Page 1

Model 2002 Multimeter

User’s Manual

2002-900-01 Rev. E / February 2009

www.keithley.com

EC N E D I FN OC F O E RUSA E M R E TA E R G A

Page 2

Model 2002 Multimeter

User’s Manual

©2009, Keithley Instruments, Inc.

Cleveland, Ohio, U.S.A.

All rights reserved.

Any unauthorized reproduction, photocopy, or use of the information herein, in whole or in part, without the prior written approval

of Keithley Instruments, Inc. is strictly prohibited.

TSP™, TSP-Link™, and TSP-Net™ are trademarks of Keithley Instruments, Inc. All Keithley Instruments product names are

trademarks or registered trademarks of Keithley Instruments, Inc. Other brand names are trademarks or registered trademarks of

their respective holders.

Document Number: 2002-900-01 Rev. E/ February 2009

Page 3

The following safety precautions should be observed before using this product and any associated instrumentation. Although some

instruments an d access ories would n ormally be used with non-h azardous voltag es, there are situ ations where h azardous condition s may

be present.

This product is inte nded for us e by qual ified person nel who recognize s hock haz ards and are famili ar with the s afety prec autions requ ired

to avoid possible in jury. Rea d and fo llow all inst a llatio n, opera tion, an d mai ntenanc e info rmatio n carefu lly b efore us ing the product. Ref er

to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Safety Precautions

Responsible body i

operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators

They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel

replacing consuma ble ma terials . Main tenanc e proc edures are descri bed in t he u ser docum ent ation. The proced ures expl icitly st ate if th e

operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained service

personnel may perform installation and service procedures.

Keithley Instruments products are designed for use with electrical signals that are rated Measurement Category I and Measurement

tegory II, as described in the International Electrotechnical Commission (IEC) Standard IEC 60664. Most measurement, control, and

Ca

data I/O signals are Measurement Ca tegory I and must not be dire ctly connected to ma ins voltag e or to voltage sourc es with high transient

over-voltages. Measurement Category II connections require protection for high transient over-voltages often associated with local AC

mains connect ions. Assume all measurement, co ntrol, and dat a I/O connec tions are for conn ection to Cate gory I sources u nless otherwise

marked or described in the user documentation.

Exercise extreme caution when a shock hazard is present. Lethal vo

American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than 30V RMS, 42.4V peak,

or 60VDC are present. A good safety practice is to expect that hazardous voltage is present in any unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators are

p

revented access and /or insulate d from every connection point. In some case s, connect ions must b e exposed to potential human contact.

Product operators in th ese ci rcu ms t ances must be train ed t o p r otec t themselves from the ri sk of electric shock. If the ci rcu it is capable of

operating at or above 1000V, no conductive part of the circuit may be exposed.

use the product for its inten ded function. T hey must be trained in e lectrical safe ty procedures a nd proper us e of the inst rument.

s the individual or group responsible for the use and maintenance of equipment, for ensuring that the equipment is

perform routine procedures on the produ ct to keep it operatin g p rop erly, for example, setting the li ne v oltage or

ltage may be present on cable connector jacks or test fixtures. The

Do not connect switc hing cards direc tly to unlim ited power circui ts. They ar e intended to b e used with im pedance-lim ited sources

connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current

and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the conne

cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

. NEVER

cting

11/07

Page 4

When installing equipment wh ere access to the main power cord is restricted, such as rack mounting, a separate main input power

!

disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under te

AL W AYS remove powe r from the entire te st system and d ischarge an y capa citors before: c onnecting or disconne cting cab les or jumpers,

installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any o bject that could pro vide a c urrent p ath to the com mon sid e of the c ircuit under t est or p ower line (e arth) gro

make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions, or the safety of the

equipment may be impaired.

Do not exceed the maxi mum s ignal levels of the ins tru ment s and acces sories , as defi ned in th e spec ifica tion s and op erating inform

and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the

interlock.

If a screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

The symbol on an instrument indicates that the user should refer to the operating instructions located in the user documentation.

The symbol on an instrument shows that it can source or measure 1000V or more, including the combined effect of normal and

common mode voltages. Use standard safety precautions to avoid personal contact with these voltages.

st.

und. Always

ation,

use of a lid

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

If this symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp must be properly

disposed of according to federal, state, and local laws.

ARNING heading in the user documentation explains dangers that might result in personal injury or death. Always read the

The W

associated information very carefully before performing the indicated procedure.

The CA

warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

T o main tain protecti on from electric sho ck and fire, replacem ent component s in mains circu its - includi ng the power trans former , tes

and input jacks - must be purchased from Keithley Instruments. Standard fuses with applicable national safety approvals may be used if

the rating and type are the same. Other components that are not safety-related may be purchased from other suppliers as long as they

are equivalent to the original component (note that selected parts should be purchased only through Keithley Instruments to maintain

accuracy and function ality of the product). If you ar e unsure about the applicabi lity of a replacement co mponent, call a Keithley Ins truments

office for information.

To clean an instrument, use a damp cloth or mild, water-based cleaner. Clean the exterior of the instrument only. Do not apply cl

directly to the instrumen t or allow liqui ds to enter or spi ll on the inst rument. Produ cts tha t consist of a circuit board wi th no case or chassis

(e.g., a data acquisition board for installation into a computer) should never require cleaning if handled according to instructions. If the

board becomes contaminated and operation is affected, the board should be returned to the factory for proper cleaning/servicing.

UTION heading in th e u se r documentation e xp lains hazards that could damage the i nst rum ent . Such damage may inv al ida te the

t leads,

eaner

Page 5

Table of Contents

1 General Information

1.1 Introduction ........................................................................................................................................................ 1-1

1.2 Features .............................................................................................................................................................. 1-1

1.3 Warranty information ......................................................................................................................................... 1-2

1.4 Manual addenda ................................................................................................................................................. 1-2

1.5 Safety symbols and terms .................................................................................................................................. 1-2

1.6 Specifications ..................................................................................................................................................... 1-2

1.7 Inspection ........................................................................................................................................................... 1-2

1.8 Options and accessories ..................................................................................................................................... 1-2

2 Front Panel Operation

2.1 Introduction ........................................................................................................................................................ 2-1

2.2 Power-up ............................................................................................................................................................ 2-1

2.2.1 Line power connections ............................................................................................................................. 2-1

2.2.2 Line fuse replacement ................................................................................................................................ 2-2

2.2.3 Power-up sequence .................................................................................................................................... 2-2

2.2.4 High energy circuit safety precautions ....................................................................................................... 2-4

2.2.5 Power-on default conditions ...................................................................................................................... 2-4

2.2.6 Warm-up period ......................................................................................................................................... 2-4

2.2.7 IEEE-488 primary address ......................................................................................................................... 2-4

2.3 Display ............................................................................................................................................................... 2-4

2.3.1 Multiple displays ........................................................................................................................................ 2-4

2.3.2 Information messages ................................................................................................................................ 2-7

2.3.3 Status and error messages .......................................................................................................................... 2-7

2.3.4 Navigating menus ...................................................................................................................................... 2-9

2.4 Functions ............................................................................................................................................................ 2-9

2.4.1 DC and AC voltage .................................................................................................................................... 2-9

2.4.2 DC and AC current .................................................................................................................................. 2-23

2.4.3 Two and four-wire resistance ................................................................................................................... 2-28

2.4.4 Frequency ................................................................................................................................................. 2-32

2.4.5 Temperature ............................................................................................................................................. 2-33

2.5 Range ............................................................................................................................................................... 2-40

2.5.1 Display resolution .................................................................................................................................... 2-40

2.5.2 Maximum readings .................................................................................................................................. 2-40

2.5.3 Manual ranging ........................................................................................................................................ 2-40

2.5.4 Autoranging ............................................................................................................................................. 2-40

2.6 Relative ............................................................................................................................................................ 2-40

2.6.1 Configuring rel ......................................................................................................................................... 2-41

2.6.2 Enabling rel .............................................................................................................................................. 2-41

i

Page 6

2.6.3 Multiple display of rel .............................................................................................................................. 2-41

2.7 Triggers ............................................................................................................................................................. 2-41

2.7.1 Trigger model ........................................................................................................................................... 2-41

2.7.2 Configuring the measure layer ................................................................................................................. 2-46

2.7.3 Configuring the scan layer ........................................................................................................................ 2-48

2.7.4 Configuring the arm layer ........................................................................................................................ 2-49

2.7.5 Halting triggers ......................................................................................................................................... 2-50

2.7.6 External triggering .................................................................................................................................... 2-50

2.7.7 Trigger Link .............................................................................................................................................. 2-53

2.8 Buffer ................................................................................................................................................................ 2-64

2.8.1 Burst mode ................................................................................................................................................ 2-65

2.8.2 Configuring data storage .......................................................................................................................... 2-67

2.8.3 Storing and recalling readings .................................................................................................................. 2-69

2.8.4 Buffer multiple displays ........................................................................................................................... 2-70

2.9 Filter ................................................................................................................................................................. 2-71

2.9.1 Filter types ................................................................................................................................................ 2-71

2.9.2 Filter modes .............................................................................................................................................. 2-71

2.9.3 Response time ........................................................................................................................................... 2-73

2.9.4 Auto filtering ............................................................................................................................................ 2-73

2.9.5 Configuring the filters .............................................................................................................................. 2-74

2.10 Math .................................................................................................................................................................. 2-75

2.10.1 Polynomial ................................................................................................................................................ 2-75

2.10.2 Percent ...................................................................................................................................................... 2-76

2.10.3 Percent deviation ...................................................................................................................................... 2-76

2.10.4 Selecting and configuring math ................................................................................................................ 2-76

2.10.5 Calculate multiple display ........................................................................................................................ 2-77

2.11 Scanning ........................................................................................................................................................... 2-77

2.11.1 Scanning overview ................................................................................................................................... 2-77

2.11.2 Front panel scanner controls ..................................................................................................................... 2-77

2.11.3 Using CHAN key to close and open internal channels ............................................................................ 2-78

2.11.4 Using CONFIGURE CHAN to configure channels ................................................................................. 2-79

2.11.5 Using CONFIG-SCAN to configure scanning ......................................................................................... 2-80

2.11.6 Using SCAN to configure scan parameters .............................................................................................. 2-81

2.11.7 Starting and stopping scanning ................................................................................................................. 2-83

2.11.8 Scanner operation examples ..................................................................................................................... 2-83

2.12 Menu ................................................................................................................................................................. 2-87

2.12.1 SAVESETUP ........................................................................................................................................... 2-90

2.12.2 GPIB ......................................................................................................................................................... 2-96

2.12.3 CALIBRATION ....................................................................................................................................... 2-96

2.12.4 TEST ......................................................................................................................................................... 2-97

2.12.5 LIMITS ..................................................................................................................................................... 2-97

2.12.6 STATUS-MSG ......................................................................................................................................... 2-99

2.12.7 GENERAL ............................................................................................................................................... 2-99

3 IEEE-488 Reference

3.1 Introduction ........................................................................................................................................................ 3-1

3.2 IEEE-488 bus connections ................................................................................................................................. 3-1

3.3 Primary address selection ................................................................................................................................... 3-2

3.4 QuickBASIC 4.5 programming .......................................................................................................................... 3-3

3.5 General bus commands ....................................................................................................................................... 3-4

3.5.1 REN (remote enable) .................................................................................................................................. 3-4

3.5.2 IFC (interface clear) ................................................................................................................................... 3-4

ii

Page 7

3.5.3 LLO (local lockout) ................................................................................................................................... 3-4

3.5.4 GTL (go to local) ....................................................................................................................................... 3-5

3.5.5 DCL (device clear) ..................................................................................................................................... 3-5

3.5.6 SDC (selective device clear) ...................................................................................................................... 3-5

3.5.7 GET (group execute trigger) ...................................................................................................................... 3-5

3.5.8 SPE, SPD (serial polling) ........................................................................................................................... 3-5

3.6 Front panel aspects of IEEE-488 operation ....................................................................................................... 3-5

3.6.1 Error and status message ............................................................................................................................ 3-5

3.6.2 IEEE-488 status indicators ......................................................................................................................... 3-5

3.6.3 LOCAL key ................................................................................................................................................ 3-6

3.7 Status structure ................................................................................................................................................... 3-6

3.7.1 Condition registers ..................................................................................................................................... 3-8

3.7.2 Transition filters ......................................................................................................................................... 3-8

3.7.3 Event registers ............................................................................................................................................ 3-8

3.7.4 Enable registers .......................................................................................................................................... 3-8

3.7.5 Queues ...................................................................................................................................................... 3-16

3.7.6 Status byte and service request (SRQ) ..................................................................................................... 3-16

3.8 Trigger model (IEEE-488 operation) ............................................................................................................... 3-18

3.9 Programming syntax ........................................................................................................................................ 3-23

3.10 Common commands ........................................................................................................................................ 3-29

3.10.1 *CLS — clear status ................................................................................................................................ 3-29

3.10.2 *ESE <NRf> — event enable .................................................................................................................. 3-30

*ESE? — event enable query ................................................................................................................... 3-30

3.10.3 *ESR? — event status register query ....................................................................................................... 3-31

3.10.4 *IDN? — identification query ................................................................................................................. 3-32

3.10.5 *OPC — operation complete ................................................................................................................... 3-33

3.10.6 *OPC? — operation complete query ....................................................................................................... 3-34

3.10.7 *OPT? — option identification query ...................................................................................................... 3-35

3.10.8 *RCL — recall ......................................................................................................................................... 3-35

3.10.9 *RST — reset ........................................................................................................................................... 3-36

3.10.10 *SAV — save ........................................................................................................................................... 3-36

3.10.11 *SRE <NRf> — service request enable ................................................................................................... 3-36

*SRE? — service request enable query ................................................................................................... 3-36

3.10.12 *STB? — status byte query ..................................................................................................................... 3-38

3.10.13 *TRG — trigger ....................................................................................................................................... 3-39

3.10.14 *TST? — self-test query .......................................................................................................................... 3-39

3.10.15 *WAI — wait-to-continue ....................................................................................................................... 3-40

3.11 Signal oriented measurement commands ......................................................................................................... 3-41

3.12 Calculate subsystem ......................................................................................................................................... 3-67

3.12.1 :CALCulate[1] ......................................................................................................................................... 3-67

3.12.2 :CALCulate2 ............................................................................................................................................ 3-69

3.12.3 :CALCulate3 ............................................................................................................................................ 3-71

3.13 :DISPlay subsystem ......................................................................................................................................... 3-76

3.14 :FORMat subsystem ......................................................................................................................................... 3-79

3.15 :INPut subsystem ............................................................................................................................................. 3-84

3.16 :OUTPut subsystem ......................................................................................................................................... 3-85

3.17 :ROUTe subsystem .......................................................................................................................................... 3-86

3.17.1 :CLOSe <list> .......................................................................................................................................... 3-86

3.17.2 :OPEN <list> ............................................................................................................................................ 3-86

3.17.3 :OPEN:ALL ............................................................................................................................................. 3-87

3.17.4 :SCAN commands .................................................................................................................................... 3-87

3.18 Sense subsystems ............................................................................................................................................. 3-91

3.18.1 [:SENSe[1]] subsystem ............................................................................................................................ 3-91

3.18.2 :ALTernate[1] commands ........................................................................................................................ 3-91

iii

Page 8

3.18.3 :FUNCtion <name> .................................................................................................................................. 3-91

3.18.4 :DATA commands .................................................................................................................................... 3-92

3.18.5 :APERture <n> ......................................................................................................................................... 3-93

3.18.6 :NPLCycles <n> ....................................................................................................................................... 3-94

3.18.7 :COUPling AC|DC ................................................................................................................................... 3-96

3.18.8 RANGe commands ................................................................................................................................... 3-96

3.18.9 :REFerence <n> ........................................................................................................................................ 3-99

3.18.10 :DIGits <n> ............................................................................................................................................. 3-101

3.18.11 :AVERage commands ............................................................................................................................ 3-102

3.18.12 [:FUNCTION] <name> .......................................................................................................................... 3-105

3.18.13 :PWINdow <n> ...................................................................................................................................... 3-106

3.18.14 :METHod <name> ................................................................................................................................. 3-106

3.18.15 :SOURce <name> ................................................................................................................................... 3-106

3.18.16 THReshold commands ........................................................................................................................... 3-107

3.18.17 :TRANsducer <name> ........................................................................................................................... 3-108

3.18.18 :RTD commands ..................................................................................................................................... 3-109

3.18.19 :TCouple:TYPE <name> ........................................................................................................................ 3-111

3.18.20 :RJUNctionX commands ........................................................................................................................ 3-112

3.18.21 :OCOMpensated <b> ............................................................................................................................. 3-114

3.18.22 :DTCouple commands ............................................................................................................................ 3-114

3.18.23 :SENSe2 subsystem ................................................................................................................................ 3-115

3.19 :SOURce subsystem ....................................................................................................................................... 3-116

3.20 :STATus subsystem ........................................................................................................................................ 3-117

3.20.1 [:EVENt]? ............................................................................................................................................... 3-117

3.20.2 :ENABle <NRf> ..................................................................................................................................... 3-122

3.20.3 :PTRansition <NRf> ............................................................................................................................... 3-125

3.20.4 :NTRansition <NRf> .............................................................................................................................. 3-132

3.20.5 :CONDition? ........................................................................................................................................... 3-134

3.20.6 :PRESET ................................................................................................................................................. 3-134

3.20.7 :QUEue commands ................................................................................................................................. 3-135

3.21 :SYSTem subsystem ....................................................................................................................................... 3-137

3.21.1 :PRESet ................................................................................................................................................... 3-137

3.21.2 :POSetup <name> ................................................................................................................................... 3-137

3.21.3 :FRSWitch? ............................................................................................................................................ 3-137

3.21.4 :VERSion? .............................................................................................................................................. 3-138

3.21.5 :ERRor? .................................................................................................................................................. 3-138

3.21.6 :AZERo commands ................................................................................................................................ 3-138

3.21.7 :AMEThod <name> ............................................................................................................................... 3-139

3.21.8 :LSYNc:STATe <b> .............................................................................................................................. 3-143

3.21.9 :KEY <NRf> .......................................................................................................................................... 3-143

3.21.10 :CLEar .................................................................................................................................................... 3-145

3.21.11 :LFRequency .......................................................................................................................................... 3-145

3.21.12 :DATE <yr>, <mo>, <day> .................................................................................................................... 3-145

3.21.13 :TIME <hr>, <min>, <sec> .................................................................................................................... 3-145

3.21.14 :TSTamp commands ............................................................................................................................... 3-146

3.21.15 :RNUMber:RESet ................................................................................................................................... 3-146

3.22 :TRACe subsystem ......................................................................................................................................... 3-147

3.22.1 :CLEar .................................................................................................................................................... 3-147

3.22.2 :FREE? ................................................................................................................................................... 3-147

3.22.3 :EGRoup <name> ................................................................................................................................... 3-147

3.22.4 :POINts <n> ........................................................................................................................................... 3-148

3.22.5 :FEED <name> ....................................................................................................................................... 3-148

3.22.6 :DATA? .................................................................................................................................................. 3-151

3.22.7 :TSTamp:FORMat <name> ................................................................................................................... 3-151

iv

Page 9

3.23 Trigger subsystem .......................................................................................................................................... 3-152

3.23.1 :INITiate commands .............................................................................................................................. 3-152

3.23.2 :ABORt .................................................................................................................................................. 3-152

3.23.3 :IMMediate ............................................................................................................................................. 3-152

3.23.4 :COUNt <n> ........................................................................................................................................... 3-153

3.23.5 :DELay <n> ............................................................................................................................................ 3-153

3.23.6 :SOURce <name> .................................................................................................................................. 3-154

3.23.7 :TIMer <n> ............................................................................................................................................. 3-154

3.23.8 :SIGNal .................................................................................................................................................. 3-155

3.23.9 TCONfigure commands ......................................................................................................................... 3-155

3.23.10 RTCLock commands ............................................................................................................................. 3-157

3.24 :UNIT subsystem ........................................................................................................................................... 3-159

A Specifications

B Interface Function Codes

C ASCII Character Codes and IEEE-488 Multiline Interface Command Messages

D IEEE-488 Bus Overview

E IEEE-488 Conformance Information

F SCPI Conformance Information

G Example Programs

H HP3458A Emulation Mode

v

Page 10

List of Illustrations

2 Front Panel Operation

Figure 2-1 Bar graph (zero-at-left) multiple display .................................................................................................... 2-6

Figure 2-2 Zero-centered bar graph multiple display .................................................................................................. 2-6

Figure 2-3 Maximum and minimum multiple display ................................................................................................. 2-7

Figure 2-4 Positive and negative peak spikes ............................................................................................................ 2-15

Figure 2-5 DC voltage multifunction multiple displays ............................................................................................ 2-16

Figure 2-6 AC voltage multifunction multiple displays ............................................................................................ 2-20

Figure 2-7 DC in-circuit current measurements ........................................................................................................ 2-26

Figure 2-8 AC current multifunction multiple displays ............................................................................................. 2-28

Figure 2-9 3-wire RTD temperature measurements .................................................................................................. 2-34

Figure 2-10 2-wire RTD temperature measurements .................................................................................................. 2-35

Figure 2-11 Temperature equations ............................................................................................................................. 2-38

Figure 2-12 Trigger model (front panel operation) ...................................................................................................... 2-44

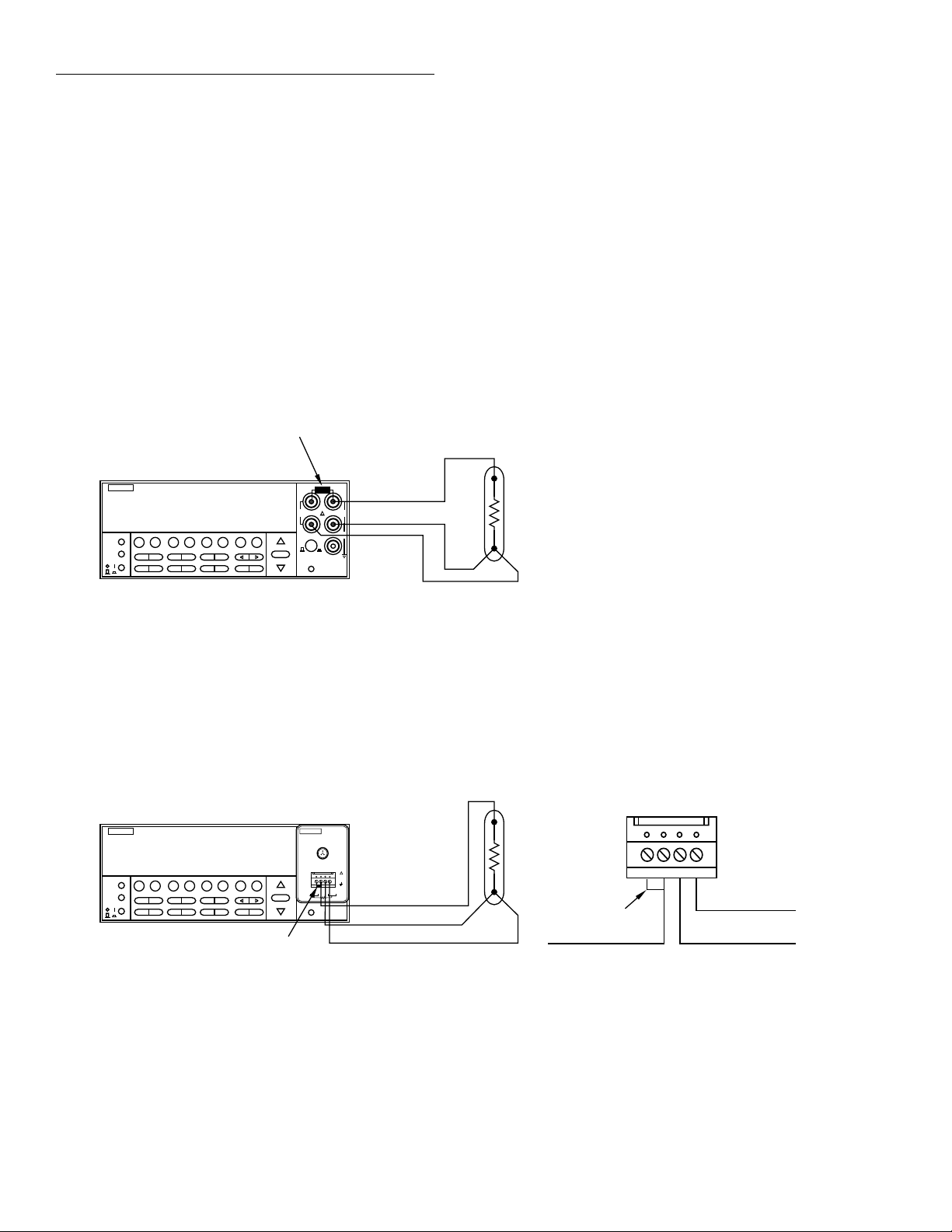

Figure 2-13 External triggering connectors (BNC) ..................................................................................................... 2-50

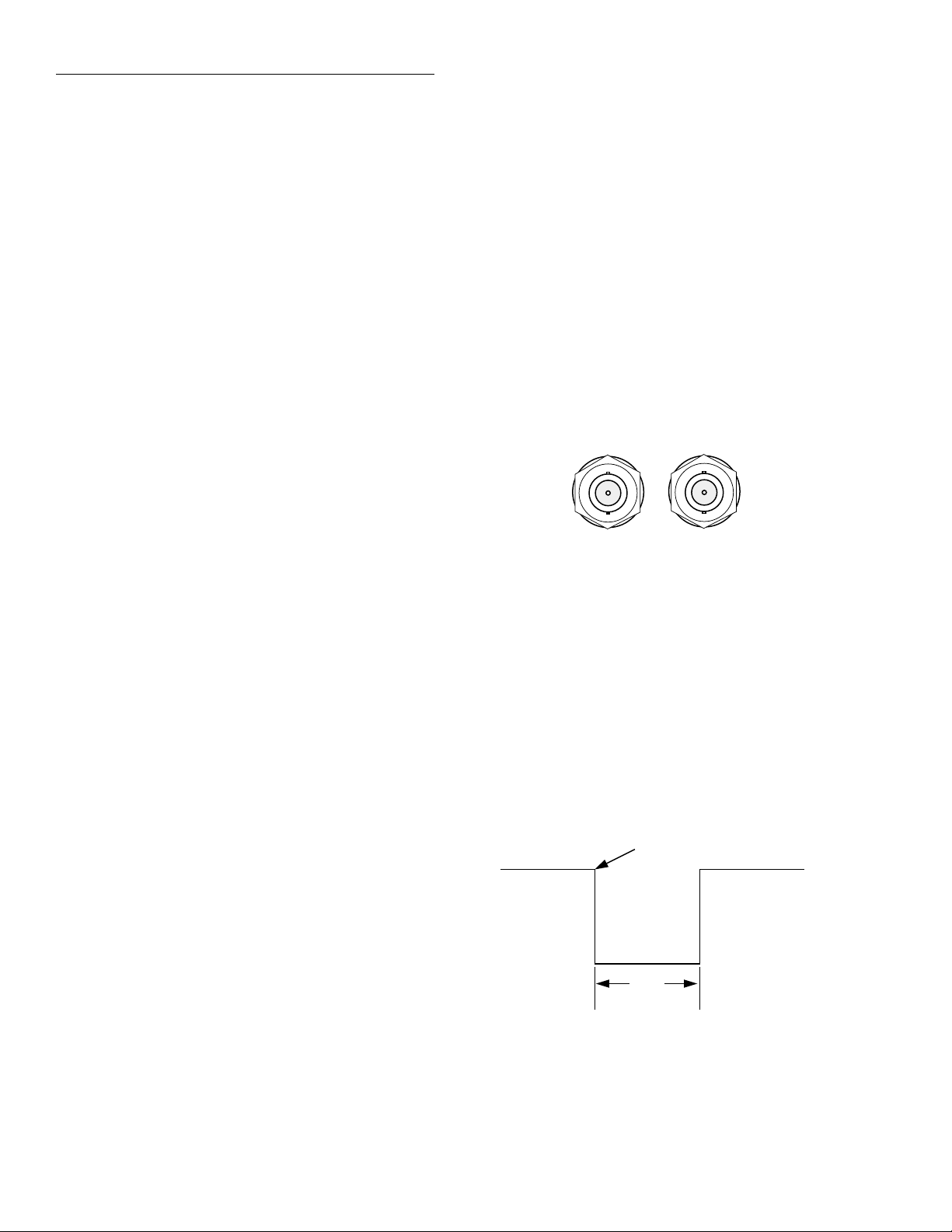

Figure 2-14 External triggering and asynchronous trigger link input pulse specifications ......................................... 2-50

Figure 2-15 Meter complete and asynchronous trigger link output pulse specifications ............................................ 2-51

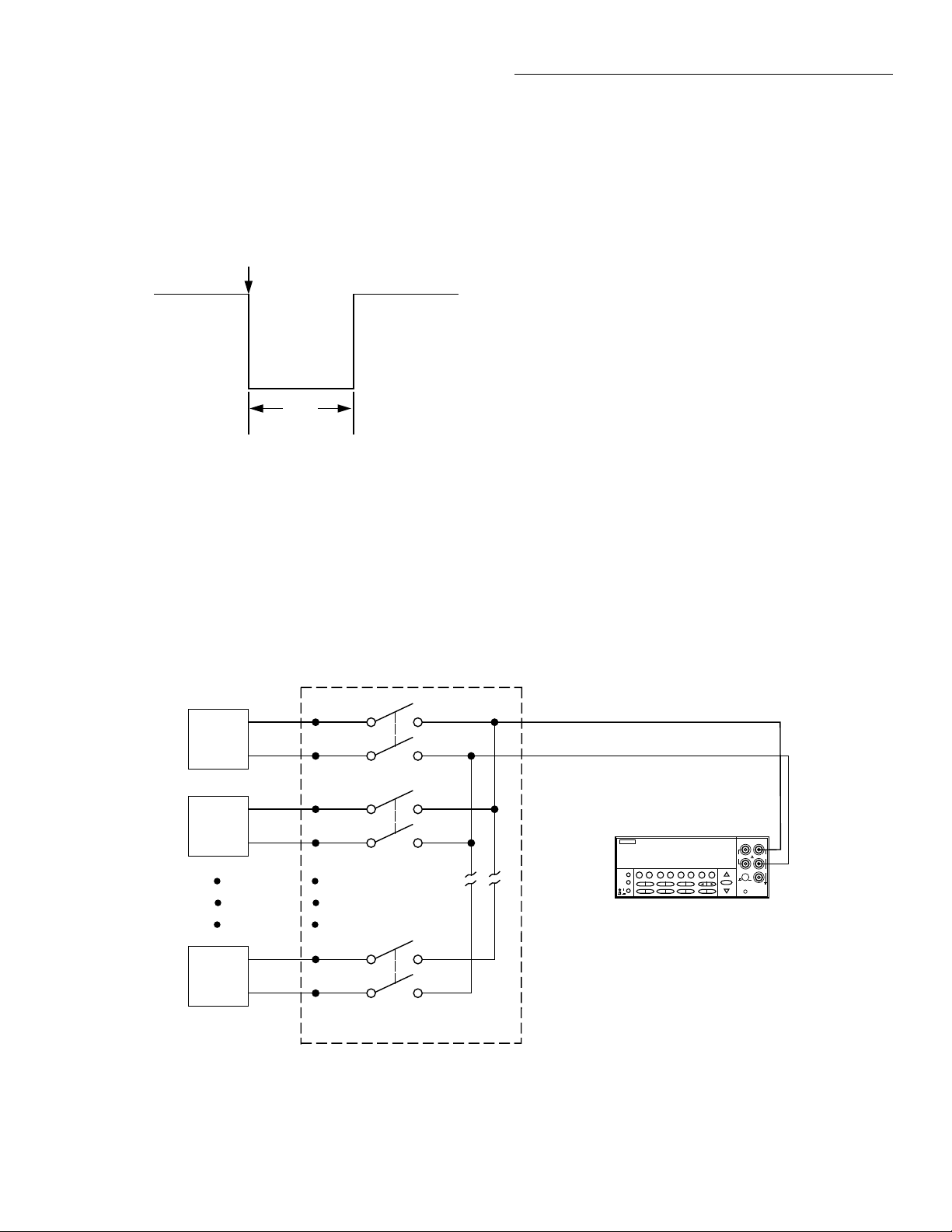

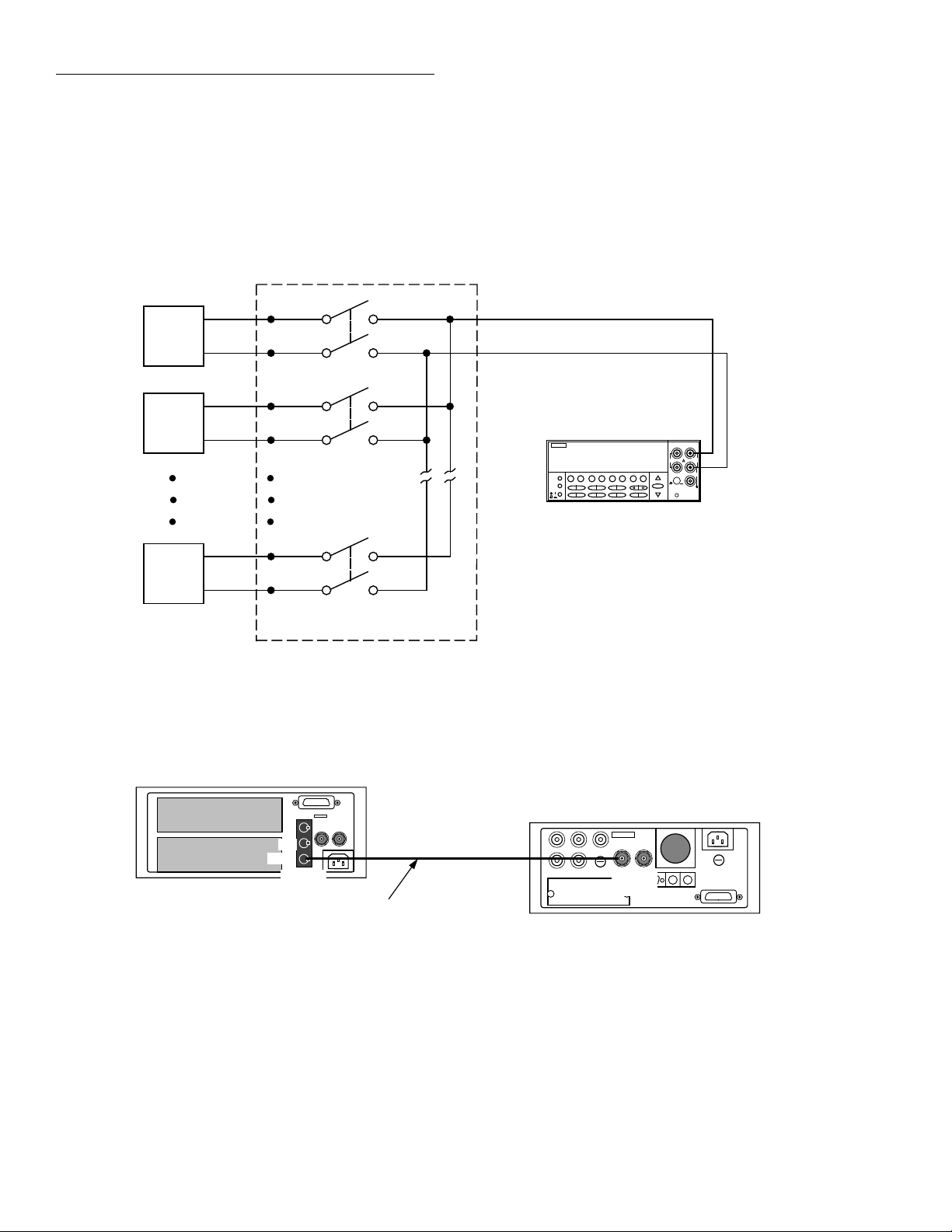

Figure 2-16 DUT test system ....................................................................................................................................... 2-51

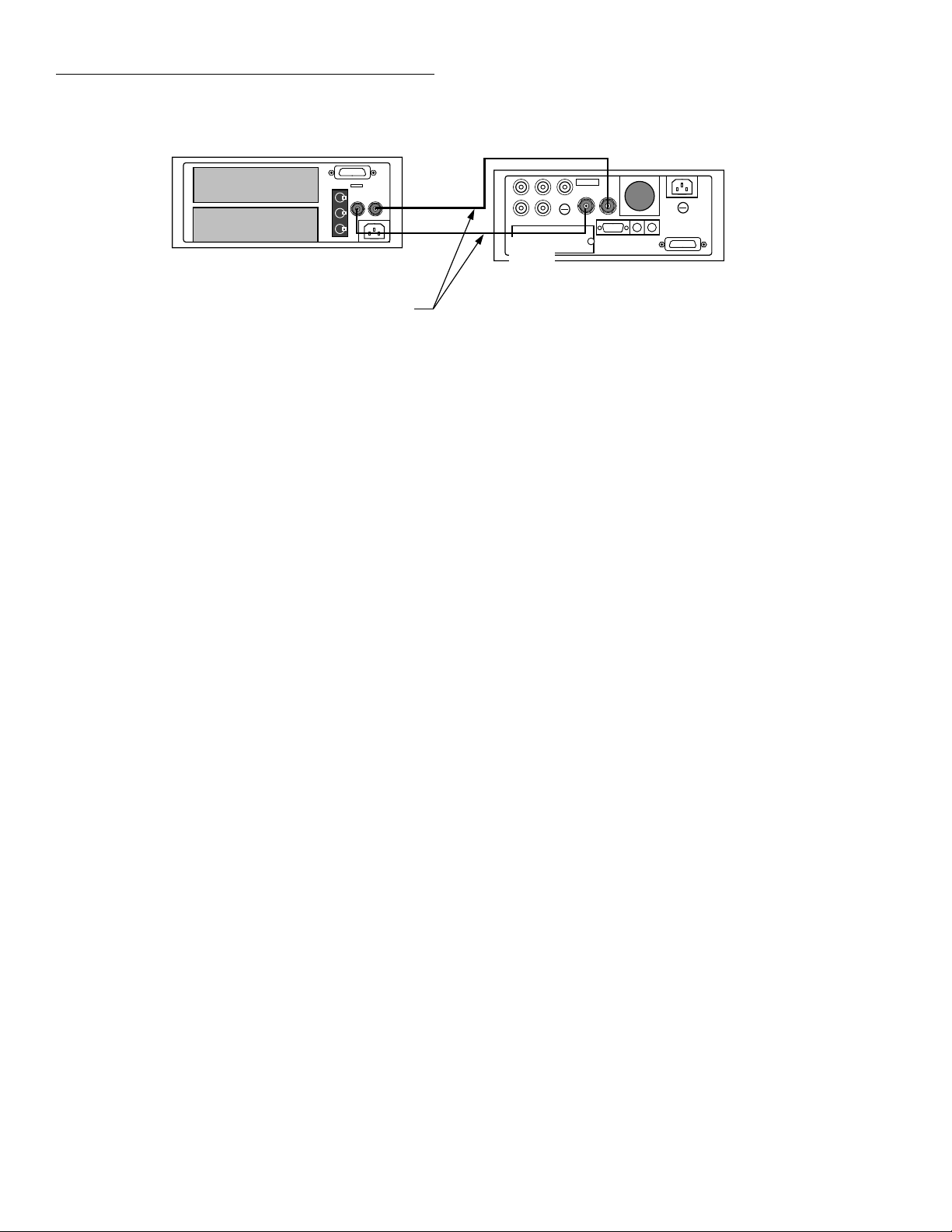

Figure 2-17 External trigger connectors ...................................................................................................................... 2-52

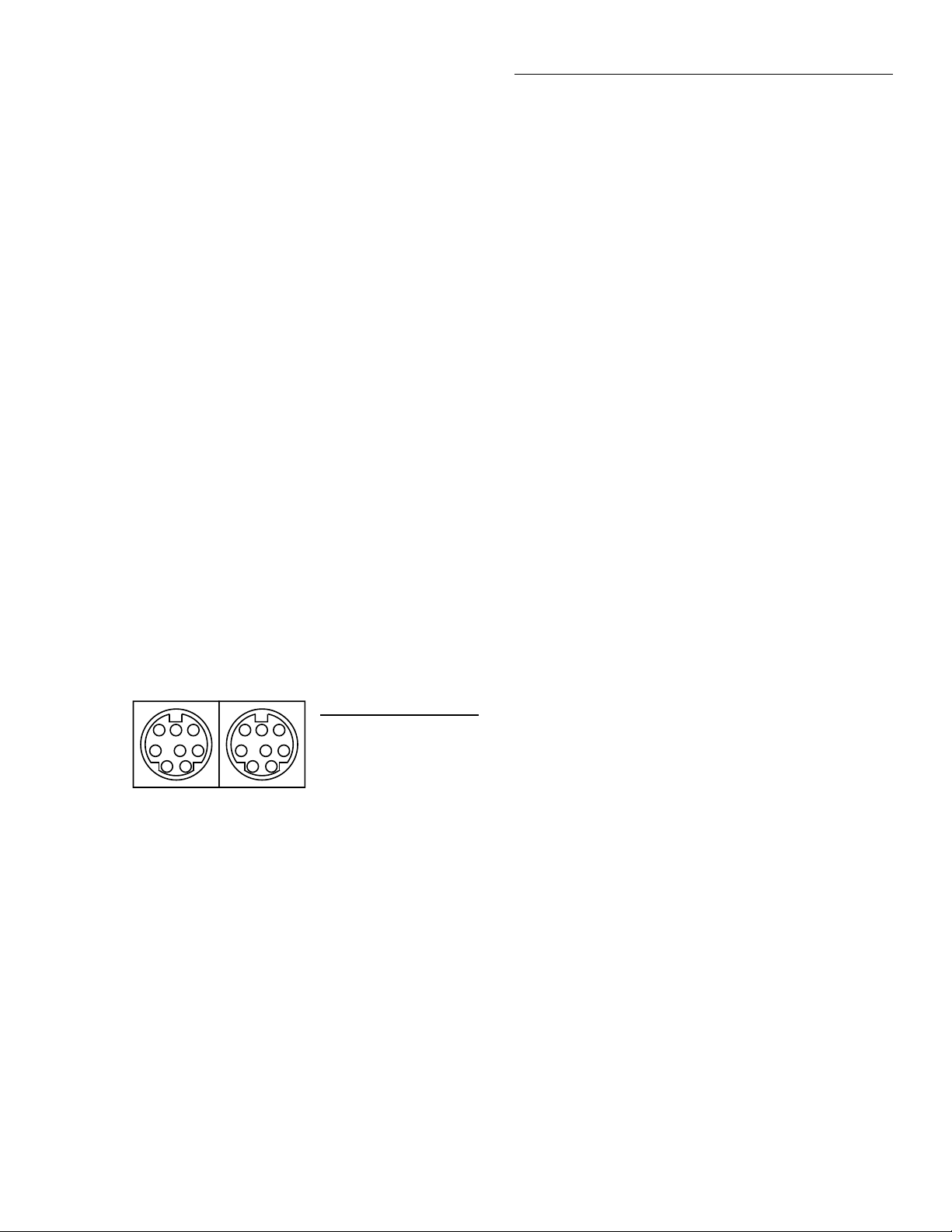

Figure 2-18 Trigger link connectors ............................................................................................................................ 2-53

Figure 2-19 DUT test system ....................................................................................................................................... 2-54

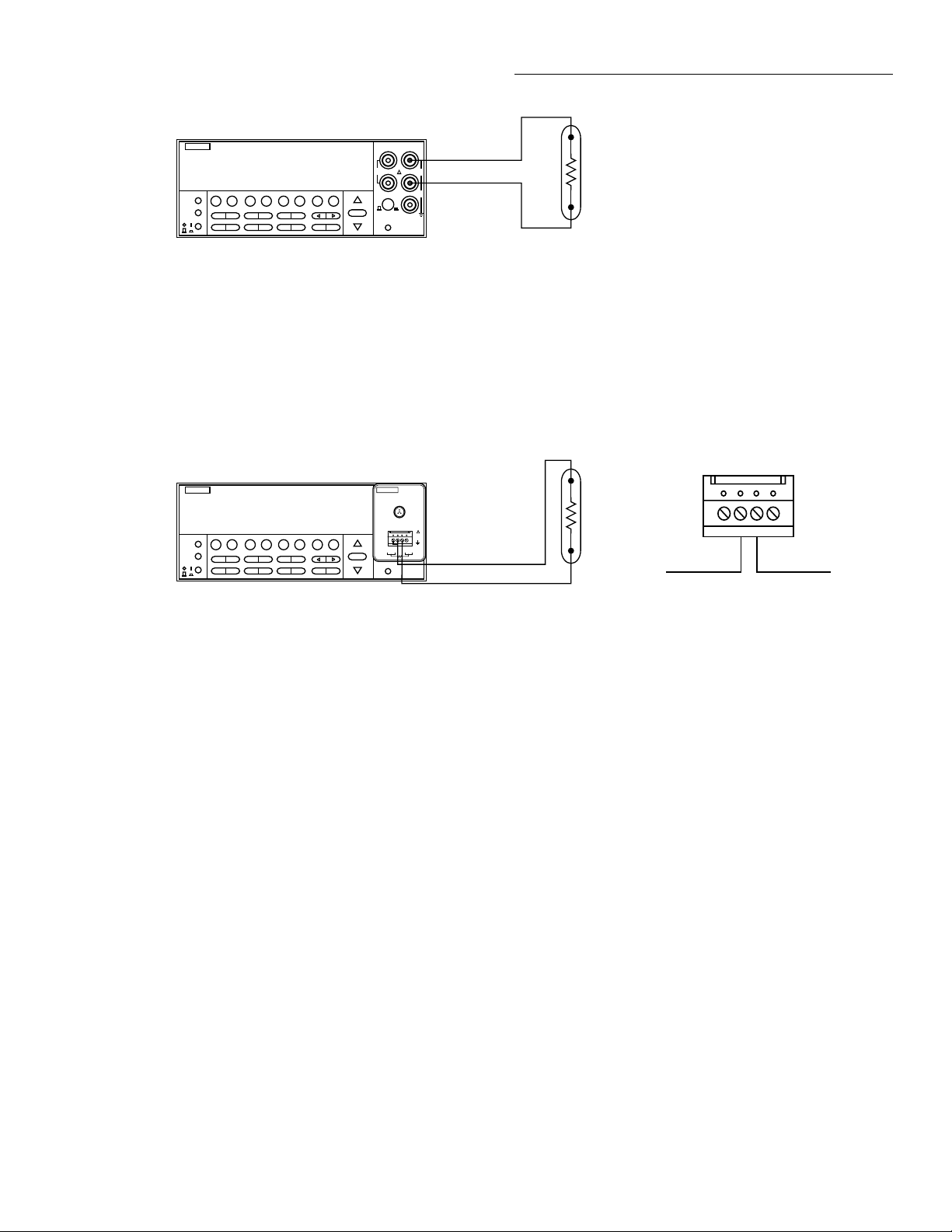

Figure 2-20 Trigger Link connections (asynchronous example #1) ............................................................................ 2-54

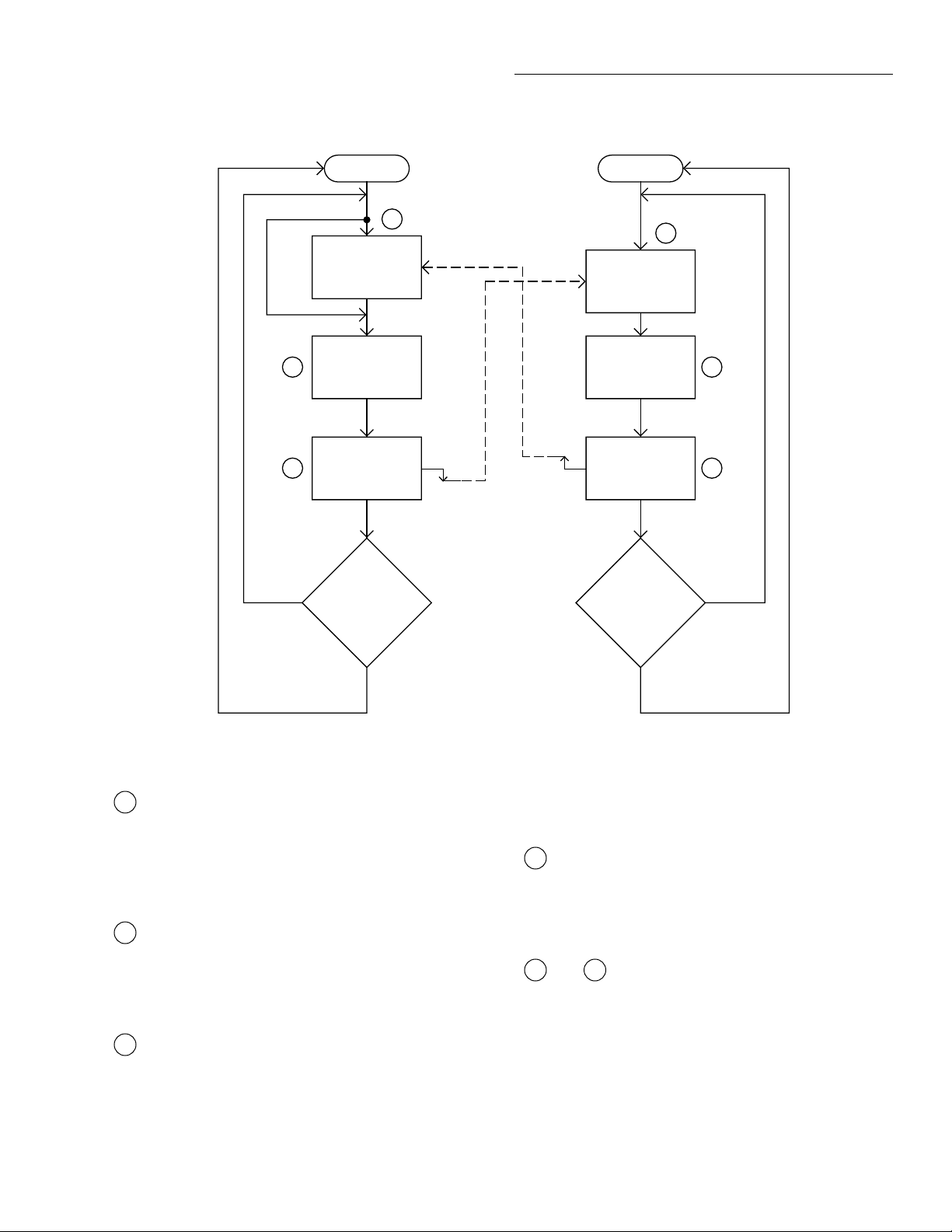

Figure 2-21 Operation model for asynchronous trigger link example #1 .................................................................... 2-56

Figure 2-22 Connections using Trigger Link adapter .................................................................................................. 2-57

Figure 2-23 DUT test system (asynchronous example #2) .......................................................................................... 2-57

Figure 2-24 Trigger Link connections (asynchronous example #2) ............................................................................ 2-58

Figure 2-25 Operation model for asynchronous Trigger Link example #2 ................................................................. 2-60

Figure 2-26 Semi-synchronous Trigger Link specifications ....................................................................................... 2-61

Figure 2-27 Typical semi-synchronous mode connections ......................................................................................... 2-61

Figure 2-28 Trigger Link connections (semi-synchronous example) .......................................................................... 2-62

Figure 2-29 Operation mode for semi-synchronous Trigger Link example ................................................................ 2-63

Figure 2-30 Averaging and advanced filter types ........................................................................................................ 2-72

Figure 2-31 Moving and repeating filter modes .......................................................................................................... 2-73

Figure 2-32 SCAN key menu structure ....................................................................................................................... 2-82

Figure 2-33 SCAN key menu structure for ratio and delta .......................................................................................... 2-83

Figure 2-34 Limits bar graph example ........................................................................................................................ 2-98

Figure 2-35 Using limit test to start 100 Ω resistor ...................................................................................................... 2-99

Figure 2-36 Digital I/O port ....................................................................................................................................... 2-100

Figure 2-37 Digital I/O port simplified schematic ..................................................................................................... 2-101

Figure 2-38 Sample externally powered relay sample ............................................................................................... 2-102

Figure 2-39 Line cycle synchronization .................................................................................................................... 2-104

vii

Page 11

3 IEEE-488 Reference

Figure 3-1 IEEE-488 connector ................................................................................................................................... 3-2

Figure 3-2 IEEE-488 connections ................................................................................................................................ 3-2

Figure 3-3 IEEE-488 connector location ..................................................................................................................... 3-2

Figure 3-4 Model 2002 status register structure ........................................................................................................... 3-7

Figure 3-5 Standard event status .................................................................................................................................. 3-9

Figure 3-6 Operation event status .............................................................................................................................. 3-10

Figure 3-7 Arm event status ....................................................................................................................................... 3-11

Figure 3-8 Sequence event status ............................................................................................................................... 3-12

Figure 3-9 Trigger event status .................................................................................................................................. 3-13

Figure 3-10 Measurement event status ......................................................................................................................... 3-14

Figure 3-11 Questionable event status ......................................................................................................................... 3-15

Figure 3-12 Status byte and service request (SRQ) ..................................................................................................... 3-17

Figure 3-13 Trigger Model (IEEE-488 bus operation) ................................................................................................ 3-19

Figure 3-14 Standard Event Enable Register ............................................................................................................... 3-31

Figure 3-15 Standard Event Status Register ................................................................................................................ 3-32

Figure 3-16 Service Request Enable Register .............................................................................................................. 3-37

Figure 3-17 Status Byte Register ................................................................................................................................. 3-39

Figure 3-18 ASCII data format .................................................................................................................................... 3-79

Figure 3-19 IEEE754 single precision data format (32 data bits) ................................................................................ 3-80

Figure 3-20 IEEE754 double precision data format (64 data bits) .............................................................................. 3-81

Figure 3-21 Measurement Event Register .................................................................................................................. 3-118

Figure 3-22 Questionable Event Register .................................................................................................................. 3-119

Figure 3-23 Operation Event Register ....................................................................................................................... 3-120

Figure 3-24 Trigger Event Register ........................................................................................................................... 3-120

Figure 3-25 Arm Event Register ................................................................................................................................ 3-121

Figure 3-26 Sequence Event Register ........................................................................................................................ 3-121

Figure 3-27 Measurement Event Enable Register ...................................................................................................... 3-123

Figure 3-28 Questionable Event Enable Register ...................................................................................................... 3-123

Figure 3-29 Operation Event Enable Register ........................................................................................................... 3-124

Figure 3-30 Trigger Event Enable Register ............................................................................................................... 3-124

Figure 3-31 Arm Event Enable Register .................................................................................................................... 3-124

Figure 3-32 Sequence Event Enable Register ............................................................................................................ 3-125

Figure 3-33 Measurement Transition Filter ............................................................................................................... 3-126

Figure 3-34 Questionable Transition Filter ................................................................................................................ 3-127

Figure 3-35 Operation Transition Filter ..................................................................................................................... 3-128

Figure 3-36 Trigger Transition Filter ......................................................................................................................... 3-129

Figure 3-37 Arm Transition Filter .............................................................................................................................. 3-130

Figure 3-38 Sequence Transition Filter ...................................................................................................................... 3-131

Figure 3-39 Key-press codes ...................................................................................................................................... 3-144

D IEEE-488 Bus Overview

Figure D-1 IEEE-488 bus configuration ...................................................................................................................... D-2

Figure D-2 IEEE-488 handshake sequence .................................................................................................................. D-3

Figure D-3 Command codes ........................................................................................................................................ D-6

viii

Page 12

Ω

Ω

Ω

List of Tables

2 Front Panel Operation

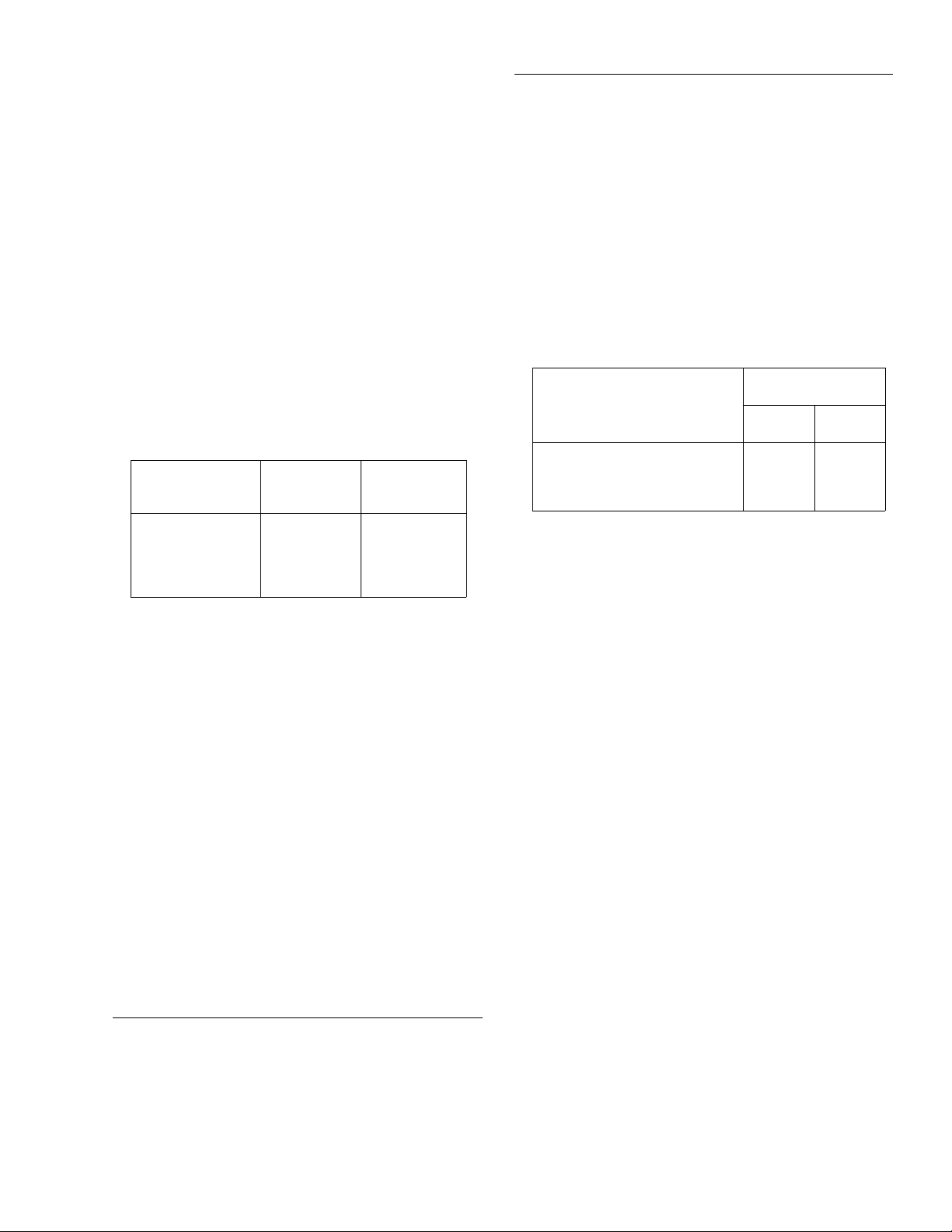

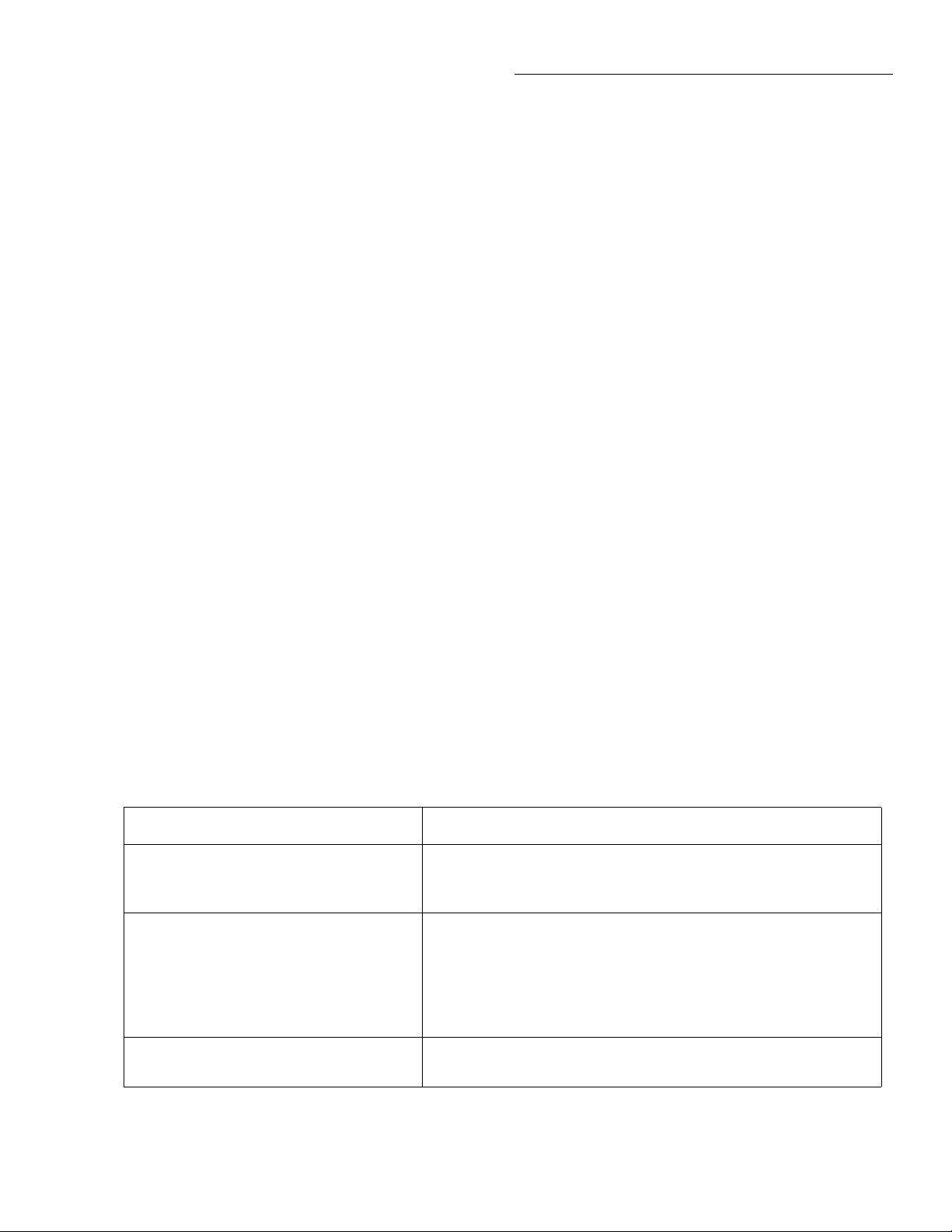

Table 2-1 Data checked on power-up ......................................................................................................................... 2-3

Table 2-2 Power-up error messages ........................................................................................................................... 2-3

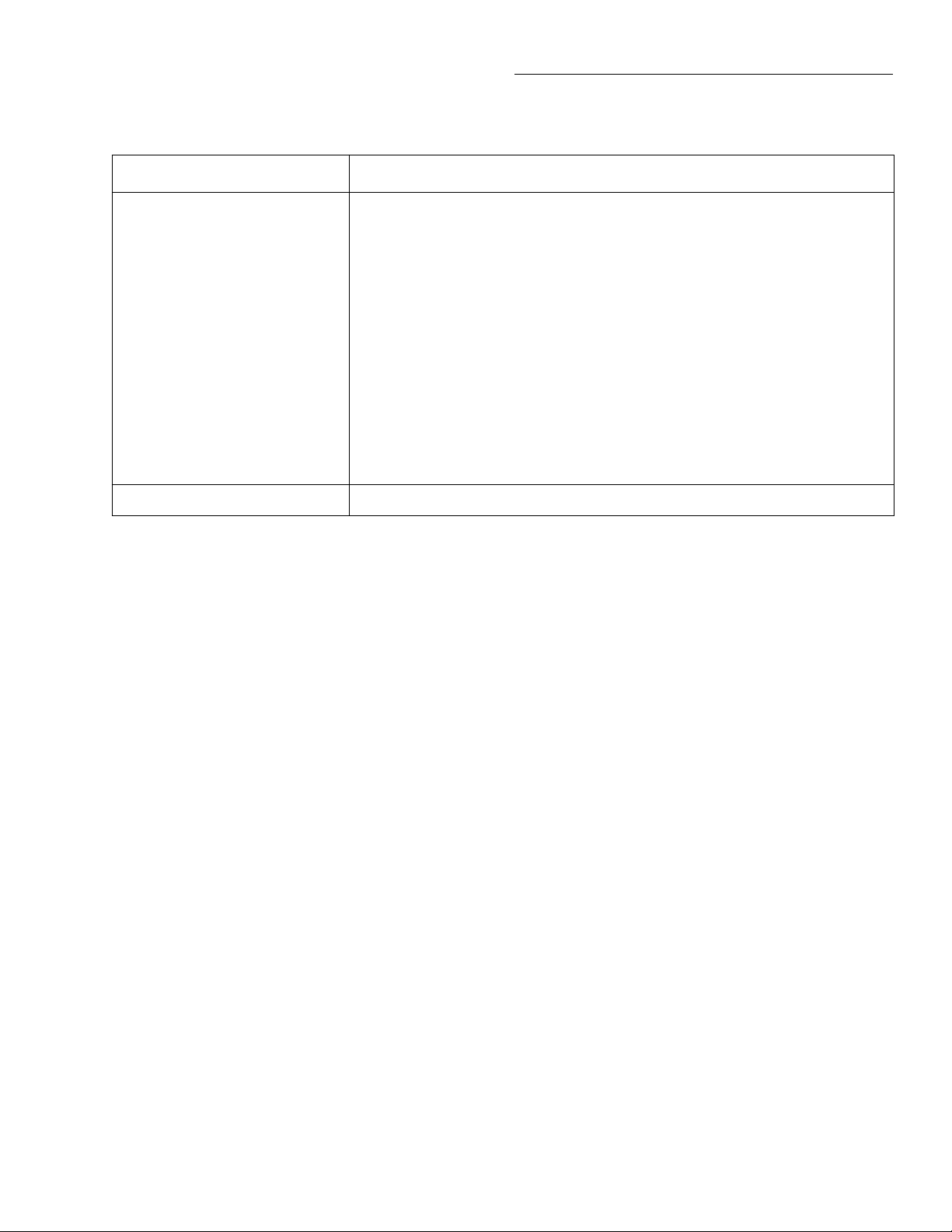

Table 2-3 Multiple displays by function .................................................................................................................... 2-5

Table 2-4 Status and error messages .......................................................................................................................... 2-8

Table 2-5 EXIT key actions ....................................................................................................................................... 2-9

Table 2-6 CONFIGURE DCV menu structure ........................................................................................................ 2-10

Table 2-7 CONFIGURE ACV menu structure ........................................................................................................ 2-11

Table 2-8 DCV and ACV integration times set-by-resolution ................................................................................. 2-12

Table 2-9 DCV and ACV auto filter ........................................................................................................................ 2-13

Table 2-10 DCV and ACV auto resolution ................................................................................................................ 2-13

Table 2-11 CONFIGURE DCI menu structure .......................................................................................................... 2-24

Table 2-12 CONFIGURE ACI menu structure .......................................................................................................... 2-24

Table 2-13 DCI and ACI integration time set-by-resolution ...................................................................................... 2-25

Table 2-14 DCI and ACI auto filter ........................................................................................................................... 2-25

Table 2-15 DCI and ACI auto resolution ................................................................................................................... 2-26

Table 2-16 CONFIGURE OHMS-2W menu structure .............................................................................................. 2-29

Table 2-17 CONFIGURE OHMS-4W menu structure .............................................................................................. 2-29

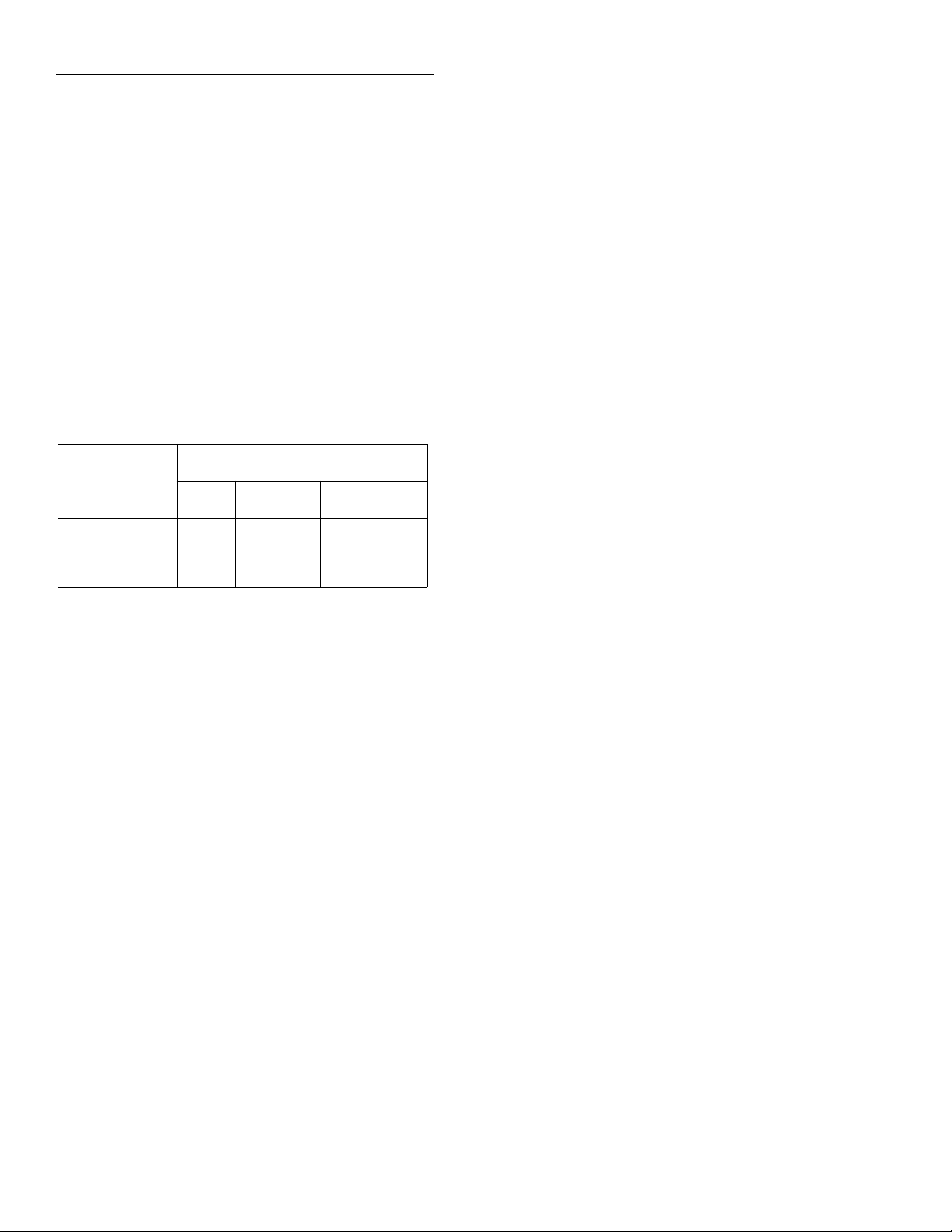

Table 2-18

Table 2-19

Table 2-20

Table 2-21 Trigger level range and increments .......................................................................................................... 2-32

Table 2-22 CONFIGURE FREQUENCY menu structure ......................................................................................... 2-33

Table 2-23 CONFIG TEMPERATURE menu structure ............................................................................................ 2-36

Table 2-24 Temperature integration time set-by-resolution ....................................................................................... 2-39

Table 2-25 Temperature auto resolution .................................................................................................................... 2-39

Table 2-26 Allowable rel values ................................................................................................................................. 2-41

Table 2-27 CONFIGURE TRIGGER menu structure ................................................................................................ 2-42

Table 2-28 Reading storage options ........................................................................................................................... 2-64

Table 2-29 CONFIGURE DATA STORE menu structure ........................................................................................ 2-65

Table 2-30 Available functions in burst mode ........................................................................................................... 2-66

Table 2-31 Burst mode sequence ............................................................................................................................... 2-67

Table 2-32 Fill-and-stop sequence ............................................................................................................................. 2-69

Table 2-33 Continuous sequence ................................................................................................................................ 2-70

Table 2-34 Pretrigger sequence .................................................................................................................................. 2-70

Table 2-35 Auto filters ............................................................................................................................................... 2-74

Table 2-36 CONFIGURE FILTER menu structure ................................................................................................... 2-74

Table 2-37 CONFIGURE MATH menu structure ..................................................................................................... 2-76

Table 2-38 CHANNEL SELECTION menu structure ............................................................................................... 2-78

Table 2-39 CONFIGURE CHANNELS menu structure ............................................................................................ 2-79

Table 2-40 SCAN OPERATION menu structure ...................................................................................................... 2-81

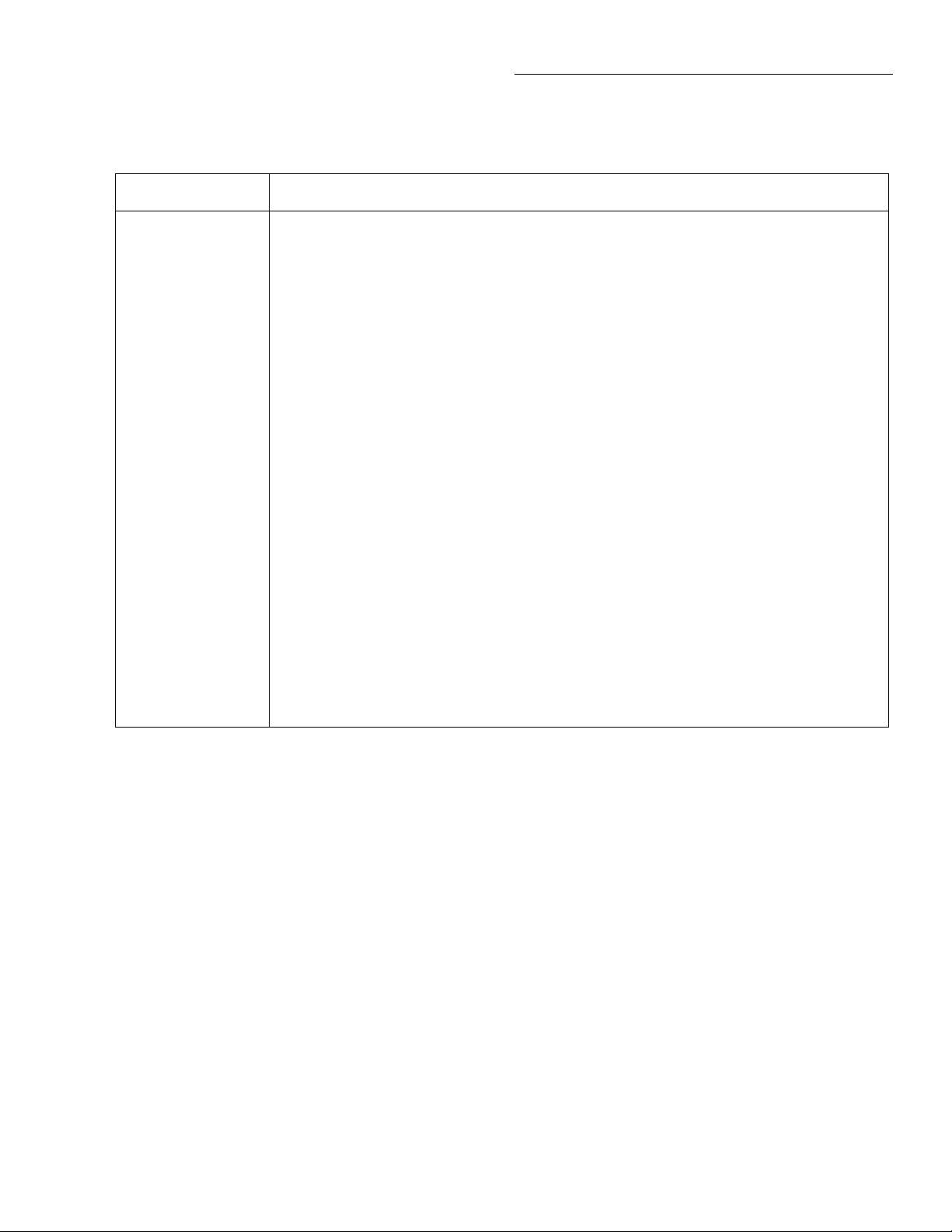

Table 2-41 Main menu structure ................................................................................................................................ 2-88

Table 2-42 Factory default conditions ........................................................................................................................ 2-91

2 and Ω 4 integration time set-by-resolution ......................................................................................... 2-30

2 and Ω 4 auto filter ............................................................................................................................... 2-30

2 and Ω 4 auto resolution ....................................................................................................................... 2-31

ix

Page 13

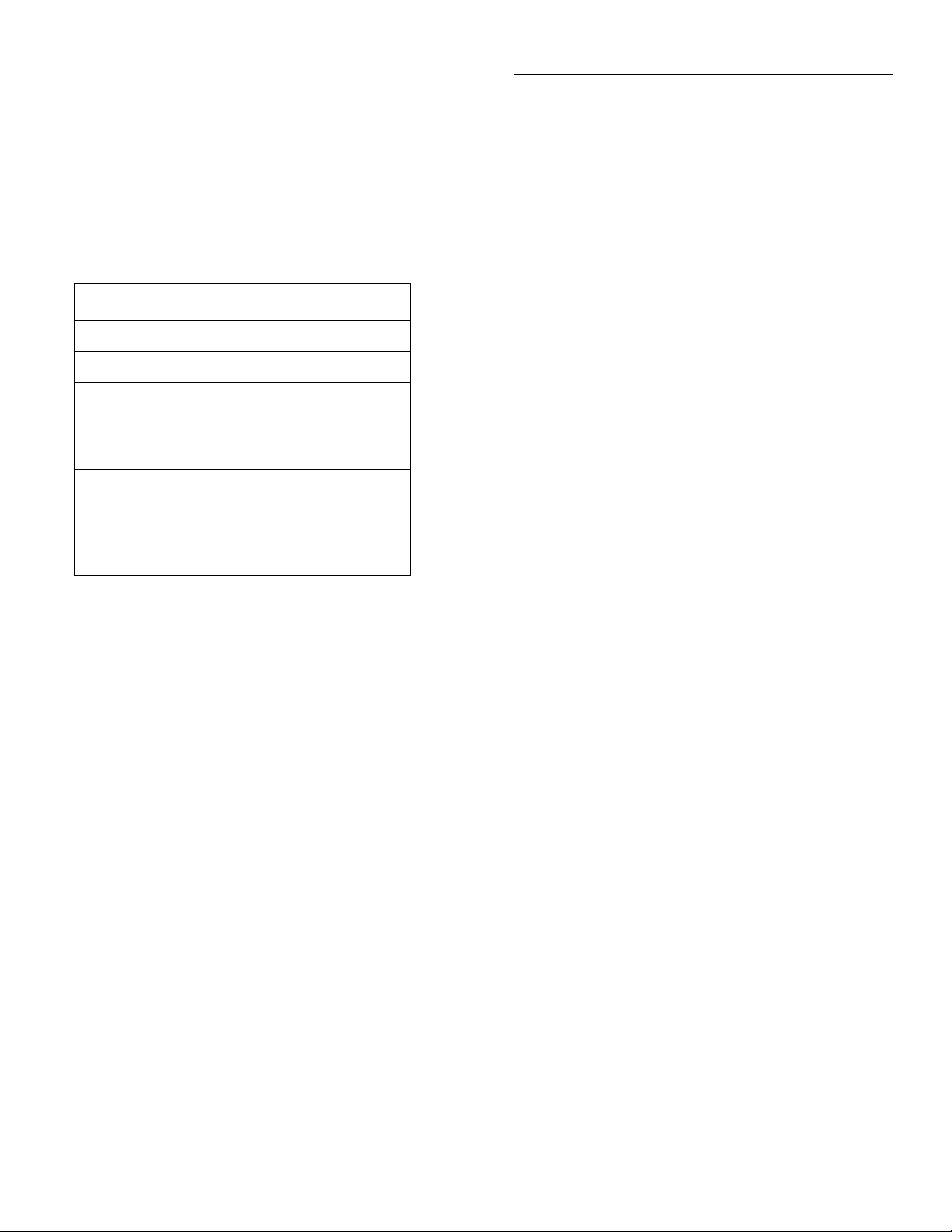

3 IEEE-488 Reference

Table 3-1 General bus commands and associated statements .................................................................................... 3-4

Table 3-2 IEEE-488.2 common commands and queries .......................................................................................... 3-29

Table 3-3 Signal oriented measurement command summary ................................................................................... 3-41

Table 3-4 CALCulate command summary ............................................................................................................... 3-46

Table 3-5 DISPlay command summary .................................................................................................................... 3-48

Table 3-6 FORMat command summary ................................................................................................................... 3-48

Table 3-7 INPut command summary ........................................................................................................................ 3-49

Table 3-8 OUTput command summary .................................................................................................................... 3-49

Table 3-9 ROUTe command summary ..................................................................................................................... 3-50

Table 3-10 SENSe command summary ...................................................................................................................... 3-50

Table 3-11 SOURce command summary ................................................................................................................... 3-59

Table 3-12 STATus command summary .................................................................................................................... 3-60

Table 3-13 SYSTem command summary ................................................................................................................... 3-62

Table 3-14 TRACe command summary ..................................................................................................................... 3-63

Table 3-15 Trigger command summary ..................................................................................................................... 3-63

Table 3-16 UNIT command summary ........................................................................................................................ 3-65

Table 3-17 Minimum delay times for stream mode .................................................................................................. 3-142

B Interface Function Codes

Table B-1 Model 2002 interface function codes ........................................................................................................ B-1

D IEEE-488 Bus Overview

Table D-1 IEEE-488 bus command summary ............................................................................................................ D-4

Table D-2 Hexadecimal and decimal command codes ............................................................................................... D-7

Table D-3 Typical addressed command sequence ...................................................................................................... D-7

Table D-4 Typical common command sequence ....................................................................................................... D-7

Table D-5 IEEE command groups .............................................................................................................................. D-8

E IEEE-488 Conformance Information

Table E-1 IEEE-488 documentation requirements .................................................................................................... E-1

Table E-2 Coupled commands ................................................................................................................................... E-3

H HP3458A Emulation Mode

Table H-1 Commands not supported by HP3458A emulation mode ......................................................................... H-2

Table H-2 Supported HP3458A commands ............................................................................................................... H-3

x

Page 14

1

General Information

1.1 Introduction

This section contains general information about the Model

2002 Multimeter. It is arranged in the following manner:

1.2 Features

1.3 Warranty information

1.4 Manual addenda

1.5 Safety symbols and terms

1.6 Specifications

1.7 Inspection

1.8 Options and accessories

1.2 Features

Some important Model 2002 features include:

• Full range of functions Among other functions, the

multimeter can measure DC voltage (normal and peak

spikes), AC voltage (RMS, average, and peak), DC

current (normal and in-circuit), AC current (RMS and

average), two and four-wire resistance (normal and

offset-compensated), frequency (voltage and current),

and temperature (resistance temperature devices or

thermocouples).

• T wo-line display Readings and front panel messages

are shown on an alphanumeric display having a 20character top line and a 32-character bottom line.

• Multifunction measuring and display From the front

panel, you can configure the instrument to sequentially

measure and simultaneously display readings of multiple functions.

• Reading and setup storage Readings and setup data

can be stored and recalled from the front panel or over

the IEEE-488 bus. For example, the buffer can be programmed to store up to 850 readings at 4.5 digits, or up

to 250 time-stamped readings at 6.5 digits. The Model

2002 can be configured with memory options that

extend the storage capacity up to 30,000 readings and

ten setups.

• High-speed measurements The instrument is capable

of acquiring, for example, 2000 readings/second at 4.5

digits of resolution, and 215 readings/second at 6.5

digits.

• T alk-only mode From the front panel, you can set the

instrument to send readings to an IEEE-488 printer or,

with an optional adapter, to a Centronics printer.

• Digital calibration The instrument may be digitally

calibrated from either the front panel or over the bus.

• Standard IEEE-488 interface Bus operation conforms to the IEEE-488.2 and SCPI standards.

• Trigger link This is a new trigger concept that provides more versatile and precise external triggering. It

is in addition to the standard Trigger In/Measurement

Complete BNC external triggering techniques.

• Optional field-installable internal scanner This is a

10-channel scanner card, which includes eight channels

of 2-pole relay switching and two channels of 2-pole

solid-state switching. All channels can be configured

for 4-pole operation.

1-1

Page 15

General Information

1.3 Warranty information

Warranty information is located on the inside front cover of

this instruction manual. Should your Model 2002 require

warranty service, contact the Keithley representative or

authorized repair facility in your area for further information. When returning the instrument for repair, be sure to fill

out and include the service form at the back of this manual to

provide the repair facility with the necessary information.

1.4 Manual addenda

Any improvements or changes concerning the instrument or

manual will be explained in an addendum included with the

manual. Be sure to note these changes and incorporate them

into the manual.

1.5 Safety symbols and terms

The following symbols and terms may be found on an instrument or used in this manual.

!

The symbol on an instrument indicates that the user

should refer to the operating instructions located in the manual.

The symbol on an instrument shows that high voltage

may be present on the terminal(s). Use standard safety precautions to avoid personal contact with these voltages.

The WARNING heading used in this manual explains dangers that might result in personal injury or death. Always

read the associated information very carefully before performing the indicated procedure.

The CAUTION heading used in this manual explains hazards that could damage the instrument. Such damage may

invalidate the warranty.

1.6 Specifications

Full Model 2002 specifications are included in Appendix A.

1.7 Inspection

The Model 2002 was carefully inspected, both electrically

and mechanically before shipment. After unpacking all items

from the shipping carton, check for any obvious signs of

physical damage that may have occurred during transit.

(Note: There may be a protective film over the display lens,

which can be removed.) Report any damage to the shipping

agent immediately. Save the original packing carton for possible future reshipment. The following items are included

with every Model 2002 order:

• Model 2002 Multimeter (with MEM1 or MEM2 memory option, if ordered) with line cord.

• Model 8605 High Performance Modular Test Leads.

• Model 2002 User’s Manual and Model 2002 Calibration Manual.

• Accessories as ordered.

• Full calibration data (conforming to MIL-STD

45662A).

If an additional manual is required, order the appropriate

manual package:

• Keithley part number 2002-900-00 for the User’ s Manual.

• Keithley part number 2002-902-00 for the Repair Manual.

• Keithley part number 2002-903-00 for the Getting

Started Manual.

• Keithley part number 2002-905-00 for the Calibration

Manual.

The manual packages include a manual and any pertinent

addenda.

1.8 Options and accessories

The following options and accessories are available from

Keithley for use with the Model 2002.

Model 1050 Padded Carrying Case: A carrying case for a

Model 2002 or a Model 7001. Includes handles and shoulder

strap.

Models 2002/MEM1 and 2002/MEM2: These optional con-

figurations of the Model 2002 extend its storage capacity.

The MEM1 option has 32K-bytes for non-volatile storage of

five setups, and 7000 readings in compact format or 1400

readings in full format. The MEM2 option has 128K-bytes

for non-volatile storage of ten setups, and 30000 compact

readings or 6000 full readings.

Model 2001-SCAN: This is a 10-channel scanner card that

installs within the Model 2002. It has eight channels of 2pole relay switching and two channels of 2-pole solid-state

switching. All channels can be configured for 4-pole operation. Included are two pairs of leads for connection to Model

2002 rear panel inputs (Keithley part number CA-109).

1-2

Page 16

M

General Information

Model 2001-TCSCAN: This is a thermocouple/general pur-

pose scanner card that installs in the option slot of the Model

2002. The card has nine analog input channels that can be

used for high-accuracy , high-speed scanning. A built-in temperature reference allows multi-channel, cold-junction compensated temperature measurements using thermocouples.

Model 4288-1 Single Fixed Rack Mount Kit: Mounts a sin-

gle Model 2002 in a standard 19-inch rack.

Model 4288-2 Side-by-side Rack Mount Kit: Mounts two

instruments (Models 182, 428, 486, 487, 2001, 2002, 7001)

side-by-side in a standard 19-inch rack.

Model 4288-3 Side-by-side Rack Mount Kit: Mounts a

Model 2002 and a Model 199 side-by-side in a standard 19inch rack.

Model 4288-4 Side-by-side Rack Mount Kit: Mounts a

Model 2002 and a 5

220, 224, 230, 263, 595, 614, 617, 705, 740, 775, etc.) sideby-side in a standard 19-inch rack.

Models 7007-1 and 7007-2 Shielded IEEE-488 Cables:

Connect the Model 2002 to the IEEE-488 bus using shielded

cables and connectors to reduce electromagnetic interference

(EMI). The Model 7007-1 is one meter long; the Model

7007-2 is two meters long.

¼

-inch instrument (Models 195A, 196,

RMS, 42.4V peak; the test probes are rated at 1000V.) These

components are designed to be used with high performance

test leads terminated with banana plugs, such as the Model

8605 High Performance Modular Test Leads.

The following test leads and probes are rated at 30V RMS,

42.4V peak:

Models 5805 and 5805-12 Kelvin Probes: Consists of two

spring-loaded Kelvin test probes with banana plug termination. Designed to be used with instruments that measure 4terminal resistance. The Model 5805 is 0.9m long; the Model

5805-12 is 3.6m long.

Model 5806 Kelvin Clip Lead Set: Includes two Kelvin clip

test leads (0.9m) with banana plug termination. Designed for

instruments that measure 4-terminal resistance. A set of eight

replacement rubber bands for the Model 5806 is available as

Keithley P/N GA-22.

Model 8604 SMD Probe Set: Consists of two test leads (3ft),

each terminated with a surface mount device “grabber” clip

on one end and a banana plug with retractable sheath on the

other end.

Model 8610 Low Thermal Shorting Plug: Consists of four

banana plugs mounted to a 1-inch square circuit board, interconnected to provide a short circuit among all plugs.

Models 8501-1 and 8501-2 Trigger Link Cables: Connect

the Model 2002 to other instruments with Trigger Link connectors (e.g., Model 7001 Switch System). The Model

8501-1 is one meter long; the Model 8501-2 is two meters

long.

Model 8502 Trigger Link Adapter: Allows you to connect

the Trigger Link of the Model 2002 to instruments that use

the standard BNC (In/Out) external triggering technique.

Model 8530 IEEE-488 to Centronics Printer Adapter

Cable: Translates the IEEE-488 connector pinout and signal

level to a Centronics termination. This permits a standard

Centronics parallel printer to be connected to a Model 2002

in TALK-ONLY mode.