC volts verification

Input

LO

Note : Use shielded, low-thermal cables

when testing 200mV and 2V ranges.

Output

LO

1-5

Page 17

Performance Verification

1.8.2 AC volts verification

AC voltage accuracy is checked by applying accurate AC

voltages at specific frequencies from an AC calibration

source and then verifying that each Model 2002 AC voltage

reading falls within the specified range. The two ACV verification procedures that follow include:

• Normal Mode

• Low-frequency Mode

CAUTION

Do not exceed 1100V peak between INPUT HI and INPUT LO, or 2 ×

7

10

V•Hz input, or instrument damage

may occur.

Normal mode

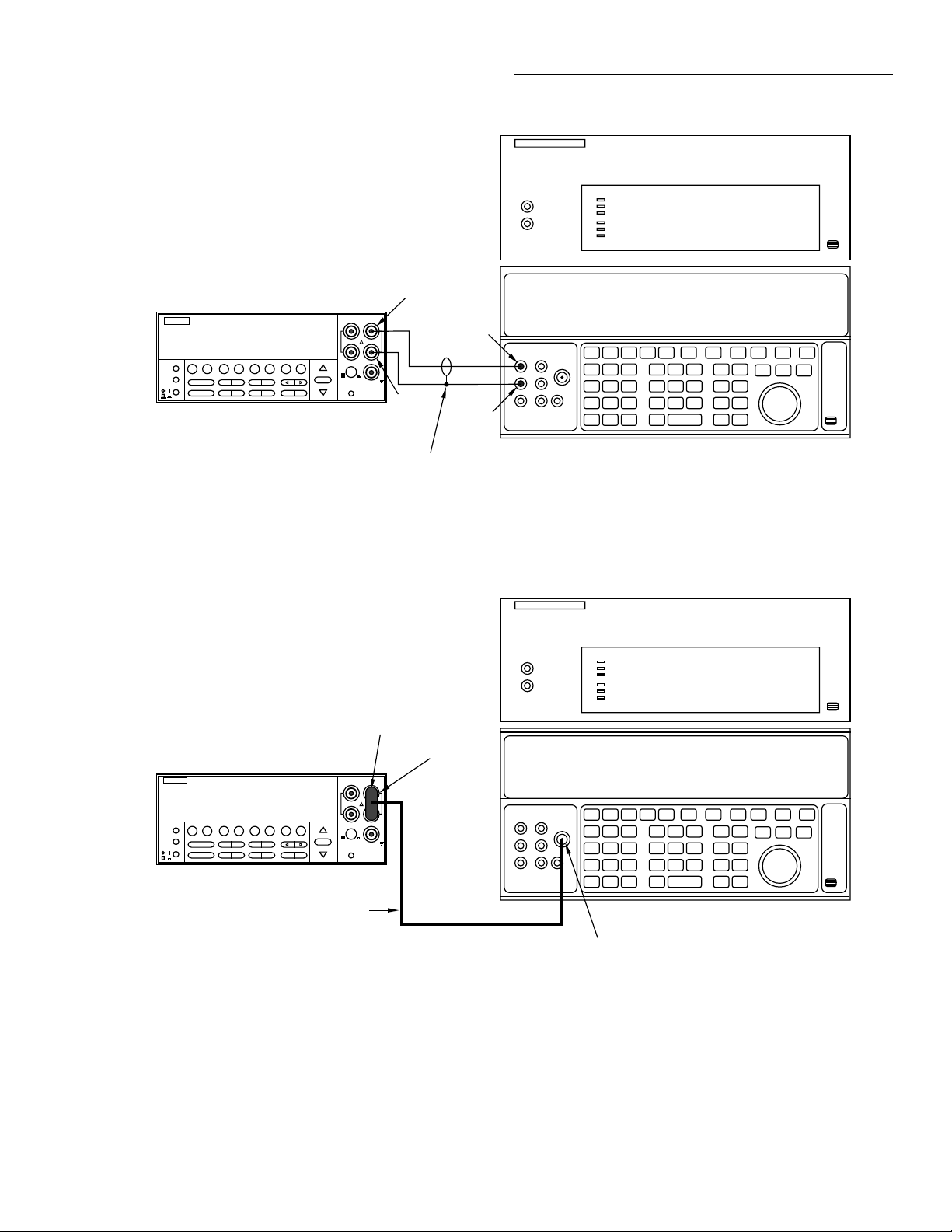

1. Turn on the Model 2002, calibrator, and amplifier, and

allow a one-hour warm-up period before making

measurements.

2. Connect the Model 2002 to the calibrator, as shown in

Figure 1-2. Be sure to connect amplifier HI to Model

2002 INPUT HI and amplifier LO to Model 2002

INPUT LO as shown. Connect the power amplifier to

the calibrator using the appropriate connector on the

rear of the calibrator.

3. Restore Model 2002 factory default conditions, as explained in paragraph 1.7.

4. Select the ACV function and the 200mV range on the

Model 2002, and make sure that REL is disabled.

NOTE

Do not use REL to null offsets when performing AC volts tests. Also, do not enable

the filter.

5. Set the calibrator output to 190.000mVAC at a frequency of 100Hz, and allow the reading to settle.

6. Verify that the Model 2002 reading is within the limits

summarized in Table 1-3.

7. Repeat steps 5 and 6 for 190mVAC at the remaining frequencies listed in Table 1-3 (except 2MHz). Verify that

instrument readings fall within the required limits listed

in the table.

8. Repeat steps 5 through 7 for the 2V, 20V, 200V, and

750VAC ranges using the input voltages and limits

stated in Table 1-3.

9. Connect the Model 2002 to the wideband calibrator output (see Figure 1-3).

10. Set the calibrator output to 190.000mV at a frequency of

2MHz.

11. Verify that the reading is within the limits shown in

Table 1-3.

12. Repeat steps 10 and 11 for 1.90000V input on the 2V

range.

CAUTION

Do not attempt to test the 20V–1000V

ranges at 2MHz.

1-6

Page 18

Performance Verification

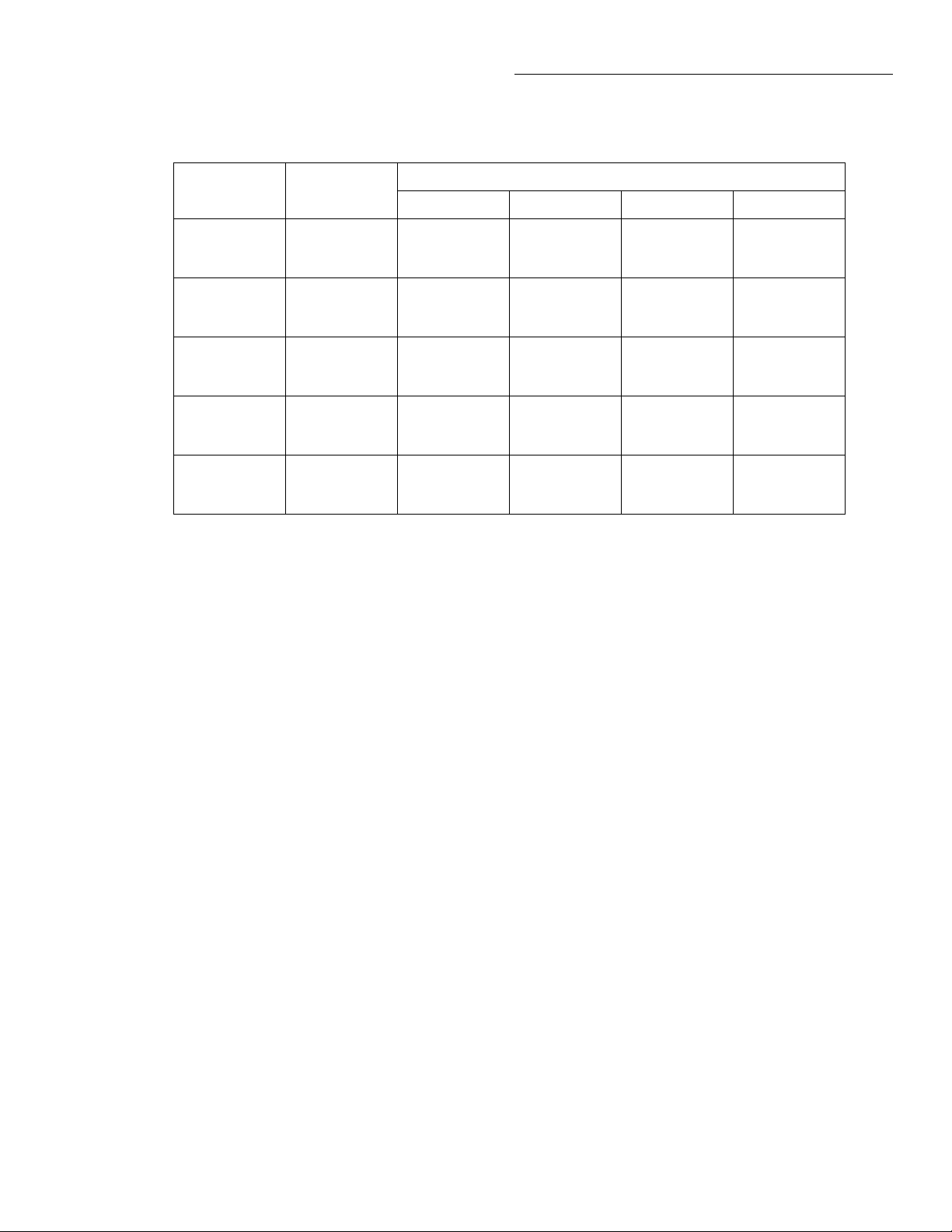

5725 Amplifier (Connect to calibrator)

Model 2002

1.90000 VAC RMS

2001 MULTIMETER

Input HI

Output HI

Input

LO

CA-18-1 Low-

capacitance cable

Figure 1-2

Connections for AC volts verification (all except 2MHz)

BNC to dual

banana

50Ω

terminator

Model 2002

Output

LO

5700A Calibrator (Output AC Voltage)

5725 Amplifier (Connect to calibrator)

1.90000 VAC RMS

2002 MULTIMETER

50Ω Coax

Figure 1-3

Connections for 2MHz AC volts verification

5700A Calibrator (Output AC Voltage)

Wideband

output

1-7

Page 19

Performance Verification

Table 1-3

Limits for normal mode AC voltage verification

*

180.100mVto199.900mV

186.000mVto194.000mV

1.80100Vto1.99900V

1.86000Vto1.94000V

18.2000Vto19.8000V

***

188.525mVto191.475mV

1.88525Vto1.91475V

18.8525Vto19.1475V

to

190.607V

189.393V

189.830Vto190.170V

189.868Vto190.132V

*****

748.87Vto751.13V

190.115mV

1.89400Vto1.90600V

to

1.89885V

1.89933Vto1.90068V

189.400mVto190.600mV

to

189.885mV

Reading limits (1 year, 18°C to 28°C)

189.933mVto190.068mV

1.90115V

18.9400Vto19.0600V

18.9837Vto19.0163V

18.9875Vto19.0125V

1-8

2002

Applied

ACV

100Hz 1kHz 5kHz 25kHz 50kHz 100kHz 200kHz 1MHz 2MHz

voltage

range

189.942mVto190.058mV

189.942mVto190.058mV

to

200mV 190.000mV 189.914mV

190.087mV

1.89942Vto1.90058V

1.89942Vto1.90058V

to

1.90087V

2V 1.90000V 1.89914V

18.9894Vto19.0106V

18.9913Vto19.0087V

to

19.0116V

20V 19.0000V 18.9885V

to

190.113V

189.887V

189.906Vto190.094V

to

190.122V

200V 190.000V 189.878V

749.02Vto750.98V

749.09Vto750.91V

V•Hz input.

to

7

751.02V

750V 750.00V 748.98V

** CAUTION: Do not exceed 2 × 10

** Use wideband option and connections for 2MHz tests.

NOTE: Reading limits shown include total absolute uncertainty of recommended calibrator (see Table 1-1). Reading limits also include the adder for AC Coupling of the input.

Page 20

Performance Verification

Table 1-4

Limits for low-frequency mode AC voltage verification

2002 ACV

range

Applied

voltage

Reading limits (1 year, 18°C to 28°C)

10Hz 50Hz 100Hz

200mV 190.000mV 189.837mV

to

190.163mV

189.904mV

to

190.097mV

189.923mV

to

190.077mV

2V 1.90000V 1.89875V

to

1.90125V

1.89923V

to

1.90078V

1.89942V

to

1.90058V

20V 19.0000V 18.9837V

to

19.0163V

18.9904V

to

19.0097V

18.9913V

to

19.0087V

200V 190.000V 189.849V

to

190.151V

189.906V

to

190.094V

189.906V

to

190.094V

750V 750.00V * 749.09V

to

750.91V

749.09V

to

750.91V

* Recommended calibrator/amplifier cannot source this voltage/frequency.

Notes:

1. Specifications above 100Hz are the same as normal mode.

2. Limits shown include total absolute uncertainty of recommended calibrator (see Table 1-1).

Low-frequency mode

1. Turn on the Model 2002, calibrator, and amplifier, and

allow a one-hour warm-up period before making

measurements.

2. Connect the Model 2002 to the calibrator, as shown in

Figure 1-2. Be sure to connect the amplifier HI to Model

2002 INPUT HI and amplifier LO to Model 2002

INPUT LO as shown. Connect the power amplifier to

the calibrator using the appropriate connector on the

rear of the calibrator.

3. Restore Model 2002 factory default conditions, as

explained in paragraph 1.7.

4. Select the ACV function and the 200mV range on the

Model 2002, and make sure that REL is disabled.

NOTE

Do not use REL to null offsets when performing AC volts tests. Also, do not enable

the filter.

5. Select the low-frequency mode as follows:

A. Press CONFIG ACV, select AC-TYPE, then press

ENTER.

B. Select LOW-FREQ-RMS, then press ENTER.

C. Press EXIT as required to return to normal display.

6. Set the calibrator output to 190.000mVAC at a frequency of 10Hz, and allow the reading to settle.

7. Verify that the Model 2002 reading is within the limits

summarized in Table 1-4.

8. Repeat steps 6 and 7 for 190mVAC at the remaining frequencies listed in the table.

9. Repeat steps 6 through 8 for the 2V, 20V, 200V, and

750VAC ranges, using the input voltages and limits

stated in Table 1-4.

1-9

Page 21

Performance Verification

AC peak mode

1. Turn on the Model 2002, calibrator, and amplifier, and

allow a one-hour warm-up period before making

measurements.

2. Connect the Model 2002 to the calibrator, as shown in

Figure 1-2. Be sure to connect the amplifier HI to Model

2002 INPUT HI, and the amplifier LO to MODEL 2002

INPUT LO as shown. Connect the power amplifier to

the calibrator using the appropriate connector on the

rear of the calibrator.

3. Restore the Model 2002 factory default conditions.

4. Select the ACV function and the 200mV range on the

Model 2002, and make sure that REL is disabled.

NOTE

Do not use REL to null offsets when performing AC volts tests. Use AC coupling

for 5kHz-1MHz tests. Use AC+DC coupling for 20Hz tests. (Use CONFIG-ACV

to set up coupling).

5. Select the AC peak and filter modes as follows:

A. Press CONFIG then ACV, select AC-TYPE, then

press ENTER.

B. Select PEAK, then press ENTER.

C. Select FILTER, then press ENTER.

D. Select AVERAGING, then press ENTER.

E. Using the cursor and range keys, set the averaging

parameter to 10 readings, then press ENTER.

F. Press EXIT as necessary to return to normal display.

G. If the FLT annunciator is off, press FILTER to

enable the filter.

6. Set the calibrator output to 100.000mVAC at a frequency of 5kHz, and allow the reading to settle.

7. Verify that the Model 2002 reading is within the limits

summarized in Table 1-5.

8. Repeat steps 6 and 7 for 100mVAC at the remaining frequencies listed in the table.

9. Repeat steps 6 through 8 for the 2V, 20V, 200V, and

750VAC ranges, using the input voltages and limits

stated in Table 1-6.

CAUTION

Do not apply more than 400V at 50kHz,

80V at 250kHz, 40V at 500kHz, or 20V

at 1MHz, or instrument damage may

occur.

10. Set input coupling to AC+DC, then repeat the procedure

for a 20Hz input signal.

Table 1-5

Limits for AC peak voltage verification

2002

ACV

range

200mV 100mV 139.9mV

2V 1V 1.407V

20V 10V 13.99V

200V 100V 140.7V

Applied

voltage*

20Hz† 5kHz 25kHz 50kHz 100kHz 250kHz 500kHz 750kHz 1MHz

139.9mV

to

142.9mV

to

142.9mV

1.407V

to

1.421V

to

1.421V

13.99V

to

14.30V

to

14.30V

140.7V

to

142.2V

to

142.2V

750V 500V — 701.3V

to

712.9V

** Calibrator voltage is given as an RMS value. Model 2002 reading limits are peak AC values.

** CAUTION: Do not apply more than 2 × 10

† Use AC+DC input coupling for 20Hz tests only. (Use CONFIG-ACV to set coupling.)

NOTE: Limits shown include uncertainty of recommended calibrator.

7

V•Hz.

Allowable readings (1 year, 18°C to 28°C)

139.9mV

to

143.0mV

1.407V

to

1.422V

13.98V

to

14.30V

140.6V

to

142.2V

701.0V

139.8mV

to

143.0mV

1.406V

to

1.422V

13.98V

to

14.31V

140.6V

to

142.3V

139.7mV

to

143.2mV

1.405V

to

1.424V

13.97V

to

14.32V

140.5V

to

142.4V

** ** ** ** ** **

to

713.2V

138.6mV

to

144.2mV

1.394V

to

1.434V

13.86V

to

14.42V

136.5mV

to

146.4mV

1.373V

to

1.456V

13.65V

to

14.64V

132.2mV

to

150.6mV

1.330V

to

1.498V

13.22V

to

15.06V

** ** ** **

127.3mV

to

155.5mV

1.281V

to

1.547V

12.73V

to

15.55V

1-10

Page 22

Performance Verification

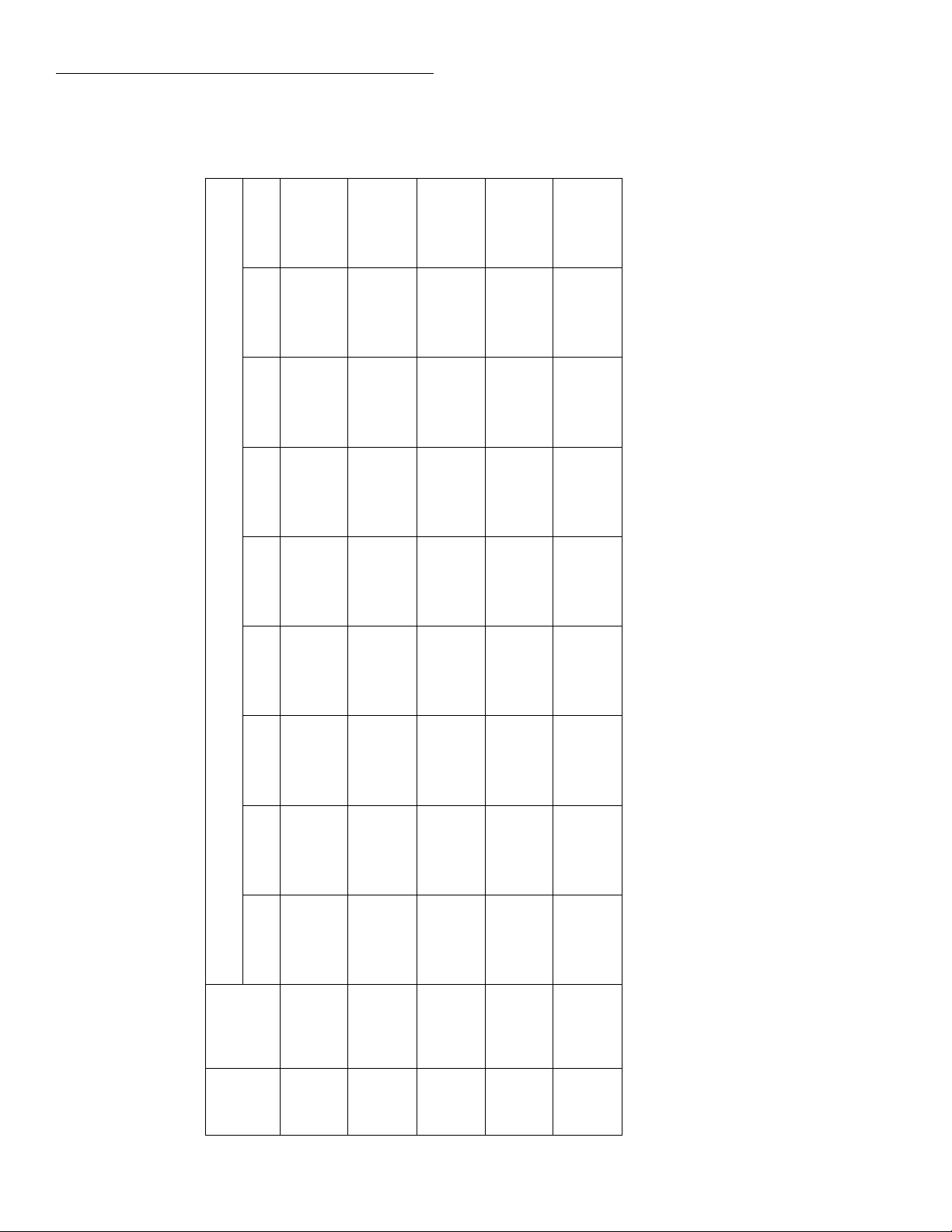

1.8.3 DC current verification

DC current accuracy is checked by applying accurate DC

currents from a calibrator to the instrument AMPS input and

then verifying that the current readings fall within appropriate limits.

Follow the steps below to verify DCI measurement accuracy.

CAUTION

Do not apply more than 2A, 250V to the

AMPS input, or the amps protection

fuse will blow.

1. Connect the Model 2002 to the calibrator, as shown in

Figure 1-4. Be sure to connect calibrator HI to the

AMPS input, and connect calibrator LO to INPUT LO

as shown.

2. Turn on the Model 2002 and the calibrator, and allow a

one-hour warm-up period before making measurements. Be sure the calibrator is set for normal current

output.

3. Restore Model 2002 factory default conditions, as

explained in paragraph 1.7.

4. Set digital filter averaging as follows:

A. From normal display, press CONFIG then DCI.

B. Select FILTER, then press ENTER.

C. Select AVERAGING, then press ENTER.

D. Using the cursor and range keys, set the averaging

parameter to 10 readings, then press ENTER.

E. Press EXIT as necessary to return to normal display.

5. Select the DC current function (DCI) and the 200µA

range on the Model 2002. (If the FILT annunciator is off,

press the FILTER key to enable the filter.)

6. Set the calibrator output to +190.0000µADC, and allow

the reading to settle.

7. Verify that the Model 2002 reading is within the limits

summarized in Table 1-6.

8. Repeat steps 6 and 7 for the remaining ranges and currents listed in Table 1-6.

9. Repeat the procedure for each of the ranges with negative currents of the same magnitude as those listed in

Table 1-6.

Table 1-6

Limits for DC current verification

2002

DCI

range

Applied DC

current

Reading limits

(1 year, 18°C to 28°C)

200µA 190.0000µA 189.9010µA to 190.0990µA

2mA 1.900000mA 1.899114mA to 1.900886mA

20mA 19.00000mA 18.99085mA to 19.00915mA

200mA 190.0000mA 189.8816mA to 190.1184mA

2A 1.900000A 1.898108A to 1.901892A

NOTES:

1. Repeat procedure for negative currents.

2. Reading limits shown include total absolute uncertainty of recom-

mended calibrator (see Table 1-1) and factory calibration uncertainty

(see specifications).

Model 2002

19.00000 mADC

2002 MULTIMETER

Figure 1-4

Connections for DC current verification

Input

LO

Amps

5700A Calibrator (Output DC Current)

Output HI

Output

LO

Note: Be sure calibrator is set for

normal current output.

1-11

Page 23

Performance Verification

1.8.4 AC current verification

AC current verification is performed by applying accurate

AC currents at specific frequencies and then verifying that

Model 2002 readings fall within specified limits.

Follow the steps below to verify ACI measurement accuracy.

CAUTION

Do not apply more than 2A, 250V to the

AMPS input, or the current protection

fuse will blow.

1. Connect the Model 2002 to the calibrator, as shown in

Figure 1-5. Be sure to connect calibrator HI to the

AMPS input, and connect calibrator LO to INPUT LO

as shown.

Model 2002

190.000 µAAC RMS

2002 MULTIMETER

Input

LO

Output HI

2. Turn on the Model 2002 and the calibrator, and allow a

one-hour warm-up period before making measurements. Be sure the calibrator is set for normal current

output.

3. Restore Model 2002 factory default conditions, as

explained in paragraph 1.7.

4. Select the AC current function and the 200µA range on

the Model 2002.

5. Set the calibrator output to 190.000µA AC at a frequency of 40Hz, and allow the reading to settle.

6. Verify that the Model 2002 reading is within the limits

for the present current and frequency summarized in

Table 1-7.

7. Repeat steps 5 and 6 for each frequency listed in Table

1-7.

8. Repeat steps 5 through 7 for the remaining ranges and

frequencies listed in Table 1-7.

5700A Calibrator (Output AC Current)

Figure 1-5

Connections for AC current verification

Amps

Output

LO

Note: Be sure calibrator is set for

normal current output.

1-12

Page 24

Table 1-7

Limits for AC current verification

Performance Verification

2002 ACI

range

200µA 190.000µA 188.260mV

2mA 1.90000mA 1.88355V

20mA 19.0000mA 18.8355V

200mA 190.000mA 188.355V

2A 1.90000A 1.88250V

NOTE: Reading limits shown include total absolute uncertainty of recommended calibrator (see Table 1-1).

Applied AC

current

40Hz 100Hz 1kHz 10kHz

to

191.740mV

to

1.91645V

to

19.1645V

to

191.645V

to

1.91750V

1.8.5 Resistance verification

Resistance verification is performed by connecting accurate

resistance values to the instrument and verifying that Model

2002 resistance readings are within stated limits.

Follow the steps below to verify resistance measurement

accuracy.

CAUTION

Do not apply more than 1100V peak

between INPUT HI and LO or more

than 150V peak between SENSE HI and

LO, or instrument damage may occur.

20Ω – 2M range verification

1. Using shielded 4-wire connections, connect the Model

2002 to the calibrator, as shown in Figure 1-6. Be sure

to connect calibrator HI and LO terminals to the Model

2002 HI and LO terminals (including SENSE HI and

LO) as shown.

2. Turn on the Model 2002 and the calibrator, and allow a

four-hour warm-up period before making

measurements.

3. Set the calibrator for 4-wire resistance (external sense

on).

4. Restore Model 2002 factory default conditions, as

explained in paragraph 1.7.

Reading limits (1 year, 18°C to 28°C)

189.562mV

to

190.439mV

1.89657V

to

1.90344V

18.9657V

to

19.0344V

189.657V

to

190.344V

1.89552V

to

1.90449V

5. Set Model 2002 operating modes as follows:

A. From normal display, press CONFIG then Ω4.

B. Select SPEED, then press ENTER.

C. Select HIACCURACY, then press ENTER.

D. Select FILTER, then press ENTER.

E. Select AVERAGING, then press ENTER.

F. Using the cursor and range keys, set the averaging

parameter to 10 readings, then press ENTER.

G. Select OFFSETCOMP, then press ENTER.

H. Select ON, then press ENTER. (Note that OFFSET-

COMP cannot be used with the 200kΩ and 2MΩ

ranges.)

I. Press EXIT to return to normal display.

6. Select the Ω4 function, and place the instrument on the

20Ω range. (If the FILT annunciator is off, press the

FILTER key to enable the filter.)

7. Set the calibrator to output 19Ω, and allow the reading

to settle. Verify that the reading is within the limits stated in Table 1-8.

Resistance values available in the Model

5700A calibrator may be slightly different

than the stated nominal resistance values.

Limits stated in Table 1-8 should be recalculated based on actual calibrator resistance values.

189.210mV

to

190.790mV

1.89742V

to

1.90258V

18.9742V

to

19.0258V

189.742V

to

190.258V

1.89390V

to

1.90610V

NOTE

189.020mV

to

190.980mV

1.89742V

to

1.90258V

18.9742V

to

19.0258V

189.685V

to

190.315V

1.89105V

to

1.90895V

1-13

Page 25

Performance Verification

8. Set the calibrator output to 190Ω, and allow the reading

to settle.

9. Verify that the reading is within the limits stated in Table

1-8. (NOTE: Recalculate limits if calibrator resistance is

not exactly as listed.)

10. Repeat steps 8 and 9 for the 2kΩ through 2MΩ ranges

using the values listed in Table 1-8. (Do not use offset

compensation for the 200kΩ and 2MΩ ranges.)

20MΩ and 200MΩ range verification

1. Connect the DC calibrator and Model 2002 using the 2wire connections shown in Figure 1-7.

2. Set the calibrator to the 2-wire mode (external sense

off).

3. Set Model 2002 operating modes as follows:

Sense HI

Sense HI

Model 2002

Input HI

1.90000000 kΩ OCmp

2002 MULTIMETER

Output HI

A. From normal display, press CONFIG then Ω2.

B. Select SPEED, then press ENTER.

C. Select HIACCURACY, then press ENTER.

D. Select FILTER, then press ENTER.

E. Select AVERAGING, then press ENTER.

F. Using the cursor and range keys, set the averaging

parameter to 10 readings, then press ENTER.

G. Press EXIT to return to normal display.

4. Select the Model 2002 Ω2 function, and change to the

20MΩ range. (If the FILT annunciator is off, press the

FILTER key to enable the filter.)

5. Set the calibrator to output 19MΩ, and allow the reading

to settle.

6. Verify that the reading is within the limits for the 20MΩ

range stated in Table 1-8. (NOTE: Recalculate limits if

actual calibrator resistance differs from value shown.)

7. Repeat steps 4 through 6 for the 200MΩ range (output

100MΩ).

5700A Calibrator (Output 4-wire Resistance)

Input

LO

Sense LO

Note : Use shielded cables to minimize noise.

Enable calibrator external sense mode.

Output

LO

Figure 1-6

Connections for resistance verification (20Ω-2MΩ ranges)

Model 2002

Input HI

19.0000000 MΩ

2002 MULTIMETER

Input

LO

Note: Use shielded cable to minimize noise.

Disable calibrator external sense mode.

Figure 1-7

Connections for resistance verification (20MΩ and 200MΩ ranges)

Output HI

Output

LO

Sense LO

5700A Calibrator (Output 2-Wire Resistance)

1-14

Page 26

Performance Verification

Table 1-8

Limits for resistance verification (20Ω-200MΩ ranges)

Nominal

2002 Ω

range

applied

resistance

Reading limits

(1 year, 18°C to 28°C)

20Ω 19Ω 18.9985025Ω to 19.0014975Ω

200Ω 190Ω 189.991277Ω to 190.008723Ω

2kΩ 1.9kΩ 1.89994714kΩ to 1.90005286kΩ

20kΩ 19kΩ 18.9994638kΩ to 19.0005362kΩ

200kΩ 190kΩ 189.989313kΩ to 190.010687kΩ

2MΩ 1.9MΩ 1.89981109MΩ to 1.90018891MΩ

20MΩ 19MΩ 18.9940619MΩ to 19.0059381MΩ

200MΩ 100MΩ 99.930910MΩ to 100.069090MΩ

Notes:

1. Limits shown include total absolute calibrator uncertainty (see Table

1-1) and factory calibration uncertainty (see specifications), and are

based on nominal calibration values shown. Recalculate limits using

Model 2002 relative accuracy specifications, factory calibration uncertainty, and calibrator absolute uncertainty if calibrator resistance values differ from nominal values shown.

2. Use 4-wire connections and function for 20Ω-2MΩ ranges. Use 2wire connections and function for 20MΩ and 200MΩ ranges.

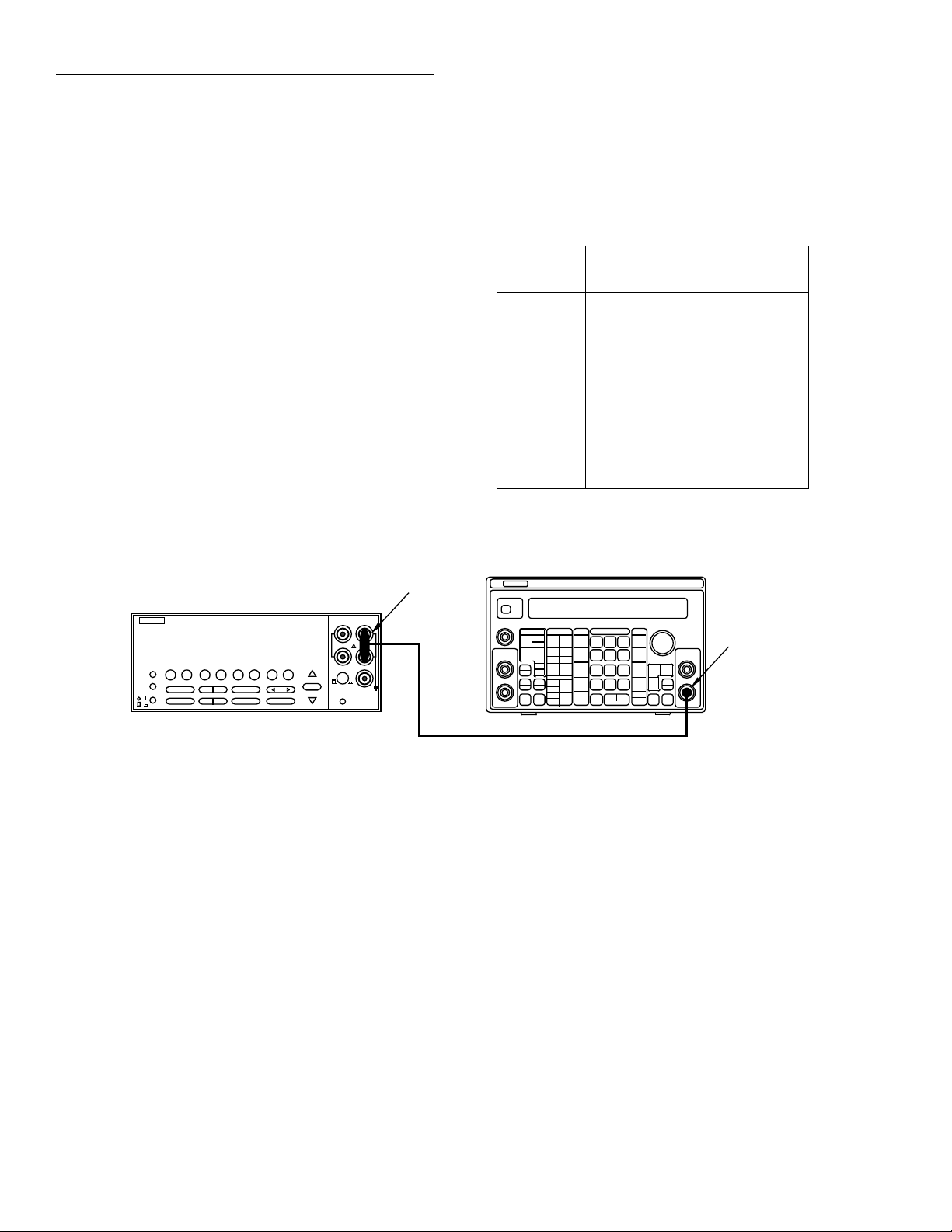

1GΩ range verification

1. Mount the 1GΩ resistor and the banana plugs to the test

box, as shown in Figure 1-8. Be sure to mount the

banana plugs with the correct spacing. The resistor

should be completely enclosed in and shielded by the

metal test box. The resistor LO lead should be electrically connected to the test box to provide adequate

shielding.

1GΩ Resistor (Keithley

part # R-289-1G)

Insulated

Plug

HI

0.75"

LO

Banana

Plugs

Non-insulated Plug

Note: Resistor must be accurately characterized

before use (see text).

Metal

Test Box

Figure 1-8

1GΩ resistor test box construction

2. Characterize the 1GΩ resistor to within ±1,000ppm or

better using an accurate megohm bridge or similar

equipment. Record the characterized value where indicated in Table 1-9. Also compute the limits based on the

value of R using the formula at the bottom of the table.

NOTE

The actual value of the 1GΩ resistor

should not exceed 1.05GΩ.

3. Set Model 2002 operating modes as follows:

A. From normal display, press CONFIG then Ω2.

B. Select SPEED, then press ENTER.

C. Select HIACCURACY, then press ENTER.

D. Select FILTER, then press ENTER.

E. Select AVERAGING, then press ENTER.

F. Using the cursor and range keys, set the averaging

parameter to 10 readings, then press ENTER.

G. Press EXIT to return to normal display.

4. Select the 2-wire ohms function (Ω2) and the 1GΩ

range on the Model 2002. (If the FILT annunciator is off,

press the FILTER key to enable the filter.)

5. Connect the 1GΩ resistor test box (from steps 1 and 2)

to the INPUT HI and LO terminals of the Model 2002.

(Be sure that the box shield is connected to INPUT LO.)

Allow the reading to settle.

6. Verify that the Model 2002 reading is within the limits

you calculated and recorded in Table 1-9.

Table 1-9

Limits for resistance verification (1GΩ range)

Characterized

resistor (R)

Reading limits

(1 year, 18°C to 28°C)

_________ GΩ _________ GΩ to _________ GΩ

* 1 year limits = R ± (0.002065R + 15,000)Ω

Where R = characterized value of 1GΩ resistor in ohms.

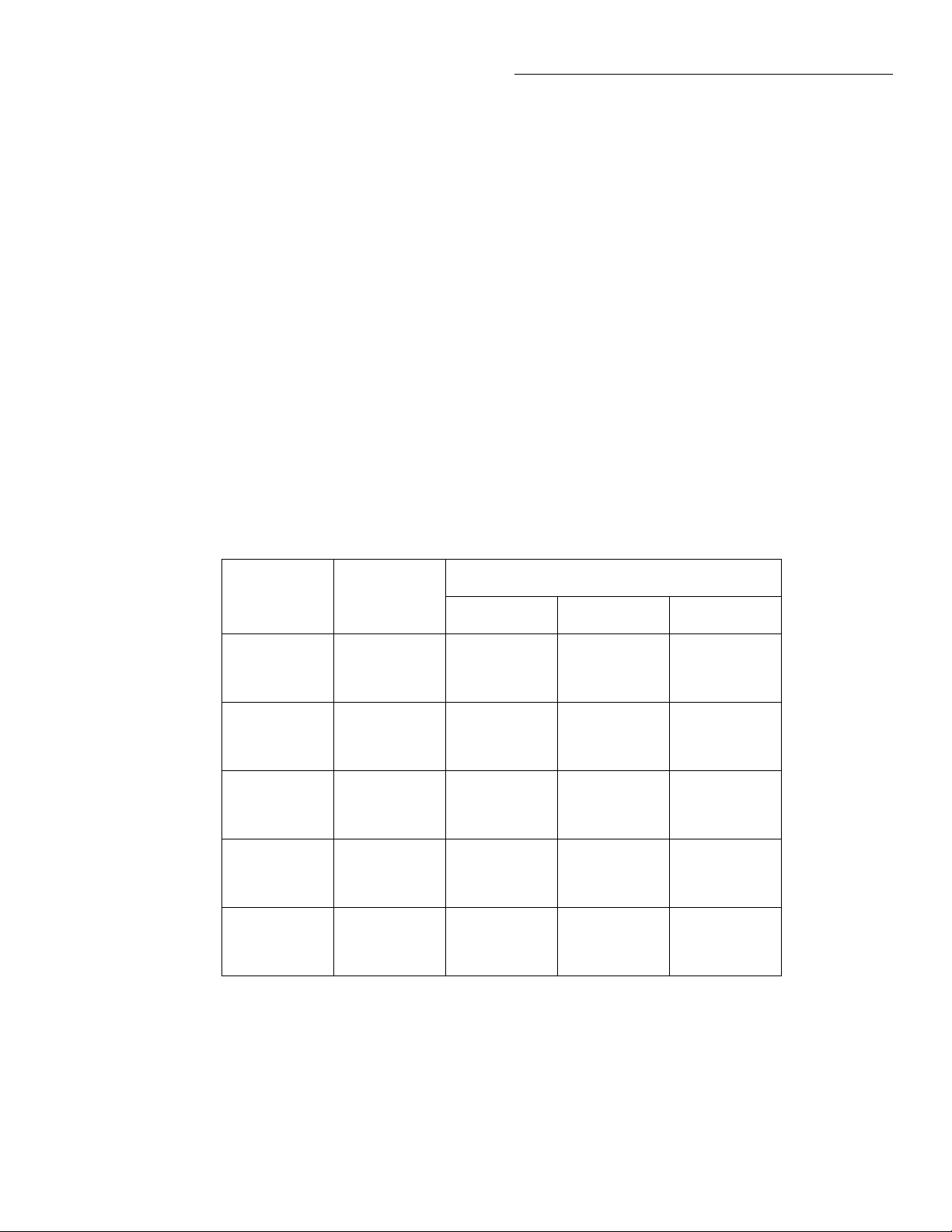

1.8.6 Frequency accuracy verification

Frequency accuracy verification is performed by connecting

an accurate frequency source to Model 2002 inputs, and then

verifying that the frequency readings are within stated limits.

Use the procedure below to verify the frequency measurement accuracy of the Model 2002.

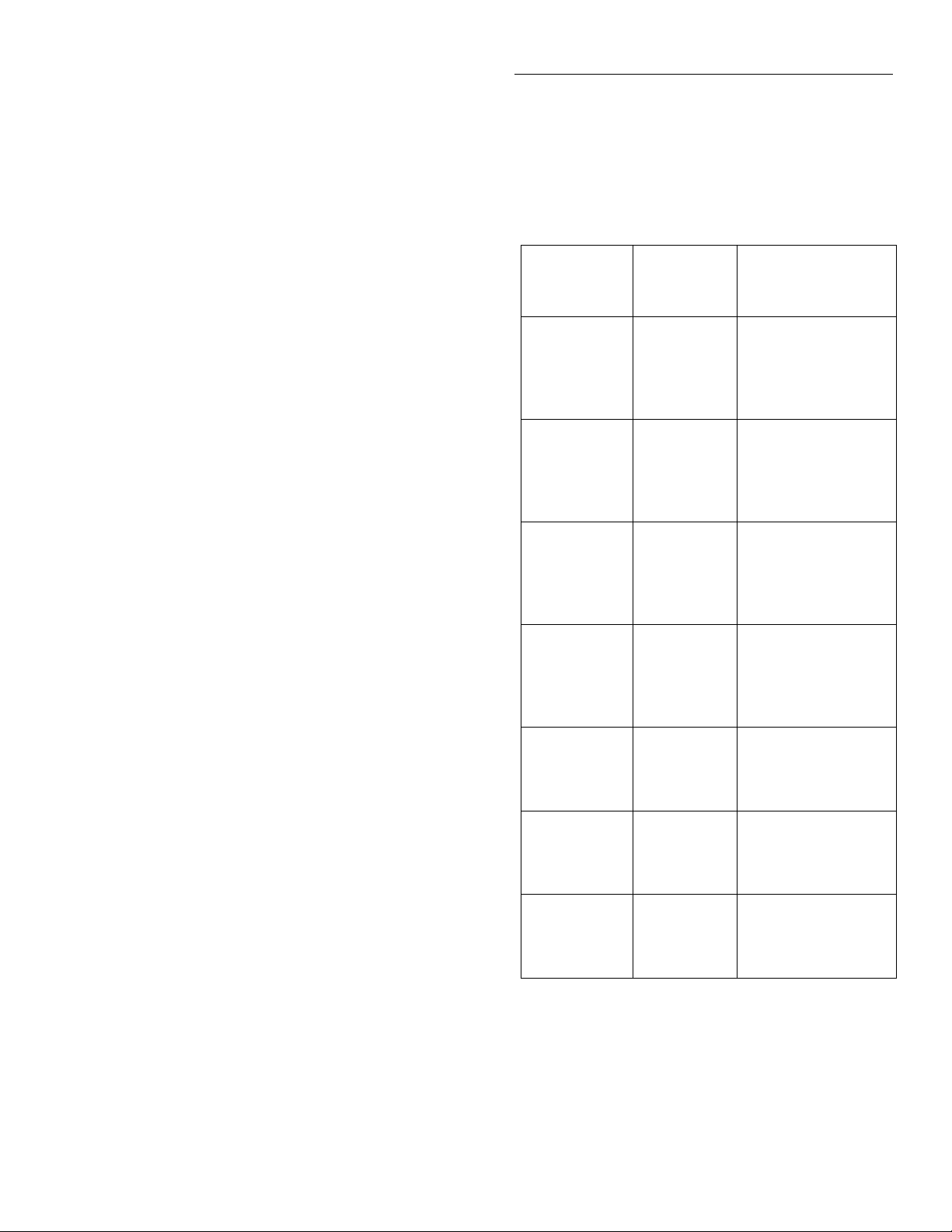

1. Connect the frequency synthesizer to the Model 2002

INPUT terminals, as shown in Figure 1-9.

2. Turn on both instruments, and allow a one-hour warmup period before measurement.

1-15

Page 27

Performance Verification

3. Set the synthesizer operating modes as follows:

FREQ: 1Hz

AMPTD: 5V p-p

OFFSET: 0V

MODE: CONT

FCTN: sine

4. Restore Model 2002 factory defaults, as explained in

paragraph 1.7.

5. Set maximum signal level to 10V as follows:

A. Press CONFIG then FREQ.

B. Select MAX-SIGNAL-LEVEL, then press ENTER.

C. Choose 10V, then press ENTER.

D. Press EXIT to return to normal display.

6. Press the FREQ key to select the frequency function.

7. Verify that the Model 2002 frequency reading is within

the limits shown in the first line of Table 1-10.

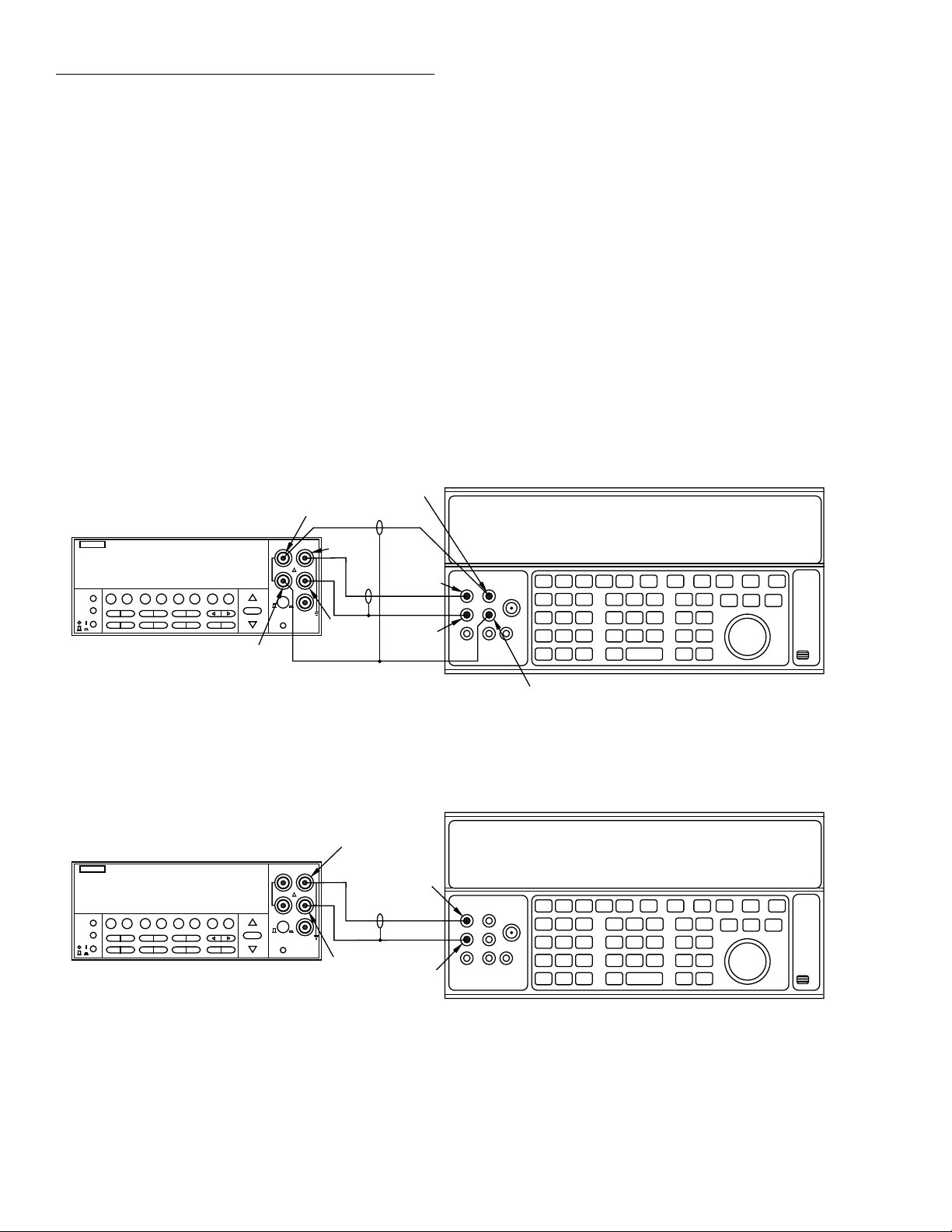

BNC-to-Dual

Banana Plug

Model 2002

1.0000 MHz

Adapter

8. Set the synthesizer to each of the frequencies listed in

Table 1-10, and verify that the Model 2002 frequency

reading is within the required limits.

Table 1-10

Frequency verification limits

Synthesizer

frequency

Reading limits

(1 year, 18°C to 28°C)

1Hz 0.9997Hz to 1.0003Hz

10Hz 9.9970Hz to 10.003Hz

100Hz 99.970Hz to 100.03Hz

1kHz 0.9997kHz to 1.0003kHz

10kHz 9.9970kHz to 10.003kHz

100kHz 99.970kHz to 100.03kHz

1MHz 0.9997MHz to 1.0003MHz

10MHz 9.9970MHz to 10.003MHz

15MHz 14.996MHz to 15.004MHz

Model 3930A or 3940 Synthesizer

Main

Function

Output

Figure 1-9

Connections for frequency accuracy verification

1-16

50Ω BNC Coaxial Cable

Page 28

Performance Verification

1.8.7 Temperature reading checks

When using thermocouples, the Model 2002 displays temperature by measuring the DC thermocouple voltage, and

then calculating the corresponding temperature. Similarly,

the instrument computes RTD temperature readings by measuring the resistance of the RTD probe and calculating temperature from the resistance value.

Since the instrument computes temperature from DCV and

resistance measurements, verifying the accuracy of those

DCV and resistance measurement functions guarantees the

accuracy of corresponding temperature measurements.

Thus, it is not necessary to perform a comprehensive temperature verification procedure if DCV and resistance verification procedures show the instrument meets its specifications

in those areas. However, those who wish to verify that the

Model 2002 does in fact properly display temperature can

use the following procedure to do so.

Selecting the temperature sensor

Follow the steps below to select the type of temperature

sensor:

1. From normal display, press CONFIG then TEMP.

2. Select SENSOR, then press ENTER.

3. Select 4-WIRE-RTD or THERMOCOUPLE as desired,

then press ENTER.

4. Select the type of RTD probe or thermocouple you wish

to test, then return to the CONFIG TEMPERATURE

menu.

5. Select UNITS, then press ENTER.

6. Select DEG-C, then press ENTER.

7. Press EXIT as necessary to return to normal display.

8. Press the TEMP key to place the Model 2002 in the temperature display mode. Refer to further information

below on how to check thermocouple and RTD probe

readings.

Thermocouple temperature reading checks

To check thermocouple readings, simply apply the appropriate DC voltage listed in Table 1-11 to the Model 2002 INPUT

jacks using a precision DC voltage source (such as the one

used to verify DC voltage accuracy in paragraph 1.8.1), and

check the displayed temperature reading. Be sure to use lowthermal cables for connections between the DC calibrator

and the Model 2002 when making these tests.

NOTE

The voltages shown are based on a 0°C

reference junction temperature. Use the

CONFIG-TEMP menu to set the default

reference junction temperature to 0°C.

Table 1-11

Thermocouple temperature reading checks

Reading limits

Thermocouple

type

J -7.659mV

K -5.730mV

T -5.439mV

E -8.561mV

R 0.054mV

S 0.055mV

B 0.632mV

* Voltages shown are based on ITS-90 standard using 0°C reference

junction temperature. Use CONFIG-TEMP menu to set default reference

junction to 0°C.

NOTE: Reading limits shown do not include DCV calibrator uncertainty.

Applied DC

voltage*

0mV

1.277mV

5.269mV

42.280mV

0mV

1.000mV

4.096mV

54.138mV

0mV

0.992mV

4.278mV

20.255mV

0mV

1.495mV

6.319mV

75.621mV

0.647mV

4.471mV

20.877mV

0.646mV

4.233mV

18.503mV

1.241mV

4.834mV

13.591mV

(°C) 1 year,

18°C to 28°C

-190.5 to -189.5

-0.5 to +0.5

24.5 to 25.5

99.5 to 100.5

749.5 to 750.0

-190.5 to -189.5

-0.5 to +0.5

24.5 to 25.5

99.5 to 100.5

1349.5 to 1350.5

-190.5 to -189.5

-0.5 to +0.5

24.5 to 25.5

99.5 to 100.5

389.5 to 390.5

-190.6 to -189.4

-0.6 to +0.6

24.4 to 25.6

99.4 to 100.6

989.4 to 990.6

7 to 13

97 to 103

497 to 503

1747 to 1753

7 to 13

97 to 103

497 to 503

1747 to 1753

355 to 365

495 to 505

995 to 1005

1795 to 1805

1-17

Page 29

Performance Verification

RTD temperature reading checks

Use a precision decade resistance box (see Table 1-1) to simulate probe resistances at various temperatures (Table 1-12).

Be sure to use 4-wire connections between the decade resistance box and the Model 2002.

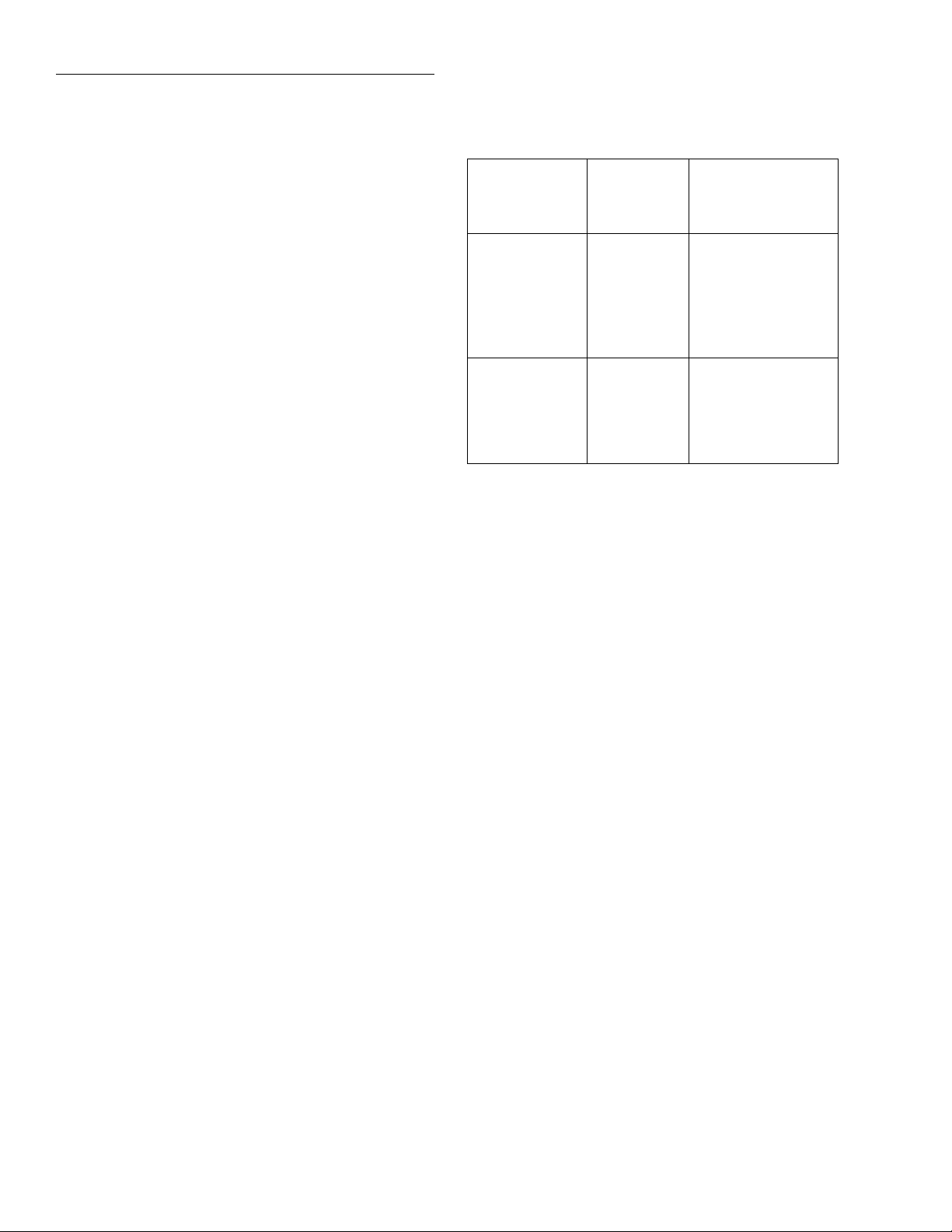

Table 1-12

RTD probe temperature reading checks

Reading limits

RTD probe

type

PT385

(α=0.00385)

PT392

(α=0.00392)

NOTE: Reading limits shown do not include uncertainty of resistance

standards.

Applied

resistance

22.80Ω

60.25Ω

100Ω

109.73Ω

138.50Ω

313.59Ω

63.68Ω

100Ω

109.90Ω

139.16Ω

266.94Ω

(°C) 1 year,

18°C to 28°C

-190.068 to -189.932

-100.021 to -99.979

-0.021 to +0.021

24.979 to 25.021

99.979 to 100.021

599.932 to 600.068

-90.021 to -89.979

-0.021 to +0.021

24.979 to 25.021

99.979 to 100.021

449.932 to 450.068

1-18

Page 30

2

Calibration

2.1 Introduction

This section gives detailed procedures for calibrating the

Model 2002. Basically, there are three types of calibration

procedures:

• Comprehensive calibration

• AC self-calibration

• Low-level calibration

Comprehensive calibration requires accurate calibration

equipment to supply precise DC voltages, DC currents, and

resistance values. AC self-calibration requires no external

equipment and can be performed at any time by the operator.

Low-level calibration is normally performed only at the factory when the instrument is manufactured and is not usually

required in the field.

NOTE

Low-level calibration is required in the

field only if the Model 2002 has been

repaired, or if the other calibration procedures cannot bring the instrument within

stated specifications.

A single-point calibration feature is also available to allow

the user to calibrate a single function or range without having

to perform the entire calibration procedure.

Section 2 includes the following information:

2.2 Environmental conditions: States the temperature

and humidity limits for calibration.

2.3 Warm-up period: Discusses the length of time the

Model 2002 should be allowed to warm up before

calibration.

2.4 Line power: States the power line voltage limits when

calibrating the unit.

2.5 Calibration lock: Explains how to unlock calibration

with the CAL switch.

2.6 IEEE-488 bus calibration commands: Summarizes

bus commands used for calibration, lists a simple calibration program, and also discusses other important

aspects of calibrating the instrument over the bus.

2.7 Calibration errors: Details front panel error messages

that might occur during calibration and also explains

how to check for errors over the bus.

2.8 Comprehensive calibration: Covers comprehensive

(user) calibration from the front panel and over the

IEEE-488 bus.

2.9 AC self-calibration: Discusses the AC user calibra-

tion process, both from the front panel and over the

IEEE-488 bus.

2.10 Low-level calibration: Explains how to perform the

low-level calibration procedure, which is normally

required only at the factory.

2.11 Single-point calibration: Outlines the basic methods

for calibrating only a single function or range instead

of having to go through the entire calibration

procedure.

2-1

Page 31

Calibration

2.2 Environmental conditions

Calibration procedures should be performed at an ambient

temperature of 23° ± 5°C, and at a relative humidity of less

than 80% unless otherwise noted.

NOTE

If the instrument is normally used over a

different ambient temperature range, calibrate the instrument at the center of that

temperature range.

If the internal temperature of the Model 2002 drifts excessively during calibration, an error will be generated. See

Appendix C for additional information.

2.3 Warm-up period

The Model 2002 must be allowed to warm up for at least four

hours before calibration. If the instrument has been subjected

to temperature extremes (outside the range stated in paragraph 2.2), allow additional time for internal temperatures to

stabilize. Typically, it takes one additional hour to stabilize a

unit that is 10°C (18°F) outside the specified temperature

range.

NOTE

Placement of the OPTION SLOT cover

affects the internal temperature of the

Model 2002. To achieve T

ifications, the OPTION SLOT cover must

be in the same position (on or off) as when

the Model 2002 is to be used.